Page 1

Excel Smart I/O Compact

HONEYWELL EXCEL 5000 OPEN SYSTEM

INSTALLATION INSTRUCTIONS

GENERAL INFORMATION

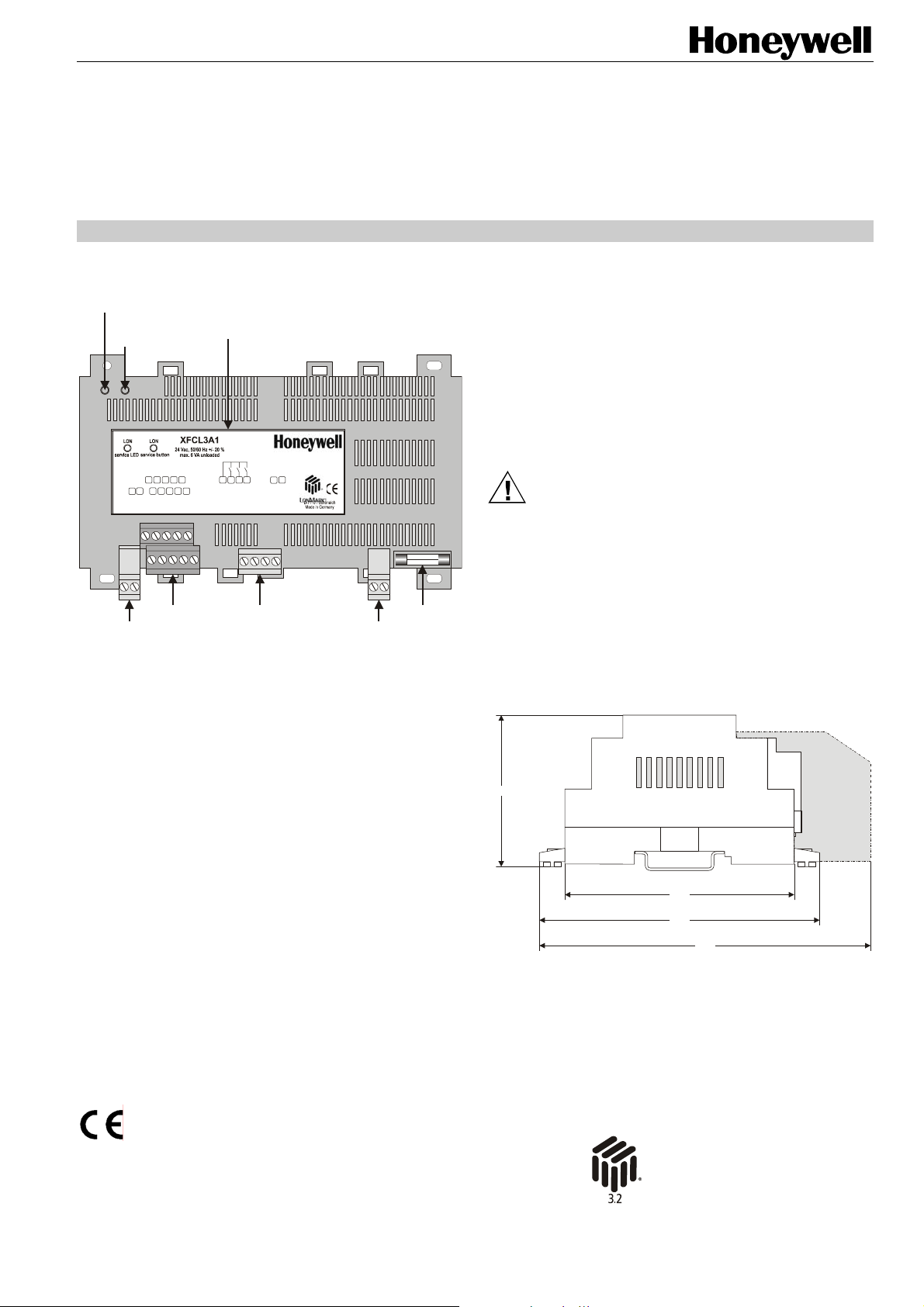

LonWorks

service LED

LonWorks

service

button

LON 1

removable LonWorks

terminal plug

Fig. 1. Top view (optional terminal cover removed)

The Excel Smart I/O Compact is equipped with:

• three relays,

• three digital inputs, and

• three analog inputs, which may be used as slow digital

inputs or as NTC20k temperature sensor inputs.

