Page 1

Put Bar Code Here

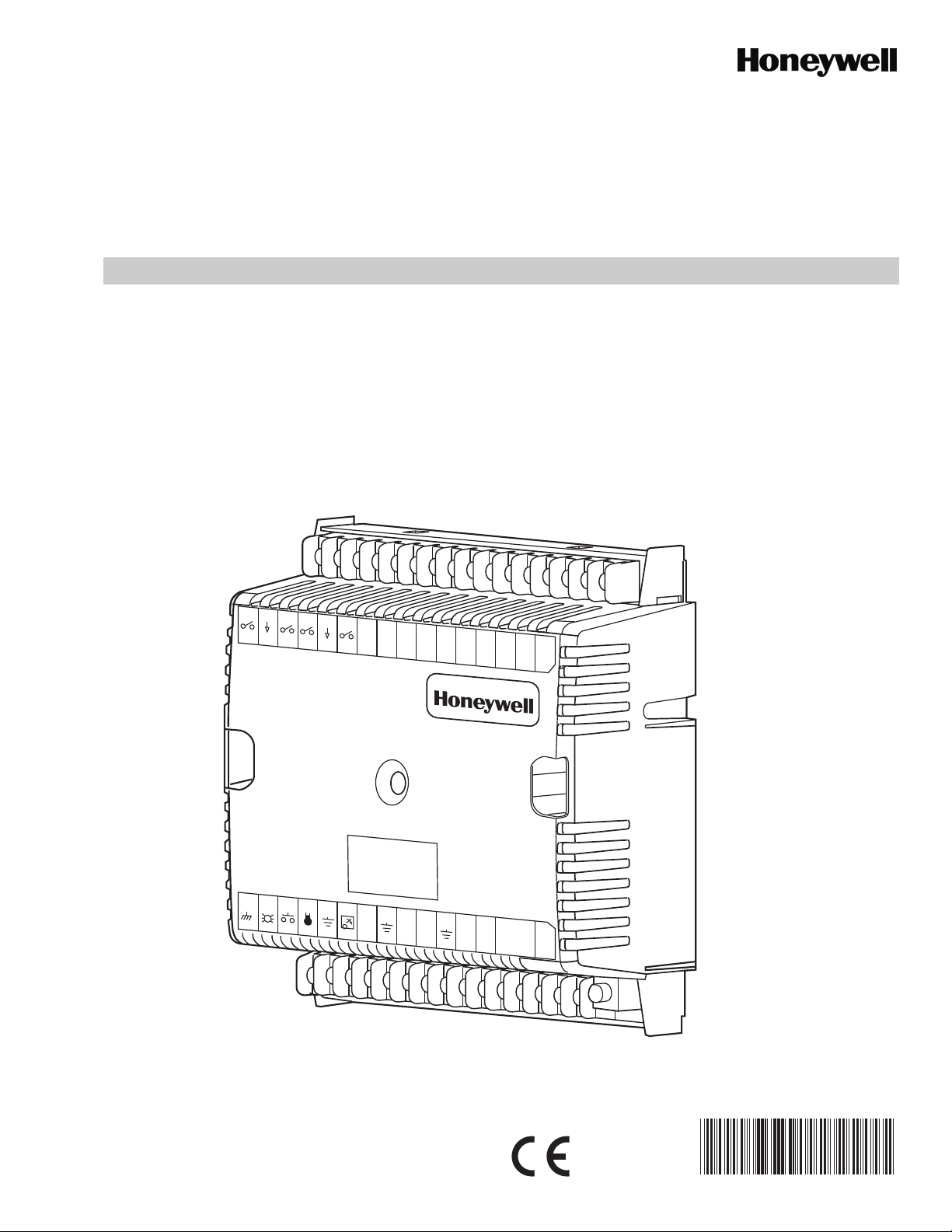

Excel 10

W7753A Unit Ventilator Controller

INSTALLATION INSTRUCTIONS

PRODUCT DESCRIPTION

The W7753A Unit Ventilator Controller is a Free Topology

Transceiver (FTT) L

in the Excel 10 family product line.

This controller can be used to monitor/control HVAC

equipment, lighting, and other miscellaneous loads in a

distributed network. The controller is field-mounted to the

equipment that it controls, and the controller wiring is attached

to the screw terminals located on the controller (see Fig. 1).

ONMARK® Compliant Unit Vent controller

31

30 29 28

DI-4 GND

DI-3

DI-2 GND DI-1

27

26 25

24

23 22

21

VAC

24

24

1

VAC

COM

OUT

OUT

20

2

3

4

OUT

OUT

The W7753A Controller communicates via the 78 kilobaud

Echelon® LonWorks® E-Bus Network.

Allowable input/output connections consist of wall module

points plus two additional resistive sensor inputs, two voltage/

current inputs, four digital inputs and eight digital Triac

outputs.

For the W7753A, any hardware driven by the Triac outputs

must have a minimum current draw, when energized, of

25 mA and a maximum current draw of 500 mA.

19 18

17

OUT

16

6

7

8

OUT

OUT

OUT

5

E

GND

1

LED

BYPASS

23

SNSR

GND

SET PT

AI-1

GND

A1-2

AI-3

5

OHM

67

89

4

OHM

GND

V/mA

10 11 12

AI-4

V/mA

22VDC

OUT

13 14

E-BUS

E-BUS

JACK

15

J3

Fig. 1. Excel 10 W7753A Unit Ventilator Controller.

M12688

95-7520—02

Page 2

EXCEL 10 W7753A UNIT VENTILATOR CONTROLLER

INSTALLATION

Mount the W7753A in a position that allows clearance for

wiring, servicing and controller removal. Avoid mounting the

W7753A in areas where acid fumes or other deteriorating

vapors can attack the metal parts of the controller, or in areas

where escaping gas or other explosive vapors are present.

