Page 1

F200 Charged-Media Air Cleaner

APPLICATION

The F200 Charged-Media Air Cleaner captures a significant

amount of the air-borne particles from the air circulated

through the unit.

FEATURES

• Charged-Media filter captures particles as small as 0.3

micron.

• Efficiency ratings based on the American Society of

Heating, Refrigerating and Air Conditioning Engineers

Standard 52.2-1999.

• Applicable to all gas, oil, and electric forced warm air

furnaces and to compressor cooling up to 5 tons.

• Mounts in the return air duct.

• Cabinet can support weight of residential furnace and

evaporator coil.

• Requires no electrical connections.

• Mounts in any position.

• Requires no maintenance except periodic battery and

media filter replacement.

• Quick and easy media filter replacement.

• Later upgrade to electronic air cleaner is easy.

• Integral pressure sensors signal when filter change is

required based on increased pressure drop threshold

at filter.

• Filter change status is transmitted to wall-mounted

AIRWATCH® Indicator.

• The RF AIRWATCH® Indicator is included.

PRODUCT DATA

Contents

Application/Features.......................................................... 1

Specifications/Ordering Information .................................. 2

Installation ......................................................................... 7

Checkout ........................................................................... 9

Parts List ........................................................................... 10

68-0238EF-2

Page 2

F200 CHARGED-MEDIA AIR CLEANER

SPECIFICATIONS

IMPORTANT

The specifications in this publication do not include

normal manufacturing tolerances; therefore, an individual unit may not exactly match the listed specifications. This product is tested and calibrated under

closely controlled conditions, and some minor differences in performance can be expected if those conditions are changed.

Model:

F200E Charged-Media Air Cleaner includes a cabinet, access

door and pleated media filter, and an RF AIRWATCH®

Indicator.

Application:

Use with gas, oil, and electric forced warm air furnaces and

with compressor cooling. Can be used with heat pumps if filter

is changed regularly to prevent excessive pressure drop.

Efficiency:

Efficiency Ratings: Based on American Society of Heating,

Refrigerating and Air-Conditioning Engineers Standard 52.2-

1999. Efficiency ranges are defined for small particles, E1=0.3

to 1.0 microns; medium particles, E2=1.0 to 3.0 microns; and

large particles, E3=3.0 to 10.0 microns.

Initial Efficiency:

E1=66%

E2=91%

E3=98%

Minimum Efficiency Reporting Valve (MERV): 13 at 492 fpm.

Filter Media: Pleated for greater media capacity.

Filter Element: Underwriters Laboratories, Inc.: UL 900,

Class 2 Listed.

