Page 1

HONEYWELL EXCEL 5000 OPEN SYSTEM

Excel 100C

CONTROLLERS

INSTALLATION INSTRUCTIONS

Copyright © 2009 Honeywell Inc. • All Rights Reserved EN1R-0144GE51 R1109

Page 2

EXCEL 100C INSTALLATION INSTRUCTIONS

Trademark Information Echelon, LON, LONMARK, LONWORKS, LonBuilder, NodeBuilder, LonManager,

LonTalk, LonUsers, LonPoint, Neuron, 3120, 3150, the Echelon logo, the LONMARK

logo, and the LonUsers logo are trademarks of Echelon Corporation registered in

the United States and other countries. LonLink, LonResponse, LonSupport, and

LonMaker are trademarks of Echelon Corporation.

EN1R-0144GE51 R1109 2

Page 3

EXCEL 100C INSTALLATION INSTRUCTIONS

Contents

REVISION OVERVIEW.................................................................................................................................................................. 5

INTRODUCTION............................................................................................................................................................................ 6

General Safety Instructions....................................................................................... 6

Technical Requirements............................................................................................ 6

Auxiliary Devices ...................................................................................................... 6

DEVICE ASSEMBLY AND SYSTEM INSTALLATION................................................................................................................... 7

Assembly of Controller Housing................................................................................ 7

Control Cabinet Installation....................................................................................... 8

Meaning of Control Lamp ......................................................................................... 9

Terminal Assignment Overview for Excel 100C ...................................................... 10

General Remarks about Electrical Connections ......................................................11

Cable Routing ..........................................................................................................11

Shielding of Sensor and Actuator Cables.................................................................11

Shielding of Data Transmitting Cables (System Bus and Operator Interface)......... 12

System Ground....................................................................................................... 12

RFI Suppression ..................................................................................................... 12

Cable Lengths and Cross Sectional Areas.............................................................. 13

Line Power Supply.................................................................................................. 14

Communication....................................................................................................... 14

ELECTRICAL CONNECTION...................................................................................................................................................... 16

Terminal Assignment for Digital Inputs .................................................................... 18

Terminal Assignment for Relay Modules ................................................................. 19

Terminal Assignment for Relays and Actuators....................................................... 21

Connection of Alarm Relays.................................................................................... 22

Normally Open/Normally Closed Attribute............................................................... 22

System Bus (C-Bus) ............................................................................................... 23

Connections to Operating Device ........................................................................... 24

REMOTE COMMUNICATIONS.................................................................................................................................................... 30

Modem or ISDN* Terminal Adapter Connections .................................................... 31

Modem Requirements ............................................................................................ 31

No Set-Up for Standard Modem Behavior............................................................... 31

Automatic Baud Rate Synchronization.................................................................... 32

Auto / Manual Answer Detection............................................................................. 32

Resetting the Modem.............................................................................................. 32

Set-Up for Special Modem Behavior....................................................................... 32

Set-Up for In-house Telephone Systems ................................................................ 32

Set-Up for Limited Communication Speed.............................................................. 33

Troubleshooting ...................................................................................................... 33

BACKLIGHT ................................................................................................................................................................................ 33

DIMENSIONS............................................................................................................................................................................... 34

3 EN1R-0144GE51 R1109

Page 4

EXCEL 100C INSTALLATION INSTRUCTIONS

U.S. SPECIFICATIONS ................................................................................................................................................................36

Electrical Connection of Sensors.............................................................................36

Transformers ...........................................................................................................38

Cables .....................................................................................................................38

Relays .....................................................................................................................39

Repeaters................................................................................................................39

EUROPEAN SPECIFICATIONS ...................................................................................................................................................40

Electrical Connection of Sensors.............................................................................40

Transformers ...........................................................................................................43

Relays .....................................................................................................................43

Cables .....................................................................................................................43

Repeaters................................................................................................................44

EN1R-0144GE51 R1109 4

Page 5

EXCEL 100C INSTALLATION INSTRUCTIONS

REVISION OVERVIEW

The changes listed below show the revisions that have been made in comparison to the previous revision.

Page

Changes

26

44

NOTE: The Excel 100 has been developed to meet control requirements worldwide. Some referenced applications /

accessories have been developed to meet specific regional requirements and may not be available or applicable in all

locations.

The adapter cables have been changed.

The ordering information for repeaters with/without housing has been changed.

5 EN1R-0144GE51 R1109

Page 6

EXCEL 100C INSTALLATION INSTRUCTIONS

INTRODUCTION

General Safety Instructions

Assembly by trained personnel

CAUTION

Assembly must be completed by trained personnel.

Persons who are not trained and authorized to carry out heating and electrical

installation may not carry out assembly work even if this appears possible on the

basis of the instructions.

Install with power off

CAUTION

All assembly work must be completed with power off.

If some parts of the system are nonfunctional or have not yet been received,

assembly may proceed only if power is disconnected from those assemblies. Simply

switching off the unit is insufficient.

Observe regulations

IMPORTANT

The regulations VDE 0800, VDE 0100, U.S. National Electric Code NEC or

others that replace them, absolutely must be observed.

Follow instructions step by step Follow instructions in accordance with the progress of the assembly step by step.

Skip sections only when requested to do so in the text.

Technical Requirements

All devices ready? Assembly can start only if all system components have been installed and are ready

to be operated and the control and measuring sensor cables have been connected

to the control cabinet.

All cables laid? All cables must be clearly marked and laid with appropriate auxiliary accessories

(cable ducts, cable ties).

Delivery complete? The delivery of all system parts must be complete.

Auxiliary Devices

Use documentation

IMPORTANT

Install all devices according to the documentation supplied with the

equipment.

The instructions are designed in such a way that they provide a suggestion for all

foreseeable situations. Should you be confronted with problem during assembly,

please contact your appropriate dealership (see last page). If there is no one to deal

with your query at that particular moment, please contact technical sales support at

the factory.

