Honeywell F300a2025 Owner's Manual

F300 Electronic Air Cleaner

PRODUCT DATA

APPLICATION

The F300 Electronic Air Cleaner is mounted in the return air

duct of a forced air heating, cooling, or ventilating system. It

captures a significant amount of the airborne particles 0.3

micron and larger from air circulated through it.

FEATURES

• Media postfilters (optional) provide enhanced filtration.

• Available in five sizes to fit most ducts; adapts to

airflow from either side.

3

• Capacity varies from 1000 cfm (2040 m

(3400 m

• Solid state power supply is self-regulating and

maintains peak efficiency during a wide range of cell

dirt loading conditions.

• Low pressure drop.

• Optional W8600F Air Cleaner Monitor indicates air

cleaner performance, reminds homeowner when filter

and cell maintenance are due and when to check the

system.

• Optional wireless W8600A AIRWATCH™ LCD indicator

provides reminder when air cleaner electronic cells

need washing, when media postfilters need replacing,

when UV lamps need replacing and when humidifier

pad needs replacing.

3

/hr), depending on size.

/hr) to 2000 cfm

Contents

Application/Features.......................................................... 1

Specifications/Ordering Information .................................. 2

Installation ........................................................................ 8

Operation .......................................................................... 11

Checkout .......................................................................... 11

Service ............................................................................. 12

Replacement Parts/Exploded View ................................... 17

68-0240EF—06

F300 ELECTRONIC AIR CLEANER

SPECIFICATIONS

IMPORTANT

The specifications given in this publication do not

include normal manufacturing tolerances. Therefore,

this unit may not exactly match the listed specifications. This product is tested and calibrated under

closely controlled conditions, and some minor differences in performance can be expected if those conditions are changed.

Model:

F300E Electronic Air Cleaner: Includes cabinet, access door,

solid state power supply, two electronic cells, two metal

mesh prefilters, and two media postfilters.

F300A,B Electronic Air Cleaner: Includes cabinet, access

door, solid state power supply, two electronic cells and two

metal mesh prefilters.

Electrical Ratings:

Voltage and Frequency: Models available for 120V, 60 Hz.,

240V, 60Hz. 120V models can be converted in the field to

240V, 60 Hz or 220/240V, 50 Hz with the 203365A

Conversion Kit.

Power Consumption:

One cell models: 22 W maximum

Two cell models: 36 W maximum.

Current Draw: See Table 1.

Ionizer Voltage: 8150 Vdc.

Collector Voltage: 4075 Vdc.

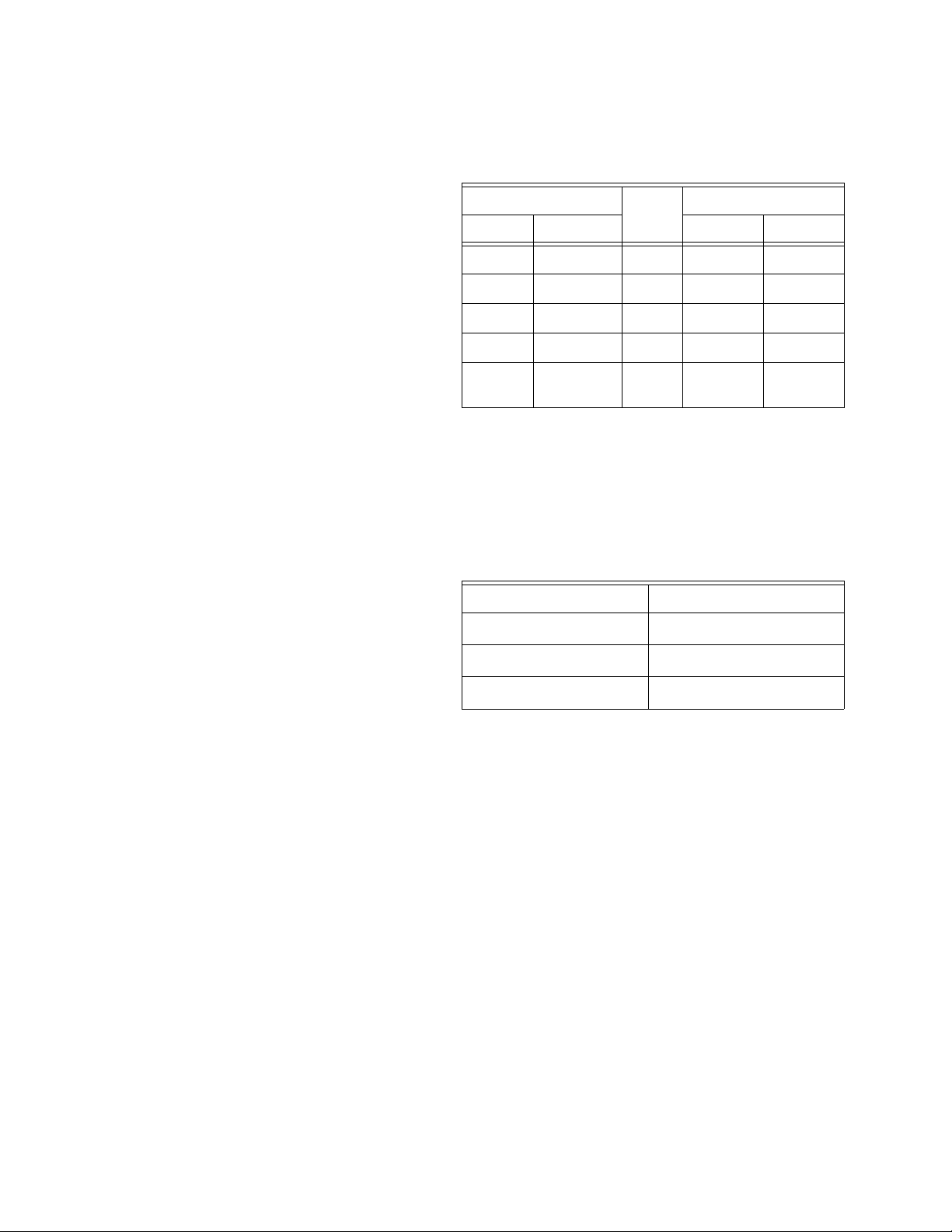

Table 1. Current Draw.

Size

in. mm 120V 220/240V

16 x 25 406 x 635 2 0.4 0.2

20 x 25 508 x 635 2 0.4 0.2

16 x 20 406 x 508 2 0.4 0.2

20 x 20 508 x 508 2 0.4 0.2

20 x

12-1/2 508 x 318 1 0.4 0.2

No.

Cells

Max Current (A)

Fractional Efficiency:

Efficiency ratings are based on American Society of Heating,

Refrigerating and Air-Conditioning Engineers Standard

52.2-1999. Efficiency ranges are defined for small particles,

E

=.3 to 1.0 micron; medium particles, E2 = 1.0 to 3.0

1

microns; and large particles, E

Table 2. Fractional Efficiency With and Without Postfilter.

With postfilter Without postfilter

= 3.0 to 10.0 microns.

3

E

= Up to 81% at 492 fpm. E1 = Up to 73% at 492 fpm.

1

E

= Up to 93% at 492 fpm. E2 = Up to 88% at 492 fpm.

2

E

= Up to 99% at 492 fpm. E3 = Up to 95% at 492 fpm.