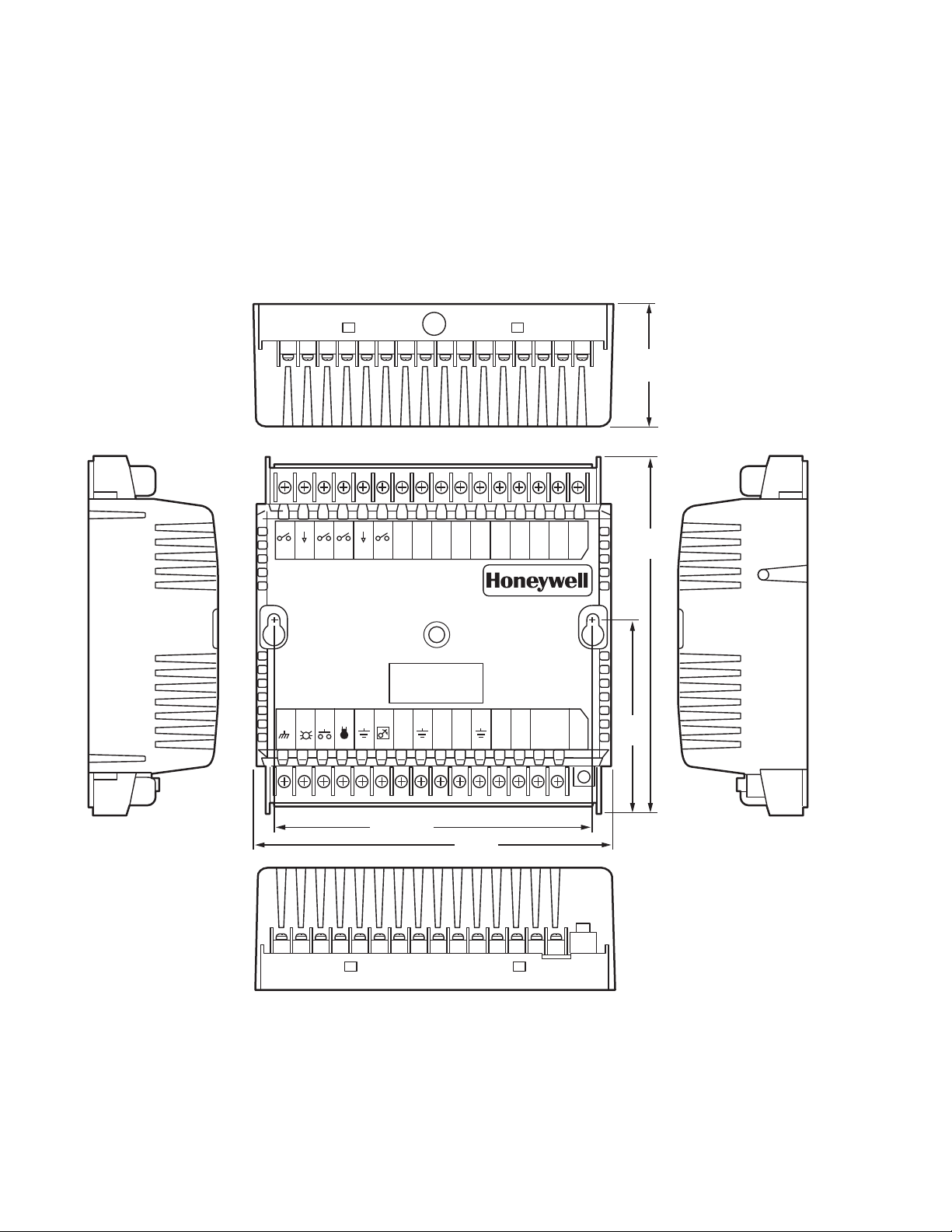

See Fig. 2 for mounting dimensions.

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16

DI-4

GND

DI-3 DI-2

GND

DI-1

24

VAC

24

VAC

COM

The controller enclosure on the W7753A is constructed of a

sheet metal housing and a plastic factory snap-on cover. The

controller mounts using two screws inserted through the

plastic cover. Use the screws appropriate for the mounting

surface. The W7753A can be mounted in any orientation.

Ventilation openings were designed into the cover to allow

proper heat dissipation regardless of the mounting orientation.

The W7753A can also be mounted using DIN rail (obtain

locally). If using DIN rail also purchase from Augat Inc. part

number 2TK2D DIN rail (adapter) two each (See Fig. 3).

2-1/8

(54)

1

OUT

2

OUT

3

OUT

4

OUT

5

OUT

6

OUT

OUT

7

8

OUT

5-5/8

(143)

E

BYPASS

SNSR

GND

SET PT

AI-1

GND

AI-2

AI-3

GND

AI-4

22VDC

LED

GND

1 23 456 789101112131415J3

OHM

5-3/16 (132)

OHM

V/mA

6 (152)

V/mA

OUT

E-BUS

E-BUS

JACK

Fig. 2. W7753A mounting dimensions in in. (mm).

