Page 1

ComfortPoint Open

CPO-VAV2A

Installation Instructions

Contents

Installation ............................................................ 1

Safety instructions ........................................ ... .... . 1

CPO-VAV2A controller dimensions ......................2

Mounting CPO-VAV2A on VAV box

electronics enclosure ............................................3

Mounting the CPO-VAV2A on round ductwork .....4

Mounting Caution .................................................4

Air Flow Pick-up ....................................................5

Serial Number Label .............................................5

Terminal Settings ..................................................6

CPO-VAV2A Terminal Overview ..........................6

Automatic MAC addressing ..................................6

Manual MAC addressing ......................................7

Analog Input .........................................................8

Analog Output .......................................................9

Digital Output ........................................................9

Integrated Actuator ............................. .................. 9

Communication .......................................... ......... 10

BACnet MS/TP ...................................................10

Sylk™ Bus ..........................................................10

Power Supply .....................................................10

Controller startup ................................................11

Cabling ............................................................... 11

Sylk Bus cable specification ...............................11

Connection drawings ..........................................11

Connecting the Honeywell

BACnet Wi-Fi Adapter ........................................17

Federal communications

commission (FCC) statement .............................18

Installation

This document provides the information needed to install

CPO-VAV2A controller. It describes the dimensions, mounting

details and the terminal connections to these devices.

Safety instructions

• When performing any work (installation, mounting, startup), all instructions given by the manufacturer and in

particular the safety instructions provided in this document

are to be observed.

• The CPO-VAV2A controller must be installed and mounted

only by authorized and trained personnel.

• If the unit is modified in any way, except by the

manufacturer, all warranties concerning operation and

safety become invalid.

• Make sure that applicable local standards and regulations

are observed at all times.

• Use only Honeywell supplied or approved accessories.

• Before the system is dismantled, disconnect the power

supply by either removing the power terminal block from

the controller, or by means of local isolation. Read the

following caution note carefully.

Caution

Disconnect the power supply before you start to install the CPO-VAV2A controller. Do not reconnect the power supply until you have completed the installation.

Trademark Information

ComfortPoint

International Inc.

BACnet

Copyright 2017 – Honeywell International Inc. EN1B-0022 IE10 R0717

TM

Open is a trademark of Honeywell

®

is a registered trademark of ASHRAE Inc.