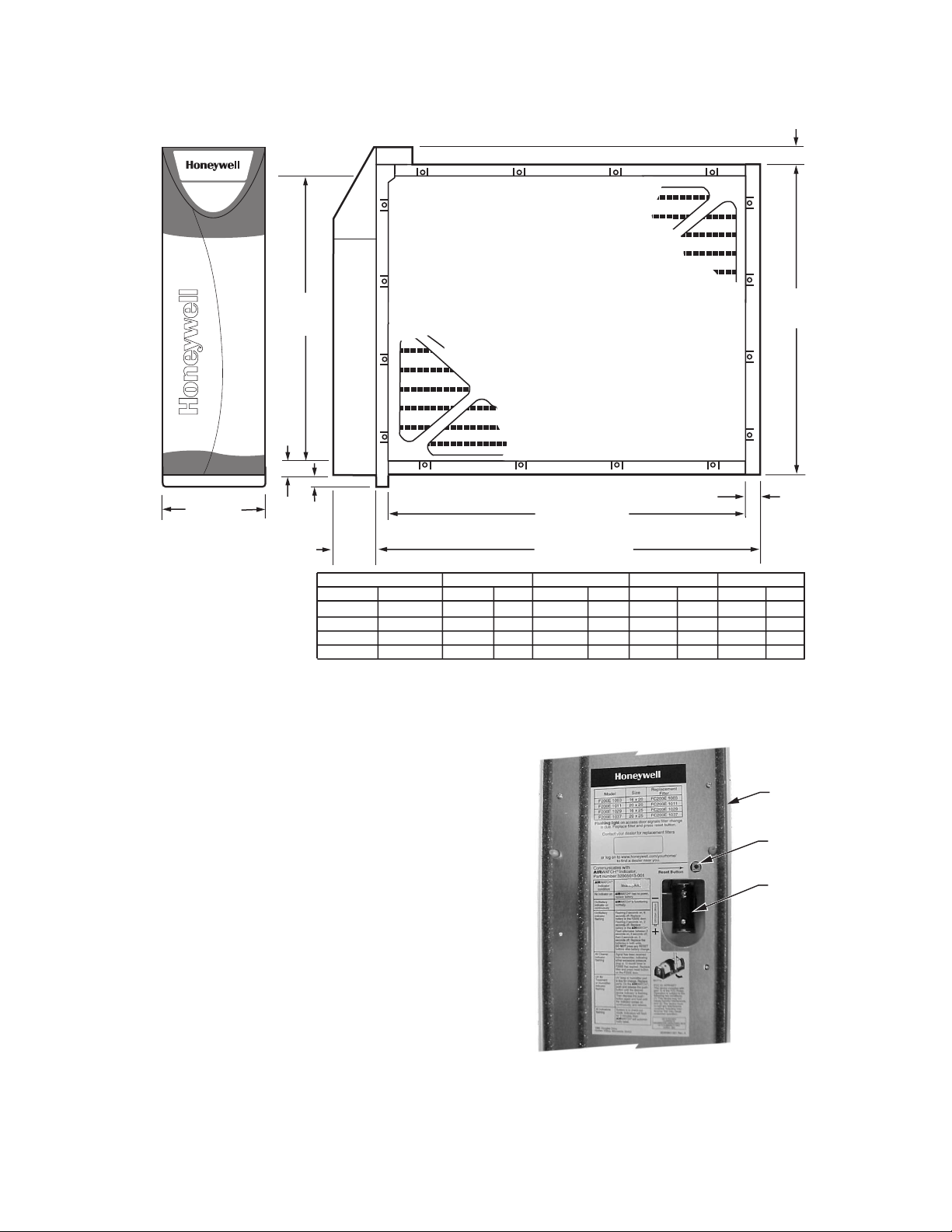

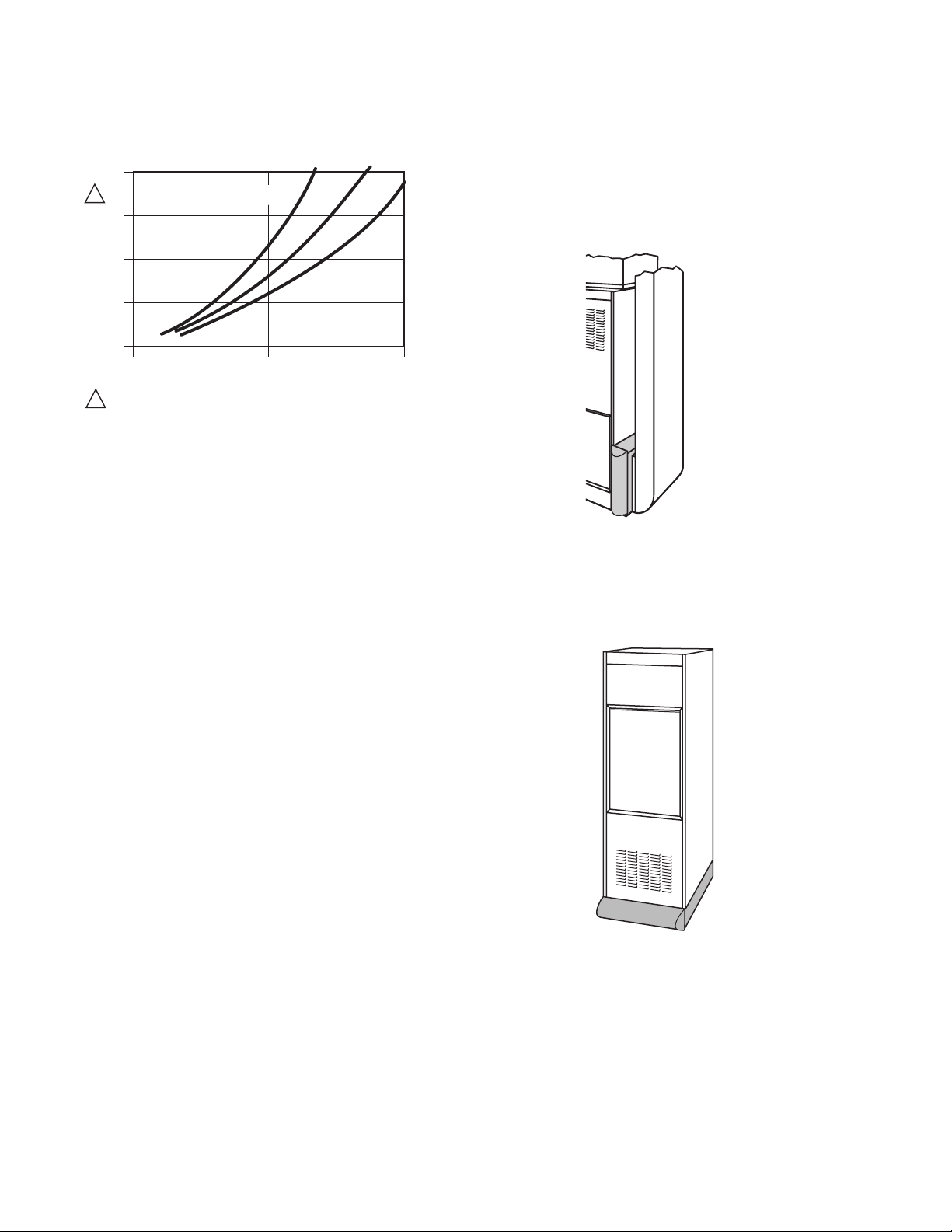

Pressure Drop: See Fig. 3.

Initial Pressure Drop: 0.28 in. wc at 492 fpm.

Temperature Rating: -40° to +140°F (-40° to +60°C).

Dimensions: See Fig. 1.

Mounting:

Mounts in any position in the return air duct, usually next to

the furnace blower compartment. Cabinet is sturdy enough to

support weight of a residential furnace and evaporator coil.

Upgrade Path:

The F200 uses the same cabinet as the F300 Electronic Air

Cleaner. Upgrade may require installing the cell key,

electronic cells, protective screens and installation and wiring

of the power box, depending on model.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

68-0238EF—2 2

Page 3

F200 CHARGED-MEDIA AIR CLEANER

.

1-1/8 (29)

6-3/4 (171)

7/8

(22)

DIM. A

(SEE

TABLE)

5/8

(16)

2-1/2

(63)

IN.

16 X 25

16 X 20

20 X 25

20 X 20

F200E SIZE

406 X 635

406 X 508

508 X 635

508 X 508

MM

DIM. C (SEE TABLE)

DIM. D (SEE TABLE)

DIM. A

IN. MM IN. MM

14 7/16

14 7/16

18 7/16

18 7/16

367

367

468

468

DIM. B

16 3/16

16 3/16

20 3/16

20 3/16

411

411

513

513

DIM. C

IN. MM IN. MM

23 1/4

591

18 1/4

457

23 1/4

591

18 1/4

457

25

20

25

20

(SEE TABLE)

DIM. D

DIM. B

7/8

(22)

648

521

648

521

M14784A

Fig. 1. Installation dimensions in in. (mm) of air cleaner.

Media Replacement:

Replace the filter at least annually or when the built-in pressure

sensors in the F200 door detect that airflow is impaired and the

filter requires cleaning. This condition causes the indicator light

on the F200 door to begin flashing and the transmitter to send

a signal to the wall-mounted RF Indicator that the filter needs

replacing.

After replacing the filter, press the reset button on the F200

door to reset both the door indicator light and the RF

AIRWATCH® Air Cleaner Indicator. See Fig. 2. (See Table 1

for AIRWATCH® operation.)

BACK SIDE OF DOOR

RESET BUTTON

BATTERY

M14864

Fig. 2. RF transmitter door - interior view.

3 68-0238EF—2

Page 4

F200 CHARGED-MEDIA AIR CLEANER

16 x 25 in.

(406 x 635 mm)

20 x 20 in.

0.4

1

0.3

0.2

0.1

PRESSURE DROP (IN. WC)

0

0

WHEN FIRST INSTALLED. PRESSURE DROP INCREASES AS FILTER

1

BECOMES LOADED. REPLACE FILTER WHEN PRESSURE DROP

REACHES 0.5 IN. WC. (0.1 kPa).

500 1000 1500

16 x 20 in.

(406 x 508 mm)

AIRFLOW (CFM)

(508 x 508 mm)

20 x 25 in.

(508 x 635 mm)

M13662

Fig. 3. Capacity, Pressure Drop and Area of F200 Filter

Media.