3-1/16

(77)

M12689

95-7520—02 2

Page 3

EXCEL 10 W7753A UNIT VENTILATOR CONTROLLER

Power

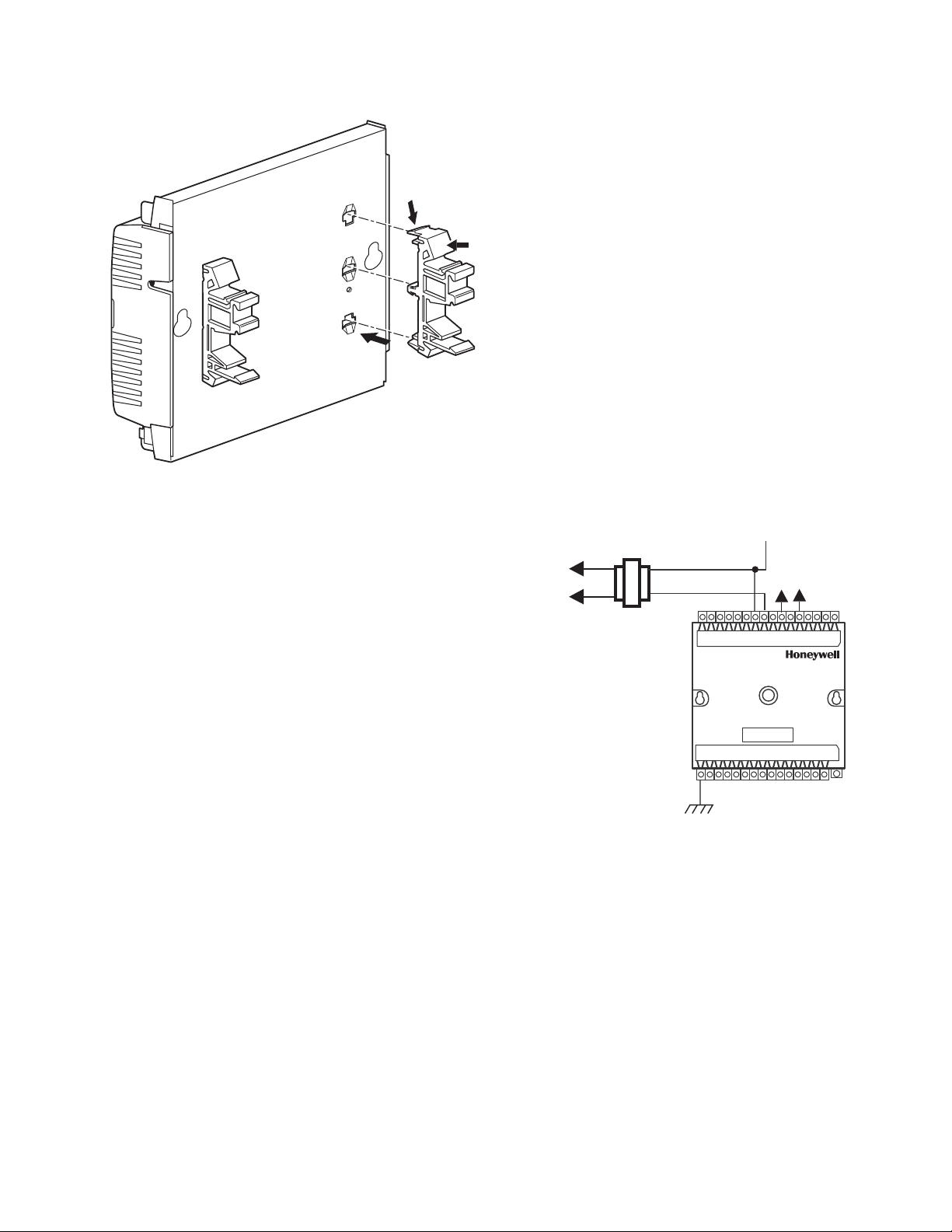

The 24 Vac power from an energy-limited Class II Power

Source must be provided to each W7753A Controller. To

conform to Class II restrictions (U.S. only), transformers must

not be larger than 100 VA.

2

A transformer that meets CE mark requirements and that

meets the Low Voltage Directive (LVD) requirements must be

used in Europe for all installations of this product. More than

3

one W7753A Controller can be powered by a single

transformer. Fig. 4 shows power wiring details for a single

controller and Fig. 5 depicts multiple controllers using one

transformer.

1

M6857

Fig. 3. W7753A DIN rail mounting.

Wiring

All wiring must comply with applicable electrical codes and

ordinances or as specified on installation wiring diagrams.

Controller wiring on the W7753A is terminated to the screw

terminal blocks located on the top and the bottom of the

controller.