Page 2

INSTALLATION

157.9

81.1

145.6

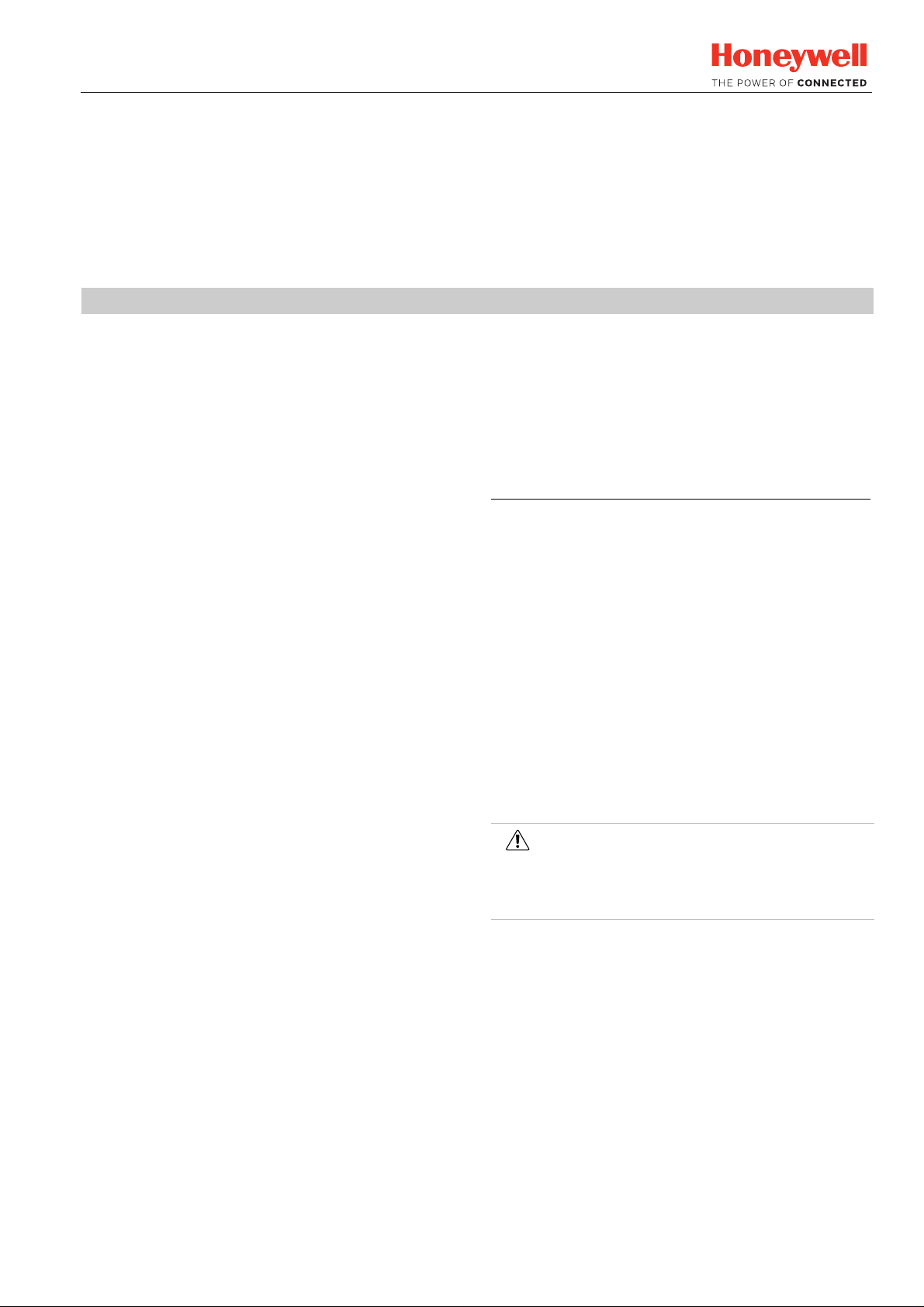

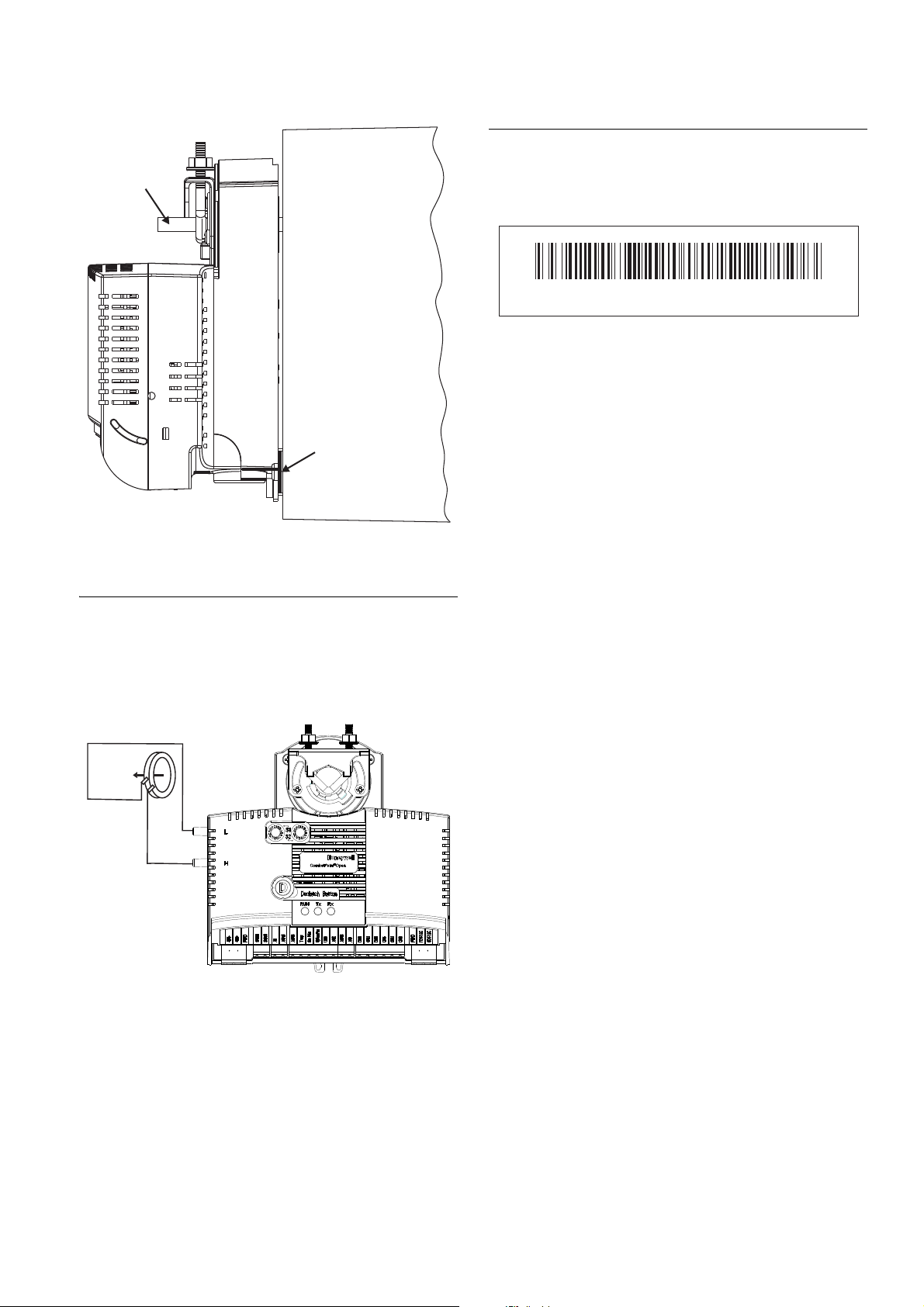

CPO-VAV2A controller dimensions

1

Figure 1 CPO-VAV2A controller dimension.

Before mounting CPO-VAV2A controller

Before mounting the CPO-VAV2A onto the VAV box damper

shaft, do the following:

1. Ensure that the diameter of the damper shaft is within the

allowed limits (round: 8…16 mm, square: 6…13 mm).

2. Ensure that the damper shaft has a length of at least 40

mm.

3. Determine the direction (CW or CCW) in which the damper

shaft rotates to open the damper. The installation

procedure varies depending on the damper direction.

4. Determine the angle of the damper opening (can be

adjusted in increments of 5.5°).

If damper rotates CW to open

If the damper rotates clockwise (CW) to open, mount the

CPO-VAV2A as follows:

1. Manually open the damper.

2. Push down the declutch button of the CPO-VAV2A, and

while holding it down, manually rotate its shaft adapter fully

to the clockwise position.

3. Mount the CPO-VAV2A to the VAV box damper shaft.

4. Set the mechanical end limits of the CPO-VAV2A (see

Figure 2 on page 3 ). When the CPO-VAV2A closes, the

damper will thus rotate

5. CCW until the mechanical end limits are reached.

If Damper Rotates CCW to Open

If the damper rotates counterclockwise (CCW) to open, mount

the CPO-VAV2A as follows:

1. Manually open the damper.

2. Push the declutch button of the CPO-VAV2A, and while

holding it down, manually rotate its shaft adapter fully to

the counterclockwise position.

3. Mount the CPO-VAV2A to the VAV box damper shaft.

4. Set the mechanical end limits of the CPO-VAV2A (see

Figure 2). When the CPO-VAV2A closes, the damper will

EN1B-0022 IE10 R0717 2

Page 3

thus rotate CW until the mechanical end limits are

1

2

3

1

2

For S

erial No. Label

For Safety Caution

Back view

30 mm

30 mm

210 mm

297 mm

F

o

r S

erial No. Label

2

1

Back view

30

m

m

3

0

m

m

21

0

m

m

297 m

m

reached.