See also Table 1 on page 2 for a complete overview of

terminals and their functions.

The two models of the Excel Smart I/O differ only in their

power supply:

• XFCL2A1: 230 Vac power supply

• XFCL3A1: 24 Vac power supply

GND9GND

DI 2

8

10

3214 5 6

AI 1

DI 1

LON 2

input terminals

terminal assignment label

DI 3

AI 3

12 15

11

AI 2

GND

7

GND

16

R123 COM

relay output terminals

Rel 1 NO17Rel 2 NO18Rel 3 NO

0441

26

25

24V 0

24V ~

fuse

removable power

supply terminal plug

BEFORE INSTALLATION

IMPORTANT

It is recommended that the controller be kept at room

temperature for at least 24 hours before applying

power; this is to allow the evaporation of any

condensation resulting from low shipping / storage

temperatures.

US requirement, only: This device must be installed

in a UL-listed enclosure offering adequate space to

maintain the segregation of line voltage field wiring

and Class 2 field wiring.

CAUTION

To avoid electrical shock or equipment damage, you

must switch OFF the power supply before attaching /

removing connections to/from any terminals.

MOUNTING

Both models have the same dimensions (W x L x H =

110 x 180 x 60 mm) (see Fig. 2) and conform to IP20 (without

optional terminal protection cover) or IP30 (with optional

terminal protection cover; width is then 130 mm).

59.5

90

110

130

Fig. 2. Excel Smart I/O Compact dimensions (in mm)

The Excel Smart I/O Compact is suitable for mounting on a

standard rail (DIN EN 50022-35 x 7,5), on walls/ceilings, as

well as for installation in wiring cabinets or fuse boxes.

terminal protection

cover (optional)