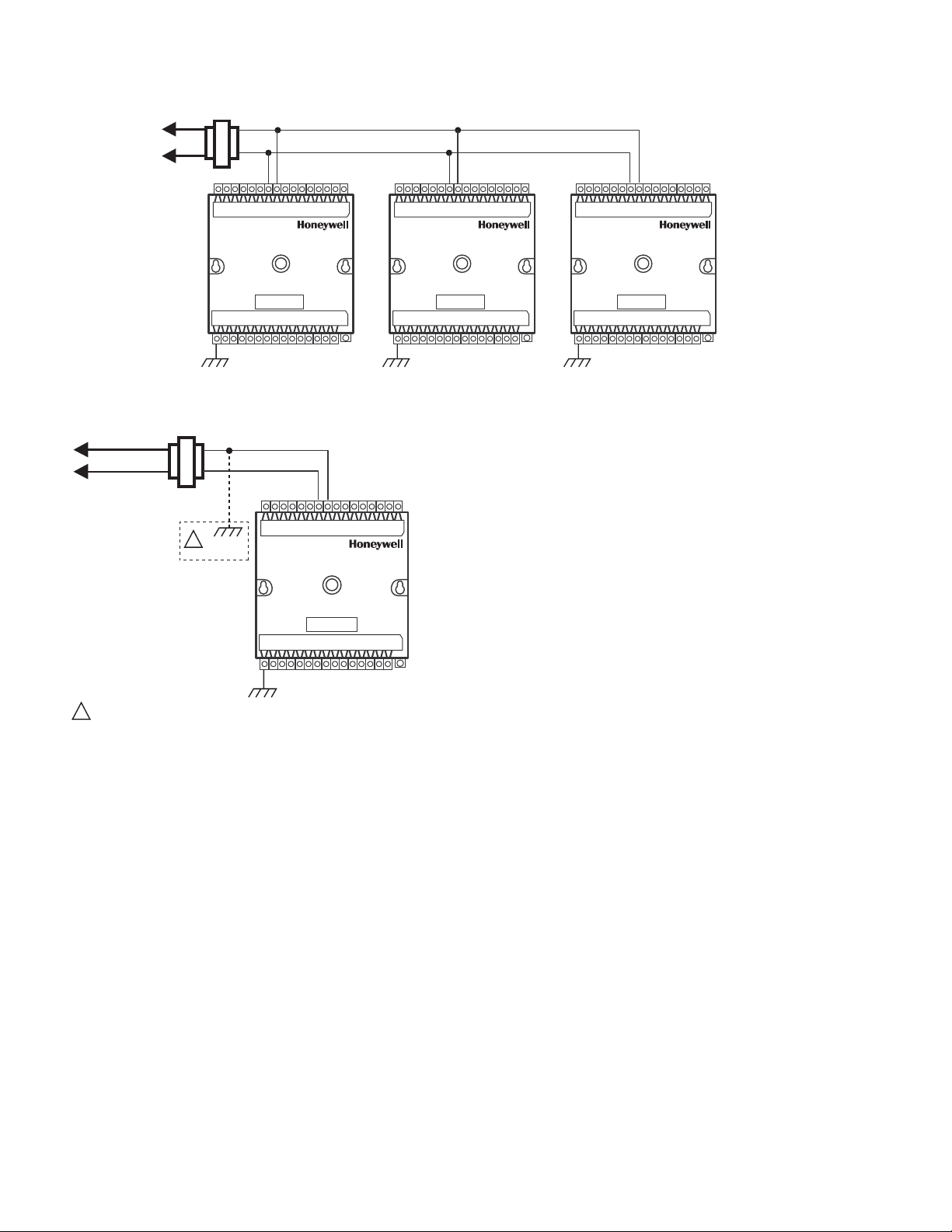

NOTES:

— For multiple controllers operating from a single

transformer, the same side of the transformer

secondary must be connected to the same power

input terminal in each controller. The ground

terminal (1 on the W7753A) must be connected to

a verified earth ground for each controller in the

group (see Fig. 5). (Controller configurations are

not necessarily limited to three controllers, but the

total power draw including accessories cannot

exceed 100 VA when powered by the same

transformer (U.S. only). See System Engineering

form 74-2964 for power wiring recommendations.)

— All loads on an Excel 10 W7753A Controller must

be powered by the same transformer that powers

the Excel 10 W7753A Controller. A W7753A

Controller can use separate transformers for

controller power and load power.

— Keep the earth ground connection (terminal 1)

wire run as short as possible. Refer to Fig. 9

through 14.

—Do not connect the analog or digital ground

terminals (5, 8, 11, 27 and 30) to earth ground.

Refer to Fig. 9 through 14.

IMPORTANT

Use the heaviest gauge wire available, up to 14

AWG (2.0 mm

(1.0 mm

2

) with a minimum of 18 AWG

2

), for all power and earth ground wiring.

Screw type terminal blocks are designed to accept

up to two 14 AWG (2.0 mm2) conductors, one on

each side of the terminal screw. More than two wires

that are 14 AWG (2.0 mm2) can be connected with a

wire nut. Include a pigtail with this wire group and

attach the pigtail to one side of the terminal block.

OUTPUT

DEVICE

POWER

TRANSFORMER

CONNECT POWER TO

TERMINALS 24 AND 25

W7753A

1

EARTH

GROUND

TRIAC LINES

TO ACTUATORS

AND

CONTACTORS

25

24

2022

M12681

Fig. 4. Power wiring details; one Excel 10 per transformer.

NOTES:

— Unswitched 24 Vac power wiring can be run in the

same conduit as the E-Bus cable.

— Maintain at least three-inch (76 mm) separation

between Triac outputs and E-Bus wiring

throughout the installation.

See the following IMPORTANT on Heating and Cooling

Equipment (UL 1995, U.S. only).

IMPORTANT

If the W7753A Controller is used on Heating and

Cooling Equipment (UL 1995, U.S. only) and the

transformer primary power is more than 150 volts,

connect the transformer secondary to earth ground

(see Fig. 6). For these applications, only one

W7753A Excel 10 controller can be powered by each

transformer.

3 95-7520—02

Page 4

M12682

24 VAC

120/240 VAC

TRANSFORMER

W7753A

EARTH

GROUND

24

25

1

W7753A

EARTH

GROUND

24

25

1

W7753A

EARTH

GROUND

24

25

1

M12680

24 VAC

LINE VOLTAGE

GREATER

THAN 150 VAC

TRANSFORMER

W7753A

EARTH

GROUND

EARTH

GROUND

IF THE W7750 CONTROLLER IS USED IN UL 1995 EQUIPMENT AND THE

PRIMARY POWER IS MORE THAN 150 VOLTS, GROUND ONE SIDE OF

TRANSFORMER SECONDARY.

1

1

1

EXCEL 10 W7753A UNIT VENTILATOR CONTROLLER

Fig. 5. Power wiring details for two or more Excel 10s per transformer.

Fig. 6. Transformer power wiring details for one Excel 10

used in UL 1995 equipment (U.S. only).

Communications

Refer to E-Bus Wiring Guidelines, form 74-2865, for a

complete description of E-Bus network topology rules.

Approved cable types for E-Bus communications wiring are

Level IV 22 AWG (0.34 mm

unshielded, twisted pair, solid conductor wire. For nonplenum

areas, U.S. part AK3781 (one pair) or U.S. part AK3782 (two

pair) can be used. In plenum areas, U.S. part AK3791 (one

pair) or U.S. part AK3792 (two pair) can be used.