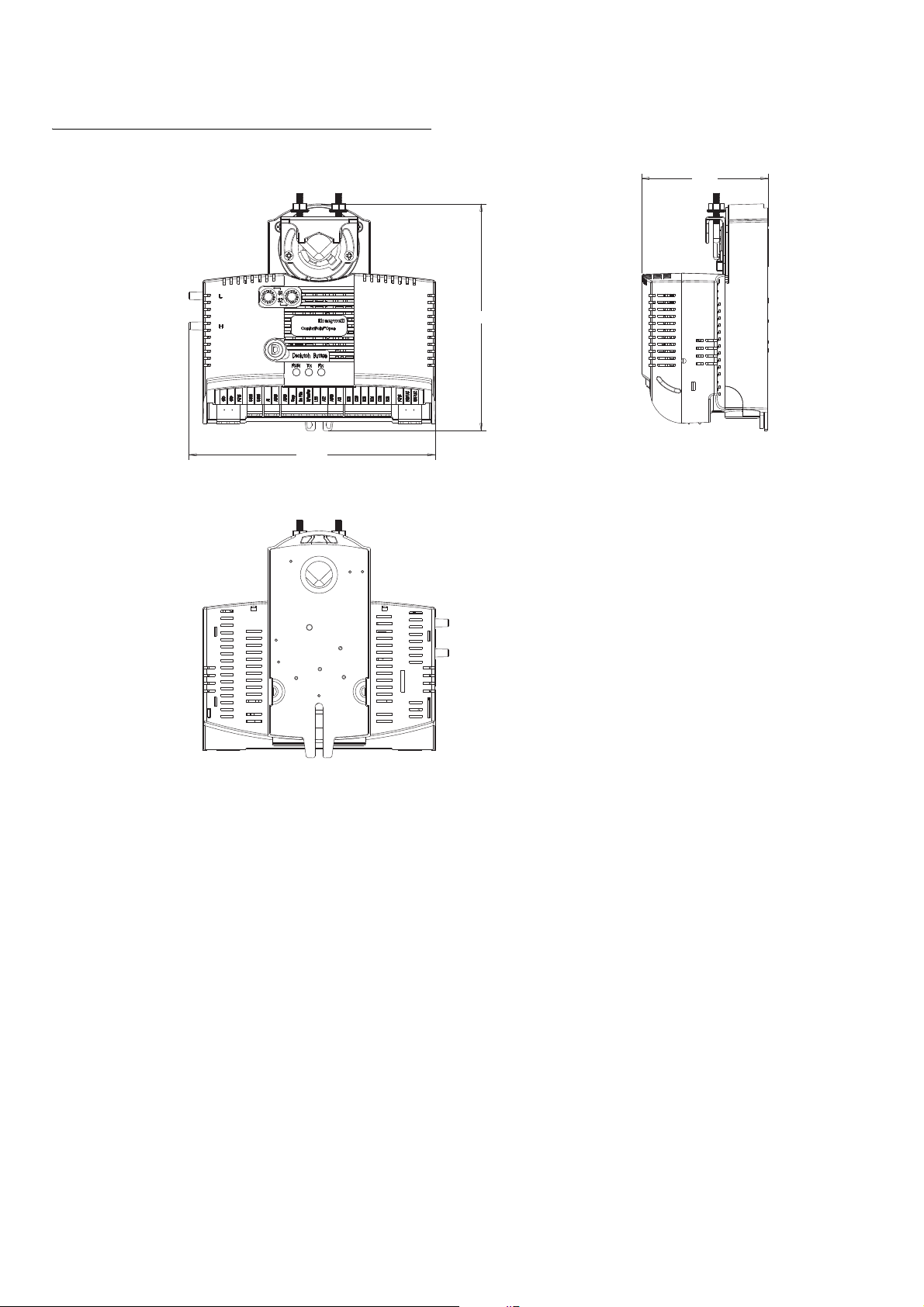

Figure 2 Setting the mechanical end limits

INSTALLATION

Figure 4 Drilling 2 holes per template indication

Mounting CPO-VAV2A on VAV box electronics enclosure

Figure 3 Paste the drilling template in VAV box electronics enclosure

Figure 5 Attach controller on damper shaft and fix with anti-rotation bracket

3 EN1B-0022 IE10 R0717

Page 4

INSTALLATION

1

2

3

3

4

2

4

1

2

1

2

3

3

4

4

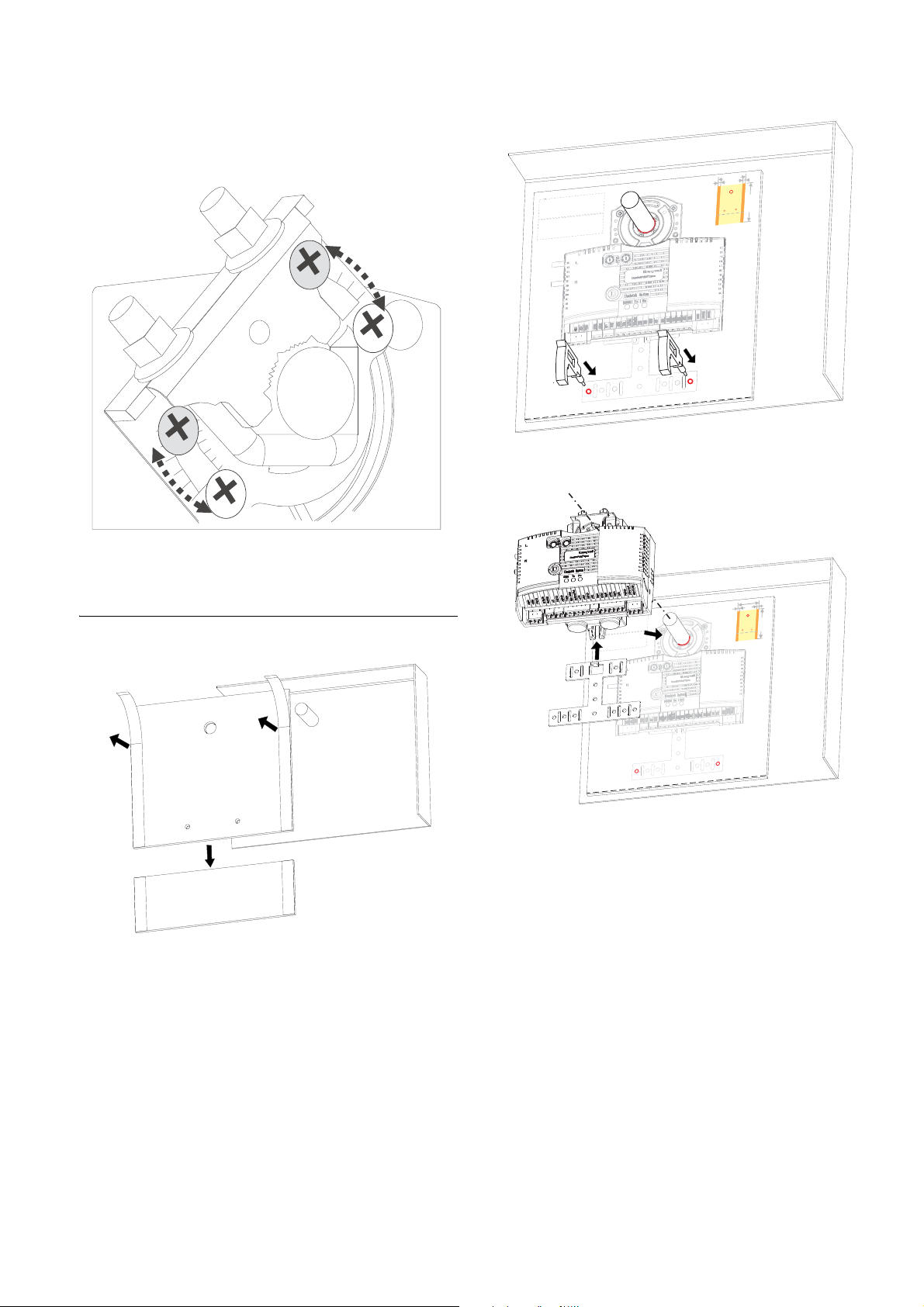

Figure 6 Fasten screws of bracket and U-Bolt to shaft

Figure 8 Attach controller to shaft and Fasten screws of bracket and U-bolt

Caution

Round ductwork installation is not applicable for America and Canada without appropriate enclosure.

