Honeywell CLLYVB4024NS, CLLYUB1012S, CLLYUB6438S, CLLYVB4022AS, CLLYVB6436AS Product Data

...Page 1

LYNX BACnet® Programmable

A

(A

VAV/Unitary Controllers

Product Data

GENERAL

The BACnet MS/TP LYNX controllers are designed to control

HVAC equipment.

LYNX controllers provide many options and advanced system

features that allow state-of-the-art commercial building

control. Each LYNX controller is programmable and configurable using the COACH

LYNX BACnet controllers require the LYNX BACnet Programmable Feature to be licensed in COACH

LYNX controllers are designed for use in VAV (Variable Air

Volume) and Unitary HVAC control applications. Each controller contains a host microcontroller to run the main HVAC

application and a second microcontroller for BACnet MS/TP

network communications. Each controller has flexible,

universal inputs for wall modules, digital inputs, and a mix of

analog and digital triac outputs (see Table 1). The models

CLLYVB6436AS, CLLYVB0000AS, and CLLYVB4022AS

include an actuator.

AX

software.

AX

.

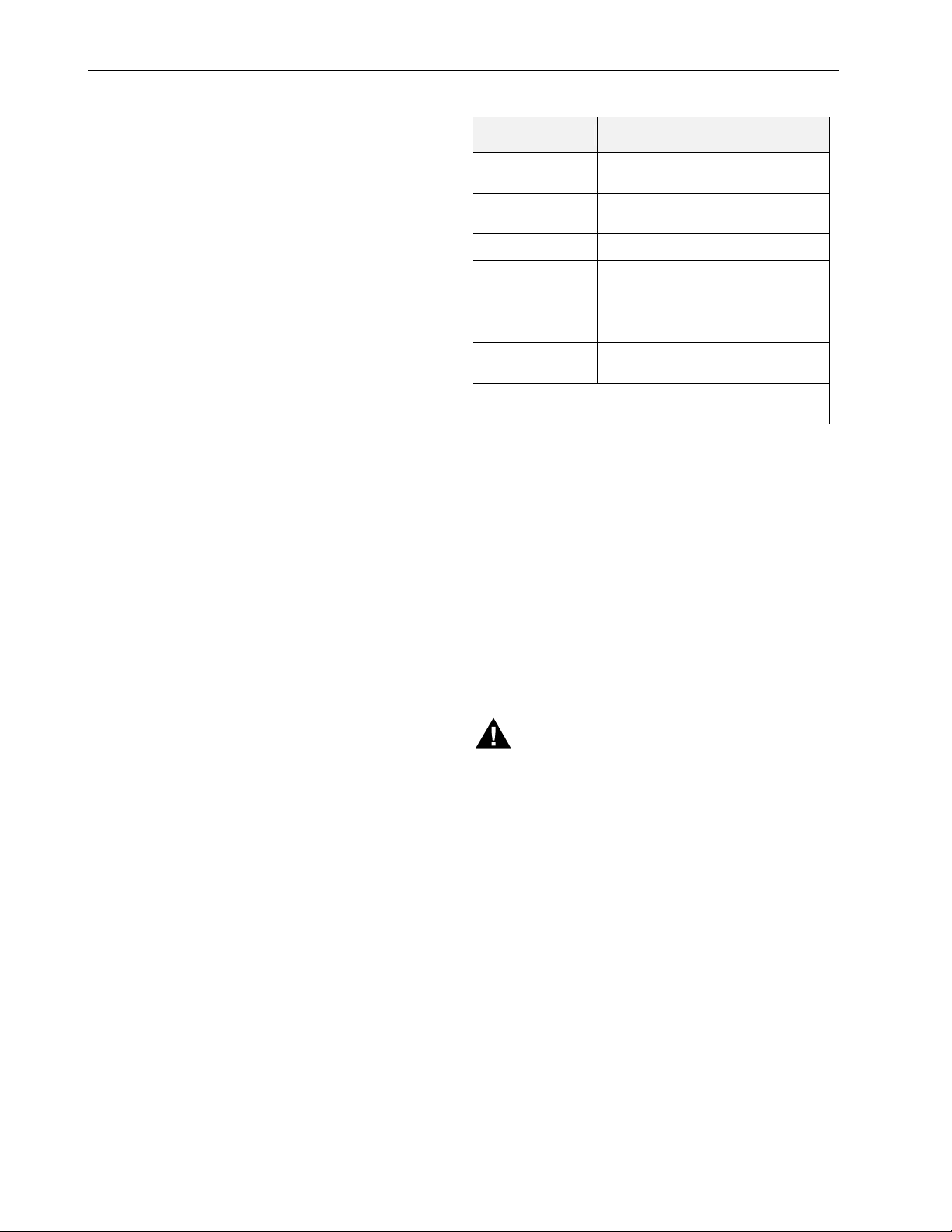

Table 1. Controller configurations

model type

CLLYUB1012S unitary 1(A 0 1 2 NO NO

CLLYUB4024S unitary 4(A 0 2 4 NO NO

CLLYUB6438S unitary 6 4 3 8 NO NO

CLLYVB0000AS VAV 0 0 0 0 YES YES

CLLYVB4022AS VAV 4(A 0 2 2 YES YES

CLLYVB4024NS VAV 4(A 0 2 4 YES NO

CLLYVB6436AS VAV 6 4 3 6 YES YES

CLLYVB6438NS VAV 6 4 3 8 YES NO

One Universal Input (UI-1*) is selectable as a fast digital pulse meter.

All of the LYNX controllers communicate via an EIA-485 BACnet MS/TP communication network, capable of baud rates of

between 9.6 and 115.2 kbits/sec.

The LYNX controllers are field-mountable to either a panel or a DIN rail.

Universal

Inputs (UI)

Digital

Inputs (DI)

nalog Out-

puts (AO)

Digital Out-

puts (DO)

velocity pressure

sensor (Microbridge)

floating

actuator

Copyright © 2015 Honeywell GmbH All Rights Reserved EN0Z-0959GE51 R0615

Page 2

LYNX BACNET PROGRAMMABLE, VAV/UNITARY CONTROLLERS – PRODUCT DATA

TECHNICAL DATA

GENERAL SPECIFICATIONS

Rated voltage: 20 … 30 Vac; 50/60 Hz

Power consumption: 100 VA for controller and all connected

Controller-only load: 5 VA max. (S- and NS-models)

Controller + actuator load: 9 VA max. (AS-models)

Wall modules

output:

VAV OPERATING & STORAGE TEMPERATURE AMBIENT RATING

VAV models: 0 … +50 °C

Unitary models: -40 … +65.5 °C

Relative humidity: 5 … 95%, non-condensing

LED: Provides status for normal operation, con-

VELOCITY PRESSURE SENSOR (VAV MODELS)

Operating range: 0 … 374 Pa

FLOATING ACTUATOR (AS-models)

Rotation stroke: 95° ± 3° for CW/CCW-opening dampers

Torque rating: 5 Nm

Runtime for 90° rotation: 90 sec at 60 Hz

Operating temperature: -20 … +60 °C

REAL-TIME CLOCK

Operating range: 24-hr, 365-day, multi-year calendar, incl.

Power failure back-up: 24 hrs at 0 … +38 °C,

Accuracy: ±1 minute per month at 25 °C

DIGITAL INPUT (DI) CIRCUITS

Voltage rating: 0 … 30 Vdc open circuit

Input type: Dry contact to detect open / closed circuit

Operating range: Open circuit = FALSE,

Resistance: Open circuit > 3k ,

DIGITAL TRIAC OUTPUT (DO) CIRCUITS

Voltage rating: 20 … 30 Vac at 50/60 Hz

Current rating: 25 … 500 mA continuous, and 800 mA

ANALOG OUTPUT (AO) CIRCUIT

Configuration for current /

voltage:

Configuration as digital

outputs:

Analog current outputs

Current output range: 4 … 20 mA

Output load resistance: 550 , max.

Analog voltage outputs

Voltage output range: 0 … 10 Vdc

Max. output current: 10.0 mA

UNIVERSAL INPUT (UI) CIRCUITS

See Table 2 for UI circuit specifications.

power

loads (incl. actuator on AS-models)

20 Vdc ± 10% at 75 mA, max.

troller download process, alarms, manual

mode, and error conditions

day of week and configuration for automatic daylight savings time adjustment to

occur at 2:00 a.m. local times on

configured start and stop dates

22 hrs at 38 … 50 °C

closed circuit = TRUE

closed circuit < 500

(AC rms) for 60 ms.

Up to 3 analog outputs can be individually

configured for current or voltage.

FALSE (0%) -> 0 Vdc (0 mA)

TRUE (100%) -> max., 11 Vdc (22 mA)

Table 2. Universal input circuit specifications

input type sensor type operating range

Room/Zone Discharge

Air Outdoor Air Temp.

Outdoor Air

Temperature

Resistive Input Generic 100 …100 k

Voltage Input Transducer,

Discrete Input Dry Contact

Pulse Input(A Counter/Meter Max. frequency: 15 Hz

(A

One Universal Input (UI-1*) is selectable as a fast digital pulse

meter.

NTC 20kOhm -40 ... +93 °C

PT1000

(IEC751 3850)

Controller

closure

-40 ... +93 °C

0 … 10 Vdc

OpenCircuit 3000

ClosedCircuit < 3000

Min. pulse width: 20 ms

NTC 20kOhm are recommended for use with these controllers, due to improved resolution and accuracy when

compared to the PT1000.