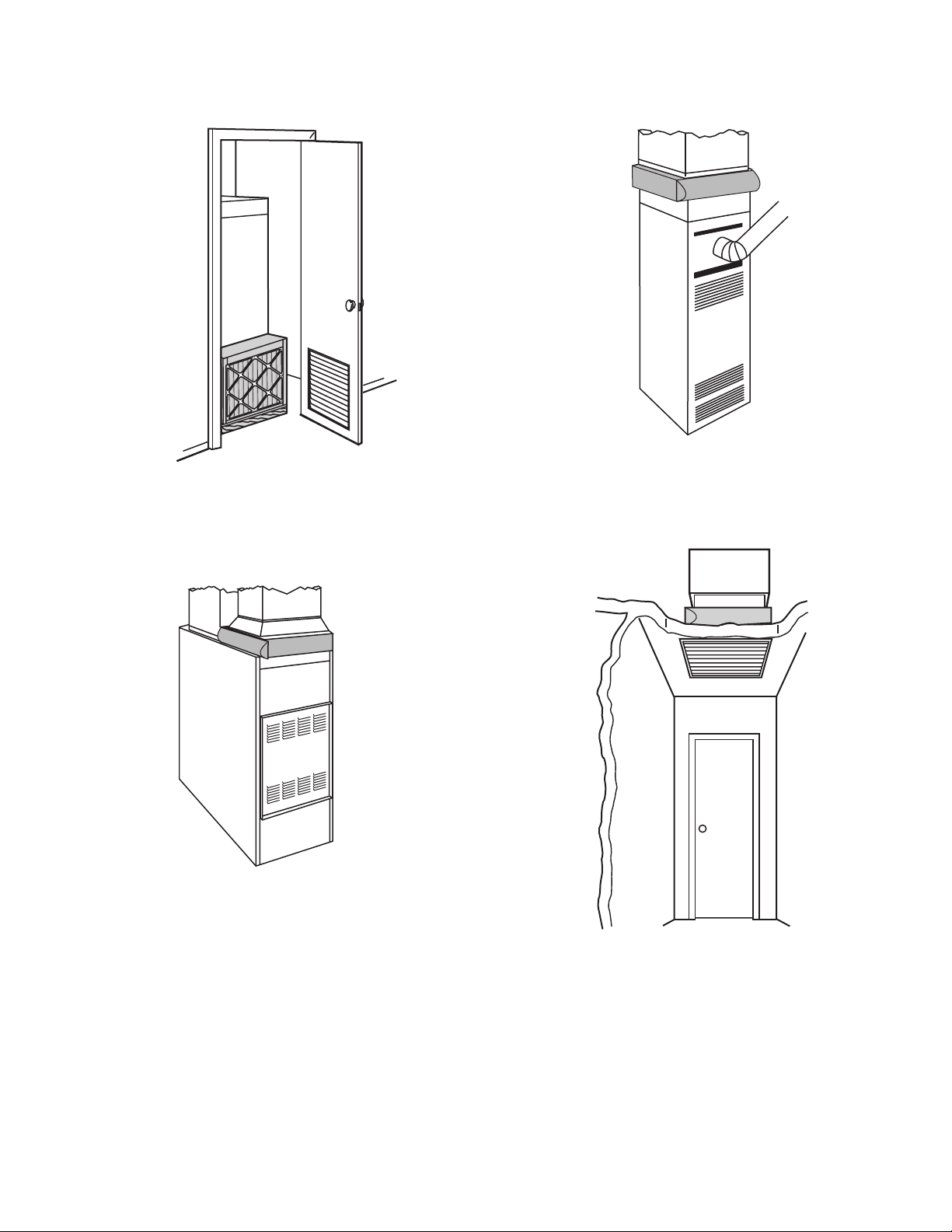

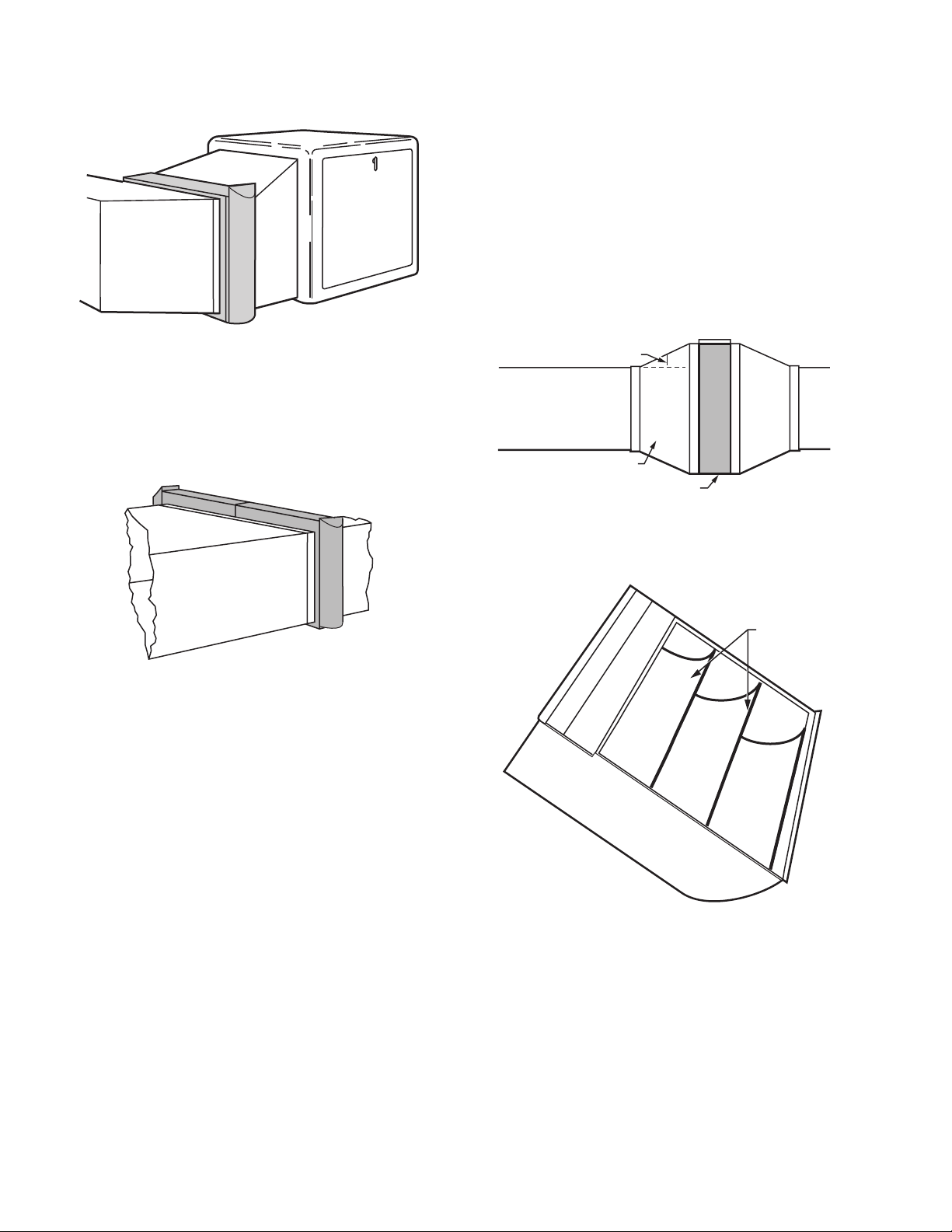

PLANNING THE INSTALLATION

Choose Mounting Position

The media air cleaner can be mounted in any position, but the

arrow on the cartridge must point in the same direction as the

airflow. See Figs. 4-11 for proper location of the media air

cleaner for a variety of furnace installations. Note that the

media air cleaner cabinet is sturdy enough to easily support

the weight of the furnace and evaporator coil. See Fig. 5.

2000

M14786

Location

The media air cleaner should be installed where all the air

passing through the system is circulated through it. The best

location is in the return air duct next to the blower compartment

so the media air cleaner can help to keep the blower motor and

evaporator coils clean. Do not mount in the supply air duct.

For most efficient air cleaning, spread airflow evenly across the

face of the media. If the duct is a different size than the media

air filter cabinet, gradual transitions are required. If the duct

turns sharply just before the air filter, turning vanes are

required.

Choose a location that is readily accessible for checking and

replacing the filter. Allow at least 26 in. (660 mm) clearance in

front of the unit for removal of the cartridge.

Install the media air filter where the temperature will not

exceed the ratings in the Specifications.

Applications With Air Conditioning

Mount the media air cleaner upstream of the evaporator coil in

a cooling system. The filter will help to keep the coil clean and

reduce maintenance.

Applications With A Humidifier

The media air cleaner is compatible with humidifiers. Avoid

applications where water mist will reach the media. If an

atomizing humidifier is used, the filter media will require

replacement more often because of minerals in the water.

Fig. 4. Highboy furnace, with side installation. Media air

filter is mounted vertically where return enters side inlet of

furnace.

M14787

Fig. 5. Media air cleaner is mounted horizontally where

return enters from below.

68-0238EF—2 4

Page 5

M941A

Fig. 6. Highboy furnace, with closet installation. Media air

cleaner is mounted vertically on furnace between furnace

and louvered return air opening in closet door.

F200 CHARGED-MEDIA AIR CLEANER

M14789

Fig. 8. Counterflow furnace, with media air cleaner

mounted horizontally in return duct or plenum just above

furnace.

M14788

Fig. 7. Lowboy furnace, with media air cleaner mounted

horizontally in return plenum just above furnace and

opposite heating plenum.

M14790

Fig. 9. Central fan installation, with media air cleaner

mounted horizontally in central return duct.

5 68-0238EF—2

Page 6

F200 CHARGED-MEDIA AIR CLEANER

Turning Vanes

If the media air cleaner is installed next to an elbow or angle

fitting, add turning vanes inside the angle to distribute airflow

more evenly across the face of the media. See Fig 13.

Offsets

If the duct connection to the furnace in a side installation allows

less than 7 in. (178 mm) for mounting media air cleaner

cabinet, attach an offset to the elbow. See Fig. 14.