Mounting the CPO-VAV2A on round ductwork

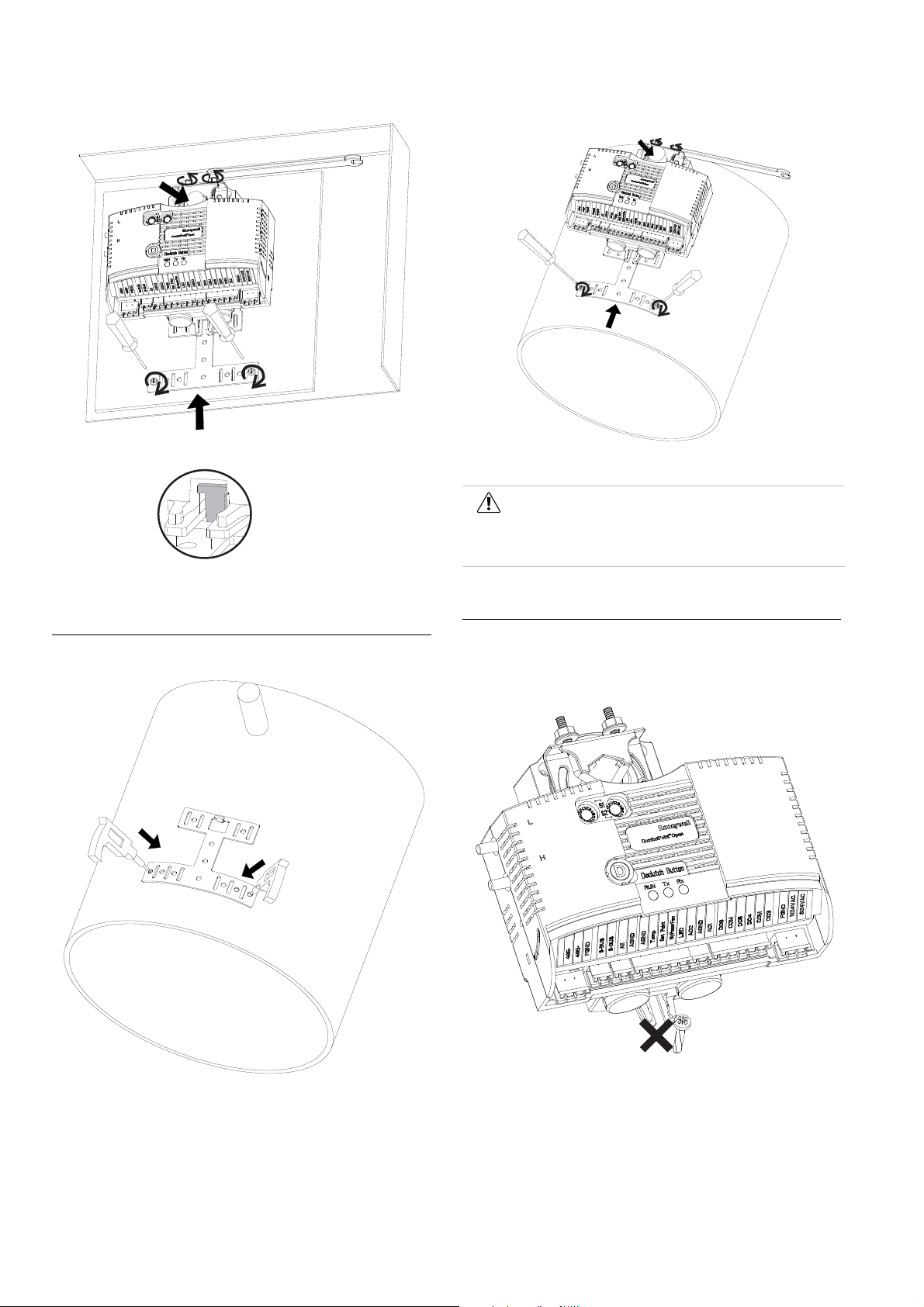

Mounting Caution

Use the anti-rotation bracket and screws included in the unit

pack to mount the CPO-VAV2A. DO NOT use the single screw

to mount the CPO-VAV2A.

Figure 7 Drill 2 holes for bended bracket

EN1B-0022 IE10 R0717 4

Figure 9 Do not use the single screw to mount the CPO-VAV2A

Mounting the CPO-VAV2A unevenly with damper housing can

damage actuator. Mount the actuator flush with the damper

housing or add a spacer between the anti-rotation bracket and

the VAV box damper housing.

Page 5

INSTALLATION

VAV box

damper shaft

VAV box

damper housing

Spacer

-LOW

+HIGH

AIRFLOW

DIRECTION

130228CP- V2A10200200075

Serial Number Label

There is a separate label with product serial number in the unit

pack. The user can choose to paste this label on the front of

housing to easily check the product serial number.

Figure 12 Serial Number Label Example

Figure 10 Mounting the CPO-VAV2A with washer/spacer

Air Flow Pick-up

Connect the air flow pick-up to the two connectors on the

CPO-VAV2A. See Figure 11. Connect the high pressure or

upstream tube to the air flow pick-up connector labeled (H)

and the low-pressure or downstream tube to the connector

labeled (L).

Figure 11 Air flow pick-up connection

Best practice for zero calibration of air flow sensor

The controller must be powered up for a minimum of 1 hour

before performing the zero calibration for the air flow sensor.

5 EN1B-0022 IE10 R0717

Page 6

TERMINAL SETTINGS

485-

485+

FGND

S-BUS

S-BUS

AI1

AGND

AGND

Tem p

Set Point

ByPass/Fan

LED

AO2

AGND

AO1

DO6

COM

DO5

DO4

COM

DO3

FGND

N24VAC

S24VAC

RxTxRun

Declutch Button

Honeywell

Comfort Point

TM

Open

L

H

S1

S2

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

485-

485+

FGND

S-BUS

S-BUS

AI1

AGND

AGND

Tem p

Set Point

ByPass/Fan

LED

AO2

AGND

AO1

DO6

COM

DO5

DO4

COM

DO3

FGND

N24VAC

S24VAC

Terminal Settings

This section describes the terminal settings on the CPO-VAV2A controller.