3

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

68-0240EF—06 2

F300 ELECTRONIC AIR CLEANER

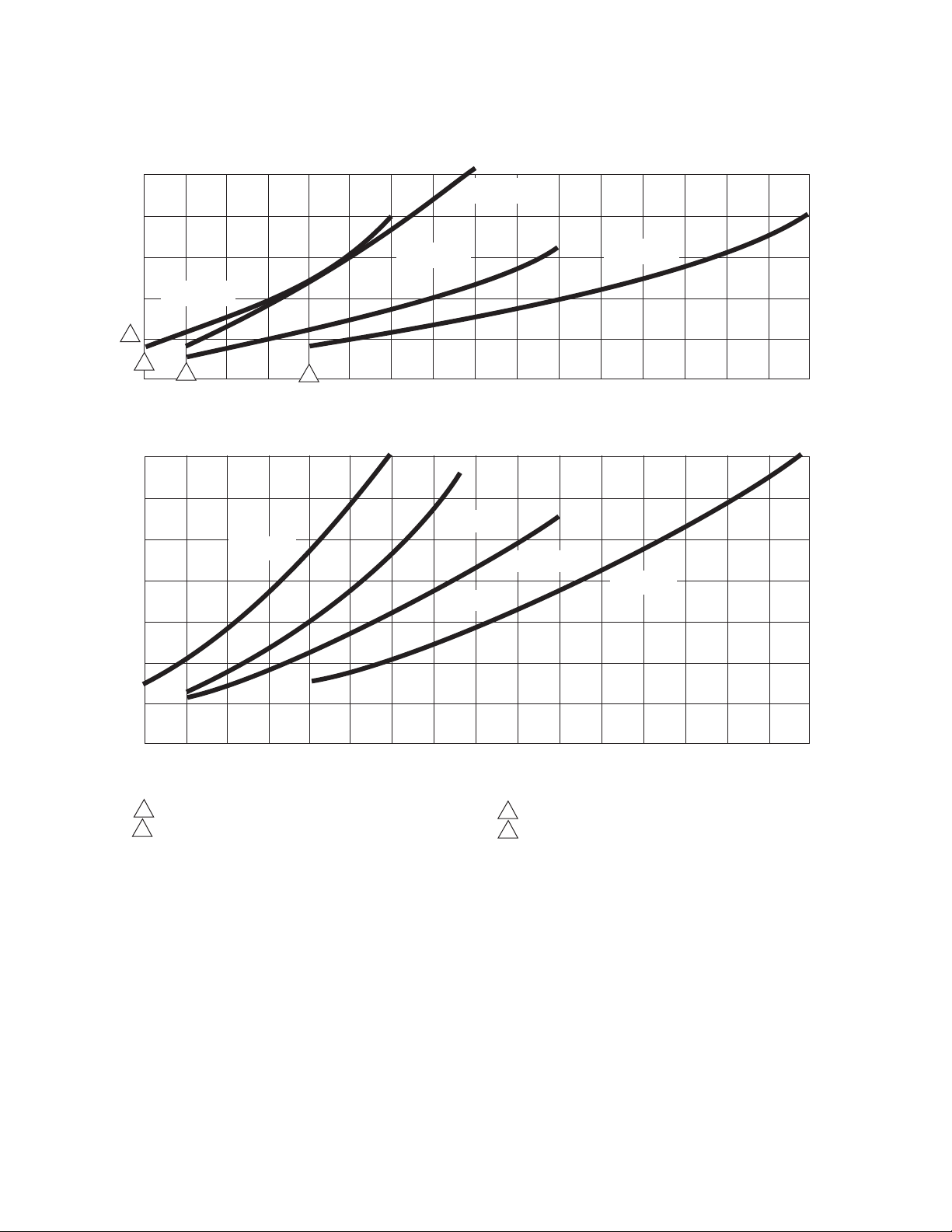

AIR CLEANER EFFICIENCY AND PRESSURE DROP AT VARIOUS AIRFLOW RATES.

WITHOUT POST FILTERS

20 x 12-1/2 in.

(508 x 318 mm)

4

1

2

400

500

(850)

600

(1020)

(680)

WITH POST FILTERS

700

(1190)

20 x 12-1/2 in.

(508 x 318 mm)

3

800

(1360)

20 x 20 in.

(508 x 508 mm)

900

(1530)

16 x 25 in.

(406 x 635 mm)

1000

(1700)

110 0

(1870)

16 x 20 in.

(406 x 508 mm)

16 x 25 in.

(406 x 635 mm)

16 x 20 in.

(406 x 508 mm)

1200

1300

(2040)

(2210)

CAPACITY IN cfm (m

20 x 20 in.

(508 x 508 mm)

1400

(2380)

3

/hr)

20 x 25 in.

(508 x 635 mm)

1500

(2550)

20 x 25 in.

(508 x 635 mm)

1600

(2720)

1700

(2890)

1800

(3060)

1900

(3230)

2000

(3400)

.25

(62.2)

.20

(49.7)

.15

(37.3)

.10

(24.9)

.05

(12.4)

0

.35

(87.2)

.30

(74.7)

.25

(62.2)

.20

(49.7)

.15

(37.3)

PRESSURE DROP IN in. wc (Pa)

400

500

(680)

(850)

1 MINIMUM RECOMMENDED cfm FOR 20 x 12-1/2 in. (508 x 318 mm) MODEL.

2 MINIMUM RECOMMENDED cfm FOR 16 x 25 in. (406 x 635 mm),

20 x 20 in. (508 x 508 mm), 16 x 20 in. (406 x 508 mm) MODELS.

600

(1020)

700

(1190)

800

(1360)

900

(1530)

1000

(1700)

110 0

1200

(1870)

(2040)

CAPACITY IN cfm (m3 /hr)

Fig. 1. Pressure Drop Vs. Airflow.

Temperature Ratings:

Operating Ambient: 40° to 125°F (4° to 52°C).

Temperature of Airflow Through Cells: 40° to 125°F

(4° to 52°C).

Maximum Cell Washing Temperature: 220°F (140°C).

Storage and Shipping Ambient: Minus 40°F to plus 140°F

(minus 40°C to plus 60°C).

Mounting:

Mounts in the return air duct of a forced air heating, cooling, or

ventilating system. Mount upstream from an atomizing

humidifier. See Planning the Installation section.

1400

1300

(2210)

3 MINIMUM RECOMMENDED cfm FOR 20 x 25 in. (508 x 635 mm) MODEL.

4 SELECT SIZE THAT MOST CLOSELY FITS DIMENSIONS OF

FURNACE/AIR HANDLER RETURN AIR OPENING

(2380)

1500

(2550)

1600

(2720)

1700

(2890)

1800

(3060)

1900

(3230)

2000

(3400)

M13654

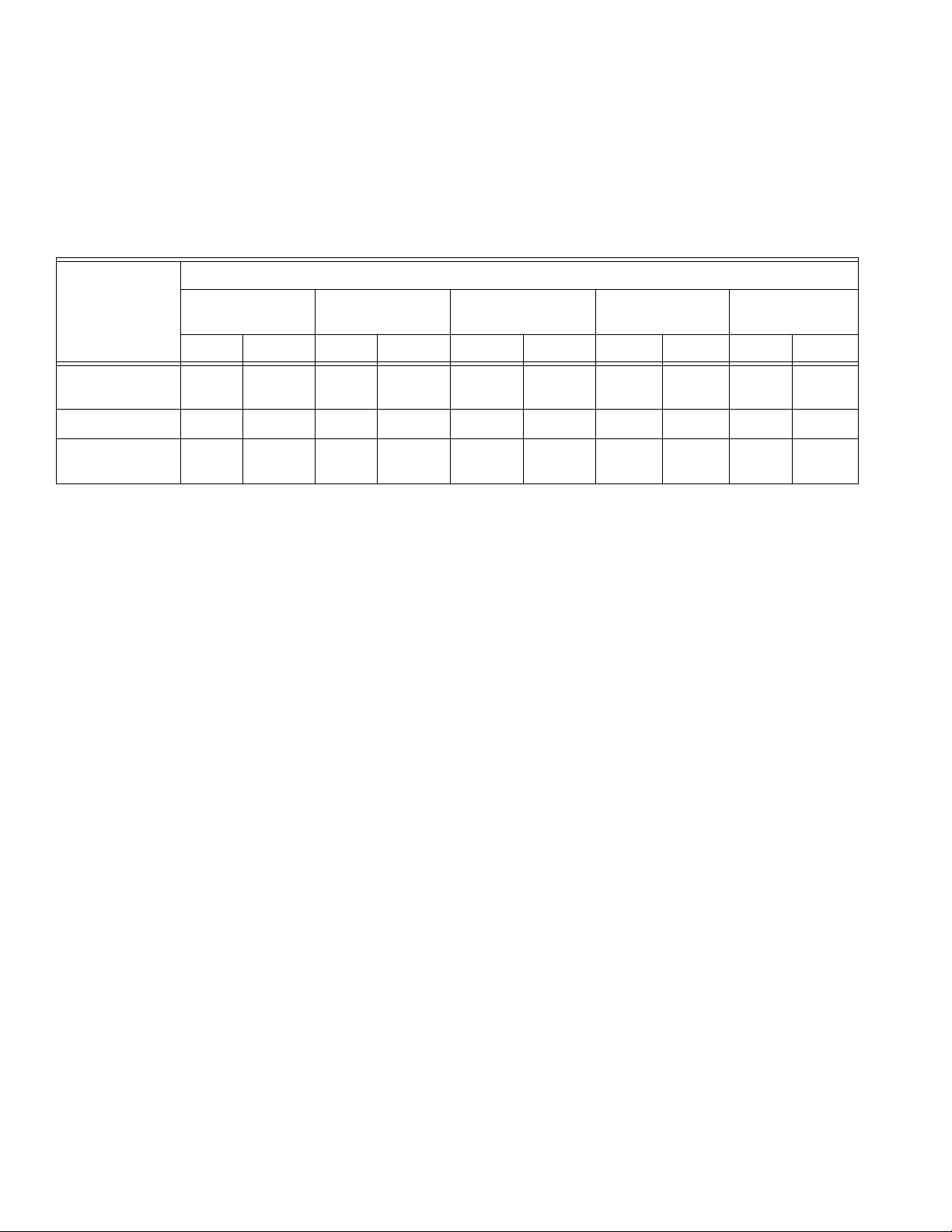

Weight:

See Table 3.