EN1R-0144GE51 R1109 6

Page 7

EXCEL 100C INSTALLATION INSTRUCTIONS

DEVICE ASSEMBLY AND SYSTEM INSTALLATION

1

3

5

7

2

4

6

8

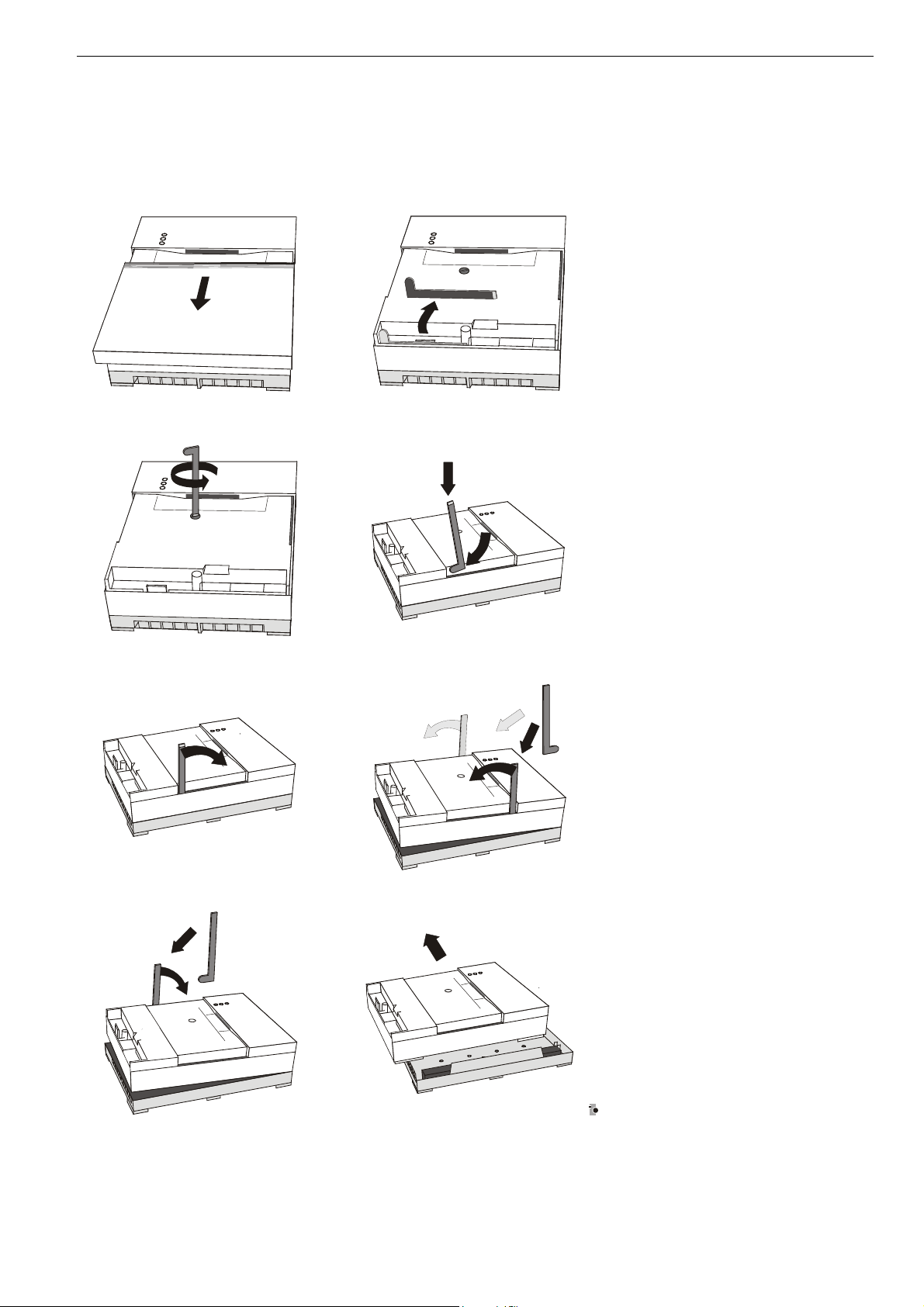

Assembly of Controller

Housing

1 Open cover

2 Remove tool

3 Remove screw

4 Loosen housing cover from

base

5 Loosen front right

6 Loosen rear

7 Loosen left

8 Lift housing off base

CB-0700-Mb

7 EN1R-0144GE51 R1109

Page 8

EXCEL 100C INSTALLATION INSTRUCTIONS

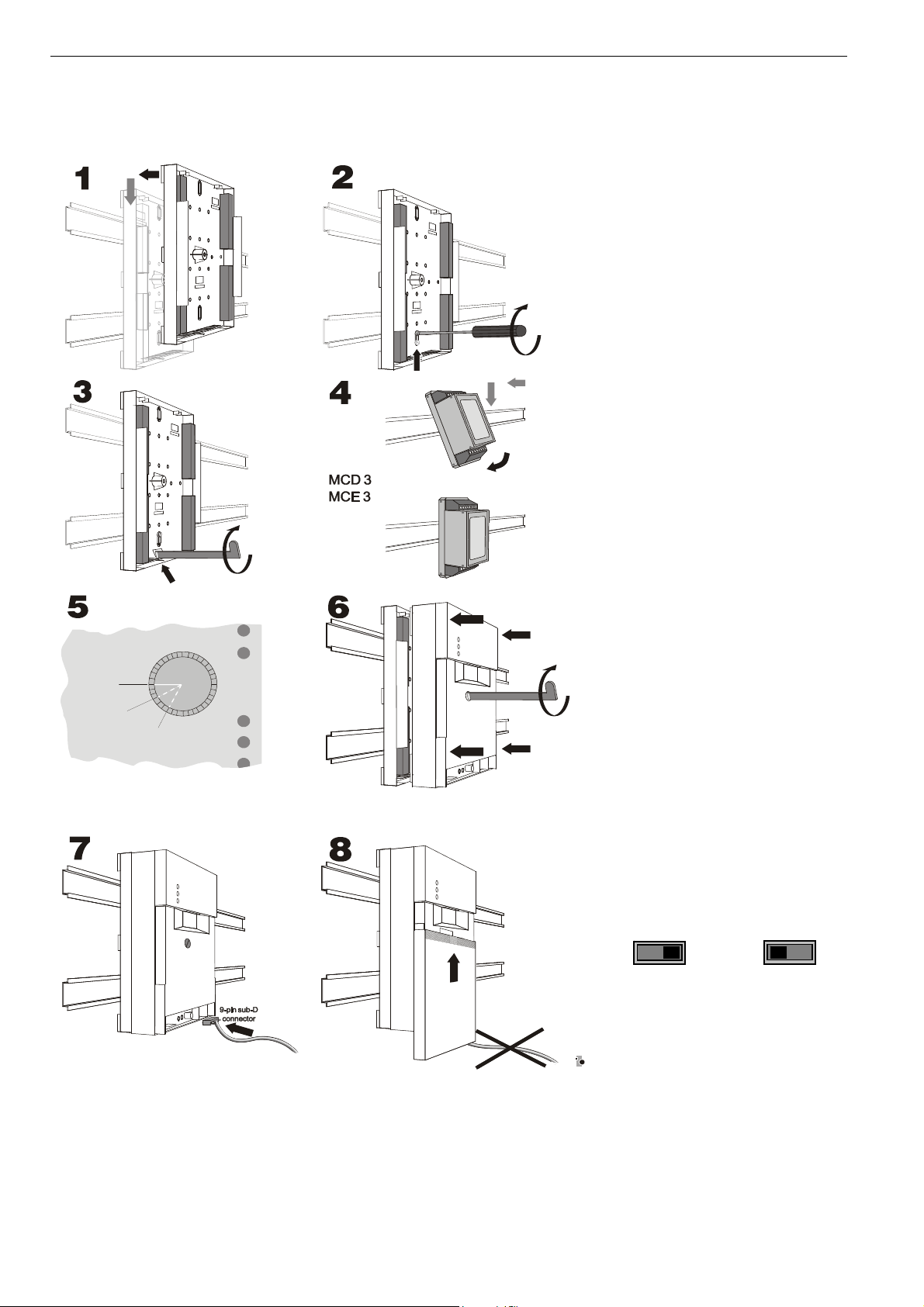

Control Cabinet Installation

XD505

XD508

middle

XD508

beg./end

IMPORTANT

The maximum ambient temperature

for the Excel 100C depends on the

mounting orientation:

Vertical

mounting: max. 122°F (50°C)

Horizontal

mounting: max. 113°F (45°C)

1 Hang onto DIN rails

(see pages 34 and 38 for

mounting dimensions)

2 Secure base

3 Cable holes

4 Snap relay modules into

place (optional)

Electrical connection

(see pages 10, 19 to 21)

5 Set the bus termination

switch on the back of the

housing according to the

system configuration

(see page 14 for details).

6 Fit housing

Make sure it is straight

EN1R-0144GE51 R1109 8

7 Connect operating device

(see pages 24 and up)

IMPORTANT

Set the port selector switch (left to the

sub-D port) according to whether the

front port or the rear terminals should

be active (see page 30 for details).

Front port Rear terminals

active active

b

1

0

7

0

8 Close cover

B

C

NOTE: Cover cannot be mounted

with front connector plugged.

Page 9

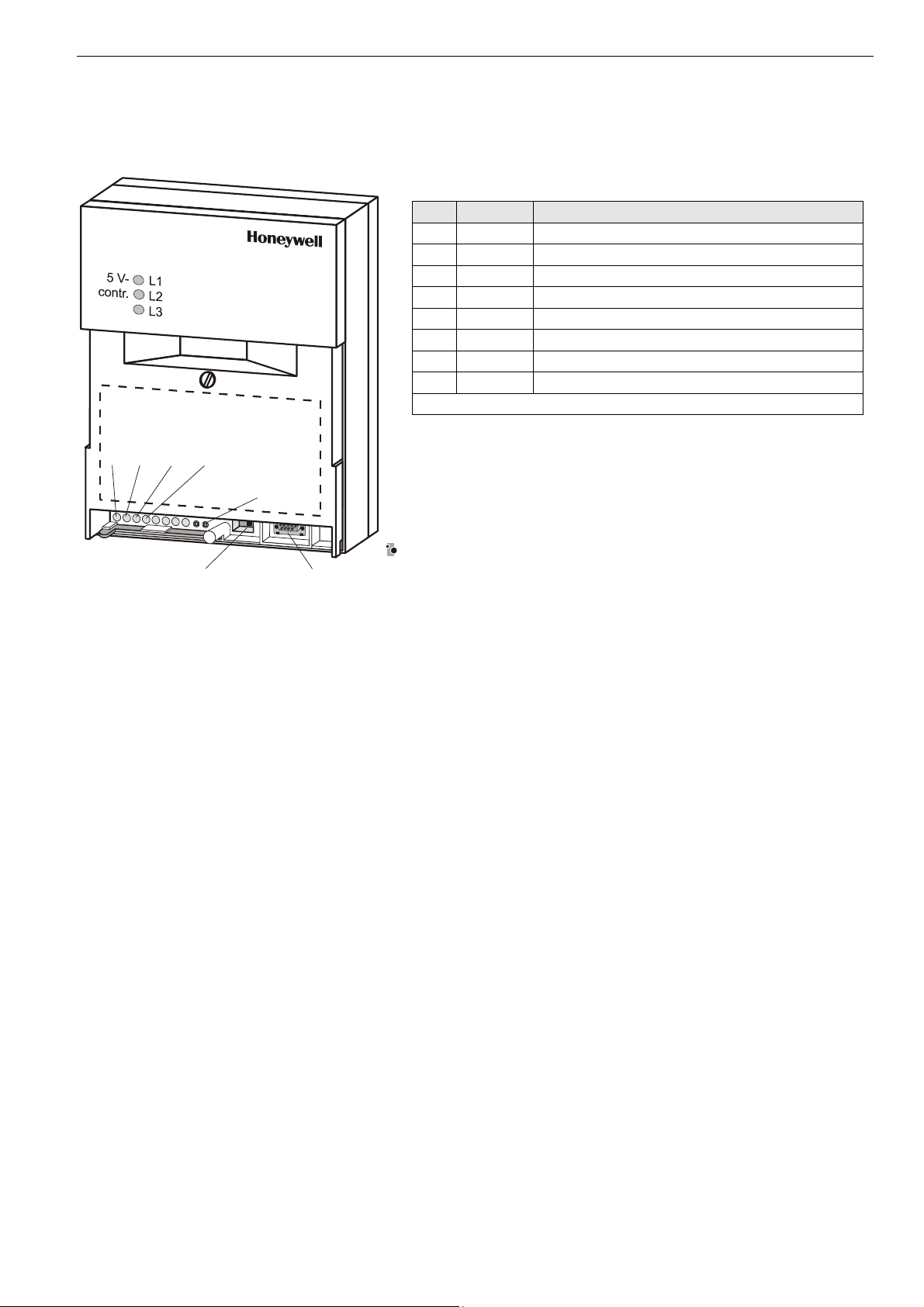

Meaning of Control Lamp

T

L4 L5 L6 L7

RESET

BUTTON

PORT

SELECTOR

SWITCH

FRONT

SERIAL

POR

EXCEL 100C INSTALLATION INSTRUCTIONS

Table 1. Control Lamps and their meanings

LED color status/meaning

L1 YELLOW Lit: Main voltage is present

L2 GREEN Lit: Program is running

Dark: Program is stopped

L3 RED Lit continuously: ALARM; program is stopped

L4 YELLOW Lit : Controller is transmitting via B-port

L5 YELLOW Lit: Controller is receiving via B-port

L6 YELLOW Lit: Transmission via C-bus to system bus interface

L7 YELLOW Lit: Reception via C-bus from system bus interface

L8, L9, L10, and L11 are for future use

NOTE: L4 to L11 are visible only if the cover plate has been removed.

IMPORTANT

The RESET button reboots the controller’s CPU. All plantspecific data held in the controller will be lost after a reboot.

CB-0603-E1

See section "Setting the Port Selector Switch" on page 30 for details on

setting the port selector switch and serial port.

Before rebooting, it is highly recommended that you save the

current application to the flash EPROM.

