Page 1

Flame Detection

FS20X Fire and Flame Detector

MultiSpectrum UV/Dual IR/VIS Fire and Flame Detector

Page 2

FS20X Detector

The FS20X is the latest generation high technology Multi Spectrum

(UV/Dual IR/VIS) Fire and Flame Detector, which is part of the FSX

family of advanced technology ElectroOptical Flame detectors.

Based on the foundation of the highly successful and reliable SS 4 detector, the FS20X detector represents a quantum

leap in integrating Infrared and Ultraviolet sensing technologies. The FS20X is a MultiSpectrum and UV/Dual IR/ VIS

fire and flame detector with a proven UV solar-blind sensor. The FS20X exhibits faster false-alarm free response to fires

over a wider temperature range and with a much longer detection range compared to conventional UV/IR detectors.

Conventional and older technology UV/IR detectors, using

narrow band 4.3 micron IR sensors, will not respond to smoky

fires or if the detector lens is contaminated with oil and

other substances since both UV and 4.3 micron signals are

attenuated, obscured or absorbed by thick smoke or detector

lens contaminations. All UV sensors will be attenuated to some

degree. Also, these old technology UV/IR detectors will not alarm

to any fire if they are installed behind ordinary window glass.

Dual microprocessors provide a high level of fail-safe operation combined with fast and reliable

performance.The master microprocessor performs high-speed digital sampling and signal

processing calculations whilst the slave microprocessor handles various sensor data, performs

communications, self-diagnostics and provides interface versatility and additional memory for

storing event log and FirePic™ data. The FS20X detector has a detection range in excess of 60 m

2

(200 feet) (very high sensitivity setting) for the detection of a 0.1m

(one square-foot) Heptane

reference fire and has a cone of vision greater in volumetric coverage than most UV/IR detectors.

This means fewer detectors can be used as compared to other manufacturers’ detectors.

The FS20 detector using advanced patented algorithms for signal processing and fire and flame analysis is

designed to alarm to all types of fires in all industrial environmental conditions. If the detector’s UV signal

is degraded due to heavy smoke or a contaminated lens, the FS20X’s patented WideBand IR™, Near Band

IR and Visible sensors will still alarm to fire, albeit at a reduced sensitivity and slower response time.