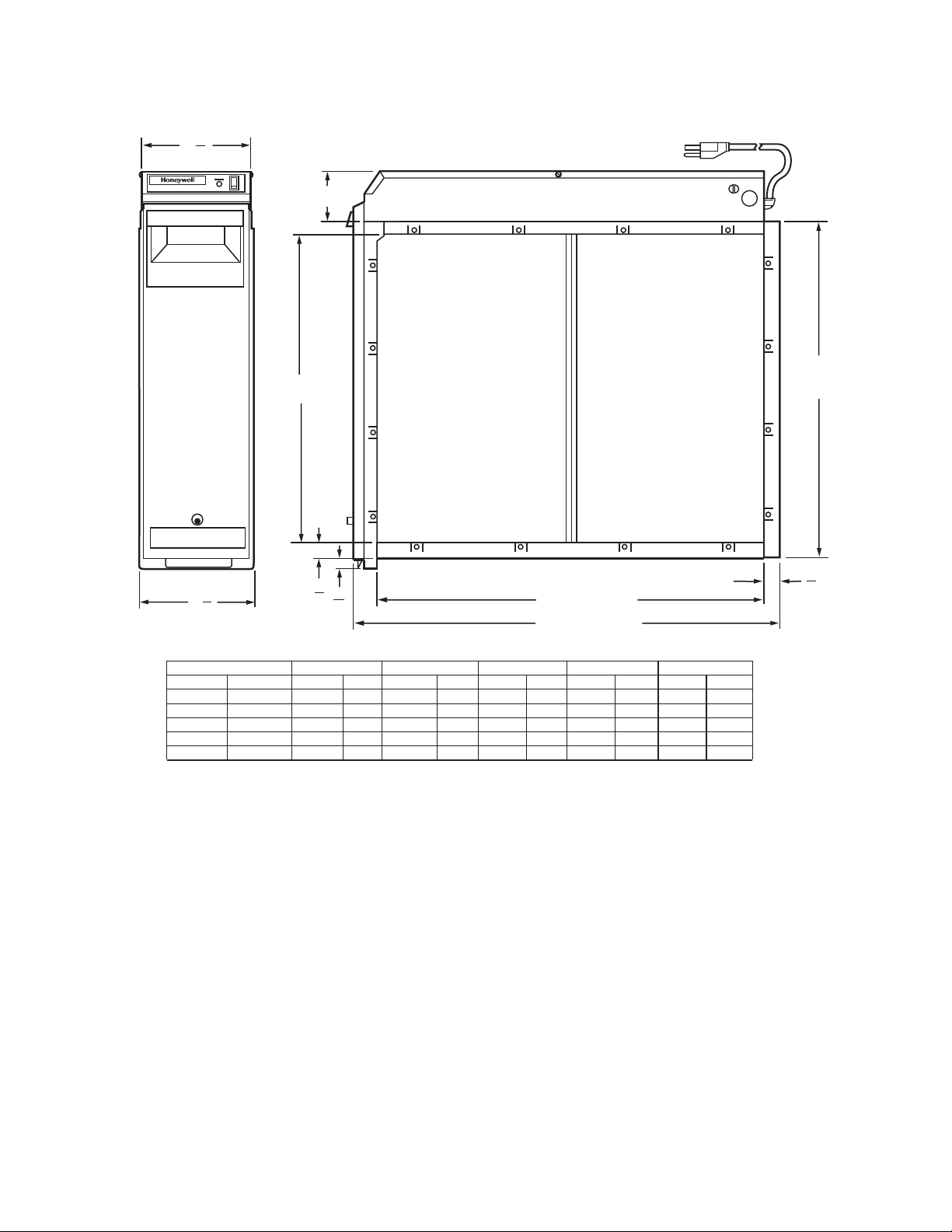

Dimensions:

See Fig. 2.

Approvals:

Underwriters Laboratories Inc. Listed: File E30954.

.10

(24.9)

.05

(12.4)

0

PRESSURE DROP IN in. wc (Pa)

3 68-0240EF—06

F300 ELECTRONIC AIR CLEANER

Accessories:

203365A Conversion Kit for changing 120V, 60 Hz power

supply to 240V, 60 Hz or 220/240V, 50 Hz.

W8600F Air Cleaner Monitor.

W8600A AIRWATCH™ Indicator.

Table 3. Shipping and Installed Weight.

16 x 20 in.

(406 x 508 mm)

Item

Electronic Cell

(each)

Shipping Weight 30 13.6 33 15.0 25 11.3 33 15.0 38 17.2

Installed Weight

(Cells included)

lb kg lb kg lb kg lb kg lb kg

5 2.25 6 2.7 7-1/2 3.4 6-3/16 2.8 7-1/2 3.4

26 11.6 28 12.7 21 9.5 29 13.2 33 15.0

16 x 25 in.

(406 x 635 mm)

Repair Parts:

See Replacement Parts/Exploded View section.

Weight

20 x 12-1/2 in.

(508 x 318 mm)

20x 20 in.

(508x 508 mm)

(508 x 635 mm)

20 x 25 in.

68-0240EF—06 4

F300 ELECTRONIC AIR CLEANER

3

6

8

(162)

ELECTRONIC AIR CLEANER

6

(172)

DIM. E

(SEE TABLE)

DIM. A

(SEE TABLE)

7

3

4

(22)

5

8

8

(16)

DIM. C (SEE TABLE)

DIM. D (SEE TABLE)

DIM. B

(SEE TABLE)

7

8

(22)

F50F SIZE

IN.

16 X 25

16 X 20

20 X 25

20 X 20

20 X 12 1/2

MM

406 X 635

406 X 508

508 X 635

508 X 508

508 X 318

DIM. A

IN. MM IN. MM

14 7/16

14 7/16

18 7/16

18 7/16

18 7/16

367

367

468

468

468

16 3/16

16 3/16

20 3/16

20 3/16

20 3/16

DIM. B

411

411

513

513

513

Fig. 2. Electronic air cleaner installation dimensions in in. (mm).

PLANNING THE INSTALLATION

Application

The F300 Electronic Air Cleaner is used in a forced air heating,

cooling, or ventilating system. It removes airborne particles

from the air circulated through it. All models have an internal air

flow switch that automatically energizes the air cleaner cells

when the system blower is on.

Review Installation Requirements

The air cleaner should be installed where all the air passing

through the system circulates through it. The best location is in

the return air duct next to the blower compartment so the air

cleaner can help keep the blower motor and evaporator coils

clean.

DIM. C

IN. MM IN. MM

23 1/4

591

18 1/4

457

23 1/4

591

18 1/4

457

10 7/8

276

DIM. D

25 1/2

20 1/2

25 1/2

20 1/2

13 1/8

648

521

648

521

333

DIM. E

IN. MM

2 3/4

2 3/4

2 3/4

2 3/4

3 5/8

70

70

70

70

92

M2872A

IMPORTANT

Do not mount in the discharge air duct.

For most efficient air cleaning, airflow must be spread evenly

across the face of the air cleaner. If the duct is a different size

than the air cleaner cabinet, gradual transitions are

recommended. If the duct turns sharply just before the air

cleaner, turning vanes are recommended.

Applications with Air Conditioning

The air cleaner should be installed upstream from the

evaporator coil. The air cleaner will help keep the coil clean,

reducing maintenance.

5 68-0240EF—06

F300 ELECTRONIC AIR CLEANER

WARNING

Applications with a Humidifier

An evaporative humidifier can be mounted upstream from the

air cleaner. An atomizing humidifier should be mounted

downstream from the air cleaner, even though hard water salts

will be blown into the living space and deposited as dust. If an

atomizing humidifier must be mounted upstream from the air

cleaner:

1. Mount it as far as possible upstream from the air cleaner.

2. Install a standard disposable furnace filter between the

humidifier and the air cleaner to trap water droplets and

hard water salts.

3. Frequently clean the air cleaner to prevent a hard water

salt buildup.

NOTE: The volume of water that is discharged from an atom-

izing humidifier can overload the air cleaner, resulting

in hard water salts being deposited as dust in the living space.

Applications with Outdoor Air Intake

Return air temperature must be at least 40°F (4°C). Lower

temperatures can cause ionizer wire failure. If outdoor air is

used, warm it upstream from the air cleaner by:

• Making sure the outdoor intake is far enough upstream from

the air cleaner so the return and outdoor air is thoroughly

mixed. Stratified air can dump a stream of very cold air into

one section of the air cleaner.

• Adding baffles upstream from the air cleaner to force

thorough air mixing.

• Installing a Honeywell Perfect Window™ Fresh Air

Ventilation System that transfers up to 80 percent of the

heat from the exhaust air to the incoming outside air. This

keeps the incoming air above 40°F (4°C) and reduces

energy usage.

• Installing a preheater if large amounts of outdoor air are

used. The preheater, which could be an electric strip heater

or hot water coil, should be controlled by a thermostat. Hot

water or steam coils should be protected by a freeze-up

control.

Optional W8600F Air Cleaner Monitor

The W8600F Air Cleaner Monitor can be mounted in the living

area or in the furnace room. It should be located in a

convenient location to observe the display.

The W8600F Air Cleaner Monitor is furnished with all the

connectors needed for easy installation. Follow the installation

instructions provided with the W8600F.

Optional W8600A AIRWATCH™ Indicator

The W8600A can be mounted next to the thermostat or in any

other location in the living area of the home where the display

can be conveniently observed. No wiring is necessary.

Choose Location

Choose a location that is readily accessible for regular

inspection and cleaning. Allow at least 13 in. (330 mm) in front

of the access door for removing the metal mesh prefilter, media

postfilter and electronic cell. Allow enough room above the

power supply so it can be serviced without removing pipes,

ducts, or other heating system components.

The air cleaner must be installed where the temperature is

between 40° to 125°F (4° to 52°C).

IMPORTANT

UV light can damage media postfilters. Avoid

installing UV lamp downstream of F300 in location

where UV light illuminates postfilter.

Choose Mounting Position

Heavy Equipment Hazard.

Can cause injury or equipment damage.

Do not mount air cleaner with access door facing down

because the latch may not hold and the cell, postfilter

and prefilter can fall unexpectedly.

NOTE: Nothing holds the cell, postfilter, and prefilter in place

when the access door is opened.

The air cleaner can be mounted in any position except with the

access door facing down. A list of air cleaner mounting

positions for a variety of furnace installations follows.

NOTE: At least 13 in. (330 mm) clearance is required

between the access door and any obstructions for

cell, postfilter and prefilter maintenance.

