Page 1

INTEGRATED ROOM CONTROL SOLUTIONS: FCU + LIGHT

2-wire FTT-10A LONWORKS® bus interface

LonMark® certified

Easily-accessible service button and service LED

Application can be configured to user-specific needs

via LNS™-based plug-in

Applications can be downloaded via L

flash memory (thus increasing flexibility)

ONWORKS into

Excel 12

PRODUCT DATA

FEATURES

Two-in-one controller for HVAC and lighting reduces

hardware costs and engineering effort (one

ONWORKS® node instead of two)

L

HVAC application supports three sequences (heat,

cool or change-over) and min. / max. control limits and

air-quality control

Light application supports three lamps. Up to two of

the three light loops can be constant light control

loops. Light switching can be done depending on light

level and occupancy (configurable via plug-in)

Unused inputs can be utilized for monitoring via the

ONWORKS network

L

Unused digital outputs (relay or triacs) can be

switched via L

Different kinds of HVAC actuators are supported

(PWM, thermal, staged, floating, or analog actuators)

Inputs / outputs can be freely assigned

DIN rail (wiring cabinet / fuse box) mounting and wall-

mounting supported

Different power supply variants available

Optional terminal protection covers for wall mounting

Optional swivel label holders for wiring information

ONWORKS

free

inputs

room

temp.

source

temp.

CO2

ppm

%

Excel 12

light #1 (corridor)

light #2 (corridor)

light #3 (window)

three-stage fan

sequence #1

sequence #2

sequence #3

MAX. / MIN. CONTROL LIMIT

VALV E

POSITION

T

END

AIR-QUALITY CONTROL LIMIT

DAMPER

POSITION

CO2

START

Fig. 1. Functional overview

T

START

CO2

range of

range of

END

operation

operation

SOURCE

TEMP.

CO2

PPM

free

outputs

thermal, floating,

0...10V, PWM, or

staged actuators

12

9 3

6

C

C

GENERAL

The Excel 12 FCU + Light application is LONMARK® certified,

and can thus be used in all open L

Excel 12 supports the following LONMARK® objects:

one Node Object (LONMARK® object #0)

one Space Comfort Controller Fan Coil Object (profile

#8501)

three Lamp Actuator Objects (profile #3040)

one Occupancy Sensor Object (profile #1060)

two Open Loop Actuator Objects (L

A variety of hardware models with different power supplies

are available. Page 7 provides a detailed overview of the

available models.

Select the model fitting your particular needs.

The application can be downloaded into the Excel 12's

FLASH memory.

Honeywell's LNS™ plug-in allows you to configure the

application to match your specific requirements (e.g.

configure the heating / cooling sequences, the light

functionality and usage of otherwise unused inputs for

monitoring according to your needs).

The Excel 12 controller is designed for maintained zones.

ONWORKS® environments.

ONMARK® object #3)

® U.S. Registered Trademark

Copyright © 2010 Honeywell Inc. • All Rights Reserved EN0B-0470GE51 R0110

Page 2

EXCEL 12: FCU + LIGHT

A

APPLICATION

The Excel 12 Fan Coil Unit (FCU) + Light application supports

three HVAC sequences (HEAT, COOL, or CHANGEOVER)

with control limits, air-quality control, free inputs, free outputs,

and up to three lights.

The application is delivered together with the plug-in and must

be downloaded into the Excel 12 controller's flash memory

during start-up. The user can customize the application using

Honeywell's LNS™ plug-in with CARE or any LNS™ tool (e.g.

LonMaker for Windows™). Customizations can be saved /

reloaded for easy configuration of multiple devices.

Application Overview

HVAC Application:

Three sequences configurable for HEAT, COOL, and

CHANGEOVER

Support of thermal actuators, floating actuators, PWM,

0...10 Vdc, and staged output via triac outputs or relay

outputs

3-stage fan via triac outputs or relay outputs

Binary inputs for condensation, occupancy sensor,

window contact, etc.

Up to two limits (any combination of temperature limits

and/or air-quality limits)

Min./max. limits can be used to limit the sequence output

according to you requirements. The limits are valid only in

the occupancy mode.

