Page 1

Excel 50/100/500/600/800

HONEYWELL EXCEL 5000 OPEN SYSTEM

CONTROLLERS

SOFTWARE DESCRIPTION

® U.S. Registered Trademark EN2B-0092GE51 R0709

Copyright © 2009 Honeywell Inc. • All rights reserved

Page 2

EXCEL 50/100/500/600/800

Trademark Information Echelon, LON, L

LonTalk, LonUsers, LonPoint, Neuron, 3120, 3150, the Echelon logo, the LONMARK

logo, and the LonUsers logo are trademarks of Echelon Corporation registered in

the United States and other countries. LonLink, LonResponse, LonSupport, and

LonMaker are trademarks of Echelon Corporation.

ONMARK, LONWORKS, LonBuilder, NodeBuilder, LonManager,

EN2B-0092GE51 R0709

Page 3

EXCEL 50/100/500/600

CONTENTS

Revision overview ........................................................................................................................................................................ 5

System Overview.......................................................................................................................................................................... 6

Datapoints..................................................................................................................................................................................... 9

Physical Datapoints .................................................................................................. 9

Flexible Datapoints ................................................................................................. 10

Pseudo Datapoints ................................................................................................. 10

Global Datapoints ................................................................................................... 11

Mapped Datapoints (V2.04.xx or higher) ................................................................ 12

Attributes .................................................................................................................................................................................... 13

Access Level........................................................................................................... 13

Acknowledge Alarm (V2.04.xx or higher)................................................................ 13

Active State (prior to V2.04.x)................................................................................. 14

Active State (Excel 800) ......................................................................................... 14

Alarm Delay ............................................................................................................ 15

Alarm Suppression ................................................................................................. 15

Alarm Status (prior to V2.04.x)................................................................................ 15

Alarm Status (V2.04.xx or higher)........................................................................... 16

Alarm Type ............................................................................................................. 16

Alarm Definition ...................................................................................................... 17

Cycle Count ............................................................................................................ 18

Delay Time Switching Up........................................................................................ 18

Delay Time Switching Down ................................................................................... 18

Descriptors ............................................................................................................. 18

Engineering Unit ..................................................................................................... 19

Feedback Delay...................................................................................................... 19

High/Low Alarm/Warning Limits.............................................................................. 19

Hours Run .............................................................................................................. 20

Hours Run Log........................................................................................................ 20

Hours Since Serviced ............................................................................................. 20

Hysteresis............................................................................................................... 21

Alarm Hysteresis ................................................................................................ 21

Trend Hysteresis ................................................................................................ 22

Broadcast Hysteresis ......................................................................................... 22

Intrinsic Hysteresis for Analog Input Signals ...................................................... 23

Input/Output Status Text (prior to V2.04.xx) ........................................................... 24

Input/Output Status Text (V2.04.xx or higher)......................................................... 24

Interval Count ......................................................................................................... 24

Interval Limit ........................................................................................................... 24

I/O Characteristic.................................................................................................... 25

Pull-Up Resistor Handling....................................................................................... 26

Last Change ........................................................................................................... 27

LED Mode (XF823x, XFL823x, and XFx830x modules) ......................................... 27

Maintenance Alarm................................................................................................. 27

Manual Value.......................................................................................................... 27

Network Variable (V2.04.xx or higher) .................................................................... 28

Normally Open/Normally Closed (V2.04.xx or higher) ............................................ 28

Motor Run Time ...................................................................................................... 29

Off Phase................................................................................................................ 29

Operating Mode ...................................................................................................... 30

Output Type............................................................................................................ 32

Subtype.............................................................................................................. 32

Point Alarms ........................................................................................................... 32

Pulse Duration ........................................................................................................ 32

Safety Position (XFx822x, XFx824x, and XFx830x modules)................................. 32

Scaling Factor......................................................................................................... 33

Sensor Offset.......................................................................................................... 33

Suppress Point ....................................................................................................... 34

Switching Down ...................................................................................................... 34

3 EN2B-0092GE51 R0709

Page 4

EXCEL 50/100/500/600/800

Switch-On Counter ..................................................................................................34

Technical Address ...................................................................................................34

Trend Logging .........................................................................................................35

Value Hysteresis .................................................................................................36

Trend Cycle (V2.03.x) .........................................................................................36

User Address...........................................................................................................37

Value .......................................................................................................................37

Write Protection.......................................................................................................37

List of Datapoint Attributes ......................................................................................39

Time Programs ............................................................................................................................................................................42

Structure..................................................................................................................42

Individual Time Programs........................................................................................42

Daily Program .....................................................................................................42

Weekly Program .................................................................................................43

Annual Program ..................................................................................................44

Special Day List ..................................................................................................44

The "TODAY" Function .......................................................................................44

Generating a Time Program ....................................................................................45

Alarm Handling............................................................................................................................................................................46

Point Alarms ............................................................................................................46

System Alarms ........................................................................................................47

System Alarms Suppression (V. 2.04.xx or higher).............................................51

User Program Alarms ..............................................................................................52

Data Storage ...........................................................................................................52

Alarms Sent across the System Bus...................................................................52

Test Mode (V2.03.x).....................................................................................................................................................................53

Communication ...........................................................................................................................................................................53

System Bus .............................................................................................................53

Access ................................................................................................................54

Bus Initialization ..................................................................................................54

Bus Communication............................................................................................54

I/O Runtime Synchronization ..............................................................................55

Initialization of Distributed I/O Modules ...............................................................55

New Bus Devices................................................................................................55

Network-Wide Controller Time Synchronization..................................................56

Point Refreshing .................................................................................................56

PC Communication..................................................................................................56

Excel IRC ................................................................................................................56

Remote Communication ..........................................................................................56

Remote Trending (dial-up).......................................................................................58

General ...............................................................................................................58

Controller Firmware 2.03.xx and Higher..............................................................58

Controller Firmware 2.04.xx and Higher..............................................................59

Excel 800 ............................................................................................................60

MODEMFAQ ...........................................................................................................61

Index.............................................................................................................................................................................................62

EN2B-0092GE51 R0709 4

Page 5

EXCEL 50/100/500/600/800

REVISION OVERVIEW

The following pages have been changed from the previous issue of this document:

page change

2

21 Table 10 “Pull-up resistor handling” revised

22

27

52 Fig. 1. “Remote Modem Connection” revised

Fig. 1 “Controllers and their supported firmware versions”

revised

Section “LED Mode (XF823x, XFL823x, and XFx830x

modules) revised

Section “Safety Position (XFx822x, XFx824x, and XFx830x

modules)” revised

5 EN2B-0092GE51 R0709

Page 6

EXCEL 50/100/500/600/800

SYSTEM OVERVIEW

General Excel 50/500/800 controllers support both LONWORKS communication and the

Honeywell proprietary C-Bus communication.

ONWORKS-related information is described in the LONWORKS Mechanism

All L

document (EN0B-0270GE51).

Excel 50/100/500/600/800 is a control and monitoring system specially designed for

use in buildings. These Excel controllers use the latest Direct Digital Control (DDC)

technology. Excel 50/500/800 controllers are also capable of communicating on an

open Echelon® L

particularly well-suited to controlling buildings such as schools, hotels, offices, and

hospitals. Excel 50/100 controllers differ from Excel 500/600/800 controllers in

having a fixed input/output configuration.

Excel 50 controllers have a smaller fixed input/output configuration, and are designed for smaller buildings such as restaurants, shops, banks, and offices.

Excel 50/100/500/600/800 functions are:

• Heating control

• Air conditioning control

• Energy management

• Energy optimization

• Other building management functionality

Software The Excel 50/100/500/600/800 system includes a comprehensive software package

specially designed to meet the requirements of application engineers. It comprises

the following:

• Datapoint description

• Time program

• Alarm handling

• Password protection

The software package comes with all the files listed. The menu-driven format allows

quick and easy operation.

ONWORKS® network. Excel 50/100/500/600/800 controllers are

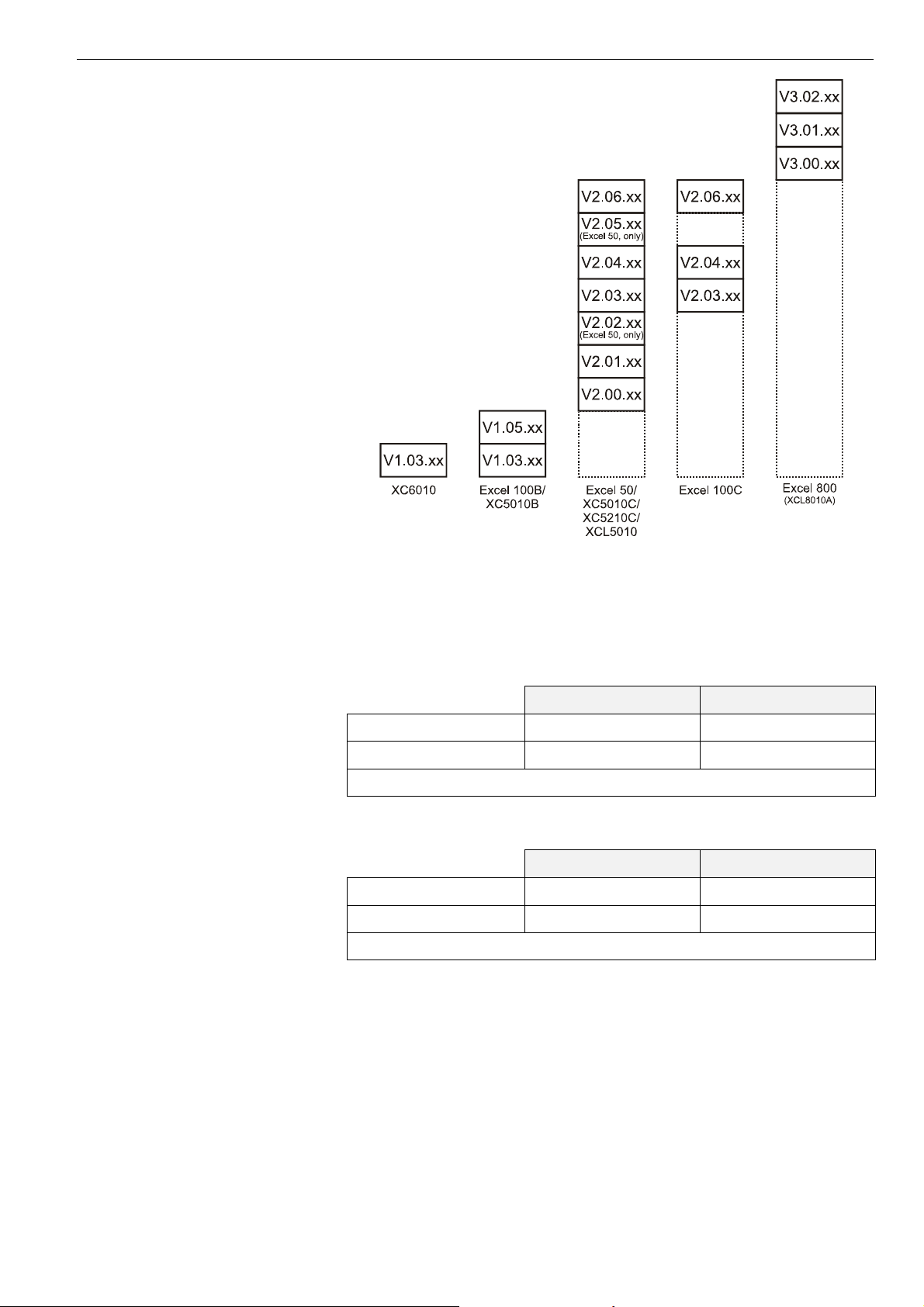

Firmware version number All information appearing in this Software Description is valid for firmware versions

