Page 1

D896 Automatic Vent Damper

PRODUCT DATA

FEATURES

• 4-wire plug receptacle.

• Includes wiring harness on select models to fit plug

receptacle onto S86/S8600/S8610/S8620 /L7148/L8148

or Penn Baso G60 or G66.

• For use only on atmospheric type gas-fired furnaces

and boilers equipped with draft hoods.

• Applicable to direct spark ignition (DSI), intermittent

pilot (IP), hot surface ignition (HSI), and standing pilot

systems.

• Ambient temperature range 32°F (0°C) to 150°F (65°C).

• Requires dual automatic combination gas control

valve or two separate single function main gas valves.

GENERAL

D896 Automatic Vent Dampers are used with atmospheric

type, gas-fired equipment to reduce home heating losses by

closing off the vent between heat cycles.

• Interlock switch provides safe operation; burner fires

only with damper in open position.

• 24V operation for easy, low-cost wiring.

• Visual indicator shows damper position.

• 30-second nominal closing time for optimum energy

savings.

• Quiet motor and relay.

• Wiring harnesses available separately to fit a variety of

applications.

Contents

General ............................................................................... 1

Features .............................................................................. 1

Specifications ...................................................................... 2

Ordering Information ........................................................... 2

Application........................................................................... 3

Installation ........................................................................... 4

Settings ............................................................................... 7

Operation and Checkout ..................................................... 7

Troubleshooting ................................................................... 8

Instructions to the Homeowner ........................................... 9

ANSI Standards .................................................................. 10

® U.S. Registered Trademark

Copyright © 1997 Honeywell Inc. • All Rights Reserved

68-0186

Page 2

D896 AUTOMATIC VENT DAMPER

SPECIFICATIONS

IMPORTANT

The specifications given in this publication do not

include normal manufacturing tolerances. Therefore,

this unit might not exactly match the listed

specifications. Also, this product is tested and

calibrated under closely controlled conditions, and

some minor differences in performance can be

expected if those conditions are changed.

TRADELINE® Models

TRADELINE® models are selected and packaged to provide

ease of stocking, ease of handling, and maximum

replacement value. TRADELINE® model specifications are

the same as those of standard models except as noted below.

TRADELINE® Models Available:

D896 Automatic Vent Damper with 4-wire plug receptacle.

Features:

• TRADELINE® pack with cross reference label.

•8 ft (2.4m), 4-wire cable with mating plug for D896 on one

end and mating plug for 86/S8600/S8610/S8620 or Penn

Baso G60 or G66 plug receptacle on the other end. Both

ends equipped with an outlet box connector.

Standard Models

Models:

D896 Automatic Aluminized Vent Dampers: available in 4

in. to 9 in.

D896 Stainless Steel Vent Dampers: available in 10 in. to

12 in.

Actuator assembly includes motor, relay, interlock switch,

safe-start circuit, and 4-pin plug receptacle. See Fig. 5.

Damper Size:

4, 5, 6, 7, 8, 9, 10, 11 and 12 in. diameter (102, 127, 152,

178, 203, 229, 254, 279 and 305 mm diameter).

Application:

For use only on Underwriters Laboratories Inc. listed and

American Gas Association design certified atmospheric type,

gas-fired furnaces and boilers equipped with a draft hood that

has an outlet area no larger than the damper inlet area. Do

not use with oil-fired furnace or boiler, power burner, or direct

vent furnace or boiler. See Location and Mounting

subsections in Installation section for additional application

considerations.

Maximum Appliance Input Rating:

Nominal Damper

Outlet Diameter

(in.) (mm) (Btuh) (W)

4 102 95,000 27,835

5 127 148,000 43,364

6 152 212,000 62,116

7 178 290,000 84,970

8 203 377,000 110,461

9 229 475,000 139,175

10 254 590,000 173,500

11 280 715,000 210,300

12 305 942,000 277,000

Electrical Ratings:

Power Supply: 24 Vac, 60 Hz.

Power:

Motor: 3.0 VA maximum.

Relay: 0.1 VA maximum.

Contact Rating:

Relay: 10.0A at 250 Vac.

End Switch (Micro): 3.0A at 24 Vac.

Do not use with 120V or millivoltage, self-generating

systems.

Maximum Appliance

Input

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Logistics

Honeywell Inc., 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

68-0186

2

Page 3

D896 AUTOMATIC VENT DAMPER

NOTE: A minimum of a 30 VA transformer must be used

when D896 is installed with S86/S8600/S8610/

S8620.

Electrical Connections:

Four-wire plug receptacle.

Thermostat Anticipator Setting:

0.13A.

Operating Times:

Approximate Damper Opening Time: 30 seconds.

Approximate Damper Closing Time: 30 seconds.

Temperature Ratings:

Minimum Ambient: 32°F (0°C).

Maximum Ambient: 150°F (66°C).

Maximum Furnace Stack: 575°F (302°C).

Shipping: -20°F to +120°F (-29°C to +49°C).

Mounting: See Fig. 2.

Vertical Stack: Any orientation.

Horizontal Stack: The damper actuator must be on the left

or right side of the vent.

IMPORTANT

Do not mount the vent damper with the actuator

above or below the vent.