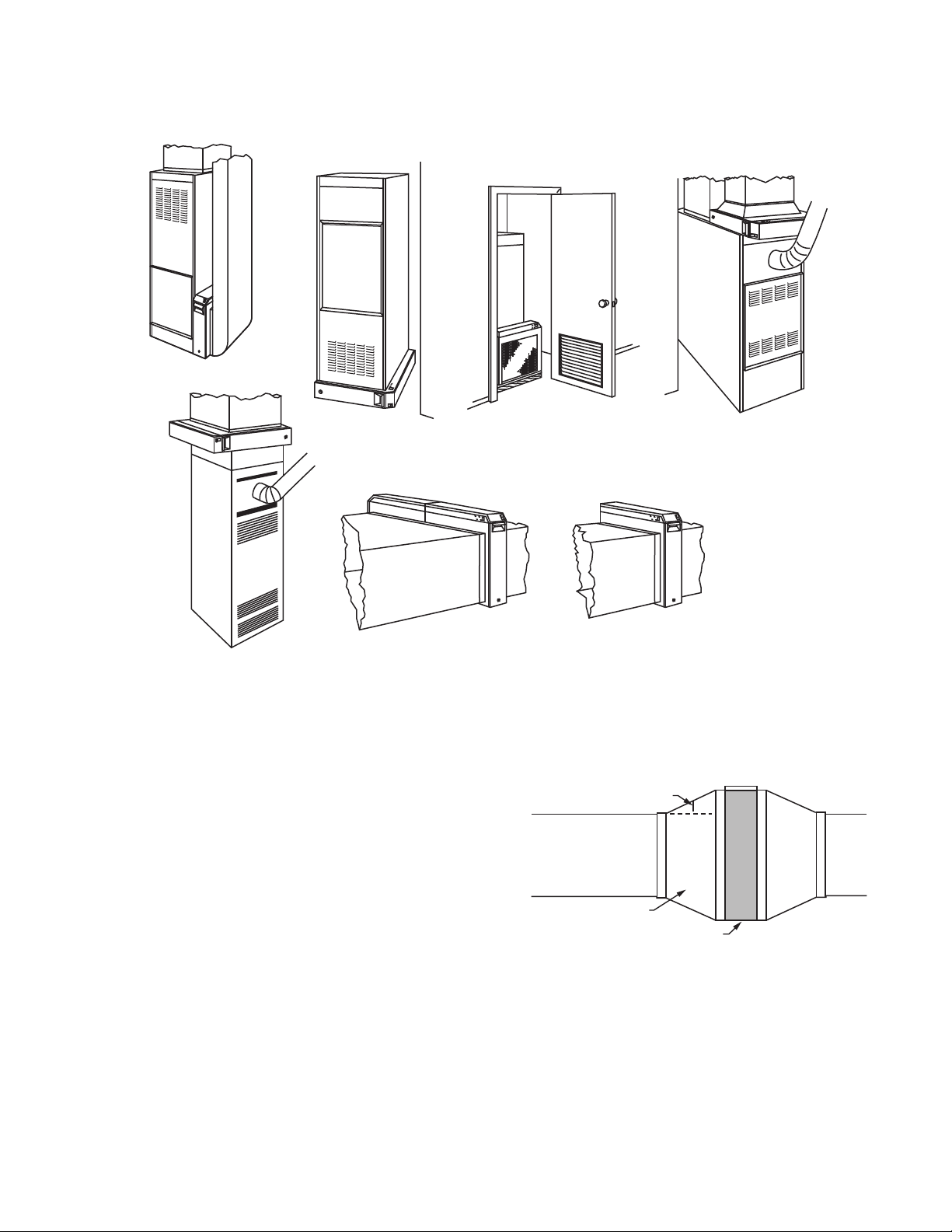

— Upflow Highboy furnace: Side installation; air cleaner is

mounted vertically where return enters side inlet of furnace.

See Fig. 3A.

— Upflow Highboy furnace: Installation beneath furnace (air

cleaner cabinet can easily support weight of furnace and air

conditioner coil). Air cleaner is mounted horizontally where

return enters from below. See Fig. 3B.

— Upflow Highboy furnace: Closet installation. Air cleaner is

mounted vertically on furnace between furnace and

louvered return air opening in closet door. See Fig. 3C.

— Lowboy furnace: Air cleaner is mounted horizontally in

return plenum just above furnace, opposite of supply

plenum. See Fig. 3D.

— Downflow Counterflow furnace: Air cleaner is mounted

horizontally in return duct or plenum just above furnace.

See Fig. 3E.

— High capacity system: Two or more air cleaners can be

used together. See Fig. 3F.

— Horizontal furnace: Air cleaner is mounted vertically where

return enters. See Fig. 3G.

68-0240EF—06 6

F300 ELECTRONIC AIR CLEANER

A

B

C

E

D

F

Fig. 3. Mounting positions with variety of furnace installations.

Determine Duct Design Requirements

The air cleaner is adaptable to all new or existing forced air

heating, cooling and ventilating systems used in residential

applications. Transitions, turning vanes, or offsets may be

needed in some applications for effective operation.

Transitions

Transitions are needed when the duct is a different size than

the air cleaner cabinet. Gradual transitions reduce air

turbulence and increase efficiency. Limit expansion to no more

than 20 degrees or about 4 in. per running foot (100 mm per

300 linear mm) on each side of a transition fitting.

See Fig. 4.

G

M19777

CHANGE DUCT SIZE GRADUALLY TO MINIMIZE TURBULENCE.

20 DEGREE EXPANSION PER SIDE PER

FITTING (4 in. PER LINEAR FOOT

[100 mm PER 300 LINEAR mm]).

RETURN

AIR DUCT

TRANSITION FITTING

ELECTRONIC AIR CLEANER CABINET

M5626A

Fig. 4. Change duct size gradually to minimize turbulence.

Turning Vanes

If the air cleaner is installed close to an elbow or angle fitting,

install turning vanes inside the angle to distribute airflow more

evenly across the face of the cell. See Fig. 5.

7 68-0240EF—06

F300 ELECTRONIC AIR CLEANER

WARNING

M5627A

LESS

THAN

7 in.

[178 mm]

OFFSET

AT LEAST

7 in.

[178 mm]

1

1 TURNING VANES HELP DISTRIBUTE AIRFLOW EVENLY.

E

L

E

CT

R

O

NI

C

AI

R

C

LE

A

N

E

R

TYPICAL USE OF DUCT OFFSET TO ALLOW

SPACE FOR ELECTRONIC AIR CLEANER.

M20804

Offsets

If the duct connection to the furnace in a side installation allows

less than 7 in. (178 mm) for mounting the air cleaner cabinet,

add an offset to the elbow. See Fig. 5.

Fig. 5. Typical use of duct offset to allow space for

electronic air cleaner.

INSTALLATION

Clean Blower Compartment

Remove and discard the existing furnace filter.

Thoroughly clean the blower compartment.

If possible, power vacuum the ductwork to remove

accumulated dust in an existing home, or construction dirt in

a new home. The electronic air cleaner cannot remove dust

that has settled in the blower compartment and distribution

ducts.

Check the edges of the furnace fan blades for dirt buildup

and clean as necessary. The fan will not deliver the rated

cfm if the blades are dirty.