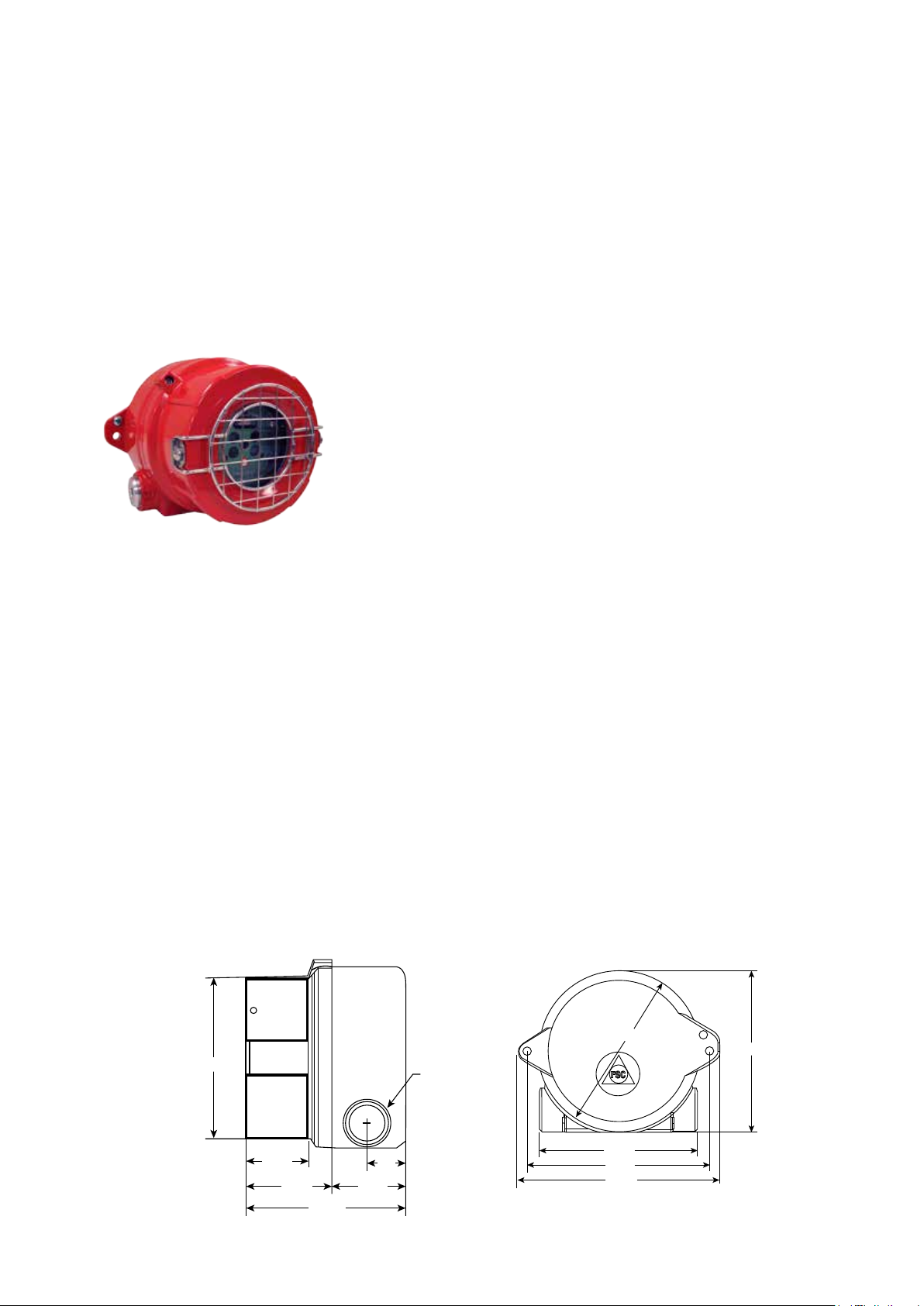

GENERAL DIMENSIONS

Side and Back Views

(All Dimensions in mm)

108,9 mm

3/4” NPT

P124,2 mm

FSC

124,2 mm

43,4 mm

59,7 mm

110,4 mm

50,8 mm

26,9 mm

120,6 mm

139,7 mm

156,4 mm

Page 3

General Specification

GENERAL SPECIFICATIONS

FIELD OF VIEW 90° Horizontal Cone of vision, ± 45° from on axis

SENSITIVITY Very high (60m), high (45m), medium (30m) and low (15m) - switch selectable

RESPONSE TIME

SPECTRAL

SENSITIVITY

OPERATING

VOLTAGE

POWER

CONSUMPTION

ALARM 135 mA @ 24 Vdc nominal

HEATER

OUTPUT RELAYS

ANALOG OUTPUT 0 - 20 mA stepped - source or sink user selectable

LOOP

RESISTANCE

COMMUNICATION

VISUAL

INDICATORS

TEMPERATURE

RANGE

HUMIDITY RANGE 5 to 98% relative humidity, non-condensing

VIBRATION Meets or exceeds MilSpec 810C Method 514.2, Curve AW12

WIRING 2.5 mm

CONDUIT ENTRIES Standard: Two M25 or two ¾” NPT

ENCLOSURE

MATERIALS

ENCLOSURE TYPE 4X, IP66 and NEMA 4

CERTIFICATIONS

SHIPPING WEIGHT

MOUNTING Swivel bracket assembly - optional

WARRANTY Three years from date of shipping

35 Seconds to 0.1 m2 (1 sq. ft.) nHeptane fire at 30 m (100 ft.)

310 Seconds to 0.1 m2 (1 sq. ft.) nHeptane fire at 60 m (200 ft.)

Ultraviolet: 185 - 260 nanometres

Visible: 400 – 700 nanometres

Near Band IR: 0.7 – 1.1 microns

Wide Band IR: 1.1 – 3.5 microns

24 Vdc nominal (1832 Vdc) - regulated

Operating: 85 mA @ 24 Vdc nominal

155 mA – additional

Note: Heater will turn on at 17ºC (0ºF)

Fire Alarm: SPDT (NO / NC) – De-energised/energised, latching/non-latching

Fault: SPST (NO) – De-energised/energised, latching/non-latching

Auxiliary: SPDT (NO / NC) – De-energised/energised, latching/non-latching

Contacts rating: 1 amp @ 24 Vdc

50 - 400 Ohms

One of the following – user selectable:

• RS485, ModBus Protocol

• RS485, FireBus II

• RS485 Special (optional)

• HART, Optional plug-in module (not available on EN5410 units)

Green LED: Power

Red LED: Alarm

Yellow LED: Fault

Operating: 40 to +85ºC (40 to +185ºF)

Storage: 55 to +110ºC (67 to +230ºF)

2

(14 AWG) to 0.326 mm2 (22 AWG); shielded cable recommended

Copper-free powder coated aluminum or 316 stainless steel

FM: Class I, Div. 1 & 2, Groups B, C, & D; Class II, Div. 1 & 2, Groups E, F, & G;

Class III

ATEX/IECEx:

Complies with EN610064 & EN501304

:

INMETRO

CU-TR

China-EX

SIL Rating: FMEDA available on request

EN54-10:

Aluminum: 1.6 kg (3.6 lbs)