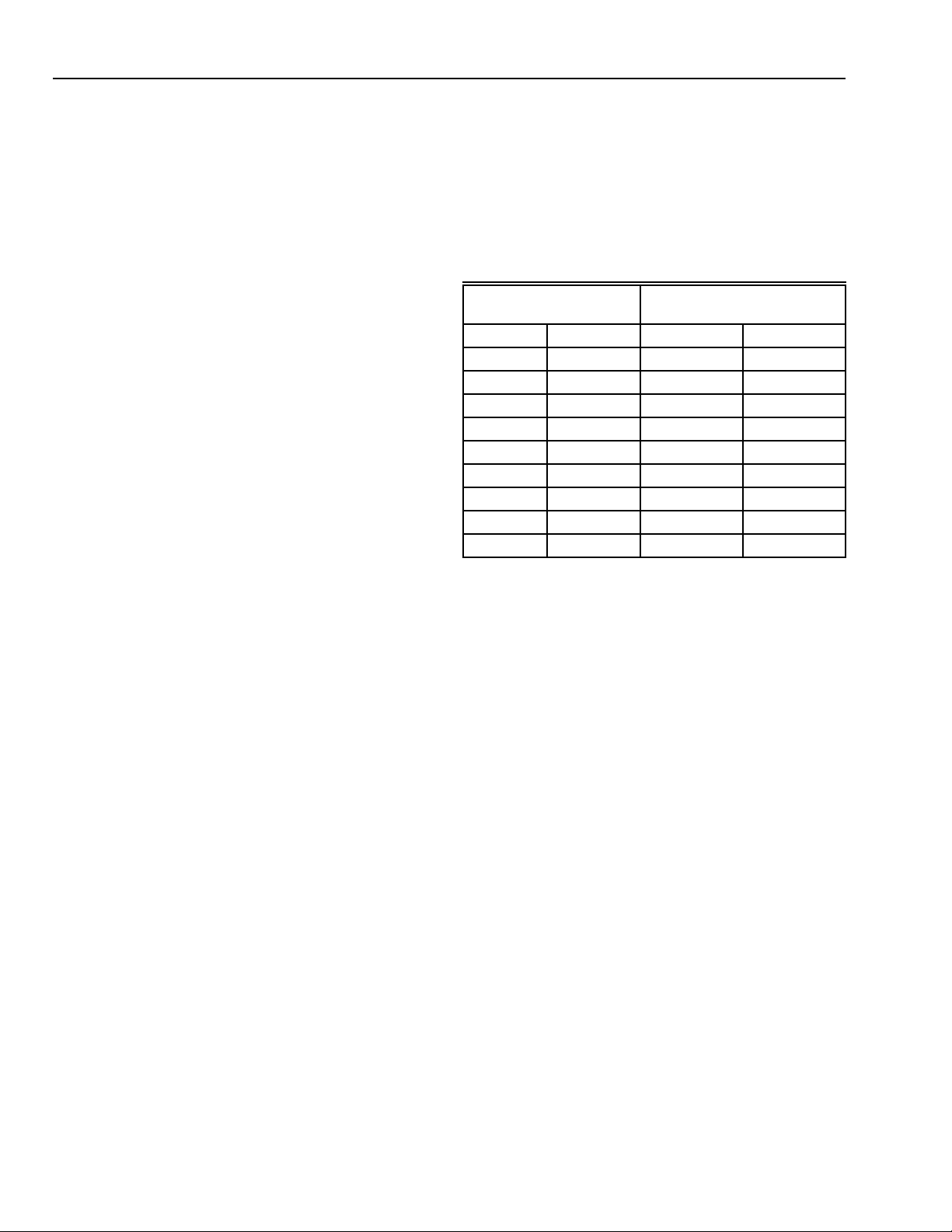

Dimensions:

See Fig. 1.

Approvals:

American Gas Association Certified:

Certificate No. U-66-2A1.

Canadian Gas Association Design Certified:

1029AVD-9081.

Replacement Parts:

Damper Actuator is field replaceable without removing the

damper assembly from the stack.

197516A Wiring Harness is a 4-wire cable, 8 feet (2.5

meters) long, with D896 mating plug on one end and

mating plug for S86/S8600/S8610/S8620 or Penn Baso

G60 or G66 on the other. An outlet box connector is on

each end.

APPLICATION

The D896 Automatic Vent Damper is a 24 Vac, motorized

stack damper. The damper closes off the furnace or boiler

stack during the heating off-cycle. Use the D896 only on

Underwriters Laboratories Inc. listed and American Gas

Association design certified atmospheric type, gas-fired

furnaces and boilers. The furnaces or boilers must be

equipped with a draft hood that has an outlet area no larger

than the damper inlet area. Do

or boiler, power burner, or direct vent furnace or boiler.

not

use with oil-fired furnace

BODY SIZE

(REF)

4 (102)

5 (127)

6 (152)

7 (178)

8 (203)

9 (229)

10 (254)

11 (279)

12 (305)

DIA. A

in. (mm)

3 15/16 (100)

4 15/16 (125)

5 15/16 (151)

6 15/16 (176)

7 15/16 (202)

8 15/16 (224)

9 15/16 (252)

10 15/16 (278)

11 15/16 (303)

DIA

A

DIA

B

DIM.

G

1

1 (32)

4

DIM.

DIA. C

in. (mm)

4 1/16 (103)

5 1/16 (129)

6 1/16 (154)

7 1/16 (179)

8 1/16 (205)

9 1/16 (230)

10 1/16 (256)

11 1/16 (281)

12 1/16 (306)

H

5 3/16 (132)

5 3/16 (132)

5 3/16 (132)

DIM. D

in. (mm)

1 9/16 (40)

1 9/16 (40)

1 9/16 (40)

3 3/16 (81)

3 3/16 (81)

3 3/16 (81)

DIM. E

in. (mm)

4 1/2 (114)

4 1/2 (114)

4 1/2 (114)

7 1/2 (191)

7 1/2 (191)

7 1/2 (191)

11 1/2 (292)

11 1/2 (292)

11 1/2 (292)

7

3 (98)

8

3

2

4

(70)

7/8 DIA. STD. KNOCKOUT (3)

(ONE, OPPOSITE SIDE)

DIA. B

in. (mm)

4 (102)

5 (127)

6 (152)

7 (178)

8 (203)

9 (229)

10 (254)

11 (279)

12 (305)

Fig. 1. Installation dimensions in in. (mm).