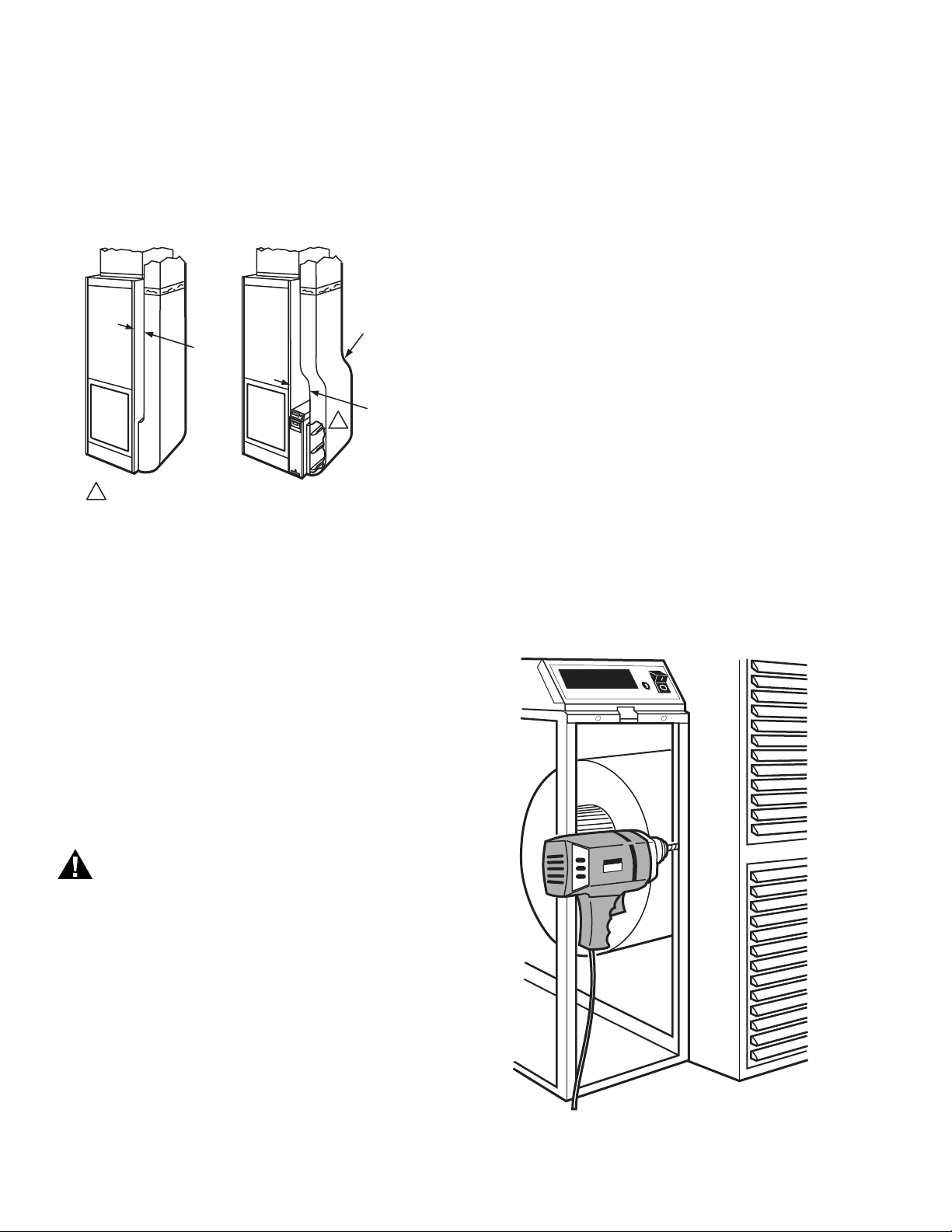

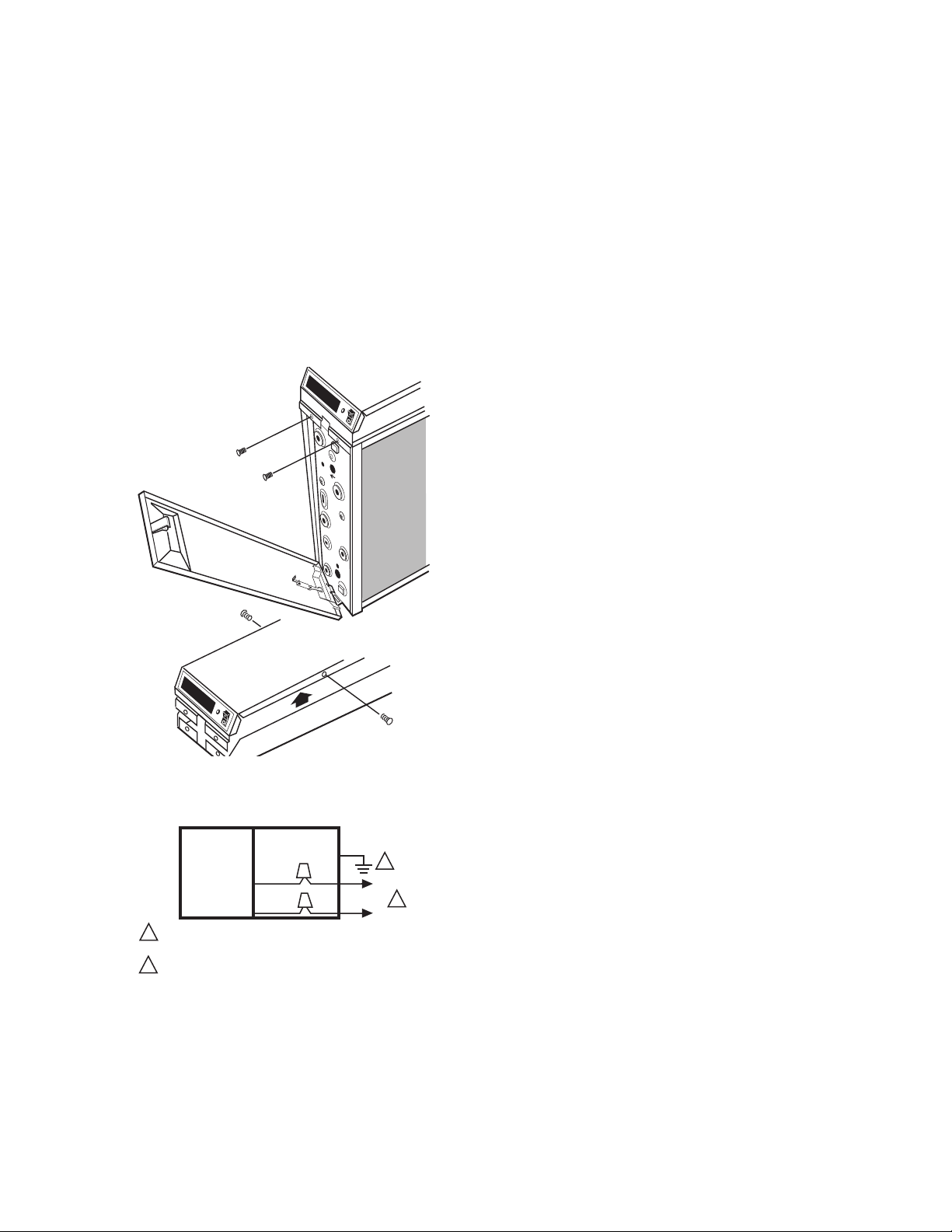

Fasten Cabinet To Furnace

NOTE: This procedure shows a side installation on a typical

highboy furnace. You may need to alter the procedure

to fit your application.

Remove and set aside the access door, electronic cells

metal mesh prefilters and media postfilters.

Align the cabinet with the return air opening.

Create opening in furnace to match air cleaner cabinet

opening.

Install a transition when the furnace and air cleaner

openings are different sizes. See Fig. 4.

Place blocks under the cabinet so the unit is firmly

supported and level. The 5/8 in. (16 mm) mounting foot on

the cabinet hinge plate provides the minimum clearance

required for the access door hinge.

Attach the cabinet securely to the furnace. The unit can be

attached directly, as shown, or a starting collar can first be

fitted in the furnace opening. Either drill holes and fasten with

sheet metal screws or rivets, or use slip joints. See Fig. 6.

When Installing this Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Electric Shock Hazard.

Can cause electrical shock or equipment damage.

Do not connect to power before installation is complete.

Unpack Electronic Air Cleaner

Check that all components are included. The electronic air

cleaner is shipped assembled. The unit consists of a

galvanized steel cabinet, power supply with On-Off switch

and neon light, two electronic cells, two metal mesh

prefilters, two media postfilters (on select models), access

door and product data literature.

Order W8600F (optional) including mounting hardware and

Order W8600A (optional) including mounting hardware,

installation literature separately.

batteries, and literature separately.

Fig. 6. Fasten cabinet to furnace.

68-0240EF—06 8

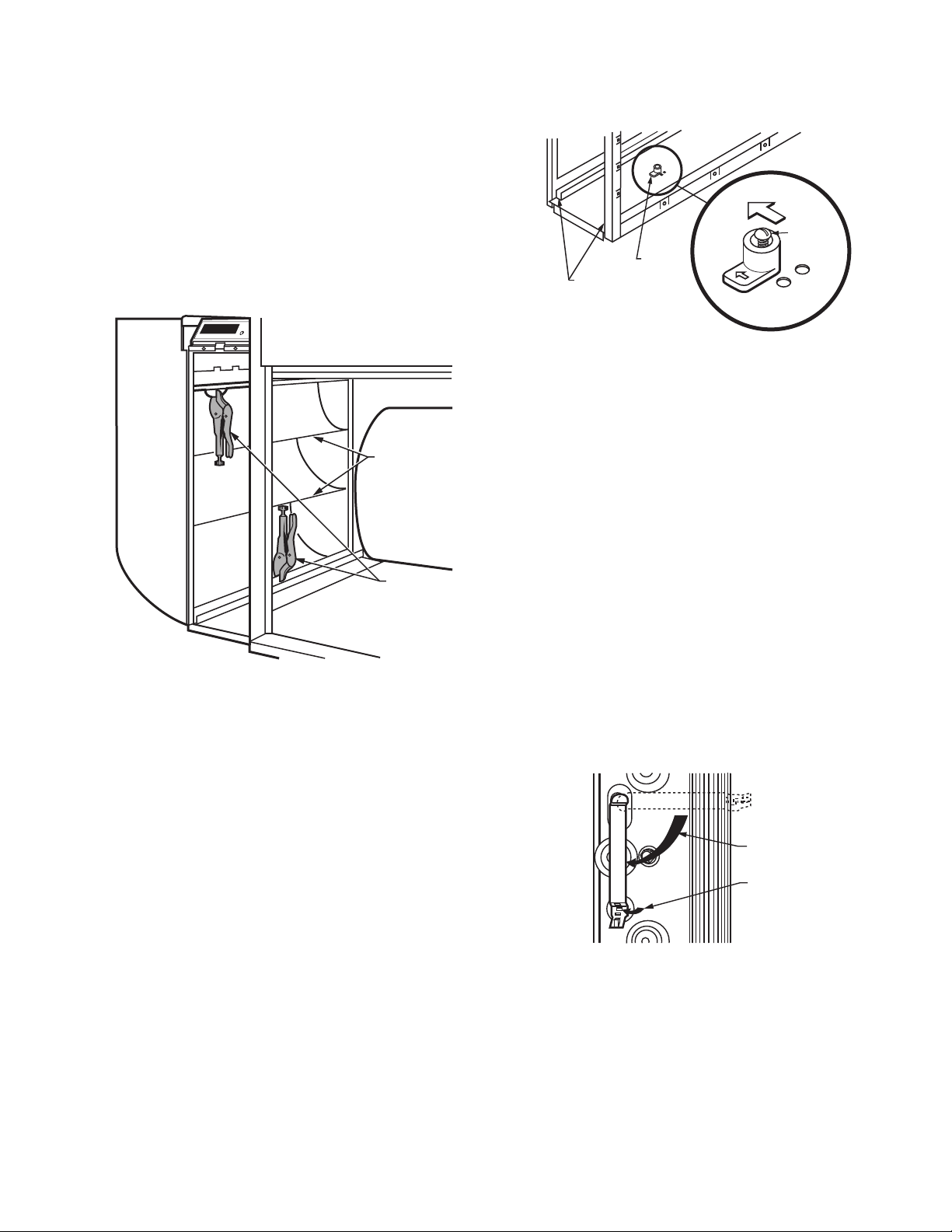

Install Turning Vanes

M20815

LOCKING

PLIERS

TURNING

VAN ES

Mount turning vanes inside the elbow or angle fitting that is

directly against the air cleaner cabinet. See Fig. 7.

F300 ELECTRONIC AIR CLEANER

Fasten Cabinet To Ductwork

Install a transition when the opening in the air cleaner

cabinet and the duct are different sizes. See Fig. 4.

