Honeywell EW776 DATASHEET

Ultrasonic Hydronic Meters

FOR HEATING AND COOLING APPLICATIONS

0102

M 07

DE-06-MI004-PTB017

500

Hydrometer

O: 3.....177K

Environm. class: E1

Mechanical class: M1

Metrological class:

heatmeter

Inst. place: low temp.

Prod.year: 2007

5N: 3400

2

6446

qi: 0.015m

qp: 1.5m

qs: 3m

O: 5.....130

DN: 15 IP 54

T.sensor: Pt

O: 0.....180°C

3

∆

/h

3

/h

3

/h

°C

PN: 16

0

Typ: 773

7730000

EW7730K1200

Design

Hydronic meters of the EW773 Series consist of:

• Electronic energy integrator with cable connection to the

ultrasonic volume measuring component, supply and return

temperature probe

• Ultrasonic volume measuring component with external

threads according to ISO228 (DN15...DN25) or flanges

(DN25…DN80)

Materials

• Housing of electronic energy integrator made of black and

transparent plastic

• Housing of ultrasonic volume measuring component made of

brass

EW773 Series

PRODUCT DATA

Application

Static compact hydronic meter with electronic measurement

based on the ultrasonic principle, consisting of electronic

energy integrator, ultrasonic volume measuring component and

temperature sensors.

Metering of hydronic heating and / or cooling energy in hydronic

systems based on volume, supply and return temperature.

EW7730 models are suitable for energy metering of heating

systems.

EW7731 models are suitable for energy metering of cooling

and combined cooling and heating systems.

Features

• MID approval

• First approval in Europe for ultrasonic heat meter with

dynamic range of qi/qp m³/h 1:250 in class 2 (qp 1.5 /

2.5 / 6.0m³/h)

• Complete dynamic range ≥ 1:1,500

• 12 years battery lifetime

• Meters up to qp 6 with patented free-beam principle and

robust swirl-free flow around reflector made of stainless

steel

• Meters qp10 and larger with direct beam principle

• Standard housing dimensions

• Can be used for heating (EW7730), cooling or both

(EW7731)

• Available in nominal sizes from qp 0.6 up to 40m³/h

• Measuring accuracy meets the requirements of EN1434

class 2 and 3

• No calming leg required on inlet or outlet for sizes up to

qp 0.6m³/h

• Power save mode

• Remote reading via M-Bus, RF, RS232 or optical interface

• Optional plug and play modules

• Individual tariff functions

• History memory for 24 months

• Extensive diagnostic displays

• Windows based HYDRO-SET parametrization software

for optimum adaptation to the user's specific needs

Honeywell y Subject to change EN0H-2600GE25 R1209

EW773 SERIES ULTRASONIC HYDRONIC METERS

Specifications

Medium Water, quality to VDI2035

Medium temperature see table below

Ambient temperature 0…55°C (32…131°F)

Operating pressure Threaded versions: PN16

Flanged versions: PN25

kvs (cv)-values see table below

Ambient class EN1434 class C / A

Protection class IP54 / IP64 (EW7731 volume measuring component only)

Type Static heat meter to EN1434

Measuring process Ultrasonic volume measurement

Display LCD, 7-digit

Units MWh – kWh – GJ – Gcal – MBtu

Total values 9 999 999 – 999 999.9 – 99 999.99 – 9 999.999

Values displayed Power – Energy – Flow rate – Temperature

Temperature sensors Pt500 with 2-wire leads

Sensor current Pt500 peak < 2; rms < 0.012mA

Measuring cycle Battery supply: 16s

Mains unit supply: 1s

Max. temperature difference 177K

Min. temperature difference 3K

Starting temperature difference 0.25K

Absolute temperature measuring range -9.9…189.9°C (14.2…373.8°F)

