Honeywell EXCEL 5000 User Manual

Control Icons

USER GUIDE

74-5577-33 (US)

EN2B-0184 GE51 R0518 (Europe)

HONEYWELL EXCEL 5000 OPEN SYSTEM

74-5577–33 (US)

EN2B-0184 GE51 R0518 (Europe)

Control Icons

V. 10.08.01

USER GUIDE

Software License Advisory This document supports software that is proprietary to Honeywell Inc. and/or to

third party software vendors. Before software delivery, the end user must

execute a software license agreement that governs software use. Software

license agreement provisions include limiting use of the software to equipment

furnished, limiting copying, pre serv ing con fid enti ality , and pro hibit ing tr an sfer to

a third party. Disclosure, use, or reproduction beyond that permitted in the

license agreement is prohibited.

EXCEL CARE CONTROL ICONS

i 74-5577–33 (US)

EN2B-0184 GE51 R0518 (Europe)

CONTENTS

INTRODUCTION ....................................................................................................................................................................... 9

Applicable Literature ............................................................................................................................................................... 10

Control Icon Operation ........................................................................................................................................................... 11

Control Icon Table ............................................................................................... 12

Control Icon Table (Excel Web / Excel Web II) .................................................... 14

Datapoints ........................................................................................................... 19

ALPHABETIC REFERENCE .................................................................................................................................................... 21

Absolute (Excel Web / Excel Web II) ................................................................... 22

Addition / ADD ..................................................................................................... 22

ADH2 (Excel Web / Excel Web II) ....................................................................... 23

Analog Switch / SWI ............................................................................................ 24

AND (Excel Web / Excel Web II) ......................................................................... 25

Arcus Cosinus (Excel Web / Excel Web II) .......................................................... 25

Arcus Sinus (Excel Web / Excel Web II) .............................................................. 25

Arcus Tangens (Excel Web / Excel Web II) ......................................................... 26

Average / AVR ..................................................................................................... 26

Cascade / CAS .................................................................................................... 27

Cascade Plus / CAS ............................................................................................ 31

Changeover Switch / CHA ................................................................................... 34

Compare 2 (Excel Web II) ................................................................................... 35

Comparison (Excel Web / Excel Web II).............................................................. 35

Cosinus (Excel Web / Excel Web II) .................................................................... 36

Counter (Excel Web / Excel Web II) .................................................................... 36

Cycle / CYC ......................................................................................................... 38

Data Transfer / IDT .............................................................................................. 41

Decimal Places (Excel Web / Excel Web II) ........................................................ 44

Delay (Excel Web / Excel Web II) ........................................................................ 44

Dewpoint (Excel Web / Excel Web II) .................................................................. 45

Differential (Excel Web / Excel Web II) ................................................................ 46

Digital Switch / 2PT / Hysteresis (Excel Web / Excel Web II) .............................. 46

Division (Excel Web / Excel Web II) .................................................................... 50

Duty Cycle / DUC ................................................................................................ 51

Economizer / ECO ............................................................................................... 58

EQL (Excel Web / Excel Web II) .......................................................................... 69

Event Counter / EVC ........................................................................................... 70

Exponential (Excel Web / Excel Web II) .............................................................. 70

Factorial (Excel Web / Excel Web II) ................................................................... 71

Fixed Applications (XFM) .................................................................................... 71

ENHANCED PID ............................................................................................. 73

ENTHALPY ...................................................................................................... 77

FLOW CALCULATION .................................................................................... 78

LEAD-LAG ....................................................................................................... 80

Power Demand Control XFMs ......................................................................... 81

RATIO .............................................................................................................. 88

Totalizer XFM .................................................................................................. 89

UP-DOWN RAMP ............................................................................................ 91

XFM 35 Description ......................................................................................... 92

Priority Groups and their Switching Behavior .............................................. 96

XFM 35 Algorithms ..................................................................................... 97

XFM 35 General Functions ......................................................................... 102

XFM 36-1 Description ...................................................................................... 106

Automatic Load Switch-On after Maximum OFF Time Expiration ............... 110

RM Functions .............................................................................................. 111

XFM 36-1 General Functions ...................................................................... 111

XFM 36-1 Priority Group Assignment ......................................................... 113

XFM 36-1/S/R Switching Behavior .............................................................. 113

XFM 36-1/S Sequential Load Switching ...................................................... 113

XFM 36-1/R Rotational Load Switching ...................................................... 115

HC (Excel Web / Excel Web II) ............................................................................ 117

Heating Curve with Adaptation / HCA ................................................................. 118

Humidity and Enthalpy / H,X ................................................................................ 121

Integral (Excel Web / Excel Web II) ..................................................................... 123

CONTENTS EXCEL CARE CONTROL ICONS

74-5577–33 (US) ii

EN2B-0184 GE51 R0518 (Europe)

J-K Flip Flop (Excel Web / Excel Web II) ............................................................. 123

Last Value (Excel Web / Excel Web II) ................................................................. 124

Linear Converter (Excel Web II) ........................................................................... 124

Limit (Excel Web / Excel Web II) .......................................................................... 125

Ln (Excel Web / Excel Web II) .............................................................................. 126

Logic Counter (Excel Web / Excel Web II) ........................................................... 126

Mathematical Editor / MAT ................................................................................... 126

Connection of the MAT Icon to a Control Icon ................................................. 128

Differential Function (DIFT) Dialog Box ........................................................... 128

Formula Entry Procedure ................................................................................ 130

Integral Function (INTEG) Dialog Box ............................................................. 134

LINEAR Dialog Box ......................................................................................... 136

Polynomial Equation (POL) Dialog Box ........................................................... 138

Maximum / MAX ................................................................................................... 140

Merge (Excel Web / Excel Web II) ....................................................................... 141

Minimum / MIN ..................................................................................................... 142

Monoflop (Excel Web / Excel Web II) ................................................................... 143

Modulo (Excel Web / Excel Web II) ...................................................................... 143

Multi-Switch In (Excel Web / Excel Web II) .......................................................... 144

Multi-Switch Out (Excel Web / Excel Web II)........................................................ 144

Multiplication (Excel Web / Excel Web II) ............................................................. 145

Negate (Excel Web / Excel Web II) ...................................................................... 145

Next Schedule (Eagle) ......................................................................................... 145

Night Purge / NIPU ............................................................................................... 146

NOT (Excel Web / Excel Web II) .......................................................................... 149

Odd Parity (Excel Web / Excel Web II) ................................................................. 149

On-Board DI (Excel Web / Excel Web II) ............................................................. 149

On-Board DO (Excel Web / Excel Web II) ............................................................ 150

On/Off Delay (Excel Web / Excel Web II) ............................................................. 150

Optimum Start/Stop / EOH ................................................................................... 151

Optimum Start/Stop / EOH3 ................................................................................. 165

Optimum Start/Stop Energy Optimized Ventilation / EOV .................................... 182

OR (Excel Web / Excel Web II) ............................................................................ 191

PID Controller / PID .............................................................................................. 191

PID Operation .................................................................................................. 197

PID Plus Controller / PID ...................................................................................... 198

Random (Excel Web / Excel Web II) .................................................................... 205

Ratio / RAMP ....................................................................................................... 205

Read Global Reg. (Excel Web II) ......................................................................... 209

Read Priority (Excel Web II) ................................................................................. 210

Read Priority Value (Excel Web II) ....................................................................... 210

Read / RIA............................................................................................................ 211

Reset Timer (Excel Web / Excel Web II) .............................................................. 214

Round (Excel Web / Excel Web II) ....................................................................... 214

Round down (Excel Web / Excel Web II) ............................................................. 214

Round up (Excel Web / Excel Web II) .................................................................. 215

RS flip-flop (Excel Web / Excel Web II) ................................................................ 215

Sequence / SEQ .................................................................................................. 215

SET (Excel Web / Excel Web II) ........................................................................... 223

Sinus (Excel Web / Excel Web II) ......................................................................... 224

Split (Excel Web / Excel Web II) ........................................................................... 224

Square Root (Excel Web / Excel Web II) ............................................................. 224

Subtract / DIF ....................................................................................................... 225

Switching Table (Excel Web / Excel Web II) ........................................................ 226

Tangens (Excel Web / Excel Web II) .................................................................... 227

Time Counter (Excel Web / Excel Web II) ............................................................ 228

Timer Value (Excel Web / Excel Web II) .............................................................. 228

Truncate (Excel Web / Excel Web II) ................................................................... 228

Tuncos (Excel Web / Excel Web II) ...................................................................... 229

Value Ramp (Excel Web / Excel Web II) .............................................................. 229

Value Ramp2 (Excel Web II) ................................................................................ 229

WIDO (Excel Web / Excel Web II) ........................................................................ 230

Write Global Reg. (Excel Web II) ......................................................................... 231

Write Priority (Excel Web II) ................................................................................. 231

Write / WIA ........................................................................................................... 232

X root Y (Excel Web / Excel Web II) ..................................................................... 237

X^2 (Excel Web / Excel Web II) ........................................................................... 237

X^Y (Excel Web / Excel Web II) ........................................................................... 237

EXCEL CARE CONTROL ICONS CONTENTS

iii 74-5577–33 (US)

EN0B-0184 GE51 R0518 (Europe)

XOR Table (Excel Web / Excel Web II) ............................................................... 237

Zero Energy Band / ZEB ..................................................................................... 238

Examples .................................................................................................................................................................................. 244

Attenuator ............................................................................................................ 246

Average Value Calculation .................................................................................. 247

Floating Limits and Alarm Suppression ............................................................... 251

Operating Pump Switchover ................................................................................ 257

Optimized Start/Stop ........................................................................................... 261

Positioning Signal Limitation ................................................................................ 262

Setpoint Adjustments .......................................................................................... 265

System Regulation .............................................................................................. 268

Trend Buffer Control ............................................................................................ 270

Appendix A: Parameter List Description ............................................................................................................................... 273

Appendix B: Startup User Address........................................................................................................................................ 276

Index ......................................................................................................................................................................................... 280

EXCEL CARE CONTROL ICONS

9 74-5577–33 (US)

EN2B-0184 GE51 R0518 (Europe)

INTRODUCTION

Purpose This manual provides descriptions and application examples for control icons in

Excel Computer Aided Regulation Engineering (CARE) software. You use control

icons in the CARE Control Strategy function.

The control strategy for a plant consists of control loops that monitor the

environment and adjust equipment oper atio n to mainta in co mfort levels. For

example, a control loop for an air handling system can turn on a return air fan when

discharge air temperature in the return air duct is greater than or equal to 68F (20C).

Control loops consist of a series of “control icons” that dictate a sequence of events.

Control icons provide preprogrammed functions and algorithms to implement

sequences of control in a plant schematic. Examples of control icons include a

Proportional-Integral-Derivative (PID) function and a Maximum function (MAX).

Assumptions This manual assumes you are familiar with the CARE process, especially the control

strategy and switching logic functions. See Excel CARE User Guide 74-5587 (US) /

EN2B-0182 ( Europe) for details and procedures for the control strategy and

switching logic functions.