® U.S. Registered Trademark

Copyright © 2005 Honeywell Inc. EN1B-0282GE51 R0305B

All Rights Reserved

Page 2

EXCEL SMART I/O COMPACT

DIN Rail Mounting/Dismounting

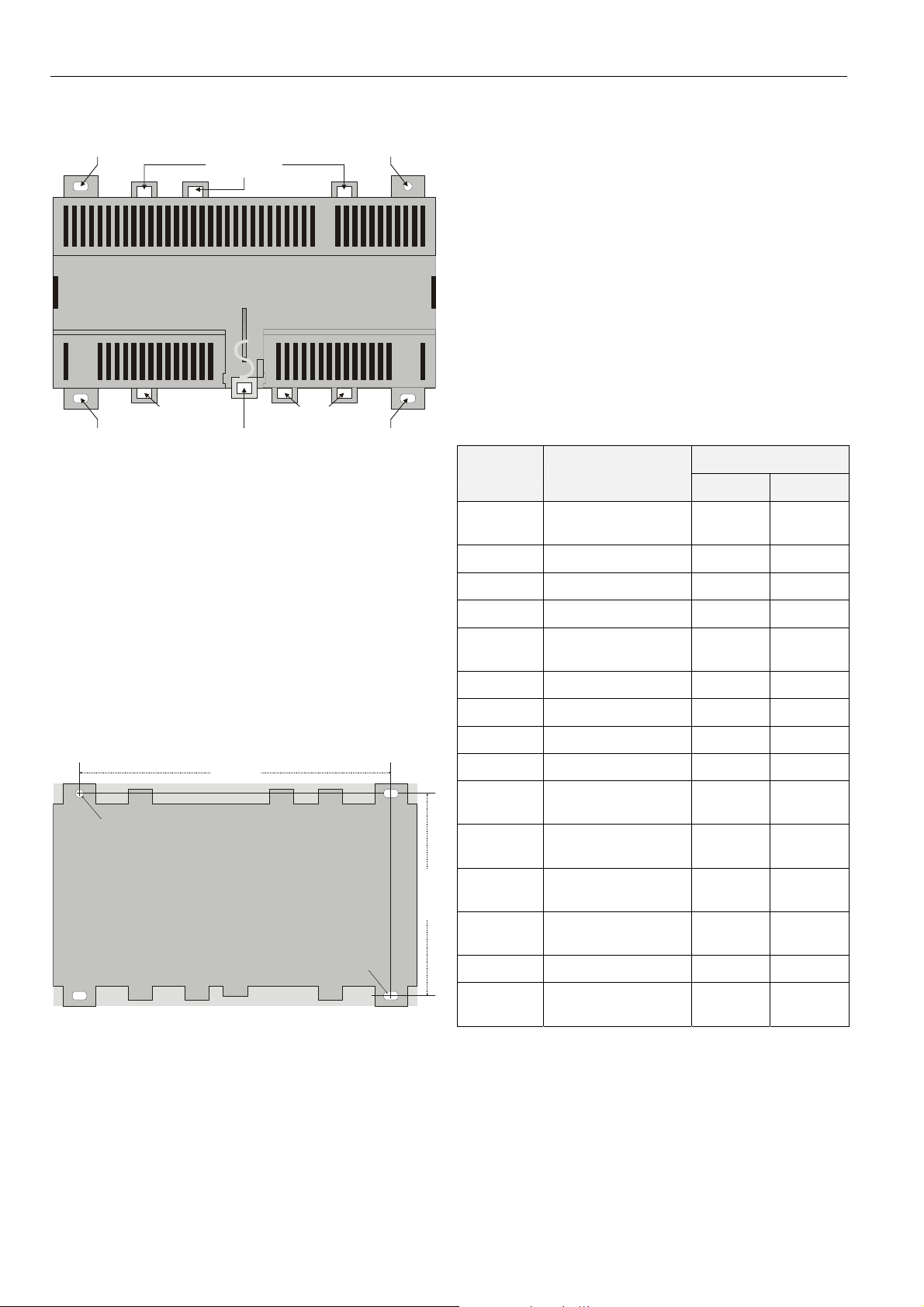

screwing nose

(oval hole)

screwing nose

(oval hole)

eyelet for

cable binder

eyelets for

cable binders

stirrup; pull to

dismount from rail

cable binders

eyelets for

Fig. 3. Housing base (view from below)

The Excel Smart I/O Compact can be mounted onto the DIN

rail simply by snapping it into place. It is dismounted by gently

pulling the stirrup located in the base of the housing (see Fig.

3). When mounted on a DIN rail, the unit must be secured in

place with a stopper to prevent sliding.

screwing nose

(round hole)

screwing nose

(oval hole)

Wall/Ceiling Mounting/Dismounting

The Excel Smart I/O Compact can be mounted on walls or

ceilings in any desired orientation. In the case of ceiling

mounting, however, it should not be operated at ambient

temperatures exceeding 50 °C. The unit is mounted by

inserting 3.5-mm dowel screws through the corresponding

screwing noses.

154 mm

round hole

(diameter: 4 mm)

protection cover's cut-out tabs and snap it (by hand) into

place on the housing. To remove the cover, place a

screwdriver in the leverage slot and pry it loose.

Terminal Assignment

The Excel Smart I/O Compact features two rows of terminal

blocks located on one side for the connection of cables to the

inputs and relay outputs as well as for connecting the removable power supply terminal plug and removable

L

ONWORKS terminal plug.

NOTE: All relay and power supply terminal blocks are

orange-colored.

NOTE: According to VDE guidelines, it is not allowed to mix

low-voltage and high-voltage signals on the relays.

The Excel Smart I/O Compact is equipped with an adhesive

terminal assignment label on the top of the housing (see Fig.

1 on page 1).

Table 1. Overview of terminals and functions

model

terminal # function

XFCL2A1 XFCL3A1

1+2

removable L

connection plug

ONWORKS

X X

3 digital input #1 X X

4 analog input #1 X X

5 analog input #2 X X

6, 7, 8, 9

GND terminals

serving all signals

X X

10 digital input #2 X X

11 digital input #3 X X

12 analog input #3 X X

13+14 not used

15

16

relay common for

relays 1, 2, and 3

relay #1, normallyopen contact

X X

X X

100 mm

oval hole

(4x7 mm)

Fig. 4. Drilling template (view from above)

When equipped with the optional terminal protection cover

(see section "Terminal Protection Cover" on page 6), the

Excel Smart I/O Compact conforms to IP30.

After mounting the Excel Smart I/O Compact onto the wall or

ceiling, provide for cable access by snipping out the terminal

EN1B-0282GE51 R0305B

17

18

relay #2, normallyopen contact

relay #3, normallyopen contact

X X

X X

19 – 24 not used

25+26

removable power

supply plug

230 Vac 24 Vac

See also section “Configuring the Inputs and Outputs” on

page 4.

2

Page 3

EXCEL SMART I/O COMPACT

(

)

Power Supply

General Information

NOTE: All wiring must comply with applicable electrical

codes and ordinances. Refer to job or manufacturers’ drawings for details. Local wiring guidelines (e.g. VDE 0100) may take precedence over

recommendations provided in these installation

instructions.