9 EN1R-0144GE51 R1109

Page 10

EXCEL 100C INSTALLATION INSTRUCTIONS

{

{

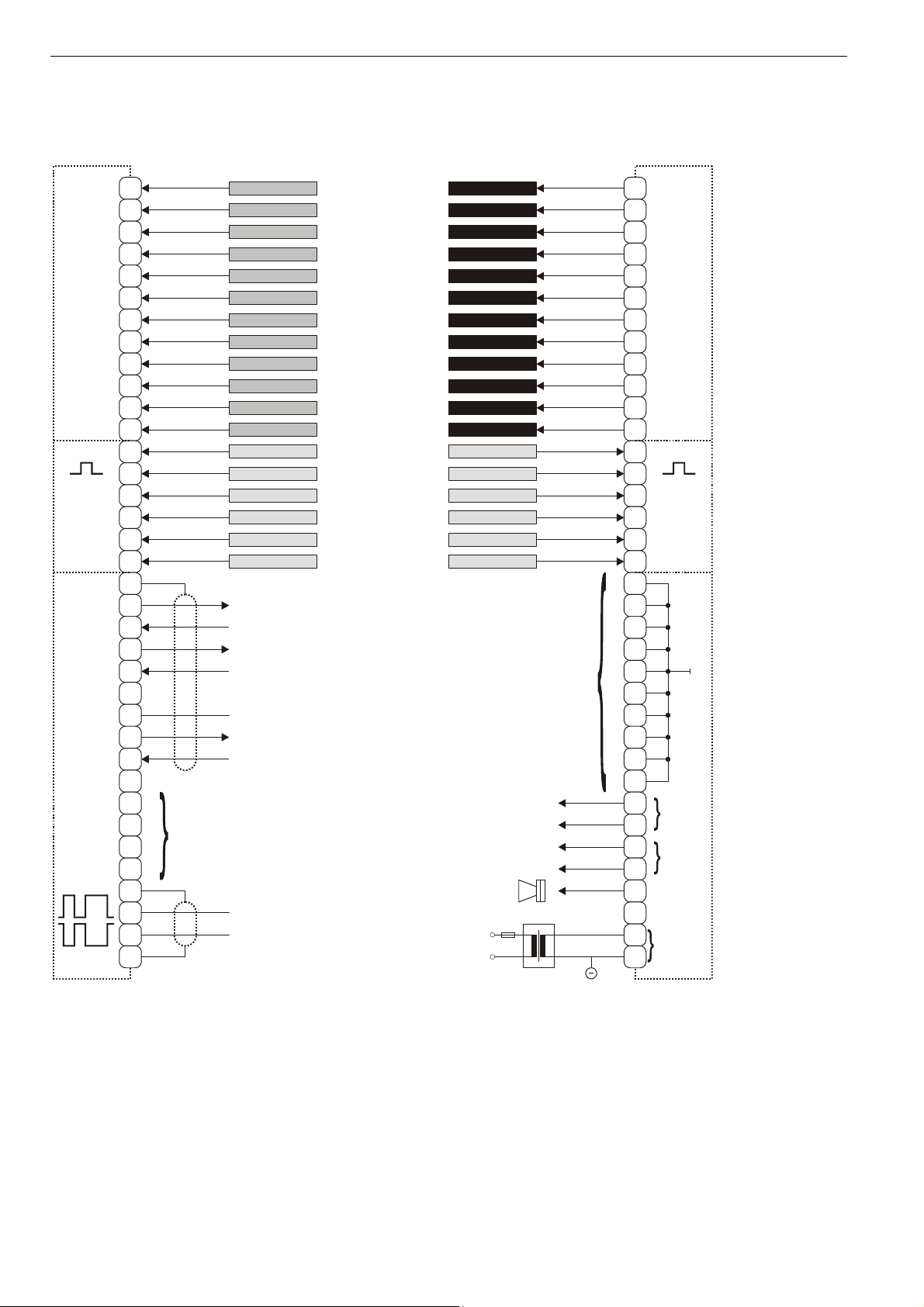

Terminal Assignment Overview for Excel 100C

ANALOG

INPUTS

DIGITAL

INPUTS

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

1

2

3

4

5

6

7

8

9

AI 1 xx0101

AI 2 xx0102

AI 3 xx0103

AI 4 xx0104

AI 5 xx0105

AI 6 xx0106

AI 7 xx0107

AI 8 xx0108

AI 9 xx0201

AI 10 xx0202

AI 11 xx0203

AI 12 xx0204

DI 1 xx0301

DI 2 xx0302

DI 3 xx0303

DI 4 xx0304

DI 5 xx0305

DI 5 xx0305

shield

T x D

R x D

+5 V (Xi582), RTS (modem)

CTS

not used

GND

DTR

DCD

not used

Output voltage 24 V / 300 mA is

protected against short-circuiting.

After short-circuiting, it takes time

(approx. 60 sec.) for voltage to

recover.

24V relay module

(MCD3/MCE3, only!)

reserved

C+

system bus

C-

IMPORTANT

Do not connect system bus shield to earth. Use terminals 33 and 36.

NOTE: Use terminals 65 and 66 for relay modules MCD 3 or MCE 3 only.

Terminals 65 and 66 provide a pulsed 24 Vdc output which is not suitable

to connect direct relays.

Do not use reference voltage 10 V (terminal 67, 68) to supply other

devices.

AO 1 xx0401

AO 2 xx0402

AO 3 xx0403

AO 4 xx0404

AO 5 xx0405

AO 6 xx0406

AO 7 xx0407

AO 8 xx0408

AO 9 xx0501

AO 10 xx0502

AO 11 xx0503

AO 12 xx0504

DI 7 xx0307

DI 8 xx0308

DI 9 xx0309

DI 10 xx0310

DI 11 xx0311

DI 12 xx0312

alarm

(not used)

transformer

REF.

common

37

38

39

40

41

42

OUTPUTS

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

-

65

+

66

+

67

+

68

69

70

71

72

21-28 Vdc

ANALOG

DIGITAL

INPUTS

24 V_

300 mA

10 V

10 mA

24 Vac

+/-20%

or

EN1R-0144GE51 R1109 10

Page 11

General Remarks about Electrical Connections

Observe all general VDE, NEC and local wiring regulations when making electrical

connections.

CAUTION

Electrical connection work is to be carried out by a qualified technician.

CAUTION

Using free terminals as support terminals can cause system damage.

Free terminals in the base plate must not be used as wiring support points under

any circumstances (danger of damage)! The electrical connection is to be made at

the base plate. The appropriate connection diagrams are on pages 10 and 11.

Further wiring diagrams are contained in the circuit diagrams.

IMPORTANT

Do not disconnect the Excel 100C controller from power supply for more

than 72 hours.

The Excel 100C is equipped with a gold capacitor buffer that holds the

RAM data and supplies the real-time clock for 72 hours in case of a power

outage. Beyond this period of time, all RAM data and time information are

lost.

EXCEL 100C INSTALLATION INSTRUCTIONS

Cable Routing

Minimum distance to mains cables:

10 mm (0.4 in.) All signal and output cables (low voltage) should be regarded as communication

circuits in accordance with VDE 0100, VDE 0800 and NEC, it should therefore be

routed separately from line voltage. Minimum distance 10 cm (4 in.) for unshielded

cable. Minimum distance 10 mm (0.4 in.) for shielded cable. Joining sensor cables

should be avoided.

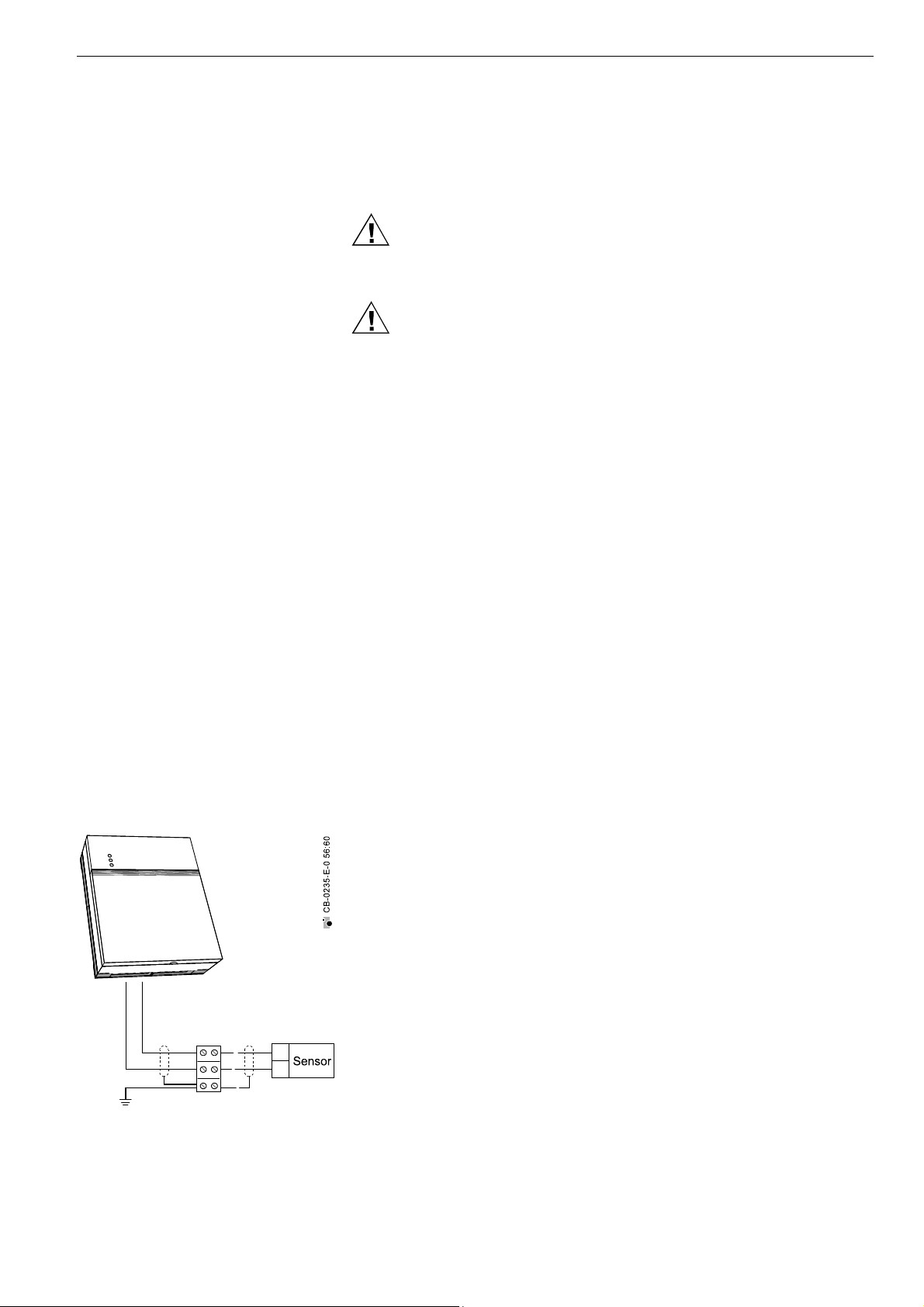

Shielding of Sensor and Actuator Cables

Shielding of sensor and actuator cables with low protective voltages is not

necessary if the general guidelines on cable routing are observed (see "Cable

Routing" on page 11). If, under certain circumstances, the routing guidelines cannot

be observed, shielded cable must always be used.