Operating voltage qp0.6…6: 3.0V lithium battery

qp10…40: 3.6V lithium battery

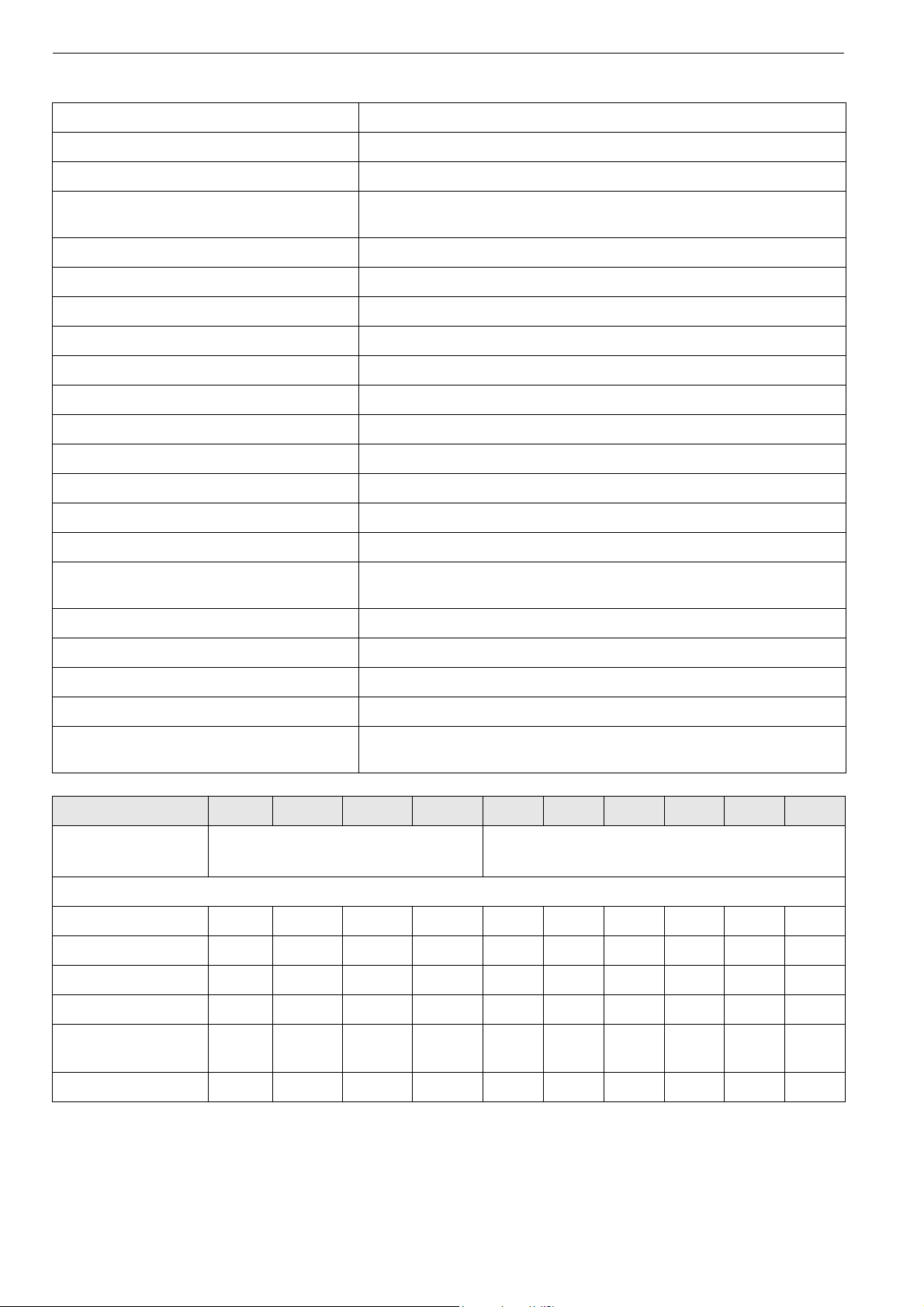

qp 0.6 1.0 1.5 2.5 3.5 6.0 10 15 25 40

Medium

temperature

EW7730: 20…130°C (68…266°F)