Temperature Differentials In the English measurement system, degrees Fahrenheit (F) usually represent both

the temperature measure and the differential measure. Dialog boxes shown in this

manual represent temperatures as °F and differentials as F Deg.

Manual Organization This manual contains the following chapters:

This Introduction lists other technical literature related to control icons, describes the

dialog boxes related to control icon operation, and provides a table that summarizes

the available control icons.

The Alphabetic Reference chapter describes each control icon. The beginning of

the chapter summarizes the type of information provided for each icon.

The Examples chapter describes applications that combine more than one control

icon to perform functions. These examples are in addition to the individual examples

for each icon in the Alphabetic Reference chapter.

Appendix A: Parameter List Description provides information about the parameter

list file generated by CARE when a plant is translated. This file documents the

parameters used in the control icons and switching logic tables. It is useful during

plant testing.

Appendix B: STARTUP User Address describes how the STARTUP user address

works and how to use it in control applications.

INTRODUCTION EXCEL CARE CONTROL ICONS

74-5577–33 (US) 10

EN2B-0184 GE51 R0518 (Europe)

APPLICABLE LITERATURE

Form No. Title

74-5587 (US) Excel CARE User Guide

EN2B-0182 (Europe) Detailed description of Excel CARE software

74-3556 (US) Excel Live CARE User Guide

EN2B-0183 (Europe) Instructions for using Live CARE software to access controller files on-line and

simulate operation

EN2B-162 RACL Editor User Guide

Graphical Editor for creation oft strategy logic programs for Excel 500 controllers.

74-3594 (US) ASPECD Editor User Guide

EN2B-0185 (Europe) Provides functions to modify the user interface for Excel Operator Terminals.

EXCEL CARE CONTROL ICONS INTRODUCTION

11 74-5577–33 (US)

EN2B-0184 GE51 R0518 (Europe)

CONTROL ICON OPERATION

Each control icon has an I/O dialog box that defines its input(s) and output(s). In

addition, some control icons have an internal parameters dialog box that defines

parameter values that govern the function of the control icon.

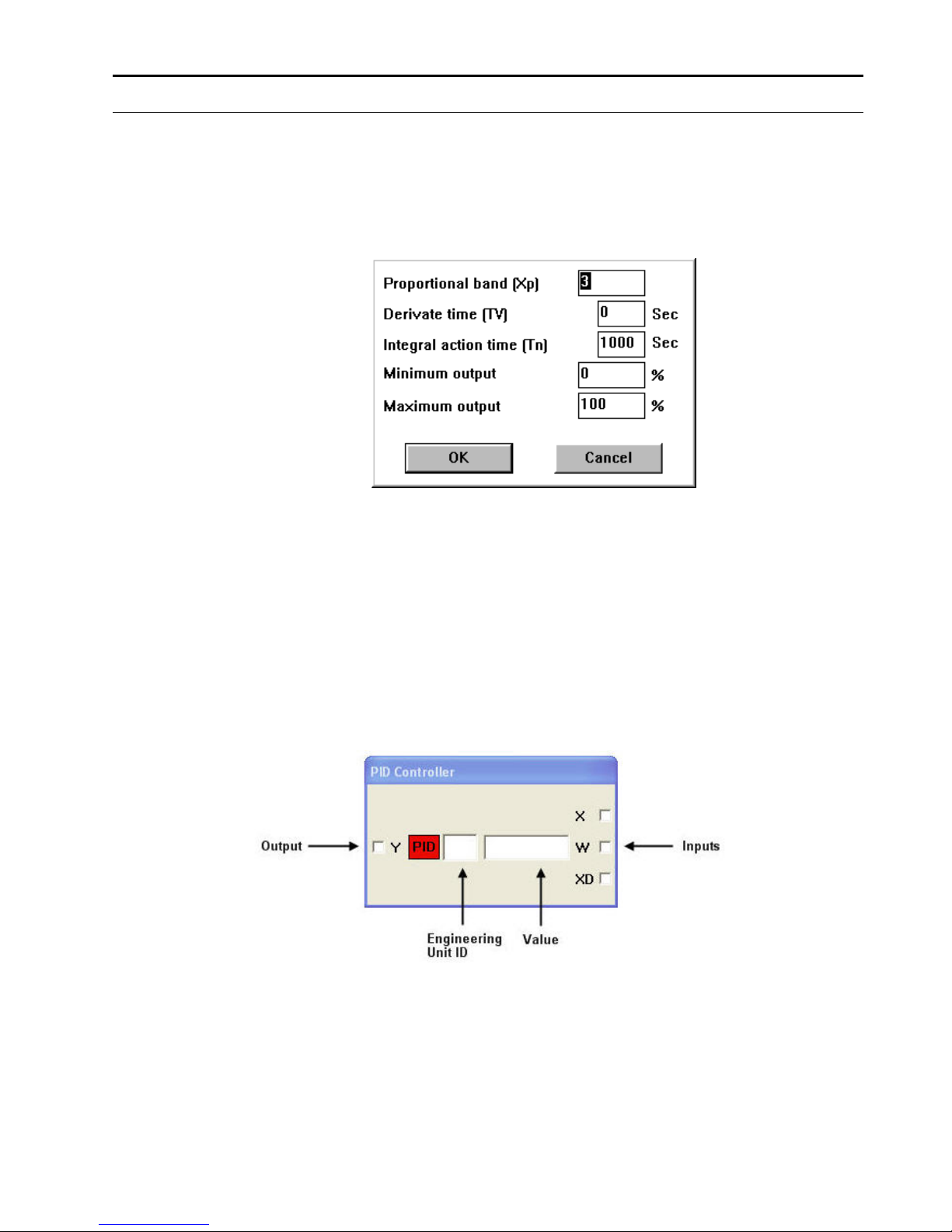

Internal Parameters Dialog Box When you first place a control icon in the Control Strategy work space, the internal

parameters dialog box, if any, displays. For example, for the PID icon, the following

internal parameters dialog box displays:

There are always default values for the parameters. You can change any of the

default values, as desired.

If you click Cancel, the dialog box closes and software does NOT place the control

icon in the control strategy.

You can redisplay the internal parameters dialog box at any time by clicking the

right-hand mouse button while the cursor is over the control icon in the control

strategy.

I/O Dialog Box After you place the control icon (and close the internal parameters dialog box, if

any), you can click the icon once (left-hand mouse button) to display the I/O dialog

box. This dialog box always shows output variables on the left, the control icon in

red, and input variables on the right.

For example, the PID icon displays the following dialog box:

You need to connect the Y, X, and W variables to either physical points,

pseudopoints, and/or other control icons. Variables on the left (Y in this case) are

always outputs. Variables on the right (X and W in this case) are always inputs. The

icon descriptions in the Alphabetic Reference chapter define the types of connection

that are valid for each variable.

INTRODUCTION EXCEL CARE CONTROL ICONS

74-5577–33 (US) 12

EN2B-0184 GE51 R0518 (Europe)

The two blank rectangles in the dialog box are editing fields where you can enter

values instead of point or icon connections. For example, in the PID dialog box, you

can type an engineering unit table ID and value for the W variable, instead of

connecting W to a point or control icon. For engineering unit, enter the

corresponding index number. Appendix E: Engineering Units in Excel CARE User

Guide 74-5587 (US) / EN2B-0182 (Europe) lists engineering units and their index

numbers.

If a variable does not have editing fields next to it, you cannot type values for a

connection; you must connect it to another icon or a point.

See Also ⇒ Excel CARE User Guide 74-5587 (US) / EN2B-0182 (Europe), Control Strategy