DIM. F

9

4 (116)

16

in. (mm)

13 (330)

13 (330)

13 (330)

DIM. E

DIM. F

6 (152)

6 (152)

6 (152)

9 (229)

9 (229)

9 (229)

DIM.

D

DIM. G

in. (mm)

6 3/4 (171)

7 1/4 (184)

7 3/4 (197)

8 1/4 (209)

8 3/4 (222)

9 1/4 (235)

9 3/4 (248)

10 1/4 (260)

10 3/4 (274)

DIA

C

DIM. H

in. (mm)

8 7/8 (225)

9 7/8 (251)

10 7/8 (276)

11 7/8 (301)

12 7/8 (327)

13 7/8 (352)

14 7/8 (378)

15 7/8 (403)

16 7/8 (428)

M11381

3

68-0186

Page 4

D896 AUTOMATIC VENT DAMPER

IMPORTANT

1. The atmospheric draft hood outlet area must be

smaller or equal to the inlet area of the damper

assembly.

2. If a second gas valve needs to be installed, refer

to the gas valve manufacturer instructions for the

procedure.

3. Using a dual automatic valve combination gas

control or two separate gas valves is required

with the D896.

4. Do not use with L8148 or L8124 with manual/

automatic switch because the switch can override

the safety interlock in the system wiring and

cause a hazardous condition.

5. Do not install on an appliance equipped with an

automatic valve with a manual opener unless the

manual opener is rendered inoperative or the

automatic valve is replaced with an automatic

valve without a manual opener.

6. On retrofit applications, installation identification

label (provided) must be filled out by installer and

applied to outside of cover.

INSTALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to follow them

could cause a hazardous condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained experienced service

technician. The D896 must be installed in compliance

with local codes or the Natural Gas Installation Code

CAN/CGA-B149.1-B149.1-M91 and CSA C22.2 #3

Electrical Features of Fuel Burning Equipment, or the

National Fuel Gas Code (ANSI Z223.1—NFPA 54) and

the National Electrical Codes (ANSI C1—NFPA70). Use

the ANSI Standard Z21.66-1994 included at the end of

this specification during installation.

NOTE: In Canada, the damper is not certified for

retrofit application. Certification for the

suitability of the damper and appliance

combination must be determined by the

Canadian Gas Association.

4. Install only on an appliance connected to a factory built

chimney or vent that complies with a recognized

standard, or to a masonry or concrete chimney that is

lined with a material acceptable to local code.

5. After installation is complete, check out product

operation as provided in the Checkout section. See

Exhibits A and B at the end of this specification.

CAUTION

Can cause electrical shock or equipment damage.

1. Disconnect power supply.

2. Do

3. Do

not

install within 6 in. (152 mm) of combustible

materials.

not

negate the action of any existing safety or

operational control.