IMPORTANT

Shielded cables must be grounded on one side only.

The grounding of the shielded cable must be as shown in the diagram.

Shielding on one sideat the control cabinet ground: Shielding of I/O cables

connected to peripherals such as

sensors and actuators must be

grounded at the control cabinet side,

only; this to avoid ground loops.

11 EN1R-0144GE51 R1109

Page 12

EXCEL 100C INSTALLATION INSTRUCTIONS

Shielding of Data Transmitting Cables (System Bus and Operator Interface)

IMPORTANT

Data transmitting cables must always be shielded to prevent radio

interference.

1. System Bus Cables

Connect shield of system bus cable

on both sides System bus cables must be shielded on both sides at the base plate terminal 33

and 36 of the controller device. Connection to the control cabinet ground or other

ground points is not permitted (see WARNING below)!

2. Operator Interface (for external operating devices, only)

To connect remote operators units, ready-made cables are available (XW582,

XW584, XW585) with the shield already connected to the computer module plug

end.

For detailed information on cable types to be used in accordance with regional

requirements, please refer to the U.S. and European Specifications chapters.

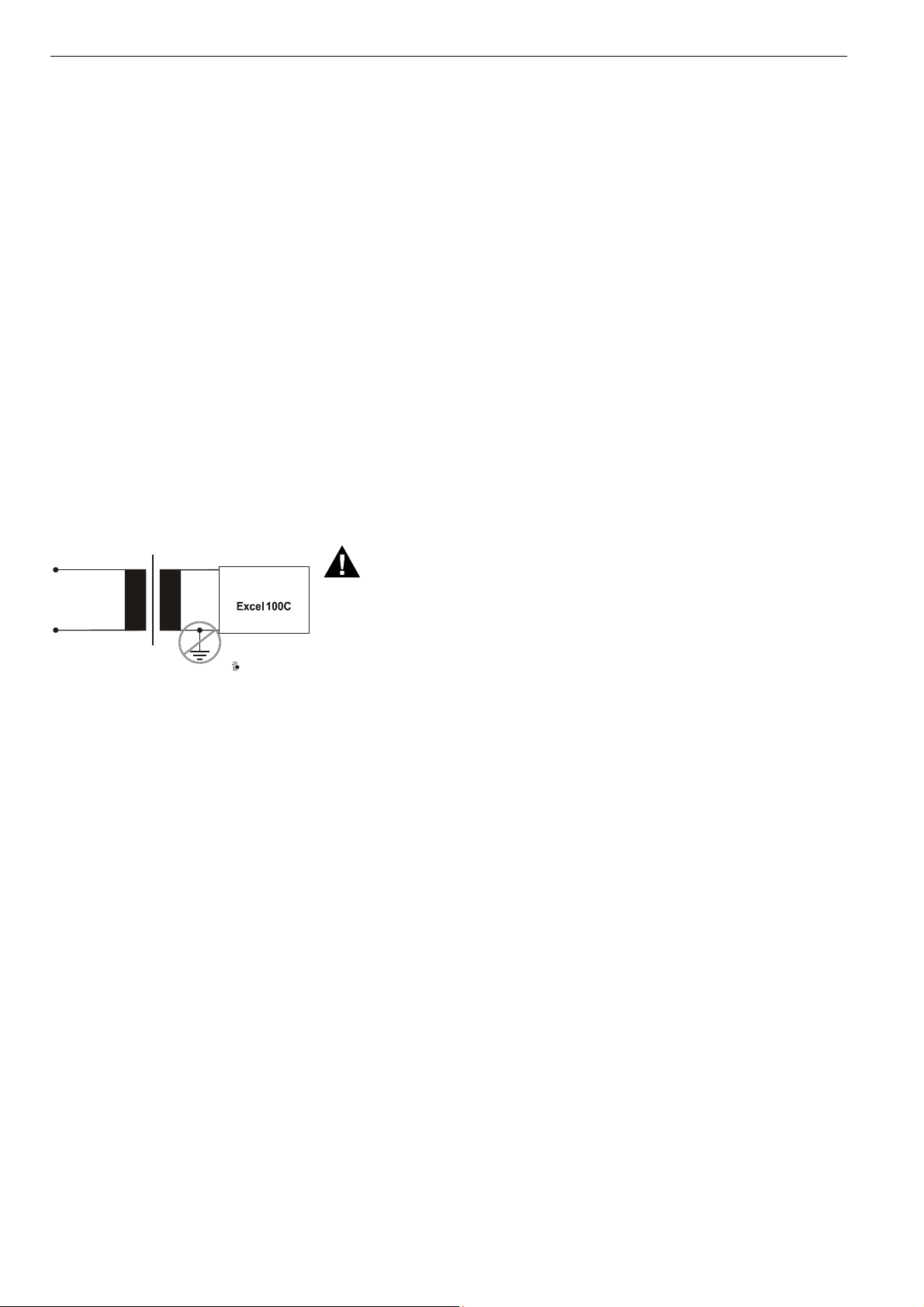

System Ground

Primary: Secondary:

RFI Suppression

CB-0236b

WARNING

High voltage

Risk of electrical shock or equipment damage

The controller's system ground must have no connection with the control cabinet

ground!

NOTE: A document providing additional information on system grounding (if

Honeywell actuators are RFI-suppressed as a standard in accordance with

EN 50 081-1/EN 55 022.

demanded) is available via the Honeywell Technical Assistance Center

(TAC) or, for Honeywell employees, on the Docu Server under:

http://web.ge51.honeywell.de/dep/mc/TAC_Tips.

EN1R-0144GE51 R1109 12

Page 13

Cable Lengths and Cross Sectional Areas

SFO

Cross sectional areas related to cable length

Table 2. Signal types and cross-sectional areas

EXCEL 100C INSTALLATION INSTRUCTIONS

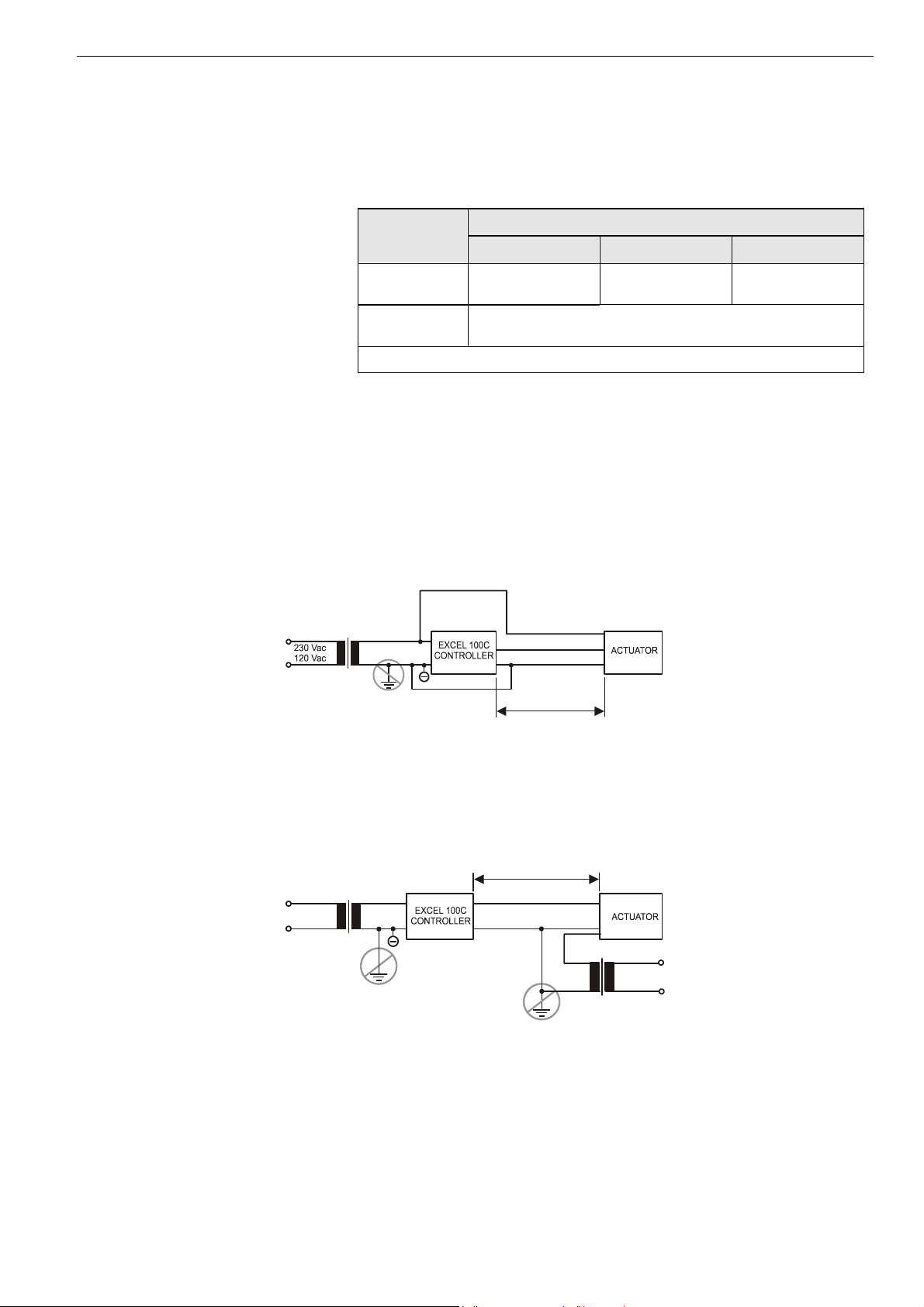

Cabling of Actuator with 24 Vac

Supply and max. 550 ft (170 m)

IMPORTANT

For detailed information on cable types to be used in accordance to regional

requirements, please refer to the U.S. and European Specifications chapters.

PRIMARY

VOLTAGE

TRANSFORMER

type of signal

cross sectional area

300 ft (100 m) 550 ft (170 m) 1300 ft (400 m)

power supply

(24 Vac)

low-current

16 AWG

( 1.5 mm

2

)

14 AWG

( 2.5 mm2)

20 AWG ( 0.5 mm2)

-

signals*

*E.g. for 0-10 V sensors, totalizers, digital inputs, 0…10 V signals for actuators.

The max. length of a signal cable with 24 Vac supply is 550 ft (170 m).

The max. length of a two-wire, 0 to 10 Vdc signal cable is 1,300 ft (400 m).