BEFORE INSTALLATION

The controller is available in eight models (see Table 1).

Before installing the controller, review the power, input, and

output specifications in section “Technical Data”.

Hardware driven by Triac outputs must have a min.

current draw, when energized, of 25 mA and a max.

current draw of 500 mA.

Hardware driven by the analog current outputs must have

a max. resistance of 550 , resulting in a max. voltage of

11 V when driven at 20 mA. If resistance exceeds 550 ,

voltages up to 18 Vdc are possible at the analog output

terminal.

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

To prevent electrical shock or equipment damage,

disconnect power supply before beginning wiring or

making wiring connections.

INSTALLATION

The controller must be mounted in a position that allows

clearance for wiring, servicing, removal, connection of the

BACnet MS/TP Molex connector and access to the MS/TP

MAC address DIP switches (see Fig. 12).

The controller may be mounted in any orientation.

IMPORTANT

Avoid mounting in areas where acid fumes or other

deteriorating vapors can attack the metal parts of the

controller, or in areas where escaping gas or other

explosive vapors are present. See Fig. 4 and Fig. 6 for

mounting dimensions.

EN0Z-0959GE51 R0615 2

Page 3

LYNX BACnet PROGRAMMABLE, VAV/UNITARY CONTROLLERS – PRODUCT DATA

In the case of the AS-models, first the actuator and then the

controller is mounted. For the other models, see section

“Mount Controller” on page 4 to begin the installation.

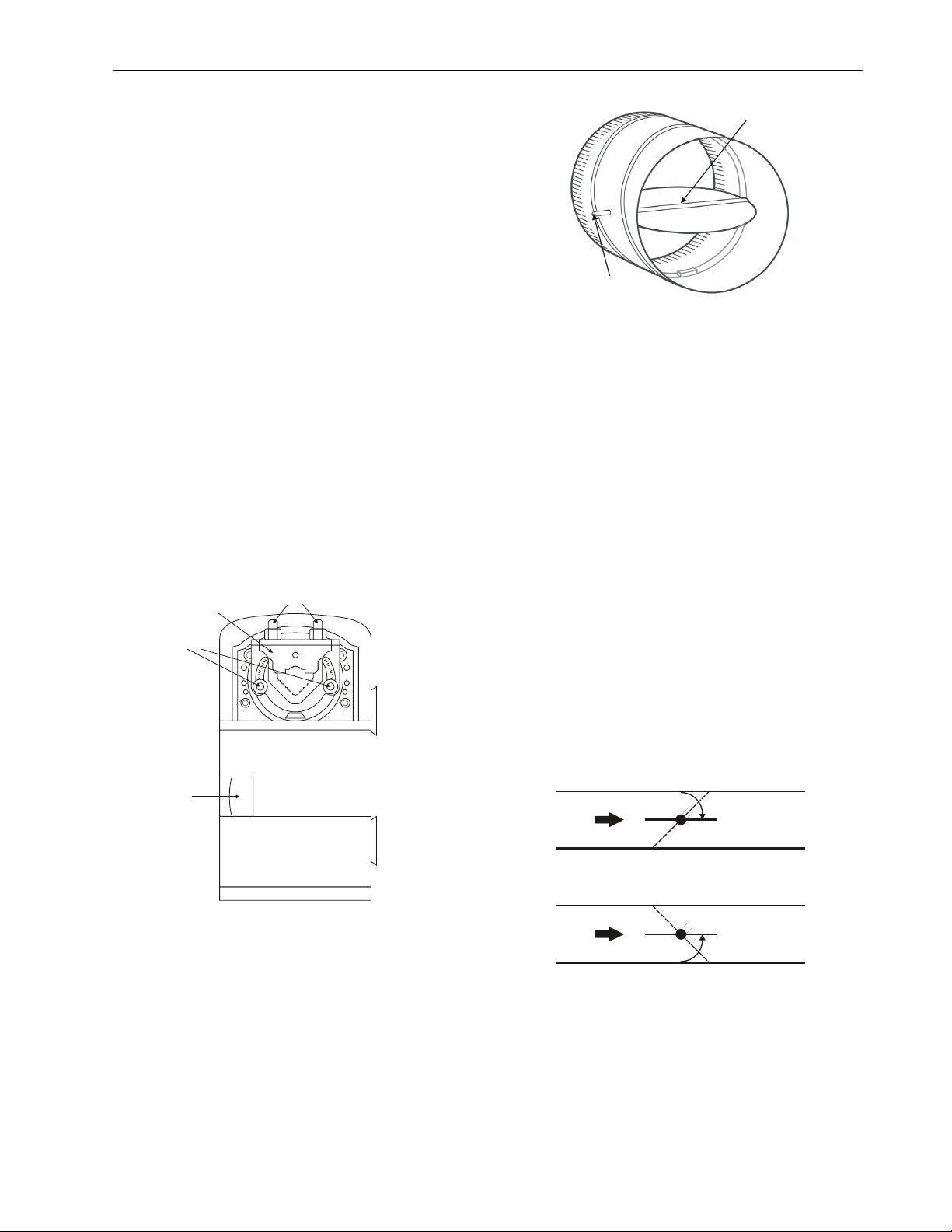

Mounting Actuator onto Damper Shaft (ASModels)

The AS-models include the direct-coupled actuator with

DECLUTCH button, which is shipped hard-wired to the

controller.

The actuator mounts directly onto the VAV box damper shaft

and has up to 5 Nm torque, 90° stroke, and 90-sec timing at

60 Hz. The actuator is suitable for mounting onto a 10 to 13

mm square or round VAV box damper shaft. The min. VAV

box damper shaft length is 40 mm.

The two mechanical end-limit set screws control the amount

of rotation from 12° to 95°. These set screws must be

securely fastened in place. To ensure tight closing of the

damper, the shaft adapter has a total rotation stroke of 95°

(see Fig. 1).

NOTE 1: The actuator is shipped with the mechanical end

NOTE 2: The DECLUTCH button, when pressed, allows you

LIMIT SET SCREWS (2)

limit set screws set to 95° of rotation. Adjust the

two set screws closer together to reduce the

rotation travel. Each “hash mark” indicator on the

bracket represents approximately 6.5° of rotation

per side.

to rotate the universal shaft adapter (see Fig. 1).

UNIVERSAL SHAFT

UNIVERSAL SHAFT

ADAPTER

MECHANICAL END

DECLUTCH

BUTTON

CLAMPING BOLTS (2)

DAMPER

DAMPER SHAFT

ROTATES CW

TO OPEN

Fig. 2. Damper with 90° clockwise rotation to open

IMPORTANT

Mount actuator flush with damper housing or add a

spacer between the actuator mounting surface and

damper box housing.

Before Mounting Actuator onto Damper

Shaft (AS-Models)

Tools required:

Phillips #2 screwdriver - end-limit set screw adjustment

8 mm wrench - centering clamp

Before mounting the actuator onto the VAV box damper shaft,

determine the following:

1. Determine the damper shaft diameter. It must be

10…13 mm.

2. Determine the length of the damper shaft. If the length of

the VAV box damper shaft is less than 40 mm, the

actuator cannot be used.

3. Determine the direction the damper shaft rotates to open

the damper (CW or CCW) (see Fig. 3). Typically, there is

an etched line on the end of the damper shaft indicating

the position of the damper. In Fig. 2, the indicator shows

the damper open in a CW direction.

4. Determine the damper full opening angle (45, 60, or 90°).

In Fig. 2, the damper is open to its full open position of

90°.

TYPE A DAMPER

AIR

FLOW

CW TO OPEN, CCW TO CLOSE

TYPE B DAMPER

Fig. 1. Floating actuator

IMPORTANT

Determine the damper rotation and opening angle prior to

installation. See Fig. 2 and Fig. 3 for examples.

Fig. 3. Determining rotation direction (CW or CCW) for

AIR

FLOW

CCW TO OPEN, CW TO CLOSE

damper opening

EN0Z-0959GE51 R0615

3

Page 4

LYNX BACNET PROGRAMMABLE, VAV/UNITARY CONTROLLERS – PRODUCT DATA

A

A

V

A

V

V

A

V

Mounting Actuator Onto Damper Shaft (ASModels)

The unit is shipped with the actuator set to rotate open in the

clockwise (CW) direction to a full 95°. The extra 5° ensures a

full opening range for a 90° damper.

The installation procedure varies depending on the damper

opening direction and angle:

1) If the damper rotates CW to open, and the angle of the

damper open-to-closed is 90°:

a) Manually open the damper fully (rotate CW).

b) Using the DECLUTCH button, rotate the universal

shaft adapter fully CW.

c) Mount the actuator to the VAV damper box and shaft.

d) Tighten the two bolts on the centering clamp (8 mm

wrench; 8...10 Nm torque). When the actuator closes,

the damper rotates CCW 90° to fully close.

2) If the damper rotates CW to open, and the angle of the

damper open-to-closed is 45 or 60°:

a) Manually open the damper fully (rotate CW).

b) The actuator is shipped with the mechanical end-limits

set at 95°. Adjust the two mechanical end-limit set

screws to provide the desired amount of rotation.

Adjust the two set screws closer together to reduce the

rotation travel.

c) Tighten the two mechanical end-limit screws (Phillips

#2 screwdriver; (3.0-3.5 Nm torque).

d) Using the DECLUTCH button, rotate the universal

shaft adapter fully CW.

e) Mount the actuator to the VAV damper box and shaft.

f) Tighten the two bolts on the centering clamp (8 mm

wrench; 8...10 Nm torque).

g) When the actuator closes, the damper rotates CCW

either 45 or 60° to fully close.