NOTE: To comply with CE requirements, devices having a

voltage of 50...1000 Vac or 75...1500 Vdc but

lacking a supply cord, plug, or other means for

disconnecting from the power supply must have the

means of disconnection incorporated in the fixed

wiring. This means of disconnection must have a

contact separation of at least 3 mm at all poles.

Use a minimum of 18 AWG (1.0 mm

14 AWG (2.5 mm

2

) for all power wiring.

Power is supplied via a removable terminal plug (attached to

terminals 25 and 26) permitting individual Excel Smart I/O

Compacts to be disconnected from the power supply without

disturbing the operation of other devices powered by the

same source. See Fig. 5.

Excel Smart I/O Compact

XFCL2A1

230

230

Vac

device 3 device 2

device 1

230 Vac (15% / +10%)

Vac

25 26

230

230

Vac

Vac

25 26

230

230

Vac

Vac

25 26

NL

50 / 60 Hz

Fig. 5. Connection to power supply

NOTE: Do not reverse the polarity of the power connection

cables, and avoid ground loops (i.e. avoid connecting one field device to several controllers) as this

may result in short circuits damaging your device.

XFCL2A1 with 230 Vac Power Supply

The XFCL2A1 with 230 Vac power supply is equipped with a

built-in 24 Vac transformer.

Power supply: 230 Vac [-15% / +10%], 50/60 Hz).

Power consumption: < 6 VA (device unloaded)

2

) and a maximum of

Excel Smart I/O Compact

XFCL3A1

24

Vac24Vac

25 26

24

device 1device 2

Vac24Vac

25 26

24 Vac

+/-20%

NL

230 Vac (15% / +10%)

50 / 60 Hz

XFCL3A1 with 24 Vac Power Supply

Power supply: 24 Vac [±20%], 50 or 60 Hz, connected.

Power consumption: < 3 VA (device unloaded)

LonWorks Communications

General Information

The Excel Smart I/O Compact is equipped with a freetopology transceiver for communication on L

networks. The L

ONWORKS network is insensitive to polarity,

eliminating the possibility of installation errors due to

miswiring.

Different network configurations (daisy-chain, loop, and star

configurations, or any combination thereof) are possible (see

also Excel 50/500 L

ONWORKS Mechanisms Interface

Description, EN0B-0270GE51).

Connecting to the LONWORKS Network

IMPORTANT

Do not bundle wires carrying field device signals or

LONWORKS communications together with highvoltage power supply or relay cables. Specifically,

maintain a min. separation of 3 inches (76 mm)

between such cables. Local wiring codes may take

precedence over this recommendation.

IMPORTANT

Try to avoid installing in areas of high electromagnetic noise (EMI).

The unit must be wired to the L

IV 22 AWG (Belden part number 9D220150) or plenum-rated

level IV 22 AWG (Belden part number 9H2201504) nonshielded, twisted-pair, solid-conductor wire. When possible,

use Honeywell 111AK3781, AK3782, AK3791, or AK3792

cable (US part numbers). See Excel 50/5000 L

Mechanisms, EN0B-0270GE51, for details, including

maximum lengths.

Use wire with a minimum size of 20 AWG (0.5 mm

maximum size of 14 AWG (2.5 mm

D-71101 Schönaich

Excel Smart

I/O Compact

1 2 1 2

Made in Germany

Fig. 6. Connection to LonWorks network and termination

module (here: daisy-chain network configuration)

The Excel Smart I/O Compact is connected to the L

network via a removable terminal plug (attached to terminals

1 and 2) permitting individual Excel Smart I/O Compacts to be

connected / disconnected from the L

without disturbing the operation of other devices.

ONWORKS network using level

2

).

Excel Smart

I/O Compact

ONWORKS network

ONWORKS®

D-71101 Schönaich

Made in Germany

ONWORKS

2

) and a

ONWORKS

termination

module

EN1B-0282GE51 R0305B

3

Page 4

EXCEL SMART I/O COMPACT

Depending upon the chosen network configuration, one or two

terminations (see section "L

ONWORKS Termination" on page

6) may be required.

Inputs/Outputs

Wiring the Inputs/Outputs

Use a minimum size of 20 AWG (0.5 mm2) and a maximum of

14 AWG (2.5 mm

maximum length of all input/output cables is 400 m.