V1.3.xx and earlier. All information, functions, and attributes valid for newer

firmware versions (V1.5.xx or higher) are marked by the corresponding version

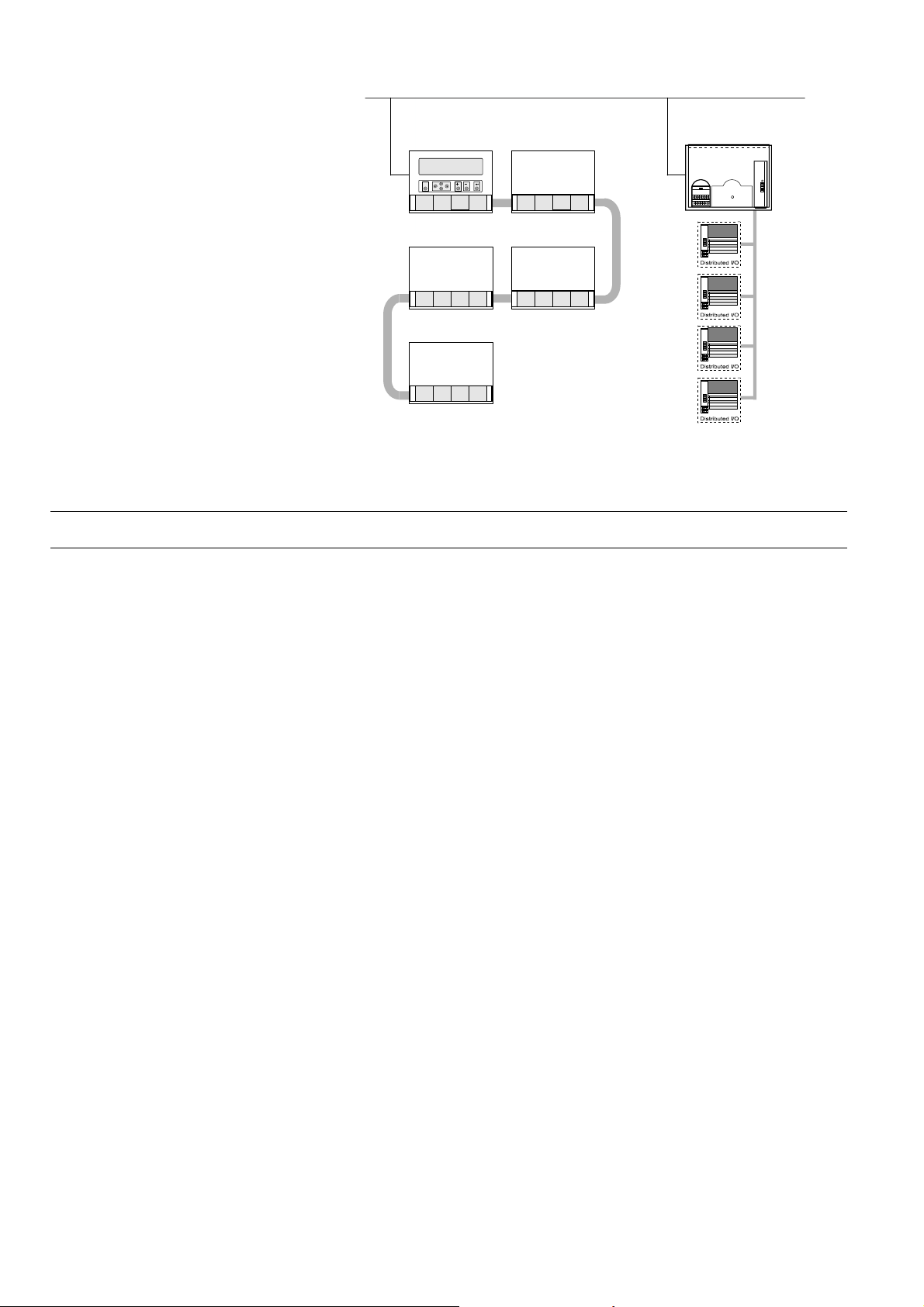

number for which they are valid. Fig. 2 shows various controllers and the firmware

version numbers that they

support.

6 EN2B-0092GE51 R0709

Page 7

Excel 50/100/500/600/800 OVERVIEW

Fig. 2. Controllers and their supported firmware versions

Excel 50 firmware compatibility Please always make sure that your firmware and the bootstrap loader match; if in

doubt, consult Software Release Bulletin(s). Special care must be taken in particular

in the case of the combinations of firmware and bootstrap loader with XD50B-xxx

modules as set forth in Table 1.

Table 1. Firmw

are / bootstrap loader compatibility with XD50B-xxx modules

firmware ≤ 2.06.07 firmware ≥ 2.06.08

bootstrap loader ≤ 1.01.07 NO* OK

bootstrap loader ≥ 1.01.08 OK OK

*Problems may occur when LONWORKS bus is in use.

Table 2. Firmware / bootstrap loader compatibility with XD50-xxx modules

firmware ≤ 2.06.07 firmware ≥ 2.06.08

bootstrap loader ≤ 1.01.07 OK OK

bootstrap loader ≥ 1.01.08 OK OK

*Problems may occur when LONWORKS bus is in use.

Datapoint description Datapoints are the basis of the Excel 50/100/500/600/800 system. Datapoints

contain system-specific information such as values, status, limit values, and default

settings. The user has easy access to datapoints and the information they contain.

The user can recall and modify information in the datapoints.

Time programs Whenever you want, you can use time programs to enter the setpoint or status for

any datapoint.

The following time programs are available:

• Daily programs

EN2B-0092GE51 R0709

7

Page 8

OVERVIEW EXCEL 50/100/500/600/800

• Weekly programs

• Annual programs

• The "TODAY" function

• Special day list

Daily programs are used to create a weekly program. The annual program is

created automatically by multiplying the weekly program and then incorporating

additional daily programs.

The "TODAY" function enables you to have a direct influence on the switching

program. This function enables you to allocate a setpoint or status to the selected

datapoints for a defined time period. This action does not depend on the current

daily program.

Alarm handling The alarm handling facility offers system security. Alarm signals can, for example,

alert the operator to maintenance work that is due. All alarms that occur are stored

in data files and reported immediately. If your system configuration allows, you can

also list alarms on a printer or transmit alarms to higher-level front-ends.

There are two kinds of alarm: Critical and Non-critical. Critical alarms have priority

over non-critical alarms. System alarms, caused by a fault in a controller, are always

critical alarms.

To distinguish between alarm types, you can generate your own alarm messages or

select appropriate messages already in the system.

The following events all generate alarm messages:

• Exceeding limit values

• Overdue maintenance work

• Totalizer readings

• Digital datapoint changes of state

Application program You can use the Honeywell CARE engineering tool to create application programs

for your system. A particular advantage offered by Honeywell CARE is the ability to

create a fully functional control program without having to be familiar with the

programming language.

CARE stands for Computer Aided Regulation Engineering.

Passwords Your control system is also protected by passwords. This ensures that only

authorized persons have access to the system data. There are four operator levels,

each protected by its own password.

• Operator level 1: Read only; the operator can display information about

setpoints, switching points, and operating hours.

• Operator level 2: Read and make limited changes; the operator can display

system information and modify certain preset values.

• Operator level 3: Read and make changes; system information can be displayed

and modified.

• Operator level 4: Programming.

Password protection prevents unauthorized access system information and ensures

permanent, secure system operation.

EN2B-0092GE51 R0709 8

Page 9

EXCEL 50/100/500/600/800

DATAPOINTS

An Excel 50/100/500/600/800 system can have the following number of datapoints:

Excel 50: 22 physical (onboard I/Os) plus up to 46 physical LON I/Os

Excel 100: 36 physical (onboard I/Os)

Excel 500: 128 physical I/Os, extendable via L

Excel 600: 128 physical I/Os

Furthermore, Excel 50/100/500/600 support an additional 256 pseudo datapoints.

Excel 800: 381 datapoints (random mix of physical and pseudo datapoints)

A datapoint has different attributes according to its type. Attributes are displayed

and modified on the XI581 (not with XCL5010, Excel 100C), XI582, and the PCbased XL-Online operator interfaces or on the Excel 50 MMI. Attributes contain

information about the given datapoint. This information could be:

• Input limits values

• Operating status

• Current temperature

• Elapsed run time

The following sections provide more-detailed information about the different kinds of

datapoints and datapoint attributes and explain which attributes are assigned to

which datapoints.

ONWORKS I/Os

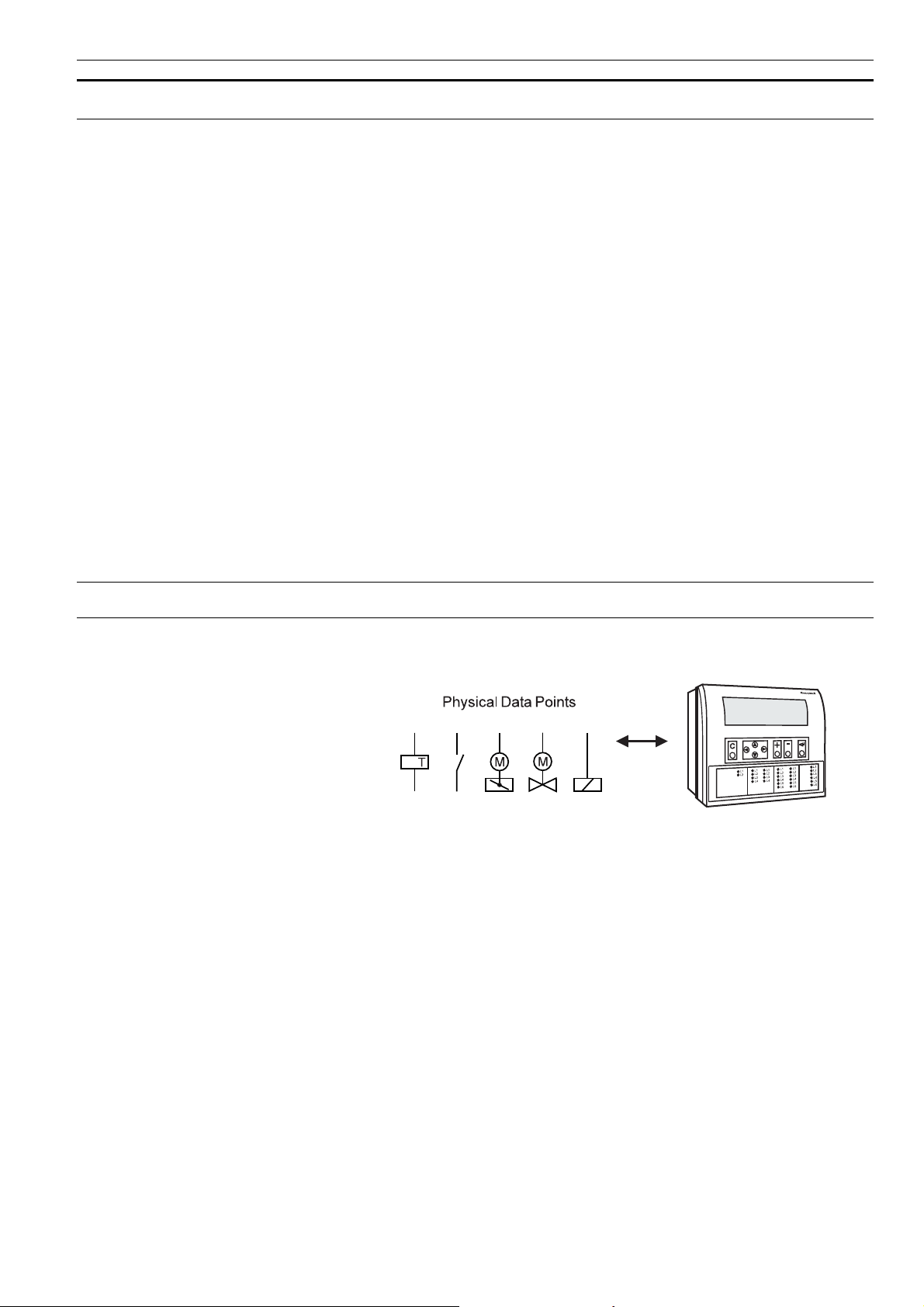

Physical Datapoints

Physical datapoints are inputs and outputs attached to hardware devices like

sensors and actuators.