M14792

Fig. 10. Horizontal furnace, with media air filter mounted

vertically in return duct near furnace.

NOTE: When more than one media air cleaner is used, each

air cleaner requires a separate RF AIRWATCH®, if

communication is desired with all units.

M14793

Fig. 11. Two or more media air cleaners used in a high

capacity system.

Determining Sheetmetal Requirements

The media air cleaner is adaptable to all new or existing forced

air heating and cooling systems used in residential

applications. Transitions or turning vanes may be required in

some applications for effective media air cleaner operation.

DUCT SIZE CHANGED GRADUALLY TO PREVENT TURBULENCE.

20 DEGREE EXPANSION PER SIDE PER

FITTING (4 IN. PER RUNNING FOOT

[100 MM PER 300 LINEAR MM])

RETURN AIR

DUCT

TRANSITION FITTING

MEDIA AIR CLEANER CABINET

M947B

Fig. 12. Duct size changed gradually to prevent

turbulence.

TURNING

VANES

Transitions

Transitions are needed when the duct is a different size than

the media air cleaner cabinet. Follow these guidelines when

fabricating:

1.Use gradual transitions to reduce air turbulence and

increase efficiency. See Fig. 12.

2.Use no more than 20 degrees (about 4 in. per running ft.

(100 mm per 300 linear mm)) of expansion on each side of a

transition fitting.

68-0238EF—2 6

M5651

Fig. 13. Turning vanes installed in bend help distribute

airflow evenly over face of media.

Page 7

LESS

THAN

7 in.

(178 mm)

OFFSET

F200 CHARGED-MEDIA AIR CLEANER

Fasten The Cabinet To The Furnace

Align the cabinet with the return air opening. Place blocks

under the cabinet, as necessary, to make sure the unit sits

securely. Create an opening in the furnace to match the

cabinet opening. Attach the cabinet securely to the furnace.

Attach the unit directly or fit a starting collar in the furnace

opening. Either drill holes and fasten with sheetmetal screws or

rivets, or use slip joints. If you are drilling holes, use a locking

pliers to help hold the unit in place during drilling.

AT LEAST

7 in.

1

(178 mm)

1 REQUIRED TURNING VANES HELP DISTRIBUTE AIRFLOW EVENLY.

Fig. 14. Typical use of duct offset to make room for media

air cleaner.

M14794

INSTALLATION AND CHECKOUT

When Installing this Product…

1. Read these instructions carefully. Failure to follow them

could damage the media air filter or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

media air cleaner to make sure the product is suitable for

your application.

3. Installer must be a trained, experienced service

technician.

Remove Furnace Filter And Clean Blower Compartment

Before starting the installation, remove and discard the existing

furnace filter (if used). Thoroughly clean the blower

compartment. If possible, power vacuum the ductwork to

remove accumulated dust in an occupied home or remove

construction dirt in a new home. The media air cleaner cannot

remove dirt that has settled in the blower compartment and

distribution ducts.

Install The Cabinet

The following procedure describes a typical side installation on

an existing highboy furnace. Alternate procedures are noted as

appropriate. Other changes in installation procedures may be

necessary to complete your installation.

Review The Installation Plan

Temporarily place the cabinet on the floor, oriented as it will be

when installed. Insert and remove the cartridge to make sure

the plan allows adequate clearance for easy removal and

replacement of the cartridge.

Install Turning Vanes

Install turning vanes to help distribute air equally over the full

surface of the upstream side of the media. Install them

whenever an abrupt 90 degree elbow is installed directly

against the media air cleaner cabinet.

Fasten Cabinet To Ductwork

Fasten side of cabinet to the ductwork using sheet-metal

screws, rivets, or slip joints, as appropriate.

Connect Ductwork

Connect the vertical duct section to the elbow. If the vertical

drop of the duct is less than 7 in. (178 mm) from the side of the

furnace, shorten the horizontal trunk or attach an offset fitting

to the elbow. See Fig. 12. When ductwork is properly aligned,

connect the vertical duct to the horizontal trunk.

Seal Joints

Seal all joints in the return air system between the media air

filter and the furnace to prevent dust from entering the clean

airstream.

Install Filter Cartridge

Slide the filter cartridge into the cabinet, making sure the arrow

on the cartridge points in the direction of air flow.

Install battery in door. Replace access door. Insert the tab on

the bottom of the door into the slot in the cabinet. Swing the

door closed and press it into place.

Install RF AIRWATCH® Indicator

The AIRWATCH® Indicator provides a signal when the F200

filter needs replacing. When the filter begins restricting airflow

because of accumulated dirt, pressure sensors in the F200

initiate a radio frequency signal to be sent to the AIRWATCH®

Indicator. The AIRWATCH Indicator also has 12-month timers

to indicate when the humidifier pad and the ultraviolet air

treatment lamps need replacing.

Install Battery

1. Remove the AIRWATCH® Indicator from the base:

a. Depress the tab on the bottom edge of the base.

b. Pull off the bottom of the front cover.

Make sure that shop-fabricated sheetmetal components, such

as turning vanes, are available.

7 68-0238EF—2

2. Install one CR123A Lithium Battery (provided) in the holder

on the back of the unit.

3. Observe that the On/Battery LCD segment comes on.

Page 8

F200 CHARGED-MEDIA AIR CLEANER

Select Location

The RF AIRWATCH can be mounted in any convenient

location in the home.

1. Select the desired location (at least six feet away from

transmitter in door).

2. Check for communication between the F200 Media Air

Cleaner and the AIRWATCH® Indicator as follows:

a. Place the AIRWATCH® Indicator in the desired

mounting location. Use a piece of masking tape to

hold the device to the wall.

b. At the F200, press the reset button on the door.

c. Verify that the arrows on the AIRWATCH® Indicator

are flashing. (The arrows will flash for about two min-

utes before returning to normal.)

3. If there is no response on the AIRWATCH® Indicator,

choose another location within the home and begin

again at step 2.

Mount AIRWATCH® Indicator

1. Remove the AIRWATCH® Indicator from the base:

a. Depress the tab on the bottom edge of the base.

b. Pull off the bottom of the front cover.

2. Position the base on the wall in the desired mounting

position; using the holes in the base as a template, mark

the locations for the anchors and screws provided.

3. Drill holes (3/16in.) and install the screw anchors pro-

vided.

4. Position the base over the holes and install the screws

provided; tighten the screws until the base is mounted

firmly to the wall.

5. Reinstall AIRWATCH® Indicator onto base:

a. Hook the top.

b. Snap the bottom into place.

The AIRWATCH® Indicator default setting is UV Light and

Humidifier timers are disabled; the Filter indicator is always

enabled. To display active timers:

1. Press and hold the button on the AIRWATCH® Indicator

for about three seconds.

2. Observe the arrow showing the active timer(s).

To activate a timer:

1. Press and release the AIRWATCH® Indicator button until

the desired device is selected, as indicated with the

flashing arrow.

2. Press and hold the button until the arrow stops flashing.

3. Release the button while the arrow is on.

To deactivate a timer:

1. Press and release the AIRWATCH® Indicator button until

the desired device is selected, as indicated with the

flashing arrow.

2. Press and hold the button until the arrow turns off (about

four seconds).

3. Release the button while the arrow is off.

AIRWATCH® Indicator Operation

The Indicator has an LCD with four indicator segments: On/

Battery, Air Cleaner, UV Air Treatment and Humidifier. See

Table 1.

Checkout

Visually check the installation. Make sure:

Initialize the AIRWATCH® Indicator to accept signals

from the F200 transmitter:

1. Be sure the RF AIRWATCH® receiver is at least six feet

away from the transmitter in the door to ensure communication.

2. Push and hold the AIRWATCH® Indicator button until all

four arrows come on (about five seconds).