Fasten the other side of the cabinet to the elbow using

sheet metal screws, rivets, or slip joints as appropriate. If

drilling holes, use locking pliers to help hold the unit in place

during drilling. See Fig. 7.

Fig. 7. Connect ductwork to air cleaner. (Note turning

vanes. Locking pliers hold duct to air cleaner cabinet

during installation.)

CELL KEY

PREFILTER GUIDES

M5639

DOWNSTREAM

CELL

KEY

AIRFLOW

CELL KEY

SCREW

ALTERNATE

HOLES FOR

KEY

Fig. 8. Position of cell key determines orientation of cell

(arrow on key must point downstream).

3. Turn the key around and place it over the opposite holes.

The tab on the bottom fits into the larger hole, and the

screw fits into the smaller hole. Make sure the arrow on

the key points in the direction of the air flow (downstream).

4. Tighten the screw into the new hole.

5. Insert the electronic cell. The ionizer section will now be

on the air-entering (upstream) side of the cabinet.

Attach Cell Handles

Cell handles included with the air cleaner must be installed on

the end of the cell closest to the access door. To install:

1. Orient the cell as it will be when installed. The gray

contact board must be up and the airflow arrow stamped

into the cell must point downstream.

2. Hold the handle sideways and insert the solid tab on the

back of the handle into the slot in the cell. Turn the

handle 90 degrees clockwise to align the divided tab with

the square hole. See Fig. 9.

Seal Joints

Seal all joints in the return air system between the air

cleaner and the furnace to prevent dust from entering the

clean airstream. Use optional air cleaner cabinet gasket kit

(part no. 32002109-001), mastic or foil tape.

Position Cell Key

The electronic cell must always be installed so the ionizer

section is on the upstream side. A factory-installed cell key on

the bottom of the cabinet allows the cell to be inserted in only

one direction. If the arrow molded into the plastic key points in

the same direction as the airflow, the ionizer is always on the

upstream side.

If position of the key must be reversed, proceed as follows:

1. Remove the electronic cell.

2.

Remove the screw holding the cell key in place. See Fig. 8.

9 68-0240EF—06

INSTALL HANDLE ON END OF CELL

CLOSEST TO ACCESS DOOR

ROTATE 90

DEGREES

FOLD TAB

TO LOCK

HANDLE

IN PLACE

M6047A

Fig. 9. Install the handle on the end of the cell closest to

the access door.

3. Insert the divided tab into the square hole.

4. Fold up the wedge and insert it into the divided tab to

lock the handle in place. If necessary, press with a blunt

instrument like the end of a pliers.

F300 ELECTRONIC AIR CLEANER

WARNING

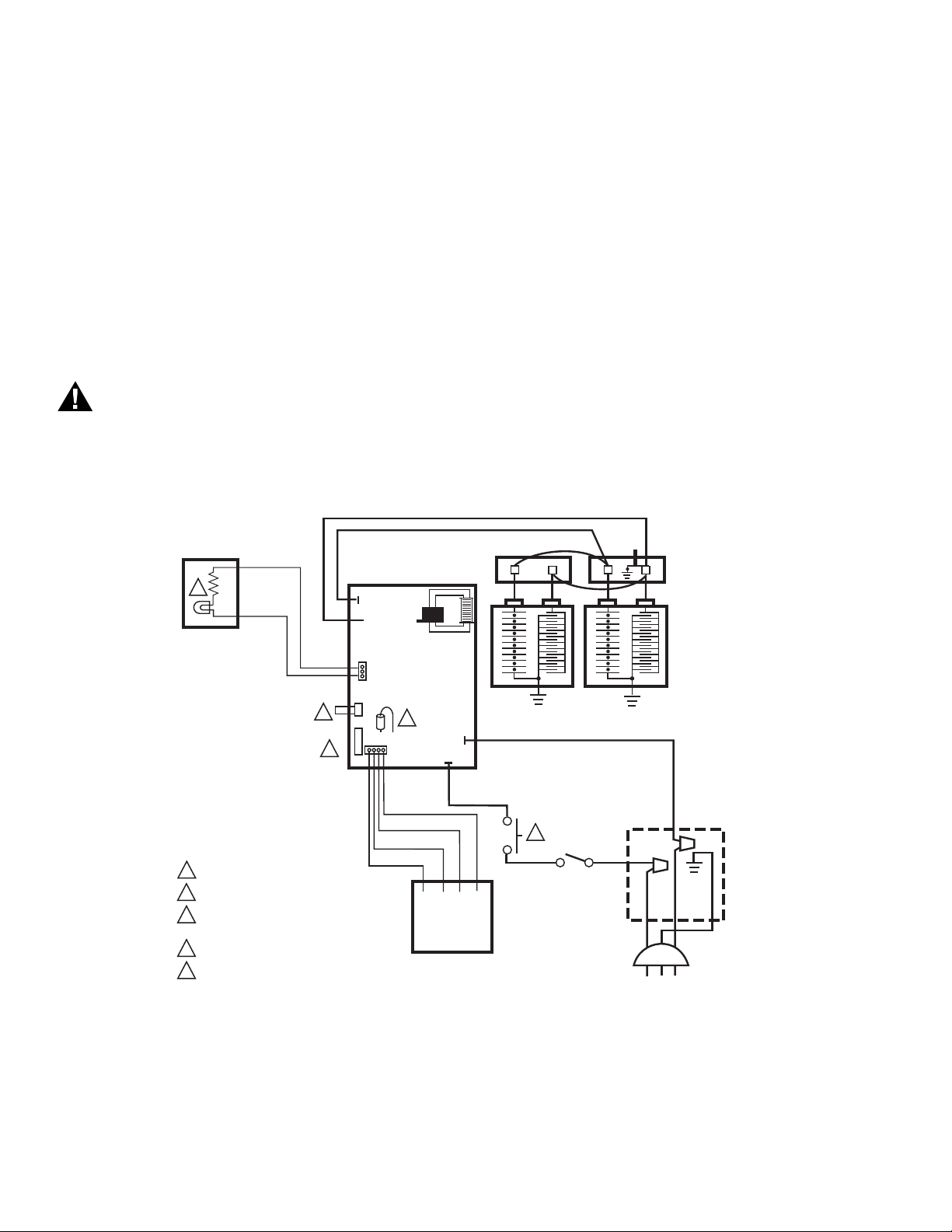

P3

P4

P1

P2

J3

BLACK

W4 W2 W1 W3

AIRFLOW SWITCH BOARD

ORANGE

GRAY

VIOLET

BLACK

1 INTERLOCK SWITCH.

2 SHORTING BAR FOR OZONE REDUCTION.

3 AIRFLOW SWITCH DISABLE JUMPER, J8.

AIRFLOW SWITCH PLUG, J3.

4 NEON LIGHT.

5 OPTIONAL W8600F AIR CLEANER MONITOR.

M23413

POWER

SUPPLY

2

4

BLACK

BLACK

BLACK

BROWN

BLACK

BLACK

WHITE

GREEN

1

3

J4

J5

J1

BLACK

RED

TEST

BUTTON

CONTACT

BOARD

RED IONIZER

BLACK COLLECTOR

5

J8

Reassemble Air Cleaner

Insert the electronic cells with the gray contact board toward

the power supply and the airflow arrow pointing

downstream. If the cell does not slide easily into the cabinet,

check the orientation of the cell key.

Insert the metal mesh prefilters on the upstream side of the

cabinet in the guide provided.

Insert the media postfilters (on select models) on the

downstream side of the cabinet in the guide provided.

Replace the access door. Insert the tab on the bottom of the

door into the slot in the cabinet, then swing it closed and

press into place. The door must be firmly in place or the air

cleaner will not operate.

Complete Wiring

Electric Shock Hazard.

Can cause personal injury.

Do not use an extension cord.

• Assure all wiring complies with local codes and ordinances.

• The line voltage power source must match the voltage and

frequency printed on the label inside the access door.

• When the System fan comes on, the Air Flow Switch (AFS)

senses the negative pressure in the duct and turns on the

power supply. If power to the air cleaner is controlled by

another switch, the AFS can be disabled by disconnecting

the AFS plug J3 and cutting the J8 jumper on the power

supply. See Fig. 10.

Plug the electronic air cleaner directly into the correct

voltage and frequency outlet. See Fig. 10 for internal

schematic. The air cleaner operates correctly with any fan

when wired with conduit or plugged in.

NOTE: To reduce the risk of electric shock, this product has a

grounding type plug that has a third (grounding) pin.

This plug only fits into a grounding type power outlet.

If the plug does not fit into the outlet, contact a qualified electrician to install the proper outlet. Do not

change the plug in any way.

Alternatively, the electronic air cleaner can be wired with

conduit.

68-0240EF—06 10

Fig. 10. Internal schematic for electronic air cleaner.

F300 ELECTRONIC AIR CLEANER

3

1

2

REMOVING COVER

FROM POWER BOX.

ELECTRONIC

AIR CLEANER

WIRING

COMPARTMENT

BLACK

BROWN

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

THE AIR CLEANER CAN BE COMPLETELY ISOLATED FROM

THE ELECTRICAL CIRCUIT OF THE HVAC SYSTEM UNLESS

REQUIRED BY LOCAL CODE TO USE SAME CIRCUIT. ANY

CONVENIENT HOUSE CIRCUIT CAN POWER AIR CLEANER,

REGARDLESS OF ELECTRICAL RATING OF HVAC SYSTEM.

M5707

2

1

2

L1 (HOT)

L2

1

1. Open access door.

2. Remove and retain the two screws from the front of the

power box and the two screws from the sides of the

power box. See Fig. 11.