3) If the damper rotates CCW to open, and the angle of the

damper open-to-closed is 90°:

a) Manually open the damper fully (rotate CCW).

b) Using the DECLUTCH button, rotate the universal

shaft adapter fully CCW.

c) Mount the actuator to the damper box and shaft.

d) Tighten the two bolts on the centering clamp (8 mm

wrench; 8...10 Nm torque). When the actuator closes,

the damper rotates CW 90° to fully close.

4) If the damper rotates CCW to open, and the angle of the

damper open-to-closed is 45 or 60°:

a) Manually open the damper fully (rotate CCW).

b) The actuator is shipped with the mechanical end-limits

set at 95°. Adjust the two mechanical end-limit set

screws to provide the desired amount of rotation.

Adjust the two set screws closer together to reduce the

rotation travel.

c) Tighten the two mechanical end-limit screws (Phillips

#2 screwdriver; (3.0-3.5 Nm torque).

d) Using the DECLUTCH button, rotate the universal

shaft adapter fully CCW.

e) Mount the actuator to the VAV damper box and shaft.

f) Tighten the two bolts on the centering clamp (8 mm

wrench; 8...10 Nm torque).

g) When the actuator closes, the damper rotates CW

either 45 or 60° to fully close.

IMPORTANT

Special precautions must be taken for dampers that

open in a CCW direction. The actuator is shipped with

its rotation direction set to CW to open, which applies

to the damper direction in steps 1 and 2 above. If the

damper shaft rotates in the CCW direction to open, the

controller software must be programmed to change the

rotation to “Reverse to Open,” which applies to the

damper direction in steps 3 and 4 above.

IMPORTANT

To avoid the possibility of over-pressurizing the duct

work on fan start-up, it is advisable to leave the

dampers in an open position after installation. To

prevent over-pressurization in the duct work on fan

start-up, use the DECLUTCH button (see Fig. 1) to

open the box damper on powered-down controllers. To

declutch, press and hold the DECLUTCH button, thus

disengaging the motor. Turn the damper shaft until the

damper is open and then release the DECLUTCH

button. When power is restored to the controller, the

controller synchronizes the damper actuator, so that

the damper is in the correct position upon start-up.

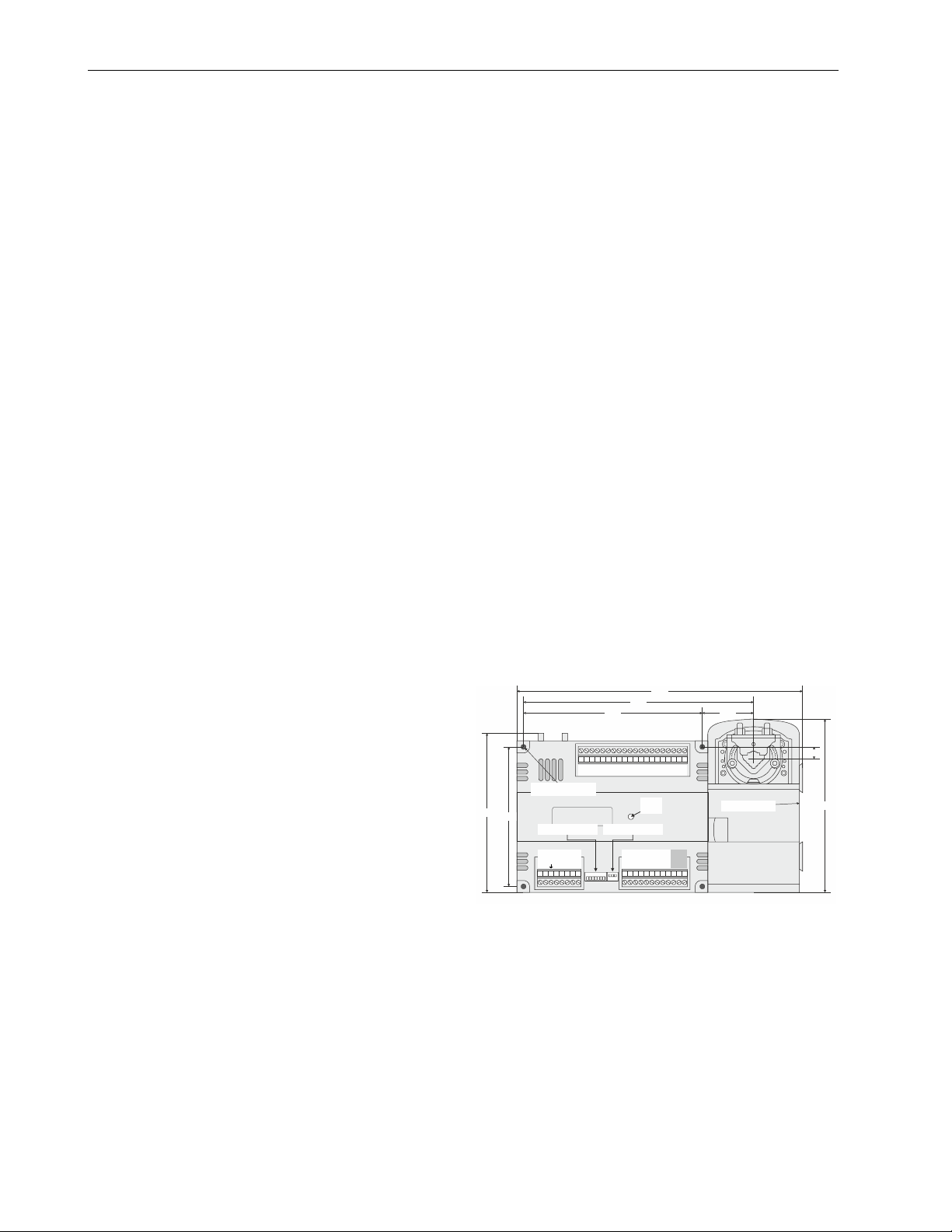

Mount Controller

NOTE: The controller may be wired before mounting to a

Terminal blocks are used to make all wiring connections to

the controller. Attach all wiring to the appropriate terminal

blocks (see section “Wiring” on page 6).

See Fig. 4 and Fig. 6 for panel mounting dimensions. See

Fig. 7 for DIN rail mounting.

146

Fig. 4. Duct mounting, dimensions in mm (AS-models)

panel or DIN rail.

2122 23 24 2526 27 28 29 30 3132 33 34 35 36 37 38 39 40

AO-1

AO-2

AO-3

COM

PANEL MOUNTING

HOLE (4 X 4.5)

128

AS MODELS

BACnet MS/TP MAC

ADDRESS DIP SWITCHES

B

B

24

20

EGND

S-BUS

S-BUS

24

C+

C-

DC

C

C

COM

1 3 4 5 62 7 8 9 10 11 12 13 1415 16 17 18 19 20

211

164

DI-1

DI-2

COM

COM

DI-3

DI-4

20

UI-1

COM

DC

HOST

STATUS

LED

LOCAL BACnet MS/TP

MOLEX CONNECTOR PINS

DO-1

DO-2

DO-4

COM

DO-3

UI-2

COM

262

211

UI-3

COM

UI-4

UI-5

COM

UI-6

DEPTH = 57

DO-6

DO-8

COM

COM

DO-5

DO-7

11

159

Panel Mounting

The controller enclosure is constructed of a plastic base plate

and a plastic factory-snap-on cover.