Fig. 3. Physical datapoint symbols

The following are examples of physical datapoints

Analog inputs NTC, PT 1000, PT 3000, BALCO Sensors (PT 3000/BALCO not with Excel 100C),

standard 0 (2)...10 V and 0 (4)...20 mA input, to connect e.g. outside air

temperature sensors.

Analog outputs Outputs with a continuous 0...10 V output signal for controlling continuous actuators

(Excel 100C supplies up to 20 mA on the analog outputs).

Digital inputs Inputs for processing voltage-free signals (switches, contacts).

Digital outputs (not Excel 100C) Outputs for driving three-position actuators, for example, a damper motor; two

position devices, for example, a circulation pump; 0...10 V and pulsed outputs

Totalizer inputs Digital inputs for processing pulsed signals up to 20 Hz (depending on Distributed

I/O module specifications), for example, metered energy consumption.

EN2B-0092GE51 R0709 9

Page 10

DATAPOINTS EXCEL 50/100/500/600/800

Flexible Datapoints

Flexible datapoints allow the control of more than one physical output with one

datapoint. There are three subordinate types of flexible datapoints:

1. Pulse 2

2. Multi-stage

3. Feedback.

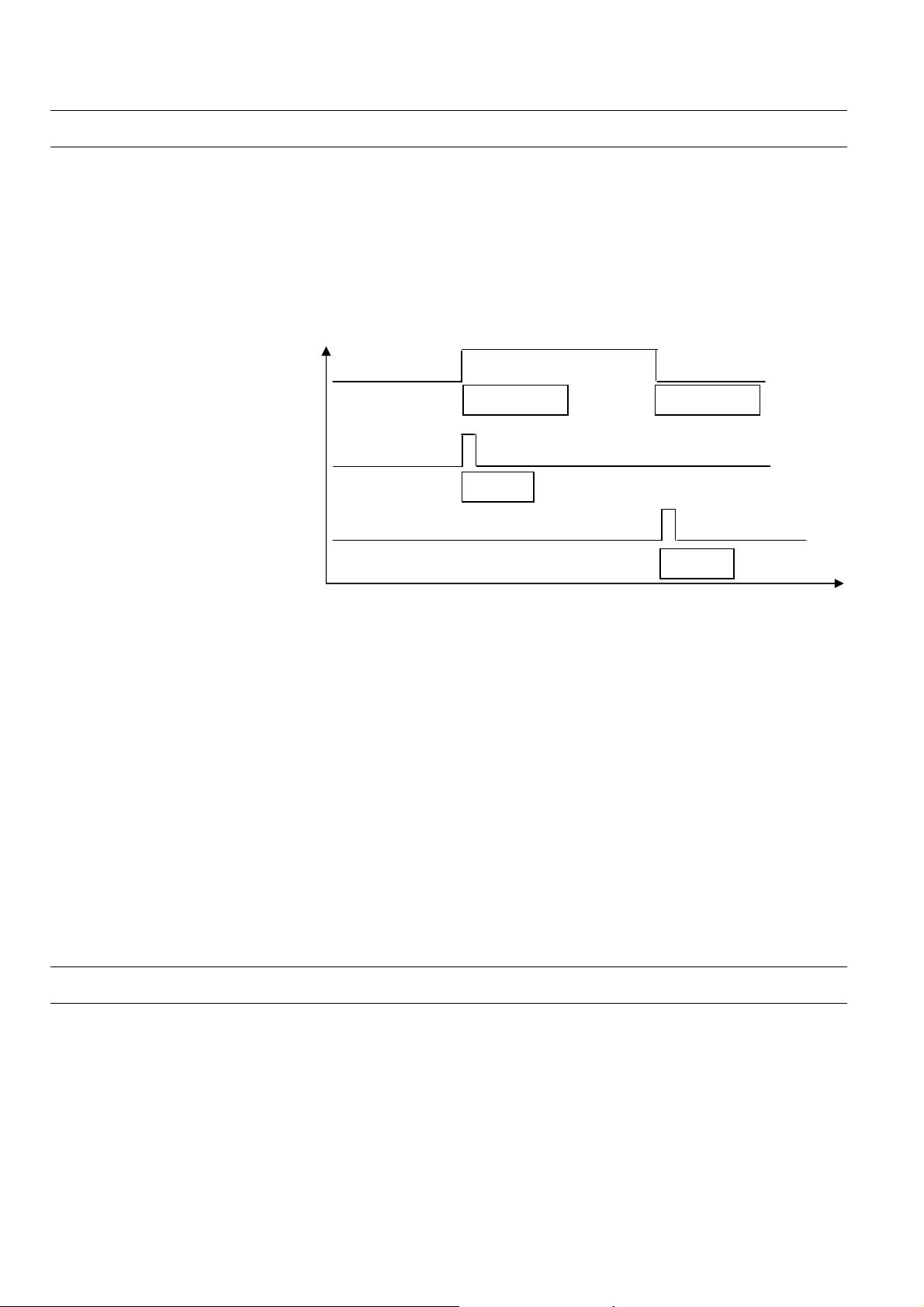

Pulse 2 flexible datapoint A pulse 2 datapoint allows to pulse two digital outputs (e.g. relays). When activated

(e.g. set to “on”), Pulse 2 triggers one of the digital outputs, and when deactivated,

Pulse 2 triggers the other digital output.

Pulse 2 “on” Pulse 2 “off”

Relay 1

Relay 2

Fig. 4. Pulse 2 flexible datapoint switching

Multistage flexible datapoint Multistage flexible datapoints allow to switch up to six physical digital outputs via

one datapoint. A typical example would be a multi-stage electric heater or a multistage fan.

A multistage flexible datapoint provides up to six editable stage texts, e.g., stage 1,

stage 2, stage 3, etc, to be edited in CARE.

Feedback flexible datapoint Feedback flexible datapoints, also called “DO feedback DI” combine up to three

pairs of digital outputs/digital inputs to form up to three-stage switching with

feedback. The digital inputs of each pair act as the feedback point.

If the digital input does not feedback the actual equipment status within a predefined

time “Off Phase”, then the software will switch down this point type until a "nonalarm" state is reached. In extreme cases, the point may be switched to the off

position. See also “Off Phase”.

Increased support (V2.04.xx or higher) Excel 500 controllers now support up to 60 flexible datapoints. In case of Feedback

flexible points, the maximum number is 128.

Previous firmware versions supported only up to 20 flexible datapoints.

Pseudo Datapoints

Excel 50/100/500/600 support 256 pseudo datapoints, while Excel 800 supports 381

datapoints (consisting of a random mix of physical and pseudo datapoints)

Pseudo datapoints are values (intermediate results and parameters) computed

while the application program is running. In contrast to physical datapoints, pseudo

datapoints are not directly connected to hardware devices.

EN2B-0092GE51 R0709 10

Page 11

EXCEL 50/100/500/600/800 DATA POINTS

Access via the user address During system operation, you may need to access these values. To simplify this

process, you can include pseudo datapoints in the datapoint list, where you can

access them directly via their user addresses.

Like physical datapoints, pseudo datapoints, too, can have different attributes; for

example, they can specify a manual value, set minimum and maximum values, or

log trends.

The following are types of pseudo datapoints:

• Pseudo analog points

• Pseudo digital points

• Pseudo totalizer inputs

• Pseudo point multistage

Pseudo analog points Pseudo analog points are software points containing an analog value in the user

program.

A pseudo analog point could, for example, contain a flow temperature setpoint calculated from the room setpoint and the outside air temperature via the heating

curve.

Pseudo digital points Pseudo digital points are software points containing a digital value in the user

program.

For example, logical AND operation.

The AND operation provides a logical 1 output when all input conditions are also

logical 1. Otherwise the output is a logical 0. If the user program contains such an

AND operation on different input conditions, then the output could be available as a

pseudo digital datapoint.

Pseudo totalizer inputs Pseudo totalizer inputs are digital software points from the user program, where a

totalizer counter input is recorded.

Pseudo point multistage Pseudo point multistage datapoints are identical to flexible datapoint of the type

"multistage" except that they allow for 16 stages (including the “off stage“) and the

attribute "Status Text" allows for 16 status texts to be attached. The attribute "Technical Address" is not required.

Global Datapoints

If your control and monitoring system contains more than one controller, the controllers communicate with one another via the system bus. Any given controller can

thus both receive (read) datapoints from other controllers and transmit datapoints to

other controllers. Such datapoints are referred to as global datapoints.

NOTE: The term “global” as used here encompasses more than just those points

explicitly labeled as “global” in the CARE engineering tool.

Global datapoints which a controller receives (reads) from other controllers are

referred to as local global datapoints, and global datapoints which a controller

transmits to other controllers are referred to as remote global datapoints.

During CARE engineering, the program engineer must take care that he does not

exceed the maximum allowed 256 global datapoints (remote and local) per

controller.

EN2B-0092GE51 R0709

11

Page 12

DATAPOINTS EXCEL 50/100/500/600/800

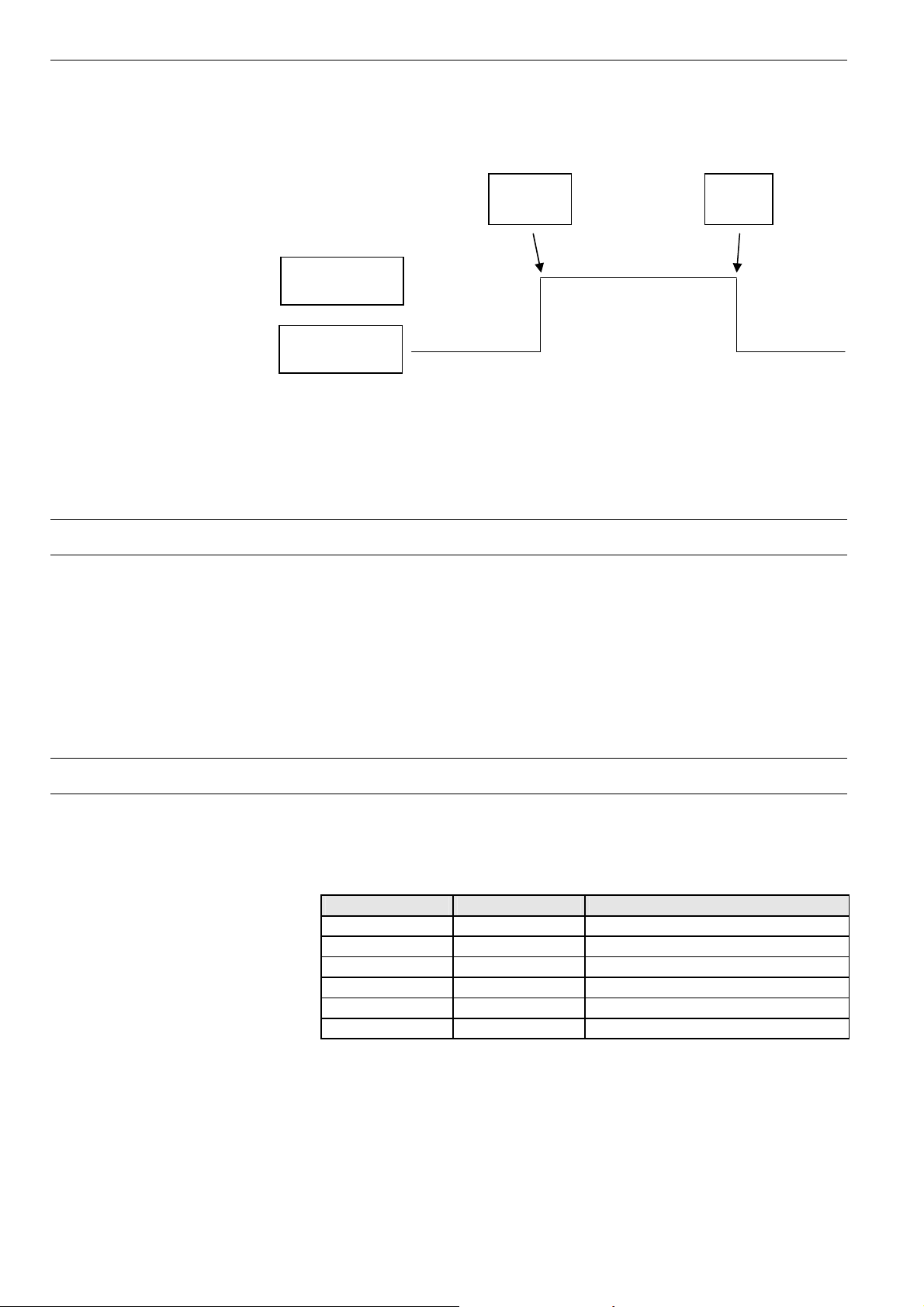

SYS

S

TEM BU

C

LON

Fig. 5. Global datapoints are available to all controllers on the system bus

Mapped Datapoints (V2.04.xx or higher)

With firmware version V2.04.xx or higher, those Excel 50/500 controllers which

feature free programmability on L

chip, i.e. date code 0044 or higher) may have I/O devices connected via the

L

ONWORKS network. LONWORKS network variables (or individual fields of structured

network variables) can be mapped to the attribute "Value" of physical datapoints

(AI/DI/AO/DO). Pseudo analog, pseudo digital, and pseudo multistage points are

also supported for NV mapping.