Communications wiring can be run in a conduit, if needed,

with non-switched 24 Vac or sensor wiring. If a longer E-Bus

network is required, a Q7740A 2-way or Q7740B 4-way

repeater can be added to extend the length of the E-Bus. Also

a Q7751A Router can be added to partition the system into

two segments and effectively double the length of the E-Bus.

Only one router is allowed with each Excel 10 Zone Manager,

and each network segment can have a maximum of one

repeater.

Pull the cable to each device on the E-Bus and connect to

communication terminals 14 and 15 (W7753A).

2

) plenum and non-plenum rated

NOTES: (For Communications Wiring)

— All field wiring must conform to local codes and

ordinances (or as specified on the installation

drawings).

— Approved cable types for E-Bus communications

wiring is Level IV 22 AWG (0.34 mm

2

) plenum

and non-plenum rated unshielded, twisted pair,

solid conductor wires. For nonplenum areas, U.S.

part AK3781 (one pair) or U.S. part AK3782 (two

pair) can be used. In plenum areas, U.S. part

AK3791 (one pair) or U.S. part AK3792 (two pair)

can be used.

— Unswitched 24 Vac power wiring can be run in the

same conduit as the E-Bus cable.

— Do not bundle output wires with sensor, digital

input or communications E-Bus wires.

— Do not use different wire types or gauges on the

same E-Bus segment. The step change in line

impedance characteristics would cause unpredictable reflections on the E-Bus. When using different types is unavoidable, use a Q7751A Router

at the junction.

— In noisy (high EMI) environments, avoid wire runs

parallel to noisy power cables, motor control centers, or lines containing lighting dimmer switches,

and keep at least 3 in. (76 mm) of separation

between noisy lines and the E-Bus cable.

— Each daisy-chained E-Bus segment that is on one

side of a Q7751A,B Router (can contain up to 60

Excel 10s) and has a length greater than 1640 ft.

(500m) must have two E-Bus 209541B

Termination Modules, one at each end of the

daisy-chain wiring run.

— Make sure that neither of the E-Bus wires is

grounded.

NOTE: If a 209541B Termination Module is required at a the

UV controller, connect two of the three termination

module wires to the E-Bus terminals. Selecting the

appropriate two wires depends on the E-Bus network

topology. Refer to the E-Bus Wiring Guidelines, form

74-2865, and the Excel 10 FTT Termination Module

Installation Instructions, form 95-7554. For example,

using a doubly terminated daisy-chained bus topology, if controllers are on either end of an E-Bus wire

run, mount the termination module on the appropriate terminals as shown in Fig. 7.

95-7520—02 4

Page 5

EXCEL 10 W7753A UNIT VENTILATOR CONTROLLER

W7753A

W7753A

1415 1415

BROWN

ORANGE

PART NO. 209541B

TERMINATION

MODULE

PART NO. 209541B

TERMINATION

MODULE

W7753A

BROWN

1415

ORANGE

M12690

Fig. 7. Termination modules (place a wire nut on each remaining wire that is not connected to a controller or device).

2

NOTE: When two or more wires are to be attached to the same terminal, other than 14 AWG (2.0 mm

), be sure to twist them

together. Deviation from this rule can result in improper electrical contact. See Fig. 8.

Wire to the terminal blocks as follows:

1. Strip 3/8 in. (10 mm) insulation from the conductor.

2. Insert the wire in the required terminal location and

tighten the screw to complete the termination.

3. If two or more wires are being inserted into one terminal

location, strip 1/2 in. (13 mm) of insulation from the conductors then twist the wires together a minimum of three

turns before inserting them.

4. Cut the twisted end of the wires to 3/16 in. (5 mm)

before inserting them into the terminal and tightening

the screw.

5. Pull on each wire in all terminals to check for good

mechanical connection.

Wiring Details

The W7753A Controller has the terminal arrangements shown

in Fig. 9 through 14. Connection for operator access to the

E-Bus is provided by plugging the Serial LonTalk® Adapter

(SLTA) connector into the E-Bus jack.

NOTE: If an Excel 10 Controller or Zone Manager is not

connected to a good earth ground, the controller

internal transient protection circuitry is compromised

and the function of protecting the controller from

noise and power line spikes cannot be fulfilled. This

can result in a damaged circuit board and require

replacement of the controller. Refer to job drawings

for specific installation wiring diagrams.

3/8

(10)

STRIP 3/8 IN. (10 MM) FROM WIRES

1. 2. TWIST WIRES TOGETHER

TO BE ATTACHED AT ONE TERMINAL.

WITH PLIERS (A MINIMUM

OF THREE TURNS).

Fig. 8. Attaching two or more wires at terminal blocks.

5 95-7520—02

TWO 14 AWG

2

) WIRES

(2.0 MM

3. CUT TWISTED END OF WIRES TO 3/16 IN. (5 MM)

BEFORE INSERTING INTO TERMINAL AND TIGHTENING

SCREW. THEN PULL ON EACH WIRE IN ALL TERMINALS

TO CHECK FOR GOOD MECHANICAL CONNECTION.

M10086

Page 6

EXCEL 10 W7753A UNIT VENTILATOR CONTROLLER

31 30 29 28 27 26 25 24 23 22 21 20

OUT 1

OUT 2

24 VAC COM

TRIAC EQUIVALENT CIRCUIT

DI-4

DI-3

GND

W7753A

DI-2

GND

24 VAC

DI-1

19 18 17 16

OUT 3

OUT 4

OUT 7

OUT 6

OUT 5

OUT 8

UNIT

VENTILATOR

CONTROLLER

GND

SETPT

LED

GND

AI-1 OHM

9 10

FAN

BYPASS

SNSR

LED

BYPASS

E GND

1234 5 6 7 8

GND

3 41 2

NET 1

SENSOR

7 85 6

NET 2

SET PT

GND

AI-3 V/mA

AI-2 OHM

9 10 11 12 14 J3 15

E-BUS

E-BUS

JACK

AI-4 V/mA

22 VDC OUT

13

E-BUS

OUTSIDE

AIR CO

SENSOR

TR23-F5

WALL MODULE

M29164

Fig. 9. Typical W7753A unit ventilator application wiring

diagram with T7770F wall module. (For note 2, refer to

Fig. 8.)