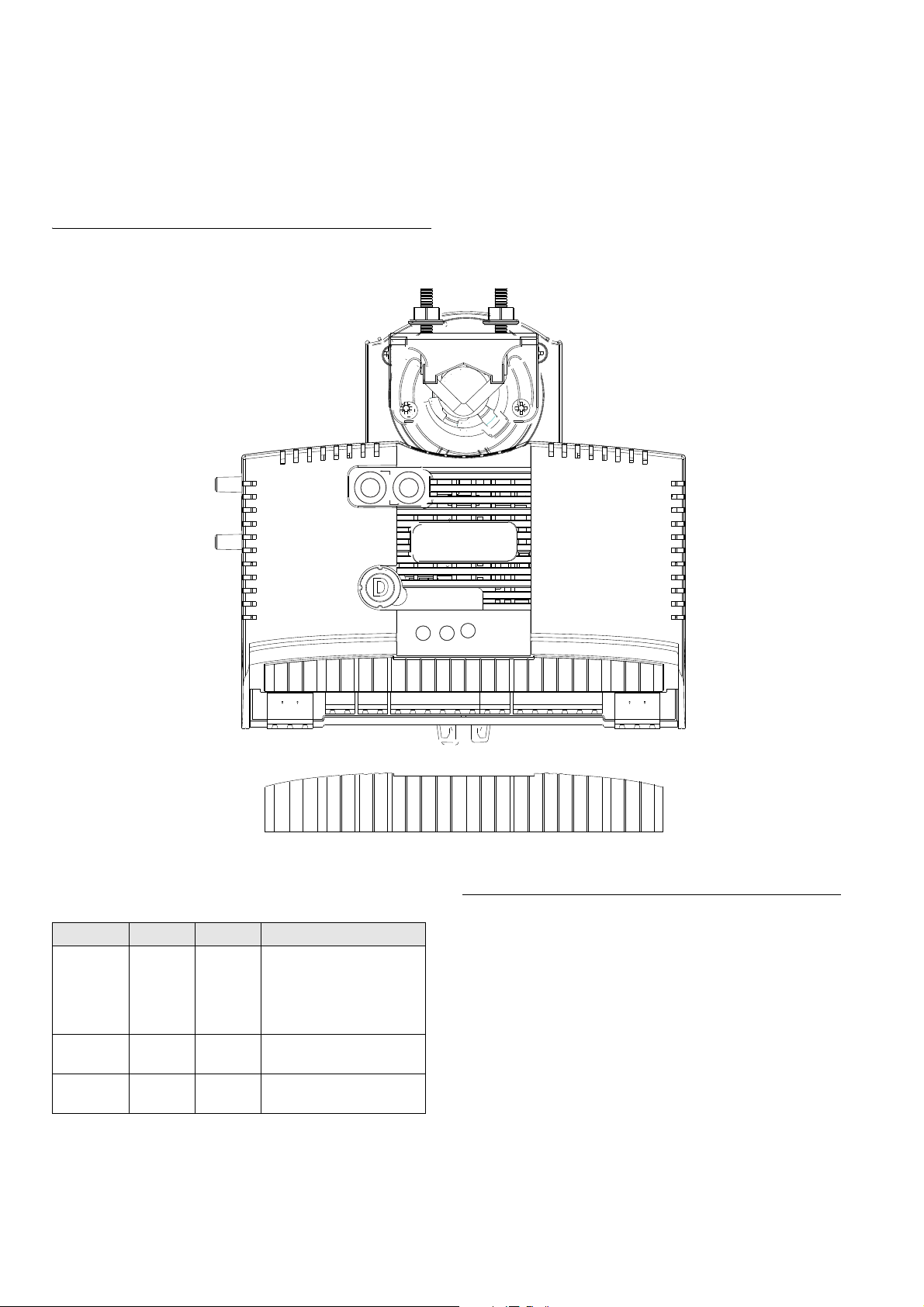

CPO-VAV2A Terminal Overview

Figure 13 describes the layout of pins on the CPO-VAV2A controller.

Figure 13 Describes the layout of pins on the CPO-VAV2A controller.

LED operation Automatic MAC addressing

Sr.No LED Label LED Color Description

1 Run Green The LED is Off when there

is no power to the controller.

LED is blinking when the

controller is working

normally.

2 Rx Yellow LED indicates Receive of

3 Tx Yellow LED indicates Transmit of

EN1B-0022 IE10 R0717 6

data on MS/TP bus.

data on MS/TP bus

Controllers with Automatic MAC addressing functionality can

be identified by a label covering the MAC address rotary

switches. This information is also printed on the product label

available on the controller. When a controller with Automatic

MAC addressing feature is powered ON, can assign its own

unique MAC address ranging from 1 to 30. It can also coexist

with other unitary controllers whose MAC addresses are set

manually. The controller can automatically adjust the MAC

address at any time to avoid duplicate addresses in the

network. The automatic MAC address assigned through this

process is retained when the controller is powered OFF.

To disable Automatic MAC addressing, remove th e label on

the rotary switches and set the switches to the manual

Page 7

TERMINAL SETTINGS

address required. By default, the switches are already set to

(0xFF) for controllers that support Automatic MAC addressing.

To enable Automatic MAC addressing again, set the switches

back to (0xFF).

For the controller to support AutoMAC, the boot loader version

must be v2.5.1 or later and the firmware version v2.7.3 or

later.

Attention

The switches are only read by the controller when turned ON. Therefore, whenever the switch positions are changed the power must be removed and reapplied before the new switch positions take effect.

Possible Automatic MAC addressing scenarios

Note

The times provided in the following table are only for information. The actual time taken for resolution of MAC address conflicts may slightly vary.

Scenario Time Remarks

A: Auto MAC controller initial start-up time and acquire MAC address on single BACnet MS/TP bus after power-on (Cold boot or reset).

B: Average initial start-up time and acquire MAC address where all controllers on a single MS/TP bus are Auto MAC controllers.

30 secs 29 Manual MAC controllers.

1 Auto MAC controller that must acquire a MAC address.

Time includes start-up time plus time to acquire MAC address.

260 secs 30 Auto MAC controllers.

All controllers must acquire a MAC address.

Time includes start-up time plus time to acquire MAC address.

Scenario Time Remarks

C: Average time for MAC conflicts to be resolved when an Auto Mac controller is added to an MS/TP bus while Auto MAC process is still operating.

D: Average time for MAC conflicts to be resolved when a Manual Mac controller is added to an MS/TP bus while Auto MAC process is still operating.

E: Average time for MAC conflicts to be resolved when a manual MAC controller with conflicting MAC address is added to an MS/TP bus.

F: Average time for Auto MAC controller restart where all controllers on MS/TP bus are Auto Mac and have previously acquired a MAC address.

Verify that the MAC address remains unchanged after restart when there is no conflicts.

50 secs 15 existing Auto MAC

controllers.

13 existing Manual MAC

controllers.

Add 1 Auto MAC controller

where there is an address

conflict with existing Auto

MAC controller.

50 secs 15 existing Auto MAC

controllers.

13 existing Manual MAC

controllers.

Add 1 Manual MAC

controller where there is an

address conflict with

existing Auto MAC

controller.

30 secs 15 Auto MAC controllers.

14 Manual MAC controllers. Add 1 Manual MAC

controller where there is an

address conflict with an

Auto MAC controller.

25 secs 30 Auto MAC controllers.

All controllers have all acquired MAC address from previous operation.

No MAC address conflicts exist before power down and restart.

All controllers retain existing MAC address after restart.

Time includes start-up time plus time to verify there are no MAC address conflicts.

Manual MAC addressing

Attention

Address Switch 1 & Address Switch 2 are HEX switches which are used in combination for addressing the CPO-VAV2A controller. The valid address for CPO-VAV2A is from 1 to 30.

7 EN1B-0022 IE10 R0717

Page 8

TERMINAL SETTINGS

S1

S2

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

There are two Hex switches on the controller: S1 and S2, as

shown in Figure 14.

Figure 14 CPO-VAV2A Hex Switches Layout

Set S1 to the lower nibble of the address and S2 to the higher

nibble of the address.

Example: If you want to set 2 as the MAC address, S1 should

be set to 2 and S2 should be set to 0.

Similarly if you want to set 17 as the MAC address, S1 should

be set to 1 and S2 should be set to 1.

The following table illustrates the S1 and S2 switch settings

for the corresponding MAC addresses.

S1 Switch S2 Switch MAC Address

101

202

303

404

505

606

707

808

909

A010

B011

C012

D013

E014

F015

0116

1117

2118

3119

4120

5121

6122

7123

8124

9125

A126

S1 Switch S2 Switch MAC Address

B127

C128

D129

E130

Attention

Make sure that each CPO-VAV2A controller on the MS/TP bus has a unique MAC address. Valid address for CPO-VAV2A is from 1 to 30. 0 is reserved for the plant controller while CPO-Studio uses addresses 32 and 35.

It also shall be ensured that CPO-VAV2A, CPVAV/SPC and CP-DIO on the same MS/TP bus

MUST NOT have the same MAC Address.

Analog Input

Analog inputs can be used, for example, to connect the wall

module, or temperature sensor to the controller.