The secondary side of the transformer must not be connected to earth

ground.

0000056c

24 Vac

24 V

Y

GND

MAX. 550 ft (170 m)

MIN. 14 AWG (2.5 mm )

2

Cabling of Actuator with 24 Vac Supply

from External Transformer and

max. 1,300 ft (400 m) If the distance between the controller and actuator or sensor with 24 Vac supply is

greater than 550 ft (170 m), a separate external transformer for the actuator or

sensor is necessary.

PRIMARY

VOLTAGE

230 Vac

120 Vac

TRANSFORMER

24 Vac

MAX. 1300 ft (400 m)

MIN.20 AWG (0.5 mm )

0 TO 10 Vdc

GND

24 Vac

2

EXTERNAL

TRAN

230 Vac

120 Vac

PRIMARY

VOLTAGE

RMER

00000057c

NOTE: The transformer must be chosen in accordance with specifications listed in

the U.S. and European Specifications chapters.

13 EN1R-0144GE51 R1109

Page 14

EXCEL 100C INSTALLATION INSTRUCTIONS

a

IMPORTANT

Line Power Supply

The Excel 100C Controller is powered by an external transformer.

PRIMARY: SECONDARY:

230 Vac

120 Vac

24 Vac

+ 2 0 %

- 20 %

9

6

0

0

0

0

0

Transformer requirements for one Excel 100C Controller:

Secondary

Voltage 24 Vac 20% or 21-28 Vdc

Current 1.1 A

Power 15 VA (Excel 100C, only; no MCE/MCD)

25 VA (if fully equipped with MCE/MCD)

The transformer, already installed in the cabinet, can be used to supply several controllers, communication devices, or peripherals (e.g. actuators, etc.) – provided it

delivers sufficient power.

RIN-APU24 is supported.

For detailed information on transformers to be used in accordance to regional

requirements, please refer to the U.S. and European Specifications chapters.

We recommend installing a fuse on the secondary side of the transformer

in order to protect the devices against miswiring.

Standard Transformers

Requirements for standard transformers

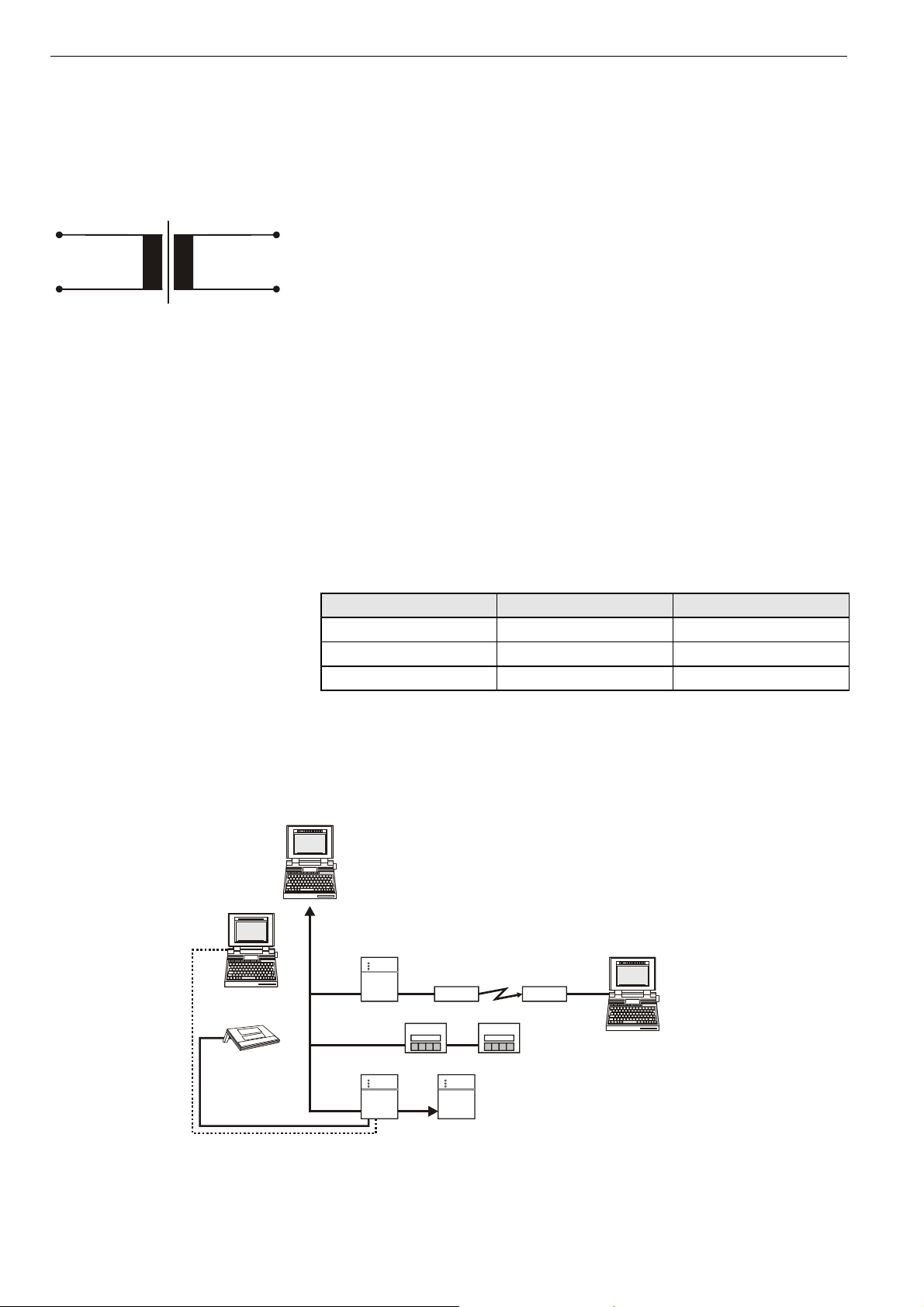

Communication

EBI/SymmetrE

XL-ONLINE

C-BUS

Table 3. Requirements for standard transformers

output voltage impedance AC current

24.5 Vac to 25.5 Vac 1.15 Ω max. 2 A

24.5 Vac to 25.5 Vac 0.40 Ω max. 6 A

24.5 Vac to 25.5 Vac 0.17 Ω max. 12 A

Excel devices may communicate in different modes and lines. The principal

communication scheme is shown in the accompanying figure.

EBI/SymmetrE

Excel 100C

OTHER

CONTROLLERS

Modem/ISDN

COMMUNICATION

Modem/ISDN

Excel 500 Excel 600

Modem

XI581/582

(providing bus-wide

access to all devices

connected to C-Bus)

EN1R-0144GE51 R1109 14

Excel 100C Excel 100C

Page 15

EXCEL 100C INSTALLATION INSTRUCTIONS

C-Bus Termination

Switch settings for C-Bus termination The back of the Excel 100C housing is equipped with a rotary switch for the C-Bus

to set the bus termination appropriate for the communication speed (see Table 4

and figure below).

Table 4. Switch settings and communication speed

XD505

XD508

middle

XD508

beg./end

switch

setting

up max. 9.6 Kbaud - XD505A, XL20XD

middle max. 76.8 Kbaud middle of C-Bus XD508, XL20XD508

BusSw_1

down max. 76.8 Kbaud beginning or end of C-Bus XD508, XL20XD508

communication

speed

controller location compatibility

NOTE: Modules listed in the "Compatibility" column are used in Excel

20/100B/500/600 Controllers.

Connection to modem This figure shows the connection between Excel 100C and modem via cable

XW571 (see page 31 for details).

19

SHIELD

TxD

RxD

+5 V

CTS

not used

GND

DTR

DCD

not used

YELLOW

GREEN

BLUE

VIOLET

WHITE

BLACK

BROWN

20

21

22

23

24

25

26

27

28

2

3

4

5

6

7

20

8

22

CB-0209b

Lightning Protection

Please check with your local Honeywell representative for information on lightning

protection.

15 EN1R-0144GE51 R1109

Page 16

EXCEL 100C INSTALLATION INSTRUCTIONS

ELECTRICAL CONNECTION

Terminal Assignment for Analog Inputs

Specifications

Twelve inputs (AI1 to AI12)

0 to 10 Vdc (see left drawings for impedance)

0 to 20 mA (via external 500-ohm resistor)

4 to 20 mA (via external 500-ohm resistor)

NTC 20k ohms (-58°F to +302°F (-50°C to +150°C))

PT 1000 (-58°F to +302°F (-50°C to +150°C))

Protected inputs up to 40 Vdc/24 Vac

12-bit resolution

75 mV accuracy (0 to 10 V)

Accuracy of Analog Input Sensors

Table 5. Accuracy of analog input sensors in relation to temperature

measurement error / ± Kelvin (without sensor

range

Pt1000 NTC (20k ohms)

-58 to -4°F (-50 to -20°C) 1.2 K 5.0 K

-4 to 32°F (-20 to 0°C) 0.7 K 1.0 K

32 to 86°F (0 to 30°C) 0.5 K 0.3 K

86 to 158°F (30 to 70°C) 0.7 K 0.5 K

158 to 212°F (70 to 100°C) 1.2 K 1.0 K

212 to 266°F (100 to 130°C) 1.2 K 3.0 K

266 to 302°F (130 to 150°C) 1.2 K 5.5 K

For examples on electrical connection of various sensors, refer to the U.S. and European Specifications chapters.

tolerance)

EN1R-0144GE51 R1109 16

Page 17

Pull-Up Resistor Handling

A

A

EXCEL 100C INSTALLATION INSTRUCTIONS

Case 1 Case 2 Case 3

10 V

24.9 k

Ω

(pull-up)

10 V

24.9 k

(pull-up)

Ω

5 V

18.2 k

(pull-up)

Ω

A

100 k

150 k

150 k

Ω

49.9 k

D

Ω

Ω

49.9 k

D

Ω

Fig. 1. Input circuit diagram

Table 6. Pull-up resistor handling

pull-up load-free voltage

device

voltage hardware

de-

activated

by @(8

XF521,

XF521A

XF526 fixed NO

10 V

XFL521,

XFL521A/B

Smart I/O

XFC

5 V

fixed NO YES case 2 8.89 V

optional

switch-off

YES

YES

configured

by DIP

switch

configured

by plug-in

activated

for DI on AI

NO

(3

config.(6 case 1

YES

(4

NO

XL20 fixed NO YES case 2 8.89 V

XL50

XL100,

10 V

XL100A

XL100B

XL100C

(1

controller firmware ≥ 2.03;

(2

controller firmware ≥ 2.02;

(3

controller firmware ≥ 2.03 (local/shared mode), CARE ≥ 5.00.01 (open mode);

(4

CARE ≥ 5.00.01;

(5

controller firmware < 2.04;

(6

controller firmware < 2.04 (local/shared mode), CARE ≥ 5.01.xx (open mode);

(7

CARE ≥ 5.01.xx;

(8

Assigning "@" as first digit of input characteristic name (e.g.: "@0-10V") in CARE text editor disables the pull-up resistor.

optional

switch-off

fixed

optional

switch-off

YES(2 YES(5 case 1 0 V

NO

NO

YES configurable

YES(1 NO

Ω

100 k

D

Ω

input

circuit

diagram

(Fig. 1)

YES case 2 8.89 V

with NTC

or low-

impedance

input

8.89 V

for voltage

input or

high-

impedance

input

0 V

YES(7 case 3 5 V

YES case 2 8.89 V

YES(5

case 1

8.89 V

0 V

17 EN1R-0144GE51 R1109

Page 18

EXCEL 100C INSTALLATION INSTRUCTIONS

Terminal Assignment for Digital Inputs

DC voltage signals or AC voltage signals can be processed via the digital

inputs. The Excel 100C has twelve digital inputs.