3. In the power box, remove and retain two wire nuts that

connect the line cord leads to the power box wiring.

4. Remove the power cord green lead from the green

grounding screw on the wiring compartment barrier.

5. Remove the power cord and the strain relief.

6. Install the plug (provided with the literature pack) in the

hole left by the power cord.

7. Attach conduit through a power box side knockout.

8. Wire the air cleaner directly to line voltage using wire

nuts. See Fig. 12. Secure ground connection to the

green ground screw on the wiring compartment barrier.

9. Replace power supply cover and access door.

Fig. 11. Removing cover from power box.

OPERATION

Large particles (lint, hair) are caught by the prefilter. As the

dirty air passes through the intense high voltage electric field

surrounding the ionizer wires, all particles are given an

electrical charge.

The air then moves through the collector part of the cell where

alternate parallel plates are charged positively and negatively,

creating a uniform electrostatic field. The charged particles are

attracted to and collect on the plates that have the opposite

electrical charge.

The air then passes through media postfilters, removing

additional particles from the air stream. The air leaving the air

cleaner has fewer particles. Each time the air circulates

through the electronic air cleaner, more particles are removed.

CHECKOUT

Inspect the Installation

Make sure:

• Turning vanes and transitions, as needed, are correctly

installed.

• Sheet metal joints between air cleaner and furnace are

sealed.

• All sheet metal connections are complete.

• Original furnace filter has been removed and the blower

compartment cleaned.

• If atomizing humidifier is installed upstream from the air

cleaner, a disposable furnace filter is installed between the

humidifier and the air cleaner.

• Outside air, if used, is mixed with return air or heated, as

necessary, before it can reach the air cleaner.

• Airflow arrows on the electronic cell point downstream.

• Metal mesh prefilter is on the upstream side and media

postfilter is on downstream side of the cell.

• Cell handle faces outward.

• Electronic cell and prefilter are clean and dry.

• W8600F wiring connections are correctly made.

Fig. 12. Conduit connection for electronic air cleaner.

11 68-0240EF—06

F300 ELECTRONIC AIR CLEANER

CAUTION

CAUTION

Check Air Cleaner Operation

With all components in place, turn on air cleaner switch and

energize system blower. Check following points of operation:

1. The neon light next to the On-Off switch is on. The neon

light shows that the air cleaner is energized and the high

voltage power supply is working correctly. If a W8600F is

part of the installation, also check the wall panel and

make sure the On indicator is lit. The W8600F Fault indicator comes on if there is a problem with the high voltage

power supply.

2. Turn off the system blower. The neon light should go off

after a few seconds.

3. Turn on the system blower. With the air cleaner ener-

gized, push the test button. A snapping sound indicates

that the collector voltage is present on the cell.

4. With a multispeed blower, repeat steps 1 through 3 for

each fan speed.

SERVICE

Sharp Edges.

Can cause personal injury.

Carefully handle the cell(s) or wear protective gloves to

avoid cuts from the sharp metal edges.

Cleaning the Cells and Prefilters

To assure optimum performance from the air cleaner, the cells

and prefilters must be cleaned regularly and the postfilters

replaced regularly—twice a year with normal use or more

frequently with heavy use. Washing frequency varies,

depending on the number of family members, pets, activities

(such as cooking or woodworking) and smoking habits. Use

the Service Reminder Schedule at the end of this document to

help establish and maintain a regular cleaning schedule. Keep

your Service Reminder Schedule in a convenient location.

If the air cleaner has a W8600F Air Cleaner Monitor, the

SERVICE indicator activates to indicate filter and cell

maintenance are due. The time between activation of the

SERVICE indicator is based on air cleaner run time that is

selected by the installer at installation.

If the air cleaner has a W8600A AIRWATCH Indicator, the Air

Cleaner LCD arrow blinks to indicate it is time to service the

cells and prefilters. The time between activations of the Air

Cleaner LCD is based on calendar time that is selected at

installation.

NOTE: To let the heating or air conditioning system operate

normally while the cells are being washed, simply turn

off the air cleaner switch.

Cleaning your Prefilter

1. The quickest and easiest way to clean your prefilter is to

use the brush attachment of your vacuum cleaner to vacuum the lint off the dirty side of the prefilter. Greasy dirt

may require soaking the prefilter in a tub or rinsing with

the garden hose. Do not wash the prefilter in the dishwasher or car wash.

2. The prefilter should be cleaned every 6 months or more

frequently with heavy use. This will keep the prefilter

clean of air choking lint that can make your system work

harder.

Cleaning your Cells

1. A quick cleaning of the cells can be done by simply wip-

ing down the ionizer wires with a damp cloth. This will

help boost the efficiency of the air cleaner between full

cleaning cycles. This quick clean can be done every time

the prefilters are cleaned.

2. A full cleaning of the cells will return the air cleaner to its

peak efficiency. An easy way to wash the cells is in a tub

of hot, soapy water. Just soak the cells until the water

cools, agitate and rinse. For details see below instructions on Cleaning in a Container, Automatic Dishwasher

or Washing Cells at the Car Wash.

3. A full cleaning of the cells can be put off for yearly main-

tenance because the efficiency of the air cleaner

remains high even as it loads up with dirt. A quick cleaning can be done more often. Those wishing to renew to

peak effeciency or with heavier use may want to wash

more frequently.

Replacing your Postfilter

1. The postfilter is an optional filter that boosts the effi-

ciency of the air cleaner. Do not wash the postfilter

because that will neutralize the factory applied charge.

2. The postfilter should be replaced every six months to

ensure peak performance.

Automatic Dishwasher

Burn Hazard.

Can cause personal injury.

Allow cells to cool completely in dishwasher at end of

wash cycle or wear protective gloves to avoid burns.

Hot water can accumulate in the tubes supporting

collector plates; tip cells so tubes drain.

IMPORTANT

• Check the dishwasher owner's manual. Some

manufacturers do not recommend washing electronic cells

in their dishwashers.

• If the dishwasher has upper and lower arms, position the

cells carefully to allow good water circulation.

• Be careful to avoid damaging the cells when placing them in

the dishwasher. Broken ionizer wires or bent collector plates

are not included in the warranty.

• Very dirty cells, especially from tobacco or cooking smoke,

can discolor the plastic parts and the lining of some

dishwashers. This discoloration is not harmful. To minimize

it, wash the cells more frequently or try a different brand of

detergent.

• Do not allow the dishwasher to run through the dry

cycle. This bakes on any contaminants not removed during

the wash cycle and reduces air cleaner efficiency.

68-0240EF—06 12

F300 ELECTRONIC AIR CLEANER

CAUTION

1. Put the cells on the lower rack of the dishwasher with the

airflow arrow pointing up. It may be necessary to remove

the upper rack. Do not block water flow to the upper arm.

NOTE: Lay a few large water glasses between the spikes on

the lower rack and rest the cell(s) on them so the

spikes do not damage the aluminum collector blades.

2. Using regular dishwasher detergent, allow the dish-

washer to run through the complete wash and rinse

cycle. Do not use the dry cycle. To avoid burns, let the

cells cool completely before removing, or wear protective

gloves when removing the cells. Remember that water

may be trapped inside the cells. Tip the cells so the

tubes can drain.

3. Wipe ionizer wires and contact board on the end of the

cell using thumb and forefinger with a small, damp cloth.

4. Inspect the dishwasher. Rerun wash and/or rinse cycle

with the dishwasher empty if there is dirt or residue from

washing the cells. If dirt or residue seems excessive,

wash cells more often or try a different detergent.