chapter, for procedures to place and connect control icons

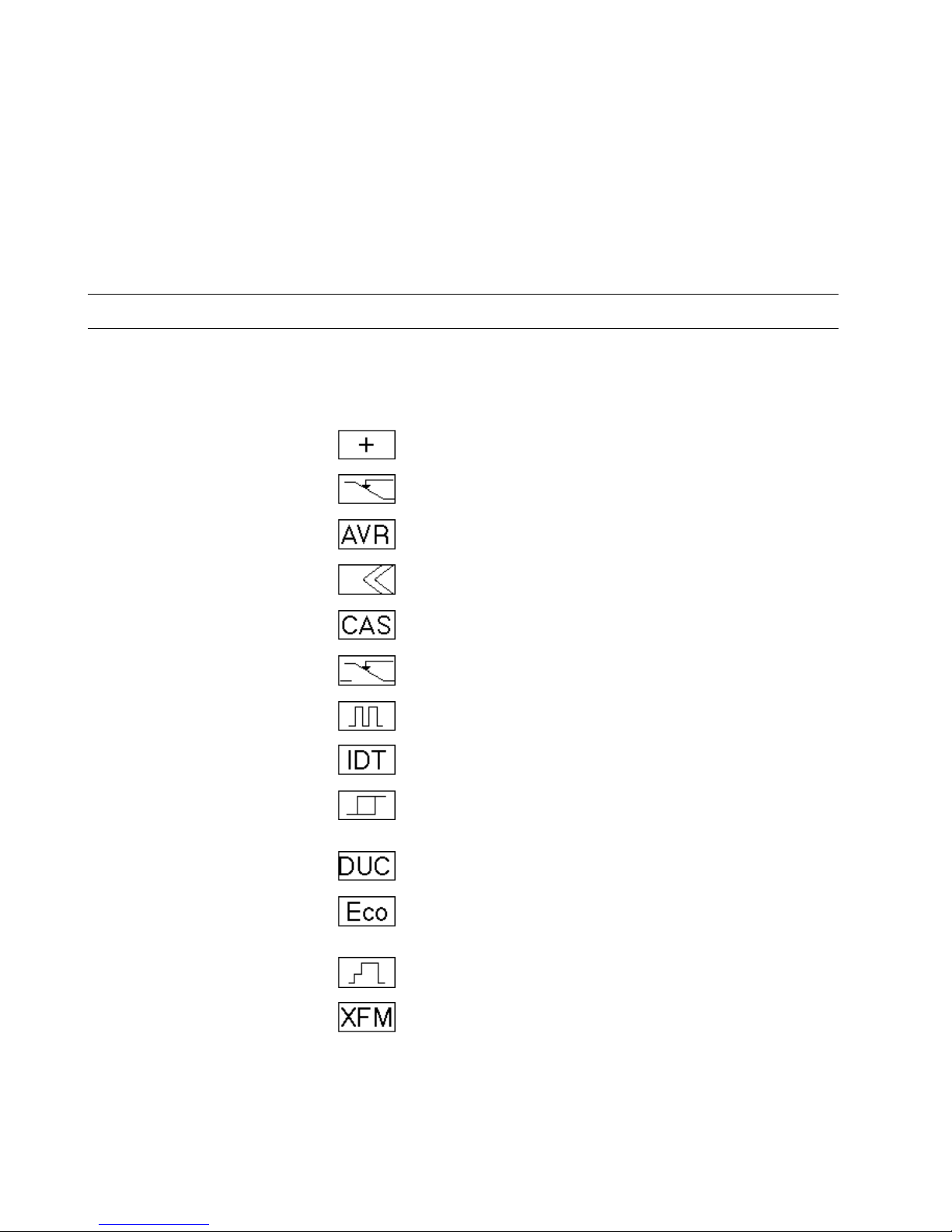

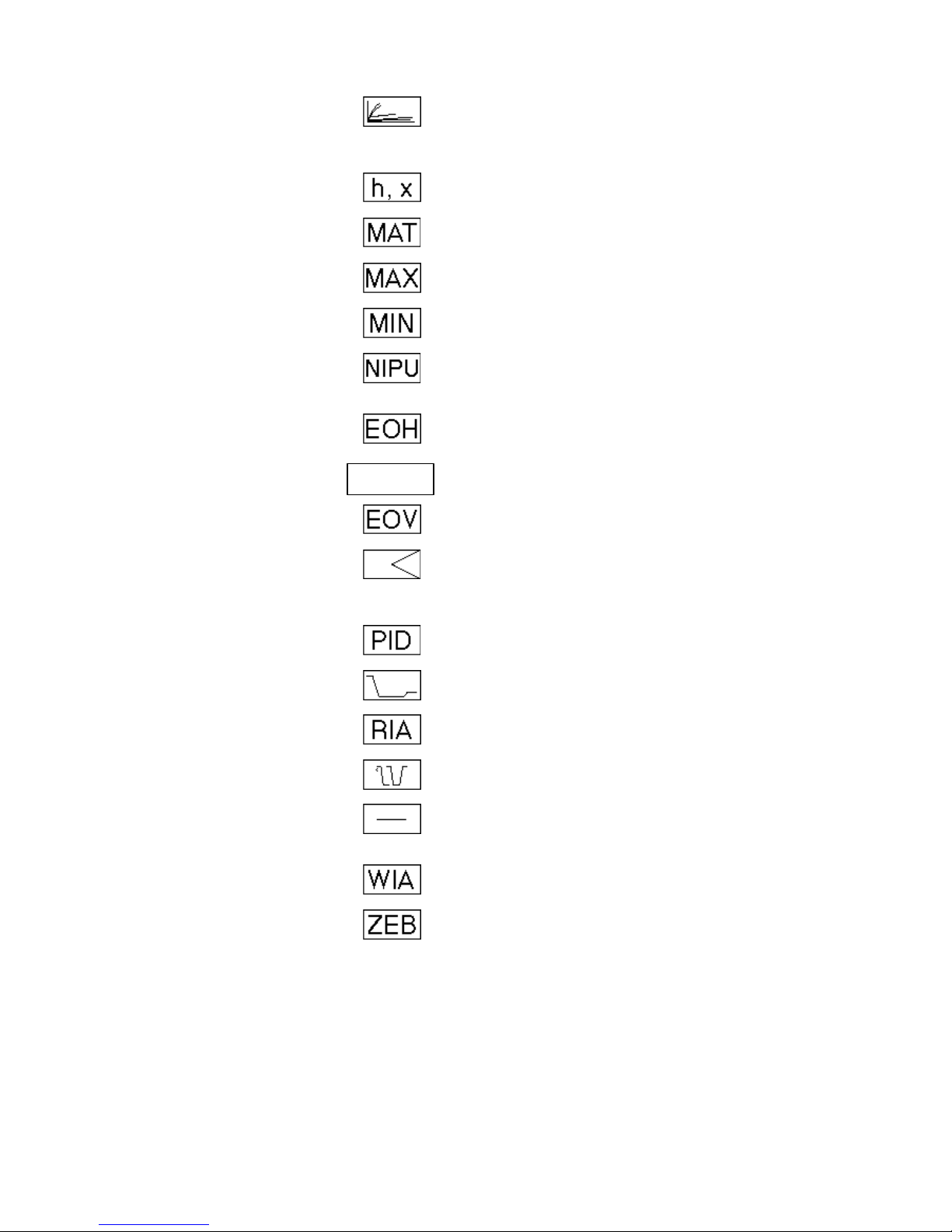

Control Icon Table

This chapter lists icons alphabetically by function name and includes function

names, symbols, and short descriptions. Function name is usually the same as the

icon name. There are exceptions such as 2PT which is functionally a Digital Switch.

Function Name

Control Icon

Icon Name

Description

Add

ADD

Sum multiple analog input values (2

through 6).

Analog Switch

SWI

Switch an analog value depending on a

digital value (for example, if digital is 0,

analog is 2; if digital is 1, analog is 1).

Average

AVR

Calculate the average of multiple analog

inputs (2 through 6).

Cascade

CAS

Cascade controller that acts as a PI

controller with a master and cascade

controller.

Cascade (with additional

digital input and

parameter registers)

CAS

Same as previously defined Cascade

controller with the addition of a digital input

and two parameter registers.

Changeover Switch

CHA

Depending on the value of a digital input,

transmit an analog input value by way of

one of two analog outputs.

Cycle

CYC

Establish cyclical operation.

Data Transfer

IDT

Transfer a value from one control icon to

other icons or points.

Digital Switch

2PT

On/off controller that transmits a digital

status depending on two analog values

(one is a controlled variable; the other, a

reference variable).

Duty Cycle

DUC

Switch HVAC systems on and off at

variable intervals to save energy while

maintaining room conditions.

Economizer

ECO

Determine the most economical system

operation for full and partial air

conditioning systems.

Event Counter

EVC

Event counter.

Fixed Applications

XFM

Fixed applications that can combine with

other submodules or points.

EXCEL CARE CONTROL ICONS INTRODUCTION

13 74-5577–33 (US)

EN2B-0184 GE51 R0518 (Europe)

Function Name

Control Icon

Icon Name

Description

Heating Curve with

Adaptation

HCA

Use a heating curve to calculate discharge

air temperature setpoint from the room

temperature setpoint and outdoor air

temperature.

Humidity and Enthalpy

H,X

Calculate enthalpy and absolute humidity.

Mathematical Editor

MAT

Mathematical editor to modify inputs to

other control icons.

Maximum

MAX

Select the highest value among analog

inputs (2 through 6).

Minimum

MIN

Select the lowest value among analog

inputs (2 through 6).

Night Purge

NIPU

Use cold outdoor air during non-working

(nighttime) hours to precondition room

space and save energy costs.

Optimum Start/Stop

EOH

Calculate optimized values for starting and

stopping heating system.

Optimum Start/Stop

EOH3

EOH3

Calculate optimized values for starting and

stopping the heating plant and for the

supply water setpoint.

Optimum Start/Stop

Energy Optimized

Ventilation

EOV

Calculate optimized values for starting and

stopping air conditioning plant s.

PID

PID

Proportional-Integral-Derivative controller

that regulates an analog output based on

two analog values (one is a controlled

variable; the other, a reference variable.)

PID (with integration time

parameter)

PID

Same as previously defined PID with the

addition of an integration time parameter.

Ratio

RAMP

Limit the variation in room temperature

over time (“ramp” function).

Read

RIA

Read an attribute of a user address.

Sequence

SEQ

Sequence from one to three analog

outputs dependent on an analog input.

Subtract

DIF

Determine the difference between multiple

analog input values

(2 to 6; X1 - (X2 + X3 + .. . X6)).

Write

WIA

Write to an attribute of a user address.

Zero Energy Band

ZEB

Determine setpoints to maintain a

predetermined comfort band divided into

heating, cooling, and zero energy bands.

EOH3

INTRODUCTION EXCEL CARE CONTROL ICONS

74-5577–33 (US) 14

EN2B-0184 GE51 R0518 (Europe)

Control Icon Table (Excel Web / Excel Web II)

This chapter lists icons alphabetically by function name and includes function

names, the previous function name, in which folder it can be found, and short

descriptions. Function name is usually the same as the icon name.

Function Name

Previous Function name

Folder

Description

Absolute

Arithmetic

Returns the absolute value.

Addition

Add

Arithmetic

Sum up the input values.

ADH2

ADH2

Legacy XL500

Legacy RACL function: Adapts the slope S of

the heating curve for the determination of the

flow temperature setpoint to the building

characteristics.

AND

Logic

AND output becomes TRUE(1) if all inputs

are TRUE(1). NAND output is the inverted

AND output.

Arcus Cosinus

Arithmetic

Calculates the arcus cosinus function of X.

Arcus Sinus

Arithmetic

Calculates the arcus sinus function of X.

Arcus Tangems

Arithmetic

Calculates the arcus tangens function of X.

Average

AVR

Arithmetic

Calculates the average of input values.

CAS Plus

Cascade controller

Controller

Cascade controller that acts as a PI

controller with a master and cascade

controller.

Compare2

(Excel Web II with OS

3.01.00 or higher only)

Comparison

Compares two analog inputs (A and B).

Comparison

Comparison

Compares input A and B.

Cosinus

Arithmetic

Calculate the cosinus function of X in rad.

Counter

Misc

Increments the output Y by 1 when input "X"

changes from 0 to 1. The counter is set to 0,

when "Reset" input becomes TRUE (1).

Cycle

Cyclic timer

Timer

Outputs an alternating value.

Decimal Places

Arithmetic

Returns the decimal places value of the input

(3.175 => 0.175).

Delay

Misc

Switch-on delay of input A to Y. if input "A" is

unequal to "B" within delay time, then Alarm

output = TRUE (1).

Dewpoint

Misc

Calculates the dewpoint temperature from

the absol ute humidity.

EXCEL CARE CONTROL ICONS INTRODUCTION

15 74-5577–33 (US)

EN2B-0184 GE51 R0518 (Europe)

Function Name

Previous Function name

Folder

Description

Differential

Controller

Calculates the derivative output signal, which

changes in proportion to changes of the input

signal. Y = 0 if the input is unchanged since

the last cycle. Y > 0 if the deviation is

increasing. Y < 0 if the deviation is

decreasing.

Division

Arithmetic

Divides input A by input B.

Duty Cycle

Duty cycling

Energy management

Switches HVAC systems alternating on and

off to save energy.

ECO

Economy

Legacy XL500

Legacy RACL function: Decide on the most

economical system operation for full and

partial air conditioning systems.

Economy

Energy management

Decide on the most economical system

operation for full and partial air conditioni ng

systems.

Enthalpy

Enthalpy

Misc

Calculate enthalpy (Ent) and absolute

humidity (HAbs) as a function of air

temperature, relative air humidity, and air

pressure. Use Enthalpy with the Economy

function.

EOH

Optimized heating

Energy management

Calculate optimized values for starting and

stopping the heating plant and for the supply

water setpoint.

EOH3

Optimized Start/Stop

Energy management

Calculate optimized values for starting and

stopping the heating plant and for the supply

water setpoint.

EOV

Optimized ventilation

Energy management

Calculate optimized values for starting and

stopping air conditioning systems. Syst em s

should start at the latest possible time and

should stop as soon as possible to save

energy.

EQL

EQL

Legacy XL500

Legacy RACL function: Compares "Comp"

input with all other inputs. If at least one input

is equal to the "Comp" input, the output is set

to TRUE (1).

Exponential

Arithmetic

Calculates the exponential.

Factorial

Arithmetic

Calculates the factorial (5! = 1*2*3*4*5).

HC

HC

Legacy XL500

Legacy RACL function: Calculates an output

according to a user-defi ned he ating

compensation curve.