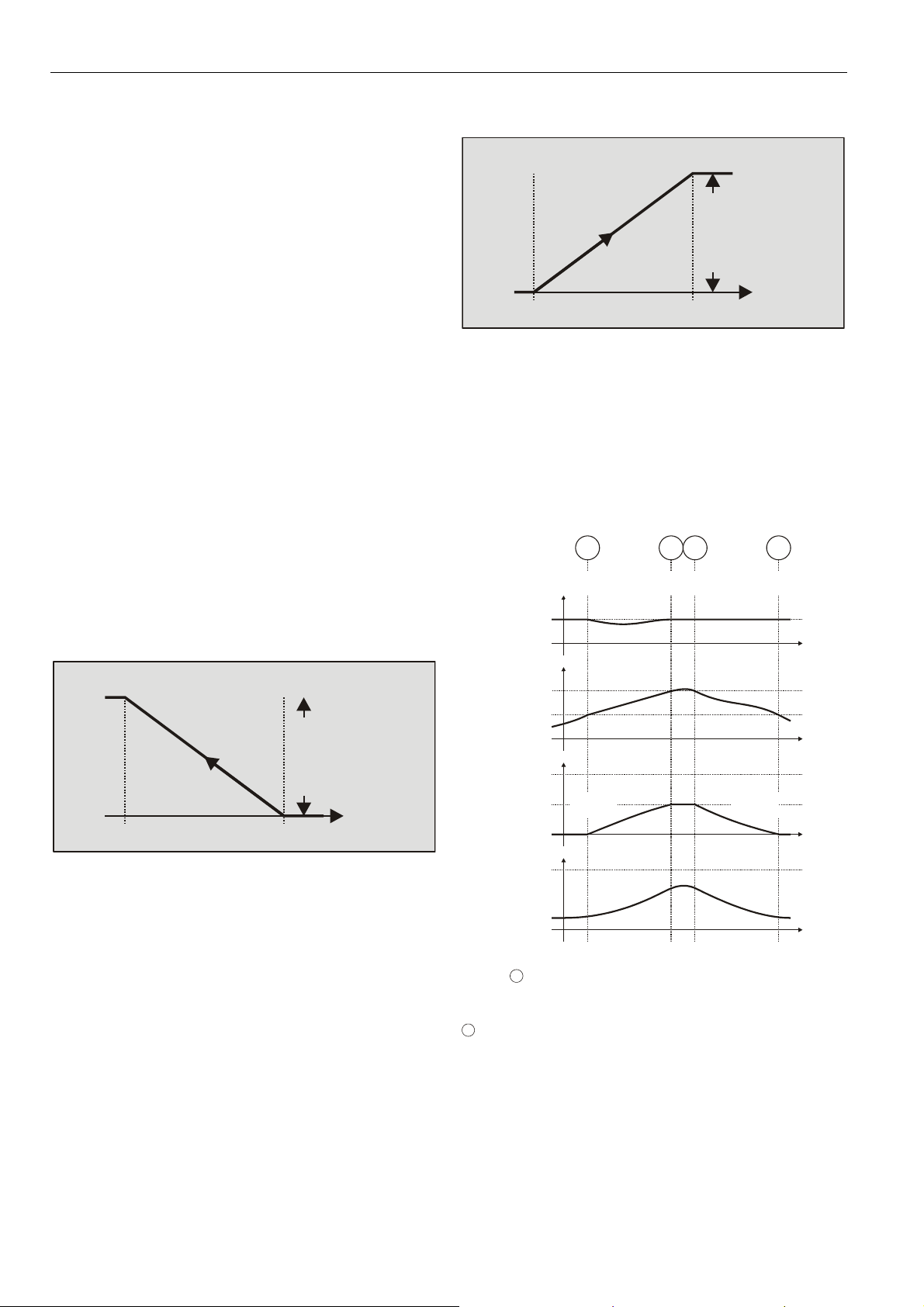

The example below shows that a heating valve will be

opened as soon as the source temperature drops below

T

. T

Start

Start, TEnd

configured using the plug-in.

MAX. / MIN. CONTROL LIMIT

VALVE

POSITION

T

END

NOTE: The min./max. limits have a higher priority than the

normal control output.