Technical specification

• 4 analog inputs

• AI 1, AI 2, AI 3, and AI 4 are universal, and can be used as

- NTC20K (-50 to +150 deg.C)

- PT1000 (-50 to +150 deg.C)

- 0 to +10 V

- 0(4) to 20 mA (with an external resistor of 499

0.25%)

- Potential Free Contact (Digital Input)

• AI 2, AI 3 and AI 4 can also be used as wall module inputs:

- Space Temperature Sensor

-Set Point

- Bypass/Fan Speed

• 12-bit A/D resolution

The CPO-VAV2A controller supports wall modules:

•TR2x

•TR40

•TR42

• T7560

• T7460

• C7110C/D

• C7262A

• CP-WM-FCU

•CP-CM

• CP-US-WM-FCU

EN1B-0022 IE10 R0717 8

Page 9

• CP-US-WM-VAV

COM

SENSOR

SETPOINT

BYP/FAN

LED

BYP/RTN

LED/RTN

T7460

Terminals

AGND

Temp

Set Point

ByPass/Fan

LED

VAV

Terminals

1

2

3

4

5

6

7

1

2

3

4

5

COM

SENSOR

SETPOINT

BYP/FAN

LED

Bypass**

Humidity

T7560

Terminals

AGND

Temp

Set Point

ByPass/Fan

LED

VAV

Terminals

1

2

3

4

5

6

7

1

2

3

4

5

24 Vac

8

COM

CO2 Output 0...10V

24 VAC/DC

NTC 20kOhm

SETPT. 1...10kOhm

LED INPUT

OCCUPANCY

C7110D

Terminals

AGND

Temp

Set Point

ByPass/Fan

LED

VAV

Terminals

1

2

3

4

5

6

7

1

2

5

6

AGND

A1

3

4

V+

Com AC/DC

TEMP

TEMP

OUT1: CO2

OUT2: CO2

RELAY NO

C7262A

Terminals

AGND

Temp

Set Point

ByPass/Fan

LED

VAV

Terminals

1

2

3

4

5

6

7

1

2

AGND

A1

4

RELAY NO

3

Common

Setpoint

MSTP+

Temperature Sensor

MSTP-

24 Vac/dc input

CP-CM

Terminals

AGND

Temp

Set Point

ByPass/Fan

LED

VAV

Terminals

1

2

3

4

5

6

1

2

3

24 Vac/dc input

Occupancy

(24Vac input contact)

Temperature Sensor

Setpoint

FAN/Bypass

Common

CP-WM

Terminals

AGND

Temp

Set Point

ByPass/Fan

LED

VAV

Terminals

1

2

3

4

5

6

1

2

3

• CP-WM-VAV

Attention

Resolution of the PT1000 sensor: 1 Fahrenheit or

0.6 Centigrade.

Do not use the datapoint associated to PT1000 in

control logic which requires a resolution less than

1 Fahrenheit.

The analog input with PT1000 can be used in

control loops only when connected to

CPO-VAV2A via a transducer with 0-10V rating.

Additionally, you must use the ComfortPoint Open

Studio tool to define custom characteristics which

matches the selected transducer.

The PT1000 sensors connected directly with CPO-VAV2A can be used only for monitoring and reporting purposes.

TERMINAL SETTINGS

Figure 17 Connection of C7710D with CPO-VAV2A

The connection between CPO-VAV2A and wall modules are

illustrated in Figure 15 through Figure 21.

Figure 15 Connection of T7460 with the CPO-VAV2A

Figure 16 Connection of T7560 with CPO-VAV2A

Figure 18 Connection of C7262A with CPO-VAV2A

Figure 19 Connection of CP-CM with CPO-VAV2A

Figure 20 Connection of CP-WM-VAV with CPO-VAV2A

Attention

The CPO-VAV2A controller does not contro l th e LCD display of the T7560 Wall module. It handles the temperature sensor input, Bypass/Fan, or Fan Control Input. The LCD Display must not be used to get the Effective Occupancy state of the controller.

Figure 21 Connection of TR40 and TR42 with CPO-VAV2A

9 EN1B-0022 IE10 R0717

Page 10

COMMUNICATION

485-

485+

FGND

MSTP Channel

Shied should be continuous

485-

485+

FGND

Internally connected

on T-terminals

Next CPO-VAV2A

Analog Output

Analog outputs can be used, for example, to operate valve or

damper actuators.

Technical specification

• 3 analog outputs

• Analog output (AO1, AO2, and AO3) details

- Voltage: 0-10 V

- Current: max. 10 mA

- Resolution: 12-Bit

- Min. Step: 2.4 mV

- Accuracy: +/- 100 mV

• AO3 (terminal labeled LED) can be used for Wall Module

LED.

Digital Output

The digital outputs are switched by Triac and can be

connected directly to the external relay- the loads are powered

from digital outputs.

Technical specification

• 6 digital outputs, 4 are free while 2 (DO 1 and DO 2) are

internally connected to the integrated actuator

• Output stages:

- Low signal - 0 V

- High signal - 24 VAC

- Type - Triac

• Load per output:

- min. 30 mA

- max. 500 mA

• Non-isolated within 6 digital outputs (first 2 are reserved

internally to drive the integrated actuator)

• Support declutch mechanism to allow the installer to

manually open or close the VAV box damper without

power or software tool

• Shaft adapter: support different round (8 to 16 mm) or

square (6 to 13 mm) shafts

• Noise (dBA at 1 meter maximum): 35

Attention

The actuator cannot be detached from the CPOVAV2A controller.

Avoid mounting the CPO-VAV2A in areas where acid fumes or other corrosive vapors can attack the integrated actuator's metal parts, or in areas where escaping gas or other explosive vapors are present.