EW7731: 5...105°C (41...221°F)

EW7730: 20…150°C (68…302°F)

EW7731: 5...105°C (41...221°F)

Flow rates

Maximum (qs) m

Nominal (qp) m

3

/h1.2 2 3 5 7 1220305080

3

/h 0.6 1 1.5 2.5 3.5 6 10 15 25 40

Minimum (qi) l/h 6 10 6 10 35 24 40

1

/100 150 250 400

Starting l/h 1 2.5 2.5 4 7 7 15 30 50 80

kvs (cv)-value m3/h 2.06

(2.41)

5.27

(6.17)

5.48

(6.41)

7.91

(9.25)

16.7

(19.5)

16.8

(19.7)

32.5

(38.0)

61.2

(71.6)

94.5

(111)

127

(149)

∆p at qp mbar 85 36 75 100 44 128 95 60 70 100

NOTE: Medium temperature may be limited by installation position, see chapter 'Installation' on page 6.

1

when mounted in horizontal position

EN0H-2600GE25 R1209 2 Honeywell y Subject to change

Function

Integrator

The integrator contains all the necessary circuits for recording

flow rate and temperature and for calculating, logging and

displaying the data. The integrator housing can be mounted

directly onto the volume measuring component or to the wall.

The meter can be conveniently read from a single line sevendigit display with units and symbols. A pushbutton provides

user friendly control of the various display loops. All failures

and faults are recorded automatically and displayed on the

LCD screen. To protect the reading data, all relevant data is

saved in a non-volatile memory (EEPROM). This memory

saves the measured values, device parameters and types of

error at regular intervals

Ultrasonic volume measuring component

The ultrasonic technology of the volume measuring component

permits very high measuring accuracy and can be used in the

supply or return pipeline. The volume measuring component

meets the requirements of EN1434 / class 2 and 3. The standard cable length between the calculator and the volume

measuring component is 1.5m for meters up to qp 6 and 2.5m

for meters qp 10-40 (other cable lengths optionally on request).

Supply voltage:

Standard (12 year life)

• Meters up to qp 6: lithium battery 3.0V DC

• Meters qp 10-40: lithium battery 3.6V DC

Optional (please enquire):

• Meters up to qp 6: lithium battery 3.6V DC (16-year life)

• Meters up to qp 25: mains unit 230V AC or 24V AC

Temperature sensors

Pairs of Pt500 temperature sensors with 2-wire leads are used.

Interfaces

The EW773 Series is equipped as standard with a ZVEI optical

interface with the M-Bus protocol as per EN1434. This interface is used, for example, for communication with the HYDROSET parametrization software. The meter has two slots for plug

and play modules. One slot for a function module and one slot

for a communications module.

The following communication modules are available as options:

•RF module

• M-Bus module to EN1434

• RS232 module

The RS232 module is a serial interface and permits data

exchange with the heat meter. A special data cable is required

for this purpose.

The RF module communicates a list of predefined data

records. This can be edited by the HYDRO-SET software.

Pulse Input

Two additional pulse inputs are available. The pulse value and

the unit is configurable for energy, water, gas or electrical

metering by the HYDRO-SET software. Also two accounting

days are available for both inputs.

Pulse Output

The meter provides levels for two optional external pulse

outputs, which can be freely programmed using the HYDROSET software.