EN0Z-0959GE51 R0615 4

Page 5

LYNX BACnet PROGRAMMABLE, VAV/UNITARY CONTROLLERS – PRODUCT DATA

V

V

V

V

A

A

V

A

V

V

A

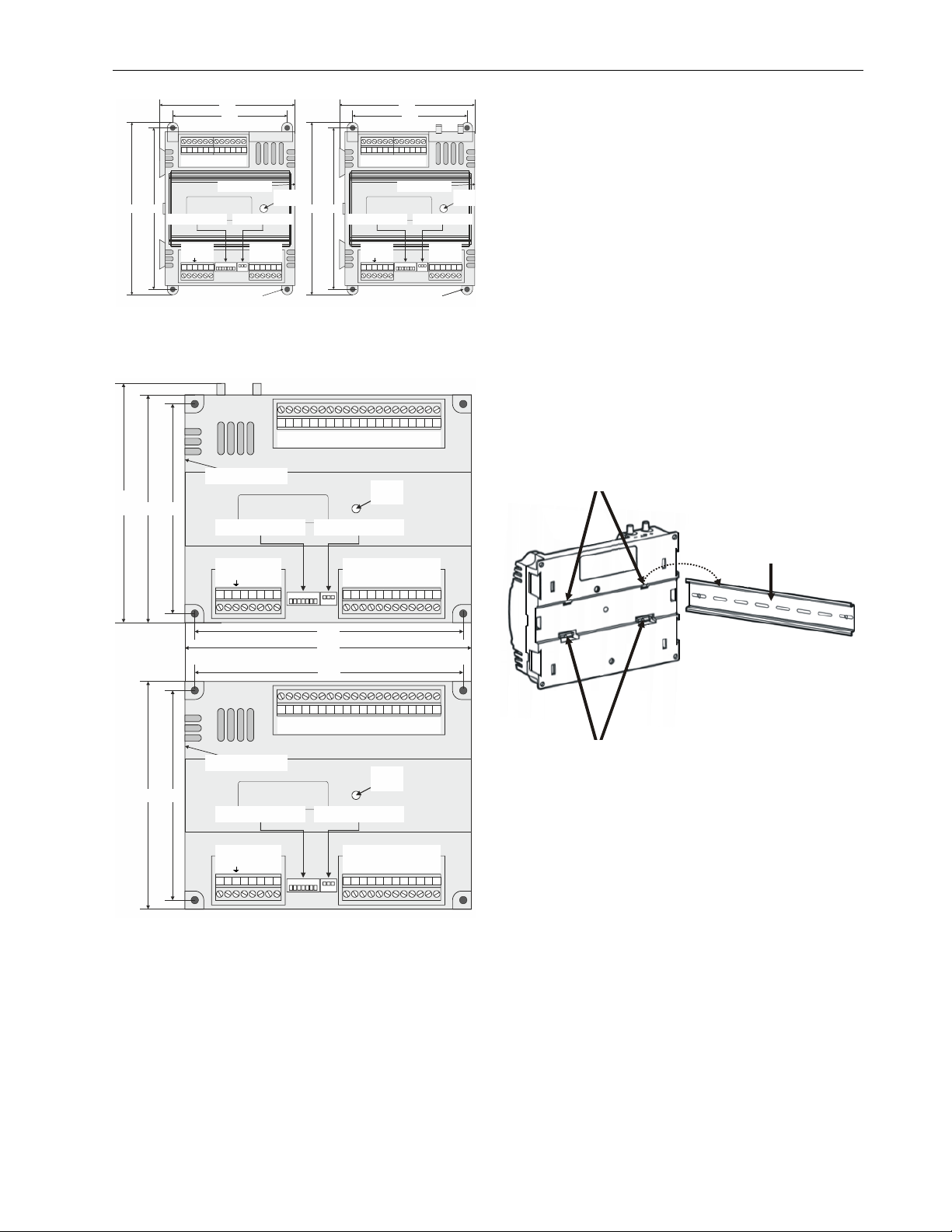

122 122

105 105

13 14 15 16 17 18 19 2021 22 23 24 1314 15 16 17 18 19 20 21 22 23 24

DO-2

COM

DO-1

COM

AO-1

UI-4

AO-2

COM

UI-3

UI-2

COM

UI-1*

HOST

STATUS

159 159149 149

CLLYUB4024S CLLYVB4024NS

BACnet MS/TP MAC

ADDRESS DIP SWITCHES

24

20

EGND

S-BUS

S-BUS

24VAC COM

AC

DC

1 3 4 5 62 7 8 9 10 1112 1 3 4 5 62 7 8 9 10 11 12

PANEL MOUNTING

HOLE (4 X 4.5)

LED

LOCAL BACnet MS/TP

MOLEX CONNECTOR PINS

BAC+

BAC-

SHIELD

DO-3

COM

DO-4

DO-2

COM

DO-1

COM

AO-1

AO-2

BACnet MS/TP MAC

ADDRESS DIP SWITCHES

24

20

EGND

S-BUS

S-BUS

24VAC COM

AC

DC

PANEL MOUNTING

HOLE (4 X 4.5)

UI-4

COM

UI-3

UI-2

COM

UI-1*

DEPTH = 57DEPTH = 57

LOCAL BACnet MS/TP

MOLEX CONNECTOR PINS

HOST

STATUS

LED

BAC+

BAC-

SHIELD

DO-3

COM

DO-4

Fig. 5. Panel mounting – dimensions (mm) for

CLLYUB1012S, CLLYUB4024S, and CLLYVB4024NS, only

(CLLYUB4024S and CLLYVB4024NS shown)

21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

AO-1 AO-1

DI-1 DI-1

DI-2 DI-2

AO-2 AO-2

AO-3 AO-3

COM COM

COM COM

COM COM

DI-3 DI-3

DI-4 DI-4

20VDC 20VDC

UI-1 UI-1

UI-2 UI-2

UI-3 UI-3

UI-4 UI-4

UI-5 UI-5

UI-6 UI-6

COM COM

COM COM

DO-6 DO-6

DO-8 DO-8

COM COM

COM COM

DO-5 DO-5

DO-7 DO-7

146

139

128

DEPTH = 57

NS MODELS

BACnet MS/TP MAC

ADDRESS DIP SWITCHES

24VAC

BAC+

20VDC

EGND

S-BUS

S-BUS

24VAC COM

BAC-

COM COM

HOST

STATUS

LED

LOCAL BACnet MS/TP

MOLEX CONNECTOR PINS

DO-1 DO-1

DO-2 DO-2

DO-4 DO-4

COM COM

COM COM

DO-3 DO-3

The controller can be mounted in any orientation. Ventilation

openings are designed into the cover to allow proper heat

dissipation, regardless of the mounting orientation.

DIN Rail Mounting (S- and NS-models)

To mount the S- and NS-models onto a DIN rail, see Fig. 7

and perform the following steps:

1. Holding the controller with its top tilted in towards the DIN

rail, hook the two top tabs on the back of the controller

onto the top of the DIN rail.

2. Push down and in to snap the two bottom flex connectors

of the controller onto the DIN rail.

IMPORTANT

To remove the controller from the DIN rail, perform the

following:

1. Push straight up from bottom to release top tabs.

2. Rotate the top of the controller out towards you and

pull the controller down and away from the DIN rail to

release the bottom flex connectors.

TOP TABS

DIN RAIL

1 3 4562

7

8

9 10 11 12 13 14 15 16 17 18 19 20

164

174

164

21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

139

128

DEPTH = 57

S MODELS

BACnet MS/TP MAC

ADDRESS DIP SWITCHES

24

C

134

B

20

EGND

S-BUS

S-BUS

24

C+

DC

C

COM

5 627 8

B

C-

LOCAL BACnet MS/TP

MOLEX CONNECTOR PINS

9 10

HOST

STATUS

11 121314

LED

15 161718 19 20

Fig. 6. Panel mounting, dimensions in mm (S- and NS-

models)

NOTE: The controller is designed so that the cover does

not need to be removed from the base plate for

either mounting or wiring.

The controller mounts using four screws inserted through the

corners of the base plate. Fasten securely with four screws.

BOTTOM FLEX

CONNECTORS

Fig. 7. Controller DIN rail mounting (S- and NS-models)

Piping (AS- and NS-models)

Air Flow Pick-Up

For AS- and NS-models, connect the air flow pickup to the

two restrictor ports on the controller (see Fig. 8).

NOTE 1: Use tubing with 6 mm outside diameter and 1 mm

NOTE 2: Always use a fresh cut on the end of the tubing that

Connect the high-pressure or upstream tube to the plastic

restrictor port labeled (+), and the low-pressure or downstream tube to the restrictor port labeled (-). See labeling in

Fig. 8. When twin tubing is used from the pickup, split the

pickup tubing a short length to accommodate the connections.

wall thickness.

connects to the air flow pickups and the restrictor

ports on the controller.

EN0Z-0959GE51 R0615

5

Page 6

LYNX BACNET PROGRAMMABLE, VAV/UNITARY CONTROLLERS – PRODUCT DATA

NOTE 1: If controllers are mounted in unusually dusty or

NOTE 2: The tubing from the air flow pickup to the controller

NOTE 3: Use caution when removing tubing from a con-

dirty environments, an inline, 5-micron disposable

air filter (use 5-micron filters compatible with

pneumatic controls) is recommended for the highpressure line (marked as +) connected to the air

flow pickup.

should not exceed 1 m. Any length greater than

this will degrade the flow sensing accuracy.

nector. Always pull straight away from the connector or use diagonal cutters to cut the edge of

the tubing attached to the connector. Never

remove by pulling at an angle.

AIR FLOW

PICK-UP

RESTRICTOR

PORTS

P

2222222222

5

1234

67890

3

1

NS- and AS-models

It is important to understand these interrelationships early in

the job engineering process, to ensure proper implementation

when configuring the controllers. See the controller

Application Guides.

Power Budget

A power budget must be calculated for each device to determine the required transformer size for proper operation. A

power budget is simply the sum of the max. power draw

ratings (in VA) of all the devices to be controlled. This

includes the controller itself and any devices powered from

the controller, such as equipment actuators and various

contactors and transducers.

IMPORTANT

When multiple controllers operate from a single

transformer, connect the same side of the transformer

secondary to the same power input terminal in each

device. The earth ground terminal (terminal 3) must be

connected to a verified earth ground for each controller

in the group (see Fig. 10).

Half-wave devices and full-wave devices must not use

the same AC transformer. If a LYNX controller is to

share its power supply with another device, make sure

the other device utilizes a half-wave rectifier and that

the polarity of the wiring is maintained.

Wiring

All wiring must comply with applicable electrical codes and

ordinances, or as specified on installation wiring diagrams.

Controller wiring is terminated to the screw terminal blocks

located on the top and the bottom of the device.

Fig. 8. Air flow pick-up connections

Power

Before wiring the controller, determine the input and output

device requirements for each controller used in the system.

Select input and output devices compatible with the controller

and the application. Consider the operating range, wiring

requirements, and the environment conditions when selecting

input/output devices. When selecting actuators for modulating

applications, consider using floating control. In direct digital

control applications, floating actuators will generally provide

control action equal to or better than an analog input actuator

for lower cost.

Determine the location of controllers, sensors, actuators, and

other input/output devices and create wiring diagrams. See

Fig. 14 through Fig. 20 for typical controller wiring configurations.