See Excel 50/500 L

for more information on L

ONWORKS (those that contain the 3120E5 Neuron

ONWORKS Mechanisms Interface Description, EN0B-0270GE51,

ONWORKS network variables and datapoint mapping.

EN2B-0092GE51 R0709 12

Page 13

EXCEL 50/100/500/600/800

ATTRIBUTES

Each datapoint type has associated with it various parameters which allow the user

to set, e.g., the user address, the level of access protection, alarm behavior, and

other options. These parameters are called attributes. Each attribute performs a

specific function related to the datapoint.

A complete list of datapoint types and their attributes appears in Table 17 through

Table 19. Not all attributes are available for every

Point refreshing (V1.5.x) Four attributes ("Value", "Manual Value", "Operating Mode", and "Alarm Status") will

be simultaneously refreshed to an XL-Online operator interface.

NOTE: A complete list of attributes associated with the various datapoint types can

be found in the section "List of Datapoint Attributes" on page 39.

Access Level

Four levels of protection The attribute "Access Level" protects datapoints against unauthorized changes on

the basis of the password level needed to modify a datapoint.

"Access Level" attributes between "1" and "4" are assigned to a point. These

attributes correspond to the four password levels found in the XI581 (not with

XCL5010, Excel 100C), XI582, and XL-Online operator interfaces and the Excel 50

MMI:

• Operator level 1: Read only.

• Operator level 2: Read and make limited changes.

• Operator level 3: Read and make changes.

• Operator level 4: Programming.

For example, setting the "Access Level" attribute for the datapoint with the user

address "room temp floor 1" to "2" means that all attributes for this datapoint can

now only be edited or modified at password level 2 or higher.

datapoint type.

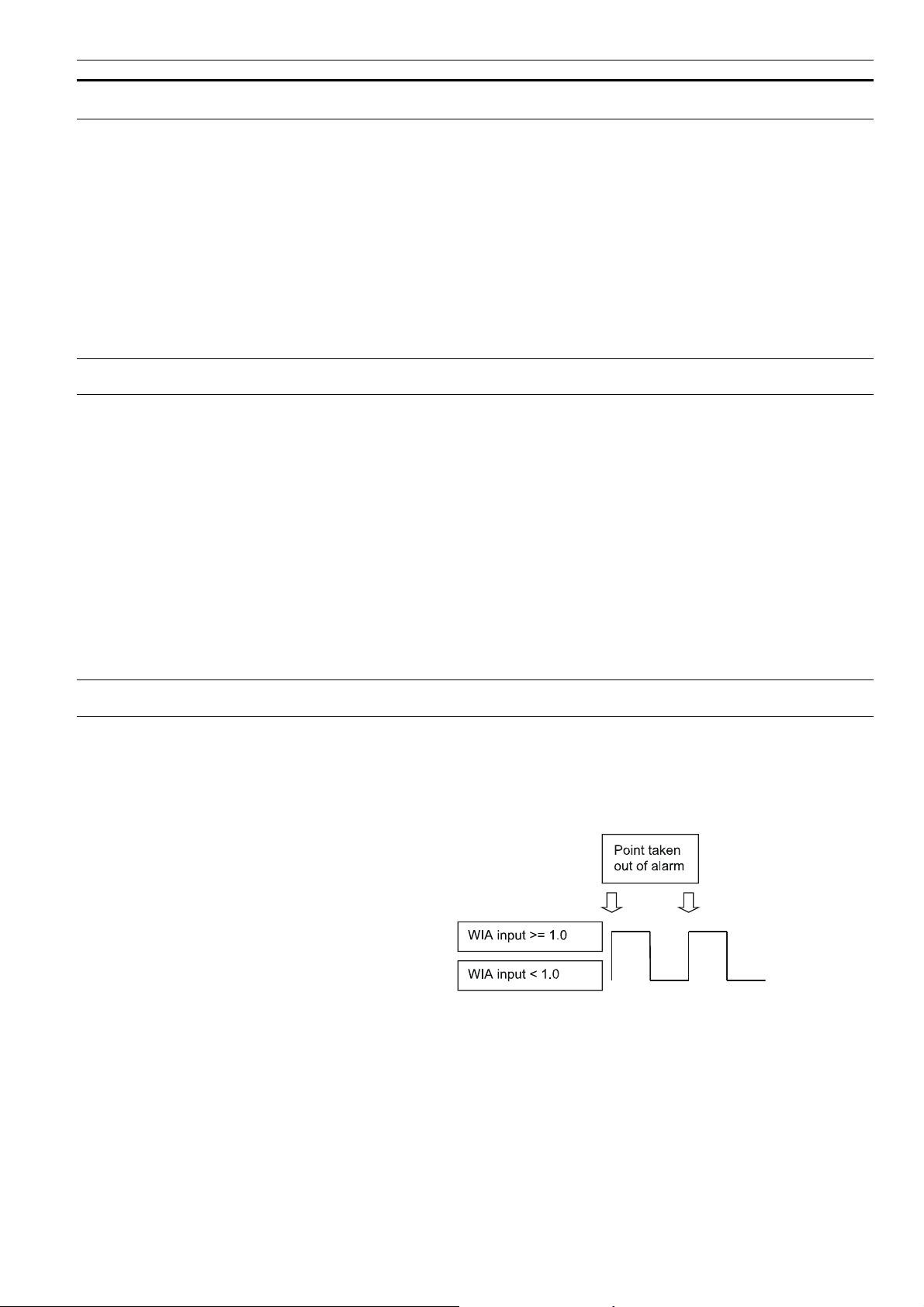

Acknowledge Alarm (V2.04.xx or higher)

The attribute "Acknowledge Alarm" allows a controller to acknowledge an alarm for

a flexible datapoint of the type "feedback" without changing the operating mode. The

controller takes the point out of alarm as soon as a rising edge is detected on the

input of the WIA statement writing to the attribute "Acknowledge Alarm".

Fig. 6. The "Acknowledge Alarm" attribute for WIA statement

This attribute is a virtual attribute and can be accessed only by a WIA statement in

CARE. It is not part of the datapoint description and therefore cannot be displayed

on an MMI or building supervisor.

EN2B-0092GE51 R0709 13

Page 14

ATTRIBUTES EXCEL 50/100/500/600/800

Active State (prior to V2.04.x)

The attribute "Active State" defines when a digital input/output is active.

NOTE: The "Active State" attribute does not reflect the current condition of a digital

datapoint.

NOTE: This is not applicable to digital inputs in applications designed for con-

trollers using V2.04.xx firmware or higher. In such applications, this

attribute is fixed at 1, and the new attribute "Normally Open/Normally

Closed" (NO/NC) is active (see section "Normally Open/Normally Closed

(V2.04.xx or higher)" on page 28 for more details).

T

he following values are possible:

• 0 = digital input/output is active when a "logical 0 signal" is present

• 1 = digital input/output is active when a "logical 1 signal" is present

Table 3 indicates the active state for various conditions of the XF523 and XFL523

modules.

Table 3. Active state for the digital input of XF523 and XFL523 modules

digital input

contact status open closed

CARE definition (NC/NO system

diagram)

definition - in XL-Online DP-Editor

attribute "Active State"

(change Active/Passive State text)

CARE interpretation (control table) 1 1 0 0 0 0 1 1

display at operator interface

(status text)

trouble:

NC NO NC NO

1 0 1 0 1 0 1 0

OFF/

alarm

ON/

operating

RTN*

* RTN = Return To Normal

NOTE: XFL523 Module is applicable only for V2.0.xx software.

OFF/

trouble:

alarm

ON/

operating

RTN*

ON/

operating

RTN*

OFF/

trouble:

alarm

ON/

operating

RTN*

OFF/

trouble:

alarm

Active State (Excel 800)

The attribute "Active State" defines when a digital input/output is active.

1 means, that a digital input/output is active when a "logical 1 signal" is present

NOTE: "Active State" = 0 is not allowed/possible.

NOTE: The "Active State" attribute does not reflect the current condition of a digital

datapoint.

EN2B-0092GE51 R0709 14

Page 15

EXCEL 50/100/500/600/800 ATTRIBUTES

Table 4. Active State for the digital input of XF823 and XFL823 modules

digital input

contact status open closed

CARE definition (NC/NO system

diagram)

definition - in XL-Online DP-Editor

attribute "Active State"

(change Active/Passive State text)

CARE interpretation (control table) 1 0 0 1

display at operator interface

(status text)

trouble:

NC NO NC NO

1 1 1 1

OFF/

alarm

* RTN = Return To Normal

OFF/

trouble:

alarm

ON/

operating

RTN*

ON/

operating

RTN*

Alarm Delay

Delaying alarm outputs The alarm delay time (in seconds) is entered in the attribute "Alarm Delay". The

alarm delay time determines how long an alarm condition must exist before an

alarm is generated. Entering an alarm delay time of 10 seconds means that the limit

value must be exceeded for at least 10 seconds before this datapoint generates an

alarm. If the limit value lasts for only 7 second, then no alarm occurs.

Alarm Suppression

The attribute “Suppress Alarm” establishes whether or not alarm messages from the

following alarm attributes should be suppressed:

• Operational status

• Min/Max. limit

• Maintenance alarm

• Interval counter

• Alarm Status

The following entries are possible:

• Off = Alarms not suppressed

• On = Alarms suppressed

Example: digital input In addition to a variety of other attributes, a digital input also has the "Operating

Mode", "Alarm Status", and "Maintenance Alarm" attributes. If alarm suppression is

activated for this datapoint, then no message is displayed during an operating mode

change-over, or when changing into the alarm condition, or when reaching the

maintenance alarm.

Suppression of system The controller will not issue a system alarm when the alarm’s system alarm text

alarms (V2.04.xx or higher) starts with an @ character.

Alarm Status (prior to V2.04.x)

Alarm monitoring In the case of a digital input or a pseudo digital point, the attribute "Alarm Status"

specifies whether or not alarm monitoring is required.

The following entries are possible:

• Yes Alarm monitoring is required

• No Alarm monitoring is not required

EN2B-0092GE51 R0709

15

Page 16

ATTRIBUTES EXCEL 50/100/500/600/800

When alarm monitoring is required, the alarm message occurs when the digital point

changes from the active state to the passive state (alarm reached). An additional

message is generated (alarm going) when the digital point returns to the active state

(see Fig. 7).

Alarm

reached

Alarm

ending

DI in

“Active State”

DI in

“Passive State”

Fig. 7. Alarm status messaging

NOTE: The active state and passive state are defined in the "Active State"

datapoint attribute.

