Page 1

D2 (Former D642), D3 (Former D640)

CONTROL DAMPERS

FEATURES

Frame:

• Standard frames utilize heavy-duty 5 in. (12.7 cm) x 1 in.

(0.25 cm) 16 ga. galvanized steel hat channel frame,

designed for installation inside ductwork. Reinforced

corners. Low profile head and sill on dampers less than 17

in. (43.2 cm) high.

Frame Options:

• Stainless steel and aluminum (14 and 12 gage galvanized

steel only).

• Single flange (either side of frame) or double flange (both

sides of frame). (See Fig. 2.)

Flange:

• Additional 1 1/2 in. on each side.

Blades:

• Standard 3-V blades are fabricated from a single thickness

of 16 ga. galvanized steel incorporating three longitudinal

structural V-grooves (each running the full length of the

blade). (See Fig. 1.) This blade has low to medium velocity

and pressure capabilities.

Honeywell International, Inc. certifies that the

models D2, and D3 shown herein are licensed to

bear the AMCA Seal. The ratings shown are

based on tests and procedures performed in

accordance with AMCA Publication 511 and

comply with the requirements of the AMCA

Certified Ratings Programs. The AMCA Certified

Ratings Seal applies to air performance ratings

only. March 2008.

The D2, D3 Control Dampers are ruggedly built with 3-V style

blades for application as automatic control or manual

balancing dampers in low to medium pressure and velocity

systems. A wide range of electric or pneumatic actuators are

available for these models.

The D2 series is an ultra low leakage control damper which

includes blade and jamb seals.The D3 series is a general

purpose damper intended for applications where low leakage

performance is not necessary.

Axles:

• 1/2 in. (1.3 cm) diameter square plated steel axles

positively locked to the blades eliminate slippage between

blades and axles. Removable shaft extends 6 in. (15.2 cm)

beyond frame. Optional stainless steel construction.

Bearings:

• Molded synthetic (acetal) bearings rotate in a polished

extruded frame raceway. Extremely low friction and long

operating life result from this advanced design. Bronze or

stainless steel bearings are optional.

Linkage:

• Blade-to-blade linkage (for parallel or opposed blade

action) is concealed within the frame.

• Linkage is engineered to accurately control each and every

blade without need for adjustment. Plated steel

construction ensures a long corrosion free life.

Seals:

• D2 Only: Flexible stainless steel compression-type jamb

seals (between blade ends and side frames) and extruded

vinyl blade seals (between blade edges) reduce leakage.

Silicone or blade seals are optional.

Sizing:

• Nominal sizing results in 1/4 in. undersizing on each side.

Actual sizing available as option.

PRODUCT DATA

Features ............................................................................ 1

Specifications .................................................................... 2

Ordering Information ......................................................... 2

Contents

63-2598-09

Page 2

D2 (FORMER D642), D3 (FORMER D640)

SPECIFICATIONS

Size Limitations:

Pressure:

2 1/2 in. - 5 in. (622 Pa - 1245 Pa) pressure differential.

Velocity:

2000 fpm - 3000 fpm (10.2 m/s - 15.2 m/s).

Size Range:

Minimum Size:

One Blade: 6 in. (15.2 cm) W x 6 in. (15.2 cm) H.

Two Blade: 6 in. (15.2 cm) W x 10 in. (25.4 cm) H.

Maximum Size:

Single Section: 48 in. (121.9 cm) W x 72 in. (182.9 cm) H.

Multiple section size unlimited.

NOTE: W and H dimensions furnished 1/4 in. (0.6 cm)

undersize.

Maximum Temperature:180° F (82° C).

NOTE: Temperatures exceeding 180° F (82° C) require

special consideration.

Parallel/Opposed Blade Operation (Fig. 3)

Control dampers are offered with either parallel or opposed

blades (silicone or vinyl blade seals are optional). Each style

has distinguishing characteristics regarding fan performance

control and change in air velocity profile:

— Parallel blade operation is preferred:

— When the damper makes up a significant portion

of the total system pressure loss.

— When greater control is required near the top end

of the volume operating range or for systems

requiring two position (fully open or fully closed)

operation.

— Parallel blades should not be used upstream of

critical components due to uneven airflow.

— Opposed blade operation is preferred:

— When the damper doesn’t make up a significant

portion of the total system pressure loss.

— For applications where it is necessary to maintain

even distribution of air downstream from the

damper.

— For ducted outlets.

— Opposed blade dampers must open farther to

obtain the same airflow resistance as parallel

blade dampers.

M20586

1-1/4 (32)

MAX.

(TYPICAL)

1-1/4 (32)

MAX.