Two wires with a total thickness of 14 AWG can be twisted

together and connected using a wire nut (include a pigtail with

this wire group and attach the pigtail to the individual terminal

block). Deviations from this rule can result in improper

electrical contact. Local wiring codes may take precedence

over this recommendation.

power--power

Rel 3

0

ON

1826 25

Configuring the Inputs and Outputs

You can configure the Excel Smart I/O Compact’s inputs and

outputs using Honeywell's LNS plug-in or CARE.

NOTE: The switching logic functionality can be configured

using CARE, only. The LNS plug-in does not support

the switching logic functionality.

Digital Inputs

The Excel Smart I/O Compact is equipped with three digital

inputs suitable for use as fast digital inputs (static digital

inputs or push-buttons for flip-flop) or as totalizer inputs

(square waves).

software detects

inputs as

closed < 400 Ω < 0.8 Vdc max. 2.5 mA

open > 1.5 kΩ > 2.0 Vdc 0…1.5 mA

Totalizer input:

• digital input #1: up to 20 Hz; reacts on falling edge;

• digital input #2: up to 5 Hz; configurable (using

Honeywell’s LNS plug-in) to react on rising or falling edge;

• digital input #3: up to 5 Hz; configurable (using

Honeywell’s LNS plug-in) to react on rising or falling edge.

2

) for all input/output connections. The

Excel Smart I/O Compact

R123

Rel 1

Rel 2

COM

ON

ON

15

16

17

COMST1ST2ST3

3-stage fan

Fig. 7. Overview of inputs and outputs

Table 2. Digital input characteristics

AI3 DI3 DI2 GND GND GND GND AI2 AI1 DI 1 LON2 LON1

10 9 8 7 6 5

12 11

1 2

1 2

AI as

NTC20kOhm

DI as

totalizer

N L

resistive input

(dry contact)

AI as slow DI

voltage

input

3

4

2 1

DI

current out

of terminal

Analog Inputs

The Excel Smart I/O Compact is equipped with three analog

inputs. The analog inputs may be used as NTC20k temperature sensor inputs or as slow digital inputs. The analog

inputs do not support 0…10 V input.

Table 3. Slow digital input characteristics

software de-

tects inputs as

resistive input

(dry contact)

high/low

switching at

current out

of terminal

closed < 200 Ω < 1.5 Vdc < 0.3 mA

open > 50 kΩ > 3.5 Vdc < 0.1 mA

Table 4. Accuracy, resolution of inputs (NTC20k sensors)

temperature range accuracy resolution

-50 to -40 °C (-58 to -40 °F)

-40 to -30 °C (-40 to -22 °F)

-30 to -20 °C (-22 to -4 °F)

-20 to -10 °C (-4 to 14 °F)

-10 to 0 °C (14 to 32 °F)

0 to 10 °C (32 to 50 °F)

10 to 50 °C (50 to 122 °F)

50 to 70 °C (122 to 158 °F)

70 to 90 °C (158 to 194 °F)

90 to 100 °C (194 to 212 °F)

100 to 120 °C (212 to 248 °F)

120 to 150 °C (248 to 302 °F)

≤ 4.11 K

≤ 2.12 K

≤ 1.39 K

≤ 0.65 K

≤ 0.42 K

≤ 0.27 K

≤ 0.30 K

≤ 0.45 K

≤ 1.17 K

≤ 1.44 K

≤ 2.29 K

≤ 5.11 K

For all NTC20k sensor inputs, temperatures of ≤ -50 °C are

interpreted as being due to a sensor break, and temperatures

of ≥ +150 °C are interpreted as being due to a sensor shortcircuit.

Relay Outputs

The Excel Smart I/O Compact is equipped with three

normally-open relay outputs.

Current Limitations

NOTE: If inductive components are to be connected to the

relays and if these relays switch more often than

once every two minutes, these components must be

prevented from causing harmful interference to radio

or television reception (conformance with

EN 45014).

• A min. current of 50 mA is required to ensure a reliable

contact.

• The normally-open contacts are designed for a max. continuous current of 3 A at max. 230 Vac and cos φ = 1. The

d.c. characteristic is shown in Fig. 8.