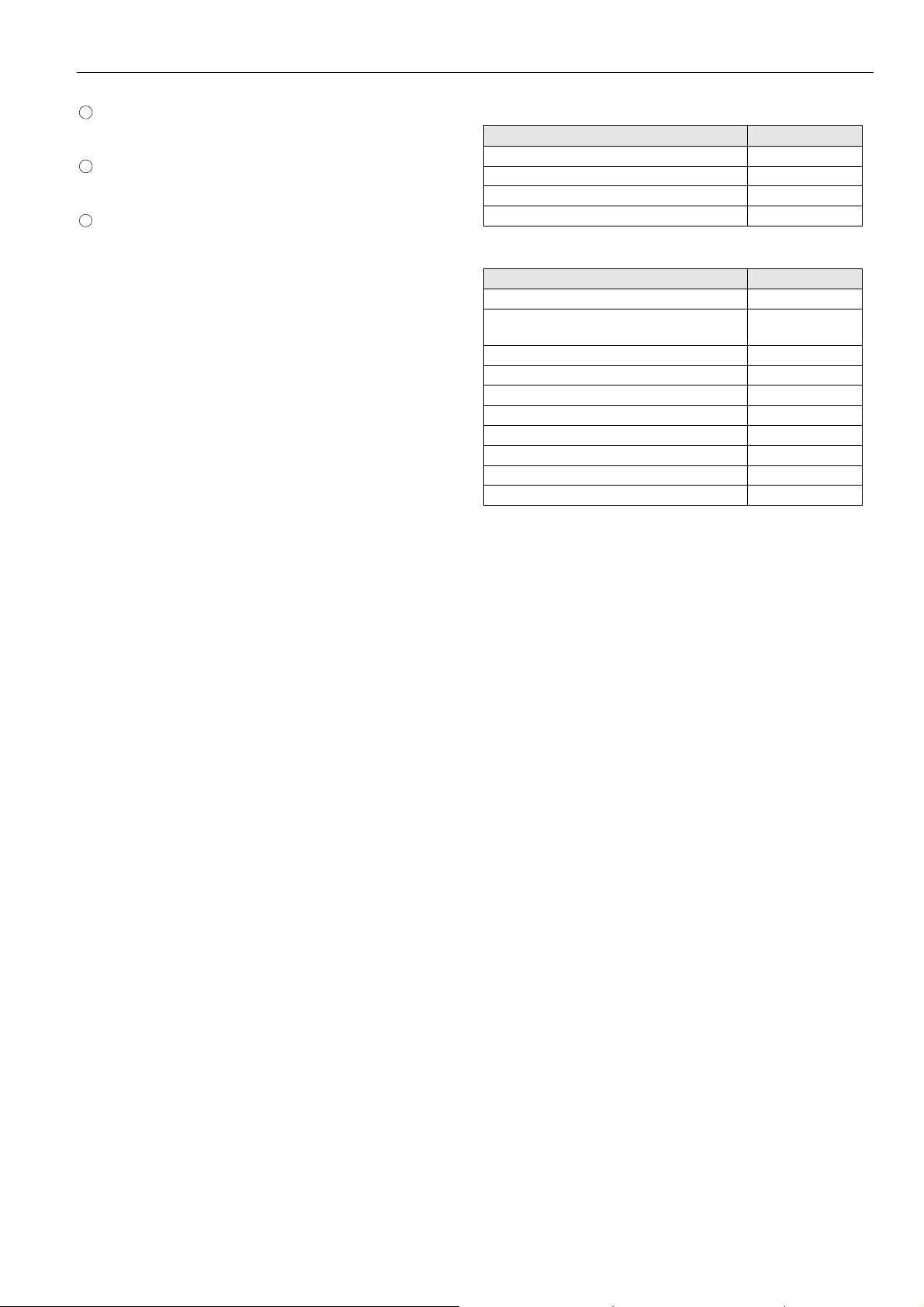

The air-quality can be controlled by opening a damper in

dependence on the CO2 level. The CO2 ramp is defined

by CO2

(entered using the plug-in).

Example:

CO2

CO2

range of operation = 50%

The damper starts opening as soon as the level of 1000 ppm

is reached. The maximum value (range of operation) is

reached at position CO2

START

START

= 2000 ppm

END

and the range of operation can be

range of

operation

SOURCE

T

START

Fig. 2. Minimum Heating Example

, CO2

, and the range of operation

END

= 1000 ppm

.

END

TEMP.

IR-QUALITY CONTROL LIMIT

range of

DAMPER

POSITION

CO2

START

CO2

Fig. 3. Air-quality control (example)

Example:

sequence 1: heating via radiator

sequence 2: cooling via damper

setpoint: 20 °C

CO2 control for sequence 2

CO2

CO2

= 1000 ppm

START

= 1500 ppm

END

range of operation = 50%

1 2

1000

ROOM TEMP.

SEQUENCE 2

SEQUENCE 1

20 °C

CO2 LEVEL

1500 ppm

1000 ppm

100%

50%

0%

100%

0%

ppm

<1000

(1000 ppm, 1500 ppm)

ppm

<1000

(1000 ppm, 1500 ppm)

ppm

DAMPER

OPENS

Fig. 4. Example

1

Before

:

CO2 level is OK → room temperature control, only

Temperature at 20 °C

1

CO2 level rises above CO2

CO2 level is too high, CO2 control starts with priority over

the temperature control

Damper opens, room temperature drops

Temperature drops to below 20 °C → heating sequence

starts heating

1500

ppm

>1500

>1500

START

ppm

ppm

operation

END

3

1500

ppm

(1000 ppm, 1500 ppm)

(1000 ppm, 1500 ppm)

DAMPER

CLOSES

:

4

1000

ppm

CO2

PPM

<1000

ppm

<1000

ppm

TIME

TIME

TIME

TIME

EN0B-0470GE51 R0110

2

Page 3

EXCEL 12: FCU + LIGHT

2

CO2 level rises above CO2

END

:

Damper reaches max. range of operation

Heating sequence achieves room temperature of 20 °C

3

CO2 level drops below CO2

END

:

Damper starts closing

Room temperature is maintained at setpoint value

4

CO2 level drops below CO2

CO2 level falls below CO2

T:

STAR

→ room temperature

START

control, only

Temperature is maintained at 20 °C

NOTE: The temperature limitation and the air-quality control

have priority over the temperature control.