The application engineer must review the control job requirements. This includes the sequences of operation for the controller, and for the system as a whole. Usually, there are

variables that must be passed between the controller and

other controllers that are required for optimum system wide

operation. Typical examples include the outdoor air temperature, the demand limit control signal, and the smoke

control mode signal.

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

To prevent electrical shock or equipment damage,

disconnect power supply before beginning wiring or

making wiring connections.

NOTE 1: For multiple controllers operating from a single

transformer, the same side of the transformer

secondary must be connected to the same power

input terminal in each controller. Controller configurations will not necessarily be limited to three

devices, but the total power draw, including

accessories, cannot exceed 100 VA when powered

by the same transformer (U.S., only). For power

and wiring recommendations, See section “Power”

on page 6. The earth ground terminal (terminal 3)

must be connected to a verified earth ground for

each controller in the group (see Fig. 10).

NOTE 2: All loads on the controller must be powered by the

same transformer powering the controller itself. A

controller can use separate transformers for controller power and output power.

EN0Z-0959GE51 R0615 6

Page 7

LYNX BACnet PROGRAMMABLE, VAV/UNITARY CONTROLLERS – PRODUCT DATA

NOTE 3: A jumper should be installed between 24 VAC

COM (term. 2) and EGND (term. 3). Further,

EGND (term. 3) should be connected to a verified

earth ground, and kept as short as possible.

NOTE 4: Do not connect the universal input COM terminals,

analog output COM terminals or the digital

input/output COM terminals to earth ground. See

Fig. 13 through Fig. 18 for wiring examples.

The 24 Vac power from an energy limited Class II power

source must be provided to the controller. To conform to

Class II restrictions (U.S., only), the transformer must not be

larger than 100 VA.

Fig. 9 depicts a single controller using one transformer.

IMPORTANT

Power must be OFF prior to connecting to or removing

connections from the 24 Vac power (24 Vac/24 Vac

COM), earth ground (EGND), and 20 Vdc power (20

Vdc) terminals.

IMPORTANT

Use the heaviest gauge wire available, up to 2.0 mm

with a min. of 1.0 mm

2

, for all power and earth ground

2

wiring.

Screw-type terminal blocks are designed to accept up

to one 2.0 mm

ductors. More than two wires that are 2.0 mm

2

conductor or up to two 1.0 mm2 con-

2

can be

connected with a wire nut. Include a pigtail with this

wire group and attach the pigtail to the terminal block.

IMPORTANT

Connect terminal 2, (the 24 Vac common [24 VAC

COM] terminal) to earth ground (see Fig. 9).

NOTE: Unswitched 24 Vac power wiring can be run in the

same conduit as the BACnet MS/TP cable.

CONNECT POWER TO

TERMINALS 1 AND 2.

5

1234

OUTPUT

DEVICE POWER

678

EARTH GROUND

(TERMINAL 3)

COM

TRANSFORMER

24 VAC

EARTH

WHEN CONNECTING POWER TO THE LYNX BACnet

CONTROLLER, CONNECT THE COM LEG OF THE VAC

SECONDARY CIRCUIT TO A KNOWN EARTH GROUND.

GROUND

9

LI N E V O LTAGE

> 150 VAC

Fig. 9. Power wiring details for one LYNX controller per

transformer

More than one controller can be powered by a single transformer. Fig. 10 shows power wiring details for multiple controllers.

NOTE: Controller configurations are not necessarily limited

to three devices, but the total power draw,

including accessories, cannot exceed 100 VA

when powered by the same transformer (U.S.,

only). For power wiring recommendations, see

section “Power” on page 6.

CONNECT POWER TO

TERMINALS 1 AND 2.

EARTH GROUND

(TERMINAL 3)

CONNECT POWER TO

TERMINALS 1 AND 2.

EARTH GROUND

(TERMINAL 3)

CONNECT POWER TO

TERMINALS 1 AND 2.

123456781234567812345678 999

EARTH GROUND

(TERMINAL 3)

COM

OUTPUT DEVICE POWER

24 VAC

WHEN CONNECTING POWER TO THE LYNX BACnet

CONTROLLER, CONNECT THE COM LEG OF THE VAC

SECONDARY CIRCUIT TO A KNOWN EARTH GROUND.

GROUND

Fig. 10. Power wiring details for two or more LYNX

,

controllers per transformer

Communications

Each LYNX controller uses a BACnet MS/TP communications

port. The controller’s data is presented to other controllers

over a twisted-pair MS/TP network, which uses the EIA-485

signaling standard capable of the following baud rates: 9.6,

19.2, 38.4, 76.8 or 115.2 kilobits per sec (configured at global

controller). The LYNX controllers are master devices on the

MS/TP network. Each LYNX controller uses a high-quality

EIA-485 transceiver and exerts ¼ unit load on the MS/TP

network.

Cabling should be selected that meets or exceeds the

BACnet Standard which specifies the following: An MS/TP

EIA-485 network shall use shielded, twisted-pair cable with

characteristic impedance of 100…130 . Distributed

capacitance between conductors shall be less than 100 pF

per meter. Distributed capacitance between conductors and

shield shall be less that 200 pF per meter. Foil or braided

shields are acceptable. The Honeywell tested and

recommended MS/TP cable is Honeywell Cable 3322 (18

AWG, 1-Pair, Shielded, Plenum cable), alternatively

Honeywell Cable 3251 (22 AWG, 1-Pair, Shielded, Plenum

cable) is available and meets the BACnet Standard requirements (www.honeywellcable.com).

The max. BACnet MS/TP network Bus segment length is

1,219 m using recommended wire. Repeaters must be used

when making runs longer than 1,219 m. A max. of three

repeaters can be used between any two devices.

Setting the MS/TP MAC Address

The MS/TP MAC address for each device must be set to a

unique value in the range of 0-127 on an MS/TP network

segment (address 0, 1, 2, & 3 should be avoided as they are

commonly used for the router, diagnostic tools, and as spare

addresses). DIP switches on the LYNX controller are used to

set the controller's MAC address.

To set the MS/TP MAC address of a LYNX controller:

TRANSFORMER

120/240 VAC

EARTH

EN0Z-0959GE51 R0615

7

Page 8

LYNX BACNET PROGRAMMABLE, VAV/UNITARY CONTROLLERS – PRODUCT DATA

1. Find an unused MAC address on the MS/TP network to

which the LYNX controller connects.

2. Locate the DIP switch bank on the LYNX for addressing.

This is labeled “MAC Address.”

3. With the LYNX Controller powered down, set the DIP

switches for the MAC Address you want. Add the value of

DIP switches set to ON to determine the MAC address.

See Table 3. For example, if only DIP switches 1, 3, 5,

and 7 are enabled, the MAC address would be 85 (1 + 4 +

16 + 64 = 85).

NOTE: See Fig. 12 for DIP switch orientation and arrange-

ment.

Table 3. DIP switch values for MS/TP MAC address

DIP

VALUE

7 6 5 4 3 2 1

64 32 16 8 4 2 1

Setting the Device Instance Number

The Device Instance Number must be unique across the

entire BACnet system network because it is used to uniquely

identify the BACnet devices. It may be used to conveniently

identify the BACnet device from other devices during

installation. The LYNX controller’s Device Instance Number is

automatically set when it is added to a WEBStation-AX

project.

The Device Instance Number can be changed by the user,

which may be necessary when integrating with a third party or

when attempting to replace an existing controller and it is

desired to maintain the existing Device Instance Number.

To edit the Device Instance Number using WEBs AX:

1. Identify an unused Device Instance Number on the

BACnet Network, in the range of 0 - 4194302.

2. Open the LYNX BACnet Device Mgr View

a. Double click on the BACnet Network located in the

navigation tree.

b. Select the LYNX controller to be modified.

c. Click on the Edit button.

d. Enter an unused value in the Device ID field.

e. Select OK

3. Right click on the LYNX Controller and select “Actions >

Write Device Instance” to complete the update.

Termination Resistors

Matched terminating resistors are required at each end of a

segment bus wired across (+) and (-). Use matched precision

resistors rated ¼ W ±1% / 80…130 . Ideally, the value of the

terminating resistors should match the rated characteristic

impedance of the installed cable. E.g., if the installed MS/TP

cable has a listed characteristic impedance of 120 , install

120 matched precision resistors.

NOTE: LYNX controllers do not provide network biasing.

Shield Terminating

Following proper MS/TP cabling shield grounding procedures

is important to minimize the risk of communication problems

and equipment damage caused by capacitive coupling.

Capacitive coupling is caused by placing MS/TP cabling close

to lines carrying higher voltage. The shield should be

grounded on only one end of the MS/TP segment (typically,

on the router end). Tie the shield through using the SHLD

(terminal 4) on the LYNX Controller.

Sylk™ Bus

Sylk is a two-wire, polarity-insensitive bus that provides both

18 Vdc power and communications between a Sylk-enabled

sensor and a Sylk-enabled controller. Using Sylk-enabled

sensors saves I/O on the controller and is faster and cheaper

to install since only two wires are needed and the bus is

polarity-insensitive. Sylk sensors are configured using the

latest release of the LYNX Tool for COACH

BAC -

BAC +

SHIELD

ADD APPROPRIATE TERMINATION RESISTOR

12345678 1234567812345678 999

BETWEEN BAC+ BAC- TERMINALS.

BAC -

BAC +

SHIELD

AX

.

BAC -

BAC +

SHIELD

Fig. 11. Termination modules (BACnet MS/TP daisy chain

connections)

Wiring Details

Each controller is shipped with the digital outputs, which

switch the 24 Vac to the load (high side).