Alarm Status (V2.04.xx or higher)

Alarm monitoring In the case of a digital input or a pseudo digital point, the attribute "Alarm Status"

specifies whether or not alarm monitoring is required.

The following entries are possible:

• Yes Alarm monitoring is required

• No Alarm monitoring is not required

When alarm monitoring is required, the alarm message occurs depending on the

physical contact status and on the logical status as defined in the online attribute

“Normally Open/Normally Closed”.

Alarm Type

The attributes listed in Table 5 are capable not only of generating alarms, but also of

writing them to the internal alarm memory and sending them to the PC front-end or

to the modem module (when connected).

Table 5. Alarm attributes

attribute always critical optional critical or non-critical

Operating Mode X

Min. Limit X

Max. Limit X

Maintenance Alarm X

Interval Counter X

Alarm Status X

Changing over the attribute "Operating Mode" always results in a critical alarm, but

the attribute "Alarm Type" offers a choice for the alarm attributes "Min. Limit", "Max.

Limit", "Maintenance Alarm", "Totalizer", and "Alarm Status" whether an alarm is

classified as critical or non-critical.

EN2B-0092GE51 R0709 16

Page 17

EXCEL 50/100/500/600/800 ATTRIBUTES

Distinguishing between critical and non-critical alarms is significant for the subsequent reporting of the alarms to the PC front-end or to the modem module. Compared to non-critical alarms, critical alarms are given priority on the bus when

several alarms are in the alarm queue.

When the type of alarm for a datapoint has been decided, e.g. "critical" alarm type, it

refers to all alarm attributes for this datapoint.

Alarm Definition

In the datapoint description, the alarms can be influenced using the functions

described below (see also Table 6 on page 18).

A

Alarm delay An alarm signal can be delayed by entering an alarm delay time. An alarm signal will

Suppress alarm If an alarm signal is not desired from a particular datapoint, this can be fixed in the

larm type For each datapoint in the datapoint description, the user can determine whether the

signals generated are to be treated as critical or non-critical alarm.

be generated only if an alarm continues uninterrupted during the alarm delay time.

datapoint description. Thus, all the alarm signals relevant to the particular datapoint

and the "Operating Mode" alarm types are suppressed.

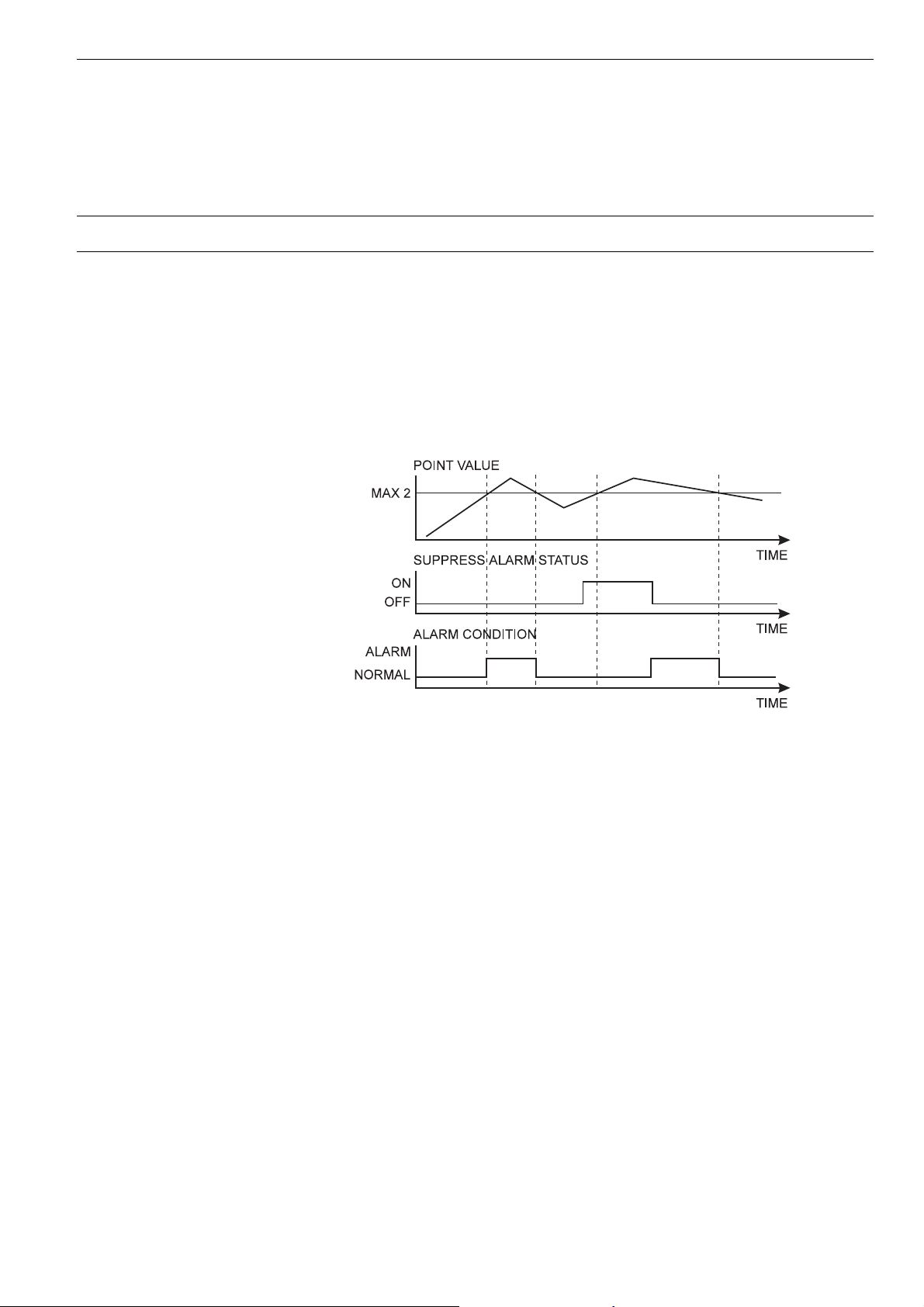

Fig. 8. Alarm condition depending on point value and Suppress Alarm status

Fig. 8 shows an example of a changing point value that rises above and falls below

the limit Max 2. If Suppress Alarm is not active, then the alarm condition switches

between normal to alarm, according to the limit Max 2. If Suppress Alarm is active,

then the alarm condition remains normal unless Suppress Alarm is switched off

before the point value falls below the limit Max 2. Regardless of the setting of the

Alarm suppression flag, an alarm is entered into the controller's history buffer and is

also available in the EBI alarm report.

Point alarm It is possible to view all datapoints at the operator interfaces for which the limit value

(analog point) or the alarm status (digital point) is currently exceeded.

Driven by a menu, the user address and the accompanying alarm text are displayed

on the XI581 (not with XCL5010, Excel 100C) or XI582 operator interfaces or Excel

50 MMI.

On the XL-Online operator interface, a datapoint within the framework of the

datapoint description can be seen in all four password levels. If a current alarm is

present for the point in question, the attribute “Point in Alarm” produces the display

“Yes”, otherwise “No”.

Within the framework of the datapoint description, it is possible, under the attribute

“Alarm text”, to enter an alarm text of up to 18 characters in addition to the preprogrammed text. There are 256 alarm texts in total.

Table 6 presents a summary of various alarm types and attributes.

EN2B-0092GE51 R0709

17

Page 18

ATTRIBUTES EXCEL 50/100/500/600/800

Table 6. Alarm summary

alarm type/attributes alarm status

Limit Values selection in DPD* possible possible X 8 possible

Alarm Status selection in DPD* possible possible X 2 possible

Maintenance Alarm selection in DPD* - possible - 1 -

Totalizer selection in DPD* - possible - 1 -

Operating Mode always critical - possible - 2 -

System Alarms always critical - - - approx. 110 -

user program reports always non-critical - - - - -

*DPD = datapoint description

enter alarm

delay time

NOTE: A point is still seen as “in alarm” even when alarm suppression is enabled.

alarm

suppression

point in

alarm

no. of prepro-

grammed texts

supplementary

text

Cycle Count

The attribute "Cycle Count" contains the value indicating the number of transitions

to the active state (see "Active State (prior to V2.04.x)" on page 14).

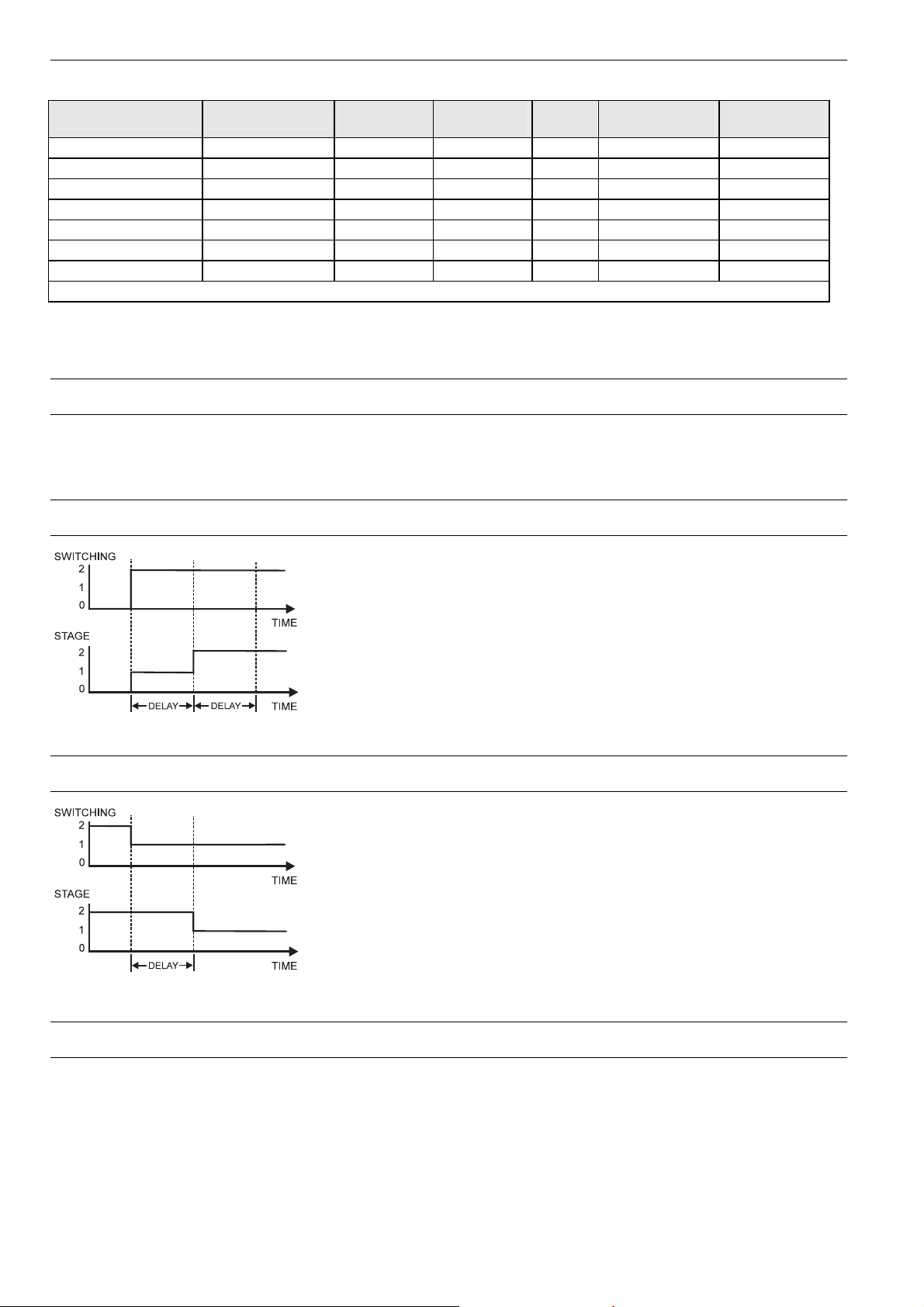

Delay Time Switching Up

Fig. 9. Delay time switching up

Delay Time Switching Down

Fig. 10. Delay time switching down

This attribute is used in conjunction with flexible points of

the type "feedback". It defines the delay time between

switching upwards from one stage to another. The delay

time affects every stage. The delay time also takes effect

when switching, e.g. from manual value 0 to 2. In this case,

it is switched from stage 0 to stage 1, then to stage 2 with

the delay time between the switching processes.