Relative or absolute temperature setting via wall module.

Light Application:

Three times ON / OFF switching dependent on:

Occupancy

Internal light level: The light will be switched ON if the

light level drops below the "dark level" and it will be

switched OFF if it increases above the "bright level”.

The "dark level" and the "bright level” can be

configured via the plug-in.

NOTE: Do not select the “Auto Off Delay Timer” checkbox

insofar as this functionality is currently not supported.

Manual switching (via hardwired switches or

L

ONWORKS® wall module)

Two times dimming / constant light control for two lights

with just one sensor.

Dimming / constant light control is performed via analog

outputs (this requires an HFD [High-Frequency Device] for

dimming with 1...10 Vdc input). An additional relay is

required to switch the light ON/OFF.

Constant light control helps to save additional energy.

Normally, fluorescent tubes lose about 15% of their

illumination over their lifecycle. To compensate for this,

rooms are therefore usually dimensioned with 15% more

illumination than actually necessary. With constant light

control, the light level needs to be only 85% in order to

achieve the required brightness. Further savings and

comfort can be achieved if there is a constant light level in

the room and the light is automatically dimmed when more

outside light enters. The Excel 12 supports window

correction in order to reduce the light output of the window

light. This functionality can be configured via the plug-in.

Grouping of lights, e.g. switch three lights via a single

pushbutton.

Soft ON/OFF switching for dimmable lamps.

Light sensor: The light intensities typically encountered in

everyday life are listed in Table 1, while Table 2 presents

the recommended light levels in various environments as

set forth by DIN5035.

NOTE: One lux is equivalent to 0.0929 foot-candle.

Refer also to the plug-in help information for details.

Table 1. Typical light intensities

ambient conditions intensity (lux)

summer day, cloudless 100,000

summer day, cloudy 20,000

winter day, cloudy 400

night, with full moon 0.3

Table 2. Recommended light intensities (DIN5035)

area intensity (lux)

storage rooms 50...200

washrooms, cloakrooms, technical

rooms, corridors

100

office rooms (near windows) 300

office rooms (minimal outside light) 500

open-plan office rooms 750

schools (daytime) 300

night schools 500

gymnasiums 200

show rooms 300

commercial kitchens 500

NOTE: The intensity level depends on the sensor type and

the mounting location.

NOTE: The indoor light sensor must be suitable for sensing

artificial light, and should be mounted more towards

the corridor.

Free Inputs for Monitoring:

Unused inputs can be used for monitoring. This

application supports the following free inputs:

one temperature input (NTC20k)

one percentage input (0..10 V or 2..10 V)

three binary inputs

The input values are communicated via nvoXL12Status.

Free Binary Outputs Can Be Switched Via L

ONWORKS:

Up to two unused digital outputs (triac or relay outputs)

may be switched via L

ONWORKS® (nviFreeOutput[0/1]).

Occupancy Modes:

Occupied mode: The Excel 12 operates according to the

"occupied" heating and cooling set-points.

Bypass: After the bypass button of a hardwired wall

module has been pressed or when corresponding data is

received via the L

ONWORKS® network, the Excel 12

operates temporarily according to the "occupied" heating

and cooling set-points. When the bypass time has

elapsed, the controller reverts to scheduled mode. The

bypass time can be configured via plug-in.

Standby mode: The Excel 12 operates according to the

"standby" heating and cooling set-points.

Unoccupied mode: The Excel 12 operates according to

the "unoccupied" heating and cooling set-points.

3 EN0B-0470GE51 R0110

Page 4

EXCEL 12: FCU + LIGHT

Occupancy sensor: The occupancy sensor is used for the

HVAC and light application. Hardwired and L

ONWORKS®

occupancy sensors are supported. The occupancy sensor

determines the effective occupancy mode during

scheduled occupied periods (time program with

occupancy schedule runs on a different controller connected to the L

ONWORKS® network). Depending upon the

actual occupancy sensor state, the effective mode will be

either "occupied" or "standby."

Wall Modules:

L

ONWORKS® wall modules

Hardwired wall modules (e.g. T7460, T7560)

Wireless wall modules (e.g. W7070+T7270 or RT7070)

Master / Slave Functionality:

The master / slave functionality allows easy adaptation to

changed room usage.

The sequences and the outputs of the slave controller must

be configured in the same way as the master (e.g. sequence

1: heat, actuator type: thermal).