The three analog outputs (AO) are used to control modulating

heating, cooling and economizer equipment. Any AO may be

used as a digital output, as follows:

False (0%) produces 0 Vdc (0 mA)

True (100%) produces the max. 11 Vdc (22 mA)

The wiring connection terminals described in Table 4 are

shown in Fig. 12.

IMPORTANT

If the controller is not connected to a good earth

ground, the controller's internal transient protection

circuitry is compromised and the function of protecting

the controller from noise and power line spikes cannot

be fulfilled. This could result in a damaged circuit

board and require replacement of the controller. See

installation diagrams for specific wiring.

All controllers have terminal arrangements similar to the

example shown in Fig. 12 as described in Table 4.

EN0Z-0959GE51 R0615 8

Page 9

LYNX BACnet PROGRAMMABLE, VAV/UNITARY CONTROLLERS – PRODUCT DATA

A

A

A

A

Table 4. Description of wiring terminals (CLLYUB6438S,

CLLYVB6436AS, and CLLYVB6438S)

TERMINAL LABEL CONNECTION

INPUT POWER & GROUND

1 24 VAC 24 VAC POWER

(

2

24 VAC COM 24 VAC POWER

(

3

EGND EARTH GROUND

4 SHLD SHIELD

5 SBUS 1 SYLK

6 SBUS 2 SYLK

NETWORK CONNECTIONS

7 BAC+ BACnet COMMUNICATIONS

8 BAC- BACnet COMMUNICATIONS

DIGITAL OUTPUTS

9 DO-1 DIGITAL OUTPUT

10 DO-2 DIGITAL OUTPUT

11 COM COMMON

12 DO-3 DIGITAL OUTPUT

13 DO-4 DIGITAL OUTPUT

14 COM COMMON

15 DO-5 DIGITAL OUTPUT

16 DO-6 DIGITAL OUTPUT

17 COM COMMON

18(B DO-7 DIGITAL OUTPUT

19(B DO-8 DIGITAL OUTPUT

20(B COM COMMON

ANALOG OUTPUTS(C

21 AO-1 ANALOG OUTPUT

22 COM COMMON

23 AO-2 ANALOG OUTPUT

24 AO-3 ANALOG OUTPUT

25 COM COMMON

DIGITAL INPUTS(D

26 DI-1 DIGITAL INPUT

27 DI-2 DIGITAL INPUT

28 COM COMMON

29 DI-3 DIGITAL INPUT

30 DI-4 DIGITAL INPUT

ATTACHED DEVICE(S) POWER

31 20 VDC 20 VDC POWER

UNIVERSAL INPUTS

32 UI-1* UNIVERSAL INPUT

33 COM COMMON

34 UI-2 UNIVERSAL INPUT

35 UI-3 UNIVERSAL INPUT

36 COM COMMON

37 UI-4 UNIVERSAL INPUT

38 UI-5 UNIVERSAL INPUT

39 COM COMMON

40 UI-6 UNIVERSAL INPUT

(A

A jumper should be installed between 24 VAC COM (term. 2) and EGND

(term. 3). Further, EGND (term. 3) should be connected to a verified earth

ground.

(B

In the case of the CLLYVL6436AS controller, only, terminals 18, 19, and 20

(DO-7, DO-8, and COM) are not present. The actuator is internally hardwired to

these terminals.

(C

Analog outputs may be configured as digital outputs and operate as follows:

FALSE (0%) -> 0 Vdc (0 mA), TRUE (100%) -> the max. 11 Vdc (22 mA)

(D

Digital inputs: open circuit = FALSE, closed circuit = TRUE

*UI-1 is selectable as a fast digital pulse meter.

Table 5. Description of wiring terminals (CLLYVB0000AS,

CLLYVB4022AS, and CLLYVB6436AS)

TERMINAL LABEL CONNECTION

INPUT POWER & GROUND

1 24 VAC 24 VAC POWER

(

2

24 VAC COM 24 VAC POWER

(

3

EGND EARTH GROUND

4 20VDC 20 VDC

5 SBUS 1 SYLK

6 SBUS 2 SYLK

NETWORK CONNECTIONS

7 BAC+ BACnet COMMUNICATIONS

8 BAC- BACnet COMMUNICATIONS

9 SHIELD SHIELD

DIGITAL OUTPUTS

10 DO-3 DIGITAL OUTPUT

11 COM COMMON

12 DO-4 DIGITAL OUTPUT

13 DO-2 DIGITAL OUTPUT

14 COM COMMON

15 DO-1 DIGITAL OUTPUT

ANALOG OUTPUTS

16 AO-2 ANALOG OUTPUT

17 COM COMMON

18 AO-1 ANALOG OUTPUT

UNIVERSAL INPUTS

19 UI-4 UNIVERSAL INPUT

20 COM COMMON

21 UI-3 UNIVERSAL INPUT

22 UI-2 UNIVERSAL INPUT

23 COM COMMON

24 UI-1* UNIVERSAL INPUT

(A

A jumper should be installed between 24 VAC COM (term. 2) and

EGND (term. 3). Further, EGND (term. 3) should be connected to a

verified earth ground.

*

UI-1 is selectable as a fast digital pulse meter.

MS/TP MAC Address DIP Switches

The MS/TP MAC address DIP switches are used to set the

unit's MAC address. Each LYNX controller on an MS/TP network must have a unique MAC address in the range of 0-127

(address 0 should be avoided as it is the Honeywell factory

default MAC address for all MS/TP devices).

MS/TP Service Connector Pins

Local device MS/TP network connection is provided via the

molex connector pins.

EN0Z-0959GE51 R0615

9

Page 10

LYNX BACNET PROGRAMMABLE, VAV/UNITARY CONTROLLERS – PRODUCT DATA

21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

AO-1

DI-1

DI-2

AO-2

AO-3

COM

COM

COM

DI-3

DI-4

20VDC

UI-1

COM

UI-2

UI-3

COM

UI-4

UI-5

COM

WINDOW CONTACTS

(CONTACTS CLOSED

= WINDOW CLOSED)

UI-6

AIR FLOW

PICK-UP

OCCUPANCY SENSOR

(CONTACTS CLOSED

22

= OCCUPIED)

CLCM4T111

7

6

LED

5

BYPASS

4

SET-POINT

3

SENSOR

2

GND

1

HOST

STATUS

CLLYVB6438NS

BACnet MS/TP MAC

ADDRESS DIP SWITCHES

BAC+

20VDC

S-BUS

S-BUS

BAC-

24VAC

EGND

24VAC COM

1 3 4562 7 8 9 10 11 12 13 14 15 16 17 18 19 20

LOCAL BACnet MS/TP

MOLEX CONNECTOR PINS

LED

DO-1

DO-2

DO-4

DO-6

COM

COM

DO-3

DO-8

COM

DO-5

COM

DO-7

Fig. 12. LED, service, network, and terminal connections

(CLLYVB6438NS shown)

Wiring Applications (Examples)

Fig. 13 through Fig. 19 illustrate controller wiring for the

following configurations.

Typical controller wiring for VAV application using the

CLCM4T111 Wall Module and an LF20 Air Temperature

Sensor (see Fig. 13).

Typical controller wiring for VAV application with staged

reheat (see Fig. 14).

Typical controller wiring for PWM reheat and PWM

peripheral heat valve actuator (see Fig. 15).

Typical controller wiring for AHU application (see Fig. 16).

Typical controller wiring for 4…20 mA enthalpy sensors

and digital inputs (see Fig. 17).

Typical controller wiring for 4…20 mA heating, cooling,

and model ML6161 floating motor control (see Fig. 18).

Typical controller wiring for a pneumatic transducer, model

RP7517B (see Fig. 19).

25 262728 29 30 31 32 33 34 35 36 37 38 39 40

21 222324

AO-1

COM

DI-1

DI-2

AO-2

AO-3

COM

COM

DI-3

DI-4

20VDC

UI-1

COM

UI-2

UI-3

CLLYVB6438NS

DO-1

DO-2

DO-4

COM

COM

DO-3

11 121314

REHEAT STAGE 2 (OR CLOSE)

REHEAT STAGE 1 (OR OPEN)

DAMPER CLOSE

DAMPER OPEN

DO-5

15 161718 19 20

BAC+

24VAC

EGND

24VAC COM

134

24VAC BACnet MS/TP-

24VAC COM

1

BAC-

20VDC

S-BUS

S-BUS

5 627 8 9 10

BACnet MS/TP+

SHIELD

Fig. 13. Controller wiring diagram (CLLYVB6438NS

shown) for typical VAV application

NOTE 1: Earth ground wire length should be held to a

minimum. Use the heaviest gauge wire available,

up to 14 AWG (2.0 mm

AWG (1.0 mm

2

), for earth ground wire.

2

), with a minimum of 18

C770A AIR

TEMP. SENSOR

COM

UI-4

UI-5

COM

DO-6

DO-8

COM

DO-7

FAN CONTACTOR

REHEAT STAGE 3

CCW

COM

CW

UI-6

COM

SERIES OR

PARALLEL

ML6161

CONTACTORS

REHEAT STAGE

EN0Z-0959GE51 R0615 10

NOTE 2: Contacts must be suitable for dry switching, 5 V at

10 mA. Use sealed type, gold-flashed, or pimpled

contacts.