From 5 V input voltage upwards, the digital signal is set to status 1. With a

hysteresis of 2.5 V, the digital signal must fall below 2.5 V so that the

digital status 0 is transmitted (R

IMPORTANT

Line voltage must not be present at any of the terminals under any circumstances. Devices with 110 V/230 Vac must be isolated

by a transformer.

= 15 kΩ).

i

Six additional digital inputs are available at the terminals 49 to 54 for switching to

I, J, or K.

Table 7. Use of input terminals as counter inputs

input terminals frequency pulse duration pulse break bounce time

13 to 14 max. 15 Hz min. 20 ms min. 33 ms max. 5 ms

15 to 18, 49 to 54 max. 0.4 Hz min. 1.25 sec min. 1.25 sec max. 50 ms

EN1R-0144GE51 R1109 18

Page 19

Terminal Assignment for Relay Modules

The relay modules facilitate the control of peripheral devices with high load via the

analog outputs of the controller.

The analog outputs provide an output current of 0 to 20 mA. Via an external 500-Ω

resistor, an actuator with an input impedance of 500 Ω can be used as 0 to 20 mA

device.

Specifications

Twelve outputs (AO1 to AO12)

0 to 10 Vdc (+10%) output

0 to 20 mA output current (via external 500-Ω resistor, see above)

0.1 mA max. sink output current

Protected inputs up to 24 Vac

8-bit resolution

100 mV/1 LSB accuracy (1 LSB = 43 mV)

100 mV/1 LSB zero point (1 LSB = 43 mV)

EXCEL 100C INSTALLATION INSTRUCTIONS

The relay modules are supplied via the

special relay connection of the controller

(terminals 65/66)

IMPORTANT

Important during connection:

1. Correct polarity

2. Under no circumstances may

a relay module be connected to

the reference voltage.

Several relay modules can be connected

in series via the bridged terminal pair:

Plus pole: Terminals 11/12 of the relay

Minus pole: Terminals 13 to 16 of the relay

MCD 3:

L (Fig. left)

Terminal 17 controls the changeover

contact K3. Terminal 18 controls the ON

contacts K1, K2. Ground can be looped

through terminals 2/3.

19 EN1R-0144GE51 R1109

Page 20

EXCEL 100C INSTALLATION INSTRUCTIONS

MCE 3:

M (Fig. left)

Terminal 16 controls the ON contact K3.

Terminal 17 controls the changeover contact K2. Terminal 18 controls the changeover contact K1.

IMPORTANT

It is not allowed to draw more

than 300 mA out of terminal

65/66.

The number of MCE and MCD modules

that can be used depends only on the

available AOs.

This means:

5 MCE 15 relays incl. watchdog alarm

terminal 69

or

6 MCD 12 relays

EN1R-0144GE51 R1109 20

Page 21

Terminal Assignment for Relays and Actuators

EXCEL 100C INSTALLATION INSTRUCTIONS

N Connection of external relays. Each

analog output can be connected to an

external relay which has similar data to

the relays described under the U.S. and

European Specifications chapter.

The impedance of the relay must be a

min. of 500 Ω for an output voltage of

11 V; an impedance of less than 500 Ω

can cause erroneous output voltage.

The output current is limited up to max.

20 mA.

O Type of connector for actuators with

standard input signal 0 to 20 mA, but the

sensor input impedance must be 500 Ω.

Each channel can be used as an analog

output 0 to 10 V, or, respectively, as

current output 0 to 20 mA with an external

500 Ω impedance.

The outputs are protected against overvoltage and overload 24 Vac.

21 EN1R-0144GE51 R1109

Page 22

EXCEL 100C INSTALLATION INSTRUCTIONS

Connection of Alarm Relays

66 65

11 12 13 14 15 16 17 18

MCE 3

K2

K1

12345678

The selection of a signal transmitter for the

watchdog alarm is optional. It is recommended

that a switch for turning off the alarm be

provided.

NOTE:

Terminal 69 is used to control the module MCE

3, only. The digital output cannot be used for a

relay.

COMMON

not used

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

+

+

24V~

K3

Watchdog

max. 240 V /

External supply

1

E

8

0

7

0

B

A

2

C

Normally Open/Normally Closed Attribute

Beginning with V2.04.00 firmware, the point attribute NO/NC defines the relation

between the physical states (contact position and relay ON/OFF, respectively) at the

digital inputs and outputs and their logical status; see also Table 8 and Table 9.

contact position NO/NC attribute logical status input voltage

open NO 0 2.5 V

closed NO 1 5 V

open NC 1 2.5 V

closed NC 0 5 V

Table 9. Digital output parameters

relay ON/OFF NO/NC attribute logical status

ON NO 1

OFF NO 0

ON NC 0

OFF NC 1

Table 8. Digital input parameters

EN1R-0144GE51 R1109 22

Page 23

System Bus (C-Bus)

EXCEL 100C INSTALLATION INSTRUCTIONS

Up to 30 controllers can communicate with one another and a PC central via the

system bus. In addition to Excel 50, 100, 500/600/800 controllers, other system bus

compatible components can also be connected (Excel IRC Multicontroller, Excel

EMC). The system bus must be connected through the individual controllers (open

ring).

Fig. 2. Open-ring connection of controllers

Excel 800 Excel 100 Excel 500 Excel 50

NOTE: Star connection is not permissible because uncontrollable line reflections

may occur.

For setting up the system bus in the right way, three steps have to be followed:

cable specification for system bus

baud rate selection

The maximum communication speed of the XC5010C/XCL5010/Excel 50 /

Excel 100C is 76800 baud. These controllers can be mounted together with the

XC6010 or Excel 100B (with XD505A or XD508 submodule) since the XC5010C /

XCL5010 / Excel 50/Excel 100C communication speed can be adjusted to match

either submodule.

NOTE: When changing the baud rate of bus devices, proper communication

cannot be ensured until all bus devices are set to the same baud rate

again.

NOTE: When adding or removing a controller to/from the C-Bus, it may take up to

two minutes to re-initialize the bus. During this time communication on the

C-bus is lost.

See page 14 for details on setting the C-Bus termination on the Excel 100C.

IMPORTANT

For communication with more than 9600 baud it is required to enable the

termination of the first and the last device on the C-bus (see page 14). The

controllers with termination must be switched on prior to the controllers in

the middle of the C-bus. The C-bus might not work if the controllers with

termination are switched off.

System Bus Cable Types

The cable specification depends mainly on the baud rate. There are regional

differences as to whether shielded or unshielded cable must/can be used.

For detailed information on cables to be used in accordance to regional

requirements, please refer to the U.S. and European Specifications chapters.

System Bus Extension by Using Repeaters

The system bus length can be extended by using repeaters. Each repeater extends

the bus length by the amount of a single bus length. Due to differences in regional

guidelines, the maximum number of repeaters that may be added to a bus varies.

For detailed information on repeaters to be used in accordance to regional requirements, please refer to the U.S. and European Specifications chapters.

23 EN1R-0144GE51 R1109

Page 24

EXCEL 100C INSTALLATION INSTRUCTIONS

Connections to Operating Device

Wiring to XI582 Operator's Unit

to XL100C

(front)

SHIELD

to XI582

1

6

2

7

3

8

4

9

5

to XL100C

(rear)

9

1

0

2

1

2

2

2

5

2

XW582

SHIELD

XW583

Y

Y

G

E

B

G

W

G

E

B

G

W

A

R

L

L

R

O

E

R

H

R

A

L

L

R

O

E

R

H

Y

n

t

(

o

W

O

+

W

N

E

R

N

G

E

T

I

to XI582

o

n

t

(

Y

W

O

+

W

N

E

N

G

E

T

I

d

e

)

s

u

T

D

x

V

5

D

x

N

1

E

2

3

4

D

u

)

d

e

s

T

D

x

V

5

D

x

R

N

1

E

2

3

4

D

EXCEL 100C

XI582

XW582

XI582

XW583

The XI582 operator’s unit can be connected to either the front connector (using the XW582 cable) or the rear terminals (using

the XW583 cable) of the Excel 100C.

XW582 cable, length 15 ft (5 m)

XW583 cable, length 15 ft (5 m)

NOTE: The controller will warm-start if the 5 V supply for the XI582 is shorted.

EN1R-0144GE51 R1109 24

Page 25

Wiring XL-Online and Service Computer

EXCEL 100C INSTALLATION INSTRUCTIONS

to XL100C to XL-Online

1

6

2

7

3

8

4

9

5

SHIELD

D

x

T

R

D

x

D

N

G

XW585

PC with

XL-Online

EXCEL 100C

XW585

1

6

2

7

3

8

4

9

5

A tailor-made cable for the Excel 100C controller is available with plugs on both ends (XW585).

XW585 cable, length 16 ft (5 m)

NOTE: You can also use a standard "Null modem" cable.