Communication

BACnet MS/TP

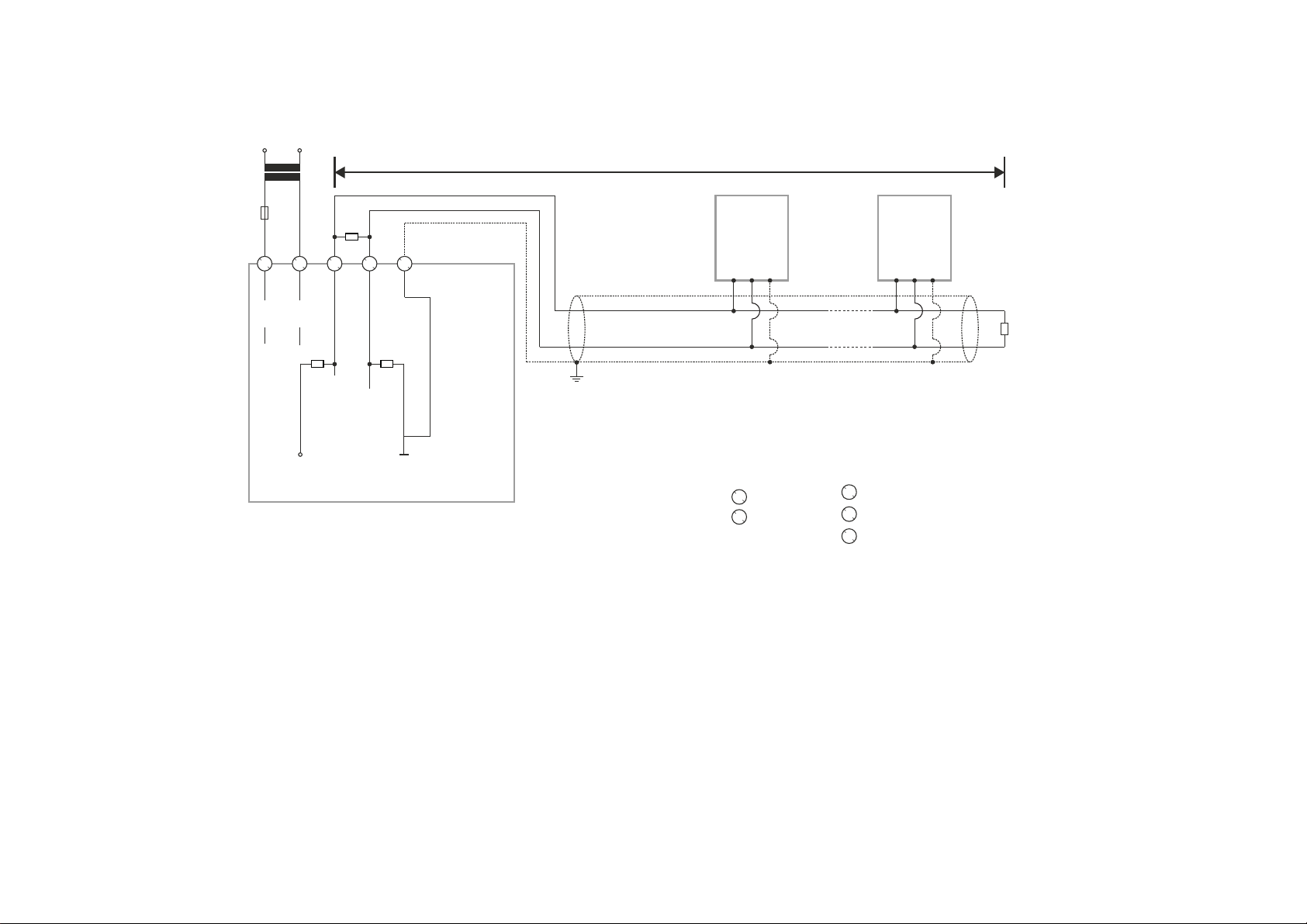

The CPO-VAV2A controller has one BACnet MS/TP port.

MSTP connection is internally looped in T-terminal and

remains looped after T-terminal is unplugged from the CPOVAV2A controller.

Figure 22 MS/TP Bus Connection

Integrated Actuator

There is an actuator vertically integrated with the CPO-VAV2A

controller centre in-line. The power supply and digital outputs

to the integrated actuator are internally provided by the CPOVAV2A controller, no need of additional wiring to the

integrated actuator from outside of the CPO-VAV2A controller.

Technical specification

• Type: Non Spring Return, Low Torque, Direct Coupled

Actuator (NSR, LT, DCA)

• Control Scheme: Series 60

• Torque Rating: 5 Nm

• Stroke Rating: 95°

• 90° Stroke Timing: 110 +/- 3 sec @ 50Hz, 90 +/- 2 sec @

60Hz

EN1B-0022 IE10 R0717 10

Page 11

CONTROLLER STARTUP

TO CPO-VAV2A

DAISY-CHAINING MULTIPLE ZIOS

TO ZIO

S24VAC

N24VAC

FGND

230 VAC 24 VAC

Sylk™ Bus

The CPO-VAV2A controller has one Sylk port which is a two

wire, polarity insensitive bus that provides both 24VAC power

and communications between a Sylk-enabled sensor and a

Sylk-enabled controller. Using Sylk-enabled sensors saves I/

O on the controller and is faster and cheaper to install since

only two wires are needed and the bus is polarity insensitive.

Sylk sensors are configured using the ComfortPoint Open

Studio.

Transformer requirements for one CPOVAV2A controller

• Voltage: 24 VAC +/- 10% (50/60Hz)

• Power: 15 VA

Note

• Includes Sylkbus and actuator.

• Does not include Triac power. (Allow additional

capacity for equipment controlled from Triacs

where required).

Power consumption by various components

Components Maximum Power (VA)

Control board 8 Sylkbus 3 Actuator 2 Buffer 2

Total 15

Figure 23 Sylk™ Bus Connection

Power Supply

The CPO-VAV2A controller is powered by an external NEC

Class 2 transformer. Power is internally looped in T-terminal

and remains looped after T-terminal is unplugged from the

CPO-VAV2A controller.

Figure 24 Powering CPO-VAV2A through an external transformer

Attention

There are no internal fuses inside T-terminal for looped power supply. The maximum current rating is 9 Amp. Drawing more current can damage the product. Connect an external fuse.

Controller startup

When the controller delivered from the factory is powered up

for the first time, the device instance ID is set to a value

between 1 ~ 30 which is based on the MAC address. If the

MAC address changes, the device instance ID also changes

to match the MAC address. After downloading the application

to the controller, the instance ID is modified to a new value as

defined in the CPO Studio project. Subsequently, the device

instance ID does not change despite the MAC address

changes.

Therefore, to discover this unitary controller from CPO Online

tool with instance ID less than 128, enable the MSTP

channels in the system settings page of plant controller.

See “Managing system settings” section from “CPO Online

User’s Guide (EN2B 0002 IE10)”.

Cabling

This Section describes the specifications for cables used in

making connections to the CPO-VAV2A controller.

Cable Routing

All signal cables (input/output, low voltage) are

communication circuits and should therefore be routed

separately from the line voltage. Minimum distance is 4in (100

mm).

Attention

Avoid using joints in sensor cables.

11 EN1B-0022 IE10 R0717

Page 12

CABLING

Cable lengths and cross sectional areas

Signal type Cross-sectional

Less than or equal to 300 Ft. (100m)

Power supply (24

VAC)

Low current

signals

1.E.g. for 0-10 VDC input, NTC20K, PT1000, dry

contact, 0-10 VDC output.

Less than or equal to 16

AWG (Greater

than or equal

to 1.5 mm

Less than or equal to 20 AW G (Greater th an or

1

equal to 0.5 mm

Attention

The maximum length of a signal cable with 24 VAC supply is 550 ft. (170 m). The max. length of a two-wire, 0-10 Vdc signal cable is 1300 ft. (400 m). The secondary side of the transformer must not be connected to earth ground.

Installing a fuse on the secondary side of the transformer is recommended to protect the devices against incorrect wiring.

Less than or equal to 500 ft. (170 m)

Less than or equal to 14

AWG (Greater than or equal to

2

)

2

Less than or equal to 1300 ft. (400 m)

-

)

Recommended maximum distance

from controller to any Sylk device

Quantity

and type of

device

3 wall

modules,

any type

Single twisted pair, non-

shielded, stranded or solid

18-22 AWG 24 AWG 18-24 AWG

500 ft

(150 m)

400 ft

(120 m)

Standard

thermostat wire, (non-

twisted), shielded or

nonshielded, stranded or

solid

100 ft

(30 m)

Connection drawings

This section describes example connection drawings of the

CPO-VAV2A controller with:

• MS/TP bus

• Sylk bus

• 24 VAC power, and IO connection

MS/TP cable specification

Use Belden 9841 or Equivalent cable with the following

specifications

• An MSTP EIA-485 network shall use shielded, twisted-pair

cable with characteristic impedance between 100 and 130

ohms.

• Distributed capacitance between conductors shall be less

than 100 pF per meter (30 pF per foot).