HCA

Heating curve

Energy management

Calculates an output according to a user-

defined and adaptable heating compensation

curve.

Hysteresis

Digital Switch (2PT)

Controller

On/off controller that generates a digital

output depending on the deviation of the

controlled variable from the reference

variable. Y1 = 1 if X >= W, Y1 = 0 if X < W –

Hysteresis. Y2 = 1 if X <= W, Y2 = 0 if X > W

+ Hysteresis.

INTRODUCTION EXCEL CARE CONTROL ICONS

74-5577–33 (US) 16

EN2B-0184 GE51 R0518 (Europe)

Function Name

Previous Function name

Folder

Description

IDT

IDT

Misc

Copies the input to all outputs.

Integral

Controller

Calculate the integral (sum) of the input

signal.

J-K flip-flop

(Excel Web II with OS

3.01.00 or higher only)

Misc

Toggles an output depending to the set, clear

command and clock conditions

Last Value

Misc

Provides the current value and the value of

the last control cycle.

Limit

Comparison

Limits input X to a range between minimum

and maximum.

LIN

LINEAR

Legacy XL500

Legacy RACL function: Calculates the linear

product of the inputs.

Linear converter

(Excel Web II with OS

3.01.00 or higher only)

Misc

Converts an input value within definable

limits to an output value

Ln

Arithmetic

Calculates the natural logarithm.

Logic Counter

Logic

Compares binary values. Returns in output

N(1) the number of TRUE(1) values and in

output N(0) the number of FALSE(0) values.

Maximum

Max

Comparison

Returns the highest value of all inputs.

Merge

Misc

Merges multiple inputs to a combined output.

Result for 4 inputs: Y = X1 + X2*P1 +

X3*P1*P2 + X4*P1*P2*P3

Minimum

Min

Comparison

Returns the lowest value of all inputs.

Modulo

Arithmetic

Calculates the remainder of the division A by

B.

Monoflop

Timer

Sets the output to TRUE (1) for the time

defined in the parameter "signal time".

Multiplication

Arithmetic

Multiplies the input values.

Multi-Switch In

Misc

Conditional Switch. Switches the value of a

specified input to the output, depending on

the "Sel X" input.

Multi-Switch Out

Misc

X input is copied to the output selected by

the "Sel Y" input. The parameter defines if

the other outputs are left unchanged or set to

0.

Negate

Arithmetic

Negates the analog input value

mathematically.

Next Schedule

(Excel Web II with OS

3.02.00 or higher only)

Misc

Reads the next scheduled value and the time

until the value changes from the schedule

Night Purge

Energy management

Starts and stops ventilation systems to

precondition rooms when cold outside air is

available during nighttime.

NOT

Logic

Negates the binary input value.

EXCEL CARE CONTROL ICONS INTRODUCTION

17 74-5577–33 (US)

EN2B-0184 GE51 R0518 (Europe)

Function Name

Previous Function name

Folder

Description

Odd Parity

Logic

Compares binary values and returns TRUE

(1), if the number of TRUE (1) elements are

odd.

On-Board DI

Misc

Read on-board digital input.

On-Board DO

Misc

Write on-board digital output.

On/Off Delay

Timer

Switch On- and Off delay of input A to output

Y.

OR

Logic

OR output becomes TRUE(1) if at least one

input is TRUE(1). NOR output is the inverted

OR output.

PID

PID controller

Legacy XL500

Legacy RACL function: PID-Controller that

generates a signal depending on the

deviation of the controlled variable from the

reference variable.

PID Plus

PID controller

Controller

PID-Controller that generates a signal

depending on the deviation of the controlled

variable from the reference variable.

POL

POLYNOMIAL

Legacy XL500

Legacy RACL function: Calculates the

polynomial.

Ramp

Misc

Calculates the output value in relation to the

input, depending on a pre-defined graph.

Random

Misc

Returns a random value in a range between

lower and upper limit.

Read Global

Req.

(Excel Web II with OS

3.00.00 or higher only)

Misc

Reads values from global registers

Read Priority

(Excel Web II with OS

3.01.00 or higher only)

Misc

Returns the value of the highest valid priority

in the priority array

Read Priority

Value

(Excel Web II with OS

3.02.00 or higher only)

Misc

Reads the selected priority of the datapoint

Reset Timer

Timer

Resets the timer of a "Timer value" function.

Round

Arithmetic

Rounds the input value to the next integer

value.

Round down

Arithmetic

Rounds the input value down to the next

integer value (3.1 => 3, -3.1 => -4).

Round up

Arithmetic

Rounds the input value up to the next integer

value (3.1 => 4, -3.1 => -3).

RS flip-flop

Misc

Sets the output to TRUE(1) if the "SET" input

is TRUE(1) until the "RESET" input becomes

TRUE(1).

SET

SET

Legacy XL500

Legacy RACL function: Set the output

depending on the compar ison of the inputs .

Y=FALSE(0) if A < B Y=TRUE(1) if A > B Y is

not changed if A = B.

Sequence

Misc

Calculates three output values in relation to

the input, depending on pre-defined graphs.

INTRODUCTION EXCEL CARE CONTROL ICONS

74-5577–33 (US) 18

EN2B-0184 GE51 R0518 (Europe)

Function Name

Previous Function name

Folder

Description

Sinus

Arithmetic

Calculate the sinus function of X in rad.

Split

Misc

Splits the input into multiple outputs. Result

for a split into 3 outputs: Y3 = (((X-Y1) / P1) Y2) / P2) modulo P3.

Square root

Arithmetic

Calculates the square root.

Subtraction

Minus

Arithmetic

Subtracts the sum of S inputs from the input

value M.

Switching Table

Logic

Switching logic module

Time Counter

Timer

Counts the runtime of the input signal.

Timer Value

RTIM

Timer

Legacy RACL function "RTIM": Counts the

time in seconds. Can be reset by the "Reset

Timer" function.

Truncate

Arithmetic

Truncates the decimal places (3.1 => 3, -3.1

=> -3).

Tuncos

Misc

Provides time until next change of state

information from schedule for the connected

input.

Value Ramp

Misc

Defines the slope by which the output will

follow the input.

Value Ramp2

(Excel Web II with OS

3.00.00 or higher only)

Misc

Defines the slope by which the output will

follow the input.

WIDO

Legacy XL500

Legacy RACL function: Checks if the input

value is within the range between minimum

and maximum.

Write Global

Reg.

(Excel Web II with OS

3.00.00 or higher only)

Misc

Writes a value to a global register.

Write Priority

(Excel Web II with OS

3.00.00 or higher only)

Misc

Write the value of an input with a defined

priority to an output which must be connected

with the present value of a datapoint.

X root Y

Arithmetic

Calculates X to the root of Y.

X^2

Arithmetic

Calculates X * X.

X^Y

Arithmetic

Calculates X to the power of Y.

XOR Table

Logic

XOR output becomes TRUE (1) if exactly

one input is TRUE(1). XNOR output is the

inverted XOR output.

ZEB

Zero Energy Band

Energy management

Divides a specified range into Heating range,

Zero energy band and Cooling range.

EXCEL CARE CONTROL ICONS INTRODUCTION

19 74-5577–33 (US)

EN2B-0184 GE51 R0518 (Europe)

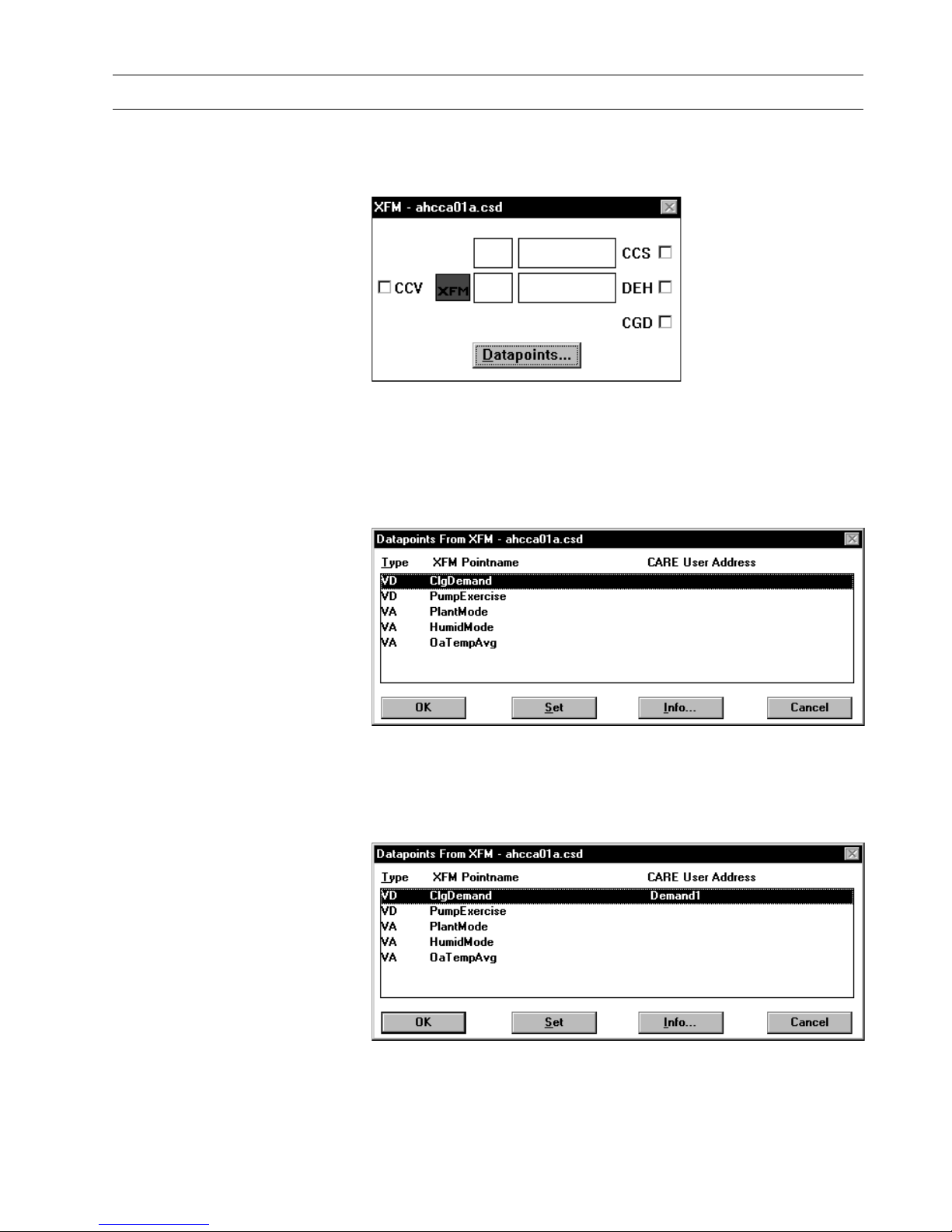

Datapoints

Datapoints Datapoints are a technique of transferring information between XFMs when there

are not enough of the regular inputs and outputs. Datapoints are pseudopoints that

can be written to or read by other XFMs. Create datapoint points by clicking on the

Datapoint button after the XFM has been displayed.