Possible pulse output values

• Energy (standard setting)

• Volume (standard setting)

• Tariff energy 1

• Tariff energy 2

• Tariff condition 1, limit switch

• Tariff condition 2, limit switch

EW773 SERIES ULTRASONIC HYDRONIC METERS

• Energy error

• Volume error

Module Combinations

The following module combinations for data transmission are

available ex works or for retrofitting in the field:

Function modules

• Pulse input module (2 inputs)

• Pulse output module (2 outputs)

• Pulse input module and pulse output module (1 input and 1

output)

• Combined pulse in- and output module (2 inputs / 1 output)

Communication modules

•M-Bus

• RS232

•RF

Accessories / Software

The HYDRO-SET parametrization software based on the MBus is a convenient tool for handling the hydronic meter. It runs

on Windows® 2000, and XP and is used for logs memories:

• setting up for operation

• reading out measured values

• printing of meter logs

• meter configuration

Event Memory

Events such as changes and faults are stored in a non-volatile

memory with a capacity of up to 31 entries. The following

events are recorded:

• Checksum error

• Temperature measurement error

• Ultrasonic echo time measurement errors

• Start and end of test mode

Monthly Memory

The EW773 Series has a history memory of 24 months. The

following values are stored in the EEPROM on the

programmed date 1…31 of the actual month:

• Date / Time

•Volume

• Energy

• Error day counter

• Maximum monthly flow rate

• Maximum monthly power

• Date of maximum monthly flow rate

• Date of maximum monthly power

• Tariff energy 1

• Tariff energy 2

• Tariff definition 1

• Tariff definition 2

• Impulse counter 1

• Impulse counter 2

Honeywell y Subject to change 3 EN0H-2600GE25 R1209

EW773 SERIES ULTRASONIC HYDRONIC METERS

Log Memory

The log memory is used to store consumption values. The

storage frequency can be selected from various storage intervals (1, 2, 3, 4, 5, 6, 10, 12, 15, 20, 30, 60 minutes or the default

setting of 24 hours, see Table 1). The data saved in the log

memory can be used for the following analyses:

• Reading the meter on a certain day

• Example: if the day for reasing is 01.10 (1 October), the

meter reading is displayed for the period from 01.10 of the

previous year to 30.09 of the current year.

• Comparison of the last consumption period with the preceding period

Table 1. Extract of possible log memory settings

Storage

interval

5 minutes Error status, overload

15 minutes 440 110 hours

1 hour 440 18.3 days

24 hours 440 440 days

Values Number of

data

records

440 36.6 hours

time temperature,

overload time flow rate,

forward temperature,

return temperature,

date and time,

energy,

tariff energy 1,

tariff energy 2,

tariff definition 1,

tariff definition 2,

volume,

error day counter

Recording

period

Maximum Values

The integrator creates max. values for power and flow rate

based on consumption time, which are stored in the EEPROM.

The integration intervals are adjustable to 6, 15, 30 or 60

minutes. Default setting is 60 minutes.

Tariff Function

The integrator offers two optional tariff memories for monitoring

plant load states for limit tariffs. Extensive tariff conditions

make it possible to adapte the meter individually to the required

customer-specific applications. Apart from the energy a timebased tariff can also be programmed.

The following limit types are possible (this example applies to

the display with 3 decimal places):