WINDOW CONTACT

(CONTACT CLOSED =

WINDOWCLOSED)

3

OCCUPANCY SENSOR

(CONTACT CLOSED =

OCCUPIED)

3

31 30 29 28 27 26 25 24 23 22 21 20

OUT 1

OUT 2

24 VAC COM

TRIAC EQUIVALENT CIRCUIT

DI-4

DI-3

GND

W7753A

DI-2

GND

24 VAC

DI-1

OUT 3

OUT 4

19 18 17 16

OUT 6

OUT 5

UNIT

VENTILATOR

CONTROLLER

AI-4 V/mA

22 VDC OUT

13

2

E-BUS

GND

SNSR

SETPT

LED

BYPASS

E GND

12345678

1

1

EARTH GROUND WIRE LENGTH SHOULD BE HELD TO A MINIMUM.

USE THE HEAVIEST GAUGE WIRE AVAILABLE, UP TO 14 AWG (2.O MM

WITH A MINIMUM OF 18 AWG (1.O MM

2

TO ASSURE PROPER ELECTRICAL CONTACT, WIRES MUST BE TWISTED

TOGETHER BEFORE INSERTION INTO THE TERMINAL BLOCK.

3

CONTACTS MUST BE SUITABLE FOR DRY SWITCHING, 5V AT 10 mA. USE

SEALED TYPE, GOLD FLASHED OR PIMPLED CONTACTS.

GND

AI-1 OHM

9101112 14 J315

GND

AI-3 V/mA

AI-2 OHM

2

), FOR EARTH GROUND WIRE.

24 VAC

OUT 7

E-BUS

M12692

+

-

OUT 8

E-BUS

JACK

2

)

95-7520—02 6

Fig. 10. Typical window and occupancy sensor wiring

diagram. (For note 2, refer to Fig. 8.)

Page 7

EXCEL 10 W7753A UNIT VENTILATOR CONTROLLER

12345678

E-BUS

24 VAC

W7753A

UNIT

VENTILATOR

CONTROLLER

1

2

E-BUS

E GND

GND

SNSR

SETPT

LED

BYPASS

GND

GND

9101112 14 J315

31 30 29 28 27 26 25 24 23 22 21 20

24 VAC COM

E-BUS

JACK

22 VDC OUT

19 18 17 16

AI-1 OHM

AI-2 OHM

AI-4 V/mA

OUT 7

OUT 6

OUT 5

OUT 4

OUT 8

OUT 1

OUT 3

OUT 2

AI-3 V/mA

13

DI-2

DI-4

DI-1

DI-3

M12695

GND

GND

TRIAC EQUIVALENT CIRCUIT

C7600C

1

2

EARTH GROUND WIRE LENGTH SHOULD BE HELD TO A MINIMUM. USE

THE HEAVIEST GAUGE WIRE AVAILABLE, UP TO 14 AWG (2.O MM

2

) WITH

A MINIMUM OF 18 AWG (1.O MM

2

), FOR EARTH GROUND WIRE.

TO ASSURE PROPER ELECTRICAL CONTACT, WIRESMUST BE TWISTED

TOGETHER BEFORE INSERTIONINTO THE TERMINAL BLOCK.

+

S

C7600C

+

S

ENTHALPY

(4 TO 20mA)

HUMIDITY

(4 TO 20mA)

MMC325 PNEUMATIC

TRANSDUCER

24 (H)

24 (N)

24 (H)

24 (N)

INCREASE

DECREASE

OUT 1

PNEUMATIC

VALV E

OUT 3

OUT 2

1

31 30 29 28 27 26 25 24 23 22 21 20

DI-3

GROUND

DI-2

GROUND

DI-4

2

DI-1

24 VAC

24 VAC COM

W7753A UNIT

VENTILATOR

CONTROLLER

M

B

19 18 17 16

OUT 5

OUT 4

M

3

+

24 VAC

-

OUT 7

OUT 6

OUT 8

1

MAKE SURE ALL TRANSFORMER/POWER WIRING IS AS SHOWN;

REVERSING TERMINATIONS RESULTS IN EQUIPMENT

MALFUNCTION.

2

OPTIONAL 24 VAC WIRING TO NEXT CONTROLLER.

3

USE 1/4 IN (6 MM) PNEUMATIC TUBING. MINIMUM BRANCH LINE

MUST BE 6 FT. (1.8M) OR LONGER.

Fig. 11. Typical Pneumatic Transducer to W7753A.

Fig. 12. Typical 4 to 20 mA Humidity and Enthalpy Sensor

to W7753A. (For note 2, refer to Fig. 8.)