(TYPICAL)

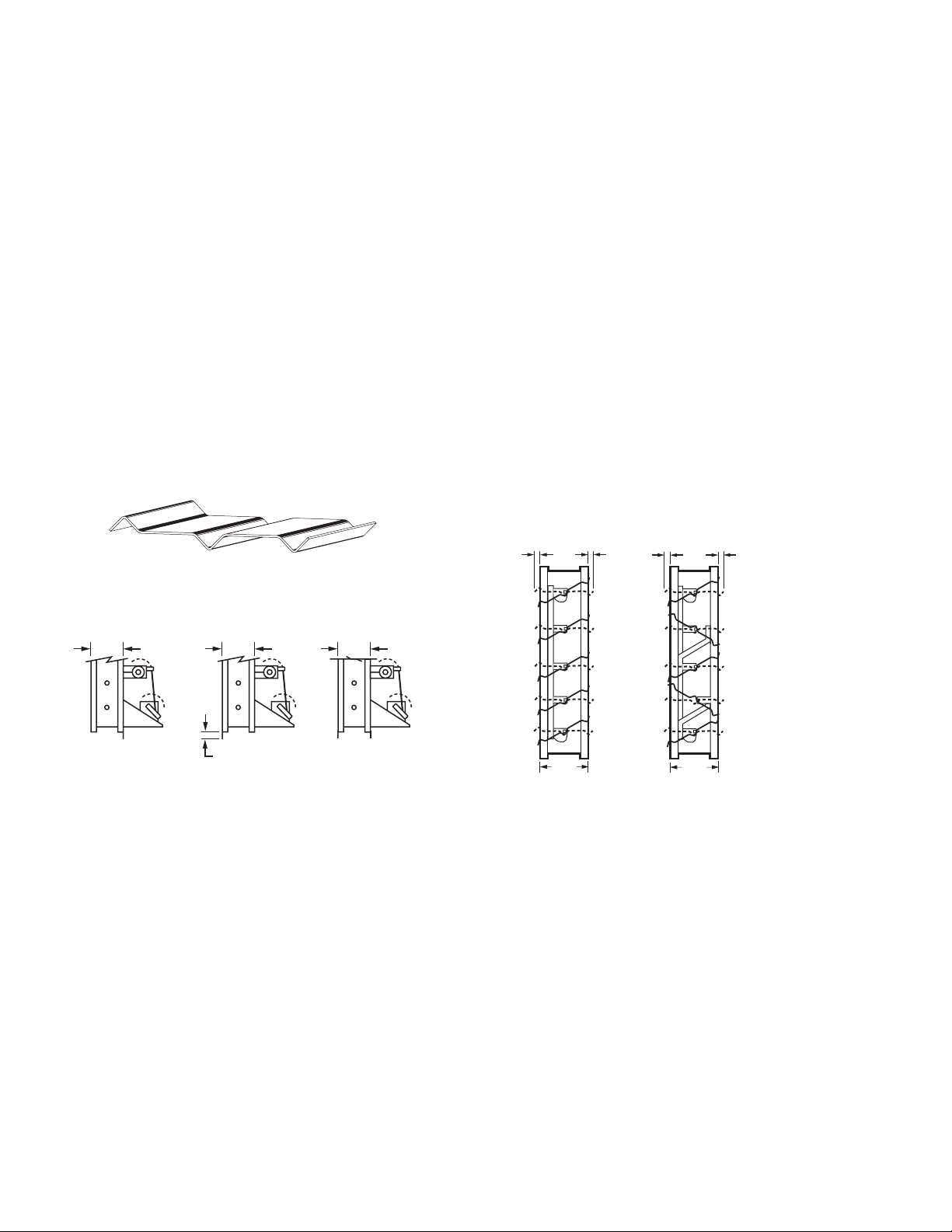

Fig. 1. 3-V blade.

5-1/8

(130)

SINGLE FLANGE

Fig. 2. Flange options.

5-1/8

(130)

1-1/2 (38) (TYPICAL)

SINGLE REVERSED

FLANGE

5-1/4

(132)

DOUBLE FLANGE

M23950

5 (127)

PARALLEL BLADES

5 (127)

OPPOSED BLADES

Fig. 3. Parallel and opposed blades.

M23951

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE

®

Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée,

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

63-2598—09 2

Page 3

D2 (FORMER D642), D3 (FORMER D640)

Multi-Section Assembly

Dampers larger than the maximum single section size will be

made up of equal size sections which can be jackshafted

together so that all sections operate together. A damper larger

than the maximum single section size can only ship two

sections wide and will be jackshafted together requiring one

actuator drive location as shown in Fig. 4. (Max. section is 48

in. x 74 in.)

NOTE: Dampers larger than 48 in. x 74 in. (1219 mm x

1880 mm) are not intended to be structurally self-supporting. Additional horizontal bracing is recommended to support the weight of the damper and

vertical bracing should be installed as required to hold

against system pressure.

and temperature limitations shall be submitted for approval

showing damper suitable for pressures to 5 in. (12.7 cm) wg,

velocities to 3,000.0 ft./min. and temperatures to 180 F (82 C).