Table 2. Limit types

Type LIMIT LIMIT resolution

∆T 1 ... 190 °C 1 °C

T

P 1 ... 255 kW 1 kW

Q 100 ... 25 500 l/h 100 l/h

1 ... 190 °C 1 °C

Display Control

The readings are displayed on the meter by a 7-digit LCD with

units and symbols

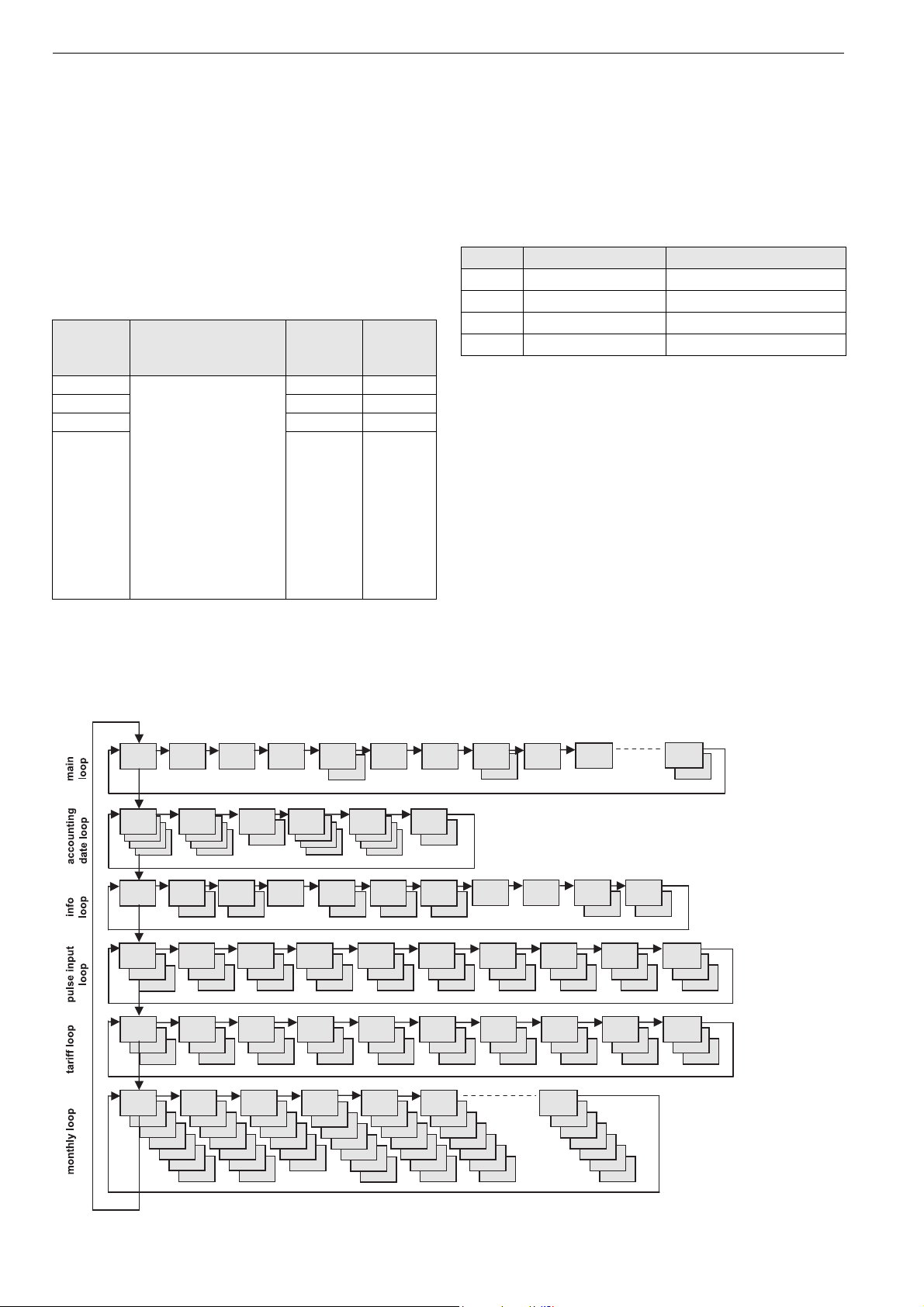

Loop Structure

The EW773 Series display has six loops. Some display

windows consist of two (to maximum seven) displays that are

shown alternately at 4-second intervals.

Some pictures in the loops can be deactivated separately.

NOTE: For quick visual guidance, the loops in the display are

The main loop with the current data, e.g. for energy, volume

and flow rate, is programmed as default setting. In the standard

setting loop No. 5 (tariff loop) is not active.

numbered from 1 to 6.

Fig. 1. Loop overview

EN0H-2600GE25 R1209 4 Honeywell y Subject to change

Loading...

Loading...