The following figure shows how two XFMs could be wired by a datapoint.

A pseudo digital point Demand1 connects to both XFM 1 and XFM 2 by the use of

datapoints.

After clicking on the datapoint button the following screen appears:

There are two methods of creating the datapoints. One method is by clicking the Set

command to automatically create the pseudopoints with the user address as shown

in the dialog box. The other method is to click an existing point (pseudo or physical)

and then click the point in the dialog box, such as ClgDemand. This selection

locates the subject user address (Demand1) next to the desired datapoint. To

connect the datapoint to that user address click OK.

INTRODUCTION EXCEL CARE CONTROL ICONS

74-5577–33 (US) 20

EN2B-0184 GE51 R0518 (Europe)

For detailed information see XFMs section in the CONTROL STRATEGY chapter of

the CARE USER GUIDE.

EXCEL CARE CONROL ICONS

21 74-5577–28 (US)

EN2B-0184 GE51 R1114 (Europe)

ALPHABETIC REFERENCE

Chapter Contents This chapter describes each control icon as follows:

Function Statement of control icon purpose.

Formula Formula related to icon, if any.

I/O Dialog Box Reproduction of the I/O dialog box that displays in the control

strategy work space for selection of control icon inputs and

outputs.

Inputs Description of required inputs.

Outputs Description of required outputs.

Internal

Parameters Description of the icon’s internal parameters dialog box that

xdisplays for entry of the parameters in the Control strategy work

space. Not all control icons have an internal parameters dialog

box.

Parameter

Number

Descriptions Parameter number assignments. Parameters are identified with

a P and a number, for example, P3, P4. The parameter list file

generated during CARE translation documents control icon

parameters and references them via these numbers. See

Appendix A: Parameter List Description for more information

about the list file.

Note that parameters 1 and 2 are reserved for system use.

Therefore, all parameters described for the control icons start at

number 3.

Operation Some icons have an operation section that details special steps

or provides a functional description of the icon.

Example(s) Sample application(s) of icon.

See Also ⇒ Control Icon Operation in the Introduction chapter for a general description of the I/O

dialog box and the internal parameters dialog box

Examples chapter for descriptions of applications that use multiple icons

ALPHABETIC REFERENCE EXCEL CARE CONTROL ICONS

74-5577–33 (US) 22

EN2B-0184 GE51 R0518 (Europe)

Absolute (Excel Web / Excel Web II)

Function Returns the absolute value and the algebraic sign of an analog value.

I/O Dialog Box

Input One analog input.

Output One analog output (Abs = Absolute value of input)

One digital output (Sign = sign (TRUE(1) if input is negative).

Internal Parameters None.

Addition / ADD

Function Sum multiple analog input values.

I/O Dialog Box

Excel Web / Excel Web II

Inputs Two through six analog inputs (X1 through X6).

You can enter the first input as a parameter (engineering unit index number and

value).

Two through thirty two analog inputs (1 through 32, Excel Web / Excel Web II).

Output One analog output (Y).

EXCEL CARE CONTROL ICONS ALPHABETIC REFERENCE

23 74-5577–33 (US)

EN2B-0184 GE51 R0518 (Europe)

Internal Parameters None.

Example See the Examples chapter for a description of how to use the ADD icon in a floating

limits and alarm suppression applicat ion.

Also see the Data Transfer (IDT) section for examples that show how to use ADD

with IDT.

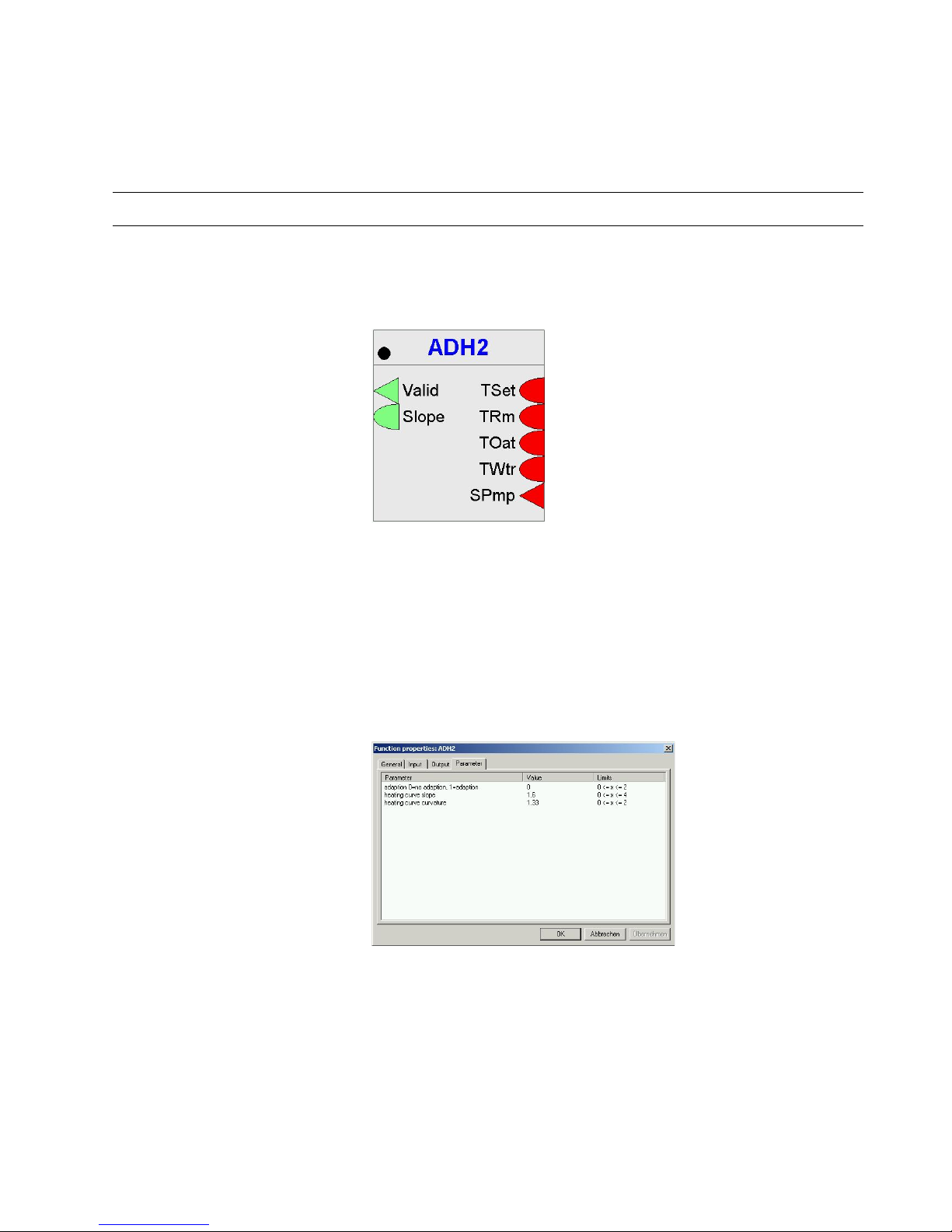

ADH2 (Excel Web / Excel Web II)

Function Legacy RACL function: Calculates the slope S of the heating curve for the

determination of the flow temperature setpoint option to adapt the slope to the

building characteristics.

I/O Dialog Box

Inputs Five inputs where:

TSet = room temperature setpoint

TRm = room temperature

TOat = outside air temperature (req. with adaptation)

TWtr = supply water temperature (req. with adaptation)

SPmp = heating pump status (req. with adaptation)

Outputs Two outputs where:

Valid = slope value validity (0=invalid, 1=valid)

Valid means the slope value is in a possible relation to the inputs, e.g. values below

the freezing point may be impossible.

Slope = calculated slope value

Internal Parameters

Parameter Description P1 Adaptation (0 = no adaptation, 1 = adaptation) with default = 0 and a limit

of 0 < = x < = 1.

P2 Heating curve slope with default = 1, 6 and a limit of 0 < = x < = 4.

P3 Heating curve curvature with default = 1,33 and a limit of 0 < = x < = 2.

ALPHABETIC REFERENCE EXCEL CARE CONTROL ICONS

74-5577–33 (US) 24

EN2B-0184 GE51 R0518 (Europe)

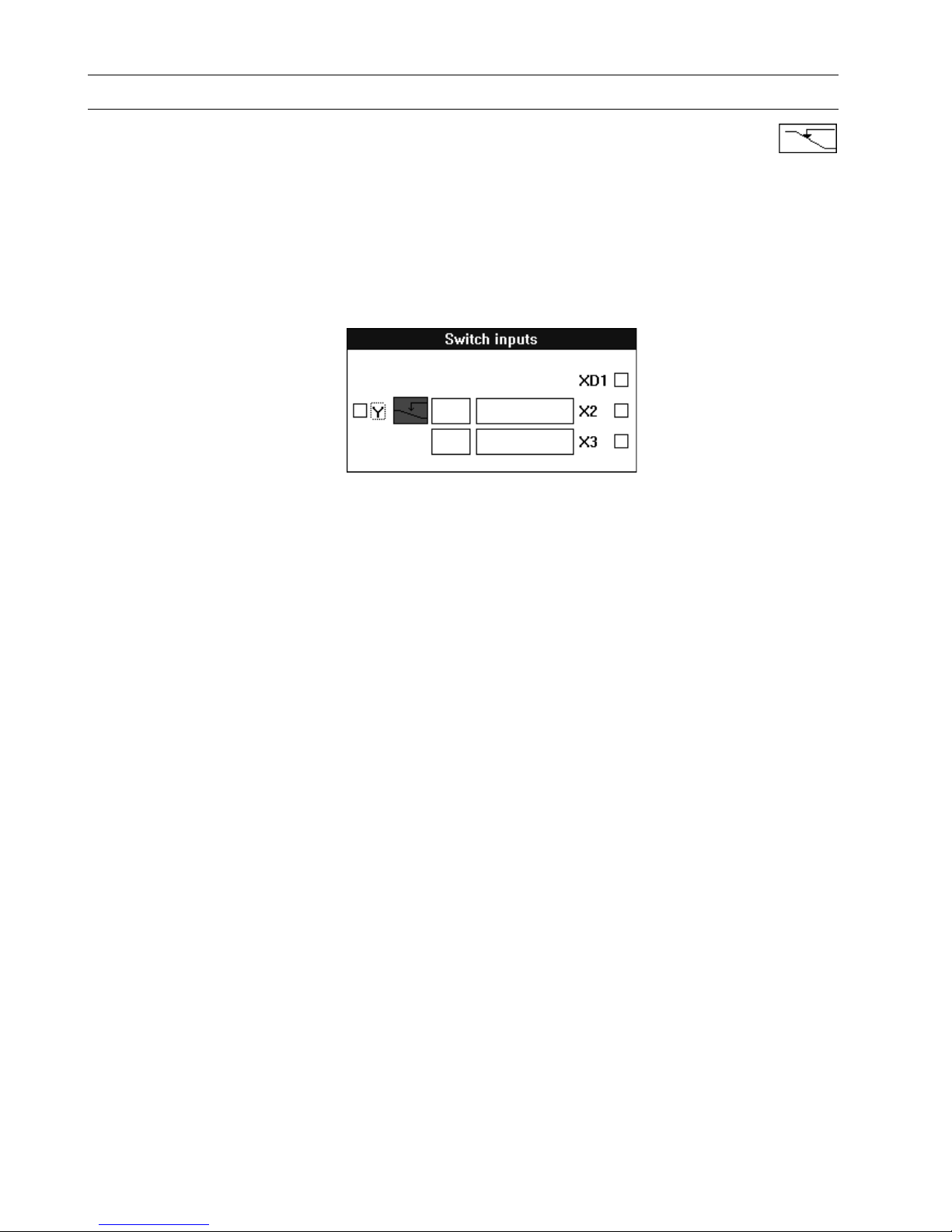

Analog Switch / SWI

Function Switch an analog value depending on a digital value.