3. Push the red reset button on the F200 door within two

minutes.

4. Observe the indicator arrows on the RF AIRWATCH®

begin to flash and continue for about two minutes until

initialization is completed.

• Airflow is in the direction of the arrow on the media air filter

cartridge.

• Turning vanes and transitions, if used, are properly

installed.

• Joints in sheetmetal between media air filter and furnace

are sealed.

• All sheetmetal connections are complete.

• Original furnace filter has been removed and blower

compartment is cleaned.

Replace any access doors removed during the Installation or

Checkout.

Run the furnace or cooling system through one complete cycle

to make sure the system operates as desired.

68-0238EF—2 8

Page 9

F200 CHARGED-MEDIA AIR CLEANER

Table 1. AIRWATCH® Indicator LCD Description.

AIRWATCH® Indicator Condition Meaning/Action

No indicator on. AIRWATCH® has no power; replace battery in AIRWATCH®

On/Battery indicator on continuously. AIRWATCH® is functioning normally.

On/Battery indicator flashing. Flashing two seconds on, six seconds off: Replace battery in the RF door.

Do not press any reset buttons after battery change.

Flashing two seconds on, two seconds off: Replace battery in AIRWATCH®.

Do not press any reset buttons after battery change.

Flashing alternates between two seconds on, six seconds off; then two

seconds on, two seconds off: Replace the batteries in both units. Do not

press any reset buttons after battery change.

Air Cleaner indicator flashing. Signal was received from transmitter, indicating either excessive pressure

drop or 12-month timer has expired. Replace filter and press reset button

inside RF door. See Fig. 2.

UV Air Treatment indicator flashing or

Humidifier indicator flashing.

UV lamp(s) or humidifier pad needs replacing. Replace parts.

On the AIRWATCH®, push and release button until desired device indicator

is flashing. Then press button again and hold until indicator comes on

continuously; then release.

All indicators flashing. System is in checkout mode. Indicators flash for two minutes, then

AIRWATCH® automatically resets.

9 68-0238EF—2

Page 10

F200 CHARGED-MEDIA AIR CLEANER

Table 2. F200E Parts List.

Callout

No. Description

F200E1003

16 x 20 in.

F200E1029

16 x 25 in.

F200E1011

20 x 20 in.

F200E1037

20 x 25 in.

1 Replacement filter FC200E1003 FC200E1029 FC200E1011 FC200E1037

2 Door with RF Transmitter 32004876-002 32004876-002 32004876-001 32004876-001

3

AIRWATCH®

RF Receiver

W8600B1005 W8600B1005 W8600B1005 W8600B1005

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2005 Honeywell International Inc.

68-0238EF—2 M.S. Rev. 09-05

Page 11

APPLICATION

Filtre à air à auto-ionisation F200

DONNÉES TECHNIQUES

CARACTÉRISTIQUES

• Filtre à auto-ionisation qui retient des particules dont

la taille fait aussi peu que 0,3 micron.

• Efficacité et capacité de rétention établies d'après la

norme 52.2-1999 de l'American Society of Heating,

Refrigerating and Air-Conditioning Engineers.

• Convient à tous les systèmes de chauffage à air pulsé

au gaz, au mazout ou à l'électricité et aux

compresseurs de refroidissement allant jusqu'à 5

tonnes.

• S'installe dans la gaine de reprise d'air.

• Le boîtier résistant peut recevoir le poids d'un appareil

de chauffage résidentiel et d'un serpentin

d'évaporation.

• Ne requiert aucun raccordement électrique.

• S'installe dans n'importe quelle position.

• N'exige aucun entretien à l'exception du remplacement

périodique du filtre à fibres.

• Remplacement simple et rapide du filtre à fibres.

• Peut par la suite être remplacé facilement par un filtre à

air électronique.

• Capteurs de pression intégrés qui indiquent quand il

faut remplacer le filtre en fonction du seuil de chute de

pression plus élevé au filtre.

• Le signal de remplacement du filtre est transmis à un

indicateur mural AIRWATCH

• L'indicateur AIRWATCHMC à radiofréquences est inclus.

MC

.

Le filtre à air à auto-ionisation F200 retient une importante

quantité de particules contenues dans l'air qui le traverse.

68-0238EF-2

Page 12

FILTRE À AIR À AUTO-IONISATION F200

FICHE TECHNIQUE

IMPORTANT

Les caractéristiques techniques indiquées dans la

présente publication ne comprennent pas les

tolérances normales de fabrication. Par conséquent,

il se peut que l'appareil ne corresponde pas exactement aux caractéristiques indiquées. De même, le

produit a été mis à l'essai et étalonné dans des conditions entièrement contrôlées et on peut s'attendre

à de légères différences de fonctionnement si ces

conditions sont modifiées.

Modèle :

Filtre à auto-ionisation F200 avec boîtier, porte d'accès,

médium filtrant en papier accordéon et indicateur à

radiofréquences AIRWATCH

Application :

Convient aux appareils de chauffage à air pulsé au gaz, au

mazout et à l'électricité et aux compresseurs de

refroidissement. Peut être utilisé dans un système à pompe à

chaleur si le filtre est remplacé à intervalle régulier pour éviter

une trop grande chute de pression.

Efficacité :

Efficacité établie d'après la norme 52.2-1999 de l'American

Society of Heating, Refrigerating and Air-Conditioning

Engineers. Les pourcentages d’efficacité sont définis pour les

petites particules, E

= 1,0 à 3,0 microns; et les grosses particules, E3 = 3,0 à

E

2

10 microns.

= 0,3 à 1 micron; particules moyennes,

1

MC

.

Efficacité initiale :

E1=66%

E2=91%

E3=98%

Médium filtrant : Papier plissé pour une plus grande

capacité.

Élément de filtration répertorié par les : Underwriters

Laboratories Inc., UL 900, classe 3.

Capacité hute de pression : Voir la Fig. 2.

Chute de pression initiale : 0,28 po c.e. à 492 pi3/min.

Température ambiante nominale : -40 à 60 C (-40 à 140 F).

Encombrement : Voir la Fig. 1.

Installation :

S'installe dans n'importe quelle position dans la gaine de

reprise d'air, habituellement près du compartiment du

ventilateur de l'appareil de chauffage. Le boîtier est

suffisamment résistant pour recevoir le poids d'un appareil de

chauffage résidentiel et d'un serpentin d'évaporation.

Possibilité de mise à niveau :

Le F200 fait appel au même boîtier que le filtre à air

électronique F300. La mise à niveau peut nécessiter

l'installation d'un clavette de cellule, de cellules électroniques,

d'écrans protecteurs; selon les modèles, il faudra également

installer et raccorder le bloc d'alimentation.

POUR COMMANDER

Au moment d'acheter des produits de modernisation et de remplacement auprès de votre grossiste ou distributeur

TRADELINE(c), consultez le catalogue TRADELINE ou les tarifs pour obtenir le numéro de pièce.

Prière d'adresser toute question additionnelle, demande d'information ou commentaires sur les produits et services par écrit :

1. Honeywell Customer Care, 1885 Douglas Drive North, Golden Valley, MN 55422-4386

2. Ou visiter notre site Web à www.honeywell.com/yourhome.

Au Canada : Honeywell Limited-Honeywell Limitée, 35 Dynamic Dr., Scarborough, Ontario, M1V 4Z9

Points de vente et de service dans toutes les grandes villes du monde. Usines en Allemagne, en Australie, au Canada, en

Espagne, aux États-Unis, en Finlande, en France, au Japon, au Mexique, aux Pays-Bas, au Royaume-Uni et à Taiwan.