M12693

7 95-7520—02

Page 8

EXCEL 10 W7753A UNIT VENTILATOR CONTROLLER

+

24 VAC

-

31 30 29 28 27 26 25 24 23 22 21 20

OUT 1

OUT 3

OUT 2

24 VAC COM

TRIAC EQUIVALENT CIRCUIT

DI-4

DI-3

GND

W7753A

DI-2

GND

24 VAC

DI-1

UNIT

VENTILATOR

CONTROLLER

GND

SNSR

SETPT

LED

BYPASS

E GND

12345678

1

GND

AI-1 OHM

GND

AI-3 V/mA

AI-2 OHM

9101112 14 J315

19 18 17 16

OUT 6

OUT 5

OUT 4

E-BUS

AI-4 V/mA

22 VDC OUT

13

2

OUT 7

E-BUS

OUT 8

E-BUS

JACK

ML7984B

PWM VALVE ACTUATOR

24 (H)

24 (N)

PWM

(H 24 VAC)

PWM OUTPUT

T6 T5 C B W R

2

3

1

EARTH GROUND WIRE LENGTH SHOULD BE HELD

TO A MINIMUM. USE THE HEAVIEST GAUGE WIRE

AVAILABLE, UP TO 14 AWG (2.O MM

OF 18 AWG (1.O MM

2

TO ASSURE PROPER ELECTRICAL CONTACT, WIRES

MUST BE TWISTED TOGETHER BEFORE INSERTION

INTO THE TERMINAL BLOCK.

3

MAKE SURE ALL TRANSFORMER/POWER WIRING

IS AS SHOWN:REVERSING TERMINATIONS WILL

RESULT IN EQUIPMENT MALFUNCTION.

4

TURN POWER OFF BEFORE SETTING THE DIP SWITCHES.

FROM CNTRL

PWM VALVE

ACTUATOR

1234

ON

OFF

CONFIGURATION DIP SWITCHES

(LOCATED ADJACENT TO THE

INPUT TERMINAL BLOCK)

2

), FOR EARTH GROUND WIRE.

4

2

) WITH A MINIMUM

M12694

Fig. 13. Typical PWM Valve Actuator to W7753A. (For note 2, refer to Fig. 8.)

NOTE: Make sure to set the Configuration DIP Switch as shown in Fig. 13. Switches 1 through 3 set the timing of the ML7984B

valve actuator to match the W7753A outputs (0.1 sec. Min. with a max. time of 25.6 sec.).

Switch 4 determines the action of the actuator (Off = Direct Acting, On = Reverse Acting).

CHECKOUT

W7753A Checkout

Step 1. Check Installation and Wiring

Inspect all wiring connections at the W7753A terminals and

verify compliance with installation job drawings. If any wiring

changes are required, first be sure to remove power from the

controller before starting work. Pay particular attention to:

— 24 Vac power connections. Verify that multiple controllers

powered by the same transformer are wired with the

transformer secondary connected to the same input

terminal numbers on each W7753A. See Fig. 5. (Controller

configurations are not necessarily limited to three

controllers, but the total power draw including accessories

cannot exceed 100 VA when powered by the same

transformer (U.S. only). See System Engineering,

form 74-2964, for power wiring recommendations.

— Controller wiring. Be sure that each controller is wired

(terminal 1) on the W7753A to a verified earth ground

using a wire run as short as possible with the heaviest

gauge wire available, up to 14 AWG (2.0 mm

minimum of 18 AWG (1.0 mm

2

) for each controller in the

group. See Fig. 4.

— Verify Triac wiring to external controllers uses the proper

load power/24 Vac hot terminal (terminal 25 on the

W7753A).

NOTE: All wiring must comply with applicable electrical

codes and ordinances or as specified on installation

wiring diagrams.

2

) with a

31 30 29 28 27 26 25 24 23 22 21 20

OUT 1

OUT 2

24 VAC COM

TRIAC EQUIVALENT CIRCUIT

DI-4

DI-3

GND

W7753A

DI-2

GND

24 VAC

DI-1

OUT 3

OUT 4

19 18 17 16

OUT 7

OUT 6

OUT 5

OUT 8

UNIT

VENTILATOR

CONTROLLER

AI-4 V/mA

22 VDC OUT

13

2

E-BUS

E-BUS

E-BUS

2

) WITH

M12696

GND

SNSR

SETPT

LED

BYPASS

E GND

12345678

1

1

EARTH GROUND WIRE LENGTH SHOULD BE HELD TO A MINIMUM. USE

THE HEAVIEST GAUGE WIRE AVAILABLE, UP TO 14 AWG (2.O MM

A MINIMUM OF 18 AWG (1.O MM

2

TO ASSURE PROPER ELECTRICAL CONTACT, WIRESMUST BE TWISTED

TOGETHER BEFORE INSERTIONINTO THE TERMINAL BLOCK.

C7600B

+V

OUT

GND

AI-1 OHM

HUMIDITY

SENSOR

(2 TO 10 VOLT)

GND

2

), FOR EARTH GROUND WIRE.

GND

AI-3 V/mA

AI-2 OHM

9101112 14 J315

Fig. 14. Typical 2 to 10 Volt DC humidity sensor to

W7753A. (For note 2, refer to Fig. 8.)

JACK

95-7520—02 8

Page 9

EXCEL 10 W7753A UNIT VENTILATOR CONTROLLER

Verify Termination Module Placement

The installation wiring diagrams should indicate the locations

for placement of 209541B Termination Module(s). Refer to the

E-Bus Wiring Guidelines, form 74-2865, and the Excel 10 FTT

Termination Module Installation Instructions, form 95-7554.

Correct placement of the termination module(s) is required for

proper E-Bus communications.

Step 2. Startup

W7753A CONTROLLER STATUS LED

The LED on the front and center of a W7753A Controller

provides a visual indication of the status of the controller. See

Fig. 15. When the W7753A receives power, the LED should

appear in one of the following allowable states:

1. Off—no power to the processor.

2. Continuous On—processor is in initialized state.

3. Slow Blink—controlling, normal state.

4. Fast Blink—when the Excel 10 has an alarm condition.

W7753A

31 30

29 28 27

26 25

24

23 22

21

20

DI-4 GND

GND DI-1

24

24

1

VAC

VAC

COM

OUT

DI-3

DI-2

19 18 17

2

3

4

OUT

OUT

OUT

16

5

6

7

8

OUT

OUT

OUT

OUT

• Node Number: This is the Excel 10 node that has the alarm

condition (see Network Statics).