The temperature limit functionality and the air-quality functionality shall not be used in the slave controller if there is an

EnergyHoldOff binding from the slave to the master.

nviEnergyHoldOff

SEQUENCE 0, POSITION *1

SEQUENCE 1, POSITION *1

MASTER

SEQUENCE 2, POSITION *1

FANSPEED, POSITION *2

OCCUPANCY MODE

HEATING/COOLING POSITION *3

SLAVE

nviSequence [ 0]

nviSequence [ 1]

nviSequence [ 2]

nvoFanSpeedCmd

nviOccManCmd

nviApplicMode

nvoEnergyHoldOff

master

Excel 12

*1: ONLY IF SEQUENCE IS CONFIGURED

*2: ONLY IF FAN IS CONFIGURED

*3: ONLY IF CHANGEOVER SEQUENCE IS CONFIGURED

nvoSequence [0]

nvoSequence [1]

nvoSequence [2]

nvoFanSpeed

nvoEffectOcc

nvoHeatCool

THIS NV ALWAYS BINDS THE MASTER XL12 TO THE FINAL SLAVE XL12.

Excel 12

Excel 12

WINDOW CONTACTWINDOW CONTACT

Excel 12

WINDOW CONTACT

slave

slave

slave

nvoEnergyHoldOff

nviEnergyHoldOff

Fig. 5. Master/slave functionality and window contact

master

Excel 12

nvoLampValue nviLampValue

LIGHT

nviLampValue

slave

Excel 12

slave

Excel 12

master

Excel 12

THIS NV ALWAYS BINDS THE MASTER XL12 TO THE FINAL SLAVE XL12.

nvoLampValue nvoLampValuenviLampValuenviLampValue

LIGHT LIGHT

nvoLampValue nviLampValue

slave

Excel 12

slave

Excel 12

LIGHT

Fig. 7. All lights switched on via any pushbutton

NOTE: This binding shall not be used for applications

involving dimming or constant light control. Binding

via L

ONWORKS results in a short delay between the

switching of the different lamps. Pressing the

pushbutton repeatedly and rapidly may cause toggle

effects.

Benefits of Integrated Room Control

The Excel 12 functionality provides you with a number of

significant advantages:

Considerable Reduction in Energy Consumption:

25...75% savings on electrical energy consumption for

illumination.

Decreased heat generated by electric lights, thus reducing

cooling energy requirements.

Increased Convenience:

Occupancy sensor switches the light ON/OFF

automatically.

Constant light control always provides the correct lighting.

Optional air-quality control in the occupancy mode.

Wireless control via ZAPP (see ZAPP System

Engineering, EN0B-0286GE51).

Increased Flexibility:

Flexible room usage if a L

ZAPP (wireless remote control) is used.

Reduced Engineering Effort / Expenses:

Just one L

ONWORKS® node (instead of two) is required to

cover HVAC and Light.

reduced engineering and installation effort (e.g. wiring,

binding, commissioning, etc.)

reduced integration effort

lower cost due to reduced number of LNS™ credits

lower hardware total loop costs

ONWORKS® wall module or

Fig. 6. All lights switched via master pushbutton

NOTE: Binding via LONWORKS results in a short delay

between the switching of the different lamps.

EN0B-0470GE51 R0110

4

Page 5

EXCEL 12: FCU + LIGHT

Interoperability

See also section “Approvals, Certifications, and Standards”

on page 8.

Device Configuration

The controller is configured using Honeywell's LNS™ plug-in.

The plug-in can be started from CARE 4.0 or any LNS™ tool

(e.g. LonMaker for Windows™).

LONMARK® Objects Network Variables

The Excel 12 supports the following LONMARK® objects:

one node object (see Fig. 11)

one space comfort controller object (#8501 SCC – Fan

Coil) (see Fig. 12)

three lamp actuator objects (#3040) (see Fig. 8)

one occupancy sensor object (#1060) (see Fig. 9)

two open loop actuator objects (#3) (see Fig. 10)

See also Table 5 through Table 8 on page 9.

Lamp Actuator Object

LonMark Lamp Actuator Object

(profile #3040)

Open Loop Actuator Object

LonMark Open Loop

Actuator Object (#3)

nviFreeOutput

SNVT_switch

mandatory

1

Network

Variables

Fig. 10. Open Loop Actuator Object

Node Object

Node Object

(LonMark Object type no. 0)

nviRequest

SNVT_obj_request

mandatory

1

Network

Var iab le s

optional

Network

Variables

nvoStatus

SNVT_obj_status

nvoFileDirectory

SNVT_address

nvoHwType

UNVT_HWType

2

8

9

nviLampValue

SNVT_switch

nviOccManCmd

SNVT_occupancy

nviLuxLight

SNVT_lux

nviOccSchedule

SNVT_tod_event

nviOccSensor

SNVT_occupancy

1

mandatory

Network

Var iab les

Network

Var iab le s

shared

among Objects

Fig. 8. Lamp Actuator Object

Occupancy Sensor Object

LonMark Occupancy

Sensor Object

(profile #1060)

mandatory

Network

Var iab le s

Fig. 9. Occupancy Sensor Object

nvoLampValueFb

SNVT_switch

nvoOccSensor

SNVT_occupancy

nvoHwIdentify

UNVT_HWIdentify

nvoDiagnostic

UNVT_Diagnostic

nvoXL12Status

UNVT_XL12Status

2

nviDiagnRequest

UNVT_DiagRequest

nviLuxLight

SNVT_lux

11

14

Manufacturer-

specific

(device-related)