• Range: 0 to 255s

• Default value : 10s

• Resolution: 1s

This attribute is used in conjunction with flexible points of

the type "feedback". It defines the delay time between

switching downwards from one stage to another. The delay

time affects every stage.

• Range: 0 to 255s

• Default value: 10s

• Resolution: 1s

The feedback delay time starts to count after termination of

delay time switching up/delay time switching down.

Descriptors

Informative descriptors A controller contains up to 128 physical datapoints and up to 256 pseudo

datapoints. The Excel 100C provides 36 physical datapoints. An individual user

address can be assigned to each of these 384 datapoints.

EN2B-0092GE51 R0709 18

Page 19

EXCEL 50/100/500/600/800 ATTRIBUTES

255 plain-language descriptors can be created with a maximum of 32 characters

each. These descriptors are then assigned to datapoints in the datapoint description

via the attribute "Descriptor".

Descriptors complete the information concealed behind the user address. They can

contain, for instance, a reference to a section of a building.

The following list is an example of the relationship between user addresses and

descriptors:

User Address Descriptor

Room temp floor 1 Heating circuit, West wing

Room temp floor 3 Heating circuit, West wing

Room temp floor 10 Heating circuit, East

Room temp corridor Heating circuit, East

Flow temp floor 1 Heating circuit, West wing

Lights floor 1 Building section V

Lights corridor Building section V

Engineering Unit

The attribute "Engineering Unit" contains a list for selecting different engineering

units for both analog datapoints (physical and pseudo), totalizer inputs (physical and

pseudo), and digital datapoints.

If, for instance, the external temperature is measured by an analog datapoint, the

engineering unit of this datapoint must be set to "°C" or "°F". If the electrical load is

detected by a totalizer input, the engineering unit must be set to "kWh" for kilowatthours.

Feedback Delay

The attribute "Feedback Delay" determines the time delay between, e.g. when a

pump switched on (and detected) and when this status is made available to a

program.

High/Low Alarm/Warning Limits

Specifying limit values In the case of analog inputs (e.g. inputs for sensing room temperature) and pseudo

analog points (for instance, internally computed datapoints for the heating flow

setpoint), two minimum and two maximum monitored limit values may be entered.

The following four limit value attributes exist:

• Low Warning Limit

• Low Alarm Limit

• High Warning Limit

• High Alarm Limit

Exceeding the limit values generates an alarm.

Example: Monitoring supply air temperature limits (see Fig. 11).

EN2B-0092GE51 R0709

19

Page 20

ATTRIBUTES EXCEL 50/100/500/600/800

Fig. 11. Monitoring supply air temperature limits

Hours Run

Display of elapsed hours The attribute "Hours Run" returns the total number of hours during which any of the

stages is in the ON position. However, if more than one stage is in the ON position,

the "Hours Run" count is not added up, but rather counted only once.

Display of the elapsed hours run with activated hours run logging (see also "Hours

Run Log" on page 20).

NOTE:

If the attribute "Active State" of the point is 0, then the OFF position is also

counted.

Hours Run Log

Hours run log An hours run log can be carried out for digital datapoints (physical and pseudo) and

for flexible datapoints, e.g. logging the hours run by a heating circuit pump. This

requires the decision: hours run log = Yes/No to be made in the attribute "Hours

Run Log". The accumulated hours run are displayed in the attribute “Hours Run”.

Hours run are logged with a sample rate of 1 minute.

Hours Since Serviced

Display hours run since last maintenance The elapsed hours run since the last maintenance work are totaled in the attribute

"Last Maintained". If, for example, the maintenance alarm is 500 hours, and a pump

has already been running for 120 hours, then the entry in the attribute “Last

maintained” will be 120 hours. By comparing the attributes "Maintenance Alarm" and

"Last Maintained", the user can see that the next maintenance period will be after

an additional 380 hours have elapsed.

If the maintenance alarm is reached, and the maintenance work has been performed, the counter can be reset manually. The counter can also be reset manually

before reaching the maintenance alarm if, for instance, the maintenance has been

performed earlier.

EN2B-0092GE51 R0709 20

Page 21

EXCEL 50/100/500/600/800 ATTRIBUTES

If the counter is not reset, on expiration of the maintenance alarm, e.g. after 500

hours, the elapsed hours run continues to be incremented, and an additional alarm

will be generated when 1000 hours running has been reached.

Hysteresis

The following hysteresis attributes allow the user to control the triggering conditions

based on a changing parameter under which actions are taken, such as alarm

signaling, writing values to buffers, etc. A hysteresis can be used, e.g., to prevent an

alarm from being generated unless the value being monitored changes by more

than a given value. This eliminates unnecessary alarm generation and reduces bus

communication traffic.

Alarm Hysteresis

Alarm hysteresis (V1.5.x) In the case of analog inputs and pseudo analog points, the attribute "Alarm

Hysteresis" is available. It provides variable hysteresis that can be implemented,

e.g., in order to reduce the cost of communicating with a remote front-end.

The hysteresis value is set from an MMI and can have a value anywhere in the

range defined by [10

set in the attribute "Engineering Unit". The minimum value for the hysteresis is 10

Alarms are generated under the following conditions:

• Max 1 Alarm (generated if MAX 1 is exceeded)

• Max 2 Alarm (generated if MAX 2 is exceeded)

• Max 2 Normal (generated if the value falls below MAX 2-Hysteresis)

• Max 1 Normal (generated if the value falls below MAX 1-Hysteresis)

• Min 1 Alarm (generated if the value falls below MIN 1)

• Min 2 Alarm (generated if the value falls below MIN 2)

• Min 2 Normal (generated if the value MIN 2+Hysteresis is exceeded)

• Min 1 Normal (generated if the value MIN 1+Hysteresis is exceeded)

The CARE default value (i.e. 1% of actual value and no less than 0.2) for this

attribute is 0. Access to "Alarm Hysteresis" is also possible via RIA/WIA.

NOTE: The number of decimal places can be changed only using CARE.

NOTE: Attempting to enter a hysteresis value that is less than the allowed

minimum will result in the attribute being assigned the minimum value as

defined above.

Example:

In this example, the number of decimal places in the attribute "Engineering Unit" has

been chosen to have a value of 2. Fig. 12 shows an example datapoint value as a

function of time that increases and decreases over the range from Max 1 to Min 1.

-a

to (Max1 - Min1)] where “a” is the number of decimal places

-a

.

Fig. 12. Example of alarm hysteresis

The “normal” and “alarm” states as defined by the attribute "Alarm Hysteresis" are

the determined using the appropriate values in the formula given above:

EN2B-0092GE51 R0709

21

Page 22

ATTRIBUTES EXCEL 50/100/500/600/800

Range = [10-2 to (Max1 -Min1)] = [0.01 to 2]

Table 7 lists the resulting alarm conditions for the chosen hy

Table 7. Alarm conditions for alarm hysteresis

limit normal to alarm condition alarm to normal condition

Max 1 4.00 4.00 - 0.05 = 3.95

Max 2 5.00 5.00 - 0.05 = 4.95

Min 1 2.00 2.00 + 0.05 = 2.05

Min 2 0.5 0.5 + 0.05 = 0.55

steresis value of 0.05:

Trend Hysteresis

Trend hysteresis (V1.5.x) The attribute "Trend Hysteresis" is available for the trend functions “Local Trend

Data” and “Trend Setup Data”. The attribute "Trend Hysteresis" prevents new

values from being written to the trend buffer unless the datapoint value changes

(positively or negatively) at more than the specified trend hysteresis. The minimum

hysteresis value is 10

"Engineering Unit"). The CARE default value (i.e. 1% of actual value and no less

than 0.2) for this attribute is 0. Access to "Trend Hysteresis" is also possible via

RIA/WIA.

This value can be edited from an operator interface (XI581 (not with XCL5010,

Excel 100C), XI582, XL-Online, or Excel 50 MMI) via the B port (XC5010C/XC6010)

or the serial port, the system bus (XBS 1.3.3 and higher and XFI 1.6.1 and higher)

and CARE RIA/WIA statements. The password level for this attribute is determined

by the attribute "Access" (default initialization value in CARE is 0).

-a

(a = number of decimal places set in the attribute

Fig. 13. Example of the attribute "Trend Hysteresis"

Broadcast Hysteresis

Broadcast hysteresis (V1.5.x) The attribute "Broadcast Hysteresis" is available for the datapoint type "Global

Analog". The attribute "Broadcast Hysteresis" prevents new values from being

broadcast to other controllers unless the datapoint value changes (positively or

negatively) at least by the amount specified in the attribute "Broadcast Hysteresis".

The minimum hysteresis value is 10

attribute "Engineering Unit"), but not smaller than 0.2 (see also the example in

section "Value Hysteresis" on page 36). The CARE default value (i.e. 1% of actual

value and no less than 0.2) for this attribute is 0. Access to the attribute "Alarm

Hy

steresis" is also possible via RIA/WIA.

This value can be edited from an operator interface (XI581 [not with XCL5010,

Excel 100C], XI582, XL-Online, and Excel 50 MMI) via the B port (XC5010C /

EN2B-0092GE51 R0709 22

-a

(a = number of decimal places set in the

Page 23

EXCEL 50/100/500/600/800 ATTRIBUTES

XC6010) or the serial port (Excel 100C, Excel 500), the system bus (XBS 1.3.3 and

higher and XFI 1.6.1 and higher), and CARE RIA/WIA statements. The password

level for this attribute is determined by the "Access" attribute (default initialization

value in CARE is 0). If several global points (remote points) are assigned to the

same physical point, the lowest global point "Broadcast Hysteresis" value of all

assigned global points is used.

Intrinsic Hysteresis for Analog Input Signals

A minimum default hysteresis of 37 mV (24 - 1 bit) for 0 to 10 V input signals is

implemented. Due to the nonlinearity of NTC sensors, the hysteresis varies over the

temperature range, whereas it is approximately constant for PT 100/1000/3000 and

Balco 500 sensors. Approximations of hysteresis depending on the sensor and

temperature range are summarized below.

NOTE The Intrinsic Hysteresis for analog input signals is not a user-

programmable attribute, but rather an intrinsic hysteresis of the Excel

50/100/500/600/800.

NTC 20k Ω Hysteresis varies nonlinearly over the entire temperature range and depending on

whether the upper boundary (MAX LIMIT) or the lower boundary (MIN LIMIT) is

exceeded. The approximations shown in Table 8 can be used in practice

(intermediate values can be interpolated):

T

able 8. Intrinsic hysteresis values for various temperature ranges

temperature range

-40 °C (-40 °F) 2.2 K (4.0 °F) 2.5 K (4.5 °F)

-30 °C (-22 °F) 1.3 K (2.3 °F) 1.3 K (2.3 °F)

0 °C (32 °F) 0.4 K (0.7 °F) 0.4 K (0.7 °F)

40 °C(104 °F) 0.5 K (0.9 °F) 0.4 K (0.7 °F)

80 °C (40 °F) 1.5 K (2.7 °F) 1.5 K (2.7 °F)

100 °C (212 °F) 3.0 K (5.4 °F) 2.7 K (4.9 °F)

130 °C (266 °F) 8.5 K (15.3 °F) 7.2 K (13.0 °F)

average hysteresis

MIN LIMIT

average hysteresis

MAX LIMIT

PT 100 (not with Excel 100C) Hysteresis increases approx. linearly with temperature.

Average hysteresis: 0.75 K (1.35 °F)

Hyst. At -45 °C (-49 °F): 0.7 K (1.3 °F)

Hyst. At 145 °C (293 °F): 0.8 K (1.4 °F)

PT 1000/1 Hysteresis increases approx. linearly with temperature.