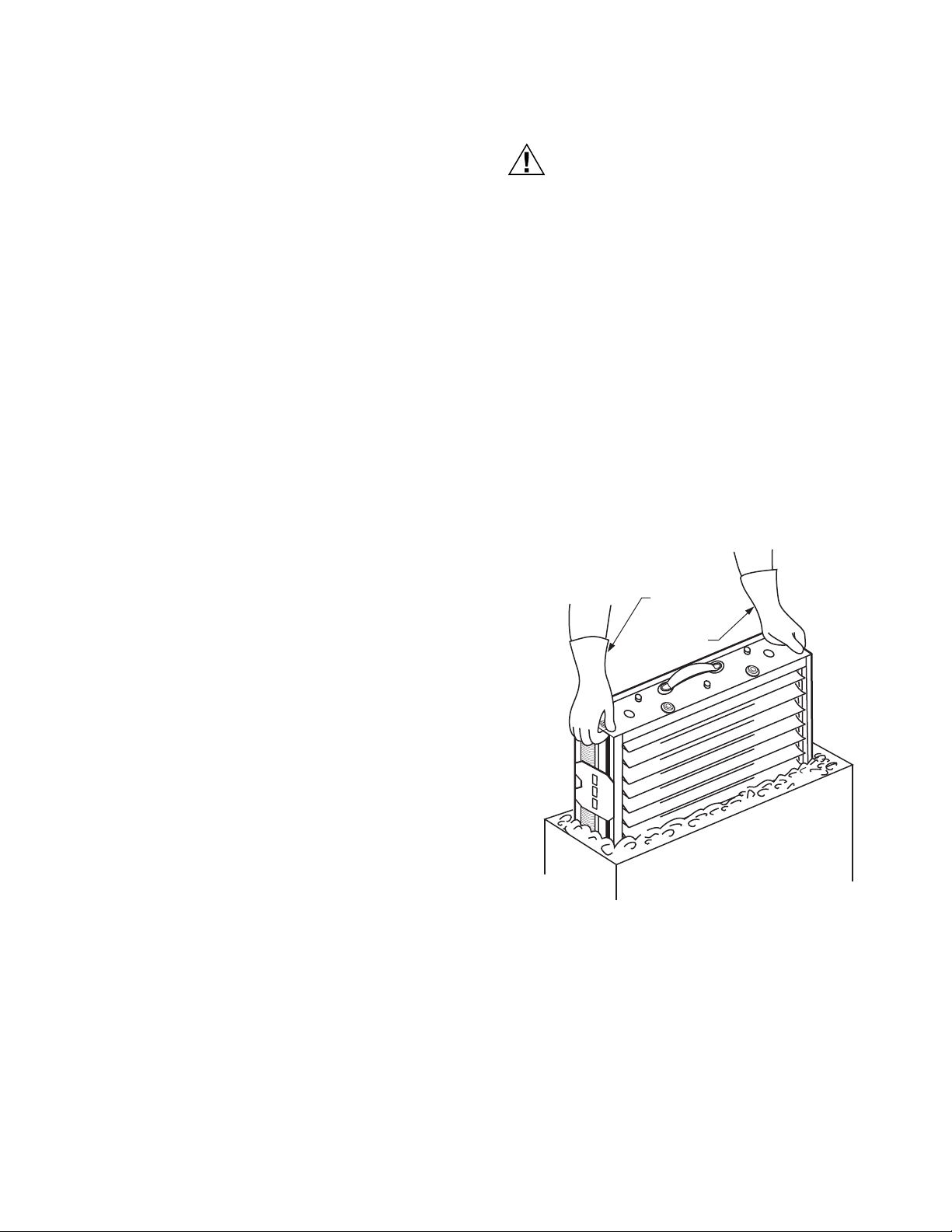

Washing Cells in a Container

Hazardous Chemical.

Can cause personal injury.

Do not splash detergent solution in eyes. Wear rubber

gloves to avoid prolonged detergent contact with skin.

Keep detergent and solution out of reach of children.

NOTE: Always wash the cells first, then the prefilters, to keep

heavy prefilter lint from getting caught in the cells.

1. Use a large enough container, such as a laundry tub or

trash container, to hold one or both cells.

NOTE: Sharp corners on cells can scratch surface of

bathtub.

2. Dissolve about 3/4 cup of automatic dishwasher deter-

gent per cell in enough hot water to cover the cells. If

detergent does not dissolve readily, or forms a scum on

the water, try another brand, or use softened water

3. After detergent has completely dissolved, place cells in

the container and let soak for 15 to 20 minutes. Agitate

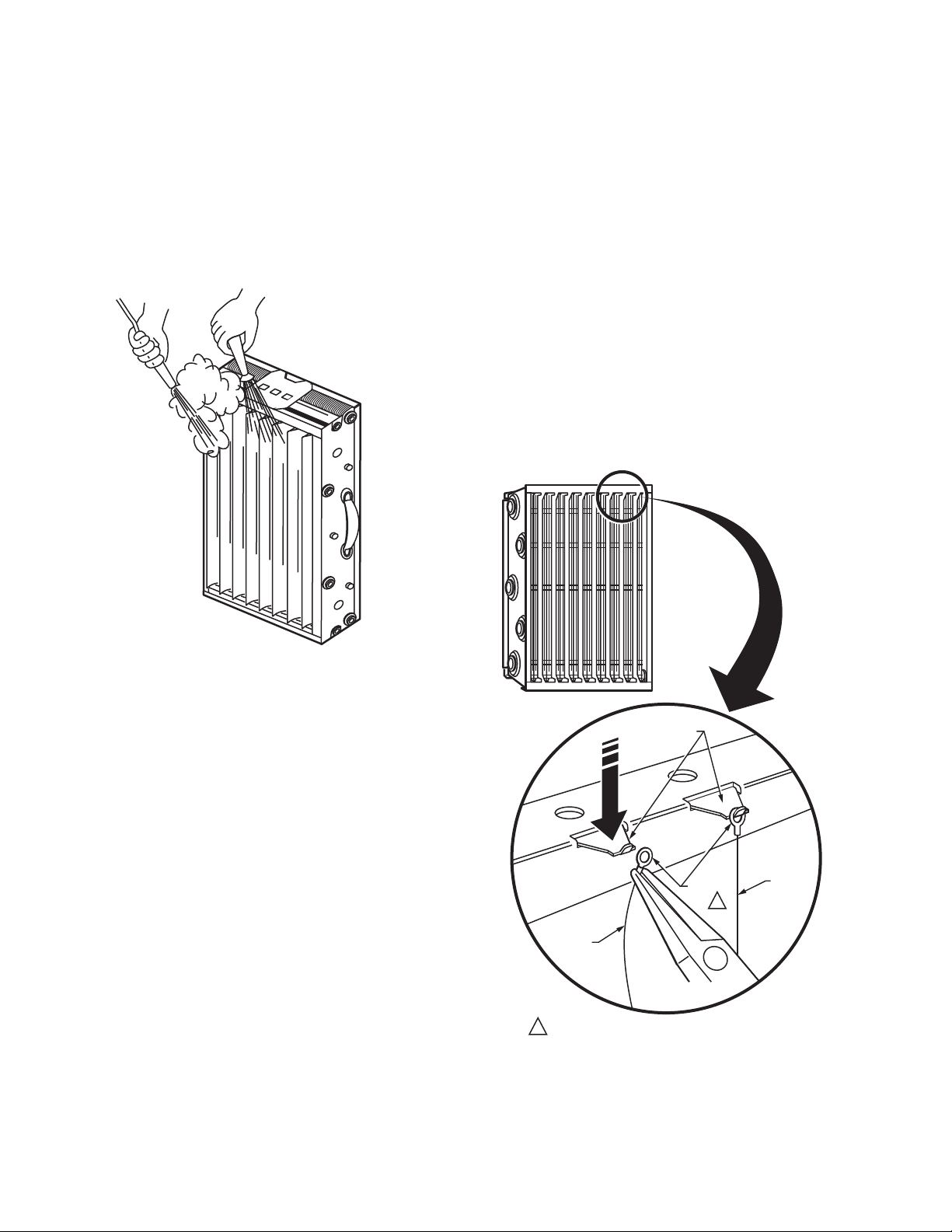

up and down a few times and remove. See Fig. 13.

WEAR GLOVES

TO PROTECT

HANDS FROM

DETERGENT

SOLUTION.

M922A

Fig. 13. Washing cells in container.

4. Next, wash the prefilters the same way. Empty and rinse

the wash container.

5. Rinse the cells and prefilters with a hard spray of very

hot water; rinse the tub clean, then fill the tub with clean

hot water and soak for 5 to 15 minutes. Rinse until the

water draining from the cells and prefilters no longer

feels slippery.

6. Soak cells and prefilters in a final clear water rinse for

ten minutes.

7. Wipe ionizer wires and contact board on end of cell using

your thumb and forefinger with a small, damp cloth.

13 68-0240EF—06

F300 ELECTRONIC AIR CLEANER

HIGH VELOCITY

DETERGENT SPRAY

STEAM

M20831

M1540B

IONIZER

WIRE

IONIZER

WIRE

NEEDLENOSE

PLIERS

SPRING

CONNECTORS

PRESS

DOWN

EYELETS

REPLACING AN IONIZER WIRE.

TWO EYELETS HOLD IONIZER WIRE TO CELL.

1

1

Washing Cells at the Car Wash

Use the hand sprayer at a coin-operated do-it-yourself car

wash to clean the cells. Hold the nozzle at least two feet away

from the unit to avoid damage (such as broken ionizer wires or

bent collector plates) from the high pressure stream of water.

See Fig. 14. Follow the same sequence of wash and rinse as

recommended for cars. However, do not wax the cells. Be sure

to rinse until the water draining from the cells no longer feels

slippery.

Replacing Ionizer Wires

Broken or bent ionizer wires can cause an electrical short to

ground, often resulting in visible arcing or sparking. Do not use

cells until broken wires are removed. Cells can be used

temporarily with one wire missing, but replace the wire as soon

as possible.

Replacement wires are supplied cut to length with eyelets on

both ends for easy installation. See Parts and Accessories Not

Illustrated section. To install:

1. Hook the eyelet on one end of the wire over the spring

connector on one end of the cell. See Fig. 15. Be careful

to avoid damaging spring connectors or other parts of

the cells.

2. Hold the opposite eyelet with a needle nose pliers and

stretch the wire the length of the cell. Depress the

opposite spring connector and hook the eyelet over it.

3. Check the cell for short circuits using an ohmmeter; see

Fig. 16. Check the resistance between the frame of the

cell and both the ionizer and the collector contacts. In

each case, the resistance should be infinite.

Fig. 14. Washing cells at car wash.

Reinstall the Cells and Prefilters

1. Inspect the cells for broken ionizer wires and bent collec-

tor plates. Repair as necessary or take to a

Honeywell Authorized Air Cleaner Repair Station.

2. Slide the prefilters into the upstream prefilter guides.

3. Slide in the air cleaner cells so the airflow arrow points

downstream and the handles faces outward.

4. Firmly close the access door.

5. Turn on the air cleaner. If the cells and prefilters are wet,

the neon light may not come on and you may hear

arcing. If the arcing is annoying, simply turn off the air

cleaner for two to three hours or until the cells are dry.

Replacing Media Postfilters

To maximize the filtration efficiency of the media postfilters,

replace them every six months. Replacement filters are

available in the same size and configuration as the original

unit. Contact your local Honeywell distributor to purchase

replacement filters. Install the replacement filters exactly as the

filters provided with the equipment. Use the Service Reminder

Schedule at the end of this document to help you establish and

maintain a regular replacement schedule. Keep your Service

Reminder Schedule in a convenient location.

Fig. 15. Replacing an ionizer wire.

68-0240EF—06 14

Loading...

Loading...