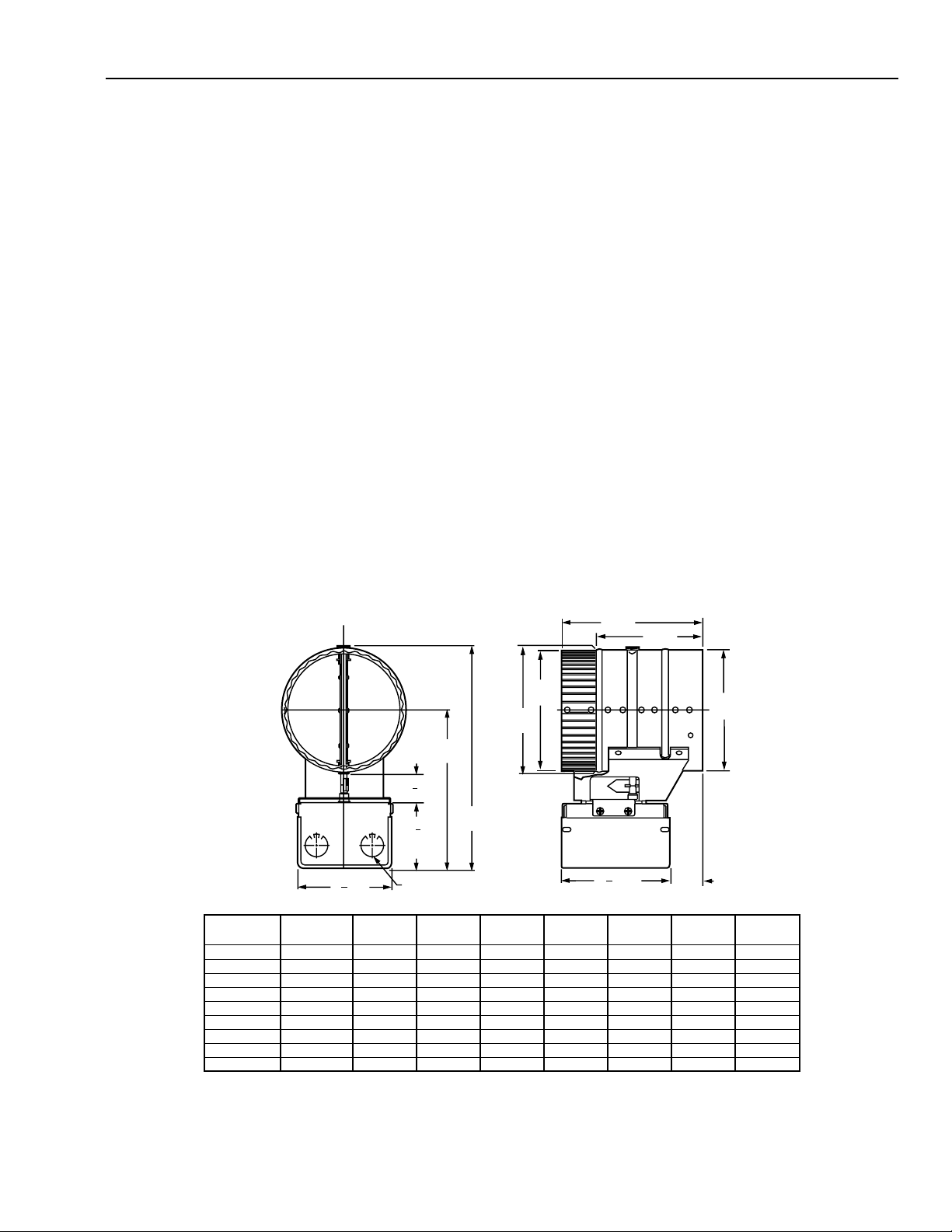

Location

The D896 must be installed

hood. See Fig. 2. Make sure the D896 Motor Actuator is

readily visible and accessible. The damper must be located

where air can freely circulate around it.

WARNING: DO NOT INSTALL THE

VENT DAMPER WITHIN 6 IN. (152 mm)

OF COMBUSTIBLE MATERIAL.

D896 MOTOR

ACTUATOR

VENT PIPE

CURVE

DRAFT

HOOD

FURNACE OR BOILER

2

1

INSTALL THE VENT DAMPER TO SERVICE ONLY THE SINGLE

APPLIANCE FOR WHICH IT IS INTENDED. IF IMPROPERLY

INSTALLED, A HAZARDOUS CONDITION, SUCH AS AN EXPLOSION

OR CARBON MONOXIDE POISONING, COULD RESULT.

DO NOT INSTALL THE VENT DAMPER ON VENT PIPE CURVE.

2

DO NOT RUN WIRES NEAR HIGH TEMPERATURE SURFACES.

3

USE STAND-OFF BRACKETS IF NECESSARY.

Fig. 2. D896 location.

Do

not

install the D896:

— Where the stack temperature is higher than 575°F (284°C).

— Where the ambient temperature is higher than 150°F

(66°C).

— In small or enclosed spaces where temperature can

exceed 150° F (66°C). See WARNING following.

— On the vent pipe curve. See Fig. 2.

1

3

after

the furnace or boiler draft

NO

WATER HEATER

CHIMNEY

M11370

WARNING

Severe illness or death possible. Prevent

explosion or carbon monoxide poisoning.

Overheating can cause premature device failure. Be

sure the D896 is used to control only one appliance.

Mounting

The damper must be mounted as close as possible to the

draft hood without modifying the draft hood. The D896 can be

mounted vertically or horizontally. When vertically mounting

the vent damper, the motor actuator can be in any position.

See Fig. 3.

Horizontal mounting requires the actuator to be located within

45 degrees directly above or directly below the horizontal

diameter of the stack pipe. See Fig. 2 and 3.

68-0186

4

Page 5

HORIZONTAL VENT INSTALLATION

D896

YES

D896 AUTOMATIC VENT DAMPER

NO

YES

FROM FURNACE

OR BOILER

VERTICAL VENT INSTALLATION

TO

CHIMNEY

FLOW

FROM FURNACE

OR BOILER

FLOW

TO CHIMNEY

D896

INSTALL VENT DAMPER

ONLY WITH ACTUATOR

TO SIDES OF VENT.

DO NOT MOUNT VENT

DAMPER WITH

ACTUATOR ABOVE

OR BELOW THE VENT.

INSTALL VENT

DAMPER WITH

ACTUATOR IN

ANY POSITION.

NO

M11371

Fig. 3. Installing D896 Vent Damper.

IMPORTANT

Never mount the vent damper with the motor

actuator above or below the vent.

Do

not

install the damper blade plug if the vent damper is

installed on a system with a continuous or standing pilot. The

hole provides the minimum vent area required by code for

safe operation.

Use the damper blade plug when the damper is installed on a

system with either an intermittent pilot or direct ignition. The

plug will increase system efficiency. See Fig. 4.

To install the D896:

1. Push the female end of the vent damper over the

section of vent pipe coming from the furnace or boiler,

but after the draft hood. Push the section of the vent

pipe coming from the chimney over the male end of the

vent damper.

2. Secure the vent damper to the vent pipe with 1/2 in. (12

mm) sheet metal screws. Use only the holes provided.

3. Visually inspect the venting system for proper pitch.

Pitch must comply with local codes or ANSI Z223.1—

NFPA54.

To install an additional gas valve:

1. Shut off the gas and electricity to the gas burner. (Use

the manual shutoff valve in the supply line to the

appliance.)

2. Locate a position in the supply line between the

appliance automatic gas valve and the burner.

3. At the determined position, install an approved

appropriately-sized, single-function automatic gas valve

downstream from the existing automatic gas valve.

Follow the valve manufacturer instructions for flow

direction and position.

4. Restore the gas line supply and conduct a leak test on

the gas piping and control system downstream from the

appliance shutoff valve.

MOTOR

ACTUATOR

DAMPER

BLADE PLUG

FOR DSI AND IP INSTALLATIONS ONLY – PLACE PLUG ON HOLE:

HOLD DAMPER BLADE AND PUSH DOWN ON PLUG.

DAMPER

BLADE

M9675

Fig. 4. Installing damper blade plug.

Wiring

WARNING

Severe illness or death possible. Prevent

explosion or carbon monoxide poisoning.

1. Use dual automatic valve combination gas

controls or two separate single function main gas

valves with the D896.

2. Do not use the D896 with an L8148 or L8124 with

a manual/automatic switch because the switch

can override the safety interlocks in the system

wiring and cause carbon monoxide buildup.