68-0238EF—2 2

Page 13

FILTRE À AIR À AUTO-IONISATION F200

1-1/8 (29)

DIM. A

(SEE

TABLE)

7/8

(22)

6-3/4 (171)

5/8

(16)

2-1/2

(63)

IN.

16 X 25

16 X 20

20 X 25

20 X 20

F200E SIZE

406 X 635

406 X 508

508 X 635

508 X 508

MM

IN. MM IN. MM

14 7/16

14 7/16

18 7/16

18 7/16

Fig. 1. Encombrement du filtre à air in mm (po).

Remplacement du médium filtrant :

Remplacer le filtre au moins une fois par année ou lorsque les

capteurs de pression intégrés dans la porte du F200 détectent que

l'écoulement d'air a diminué et qu'il faut nettoyer le filtre. Dans un tel

cas, le voyant situé sur la porte du F200 s'allume et clignote, et le

transmetteur envoie un signal à l'indicateur mural à radiofréquences,

indiquant ainsi à l'utilisateur qu'il faut remplacer le filtre.

Une fois le filtre remplacé, appuyer sur le bouton de réarmement

situé sur la porte du F200 ainsi que sur celui de l'indicateur mural

à radiofréquences

pour savoir comment fonctionne l'indicateur

AIRWATCHMC. Voir Fig. 2. (Voir le Tableau 1

AIRWATCHMC.)

DIM. A

DIM. C (SEE TABLE)

DIM. D (SEE TABLE)

367

367

468

468

16 3/16

16 3/16

20 3/16

20 3/16

DIM. B

411

411

513

513

(SEE TABLE)

DIM. C

IN. MM IN. MM

23 1/4

591

18 1/4

457

23 1/4

591

18 1/4

457

DIM. D

25

20

25

20

M14784A

INTƒRIEUR DE LA PORTE

BOUTON

DE R

PILE

DIM. B

7/8

(22)

648

521

648

521

ƒ

ARMEMENT

MF14864

Fig. 2. Porte avec transmetteur RF- vu de l'intérieur.

Taille du filtre (en po) Numéro de pièce

16 x 25 FC100A1029

16 x 20 FC100A1003

20 x 25 FC100A1037

20 x 20 FC100A1011

3 68-0238EF—2

Page 14

FILTRE À AIR À AUTO-IONISATION F200

406 x 635 mm

(16 x 25 po)

508 x 508 mm

0.4

1

0.3

0.2

0.1

CHUTE DE PRESSION (PO C.E.)

0

0

1

APRÈS L’INSTALLATION, LA CHUTE DE PRESSION AUGMENTE À

MESURE QUE LE FILTRE SE CHARGE DE PARTICULES. REMPLACER

LE FILTRE LORSQUE LA CHUTE DE PRESSION ATTEINT

1 kPa (0,5 po c.e.).

500 1000 1500

406 x 508 mm

(16 x 20 po)

DÉBIT D’AIR (EN pi3/min)

(20 x 20 po)

508 x 635 mm

(20 x 25 po)

2000

MF13662

Fig. 3. Appareil de chauffage à caissons superposé. Filtre

à air installé sur le côté à la verticale, à l'endroit où entre

l'air repris, sur le côté de l'appareil de chauffage.

PLANIFICATION DE L'INSTALLATION

Choisir la position d'installation du filtre

Le filtre à air peut être installé dans n'importe quelle position,

mais les flèches figurant sur la cartouche doivent pointer dans

le même sens que celui de l'écoulement de l'air. Voir les figures

4 à 11 pour observer l'emplacement adéquat du filtre à air

selon le type d'appareil de chauffage. Il est à noter que le

boîtier du filtre à air est robuste et qu'il peut facilement recevoir

le poids de l'appareil de chauffage et du serpentin

d'évaporation. Voir la Fig. 5.

M14786

Emplacement

Installer le filtre à air de manière que tout l'air qui passe dans le

système puisse circuler dans le filtre. Le meilleur endroit est la

gaine de retour d'air, à côté du compartiment de ventilation; à

cet endroit, le filtre à air contribuera en effet à garder le moteur

du ventilateur et les serpentins de l'évaporateur plus propres.

Ne pas installer le filtre dans la gaine de soufflage.

Le filtrage de l'air sera plus efficace si le débit d'air est réparti

uniformément sur la surface du filtre. Si la gaine et le boîtier du

filtre à air n'ont pas les mêmes dimensions, il est préférable

d'installer des raccords de transition. Si la gaine présente un

angle aigu juste avant le filtre à air, il est recommandé d'utiliser

des déflecteurs.

Choisir un emplacement facile d'accès pour la vérification et le

remplacement du filtre. Prévoir un dégagement d'au moins 660

mm (26 po) sur le devant de l'appareil pour le retrait de la

cartouche.

Installer le filtre à air à fibres à un endroit où la température ne

dépasse pas les limites indiquées dans la fiche technique.

Applications - appareil de refroidissement

Le filtre à air devrait être installé en amont du serpentin de

l'évaporateur. Le filtre à air aidera à garder le serpentin propre

et permettra de réduire la fréquence de l'entretien.

Applications - humidificateur

Le filtre à air convient aux systèmes avec humidificateurs.

Éviter les installations où l'eau vaporisée peut atteindre le

médium filtrant. Dans le cas d'une installation avec

humidificateur atomiseur, il faudra remplacer le médium filtrant

plus souvent en raison des sédiments que contient l'eau.

Fig. 4. Appareil de chauffage à caissons superposé.

installé sous l'appareil de chauffage à l'horizontale, à

l'endroit où entre l'air repris, au bas de l'appareil de

chauffage.

M14787

Fig. 5. Appareil de chauffage à caissons superposé, dans

une armoire. Filtre à air installé sur le côté à la verticale

sur l'appareil de chauffage, entre l'appareil de chauffage et

la grille de reprise d'air placée dans l'ouverture de la porte

de l'armoire.

68-0238EF—2 4

Page 15

M941A

Fig. 6. Appareil de chauffage à caissons juxtaposés. Filtre

à air installé à l'horizontale dans le plénum d'air repris

juste au-dessus de l'appareil de chauffage, face au plénum

d'alimentation.

FILTRE À AIR À AUTO-IONISATION F200

M14789

Fig. 8. Appareil de ventilation centrale. Filtre à air installé

à l'horizontale dans une gaine de reprise centrale.

M14788

Fig. 7. Appareil de chauffage à contre-courant. Filtre à air

installé à l'horizontale dans la gaine de reprise d'air ou

dans le plénum juste au-dessus de l'appareil de chauffage.

5 68-0238EF—2

M14790

Fig. 9. Appareil de chauffage horizontal. Le filtre à air est

monté à la verticale à l'endroit où entre l'air repris près de

l'appareil de chauffage.

Page 16

FILTRE À AIR À AUTO-IONISATION F200

M14792

Fig. 10. Appareil de chauffage horizontal. Le filtre à air est

monté à la verticale à l’endroit où entre l’air repris près de

l’appareil de chauffage.

REMARQUE : Lorsqu’il y à plus d’un filtre à air element filtrant

à fibres, il faut un indicateur AIRWATCH

MC

à

radiofrequences par filtre si l’on souhaite communiquer avec chacun des appareils.

Déflecteurs

Si le filtre à air est installé près d'un coude (raccord à angle),

installer les déflecteurs à l'intérieur du coude pour assurer une

distribution d'air plus uniforme à la surface du filtre. Voir la Fig. 13.

Raccords de dérivation

Si le raccord entre la gaine et l'appareil dans le cas d'une

installation sur le côté offre un dégagement inférieur à 178 mm

(7 po) pour le boîtier du filtre à air, ajouter un raccord de

dérivation au coude. Voir la Fig. 14.

MODIFICATION GRADUELLE DE LA TAILLE DE LA GAINE D'AIR

EN VUE DE RÉDUIRE LA TURBULENCE.