Network

Variables

shared

among Objects

Configuration

Parameter

Value File

10

12

13

Fig. 11. Node Object

1

5 EN0B-0470GE51 R0110

Page 6

EXCEL 12: FCU + LIGHT

Space Comfort Controller Object

Space Comfort Controller -

Fan Coil Object #8501

nviSpaceTemp

SNVT_temp_p

nviSetPoint

SNVT_temp_p

nviSetptOffset

SNVT_temp_p

nviOccSchedule

SNVT_tod_event

nviOccManCmd

SNVT_occupancy

nviOccSensor

SNVT_occupancy

nviApplicMode

SNVT_hvac_mode

nviFanSpeedCmd

SNVT_switch

nviEnergyHoldOff

SNVT_switch

SCPTsetPnts

SCPTbypassTime

nviSequence[0]

nviSequence[1]

SNVT_lev_percent

nviSequence[2]

SNVT_lev_percent

SNVT_lev_percent

|1 |26

|2

|3

|5

|6

|7

Optional Mandatory

|8

|10

|14

Manufacturer-

Specific

nvoSpaceTemp

SNVT_temp_p

nvoUnitStatus

SNVT_hvac_status

nvoEffectOcc

SNVT_occupancy

nvoHeatCool

SNVT_hvac_mode

nvoFanSpeed

SNVT_switch

nvoEnergyHoldOff

SNVT_switch

nvoSequence[0]

nvoSequence[1]

SNVT_lev_percent

nvoSequence[2]

SNVT_lev_percent

SNVT_lev_percent

|27

|29

|30

|33

|49

LONWORKS® Network Interface

The Excel 12 communicates within the LONWORKS® network

at a rate of 78 kbs via an FTT-10A Free Topology

Transceiver, which provides transformer isolation; the bus

wiring is thus insensitive to polarity.

Devices so equipped can be wired in daisy chain, star, loop,

or any combination thereof as long as the max. wire length

requirements are met. The recommended configuration is a

daisy chain with two termination modules. This layout allows

for max. bus length and has the highest communication

reliability, particularly when adding on to an existing bus.

Refer also to http://www.echelon.com

Configuration and Binding

Configuration is performed using Honeywell's LNS™ plug-in,

which can be started from CARE 4.0 or any LNS™ tool (e.g.

LonMaker for Windows™). Likewise, binding is performed

using CARE 4.0 or any LNS™ tool.

LONWORKS® Service Button and LED

All models feature a LONWORKS® service button (accessible

from the outside on top of the module).

The service pin message is broadcast:

whenever the L

after each reset due to power-up, software reset;

if a hardwired pushbutton for lighting is pushed for more

than 10 seconds.

See also Excel 12 Installation Instructions (EN1B-0201GE51)

for more-detailed information.

All models feature a L

missioning and troubleshooting. The service LED displays

numerous different behaviors indicating various module states

for use in troubleshooting (see also Excel 12 Installation

Instructions).

ONWORKS® service button is pressed;

ONWORKS® service LED for com-

nviSrcTemp[0]

nviSrcTemp[1]

SNVT_temp_p

SNVT_temp_p

Fig. 12. FCU Controller Object

EN0B-0470GE51 R0110

6

Page 7

Models

EXCEL 12: FCU + LIGHT

Table 3. Overview of Excel 12 models

W7704A1004*1

W7704B1002*1

W7704C1000*1

W7704D1008

W7704D1016

W7704F1003*1*2

short housing

long housing

24 Vac

230 Vac

binary input 1

binary input 2

binary input 3

binary input 4

relay 1 (N-O)

relay 2 (N-O)

relay 3 (N-O)

relay 4 (C-O)

relay 5 (C-O)

triac 1

triac 2

triac 3

traic 4

triac 5

triac 6

wall module LED

output

AI1 (NTC20k + V)

AI2 (NTC20k)

AI3 (fan speed /

bypass)

AI4 (setpoint)

AI5 (NTC20k + V)

X X X X X X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X X X

X X X X X X XXXXXXXXXXX X X X X X XXXXX

X XX X X X XXXXXXXXXXX X X X X X XXXXX

X X X X X X X X X X X X X X

*1 These hardware versions have been discontinued.