1.42 K

0.77 K

0.44 K

0.27 K

0.17 K

0.12 K

0.11 K

0.19 K

0.35 K

0.48 K

0.92 K

2.3 K

EN1B-0282GE51 R0305B

4

Page 5

EXCEL SMART I/O COMPACT

300

200

100

ohmic load

switching voltage (Vdc)

10

0.1 0.2 0.5 1.0 2.0 5.0 10.0 20.0

switching current (A)

Fig. 8. Relay characteristic

Replacing the Fuse

NOTE: Before replacing the fuse (see also Fig. 1 on page

1), disconnect the Excel Smart I/O Compact from the

power source by detaching the removable terminal

plug attached to terminals 25 and 26.

CAUTION

Depending upon actual wiring, even after you have

switched OFF the power supply, the relays may still be

under high voltage.

Troubleshooting

The Excel Smart I/O Compact features a LONWORKS service

LED and corresponding L

1) for commissioning and troubleshooting.

When the service button is pressed, the service pin message

is broadcast.

See Table 5 for a description of the meaning of the various

different possible behaviors of the L

For more information on standard service LED behavior, refer

to Motorola L

ONWORKS Technology Device Data Manual,

page AL-190.

Possible Problems and Recommended Actions

Check to see if the LONWORKS service LED's behavior is

changed when you switch the power OFF/ON. Please contact

Honeywell if this does not solve the problem.

ONWORKS service button (see Fig.

ONWORKS service LED.

Table 5. L

1

2

3

4

5

6a

6b

6c

6d

7

8

9

ONWORKS Service LED Behaviors and Meanings

LED blinking pattern

LED remains OFF after

power-up.

LED is lit continuously

after first power-up.

LED flashes at power-up,

goes OFF, then is lit continuously.

LED flashes briefly

periodically.

LED repeatedly blinks ON

for 1 s and OFF for 1 s.

OFF duration ≈ 10 s.

Afterwards, the service

LED turns ON and remains ON, indicating

completion of the blanking

process.

OFF duration ≈ 1 s.

Afterwards, the service

LED is lit continuously.

OFF duration is 1...15 s,

depending on application

size and system clock.

Afterwards, service LED

repeatedly blinks ON for

1 s and OFF for 1 s.

OFF duration is indefinite

(1...15 s to load internal

EEPROM; remains OFF).

LED remains OFF after a

short ON duration.

LED flashes for 1 minute

in following pattern: 5x

ON/OFF, 5 sec OFF, 5x

ON/OFF

LED flashes continuously

in following pattern: 4x

ON/OFF followed by 5 sec

pause.

meaning

Defective device hardware. Suspect

power supply problems, clock

problems, or defective Neuron Chip.

Defective hardware.

Controller lacks application.

Controller is probably experiencing

continuous watchdog resets, or

external memory or EEPROM is

corrupt.

Controller is unconfigured but has an

application.

Using EEBLANK on a Neuron 3150

Chip-based custom node.

First power-up with a new PROM on

a Neuron 3150 Chip-based

customized node. Application-less

firmware state exported.

First power-up with a new PROM on

a Neuron 3150 Chip-based

customized node. Unconfigured

firmware state exported.

First power-up with new PROM on

Neuron 3150 Chip-based customized node. Configured firmware

state exported.

Controller is configured and running

normally.

Controller has received WINK

command from network. Other

physical outputs are unaffected.

Neuron communication failure or

sensor break.

EN1B-0282GE51 R0305B

5

Page 6

EXCEL SMART I/O COMPACT

Accessories

Terminal Protection Cover

Required for wall/ceiling mounting. Set of eight covers.

order no.: XAL_COV_L

LONWORKS Termination

One or two LONWORKS terminations are required, depending

on the given LonWorks bus layout. See section "Connecting

to the L

ONWORKS Network" on page 3.

Two different L

LONWORKS termination module, order no.: 209541B

LONWORKS connection / termination module (mountable on

DIN rails and in fuse boxes), order no.: XAL-Term

removable screw-type

3-pole terminal block

ONWORKS termination modules are available:

l

l

e

w

y

e

n

o

H

m

r

e

T

-

L

A

X

4

3

L

L

O

O

N

N

plug-in

jumper

3

4

LON

Termi nat ion

FTT/LPT Bus

FTT/LPT Free

Park Position

5

1

shield shield

06

Fig. 9. L

ONWORKS connection and termination module

Automation and Control Solutions

Honeywell GmbH

Böblinger Straβe 17

D-71101 Schönaich

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://europe.hbc.honeywell.com

Subject to change without notice. Printed in Germany Manufacturing location certified to

EN1B-0282GE51 R0305B

Loading...

Loading...