Alarm Type: The specific alarm being issued. An Excel 10 can

provide the alarm types listed in Table 1.

Broadcasting the Service Message

The Service Message allows a device on the E-Bus to be

positively identified. The Service Message contains the

controller ID number and, therefore, can be used to confirm

the physical location of a particular Excel 10 in a building.

There is one method of broadcasting the Service Message

from an Excel 10 W7753A Controller. This uses a hardware

push button on the side of the controller (see Fig. 16).

When an Assign ID command is issued from the

commissioning tool, the node goes into the

SERVICE_MESSAGE mode for five minutes. In the

SERVICE_MESSAGE mode, pressing the service pin on the

controller or the bypass button on a wall module causes the

Service Message to be broadcast on the network. All other

functions are normal in the SERVICE_MESSAGE mode.

Step 3. I/O Tests

The controller must be configured using the Excel 10 E-Vision

PC configuration tool. Once this is done, the W7753A can be

commanded to MANUAL mode, and each output can be

exercised/viewed to verify proper wiring connections and

equipment operation. See the Excel 10 E-Vision Users Guide,

form 74-2588 for details on configuring and testing W7753A

Controllers.

E

LED

BYPASS

SNSR

23

GND

SET PT

AI-1

GND

OHM

45678

A1-2

OHM

910

AI-3

V/mA

GND

11 12

AI-4

V/mA

22VDC

OUT

13 14

E-BUS

E-BUS

JACK

15

J3

M12697

GND

1

STATUS

LED

Fig. 15. LED location on W7753A.

ALARMS

When an Excel 10 has an alarm condition, it reports it to the

central node on the E-Bus (typically, the Excel 10 Zone

Manager, or Small Building Controller). See Table 1. The

information contained in an alarm message follows:

• Subnet Number: This is the E-Bus subnet that contains the

Excel 10 node that has the alarm condition. Subnet 1 is on

the Zone Manager side of the router; Subnet 2 is on the

other side of the router.

SERVICE

PIN

BUTTON

M10094

Fig. 16. Location of the service pin button.

Step 4. Verify Sequences of Operation

For the detailed descriptions of the sequences of operation,

see the Excel 10 Unit Ventilator System Engineering,

form 74-2964 Appendix B.

9 95-7520—02

Page 10

EXCEL 10 W7753A UNIT VENTILATOR CONTROLLER

Table 1. Excel 10 Alarms.

Alarm type

Name of alarm or error bit

number

NO_ALARM 0 No alarms presently detected.

INPUT_NV_FAILURE 1 One or more NV inputs have failed while receiving an update within their

specified FAILURE_DETECT_TIME.

NODE_DISABLED 2 The control algorithm stopped because the controller is in DISABLED_MODE,

or FACTORY_TEST mode. The control is shut down and disabled until power is

cycled or the node is reset. See NOTE 1 below.

SENSOR_FAILURE 3 One or more sensors have failed.

FROST_PROTECTION_ALARM 4 The space temperature is below the frost alarm limit 42.8°F (6°C) when the

mode is FREEZE_PROTECT. The alarm condition remains until the

temperature exceeds the alarm limit plus hysteresis.

INVALID_SET_POINT 5 One of the Setpoints is not in the valid range.

LOSS_OF_AIR_FLOW 6 The Fan Status DI indicates that there is no air flow when the node is

commanding the fan to run. The control is shut down and disabled until power is

cycled or the node is reset. The alarm is not issued until FanFailTime seconds

have elapsed since the loss-of-flow condition was first reported.

DIRTY_FILTER 7 The pressure drop across the filter exceeds the limit and the filter requires

maintenance. The control runs normally.

SMOKE_ALARM 8 The smoke detector has detected smoke and the node has entered an

emergency state.

IAQ_OVERRIDE 9 The indoor air quality sensor has detected that the indoor air quality is poorer

than the desired standard and additional outdoor air is being brought into the

conditioned space.

LOW_LIM_ECON_CLOSE 10 The economizer has to close beyond the minimum position to prevent the

discharge air temperature from going below the discharge temperature low

limit.

DRIP_PAN_FULL 11 Drip pan maintenance is required. Cooling control is disabled. Fan continues to

run.

FREEZE_STAT 12 Very Cold Temperature detected inside the Unit Ventilator Cabinet. Control

closes OA Damper, and open heat valve.

OAQ_ALARM 13

The configured outdoor air quality sensor has detected CO or CO

2

levels that

exceeds OaQStPt (plus 30 ppm hysteresis). When there is an OAQ_ALARM,

the economizer damper is closed.

RETURN_TO_NORMAL 128 Return to no alarm after being in an alarm condition. This code is added

numerically to another alarm code to indicate that the alarm condition has

returned to normal.

ALARM_NOTIFY_DISABLED 255 The alarm reporting was turned off by the nviManualMode. No more alarms are

reported until nviManualMode turns on alarm reporting or upon application

restart.

NOTE: The node can be reset by switching the node to MANUAL and then switching to the normal operating mode

(using DestManMode).

Also, the Excel 10 network variables, AlarmLogX, where X is 1 through 5, that store the last five alarms to occur in the

controller, are available. These points can be viewed through XBS, XI584 or E-Vision.

95-7520—02 10

Page 11

EXCEL 10 W7753A UNIT VENTILATOR CONTROLLER

11 95-7520—02

Page 12

EXCEL 10 W7753A UNIT VENTILATOR CONTROLLER

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Toronto, Ontario M1V 4Z9

Honeywell GmbH

Böblinger Straße 17

D-71101 Schönaich

customer.honeywell.com

® U.S. Registered Trademark

© 2009 Honeywell International Inc.

95-7520—02 K.K. Rev. 03-09

Loading...

Loading...