Stainless Steel: 3.2 kg (7 lbs)

II 2 G Ex db IIC T4 (Ta: 40 to +110°C), T5 (Ta: 40 to +75°C),

T6 (Ta: 60 to +60°C), II 2 D Ex tb IIIC T135°C

II 2 G Ex db IIC T4 (Ta: 60 to +110°C), T5 (Ta: 60 to +75°C),

T6 (Ta: 60 to +60°C), II 2 D Ex tb IIIC T135°C

FS20X certified 1175a/01 (LPCB); CPR 0832CPRF0515

FEATURES

• Patented WideBand IR™ Infrared combined with

Ultraviolet

• Detection range greater than 60 m (200 feet)

to 0.1 m

• Patented Electronic Frequency Analysis

• Visible sensor for optimum false alarm rejection

• Selectable detection sensitivities

• Solar blind 90° cone-of-vision

• Dual microprocessors for reliable performance

• Real-time clock for accurate time dating

of events

• FirePic™ — Up to 6 pre-fire event data storage

• Event log — Up to 200 events with date and

time stamp

• Built-in RS485 ModBus communication

• Built-in non-isolated 420 mA analog output

(sink or source)

• Alarm, Fault and Fire Verification relays

• Automatic Optical Path and Electronic self-test

• Patented Electronics Module for component

protection with plug-in terminations for easy

field installation

• Two 25 mm conduit entries or two ¾” NPT

• Low power consumption

• High RFI and EMI immunity

• FM hazardous area approved

• Ex d ATEX approved

• CUTR approved

• INMETRO approved

• Meets SIL 2 requirements

• Certified to EN5410:2002 (option)

• FM 3260 performance

BENEFITS

• Detects hydrocarbon and non-hydrocarbon

fuel fires in all environmental conditions

• Wide operating temperature range

• Arc welding immunity

• False alarm rejection

• Minimal maintenance for trouble-free

operation

• PC software and interface module (FSIM) for

fault diagnostics real-time graphs (RTGs), and

downloading of FirePics™ and event log

• Suitable for a wide variety of applications

APPLICATIONS

• Refineries and oil production facilities

• OffShore platforms

• Turbine/Compressor enclosures

• Acetylene processing and storage

• Oil and Gas pipelines and pumping stations

• LNG/LPG loading and unloading facilities

• Natural Gas and CNG plants

• Ethanol, Methanol, and IPA production

and storage

• Crude oil and gasoline storage and tank farms

• Aircraft hangars

• Hydrogen plants and storage

• Paint and solvent storage

•

Chemical production, storage, and loading facilities

• Power plants

• Silane gas storage

2

(1 sq. ft.) heptane fire

Page 4

Honeywell Gas and Flame Detection

Honeywell Gas and Flame Detection is able to provide gas detection solutions to meet the

requirements of all applications and industries. Contact us in the following ways:

HEADQUARTERS

Europe, Middle East, Africa

Life Safety Distribution GmbH

Javastrasse 2

8604 Hegna u

Switzerland

Tel: +41 (0)44 943 4300

Fax: + 41 (0)44 943 4398

gasdetection@honey well.com

Customer Service:

Tel: 00800 333 222 44 ( Freephone numb er)

Tel: +41 44 943 4380 (A lternative nu mber)

Fax: 0 0800 333 222 55

Middle East Tel: +971 4 450 5800 (Fixed Ga s

Detection)

Middle East Tel: +971 4 450 5852 (Portable G as

Detection)

Americas

RAE Systems by H oneywell

3775 North Fir st Street

San Jos e, CA 95134

USA

Tel: +1 877 723 2878

Honeywell Analytics Distribution Inc.

405 Barclay Blvd.

Lincol nshire, IL 60069

USA

Tel: +1 847 955 8200

Toll free: +1 800 538 0363

Fax: +1 847 955 8210

detectgas@honey well.com

Asia Pacific

Honeywell Industrial Safety

7F SangA m IT Tower,

434, Worldcupbuk-ro, Mapo-gu,

Seoul 03922,

Korea

Tel: +82 (0) 2 6909 0300

Fax: + 82 (0) 2 2025 0328

India Tel: +91 124 4752700

China Tel: +86 10 5885 8788 3000

analytics.ap@honeywell.com

www.honeywellanalytics.com

www.raesystems.com

Pleas e Note:

While ev ery effor t has been made to ensure accuracy in this publication, no

responsibilit y can be accept ed for errors or o missions. Data may change , as well

as legislation, an d you are strongl y advised to obt ain copies of the m ost recentl y

issue d regulation s, standards , and guideline s. This public ation is not inten ded to

form the basis of a cont ract.

F S20 X_ DS 011 25 _V5 _0 117_E ME A

01/17

© 2017 Honeywel l Analytic s

Loading...

Loading...