CAUTION

1. Remove the shorting plug on the S8600, S8610

or L8148E before attaching the wiring harness.

2. Do

3. Label all wires prior to disconnecting when

Important

D896 to L8148E, S8600F,H,M; S8610F,H

Use the wiring harness included with the D896 to wire it

according to the following instructions:

1. Connect the molex plug to the D896 Harness Cable

Connector. See Fig. 5.

2. Use Fig. 6 and 7 to connect the other end of the

harness to the furnace, boiler or control module.

3. Cycle system through at least two appliance operations.

not

permit device wiring to contact high

temperature surfaces.

servicing controls. Wiring errors can cause

explosion or carbon monoxide buildup.

Do not operate the system with the D896 unplugged.

Once the system has operated with the D896

plugged into the S8600, S8610 or L8148E, the

control module will not operate.

5

68-0186

Page 6

D896 AUTOMATIC VENT DAMPER

D896

SERVICE

SWITCH

NORM

SERV

1

S3 SWITCH

1

USE STANDARD SCREWDRIVER TO MANUALLY OPEN AND

CLOSE VENT DAMPER. PLACE SCREWDRIVER IN SLOTTED

KNOB AND ROTATE COUNTERCLOCKWISE UNTIL

BOTH LEDS TURN ON.

RELAY 1K

Fig. 5. D896 with cover off.

IGNITION GAS

PWR LED

CALL FOR

HEAT LED

HARNESS

CABLE

CONNECTOR

M11373

Replacing D80B, D892 or Competitive

Control with D896

WARNING

Bodily harm and/or death possible. Prevent

unsupervised gas flow.

Improper wiring (device malfunction) of the D80B,

D892, D896 or competitive devices can cause

unsupervised gas flow.

A wiring harness is included with most D896 models. Use the

harness to wire the D896 according to the furnace or boiler

manufacturer wiring instructions, if available; otherwise, follow

these instructions. If field wiring is required, see appliance

manufacturer instructions or see Fig. 8 for a typical wiring

example. See Table 1 for competitive wiring cross reference.

Always cycle system through at least two appliance

operations.

Honeywell

D892/D896

Wires

Yellow Orange Green 1

Orange Blue and Red White 2

Black Yellow Black 4

Table 1. Wiring Cross Reference.

Honeywell

D80B Wires

Johnson

Q35 Wires

EFFIKAL

RVG Wires

Blue Black Red 3

D896

LED 2

4

N.O.

S2

C

K1

C

N.O.

S3

K1

DAMPER OPEN

DAMPER CLOSED

MOTOR

NORMAL

S4

5

SERVICE

N.O.

N.C.

S1

C

N.C.

LED 1

3

POLARIZED 4-PRONG MALE MOLEX PLUG AND

4-PRONG FEMALE MATING PLUG ON CABLE

SWITCHES AS SHOWN: S1,S2,S3

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

AFTER D896 VENT DAMPER IS PLUGGED TO L8148E1166, FUSE

2

BLOWS WHEN THERMOSTAT FIRST CLOSES. AFTER FUSE BLOWS,

L8148E1166 OPERATES ONLY WHEN VENT DAMPER IS CONNECTED.

3

LED 1 LIGHTS WHEN DAMPER IS OPEN.

4

LED 2 LIGHTS WITH CALL FOR HEAT.

5

SERVICE SWITCH. THE NORMAL SWITCH SETTING IS NORM. IF THE

SWITCH IS MOVED TO THE SERV POSITION, THE DAMPER REMAINS OPEN.

6

NO W,Z TERMINALS ON L7148.

R1, R2, R3

250 OHMS

N.C.

4

2

1

3

WIRING

HARNESS

24 Vac

THERMOSTAT

4

2

3

FUSE

2

5

1

6-PRONG FEMALE MOLEX

RECEPTACLE IN L8148E

AND 5-PRONG MALE

MOLEX PLUG ON CABLE

TW

1K

B1

Z

6

24V GND

24V

TV

L8148E1166/L7148

C2

C1

1K1

L2

L1B2

L1

L2

(HOT)

CIRCULATOR

1

M11382

Fig. 6. Wiring diagram for D896 connection to L8148E1166 /L7148 using wiring harness with two Molex plugs.

68-0186

6

Page 7

MV MV/PV PV

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

CONNECT COLORS OF WIRING HARNESS AS SHOWN.

ALTERNATE LIMIT CONTROLLER HOOKUP.

2

3

M11372

WIRING

HARNESS

YELLOW

BLUE

BLACK

ORANGE

THERMOSTAT

LIMIT

CONTROLLER

L1

(HOT)

L2

LIMIT

CONTROLLER

1

D896

1

TH TH

2

DUAL AUTOMATIC

VALVE COMBINATION

GAS CONTROL

TRANSFORMER

2

1

3

1234

M11383

YELLOW

BLACK

ORANGE

BLUE

RED

YELLOW

ORANGE

BLUE

D80B

CONNECTOR

D80B

CABLE

D892/D896

CABLE

BLACK

GND

(BURNER)

S8600F, H, M; S8610F,H

1

24V

GND

24V SPARK

2

VENT

DAMPER

PLUG

D896 AUTOMATIC VENT DAMPER

SENSETH-W

POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

REMOVE PLUG ONLY IF USING VENT DAMPER. FUSE

2

BLOWS ON STARTUP WHEN PLUG IS REMOVED;

THEN MODULE OPERATES ONLY WHEN VENT

DAMPER IS CONNECTED.

WIRING

HARNESS

D896

VENT

DAMPER

M11375

Fig. 7. Wiring diagram for D896 connection to S8600/S8610 using wiring harness with two Molex plugs.