Average hysteresis: 0.8 K (1.4 °F)

Hyst. At -45 °C (-49 °F): 0.7 K (1.3 °F)

Hyst. At 145 °C (293 °F): 0.9 K (1.6 °F)

PT 1000/2 Hysteresis increases approx. linearly with temperature.

Average hysteresis: 1.6 K (2.9 °F)

Hyst. At 0 °C (32 °F): 1.3 K (2.3 °F)

Hyst. At 400 °C (752 °F): 2.0 K (3.6 °F)

PT 3000 (not with Excel 100C) Hysteresis increases approx. linearly with temperature.

Average hysteresis: 0.8 K (1.4 °F)

Hyst. At -45 °C (-49 °F): 0.7 K (1.3 °F)

Hyst. At 145 °C (293 °F): 1.0 K (1.8 °F)

Balco 500 (not with Excel 100C) Hysteresis decreases approx. linearly with temperature.

Average hysteresis: 0.9 K (1.6 °F)

Hyst. At -50 °C (-49 °F): 1.0 K (1.8 °F)

Hyst. At 150 °C (293 °F): 0.7 K (1.3 °F)

EN2B-0092GE51 R0709

23

Page 24

ATTRIBUTES EXCEL 50/100/500/600/800

Input/Output Status Text (prior to V2.04.xx)

2 status texts per digital data output Two status texts can be assigned to each digital datapoint status. Status texts give

an overview of the condition of the sensor or switching device connected to the

datapoint.

The associated status text appears in the attribute "Value" depending on the actual

point status.

For instance, the status texts could be as follows for a point connected to a digital

output:

Digital point status 0: Status Text: "Passive”

Digital point status 1: Status Text: "Active”

Table 9. Relationships between I/O Status, Active State, and Status Text

Input/Output Status Active State (prior to V.2.04.x) Status Text

0 0 active

0 1 passive

1 0 passive

1 1 active

Status Text with flexible datapoints The attribute "Status Text" allows you to describe the value sent to the controller by

the digital output Pulse 1 and by flexible datapoints. In the case of flexible

datapoints of the type "feedback", the status text refers to the value of the feedback

flexible datapoint and not to the required value.

Input/Output Status Text (V2.04.xx or higher)

With firmware 2.04.xx or higher, the relationship between physical output status and

logical output status as defined by the attribute "Normally Open/Normally Closed"

determines the display of the equivalent status text. See section "Normally

Open/Normally

Closed (V2.04.xx or higher)" on page 28 for details.

Interval Count

Interval count The attribute "Interval Count" shows the totalizer value (pulse x scaling factor)

accumulated since the last reset.

Displaying the interval count The attribute "Interval Count" can be viewed on the XI581, XI582, and Excel 50 MMI

operating units as well as via the XL-Online Operating Software and building

Supervisor front-ends like XBS, EBI and XFI. Based on mathematical rounding, it is

possible that not every value is displayed when high frequency values with high

scaling factors are received.

Resetting the interval count Resetting takes place either manually via an operating unit, by reaching the “Interval

Limit” value, or by reaching the “totalized” constant, which is 2 to the power of 31.

Totalizer overflow When the “Interval Limit” or the “totalized” constant is reached, a “Totalizer

Overflow” system alarm is created.

Interval Limit

The attribute “Interval Limit” is that value of the "Interval Count" attribute which,

when reached, will generate a “Totalizer Overflow” alarm. The highest possible

value for the attribute "Interval Count" is 99,999,999.

EN2B-0092GE51 R0709 24

Page 25

EXCEL 50/100/500/600/800 ATTRIBUTES

Electrical energy example A message should be generated after the “consumption” of 5 MWh of electrical

power. The input in the attribute “Interval Limit” must therefore be 5 MWh.

Once the interval count reaches its reporting level of 5 MWh, then a report is

generated, the interval count is reset to “Zero”, and a new totalizing period is

started.

I/O Characteristic

The attribute "I/O Characteristic" enables the user to display special input and output characteristics (see Fig. 14) for analog inputs/outputs. Special characteristics

permit, for instance, the adaptation of Excel 50/100/500/600/800 to many

sensor types. Ten individual input/output characteristics are available per

Excel 50/100/500/600/800 controller.

Each special characteristic is assigned a name that can be recalled from the

attribute "I/O Characteristic". Thus, the desired characteristic can be assigned to the

selected datapoint.

different

Fig. 14. Example of a special output characteristic

Creation of characteristics is carried out at programming level. Up to a maximum of

four reference points can be specified per characteristic. Up to ten different

characteristics can be defined for each controller.

For XFL and XFC I/O modules, user-defined characteristics are supported from

CARE 5.0 and controller firmware 2.06.05 onwards.

CAUTION

Regarding I/O characteristic, the behavior of controllers with OS < 2.06.05

engineered using CARE 4 differs significantly from controllers with OS 2.06.05 and

higher engineered using CARE 7 and higher. See also section “Controller OS 2.06

usage and functionality in CARE 4 and CARE – XL500 7.01.02” in Excel CARE –

User Guide (EN2B-0182GE51).

EN2B-0092GE51 R0709

25

Page 26

ATTRIBUTES EXCEL 50/100/500/600/800

A

A

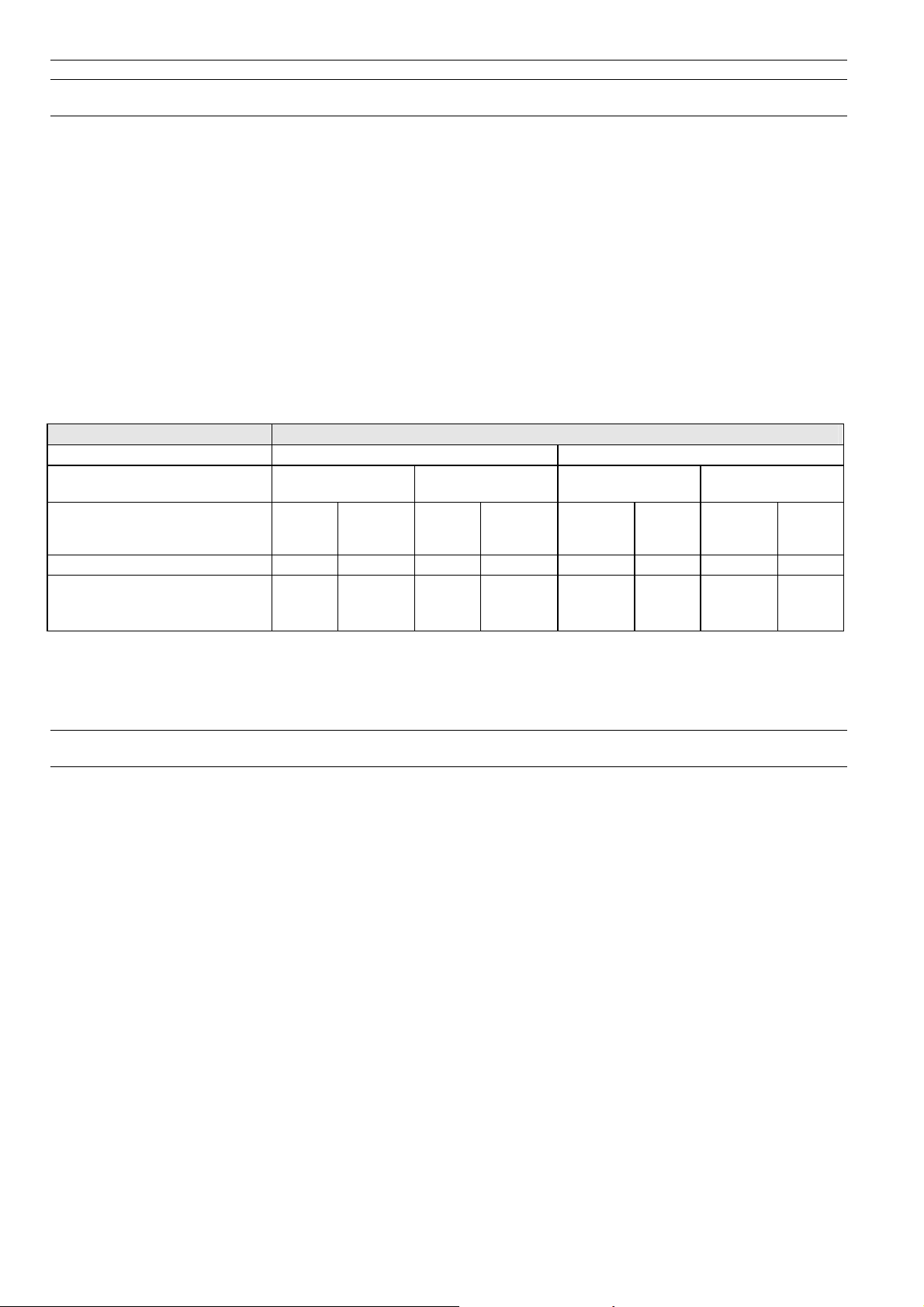

Pull-Up Resistor Handling

Table 10. Pull-up resistor handling

pull-up load-free voltage

device

voltage hardware

de-

activated

by @ (8)

configured

by DIP

switch

configured

by plug-in

activated

for DI on AI

input

circuit

diagram

(Fig. 15)

with NTC

or low-

impedance

input

XF830A

XFU830A

XF821A

XFL821A

XF521,

XF521A

10 V

optional

switch-off

YES

fixed NO NO

NO

YES

case 1 0 V

YES

8.89 V

case 2 8.89 V

XF526

XFL521,

XFL521A/B

Smart I/O

XFC

5 V

optional

switch-off

(3

YES

config.(6 case 1

(4

YES

NO

YES

YES(7 case 3 5 V

XL20 fixed NO YES case 2 8.89 V

XL50

XL100,

10 V

XL100A

XL100B

XL100C

(1

controller firmware ≥ 2.03;

(2

controller firmware ≥ 2.02;

(3

controller firmware ≥ 2.03 (local/shared mode), CARE ≥ 5.00.01 (open mode);

(4

CARE ≥ 5.00.01;

(5

controller firmware < 2.04;

(6

controller firmware < 2.04 (local/shared mode), CARE ≥ 5.01.xx (open mode);

(7

CARE ≥ 5.01.xx;

(8

Assigning "@" as first digit of input characteristic name (e.g.: "@0-10V") in the CARE text editor disables the pull-up resistor.

optional

switch-off

fixed

optional

switch-off

YES(2 YES(5 case 1 0 V

NO

YES configurable

YES(1 NO

NO

YES case 2 8.89 V

YES(5

case 1

8.89 V

When using the XF821A/XFL821A for current inputs, be sure to assign "@" as the first digit of the input characteristic name.

for voltage

input or

high-

impedance

input

0 V

0 V

Case 1 Case 2 Case 3

10 V

24.9 k

Ω

(pull-up)

10 V

24.9 k

(pull-up)

Ω

5 V

18.2 k

(pull-up)

Ω

A

100 k

150 k

150 k

Ω

49.9 k

D

Ω

Ω

49.9 k

D

Ω

Fig. 15. Input circuit diagram

EN2B-0092GE51 R0709 26

Ω

100 k

D

Ω

Page 27

EXCEL 50/100/500/600/800 ATTRIBUTES

Last Change

In the attribute "Last Change", the last change of state of a digital input/output is

stored with the time and date.

In this way it is possible to determine the last switch-on point of a fan, pump, etc.

connected via a digital output.

In the case of analog inputs and pseudo analog points, the last time an alarm limit

occurred is stored.

LED Mode (XF823x, XFL823x, and XFx830x modules)

The XF823x Panel Bus Binary Input Module, the XFL823x Lonworks Bus Binary

Input Module, and the XF830x / XFU830x modules support the “LED Mode”

attribute, which can be set in the CARE datapoint editor. The following attribute

options are provided:

“Alarm” LEDs will be red/green (red = alarm state, not XF830x /

XFU830x modules)

“Status” LEDs will be yellow/off (yellow = active state)

NOTE: XF830x / XFU830x modules do not support the Alarm option. Hence, do

not assign this attribute to datapoints allocated to one of these modules.