Testing and ratings to be in accordance with AMCA Standard

500. Basis of design is Honeywell's model D3.

Low-Leakage Volume Control Dampers

Control dampers meeting the following specifications shall be

furnished and installed where shown on plans and/or as

described in schedules. Dampers shall consist of: a 16 ga.

galvanized steel channel frame with 5 in. (12.7 cm) depth;

triple V type blades fabricated from 16 ga. galvanized steel;

blades shall be completely symmetrical relative to their axle

pivot point, presenting identical resistance to airflow in either

direction or pressure on either side of the damper; 0.5 in.

(1.3 cm) diameter plated steel axles turning in synthetic

(acetal) sleeve bearings; and external (out of the airstream)

blade-to-blade linkage. Standard blade seals shall be extruded

vinyl. Standard jamb seals to be flexible stainless-steel

compression type to prevent leakage between blade end and

damper frame. Damper manufacturer's printed application and

performance data including pressure, velocity and temperature

limitations shall be submitted for approval showing damper

suitable for pressures to 5 in. (12.7 cm) wg, velocities to

3,000.0 ft./min. and temperatures to 180 F (82 C). Testing and

ratings to be in accordance with AMCA Standard 500. Basis of

design is Honeywell's model D2.

M23949

Fig. 4. Multiple section damper.

Guide Specifications

Standard Volume Control Dampers

Control dampers meeting the following specifications shall be

furnished and installed where shown on plans and/or as

described in schedules. Dampers shall consist of: a 16 ga.

galvanized steel channel frame with 5 in. (12.7 cm) depth;

triple V type blades fabricated from 16 ga. galvanized steel;

blades shall be completely symmetrical relative to their axle

pivot point, presenting identical resistance to airflow in either

direction or pressure on either side of the damper; 0.5 in.

(1.3 cm) diameter plated steel axles turning in synthetic

(acetal) sleeve bearings; and external (out of the airstream)

blade-to-blade linkage. Damper manufacturer's printed

application and performance data including pressure, velocity

5.0 INCHES WG

5

4.0 INCHES WG

4

3

PRESSURE

(INCHES WG)

2.5 INCHES WG

2

BLADE

BEARING

SHAFT

EXTENSION

(OPTIONAL)

AXLE

LINKAGE

BLADE SEAL

(D2 ONLY)

Fig. 5. Damper components.

Selection Criteria

74

60

48

DAMPER

HEIGHT

(INCHES)

3000 FPM

36

24

FRAME

2500 FPM

JAMB SEAL

(D2 ONLY)

2000 FPM

M20591B

1

0

0 12 24 36 48

DAMPER WIDTH (INCHES)

M23952

12

0

0 12 24 36 48

3 63-2598—09

DAMPER WIDTH (INCHES)

M23953

Page 4

D2 (FORMER D642), D3 (FORMER D640)

Performance Data

Table 1. D2, D3 Pressure and Velocity Limits.

Damper Size

in inches

Maximum

System

Pressure

Maximum

System

Velocity

12 x 12 5.0 in. wg 3000 fpm

24 x 24 5.0 in. wg 3000 fpm

36 x 36 4.0 in. wg 2500 fpm

48 x 48 2.5 in. wg 2000 fpm

NOTE: D2 and D3 will withstand higher pressures and

velocities. Displayed ratings are conservative to

prevent misapplication. Consult Honeywell if you

have an application outside these limitations.

Actuator Torque Multiplier

Table 2. Actuator Torque Multiplier

Pounds Per

Damper

D3 5 lb-in/SF

D2 7 lb-in/SF

NOTE: Assumes 1,500 fpm.

Square Foot

Leakage Data

Leakage testing was conducted in accordance with AMCA

Standard 500D and is expressed as cfm/ft

area. All data has been corrected to represent standard air at

a density of 0.075 lb/cubic ft. (See Fig. 6)

6.0

5.0

4.0

3.0

2.0

1.0

.8

.6

.5

.4

.3

.2

STATIC PRESSURE DIFFERENCE (IN. WG)

1

D2

2 3 5 6 8 10 20 30 50 6080

4 150

AIR LEAKAGE (CFM/FT2)

Fig. 6. D2, D3 leakage data.

Table 3. Pressure Loss Coefficient (in. wg).

12x1224x2436x3612x4848x

AMCA Figure 5.3 1.52 0.67 0.43 0.7 1.2

2

of damper face

D3

100

40

M23317A

12

AMCA Figure 5.2 2.25 1.19 0.67 0.91 1.7

AMCA Figure 5.5 3.64 2.28 1.89 2.15 2.84

NOTE: Data is corrected to standard air density. Average of

4,000 fpm.

Pressure loss can be determined using the following:

ΔpCoV 4005⁄()

×=

2

where

Δp = pressure drop (in. wg)

= pressure loss coefficient

C

o

V = face velocity (fpm)

5 lb-in/SF

7 lb-in/SF

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use or modification

to, the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against any liability, cost, or damages,

including attorneys’ fees, arising out of, or resulting from, any modification to the literature by you.

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

® U.S. Registered Trademark

© 2008 Honeywell International Inc.

63-2598—09 M.S. Rev. 04-08

Loading...

Loading...