1. When replacing a D80B or D892 with a D896, use the

included wire nuts to connect the D80B or D892 cable

to the D896 cable. See Fig. 9.

a. Remove the black wire from the D80B (or D892)

terminal 1.

furnace or boiler burner lights. When the heating cycle ends,

both LEDs turn off, the burner turns off and the damper

automatically closes. Heating system efficiency is increased

because the closed damper reduces the loss of residual

appliance heat and heated room air through the draft diverter.

b. Use a wire nut to connect the D80B (or D892)

black wire to the D896 blue wire.

c. Remove the orange wire from the D80B (or

D892) terminal 2.

d. Wire nut the D80B (or D892) orange wire to the

D896 yellow wire.

e. Remove the red wire from the D80B (or D892)

terminal 3 and the blue wire from the D80B (or

D892) terminal 5.

f. Wire nut the D80B (or D892) red and blue wires

to the D896 orange wire.

g. Remove the yellow wire from the D80B (or D892)

terminal 4.

h. Wire nut the D80B (or D892) yellow wire to the

D896 black wire.

2. Cycle the system through at least two appliance

operations.

Snap-Tite™ Connector Release

To release the D896 cable from the knockout hole when

secured with a Snap-Tite™ Box Connector (Fig.10), slip a

screwdriver under the tab and twist.

SETTINGS

The service switch operates in both normal (NORM ) or

service (SERV) modes. See Fig. 5.

NORM—D896 opens on a call for heat and closes at the end

of the heating cycle.

SERV—D896 remains open at the end of a call for heat. The

switch must be in the SERVICE position before manually

opening the damper.

OPERATION AND CHECKOUT

Operation

On a call for heat, the CALL FOR HEAT LED on the actuator

lights and the damper begins to open. When the damper is

fully open, the IGNITION GAS PWR LED lights and the

Fig. 8. Wiring diagram for D896 connection to continuous

pilot system using wiring harness with one Molex plug.

Fig. 9. Connecting D80B, D892 Cable to D896 Cable.

7

68-0186

Page 8

D896 AUTOMATIC VENT DAMPER

Fig. 10. Snap-Tite™ Box Connector release.

Checkout

Heating

1. Tu rn on the power supply.

2. If using a thermostat, set the heat anticipator at 0.13A.

3. Set the thermostat or controller to 10°F (6°C) above the

room temperature to call for heat.

4. Check that the D896 CALL FOR HEAT and IGNITION

GAS PWR LEDs light and that the damper opens

before the gas valve opens and the pilot or main burner

ignites. See Fig. 11.

NOTE: If a boiler gas control is sequenced by the

Aquastat® Controller, make sure that the

damper opens prior to the opening of the gas

control.

5. Tu rn the thermostat or controller 10°F (6°C) below the

room temperature. Make sure the LEDs turn off and the

D896 closes.

6. Cycle the heating system at least three times using the

thermostat or controller to assure the system is

operating safely.

Cooling

CAUTION

Damage to air conditioner condenser possible.

Do not operate cooling if outdoor temperature is below

50°F (10°C).

1. Set the thermostat or controller to COOL. Move the

setpoint to 10°F (6°C) below the room temperature.

2. Make sure the cooling system operates.

3. Check that the D896 is in the closed position. See Fig.

11.

4. Return the thermostat or controller to the desired

settings.

NOTE TO INSTALLER: Explain to the homeowner that a

yearly inspection by a trained, experienced service

technician is necessary for safe, efficient operation

of the vent damper and heating system. The

homeowner should check for deterioration from

corrosion or other sources between service

technician calls.

TROUBLESHOOTING

WARNING

Fire or explosion hazard can cause property

damage, severe injury or death.

Explosion or carbon monoxide poisoning

possible.

Never apply a jumper across or short gas control

terminals or wires because this can force the D896 to

remain closed and cause an explosion.

68-0186

M3431

THE AIR DUCT IS CLOSED WHEN THE

INDICATOR POINTS PERPENDICULAR TO

THE DIRECTION OF THE AIR DUCT

Fig. 11. Determining damper position.

THE AIR DUCT IS OPEN WHEN

THE INDICATOR POINTS IN THE

DIRECTION OF THE AIR DUCT

8

Page 9

D896 AUTOMATIC VENT DAMPER

NOTE: If there is a power failure, the damper remains

exactly where it is at the moment of failure (open,

closed or any position in between). When power is

restored, the damper opens if the thermostat is

calling for heat or closes if the thermostat is not

calling for heat.

If system fails to start, set the thermostat 10°F (6°C) below

the room temperature for approximately three minutes, and

refer to Table 2 to troubleshoot the system.

INSTRUCTIONS TO THE HOMEOWNER

A yearly inspection by a trained, experienced service

technician is necessary for safe, efficient operation of the vent

damper and all flue product-carrying areas of the appliance.

The homeowner should check for deterioration from corrosion

and other sources between service technician calls. If

corrosion or other deterioration is noticed, contact your

Table 2. Troubleshooting.

Thermostat Setting Symptom Possible Cause Action

Set thermostat 10°F

above room temperature

to call for heat.

Set thermostat 10°F

below the room

temperature to end the

call for heat.

No response from D896. Incorrect wiring or blown

fuse.

24 Vac is present, damper

is open, CALL FOR HEAT

LED is on, IGNITION GAS

PWR LED is on, but no

heat is produced.

24 Vac is present, damper

is open, CALL FOR HEAT

LED is on, IGNITION GAS

PWR LED is off, no heat is

produced.

24 Vac is present, damper

is closed, CALL FOR HEAT

LED is off and no heat is

produced.

24 Vac is present, damper

is closed and CALL FOR

HEAT LED is off.

24 Vac is present, damper

is closed and CALL FOR

HEAT LED is on.

LEDs turn off, but damper

does not close in

approximately 30 seconds.