EXPANSION DE 20 DEGRÉS DE CHAQUE CÔTÉ,

PAR RACCORD (100 MM PAR 300 MM ÉLAIMES)

(4 PO PAR PIED ÉLAIMES).

GAINE DE REPRISE D'AIR

RACCORD DE TRANSITION

BOÎTIER DU FILTRE À AIR À ÉLÉMENT

FILTRANT À FIBRES

MF947C

M14793

Fig. 11. Deux filtres à air ou plus installés dans un

système à haut rendement.

Raccords de gaines requis

Le filtre à air se combine à tout système résidentiel de

chauffage, de refroidissement et de ventilation à air pulsé neuf

ou en place. Des raccords de transition ou de dérivation et des

déflecteurs peuvent être nécessaires pour assurer un meilleur

rendement dans certaines applications.

Raccords de transition

Des raccords de transition sont nécessaires lorsque les

dimensions de la gaine et du boîtier du filtre à air sont

différentes.

1. Les raccords de transition réduisent la turbulence et aug-

mentent l'efficacité. Voir la Fig. 12.

2. L'expansion maximale doit être de 20 degrés (environ

100 mm par 300 mm linéaires [4 po par pied linéaire]) de

chaque côté du raccord de transition.

Fig. 12. Modification graduelle de la taille de la gaine d'air

en vue de réduire la turbulence.

TURNING

VANES

M5651

Fig. 13. Utilisation de déflecteurs pour contribuer à

assurer une distribution d'air plus uniforme à la surface

du filtre.

68-0238EF—2 6

Page 17

MOINS DE

178 mm

[7 po]

1

RACCORD

DE DÉRIVATION

AU MOINS

178 mm

[7 po]

FILTRE À AIR À AUTO-IONISATION F200

S'assurer d'avoir sous la main des éléments de tôle

préfabriqués, comme des déflecteurs.

Fixer le boîtier à l'appareil de chauffage

Aligner le boîtier sur l'ouverture pour la reprise d'air. Placer des

blocs sous le boîtier pour que l'appareil soit bien soutenu et de

niveau. Percer une ouverture dans l'appareil de chauffage

correspondant à celle du boîtier du filtre à air. Fixer solidement

le boîtier à l'appareil de chauffage soit directement (voir

illustration), soit à l'aide d'un collier de démarrage dans

l'appareil de chauffage. Percer des trous et fixer l'appareil à

l'aide de rivets ou de vis pour tôle ou utiliser des écrous

coulissants. S'il faut percer des trous, utiliser une pince-étau

pour maintenir l'appareil en place pendant cette opération.

1 LES DÉFLECTEURS ASSURENT UNE MEILLEURE RÉPARTITION D’AIR.

Fig. 14. Utilisation typique d'un raccord de dérivation

pour assurer un dégagement suffisant au filtre à air.

MF14794

INSTALLATION

AVANT D'INSTALLER CE PRODUIT...

1. Lire attentivement les instructions. Le fait de ne pas les

suivre risque d'endommager le produit ou de constituer

un danger.

2. Vérifier les caractéristiques nominales indiquées dans

les instructions et sur le produit, et s'assurer que celui-ci

correspond bien à l'application prévue.

3. L'installateur doit être un technicien d'expérience ayant

reçu la formation pertinente.

4. Une fois l'installation terminée, vérifier le fonctionnement

du produit comme l'indiquent les présentes instructions.

Retirer le filtre de l'appareil de chauffage et nettoyer le compartiment du ventilateur

Avant de procéder à l'installation, retirer et mettre de côté le

filtre actuel de l'appareil de chauffage (s'il existe). Nettoyer à

fond le compartiment du ventilateur. Si c'est possible, passer

l'aspirateur dans le système de gaines pour éliminer la

poussière accumulée dans une maison déjà construite ou la

saleté due à la construction dans une maison neuve. Le filtre à

air ne peut éliminer la poussière accumulée dans le

compartiment du ventilateur et les gaines de distribution.

Installer le boîtier

L'installation d'un filtre sur le côté d'un appareil de chauffage à

caissons juxtaposés est décrite ci-dessous. D'autres

explications sont fournies au besoin. Des modifications

peuvent s'avérer nécessaires dans le cas d'un autre système.

Passer en revue le plan de l'installation

Déposer le boîtier sur le sol, orienté comme il le sera une fois

l'installation terminée. Insérer et retirer la cartouche pour

vérifier que les plans offrent un dégagement suffisant au retrait

et au remplacement de la cartouche.

Installer les déflecteurs

Installer les déflecteurs pour assurer une distribution uniforme

de l'air sur toute la surface amont du médium filtrant. Il faut les

installer à l'intérieur du coude à 90 degrés, montés directement

sur le boîtier du filtre à air.

Fixer le boîtier au système de gaines

Fixer l'autre côté du boîtier sur le coude à l'aide de rivets, de

vis pour tôle, ou d'écrous coulissants, au besoin.

Raccorder le filtre à la gaine

Raccorder la section verticale de la gaine au coude. Si la

portion verticale de la gaine est à moins de 178 mm (7 po) du

côté de l'appareil de chauffage, raccourcir la portion

horizontale ou fixer un raccord de dérivation au coude. Voir la

Fig. 13. Lorsque la gaine d'air est correctement alignée,

raccorder la partie verticale à la partie horizontale.

Sceller les joints

Sceller tous les joints du système de reprise d'air entre le filtre

à air et l'appareil de chauffage pour empêcher la poussière de

pénétrer dans le courant d'air propre.

Installer la cartouche du filtre

Faire glisser la cartouche du filtre dans le boîtier et vérifiant

que la flèche figurant sur la cartouche correspond bien au sens

d'écoulement de l'air.

Remettre la porte d'accès en place, insérer la languette au bas

de la porte dans la fente pratiquée sur le boîtier. Refermer la

porte et appuyer pour qu'elle soit solidement en place.

Installation de l'indicateur AIRWATCHMC W8600A

L'indicateur AIRWATCHMC émet un signal lorsqu'il faut

remplacer le filtre du F200. Lorsque le filtre devient trop

encrassé et qu'il diminue l'écoulement de l'air, des capteurs de

pression intégrés au F200 transmettent un signal radio à

l'indicateur AIRWATCH

aussi servir à surveiller l'état du tampon de l'humidificateur et

des lampes UV du système de traitement de l'air aux

ultraviolets.

MC

. L'indicateur AIRWATCHMC peut

7 68-0238EF—2

Page 18

FILTRE À AIR À AUTO-IONISATION F200

Configuration de l'indicateur AIRWATCHMC pour qu'il

accepte les signaux du transmetteur du F200 :

1. Placer le récepteur AIRWATCHMC à au moins 6 pieds

de la porte du transmetteur dans la porte pour assurer la

communication.

2. Appuyer sur le bouton de l'indicateur AIRWATCH

MC

et

le maintenir enfoncé jusqu'à ce que toutes les flèches

soient allumées (environ 5 secondes).

3. En moins de deux minutes, appuyer sur le bouton de

réarmement situé sur la porte du F200.

4. Observer si les flèches de l'indicateur AIRWATCH

MC

continuent de clignoter pendant environ deux minutes et

si l'appareil se réarme ensuite automatiquement.

Le réglage par défaut de l'indicateur AIRWATCH

MC

est le

suivant : les minuteries du systèmes UV et de l'humidificateur

sont hors service, l'indicateur du filtre est toujours en service.

Pour faire afficher les minuteries en service :

1. Appuyer sur le bouton de l'indicateur AIRWATCH

MC

pendant environ 3 secondes.

2. Observer la flèche qui indique quelles minuteries sont en

service.