For example:

If XD1 = 1, set output Y to X2.

If XD1 = 0, set output Y to X3.

Formula Y = X2, if XD1 = 1.

Y = X3, if XD1 = 0.

I/O Dialog Box

Inputs One digital input (XD1).

Two analog inputs (X2 and X3).

You can enter the two analog inputs as parameters (engineering unit index number

and value for each parameter).

Output One analog output (Y).

Internal Parameters None.

Parameter Number

Descriptions P3 X2 if X2 is not connected with a point.

P4 X3 if X3 is not connected with a point. If X2 is connected with a point, X3 is

numbered parameter 4.

Example See the Examples chapter in this manual for applications that use the SWI control

icon.

Also see the Digital Conversion note in the Mathematical Editor (MAT) section. You

can use SWI to convert a digital point to analog values for use in a mathematical

formula.

EXCEL CARE CONTROL ICONS ALPHABETIC REFERENCE

25 74-5577–33 (US)

EN2B-0184 GE51 R0518 (Europe)

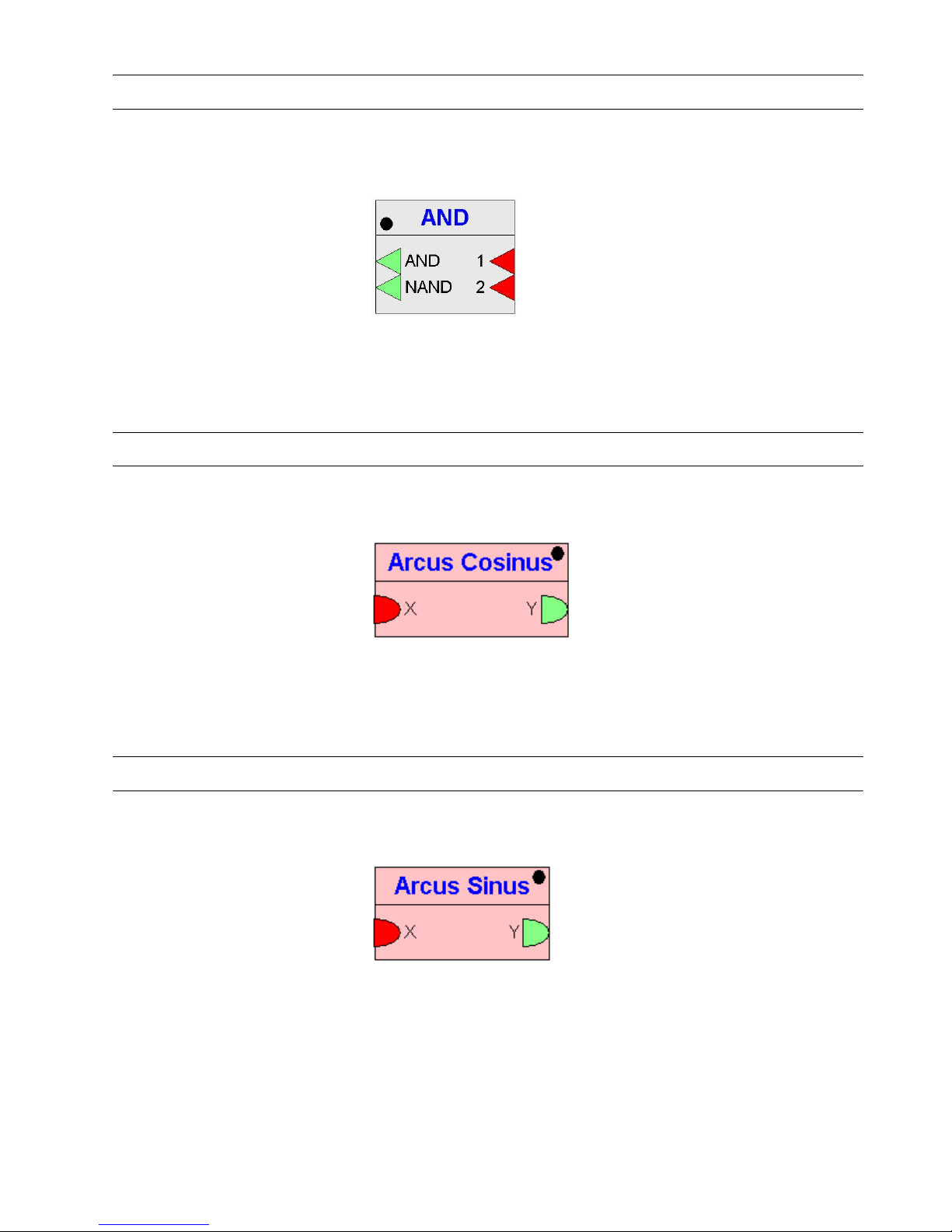

AND (Excel Web / Excel Web II)

Function AND output becomes TRUE(1) if all inputs are TRUE(1). NAND output is the

inverted AND output.

I/O Dialog Box

Inputs Two through thirty two digital inputs (1 through 32).

Output Two digital outputs.

Internal Parameters None.

Arcus Cosinus (Excel Web / Excel Web II)

Function Calculates the arcus cosinus function of X. Output value will be returned in radian.

I/O Dialog Box

Input One analog input. Range: –1 to 1. Values out of range will be adopted.

Output One analog output. Range: 0 to

π.

Internal Parameters None.

Arcus Sinus (Excel Web / Excel Web II)

Function Calculates the arcus sinus function of X. Output value will be returned in radian.

I/O Dialog Box

Input One analog input. Range: –1 to 1. Values out of range will be adopted.

Output One analog output. Range: –

π/2 to π/2.

Internal Parameters None.

ALPHABETIC REFERENCE EXCEL CARE CONTROL ICONS

74-5577–33 (US) 26

EN2B-0184 GE51 R0518 (Europe)

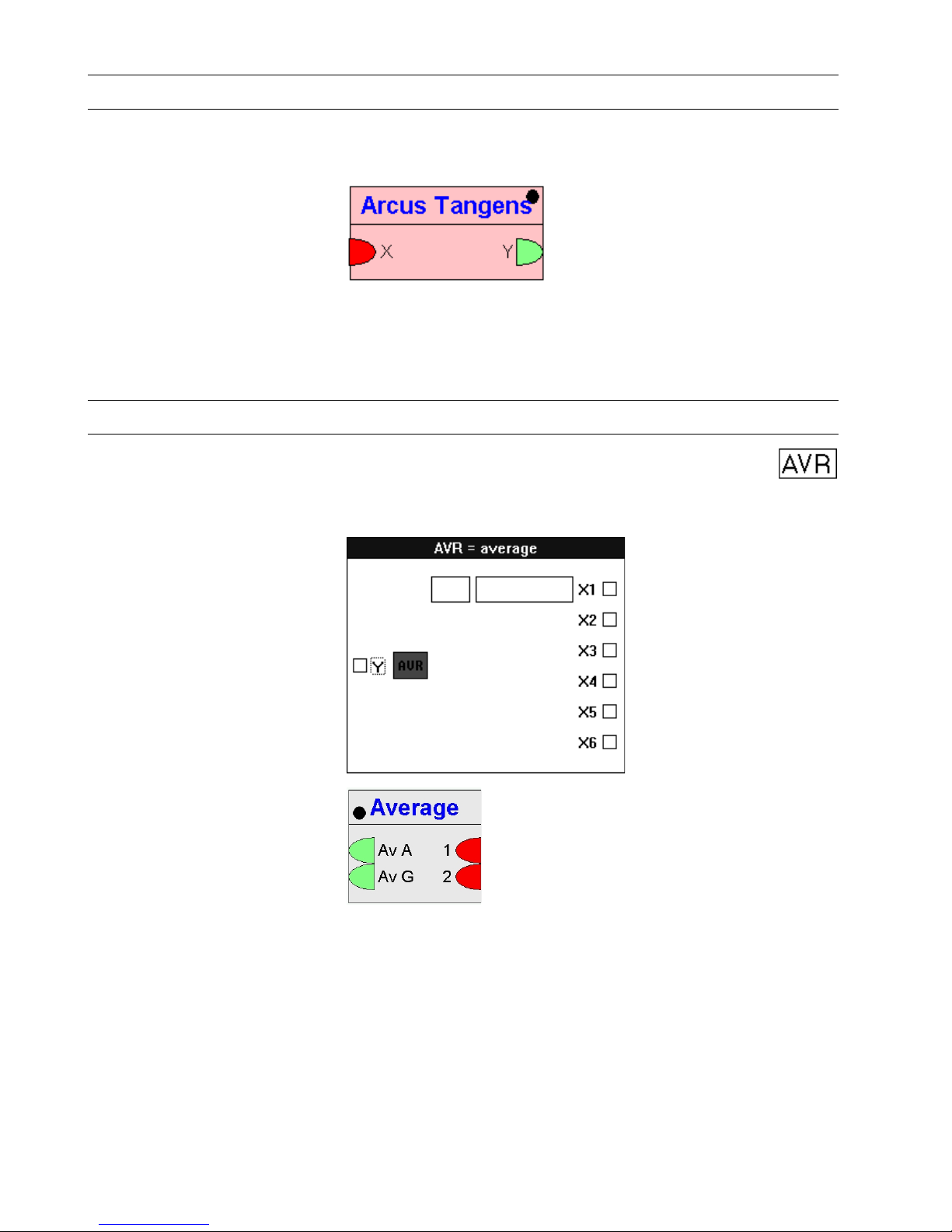

Arcus Tangens (Excel Web / Excel Web II)

Function Calculates the arcus tangens function of X. Output value will be returned in radian.

I/O Dialog Box

Input One analog input. Range: –

∞ to ∞.

Output One analog output. –

π/2 to π/2.

Internal Parameters None.

Average / AVR

Function Calculate the average of multiple analog input s.

I/O Dialog Box

Excel Web / Excel Web II

Inputs Two through six analog inputs (X1 through X6).

You can enter the first input as a parameter (engineering unit index number and

value).

Two through thirty two analog inputs (1 through 32, Excel Web / Excel Web II).

Output One analog output (Y).

Arithmetical (AvA) and geometrical (AvG) average as analog outputs (Excel Web /

Excel Web II).

Internal Parameters None.