Appliance ignition

system malfunction.

D896 malfunction. Replace the D896.

Incorrect wiring or D896

malfunction.

Incorrect wiring or D896

malfunction.

Incorrect wiring or D896

malfunction.

Incorrect service switch

setting or D896

malfunction.

heating contractor for repairs. The name of the original

installer of your vent damper is on the installation label.

Check vent damper operation as follows:

1. Turn the thermostat or controller below the room

temperature to turn off the furnace or boiler. Assure the

vent damper position indicator points to the closed

position. Refer to Fig. 11.

2. Turn the thermostat or controller above the room

temperature to call for heat. Assure the vent damper

position indicator points to the open position. Refer to

Fig. 11.

3. Turn the thermostat or controller below the room

temperature again. Assure the vent damper position

indicator returns to the closed position.

4. If the system has central air conditioning, set the

thermostat or controller to COOL and turn it below the

room temperature to call for cooling. Assure the cooling

system operates with the vent damper in the closed

position.

5. Return the thermostat or controller to the desired

settings.

• Check the circuit breaker or fuse and,

if necessary, reset or replace.

• Check the transformer and limit

control.

• Check for 24 Vac across resistor R1.

• Check for 24 Vac at the S8600, S8610

and L8148E.

• Check wiring and cable connections.

Check appliance ignition system.

Check all wiring and cable connections.

• If 24 Vac is present across resistor

R1, replace the D896.

• If 24 Vac is not present across R1,

check the appliance ignition

system.

Check all wiring and cable connections.

• If 24 Vac is present across resistor

R1, replace the D896.

• If 24 Vac is not present across R1,

check the appliance ignition

system.

If wiring is correct and the damper does

not fully open after approximately 30

seconds, replace the D896.

• Check if the service switch is in the

normal (NORM ) position. If not, move

the switch to the NORM position.

• If service switch is in the NORM

position, replace the D896.

9

68-0186

Page 10

D896 AUTOMATIC VENT DAMPER

ANSI STANDARDS

Procedure For Safety Inspection of an Existing Appliance Installation

The following procedure is intended as a guide to aid in

determining that an appliance is properly installed and is in a

safe condition for continuing use.

This procedure is predicated on central furnace, boiler and

water heater installations, and it should be recognized that

generalized procedures cannot anticipate all situations.

Accordingly, in some cases deviation from this procedure may

be necessary to determine safe operation of the equipment:

a. This procedure shall be performed prior to installation

of the automatic vent damper device.

b. If it is determined there is a condition which could result

in unsafe operation, the appliance should be shut off

and the owner advised of the unsafe condition. Do not

install the automatic vent damper device until the

unsafe condition has been corrected.

The following steps are to be followed in making the safety

inspection:

1. Conduct a gas leakage test of the appliance piping and

control system downstream of the shutoff valve in the

supply line to the appliance.

2. Visually inspect the venting system for proper size,

horizontal pitch and vent termination, and determine

there is no blockage or restriction, leakage, corrosion

and other deficiencies which could cause an unsafe

condition.

3. Determine that the chimney or vent is acceptable to the

authority having jurisdiction.

4. Shut off all gas to the appliance and shut off any other

fuel-gas burning appliance within the same room.

EXHIBIT A

Use

the shutoff valve in the supply line to each appliance.

5. Inspect burners and crossovers for blockage and

corrosion.

6.

Applicable only to furnaces

cracks, openings or excessive corrosion.

7.

Applicable only to boilers

or combustion product leaks.

8. Insofar as is practical, close all building doors and

windows and all doors between the space in which the

appliance is located and other spaces of the building.

Tu rn on clothes dryers. Turn on any exhaust fans, such

as range hoods and bathroom exhausts, so they will

operate at maximum speed. Do not operate a summer

exhaust fan. Close fireplace dampers. If, after

completing Steps 9 through 14, it is believed sufficient

combustion air is not available, refer to local codes, or

in the absence of local codes, to the National Fuel Gas

Code, ANSI Z223.1-1988 (NFPA 54), for guidance.

9. Place in operation the appliance being inspected.

Follow the lighting instructions.

appliance will operate continuously.

—inspect heat exchanger for

—inspect for evidence of water

Adjust thermostat so

10. Determine that the pilot(s), when provided, is burning

properly and that main burner ignition is satisfactory by

interrupting and reestablishing the electrical supply to

the appliance in any convenient manner.

If the appliance is equipped with a continuous pilot(s), test the

pilot safety device(s) to determine if it is operating properly by

extinguishing the pilot(s) when the main burner(s) is off and

determining, after 3 minutes, that the main burner gas does

not flow upon a call for heat.

If the appliance is not provided with a pilot(s), test for proper

operation of the ignition system in accordance with the

appliance manufacturer’s lighting and operating instructions.

11. (a) Visually determine that main burner gas is burning

properly; i.e., no floating, lifting or flashback. Adjust

the primary air shutter(s) as required.

(b) If the appliance is equipped with high and low

flame controlling or flame modulation, check for

proper main burner operation at low flame.

12. Test for spillage at the draft hood relief opening after 5

minutes of main burner operation. Use the flame of a

match or candle, or smoke from a cigarette, cigar or

pipe.

13. Turn on all other fuel-burning appliances within the

same room so they will operate at their full inputs.

Follow lighting instructions for each appliance.

14. Repeat Steps 11 and 12 on the appliance being

inspected.

15. Return doors, windows, exhaust fans, fireplace

dampers and any other fuel-gas burning appliances to

their previous conditions of use.

16.

Applicable only to furnaces

control and the fan control for proper operation. Limit

control operation can be checked by blocking the

circulating air inlet or temporarily disconnecting the

electrical supply to the blower motor and determining

that the limit control acts to shut off the main burner

gas.