Page 11

AIR FLOW

PICK-UP

(CONTACTS CLOSED

CLLYVB6436AS

24VAC

20VDC

EGND

S-BUS

24VAC COM

LYNX BACnet PROGRAMMABLE, VAV/UNITARY CONTROLLERS – PRODUCT DATA

WINDOW CONTACTS

= WINDOW CLOSED)

BAC+

S-BUS

OCCUPANCY SENSOR

(CONTACTS CLOSED

= OCCUPIED)

22

21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

AO-1

DI-1

DI-2

AO-2

AO-3

COM

COM

COM

DI-3

DI-4

20VDC

UI-1

COM

DO-1

DO-2

DO-4

COM

BAC-

DO-3

CLCM4T111

7

6

LED

5

BYPASS

4

SET-POINT

3

SENSOR

2

GND

1

C770A AIR

TEMP. SENSOR

UI-2

UI-3

COM

UI-4

UI-5

COM

UI-6

24VAC

EGND

24VAC COM

134

DO-6

DO-8

COM

COM

COM

DO-5

DO-7

21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

AO-1

DI-1

DI-2

AO-2

AO-3

COM

COM

COM

DI-3

DI-4

CLLYUB6438S

DO-1

BAC+

BAC-

20VDC

S-BUS

S-BUS

5 627 8 9 10

DO-2

20VDC

UI-1

COM

DO-4

COM

DO-3

11 121314

UI-2

UI-3

COM

UI-4

DO-6

COM

COM

DO-5

15 161718 19 20

UI-5

COM

UI-6

DO-8

COM

DO-7

5 627 8 9 10

134

24VAC BACnet MS/TP-

24VAC COM

1

BACnet MS/TP+

SHIELD

11 121314

15 161718 19 20

STAGE 3

STAGE 2

STAGE 1

Fig. 14. Controller wiring diagram (CLLYVB6436AS

shown) for typical VAV application with staged reheat

NOTE 1: Earth ground wire length should be held to a

minimum. Use the heaviest gauge wire available,

up to 14 AWG (2.0 mm

AWG (1.0 mm

2

2

), with a minimum of 18

), for earth ground wire.

NOTE 2: Contacts must be suitable for dry switching, 5 V at

10 mA. Use sealed type, gold-flashed, or pimpled

contacts.

24VAC

24VAC COM

1

2134

ON

OFF

ML7984B

CONFIGURATION DIP SWITCHES

(LOCATED ADJACENT TO THE

INPUT TERMINAL BLOCK)

3

2

ML7984B REHEAT

VALVE ACTUATOR

PWM VALVE

ACTUATOR

24 (H)

T6

24 (N)

T5

PWM (H 24 VAC)

C

PWM OUTPUT FROM

B

CONTROLLER

W

R

PERIPHERAL HEAT

VALV E AC TUATO R

PWM VALVE

ACTUATOR

24 (H)

T6

24 (N)

T5

PWM (H 24 VAC)

C

PWM OUTPUT FROM

B

CONTROLLER

W

R

Fig. 15. Controller wiring diagram (CLLYUB6438S shown)

for typical PWM heat and PWM peripheral heat valve

actuator

Ensure that the Configuration DIP Switch is set as shown in

Fig. 15. Switches 1 through 3 set the timing of the ML7984B

valve actuator to match the controller outputs (min. 0.1 sec;

max. 25.6 sec). Switch 4 determines the action of the actuator

(OFF = direct acting, ON = reverse acting).

NOTE 1: Earth ground wire length should be held to a

minimum. Use the heaviest gauge wire available,

up to 14 AWG (2.0 mm

AWG (1.0 mm

2

), for earth ground wire.

2

), with a minimum of 18

3

3

NOTE 2: Turn power OFF before setting the DIP switches.

NOTE 3: Ensure that all transformer / power wiring is as

shown. Reversing terminations will result in

equipment malfunction.

EN0Z-0959GE51 R0615

11

Page 12

LYNX BACNET PROGRAMMABLE, VAV/UNITARY CONTROLLERS – PRODUCT DATA

A

A

UI-5

499

4

UI-6

COM

2

OUTDOOR ENTHALPY

RETURN ENTHALPY

DISCHARGE

IR TEMP.

CLCM4T111

WALL MODULE

SET-POINT

SENSOR

BYPASS

7

6

LED

5

4

3

2

GND

1

2222222222

5678901234567890

1234

DI-1

DI-2

DI-3

AO-1

COM

AO-2

DI-4

COM

COM

AO-3

499

2

333333333

UI-1

UI-2

UI-3

UI-4

COM

COM

20VDC

CLLYUB6438S

FAN

DO-1

DO-2

COM

COM

COM

DO-3

24 VAC

24 VAC COM

E GND

SHLD

SBUS1

SBUS2

12345678 1

24VAC

24VAC COM

1

NET-1

NET-2

BACnet MS/TP-

BACnet MS/TP+

SHIELD

DO-4

11111111121

23456789009

Fig. 16. Controller wiring diagram (CLLYUB6438S shown)

for typical AHU application

NOTE 1: Earth ground wire length should be held to a

minimum. Use the heaviest gauge wire available,

up to 14 AWG (2.0 mm

AWG (1.0 mm

2

2

), with a minimum of 18

), for earth ground wire.

COM

DO-5

DO-6

DO-7

DO-8

HEAT 1

HEAT 2

COMP 1

COMP 2

CLCM4T111

WALL MODULE

BYPASS

SET-POINT

SENSOR

7

6

LED

5

4

3

2

GND

1

WINDOW CONTACTS

(CONTACTS CLOSED

= WINDOW CLOSED)

OCCUPANCY SENSOR

(CONTACTS CLOSED

= OCCUPIED)

2222222222

5678901234567890

1234

DI-1

DI-2

AO-1

COM

DI-3

COM

COM

AO-2

AO-3

499

333333333

UI-1

UI-2

UI-3

DI-4

UI-4

COM

COM

20VDC

OUTDOOR ENTHALPY

2

RETURN ENTHALPY

499

2

4

UI-6

UI-5

COM

CLLYUB6438S

DO-1

DO-2

COM

COM

COM

DO-3

24 VAC

24 VAC COM

E GND

SHLD

SBUS1

SBUS2

12345678 1

24VAC

24VAC COM

1

NET-1

NET-2

BACnet MS/TP-

BACnet MS/TP+

SHIELD

DO-4

11111111121

23456789009

Fig. 17. Controller wiring diagram (CLLYUB6438S shown)

with 4…20 mA enthalpy sensors and digital inputs

NOTE 1: Earth ground wire length should be held to a

minimum. Use the heaviest gauge wire available,

up to 14 AWG (2.0 mm

AWG (1.0 mm

2

), for earth ground wire.

2

), with a minimum of 18

COM

DO-5

DO-6

DO-7

DO-8

DISCHARGE

IR TEMP.

FAN

HEAT 1

HEAT 2

COMP 1

COMP 2

NOTE 2: Analog outputs from sensor are 4…20 mA signals.

A 499 1% tolerance (or better) precision resistor

is required to drive this and other 4…20 mA signal

devices. Place this resistor as close as possible to

the driven device.

EN0Z-0959GE51 R0615 12

NOTE 2: Analog outputs from sensor are 4…20 mA signals.

A 499 1% tolerance (or better) precision resistor

is required to drive this and other 4…20 mA signal

devices. Place this resistor as close as possible to

the driven device.

Page 13

LYNX BACnet PROGRAMMABLE, VAV/UNITARY CONTROLLERS – PRODUCT DATA

A

A

WATER VALVE

SERIES 70

COM

24VAC

2- OR 3-WAY HOTWATER/

INPUT

STEAM VALVE

SERIES 70

VALVE ACT UATO R

COM

24VAC

INPUT

2222222222

1234

AO-1

333333333

5678901234567890

DI-1

UI-1

DI-2

COM

COM

AO-2

AO-3

UI-2

DI-3

DI-4

COM

COM

20VDC

CLC M4T111

7

WALL MODULE

6

LED

5

BYPASS

4

SET-POINT

3

SENSOR

2

GND

1

DISCHARGE

IR TEMP.

4

UI-3

UI-6

UI-4

UI-5

COM

COM

2- OR 3-WAY CHILLER

VALVE ACTUATOR

CLLYUB6438S

FAN

DO-1

DO-2

COM

COM

COM

DO-5

DO-6

DAMPER CLOSE

DAMPER OPEN

COM

DO-7

DO-8

CCW

ML6161

DAMPER

COM

CTUATOR

CW

DO-3

24 VAC

24 VAC COM

E GND

SHLD

SBUS1

SBUS2

12345678 1

24VAC

24VAC

COM

2

NET-1

1

NET-2

BACnet MS/TP-

BACnet MS/TP+

SHIELD

DO-4

11111111121

23456789009

Fig. 18. Controller wiring diagram (CLLYUB6438S shown)

with 4…20 mA heating, cooling, and ML6161 damper

actuator

NOTE 1: Earth ground wire length should be held to a

minimum. Use the heaviest gauge wire available,

up to 14 AWG (2.0 mm

AWG (1.0 mm

2

2

), with a minimum of 18

), for earth ground wire.

2

DI-1

COM

333333333

DI-2

DI-3

DI-4

COM

4

UI-1

UI-2

UI-3

UI-5

UI-6

UI-4

COM

COM

20VDC

COM

2222222222

12345678901234567890

AO-1

COM

AO-2

AO-3

CLLYUB6438S

DO-1

DO-2

COM

COM

COM

DO-3

24 VAC

24 VAC COM

E GND

SHLD

SBUS1

SBUS2

12345678 1

24VAC

24VAC

COM

BROWN

BLACK BLUE

NET-1

NET-2

RP7517B

2B

1M

11111111121

23456789009

1

PNEUMATIC

ACTUATOR

M

DO-4

VALV E

Fig. 19. Controller wiring diagram (CLLYUB6438S shown)

for RP7517B pneumatic transducer

NOTE 1: Use 6 mm tubing. Minimum branch line must be

1.8 m or longer.