*2 The hardware variant W7704F1003 is cost-optimized for light control and does not support hardwired wall modules.

Long and Short Housings

Models powered with line power (W7704A, B, and D1016) are

equipped with a built-in transformer and feature a long

housing (W X L X H = 180 X 76 X 110 mm).

Models powered with 24 Vac (W7704C, and D1008) require

an external 24 Vac power supply and feature a short housing

(W X L X H = 126 X 76 X 110 mm).

Binary Inputs

The Excel 12 is equipped with four dry-contact binary inputs.

The binary inputs are fast (the signal must be stable for at

least 25 ms). These inputs are often used for light

pushbuttons.

Binary Outputs

The triac outputs or relay outputs can be configured for

different functions.

Relay Outputs

The Excel 12 is equipped with up to two change-over (C-O)

relays and up to three normally-open (N-O) relays.

Hardware Limits

In order to ensure a reliable contact, a min. current of

50 mA is required.

The normally-open contacts are designed for a max.

continuous current of 16 A. The normally-closed contacts

Hardware Limits for Excel 12 with Line Power Supply

Low signal: 0 V; high signal: 24 Vac

Max. 250 mA continuous current in sum for all triac

outputs together

550 mA for max. 10 sec.

cos > 0.5

Hardware Limits for Excel 12 with 24 Vac Power Supply

Low signal: 0 V; high signal: 24 Vac

Max. 500 mA continuous current in sum for all triac

outputs together

800 mA for max. 10 sec.

cos > 0.5

NOTE: For controlling thermal actuators, we recommend

using the 24 Vac models, which provide more

current.

Analog Outputs

The Excel 12 is equipped with up to two 0...11 Vdc analog

outputs each of which can drive a max. of ±1.1 mA.

Analog Inputs

The Excel 12 is equipped with up to 7 analog inputs, all of

which can be configured as slow binary inputs (in which case

the signal must be stable for at least 1.25 sec) for the

detection of a slow signals (e.g. from a window contact).

are designed for a max. continuous current of 1 A.

In order to reduce the build-up of heat in the housing, the

max. combined allowable current flowing through all relays

simultaneously is 24 A (continuous).

The max. peak in-rush current (20 ms) at the normally-

open contact is 80 A.

Triac Outputs

The Excel 12 is equipped with up to six triac outputs.

AI6 (NTC20k)

AI7 (NTC20k + V)

AO1 (0...10 Vdc)

AO2 (0...10 Vdc)

7 EN0B-0470GE51 R0110

Page 8

EXCEL 12: FCU + LIGHT

Table 4. Analog input usage (with wall modules)

analog input voltage NTC wall module

AI1 X X e.g. CO2 or humidity

AI2 X room temperature1

AI3 fan speed or bypass2

AI4 setpoint3

AI5 X X e.g. CO2 or humidity

AI6 X

AI7 X X e.g. CO2 or humidity

1

For all NTC inputs, temperatures of -50...-45 °C are interpreted as

being due to a sensor break, and temperatures of +145...+155 °C

are interpreted as being due to a sensor short-circuit.

2

A contact open for 10 seconds is interpreted as a sensor failure.

3

A resistance of > 15k is interpreted as being due to a sensor

break, a resistance of < 100 is interpreted as being due to a

sensor short-circuit.

Accessories

Swivel Label Holders

For short or long housings (required for modules equipped

with manual override switches).

24 Vac models (short), order no.: XAL_LAB_S

line power supply models (long), order no.: XAL_LAB_L

Terminal Protection Covers

For short or long housings (required for wall/ceiling mounting).

24 Vac models (short), order no.: XAL_COV_S

line power supply models (long), order no.: XAL_COV_L

LONWORKS® Termination

One or two LONWORKS® terminations are required, depending

on the given LonWorks bus layout.

Two different L

L

ONWORKS® termination module,

order no.: 209541B

LONWORKS® connection / termination module (can be

mounted on DIN rails and in fuse boxes),

order no.: XAL-Term

removable screw-type

3-pole terminal block

Fig. 13. LonWorks® connection and termination module

ONWORKS® terminations are available:

l

l

e

w

y

e

n

o

H

m

r

e

T

-

L

A

X

4

3

L

L

O

O

N

N

shield shield

plug-in

jumper

3

4

1

06

Termination

5

LON

FTT/LPT Bus

FTT/LPT Free

Park Position

Approvals, Certifications, and Standards

Approvals and Certifications

CE-approved

Certified as per LonMark® Application Layer

Guidelines V 3.3, thus interoperable with all other

devices in open L

ONWORKS® networks (incl. 3

devices)

EUBAC-certified as follows:

W7704D1016:

W7704D1008:

eu.bac

020893

Cert

eu.bac

020896

Cert

Classification according to EN60730-1

Environmental conditions: For use in home (residential,

commercial, and light-industrial)

environments

Pollution degree: Class 2

Protection against shock: Class 0 (without terminal covers)

Class II (with terminal covers)

Software class: Class A

Classification according to EN60529

(Degree of Protection Provided by Enclosures)

Without terminal covers: IP20

With terminal covers: IP30

Ambient Environmental Limits

Operating temperature: 0 … +50 °C at 5…90% r.H.