17.

Applicable only to boilers

(a) Determine that the water pumps are in operating

condition.

(b) Test low water cutoffs, automatic feed controls,

pressure and temperature limit controls, and relief

valves in accordance with the manufacturer’s

recommendations to determine they are in

operating condition.

—Check both the limit

—

68-0186

Exhibit A of ANSI Standard Z21.66-1994 for Electrically Operated Automatic Vent Damper Devices

for use with Gas-Fired Appliances.

10

Page 11

D896 AUTOMATIC VENT DAMPER

EXHIBIT B

Procedure for Installing Electrically Operated Automatic Vent Damper Devices on Existing Appliances

This procedure is intended as a guide to aid in safely

installing an electrically operated or mechanically actuated

automatic vent damper device on an existing appliance.

This procedure is based on the assumption that the history of

the specific appliance has been one of safe and satisfactory

operation.

This procedure is predicated on central furnace, boiler and

water heater installations, and it should be recognized that

generalized procedures cannot anticipate all situations.

Accordingly, in some cases deviation from this procedure may

be necessary to determine safe operation of the equipment.

The following steps are to be followed in making the

modifications:

1. Perform a safety inspection of the existing appliance

installation. See Exhibit A for the recommended

procedure for such a safety inspection.

2. Shut off all gas and electricity to the appliance.

To shut

off gas use the shutoff valve in the supply line to the

appliance.

3. Install the automatic vent damper device in strict

accordance with the manufacturer’s installation

instructions. Make certain the device is not located in

that portion of the venting system which serves any

appliance other than the one for which the damper is

installed.

4. Make certain wiring connections are tight and wires are

positioned and secured so they will not be able to

contact high temperature locations.

5. When an additional automatic valve has been

incorporated or an existing gas control replaced,

conduct a gas leakage test of the appliance piping and

control system downstream of the shutoff valve in the

supply line to the appliance.

6. Visually inspect the modified venting system for proper

horizontal pitch.

7. Check that the damper and gas valve(s) are in the

correct operating sequence.

(a) The damper must be in the full open position

before the gas valve(s) opens.

(b) The damper must remain in the full open position

while the gas valve(s) is open.

(c) The gas valve(s) must be closed before damper

begins

its return to the closed position.

(d) The damper shall remain in the closed position

8. Determine the amperage draw of the gas control circuit

9. Sequence the appliance through at least three normal

during the off cycle of the appliance.

and damper device.

(a) Check appliance transformer for adequate

capacity.

(b) Check heat anticipator in comfort thermostat to

determine if it is properly adjusted.

operating cycles.

10. Insofar as is practical, close all building doors and

windows and all doors between the space in which the

appliance is located and other spaces of the building.

Tu rn on clothes dryers. Turn on any exhaust fans, such

as range hoods and bathroom exhausts, so they will

operate at maximum speed. Do not operate a summer

exhaust fan. Close fireplace dampers.

11. Place appliance in operation.

instructions.

continuously.

12. Test for spillage at the draft hood relief opening after 5

minutes of main burner operation. Use the flame of a

match or candle, or smoke from a cigarette, cigar or

pipe.

13. (a) Visually determine that main burner gas is burning

(b) If the appliance is equipped with high and low

14. Determine that the pilot(s), when provided, is burning

properly and that main burner ignition is satisfactory by

interrupting and reestablishing the electrical supply to

the appliance in any convenient manner.

If the appliance is equipped with a continuous pilot(s), test the

pilot safety device(s) to determine if it is operating properly by

extinguishing the pilot(s) when the main burner(s) is off and

determining, after 3 minutes, that the main burner gas does

not flow upon a call for heat.

If the appliance is not provided with a pilot(s), test for proper

operation of the ignition system in accordance with the

appliance manufacturer’s lighting and operating instructions.

15.

Applicable only to furnaces

control and the fan control for proper operation. Limit

control operation can be checked by blocking the

circulating air inlet or temporarily disconnecting the

electrical supply to the blower motor and determining

that the limit control acts to shut off the main burner

gas.

16.

Applicable only to boilers

(a) Determine that the water pumps are in operating

(b) Test low water cutoffs, automatic feed controls,

17. Label the damper device (see 1.7.5) with information as

to:

(a) Name of qualified agency responsible for damper

(b) Date of installation.

Adjust thermostat so appliance will operate

properly; i.e., no floating, lifting or flashback. Adjust

the primary air shutter(s) as required.

flame controlling or flame modulation, check for

proper main burner operation at low flame.

condition.

pressure and temperature limit controls, and relief

valves in accordance with the manufacturer’s

recommendations to determine they are in

operating condition.

installation.

Follow the lighting

—Check both the limit

—

Exhibit B of ANSI Standard Z21.66-1994 for Electrically Operated Automatic Vent Damper Device

for use with Gas-Fired Appliances.

11

68-0186

Page 12

D896 AUTOMATIC VENT DAMPER

Home and Building Control

Honeywell Inc.

Honeywell Plaza

P.O. Box 524

Minneapolis MN 55408-0524

Home and Building Control

Honeywell Limited-Honeywell Limitée

155 Gordon Baker Road

North York, Ontario

M2H 2C9

Honeywell Asia Pacific Inc.

Room 3213-3225

Sun Hung Kai Centre

No. 30 Harbour Road

Wanchai

Hong Kong

Honeywell Latin American Division

Miami Lakes Headquarters

14505 Commerce Way Suite 500

Honeywell Europe S.A.

3 Avenue du Bourget

B-1140 Brussels Belgium

Miami Lakes FL 33016

Helping You Control Your World

68-0186 J.S. 3-97 Printed in U.S.A. customer.honeywell.com

68-0186

12

®

Loading...

Loading...