25 EN1R-0144GE51 R1109

Page 26

EXCEL 100C INSTALLATION INSTRUCTIONS

X

X

Adapter Cables from XI582 and XL-Online to Excel 100B and Excel 100C

EXCEL 100B EXCEL 100B

XW584 + XW585

W584 + XW582

PC with

XL-Online

EXCEL 100C EXCEL 100C

XI582

XW585

W582

EN1R-0144GE51 R1109 26

Page 27

EXCEL 100C INSTALLATION INSTRUCTIONS

9 Code

The adapter cables are needed when the same XI582 or PC with XL-Online is used

on a site where there is a mix of Excel 100C and Excel 100B controllers. Always use

the following cable / combination of cables for connection:

Connecting the Excel 100B to a PC with XL-Online: use a combination of an

XW584 and an XW585;

Connecting the Excel 100B to an XI582: use a combination of an XW584 and an

XW582;

Connecting the Excel 100C to a PC with XL-Online: use an XW585;

Connecting the Excel 100C to an XI582: use an XW582.

XW 584 ....

132

56

78

910

-Pin

4

GND

white

green

RxD

brown

+5VE

yellow

TxD

shield

not connected (4x)

shield

RxD

+5VE

TxD

GND

green

brown

yellow

shield

white

12345

9678

27 EN1R-0144GE51 R1109

Page 28

EXCEL 100C INSTALLATION INSTRUCTIONS

A

Operator's Unit XI582

1. Remove the front cover from the XI582 by inserting tip of an awl (or a similar

narrow, pointed object) into the small hole on one side of the operator terminal.

When the latch releases, insert the awl into the small hole on the other side of

operator terminal and pry off the cover.

B

A

2. Route cable from the Excel 100C.

B

A

TxD(CPU)

YELLOW

BROWN

+VE

RxD(CPU)

GREEN

WHITE

GND

B

EN1R-0144GE51 R1109 28

Page 29

EXCEL 100C INSTALLATION INSTRUCTIONS

3. If mounting on a wall, remove feet.

4. Attach the housing to the wall.

5. Make electrical connections (black/gray wire not used).

YELLOW

TxD(CPU)

BROWN

GREEN

WHITE

29 EN1R-0144GE51 R1109

+VE

RxD(CPU)

GND

Page 30

EXCEL 100C INSTALLATION INSTRUCTIONS

6. Reattach the cover.

Setting the Port Selector Switch

IMPORTANT

You must properly set the port selector (left to the front port, see figure on page 30); e.g. after having operated an MMI via the

front port, the switch must be set back to its left position to reactivate a modem being connected to the rear terminals. If the

switch is set to "front port“, the rear terminals are deactivated, and vice versa.

Front port Rear terminals

active active

REMOTE COMMUNICATIONS

For remote communications with EBI/SymmetrE building supervisors, a modem or

ISDN* terminal adapter can be connected directly to the front serial port or the rear

terminals on the base of the Excel 100C (see graphics below).

NOTES: Remote communication via modem or ISDN* terminal adapter requires

firmware version V2.03.01 or higher.

EN1R-0144GE51 R1109 30

Page 31

Port

Selector

Rear Terminals for

Modem Connection

Serial Port

Front

EXCEL 100C INSTALLATION INSTRUCTIONS

Modem or ISDN* Terminal Adapter Connections

The front serial port of the Excel 100C accepts a standard modem cable with a

female 9-pin connector. Use the cable that is supplied with the modem/ISDN*

terminal adapter.

To connect to the rear terminals on the base of the Excel 100C, use cable XW571

(length: 6 ft (1.9 m)).

Table 10. XW571 Connection

pin of Excel 100C RS232 signal wire color

19 SHIELD clear

20 TxD yellow

21 RxD green

22 +5 V (RTS) blue

23 CTS violet

not used

25 GND white

26 DTR black

27 DCD brown

not used

NOTE: Pin numbers shown are for the rear connector on the base of the Excel

100C controller (also see page 14).

IMPORTANT

Make sure the port selector switch is set appropriately. Failure to do so can

cause erratic system operation (see page 30 for details).

*ISDN NOTE: Communication via ISDN is applicable only for Europe.

F

3

0

6

0

B

C

Modem Requirements

Modem must support Hayes-compatible command set (not V150 or V151 =

Microsoft command set)

Modem must support alpha-numeric return codes

Modem must follow serial baud rate of the controller

Modem must support auto-bauding (baud rate fall-back)

When carrier detect (connect) is reported, the carrier must be on simultaneously

at both modems (on controller side and on EBI/SymmetrE side) use same

modem

After a switch-on of the DTR line by the controller or EBI/SymmetrE, the modem

must accept a dial command after 3 seconds

Modem must answer AT commands in less than 3 seconds

No Set-Up for Standard Modem Behavior

If no special modem behavior is required, there is no need to set up or initialize the

modem/ISDN* terminal adapter. The Excel 100C will automatically detect the device

(MMI or modem) attached to the serial port and set the appropriate communication

speed. The controller will also automatically adapt to alphanumeric return codes

used by the modem. This automatic detection and adjustment can take up to 5

seconds.

31 EN1R-0144GE51 R1109

Page 32

EXCEL 100C INSTALLATION INSTRUCTIONS

NOTE: It is highly recommended that you use a state-of-the-art modem and leave

it in its factory setting.

Automatic Baud Rate Synchronization

The default communication speed between the Excel 100C and the local

modem/ISDN* terminal adapter is 9600 BPS.

The communication speed between the Excel 100C and EBI/SymmetrE

modems/ISDN* terminal adapters is automatically synchronized by the two devices

to the highest speed that both of the devices are capable of. This feature is called

"autobauding" and is a feature that all state-of-the-art modems/ISDN* terminal

adapters provide when left in their factory default settings.

The communication speed between the EBI/SymmetrE and its modem/ISDN*

terminal adapter is part of the modem set-up at the EBI/SymmetrE.

Auto / Manual Answer Detection

The Excel 100C will automatically detect whether the modem/ISDN* terminal

adapter is initialized in auto-answer or manu-answer mode, and it will set the

modem to manual answer mode (S0=0)

*ISDN NOTE: Communication via ISDN is applicable only for Europe.

Resetting the Modem

For those cases where it is not clear if the modem to be used is in its factory setting,

the modem can be reset to its factory setting by using the RESET MODEM

command in the Start-Up sequence on the MMI. This will allow a quick and easy

modem reset without having to run the modem set-up software or the Windows™

terminal program.

The RESET MODEM command causes the following commands to be sent to the

modem:

1. ATZ

executes hardware reset on modem

2. AT&FX3&W

resets modem to factory configuration settings, configures the modem to not

wait for the public phone system dial tone, and writes this to non-volatile

memory.

Set-Up for Special Modem Behavior

If special modem/ISDN* terminal adapter behavior is required, the communication

device should be set up according to the instructions provided with it. This typically

involves running a setup program on a computer with the device connected to the

computer serial port or using the Windows™ terminal program.

*ISDN NOTE: Communication via ISDN is applicable only for Europe.

Set-Up for In-house Telephone Systems

A common case of special modem behavior is when the modem is connected to an

in-house telephone network requiring a prefix to be dialed before the destination

number to provide access to the public telephone network. There are two important

aspects of the special initialization of the modem to consider:

1. Do not wait for the public network dial tone. Typically, the init command ATX3

will trigger the modem to dial without waiting for a public network dial tone.

Save this modem set-up in the modem EEPROM with the command AT&W.

EN1R-0144GE51 R1109 32

Page 33

Check the modem handbook to verify the correct commands. Note that these

commands are executed automatically with the RESET MODEM command.

2. Add the prefix required for access to the public telephone network to the

destination telephone number. Depending on the in-house telephone system,

a certain prefix may have to be added to the destination number in the

EBI/SymmetrE system configuration/site definition screen prior to sending the

set-up to the remote Excel 100C controller.

Set-Up for Limited Communication Speed

The communication speed of the modem can be fixed to a lower rate in case of data

transmission errors due to telephone line limitations. See the XI581/582 Buswide

Operator Interface User Guide, EN2B-126GE51, for the procedure for fixing the

baud rate.

Troubleshooting

In case of any problems, the handbook of the modem or ISDN* terminal adapter

must be consulted.

A “Frequently Asked Questions and Troubleshooting” document is available via the

Honeywell Technical Assistance Center (TAC) or, for Honeywell employees, on the

HIVE under:

Technical Assistance Center/Controllers/Excel 80 and 100 and 500 and 600/

technical literature/modemfaq.doc

or on the Docu Server under:

http://web.ge51.honeywell.de/dep/mc/TAC_Tips/

EXCEL 100C INSTALLATION INSTRUCTIONS

BACKLIGHT

Pressing any of the eight operating keys activates the backlight. If no entries are

made for approximately two minutes, the backlight turns itself off automatically until

a key is pressed again.

33 EN1R-0144GE51 R1109

Page 34

EXCEL 100C INSTALLATION INSTRUCTIONS

C

DIMENSIONS

Excel 100

192 mm (7.56 in.)

235 mm (9.25 in.)

72 mm

(2.83 in.)

XI582AH

192 mm (7.56 in.)

142 mm (5.59 in.)

MCD 3 - MCE 3

93 mm (3.66 in.)

MDE 3

48 mm

(1.89 in.)

MCE 3

40 mm

(1.57 in.)

42 mm

(1.65 in.)

~170 mm (6.69 in.)

~ 80 mm

(3.15 in.)

b

5

8

2

0

B

C

95 mm (3.74 in.)

EN1R-0144GE51 R1109 34

Page 35

EXCEL 100C INSTALLATION INSTRUCTIONS

C

)

)

Base Excel 100

(shown mounted on 35 mm (1.5 in.) DIN-rails (DIN/EN 50 022 35x15)

for wall mounting use screw holes located in the top center and bottom corners

96 mm (3.78 in.)

)

.

n

m

i

2

m

4

6

.

3

1

(

)

.

n

i

8

8

.

4

(

m

m

4

2

1

)

.

n

m

i

7

m

5

0

.

4

1

(

96 mm (3.78 in.)

)

.

n

i

5

.

8

(

m

m

6

1

2

)

.

n

i

m

2

m

3

.

8

0

(

168 mm (6.61 in.)

12 mm

(0.47 in.)

Base XI582AH

(wall mounting)

12 mm

(0.47 in.)

166 mm (6.54 in.)

)

.

n

i

5

5

.

5

(

m

m

1

4

1

95 mm (3.74 in.) 95 mm (3.74 in.)

190 mm (7.48 in.

Cable hole

12 mm

(0.47 in.)

)

.

n

m

i

7

m

4

2

.

1

0

(

)

.

n

m

i

4

m

9

4

.

2

0

(

)

.

n

i

3

1

.