Pour mettre une minuterie en service :

1. Appuyer sur le bouton de l'indicateur AIRWATCH

MC

jusqu'à ce que l'appareil voulu soit sélectionné (la flèche

pointe vers cet appareil et clignote).

2. Appuyer sur le bouton et le tenir enfoncé jusqu'à ce que

la flèche cesse de clignoter.

3. Relâcher le bouton pendant que la flèche est allumée.

Pour mettre une des minuteries hors service :

1. Appuyer sur le bouton de l'indicateur AIRWATCH

MC

jusqu'à ce que l'appareil voulu soit sélectionné (la flèche

pointe vers cet appareil).

2. Appuyer sur le bouton et le tenir enfoncé jusqu'à ce que

la flèche s'éteigne (environ 4 secondes).

3. Relâcher le bouton pendant que la flèche est éteinte.

Installation de la pile :

1. Retirer l'indicateur AIRWATCH

MC

de sa base.

a. Appuyer sur la languette sur le rebord inférieur de la

base.

b. Tirer sur le couvercle par le bas.

2. Installer une pile au lithium CR123A (fournie) dans le

porte-pile situé au dos de l'appareil.

3. Observer les segments à cristaux liquides de l'affichage

s'allumer.

Choisir un emplacement

L'apparence de l'indicateur AIRWATCHMC s'harmonise à la

plus récente gamme de thermostats programmables de luxe

ChronothermMC IV de Honeywell. L'appareil peut aussi être

installé à tout autre endroit pratique dans la maison ou près de

l'appareil de chauffage. Voir la Fig. 15.

AM

System

Tue

Wake

Heat

Room

Fan

DST

Auto

TM

On/Battery

Air Cleaner

UV Air Treatment

Humidifier

Honeywell.com/yourhome

M14697A

Fig. 15. Choix d'un emplacement.

1. Choisir l'emplacement voulu (à au moins 6 pieds de la

porte du transmetteur dans la porte).

2. Vérifier la communication entre le filtre à auto-ionisation

F200 et l'indicateur AIRWATCH

a. Placer l'indicateur AIRWATCH

MC

comme suit :

MC

à l'emplacement

choisi. Utiliser du ruban adhésif pour le maintenir en

place.

b. Au F200, appuyer sur le bouton de réarmement situé

sur la porte.

c. Vérifier si les flèches de l'indicateur AIRWATCH

clignotent. (Les flèches clignotent pendant environ

deux minutes avant de revenir à la normale.)

3. S'il n'y a pas de réaction à l'indicateur AIRWATCH

choisir un autre emplacement dans la maison et reprendre la vérification à l'étape 2.

Installation de l'indicateur AIRWATCH

MC

1. Retirer l'indicateur AIRWATCHMC de sa base.

a. Appuyer sur la languette sur le rebord inférieur de la

base.

b. Tirer sur le couvercle par le bas.

2. Placer la base sur le mur à l'endroit choisi; en utilisant

les trous de la base comme gabarit, marquer l'emplacement des chevilles et des vis fournies. Marquer également l'emplacement de l'ouverture au centre de la base

si une antenne est utilisée.

3. Percer les trous (3/16 po) et insérer les chevilles fourn-

ies. Percer un autre trou de 3/16 po destiné à l'antenne

externe, selon le cas.

4. Placer la base par-dessus les trous et installer les vis

fournies; serrer les vis jusqu'à ce que la base soit fermement fixée au mur.

5. Remettre l'indicateur AIRWATCH

MC

sur sa base.

a. Insérer le fil de l'antenne dans l'ouverture du mur, au

besoin.

b. Raccrocher le couvercle.

c. Appuyer sur le couvercle pour s'assurer qu'il est bien

fermé.

MC

MC

,

68-0238EF—2 8

Fonctionnement de l'indicateur AIRWATCH

MC

L'indicateur comporte un écran à cristaux liquides à quatre

segments indicateurs : On/Battery (marche/pile), Air Cleaner

(filtre à air), UV Air treatment (système de traitement de l'air

aux ultraviolets), et Humidifier (humidificateur). Voir le Tableau

1.

Page 19

FILTRE À AIR À AUTO-IONISATION F200

VÉRIFICATION

Vérifier l'installation visuellement comme suit :

• L'air circule dans le sens indiqué par la flèche figurant sur la

cartouche du filtre à air.

• Les déflecteurs et les raccords de transition, le cas échéant,

sont bien installés.

• Les joints en tôle entre le filtre à air et l'appareil de

chauffage sont scellés.

• Le filtre original a été retiré et le compartiment du ventilateur

a été nettoyé.

Remettre en place toutes les portes d'accès retirées au

moment de l'installation.

Faire fonctionner l'appareil de chauffage ou de refroidissement

pendant un cycle complet pour vérifier que le système

fonctionne comme il se doit.

• Tous les raccords en tôle ont été posés.

Tableau 1. Description de l'affichage à cristaux liquides de l'indicateur AIRWATCH

MC

État de l'indicateur

AIRWATCH

MC

Signification/Mesures à prendre

Aucune flèche n'est allumée. L'indicateur n'est pas alimenté; remplacer la pile.

Flèche ON/Battery allumée de

L'indicateur fonctionne normalement.

façon continue.

Flèche ON/Battery clignotante. Deux secondes allumée, six secondes éteinte : remplacer la pile dans la porte du F200.

N'appuyer sur aucun bouton de réarmement après le remplacement de la pile. Deux

secondes allumée, deux secondes éteinte : remplacer la pile de l'indicateur

AIRWATCH

MC

. N'appuyer sur aucun bouton de réarmement après le remplacement de

la pile. Le clignotement alterne et passe de deux secondes allumée, six secondes

éteinte à deux secondes allumée, deux secondes éteinte : remplacer les piles des deux

appareils. N'appuyer sur aucun bouton de réarmement après le remplacement de la

pile.

Flèche du filtre à air clignotante. L'indicateur a reçu un signal du transmetteur signifiant soit que la chute de pression est

trop élevée ou que la période de 12 mois entre deux remplacement de filtre est écoulée.

Remplacer le filtre et appuyer sur le bouton de réarmement situé sur la porte du F200.

Flèche du système UV ou flèche

de l'humidificateur clignotante.

Il faut remplacer les lampes du systèmes UV ou le tampon de l'humidificateur. Effectuer

le remplacement requis. À l'indicateur AIRWATCH

MC

, appuyer sur le bouton et le

relâcher jusqu'à ce que la flèche de l'appareil voulu clignote. Appuyer à nouveau sur le

bouton et le retenir jusqu'à ce que la flèche soit allumée sans interruption, puis relâcher

le bouton.

Toutes les flèches clignotent. L'appareil procède à une auto-vérification. Les flèches clignotent pendant deux minutes,

puis l'indicateur se remet automatiquement en marche.

9 68-0238EF—2

Page 20

FILTRE À AIR À AUTO-IONISATION F200

Tableau 2. Liste des pièces du F200.

O

N

Description

F200E1003

16 x 20 en po

F200E1029

16 x 25 en po

F200E1011

20 x 20 en po

F200E1037

20 x 25 en po

1 Filtre de recharge FC200E1003 FC200E1029 FC200E1011 FC200E1037

2 Porte avec transmetteur RF 32004876-002 32004876-002 32004876-001 32004876-001

3

Rècepteur RF AIRWATCH

MC

W8600B1005 W8600B1005 W8600B1005 W8600B1005

Solutions de régulation et d’automatisation

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35, Dynamic Drive

Golden Valley, MN 55422 Scarborough (Ontario) M1V 4Z9

customer.honeywell.com

® Marque de commerce déposée aux É.-U.

© 2005 Honeywell International Inc. Tous droits réservés

68-0238EF—2 M.S. Rev. 09-05

Loading...

Loading...