Storage temperature: -30 … +70 °C at 5…90% r.H.

W7704D1008, W7704D1016 Temperature CA

Chilled ceiling: 0.5 K

Electric convector: 0.3 K

Electric floor heating: 1.2 K

Radiator heating: 0.5 K

FCU heating mode: 0.4 K

FCU cooling mode: 0.2 K

(min. Temperature Control Accuracy values requested by

EUBAC: ≤ 1.4 K for hot water radiator heating, fan coil unit,

VAV, and chilled ceiling applications; ≤ 1.8 K for water floor

heating, electric convector, electric floor heating, and electric

ceiling heating applications)

Applicable Literature

Excel 12 Installation Instructions (EN1B-0201GE51)

Excel 50/500 L

0270GE51)

Excel 10 FTT/LPT 209541B Termination Module

Installation Instructions (95-7554)

ZAPP System Engineering (EN0B-0286GE51)

XL12 / XL Smart I/O Plug-in Installation Guide (EN0B-0294

GE51)

Honeywell's XL12 / Excel Smart I/O plug-in help

ONWORKS® Mechanisms (EN0B-

rd

-party

EN0B-0470GE51 R0110

8

Page 9

EXCEL 12: FCU + LIGHT

NETWORK INTERFACE

The following tables list the NV's associated with the various

L

ONMARK® objects serving as network interfaces to the Excel

12 FCU + Light application.

Table 5. NV's associated with Space Comfort Controller

FCU Object (profile # 8051)

name type heartbeat

nviSpaceTemp SNVT_temp_p yes

nviSetPoint SNVT_temp_p no

nviSetptOffset SNVT_temp_p yes

nviOccSchedule SNVT_tod_event yes

nviOccManCmd SNVT_occupancy no

nviOccSensor SNVT_occupancy yes

nviApplicMode SNVT_hvac_mode yes

nviFanSpeedCmd SNVT_switch no

nviEnergyHoldOff SNVT_switch yes

nviEmergOverride SNVT_hvac_emerg no

nviSrcTemp[2] SNVT_temp_p yes

nviSequence[3] SNVT_lev_percent yes

nvoSequence[3] SNVT_lev_percent yes

nvoSpaceTemp SNVT_temp_p yes

nvoUnitStatus SNVT_hvac_status yes

nvoEffectOcc SNVT_occupancy no

nvoHeatCool SNVT_hvac_mode yes

nvoFanSpeed SNVT_switch yes

nvoEnergyHoldOff SNVT_switch yes

Table 6. NV's associated with Occupancy Sensor Object

(profile #1060)

name type heartbeat

nvoOccSensor SNVT_occupancy yes

Table 7. NV's associated with Lamp Actuator Object

(profile #3040)

name type heartbeat

nviLampValue[3] SNVT_switch no

nvoLampValueFb[3] SNVT_switch no

Table 8. NV's associated with the Node Object

(LONMARK® object #0)

name type heartbeat

nviRequest SNVT_obj_request no

nvoStatus SNVT_obj_status yes

nvoFileDirectory SNVT_address no

nviDiagnRequest UNVT_DiagRequest no

nvoDiagnostic UNVT_Diagnostic no

nvoXL12Status UNVT_XL12Status no

nviLuxLight SNVT_lux no

nvoHwType UNVT_HwType n/a

nvoHwIdentify UNVT_HWIdentify n/a

Table 9. NV's associated with Open Loop Actuator Object

ONMARK® object #3)

(L

name type heartbeat

nviFreeOutput[2] SNVT_switch no

Note: Device Resource Files are included in the plug-in

package and facilitate the handling of UNVTs

9 EN0B-0470GE51 R0110

Page 10

EXCEL 12: FCU + LIGHT

DIMENSIONS

swivel label

holders (optional)

terminal protection

cover (optional)

terminal protection

cover (optional)

cut-out tabs

(to expose terminal pins)

leverage slot

LonWorks

service button

long housing (with built-in transformer): 180 m (7-7/8 in.)

Short housing (without transformer): 126 mm (4-15/16 in.)

LonWorks

service LED

ventilation slits

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Rolle, Z.A. La Pièce 16, Switzerland by its Authorized Representative:

Automation and Control Solutions

Honeywell GmbH

Böblinger Strasse 17

71101 Schönaich

Germany

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://ecc.emea.honeywell.com

Subject to change without notice. Printed in Germany

EN0B-0470GE51 R0110

Loading...

Loading...