NOTE: When the XFL823x L

Excel 800 controllers, the LED mode can only be set in the LONWORKS NV

settings in CARE, and not in the CARE datapoint editor.

ONWORKS Bus Binary Input Module is used with non-

Maintenance Alarm

Specifying a maintenance alarm In the case of those datapoints for which an hours run log has been activated, a

time entry can occur within the attribute "Maintenance Alarm" to indicate after how

many operational hours an alarm message should be generated. Entering “Zero”

results in no alarm message.

Example:

Maintenance should be carried out every 500 hours on the heating circuit pump

controlled via a digital output. To achieve this, a time interval duration of 500 hours

is entered in the attribute "Maintenance Alarm" for this datapoint. At the same time,

activation of the hours run log must also take place in the attribute “Hours Run log”

for this datapoint.

An alarm message now occurs after 500 hours, to bring to the operator’s attention

the necessary pump maintenance.

Manual Value

When the attribute "Operating Mode" is set to "Manual", the operator can enter a

manual value or state, and the application program will work with this manual value

or state until the operating mode is set back to “Automatic”.

EN2B-0092GE51 R0709

27

Page 28

ATTRIBUTES EXCEL 50/100/500/600/800

Fig. 16. Example of a sensor input

In Fig. 16, the attribute "Operating Mode" is set to "Manual", i.e. the value entered

manually is processed in the application program.

NOTE:

“Value” and “Manual Value” are online attributes, relevant only during controller

operation via MMI or XL-Online. Furthermore, “Manual Value” is an internal online

attribute only, not visible to the operator! The operator will see only the online

attribute “value”, which can be edited only if the attribute "Operating Mode" is set to

"Manual". See also section "Operating Mode" on page 30.

Network Variable (V2.04.xx or higher)

Datapoints which are mapped to network variables on the LONWORKS network have

an attribute named "Network Variable" containing the network variable index (0-

4095) and the network variable name which allows this information to be displayed

on an MMI.

Normally Open/Normally Closed (V2.04.xx or higher)

The attribute "Normally Open/Normally Closed" defines the relationship between the

input/output signal of a digital datapoint and its logical status. This attribute is also

applicable when the digital point is the basic point of a flexible datapoint.

NOTE: The attribute "Active State" is fixed at 1 and is no longer relevant for

applications designed for this controller firmware version. Applications

designed for an older controller version will still work with this firmware

though, and in that case the attribute "Active State" is still active.

Table 11 and Table 12 show the relationship between the I/O signals, the attributes,

and the logical status for digital inputs and digital outputs, respectively

Table 11. The attribute " Normally Open/Normally Closed " – Digital Inputs

input signal NO/NC attribute logical status text displayed

Low (<2.5 V) N.O. 0 passive

High (>5 V) N.O. 1 active

Low (<2.5 V) N.C. 1 active

High (>5 V) N.C. 0 passive

.

EN2B-0092GE51 R0709 28

Page 29

EXCEL 50/100/500/600/800 ATTRIBUTES

Table 12. The attribute " Normally Open/Normally Closed " – Digital Outputs

output signal NO/NC attribute logical status text displayed

Low (<2.5 V) N.O. 0 passive

High (>5 V) N.O. 1 active

Low (<2.5 V) N.C. 1 active

High (>5 V) N.C. 0 passive

In the open LON mode, the "Normally Open/Normally Closed" functionality is

supported from CARE 5.0 and controller firmware 2.06.05 onwards.

CAUTION

Regarding “Normally Open/Normally Closed,” the behavior of controllers with OS <

2.06.05 engineered using CARE 4 differs significantly from controllers with OS

2.06.05 and higher engineered using CARE 7 and higher. See also section

“Controller OS 2.06 usage and functionality in CARE 4 and CARE – XL500 7.01.02”

in Excel CARE – User Guide (EN2B-0182GE51).

Motor Run Time

Time to open / time to close For actuators controlled via a three-position output, two values (time to open / time

to close) can be entered in the attribute “Motor Run Time”. This attribute defines the

time required by the actuator to change from the “Open” to the “Closed” state, and

vice versa.

If no value is entered for the “Time to Closed” motor run time, then the “Time to

Open” motor run time is assumed automatically. In the case of the motor run-on

time, when reversing directions, 1% of the “Time to Open” motor run time is added

to the calculated time.

The three-position output relay energizes when the calculated run time reaches

500 ms. The stated run time always amounts to 500 ms or a multiple thereof. A

calculated run time of, for instance, 1215 ms results in an actual run time of

1000 ms.

CAUTION

Regarding motor run time, the behavior of controllers with OS < 2.06.05 engineered

using CARE 4 differs significantly from controllers with OS 2.06.05 and higher

engineered using CARE 7 and higher. See also section “Controller OS 2.06 usage

and functionality in CARE 4 and CARE – XL500 7.01.02” in Excel CARE – User

Guide (EN2B-0182GE51).

Off Phase

Fig. 17. Off phase

The attribute "Off Phase" is used in conjunction with flexible datapoints of the type

"feedback". It defines the duration of the OFF phase on switching down. It is of

EN2B-0092GE51 R0709

29

Page 30

ATTRIBUTES EXCEL 50/100/500/600/800

relevance only if the attribute “Switching Down” is set to 0, i.e. if OFF phases are

selected on switching down.

• Range: 0 to 255s

• Default value : 10s

• Resolution: 1s

The OFF phase has to be defined for devices with large inertia, such as fans.

Operating Mode

The attribute "Operating Mode" enables the user to switch between manual and

automatic operation.

Automatic Under automatic operation, the controller processes the values at the inputs, for

instance from temperature sensors. For outputs, under automatic operation, the

status shown by the user/time switch program is adopted, e.g., "Heating circuit

pump off".

Manual During manual operation, the controller uses the manual values, for example, "flow

temperature setpoint = 60°C". Outputs adopt the preselected condition, for example,

"Heating circuit pump on".

Automatic/Manual Alarm For automatic operation, the attribute "Operating Mode" contains the inputs "Auto"

and "Manual". Each switch from automatic to manual operation and back again

generates a critical alarm.

Remote (V2.0.x) (not Excel 100C) If manual override controls are present on either the Analog Output (XFL522) or

Digital Output (XFL524) modules connected via a L

status of these controls (automatic/manual override) is stored in the attribute

"Operating Mode". If the manual override controls are set to automatic, the attribute

"Operating Mode" can be set to either automatic or manual. If the manual override

controls are set to manual override, then the attribute "Operating Mode" can be in

the remote mode, only.

Fig. 18 and Fig. 19 demonstrate the relationship betw

Mode", and both the attributes "Value" and "Manual Value" for input and output

functions.

Fig. 18. Control flow for input functions

ONWORKS network, then the

een the attribute "Operating

EN2B-0092GE51 R0709 30

Page 31

EXCEL 50/100/500/600/800 ATTRIBUTES

Fig. 19. Control flow for output functions

NOTE: The attribute "Remote" is available only if Manual Override modules are

installed on the Distributed I/O output modules. This attribute is therefore

not applicable to Excel 50/100/600.

Analog Points Table 13 indicates the analog point signals depending on the attribute "Operating

Mode":

Ta

ble 13. Analog point signals

automatic value*

manual value

remote value

resulting value

output signal

auto operating

mode

20% don’t care don't care

don't care 10% don't care

don't care don't care 50%

20% 10% 50%

2 V 1 V 5 V

* Automatic value is either the physical point value (inputs) or the value from the

program (outputs)

** Output only (V2.0.x)

manual operating

mode

remote**

operating mode

Digital points Table 14 indicates the digital point signals depending on the attribute "Operating

Mode":

Ta

ble 14. Digital point signals

automatic value*

manual Value

remote value

resulting Value

output signal

auto operating

mode

ON don’t care don’t care

don’t care OFF don’t care

n/a n/a ON

ON OFF ON

HIGH LOW HIGH

manual operating

mode

remote**

operating mode

*Automatic value is either the physical point value (inputs) of the value from the

program (outputs)

**Output only (V2.0.x)

Alarming The change from the 'automatic' to the 'manual' mode will create a point alarm if

other alarm conditions are set accordingly.

Firmware prior to V.2.04.x With controller firmware prior to V.2.04.xx, the alarm will report the status of the

operating mode as it was before the change.

Firmware V.2.04.x Beginning with controller firmware V.2.04.x, the alarm will report the status of the

operating mode as it is after the change.

EN2B-0092GE51 R0709

31

Page 32

ATTRIBUTES EXCEL 50/100/500/600/800

Output Type

Three-position outputs are digital outputs. From an operational viewpoint, they are

assigned the same datapoint description as analog outputs, i.e. a three-position

output possesses attributes similar to those of an analog output.

Analog or 3-position output The attribute "Output Type" determines whether the analog output datapoint

description should be assigned to an analog output or to a three-position output.

The following inputs are possible:

• Continuous: The analog output datapoint description is assigned to an analog

output.

• Three-position: The analog output datapoint description is assigned to a threeposition output.

• Remote three-position: Output to the Excel 100 MCE 3 and MCD 3 output

modules.

Subtype

The attribute "Subtype" is used in conjunction with digital outputs and flexible

datapoints. It determines whether the digital output is of the non-pulsed type.

Point Alarms

Pulse Duration

The attribute "Point in Alarm" refers to alarm messages from the alarm attributes

"Min. Limit", "Max. Limit", and "Alarm Status".

The attribute "Point in Alarm" indicates whether or not those datapoints using these

attributes are currently in alarm.

The following entries are possible:

• Yes = the chosen datapoint is in alarm

• No = the chosen datapoint is not in alarm

As soon as an alarm occurs (e.g. through exceeding a limit value), the attribute

"Point in Alarm" is set to "Yes". The attribute is immediately set back to "No" when

the limit value returns to normal.

The attribute "Pulse Duration" is used for the pulsed subtypes of the digital output

(i.e. "Pulse 1") and flexible datapoints of the type "Pulse 2". It defines the duration

between coming and going edge of a pulsed signal. The values for this attribute can

vary from 1 to 255 seconds; the resolution is 1 second. The default value is 1

second.

NOTE: After a power failure or disconnection of the controller, the “Pulse 1” and

“Pulse 2” outputs will resume their last output pulse behavior before the

outage.

Safety Position (XFx822x, XFx824x, and XFx830x modules)

The analog output modules XF822x/XFL822x/XFLR822x, the relay output modules

XFL824x/XFL824x/XFLR824x and the mixed I/O modules XF830x/XFU830x support

the “Safety Position” attribute, which can be set in the CARE datapoint editor.

The modules will put the outputs into the safety position as soon as communication

with the Excel 800 CPU is lost.

EN2B-0092GE51 R0709 32

Page 33

EXCEL 50/100/500/600/800 ATTRIBUTES

The XF822x/XF824x modules detect this lost communication once no more polls

are received from the Excel 800 CPU for more than one second.

The XFL822x/XFL824x and XF830x/XFU830x modules detect this lost

communication once no more polls are received from the Excel 800 CPU within the

heartbeat time of the module.

XF822x/XFL822x –”The following attribute options are provided:

“0%” equals 0 Vdc or 2 Vdc (0…11 Vdc or 2…11 Vdc characteristic)

“50%” equals 5 Vdc or 6 Vdc (0…11 Vdc or 2…11 Vdc characteristic)

“100%” equals 10 Vdc

“Remain in last position” (this is the default setting).

XF824x/XFL824x and XF830x/XFU830x –”The following attribute options are

provided:

“Off (logical)”

“On (logical)”

“Remain in last position” (this is the default setting).

NOTE: When the XFL822x/XFLR822x and XFL824x/XFLR824x modules are used

with non-Excel 800 controllers, the Safety Position can only be set in the

L

ONWORKS NV settings in CARE, and not in the CARE datapoint editor.

Scaling Factor

Input pulses from utility meters (gas, water, heat, etc.) can be connected to the