4

(

m

m

5

0

1

1

_

m

i

d

s

a

B

35 EN1R-0144GE51 R1109

Page 36

EXCEL 100C INSTALLATION INSTRUCTIONS

U.S. SPECIFICATIONS

Electrical Connection of Sensors

Sensors and Transmitters

A Type of connection for sensors

1.) PT 1000 / I (-58°F to +302°F) (50°C to +150°C)

2.) NTC sensors 20 kΩ

Example:

Room temperature sensors T7589,

T7770A

Discharge, Hot, or Chilled Water

sensors C7031B, C, D

Outside Air temperature sensor

C7031F

B Type of connection for active

sensors with standard output signal

0 to 10 V

Example:

Humidity sensor C7600B

C Type of connection for active

sensors with standard output signal 0

(4) to 20 mA to be clamped down

with a connector resistor R1 499 Ω /

0.25%

Example:

Humidity sensor C7031A, C

EN1R-0144GE51 R1109 36

Page 37

EXCEL 100C INSTALLATION INSTRUCTIONS

Further Connection Examples

D T7770B, C, D, E, F, G. Refer to

individual model instructions for specific

connection requirements

E For normally-open contacts, a digital

signal must be switched via the changeover contact of an additional relay.

Unconnected analog inputs have a default

voltage of 8.5 V.

This is interpreted by the controller as a

logical status of '1'. This means that, in

general, no external relay is needed for

normally-closed contacts.

NOTE:

The relay contact must be suitable for

switching low voltage. For long cable

distances, the analog input signal may be

sensitive to interference. In this case, an

external relay may also be used for

normally-closed contacts.

37 EN1R-0144GE51 R1109

Page 38

EXCEL 100C INSTALLATION INSTRUCTIONS

Transformers

1450 Series

All transformers of the 1450 series are designed for 50/60 Hz AC and have

insulated accessory outputs. The transformers include built-in fuses, line

transient/surge protection, and AC convenience outlets and meet NEC class 2

requirements.

Table 11. Transformer specifications

Cables

part #

1450 7287

-001 120 Vac 24 Vac, 50 VA

-002 120 Vac

-003 120 Vac 24 Vac, 100 VA, and 24 Vdc 600 mA

-004 240/220 Vac 24 Vac, 50 VA

-005 240/220 Vac

-006 240/220 Vac 24 Vac, 100 VA, and 24 Vdc 600 mA

NOTE: For installations requiring UL1995 conformance, transformer primary

voltage must not exceed 150 Vac.

The cable specification depends mainly on the baud rate. There are regional

differences as to whether shielded or unshielded cable must/can be used. The table

below summarizes cable types and gives selection guidance. Note that baud rate

and maximum bus length are related to each other.

NOTE: In the U.S., shielded or unshielded cable may be used.

primary side secondary side

2 x 24 Vac, 40 VA, and 100 VA from separate

transformer

2 x 24 Vac, 40 VA, and 100 VA from separate

transformer

Table 12. Cable specifications

max. baudrate max. bus length cable type description recommended for

76800 4,000 ft AK 3702 unshielded / twisted pair U.S.

76800 4,000 ft AK 3740A shielded U.S. (low-cost)

76800 4,000 ft Belden 9842 twisted pair U.S.

76800 4,000 ft Belden 9841 shielded U.S.

The general specification for shielded system bus cable above 76.8 Kbaud is as

follows:

shielded twisted pair installation cable

capacitance between data lines 42 pF/m (13 pF/ft)

capacitance between data line and shield 76 pF/m (23 pF/ft)

cross sectional area 0.5 mm

XC5010C/XC6010/Excel 100C, only

If shielded cable is used then both ends of the shield must be connected to

terminals 15 and 18, or 33 and 36, per following figure

EN1R-0144GE51 R1109 38

2

(24 AWG)

Page 39

EXCEL 100C INSTALLATION INSTRUCTIONS

Relays

Repeaters

15

16

17

18

XC5010C

XC6010

Honeywell Relay:

Part Number 14500087004

Impedance 500 Ω

Nominal voltage 12 V

DC Pull-In voltage 9 V

DC Current 20 mA / 10 V

Further relays: MU1S, MUS1C, RIBU1S, RIBU1C, R7600

15

16

17

18

XC5010C

XC6010

15

16

17

18

XC5010C

XC6010

Excel 100

33

34

35

36

CB-0492-X1

Each repeater extends the bus length by the amount of the single bus length. The

table below summarizes the number of repeaters allowed. Note that the maximum

length depends on the cable specification as described under the cables chapter.

Table 13. Max. baud rate in relation to cable length and no. of repeaters

max. baud rate

76.8 Kbaud 5 7,200 m (24,000 ft.)

The repeater is available either with or without a housing. The ordering information

is as follows:

repeater without housing 14507324 -001

repeater with housing 14507324 -002

max. no. of

repeaters

Table 14. Ordering information for repeater

description OS no.

resulting max. bus length

(depends upon cable specifications)

39 EN1R-0144GE51 R1109

Page 40

EXCEL 100C INSTALLATION INSTRUCTIONS

EUROPEAN SPECIFICATIONS

Electrical Connection of Sensors

Air duct temperature sensor LF 100

Sensors and Transmitters

A Type of connection for sensors

1.) PT 1000 / I (-58°F to +302°F) (50°C to +150°C)

2.) NTC sensors 20 kΩ

Example:

Room temperature sensor RF 20

Inlet temperature sensor VF 20 A

External temperature sensor AF20

B Type of connection for active

sensors with standard output signal

0 to 10 V

Example:

Humidity sensor HKT 1, HRT 1

C Type of connection for active

sensors with standard output signal 0

(4) to 20 mA to be clamped down with

a connector resistor R1 499 Ω /

0.25%

Example:

Immersion temperature sensor VF

100

EN1R-0144GE51 R1109 40

Page 41

Wind sensor WS21; Sun sensor SAF25

EXCEL 100C INSTALLATION INSTRUCTIONS

D To measure the wind effect, wind

sensor WS21 should be used.

E To measure the solar effect, the SAF

25 sun sensor should be used. In order to

operate the SAF 25, the reference voltage

from terminal 67 of the controller device

must be connected to terminal 2 SAF 25.

41 EN1R-0144GE51 R1109

Page 42

EXCEL 100C INSTALLATION INSTRUCTIONS

NC

1

2

3

4

ANALOG

INPUT

5

6

7

NC

8

9

NO

10

11

NO

12

13

14

15

16

17

18

67

+10 V

55

0V

230V / 50 Hz

120V

55

+10 V

67

55

0V

230V / 50 Hz

120V

Further Connection Examples

F VMP (10 kΩ total resistance) must be

used for the feedback potentiometer.

Connections as shown.

G TF26 must be used for temperature

sensing. Connections as shown.

H

L

N

L

N

CB-0714-E1

H For normally-open contacts, a digital

signal must be switched via the changeover contact of an additional relay.

Unconnected analog inputs have a default

voltage of 8.5 V.

This is interpreted by the controller as a

logical status of '1'. This means that, in

general, no external relay is needed for

normally-closed contacts.

NOTE:

The relay contact must be suitable for

switching low voltage. For long cable

distances the analog input signal may be

sensitive to interference. In this case, an

external relay may also be used for

normally-closed contacts.

EN1R-0144GE51 R1109 42

Page 43

Transformers

CRT-Series

EXCEL 100C INSTALLATION INSTRUCTIONS

Table 15. Number of controllers connected to one transformer

transformer

CRT 2 2 0.470 Ω 1 1.180 Ω

CRT 6 7 0.075 Ω 4 0.197 Ω

CRT 12 12 0.085 Ω 8 0.104 Ω

Backup fuse 10 A Use quick-acting backup fuse 10 A (or automatic H16 or L16) to protect transformer

primary side. On the primary side of the CRT 2, there is a fusible output of type

M 0.315 A (T) 250 V for the purpose of fine fusing.

Excel 100C without MCE/MCD Excel 100C with MCE/MCD

no. of contr. max. line resist. no. of contr. max. line resist.

Relays

FEME Relay:

Impedance: 625 Ω

Pull-In voltage: 6.7 Vac

Current at 10 Vdc: 16 mA

Current at 11 Vdc: 17.5 mA

Current at 12 Vdc: 19.2 mA

Cables

The cable specification depends mainly on the baud rate. The table below

summarizes cable types and gives selection guidance. Note that baud rate and

maximum bus length are related to each other.

Table 16. Cable specifications

max. baudrate max. bus length cable type description recommended for

76 800 1200 m

76 800 1200 m

NOTE: In Europe, only shielded cable is permitted. Cable J-Y-(ST)Y 2 x 2 x 0.8 is

The general specification for shielded system bus cable above 76 800 baud is as

follows:

shielded twisted pair installation cable

capacitance between data lines 42 pF/m (13 pF/ft)

capacitance between data line and shield 76 pF/m (23 pF/ft)

cross sectional area 0.5 mm

J-Y-(ST)Y Europe

2 x 2 x 0.8

A-Y-(ST)Y Europe

2 x 2 x 0.8

for internal applications (cables inside a panel) only. For external

applications the equivalent type A-Y-(ST) 2 x 2 x 0.8 can be used.

2

(24 AWG)

shielded,

twisted pair

shielded,

twisted pair

Inside cabinet, only

Outside cabinet, only

43 EN1R-0144GE51 R1109

Page 44

EXCEL 100C INSTALLATION INSTRUCTIONS

XC5010C/XC6010/Excel 100C, only

If shielded cable is used then both ends of the shield must be connected to terminal

15 and 18, or 33 and 36, per following figure:

Repeaters

15

16

17

18

XC5010C

XC6010

15

16

17

18

XC5010C

XC6010

15

16

17

18

XC5010C

XC6010

33

34

35

36

Excel 100

CB-0492-X 1

Each repeater extends the bus length by the amount of the single bus length. The

table below summarizes the number of repeaters allowed. Note that the maximum

length depends on the cable specification as described under the cables chapter.

Table 17. Max. baud rate in relation to cable length and no. of repeaters

max. baud rate

max. no. of

repeaters

resulting max. bus length

(depends upon cable specifications)

76.8 Kbaud 5 7,200 m (24,000 ft.)

The ordering information is as follows:

Table 18. Ordering information for repeater

description OS no.

repeater panel mount (without housing) 14507324-001/U

repeater panel mount (with housing) 14507324-002/U

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Rolle, Z.A. La Pièce 16, Switzerland by its Authorized Representative:

Automation and Control Solutions

Honeywell GmbH

Böblinger Strasse 17

71101 Schönaich / Germany

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://ecc.emea.honeywell.com

Subject to change without notice. Printed in Germany

EN1R-0144GE51 R1109

Loading...

Loading...