• Distributed capacitance between conductors and shield

shall be less that 200 pF per meter (60 pF per foot).

• Foil or braided shields are acceptable.

• The maximum recommended length of an MS/TP segment

is 1000 meters.

Sylk Bus cable specification

• Polarity insensitive

• Can use daisy chain wiring for multiple Sylk devices. If

wire size is too thick for two wires in the terminal, use

pigtails.

EN1B-0022 IE10 R0717 12

Page 13

MSTP Bus Connection

L

90 to

120 Ohm

R

T

510

Ω

510

Ω

GND-ISO

5 V-ISO

RS485+

RS485-

CP-VAV/SPC/

CPO-VAV2A #1

CP-VAV/SPC/

CPO-VAV2A #N

R

T

CP-IPC

1

1

2

2

33445

5

24 V

24 V-0

230 V

S24VAC

POWER

N24VAC

BACnet/MSTP

CH+

CH-

FGND

24 V

F1

RS485 +

RS485 -

FGND

RS485 +

RS485 -

FGND

CABLING

NOTES:

Always power the CP-IPC with a transformer separate to the connected BACnet MS/TP modules.

N = max. 30 modules.

13 EN1B-0022 IE10 R0717

Page 14

CABLING

230 V

L

24 V

F1

2

1

24 V

5 V-ISO

3 4 5

24 V-0

510

Ω

RS485+

DIP SWITCH ON

R

T

RS485-

510

Ω

GND-ISO

CPO-PC-6A

Connection (L > 3 m) of RS485 interfaces 1, 2, or 3 (RS485 interface 1 shown) to a BACnet Bus

NOTES

Always power the CPO-PC-6A with a transformer separate to the connected BACnet MS/TP modules.

N = max. 30 modules.

CP-VAV/SPC/

CPO-VAV2A #1

RS485 +

RS485 -

FGND

CP-VAV/SPC/

CPO-VAV2A #N

RS485 +

RS485 -

FGND

R

90 to

120 Ohm

T

EN1B-0022 IE10 R0717 14

Page 15

MSTP Bus Connection

120 ohm

CABLING

120 ohm

Sylk Bus

CP-CORE

®

Connection

S-BUS

534

S-BUS

FNGD

CPO-VAV2A

S-BUS

S-BUS

FNGD

CPO-VAV2A

S-BUS

S-BUS

CPO-VAV2A Sylk sensor 1

15 EN1B-0022 IE10 R0717

Sylk sensor N

Page 16

CABLING

ByPass/Fan

LED

CPO-VAV2A

485-

485+

FGND

S-BUS

S-BUS

AI1

AGND

AGND

Temp

Set Point

DO4

COM

AO2

AO1

DO6

COM

DO5

DO3

FGND

N24VAC

S24VAC

DO1

DO2

TRIAC EQUIVALENT

CIRCUIT

DO for Integrated

actuator

AIRFLOW

PICKUP

L

H

+-

+

24V AC

-

24V AC COM

MSTP Channel

Shied should

be continuous

COM

SENSOR

SETPOINT

BYP/FAN

LED

Bypass**

Humidity

T7560 Terminals

1

2

345

6

7

24 Vac

8

COM

AGND

Stage 3

Stage 2

Stage 1

Line Power

staged reheat Fan

ByPass/Fan

LED

CPO-VAV2A

485-

485+

FGND

S-BUS

S-BUS

AI1

AGND

AGND

Temp

Set Point

DO4

COM

AO2

AO1

DO6

COM

DO5

DO3

FGND

N24VAC

S24VAC

DO1

DO2

TRIAC EQUIVALENT

CIRCUIT

DO for Integrated

actuator

AIRFLOW

PICKUP

L

H

+-

+

24V AC

-

24V AC COM

MSTP Channel

COM

SENSOR

SETPOINT

BYP/FAN

LED

Bypass**

Humidity

T7560 Terminals

1

2

345

6

7

24 Vac

8

COM

Modulating valve :

3 wires external

powered 0...10V device

G0G

Y

AGND

G0G

Y

Wiring Diagram of CPO-VAV2A

Figure 25 Controller wiring diagram for typical VAV application -with Series Fan , staged Reheat, T7560 Wall Module

Figure 26 Controller wiring diagram for typical VAV application - with modulating valves,T7560 Wall Module

EN1B-0022 IE10 R0717 16

Page 17

CABLING

ByPass/Fan

LED

CPO-VAV2A

485-

485+

FGND

S-BUS

S-BUS

AI1

AGND

AGND

Temp

Set Point

DO4

COM

AO2

AO1

DO6

COM

DO5

DO3

FGND

N24VAC

S24VAC

DO1

DO2

TRIAC EQUIVALENT

CIRCUIT

DO for Integrated

actuator

AIRFLOW

PICKUP

L

H

+-

+

24V AC

-

24V AC COM

MSTP Channel

Shied should

be continuous

COM

Modulating valve :

3 wires external

powered 0...10V device

G0G

Y

AGND

G0G

Y

NET-1

NET-2

S-BUS

S-BUS

CPO-TR40/42

123

4

0

1

2

3

4

5

6

7

8

9

Sylk Bus

Address Dial

ByPass/Fan

LED

CPO-VAV2A

485-

485+

FGND

S-BUS

S-BUS

AI1

AGND

AGND

Temp

Set Point

DO4

COM

AO2

AO1

DO6

COM

DO5

DO3

FGND

N24VAC

S24VAC

DO1

DO2

TRIAC EQUIVALENT

CIRCUIT

DO for Integrated

actuator

AIRFLOW

PICKUP

L

H

+-

24V AC

MSTP Channel

COM

G0G

Y

G0G

Y

AGND

240/24 Vac

Minimum 40VA

Always use same

phase to power

controls

AC/B

N

E

Transformer secondary

remains floating

No earth

LLLL

24V AC COM

3 wires external

powered 0...10V device

T

~

+-

4 wires external

powered 0...10V device

4...20mA

Temperature

Sensor

Potential free contacts

Figure 27 Controller wiring diagram for typical VAV application - with modulating valves, CPO-TR40 and TR42 Wall Modules

Figure 28 24 Vac power and IO wiring diagram

17 EN1B-0022 IE10 R0717

Page 18

CONNECTING THE HONEYWELL BACNET WI-F I ADAPTER

2 meters (max)

BACnet MS/TP

Wi-Fi

BACnet IP

GND

-

+

-

+

GND

Connecting the Honeywell BACnet Wi-Fi Adapter

This section provides the connection drawings of CP-VAV/SPC controller with Honeywell BACnet Wi-Fi Adapter.

For more details on Honeywell BACnet Wi-Fi Adapter, see the BACnet WiFi Adapter - Mounting and ope rating instructions

(MU1B-0592GE51).

EN1B-0022 IE10 R0717 18

Page 19

Federal communications commission (FCC) statement

This section provides the Federal Communications

Commission (FCC) statement.

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this device

must accept any interference received, including interference

that may cause undesired operation.

CAN ICES-3(B)/NMB-3(B)

Caution

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate the equipment.

Honeywell Building Solutions

1985 Douglas Drive North

Golden Valley MN 55422-4386

USA

www.honeywell.com

EN1B-0022 IE10 R0717

July 2017

© 2017 Honeywell International Inc.

Loading...

Loading...