EXCEL CARE CONTROL ICONS ALPHABETIC REFERENCE

27 74-5577–33 (US)

EN2B-0184 GE51 R0518 (Europe)

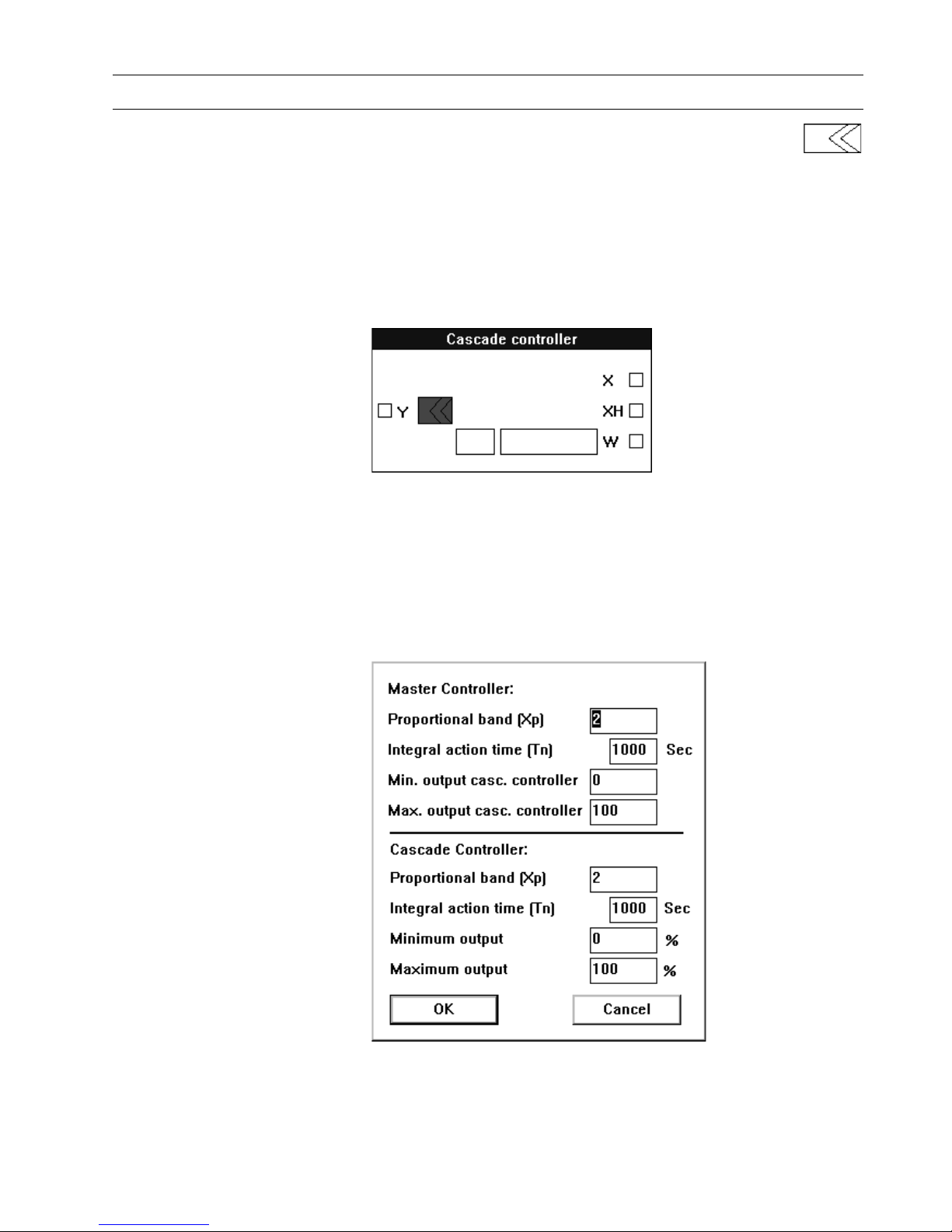

Cascade / CAS

Function Provide both a master Proportional-Integral (PI) controller and a secondary PI

controller to handle difficult control sections. The master PI manages the setpoint for

the secondary (cascade) PI. The secondary PI provides the setpoint reset schedule

which, because of the PI function, can be nonlinear.

CAS operates the same as a PI controller with the addition of a compensation input.

See the Cascade Operation note in this section for more details. Also see the PID

section for more details on PID operation.

I/O Dialog Box

Inputs Three analog inputs, where:

X = Master-controlled variable.

XH = Cascade- or auxiliary-controlled variable.

W = Reference variable, also known as setpoint.

You can enter the reference variable as a parameter (engineering unit index number

and value).

Output One analog output (Y).

Internal Parameters

ALPHABETIC REFERENCE EXCEL CARE CONTROL ICONS

74-5577–33 (US) 28

EN2B-0184 GE51 R0518 (Europe)

Master controller Proportional band Xp

Number type: decimal, Unit: same as the controlled variable (X)

Default: 2.0, Range: 0 through 100.0

Proportional band value is equivalent to the throttling range.

Integral action time Tn

Number ty pe: whole num ber, Unit: sec ond s

Default 1000 sec, Range: 0 through 7200 sec

If Integral action time is less than 15 seconds, integral control is disabled.

Minimum output

Number type: decimal, Unit: same as the cascade-controlled variable (XH)

Default: 0.0, Range: 0 through 100.0

Maximum output

Number type: decimal, Unit: same as the cascade-controlled variable (XH)

Default: 100.0, Range: 0 through 100.0

Cascade controller Proportional band Xp

Number type: decimal, Unit: same as the cascade-controlled variable (XH)

Default: 2.0, Range: 0 through 100.0

Proportional band value is equivalent to the throttling range.

Integral action time Tn

Number ty pe: whole num ber, Unit: sec ond s

Default: 1000 sec, Range: 0 through 7200 sec

If Integral action time is less than 15 seconds, integral control is disabled.

Minimum output

Number type: decimal, Unit: percent

Default: 0.0 percent, Range: 0 through 100.0 percent

Maximum output

Number ty pe: deci ma l, Unit: percent

Default: 100.0 percent, Range: 0 through 100.0 percent

Parameter Number

Descriptions P3 Xp (proportional band master controlle r)

P4 Tn (in seconds, integral action time of the master controller)

P5* Min (minimum limit of the cascade controller)

P6* Max (maximum limit of the cascade controller)

P7 Xp (proportional band of the cascade control ler)

P8 Tn (in seconds, integral action time of the cascade controller)

P9 Min (minimum limit of the positioning signal, in percent)

P10 Max (maximum limit of the positioning signal, in percent)

P11 W (reference variable if entered as a parameter, not con nect ed to a point)

Not for Excel Web / Excel Web II !

* Parameters P5 and P6 serve as the minimum and maximum limits,

respectively, of the set po int as sign men t to the casca de contr oller.

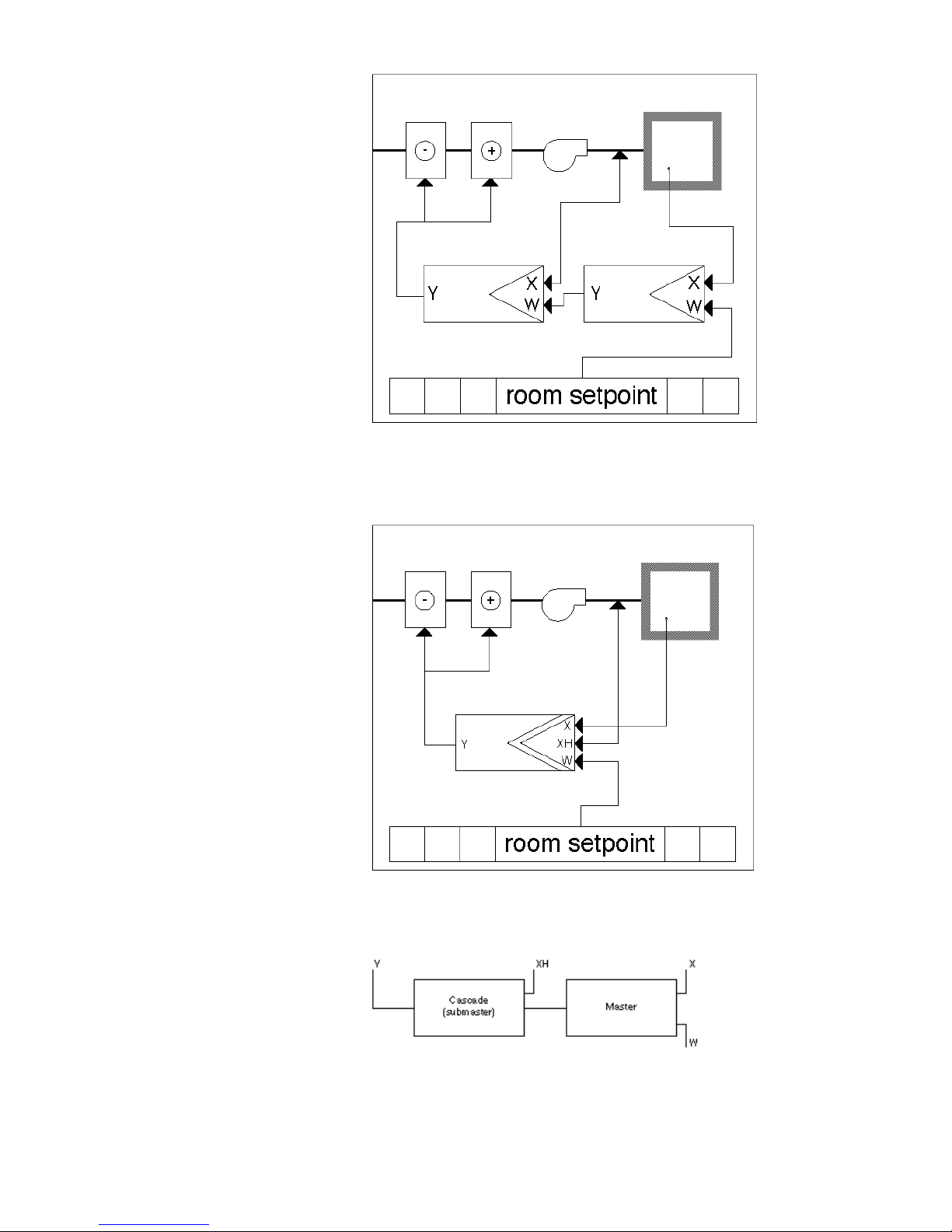

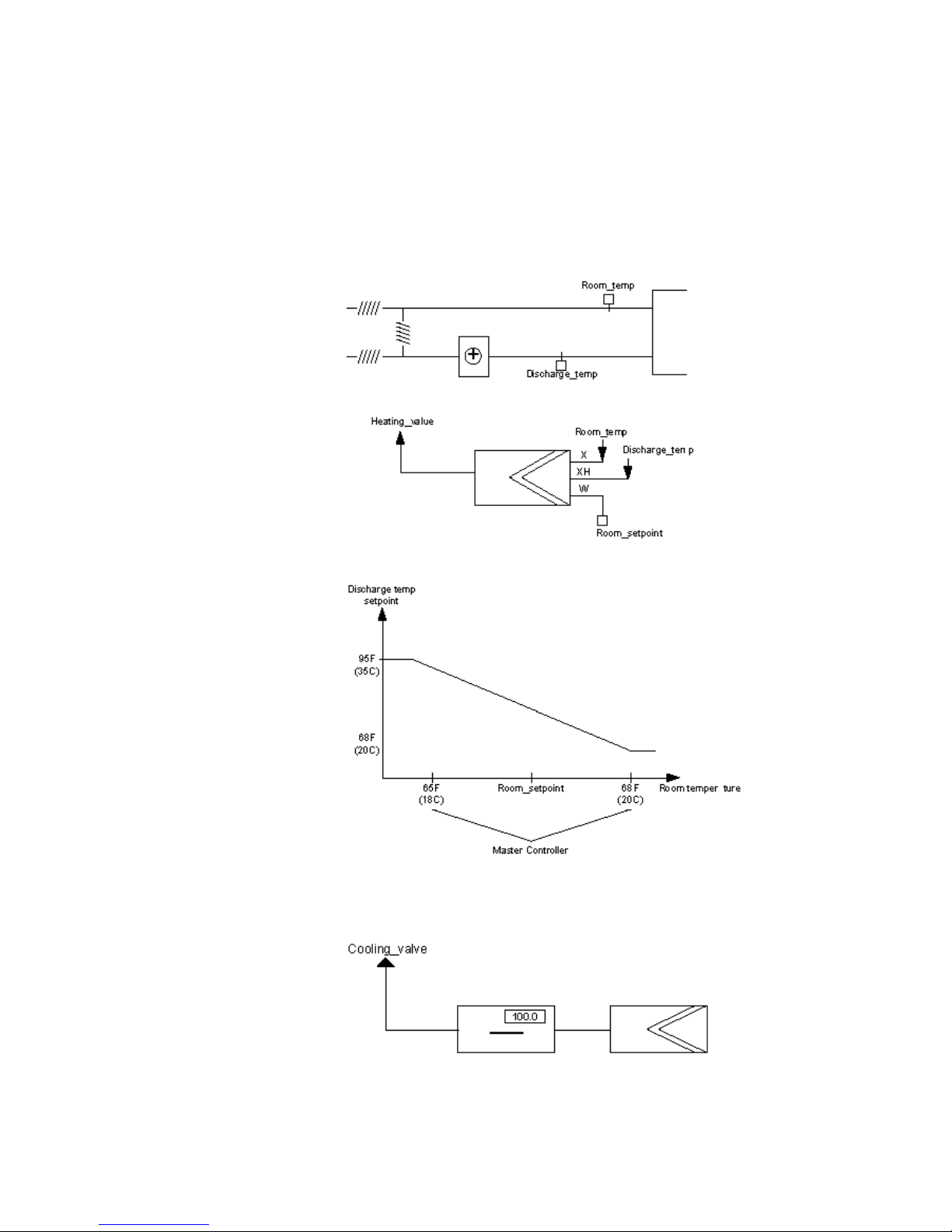

Cascade Operation As an example, the following diagram shows a master PID that is the room

temperature controller and a secondary PID that is the fresh air temperature

controller. The advantage of this arrangement is that the master controller and

secondary controller can each adapt to their own control sections.

EXCEL CARE CONTROL ICONS ALPHABETIC REFERENCE

29 74-5577–33 (US)

EN2B-0184 GE51 R0518 (Europe)

The next diagram illustrates the use of a Cascade controller to perform the same

functions. The CAS controller contains two PI controllers in a “cascade”

arrangement. The X variable reads the master-controlled variable (room

temperature). The XH variable reads the fresh air temperature (auxiliary-controlled

variable). The W variable is the room temperature setpoint (reference variable).

Setpoint Reset Example This example shows how to use cascade control to reset a discharge air controller

setpoint up to 95F (35C) if room temperature falls below its setpoint to 65F (18C).

The submaster controls the controller setpoint. The output of the master controller

resets the setpoint of the submaster up and down.

Parameters for the master controller are:

ALPHABETIC REFERENCE EXCEL CARE CONTROL ICONS

74-5577–33 (US) 30

EN2B-0184 GE51 R0518 (Europe)

Min output = 68F (20C)

Max output = 95F (35C)

W = 65F (18C)

X = ROOM_TEMP

Parameters for the cascade controller are:

Min output = 0 percent

Max output = 100 percent

XH = discharge temperature

Equipment diagram:

Cascade operation:

Direct vs Reverse Acting The output of the CAS operator is reverse acting. To use in a cooling application,

you need a direct-acting output. Use the DIF operator and set the first input to a

value of 100.0. This operation reverses the output.

EXCEL CARE CONTROL ICONS ALPHABETIC REFERENCE

31 74-5577–33 (US)

EN2B-0184 GE51 R0518 (Europe)

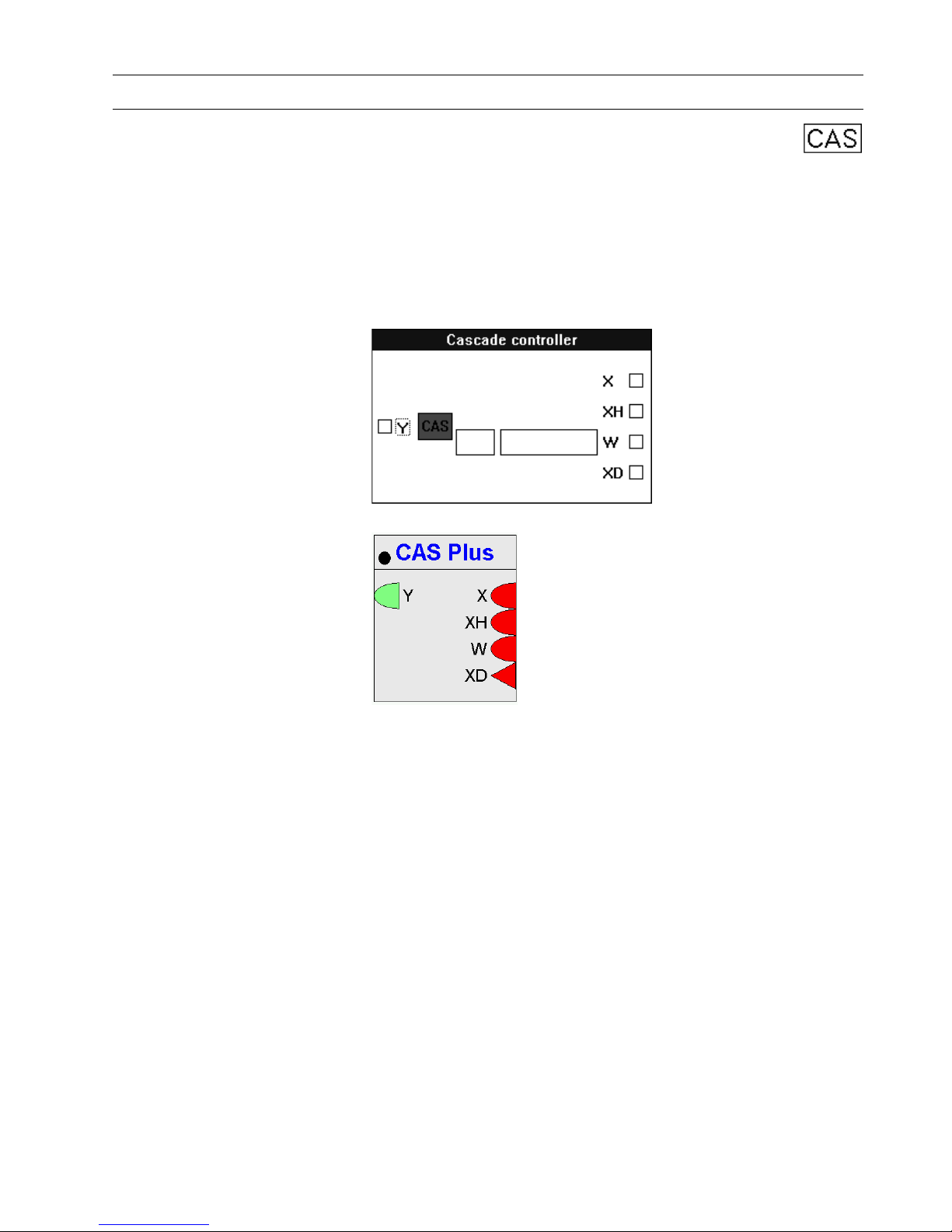

Cascade Plus / CAS

Function Cascade controller that acts as a PI controller with a master and cascade controller.

Cascade Differences This cascade cont roll er (CAS Plus) a ct s ju st like the previous cascade controller

except that it has an integral action enable/disable input. This new function requires

an additional digital input (XD) and two new parameter registers for temporary

storage.

This additional input enables CAS Plus to act as a P controller during plant start-up

and then switch on an Integral component after start-up is complete.

I/O Dialog Box

Excel Web / Excel Web II

Inputs Three analog inputs, where:

X = Master-controlled variable.

XH = Cascade- or auxiliary-controlled variable.

W = Reference variable, also known as setpoint

You can enter the reference variable as a parameter (engineering unit index number

and value). Not for Excel Web / Excel Web II !

One digital input (XD, Excel Web / Excel Web II Icon) that enables and disables

integral control action. When XD is zero, integral action in the master and cascade

controllers is disabled and the associated integral sum is reset. XD/Ion must always

be connected.

Outputs One analog output (Y).

ALPHABETIC REFERENCE EXCEL CARE CONTROL ICONS

74-5577–33 (US) 32

EN2B-0184 GE51 R0518 (Europe)

Internal Parameters

Master controller Proportional band Xp

Number type: decimal, Unit: same as controlled variable (X)

Default: 2.0, Range: 0 through 100.0

Proportional band value is equivalent to the throttling range.

Integral action time Tn

Number ty pe: whole num ber, Unit: sec ond s

Default 1000 sec, Range: 0 through 7200 sec

If Integral action time is less than 15 seconds, integral control is disabled.

Minimum output

Number type: decimal, Unit: same as the cascade-controlled variable (XH)

Default: 0.0, Range: 0 through 100.0

Maximum output

Number type: decimal, Unit: same as the cascade-controlled variable (XH)

Default: 100.0, Range: 0 through 100.0

Cascade controller Proportional band Xp

Number ty pe: decimal, Unit: same as cascade-controlled variable (XH)

Default: 2.0, Range: 0 through 100.0

Proportional band value is equivalent to the throttling range.

Integral action time Tn

Number ty pe: whole num ber, Unit: sec ond s

Default: 1000 sec, Range: 0 t h rough 720 0 sec

If Integral action time is less than 15 seconds, integral control is disabled.

Minimum output

Number type: decimal, Unit: percent

Default: 0.0 percent, Range: 0 through 100.0 percent

Maximum output

Number type: decimal, Unit: percent

Default: 100.0 percent, Range: 0 through 100.0 percent

Parameter Number

Descriptions If W is NOT entered as a parameter:

P3 Xp (proportional band master controlle r)

Loading...

Loading...