NOTE 2: Terminals 21, 23, and 24 are analog outputs.

COM

DO-5

DO-6

DO-7

DO-8

NOTE 2: Ensure that all transformer / power wiring is as

shown. Reversing terminations will result in

equipment malfunction.

EN0Z-0959GE51 R0615

13

Page 14

LYNX BACNET PROGRAMMABLE, VAV/UNITARY CONTROLLERS – PRODUCT DATA

A

CHECKOUT

Step 1. Check Installation and Wiring

Inspect all wiring connections at the controller terminals, and

verify compliance with installation wiring diagrams. If any

wiring changes are required, first be sure to remove power

from the controller before starting work. Pay particular

attention to:

24 Vac power connections. Verify that multiple controllers

being powered by the same transformer are wired with the

transformer secondary connected to the same input

terminal numbers on each controller. Use a meter to

measure 24 Vac at the appropriate terminals (see Fig.

10). Controller configurations are not necessarily limited to

three devices, but the total power draw, including

accessories, cannot exceed 100 VA when powered by the

same transformer (U.S., only).

Ensure that each controller has terminal 3 wired to a

verified earth ground, using a wire run as short as possible

with the heaviest gauge wire available, up to 2.0 mm

a min. of 1.0 mm

2

for each controller in the group (see Fig.

2

with

10).

Check that the MS/TP network polarity has been con-

nected properly on each controller. BACnet MS/TP is

polarity sensitive; communication will be lost for the entire

segment if one controller is connected improperly (see

Fig. 11).

Verify that triac wiring of the digital outputs to external

devices uses the proper load power and 24 Vac common

terminal (digital output common terminals) for high-side

switching.

NOTE: All wiring must comply with applicable electrical

codes and ordinances or as specified on

installation wiring diagrams.

For guidelines for wiring run lengths and power budget, see

section “Power” on page 6.

Verify End-of-Line Termination Resistor Placement

The installation wiring diagrams should indicate the locations

for placement of the end of line termination resistors. See Fig.

11.

Correct placement of the end-of-line termination resistors is

required for proper BACnet MS/TP Bus communications.

Step 2. Startup

See Fig. 20 and the following text for startup information.

BACnet MS/TP MAC

DDRESS DIP SWITCHES

24VAC

EGND

24VAC COM

1 3 4562 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Fig. 20. LED, service, network, and terminal connections

Set the MS/TP MAC Address

The MS/TP MAC address DIP switches are used to set the

unit's MAC address. Each LYNX controller on an MS/TP

network must have a unique MAC address in the range of 0127 (address 0 should be avoided as it is the Honeywell

factory default MAC address for all MS/TP devices).

Controller Status LED

The LED on the front of the controller provides a visual

indication of the status of the device. When the controller

receives power, the LED appears in one of the following

allowable states, as described in Table 6.

LED state blink rate status or condition

OFF not applicable No power to CPU, LED

ON ON steadily, not

very slow

blink (continuous)

slow blink

(continuous)

medium

blink (continuous)

BACNET Status LED

The LED on the front of the controller, between the BACnet

MS/TP terminals and MAC Address DIP Switches, provides a

21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

AO-1

DI-1

DI-2

AO-2

AO-3

COM

COM

CLLYVB6438NS

LOCAL BACnet MS/TP

MOLEX CONNECTOR PINS

BAC+

BAC-

20VDC

S-BUS

S-BUS

(CLLYVB6438NS shown)

Table 6. Status LED states

blinking

1 sec ON, 1 sec

OFF

0.5 sec ON, 0.5

sec OFF

0.3 sec ON, 0.3

sec OFF

COM

DI-3

DI-4

20VDC

UI-1

COM

UI-2

UI-3

COM

UI-4

UI-5

COM

UI-6

HOST

STATUS

LED

DO-1

DO-2

DO-4

DO-6

COM

COM

DO-3

DO-8

COM

DO-5

COM

DO-7

damaged, low voltage to

board, first sec of power-up, or

loader damaged.

CPU not operating. Application

Program CRC being checked.

This takes 1-2 sec and occurs

on each restart (power-up,

reset, and reflash, and

following configuration file

download).

Controller is operating

normally.

Controller alarm is active or

controller in process of configuration file download.

Controller is in reflash mode or

awaiting / receiving reflash

data via BACnet.

EN0Z-0959GE51 R0615 14

Page 15

LYNX BACnet PROGRAMMABLE, VAV/UNITARY CONTROLLERS – PRODUCT DATA

visual indication of the BACnet MS/TP communication status.

When the controller receives power, the LED appears in one

of the following allowable states, as described in Table 7.

Table 7. BACnet status LED states

BACnet LED status status or condition

solid ON Controller has power, loader is not

solid ON, blinking OFF

once in 2.5 sec

solid ON, blinking OFF

twice in 2.5 sec

solid ON, blinking OFF

three times in 2.5 sec

solid OFF, there is no

power

solid OFF, blinking ON

once in 2.5 sec

solid OFF, blinking ON

twice in 2.5 sec

solid OFF, blinking ON

three times in 2.5 sec

running.

Controller is in reflash mode, no

MS/TP communication.

Controller is in reflash mode, MS/TP

communication present.

Controller is in reflash mode, MS/TP

communication data transfer in

progress.

No power to CPU, LED damaged, low

voltage to board, or loader damaged.

Controller is running, no MS/TP communication.

Controller is running, MS/TP communication present.

Controller is running, MS/TP communication data transfer in progress

Step 3. Checkout Completion

At this point the controller is installed and powered. To

complete the checkout, the N

(run on a PC) is used to configure the I/O and functions of the

controller. Refer to the Programming Tool User Guide, form

no. 63-2662, for controller configuration and programming

details.

IAGARA FRAMEWORK® application

CONTROLLER REPLACEMENT

There are no serviceable or repairable parts inside the

controller.

WARNING

Fire, Explosion, or Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Do not attempt to modify the physical or electrical

characteristics of this device in any way. If troubleshooting indicates a malfunction, replace the

controller.

Terminal Block Removal

To simplify controller replacement, all terminal blocks are

designed to be removed with the wiring connections intact

and then re-installed on the new controller. See Fig. 21 and

refer to the following procedure:

IMPORTANT

To prevent bending or breaking the alignment pins on

longer terminal blocks, insert the screwdriver at

several points to evenly and gradually lift up the

terminal block. To prevent damage to the terminal

block alignment pins on the controller circuit board,

insert the screwdriver blade no more than 3 mm.

SHORT TERMINAL

BLOCK

Fig. 21. Removing terminal blocks

1. Use a thin-bladed screwdriver to evenly raise the terminal

block from its alignment pins:

a. For short terminal blocks (1 to 5 terminals), insert

screwdriver blade in the center of the terminal block

and use a back-and-forth twisting motion to gently

raise the terminal block from its alignment pins.

b. For long terminal blocks (6 or more terminals), insert

screwdriver blade on one side of the terminal block

and gently rotate the blade ¼ turn. Then, move to the

other side of the terminal block and do the same.

Repeat until the terminal block is evenly raised from its

alignment pins.

2. Once the terminal block is raised from its alignment pins,

grasp the terminal block at its center (for long terminal

blocks grasp it at each end) and pull it straight up.

LONG TERMINAL

BLOCK

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

To prevent electrical shock or equipment damage,

disconnect power supply before beginning controller

replacement.

EN0Z-0959GE51 R0615

15

Page 16

LYNX BACNET PROGRAMMABLE, VAV/UNITARY CONTROLLERS – PRODUCT DATA

Controller Replacement (AS-models)

For AS-models (which are hard-wired to an actuator), perform

the following actions to replace the complete assembly

(controller and actuator):

1) Remove all power from the controller.

2) Remove the two air flow pickup connections from the

pressure sensor.

3) Remove the terminal blocks (see section “Terminal Block

Removal”).

4) Remove the old controller and actuator assembly from its

mounting.

a) Loosen the two bolts on the actuator clamp to

release the actuator from the shaft.

b) Remove the controller’s mounting screws.

c) Gently pull the controller and actuator assembly

straight out, until the assembly is clear of the

actuator shaft.

5) Mount the new controller and actuator assembly (see

section “Installation” on page 2).

6) Reconnect the two air flow pickup tubes to the pressure

sensor (see section “Piping (AS- and NS-models)” on

page 5).

7) Replace the terminal blocks:

a) Insert each terminal block onto its alignment pins.

b) Press straight down to firmly seat it.

c) Repeat for each terminal block.

8) Restore power to the controller.

9) Perform procedure described in section “Checkout” on

page 14.

Controller Replacement (NS-models)

To replace NS-models, proceed as follows:

1) Remove all power from the controller.

2) Remove the two air flow pickup connections from the

pressure sensor.

3) Remove the terminal blocks (see section “Terminal Block

Removal”).

4) Remove the old controller from its mounting.

IMPORTANT

(IN THE CASE OF CONTROLLERS MOUNTED TO A DIN

RAIL):

1) Push straight up from the bottom to release the top

pins.

2) Rotate the top of the controller outwards to release the

bottom flex connectors (see Fig. 7).

5) Mount the new controller (see section “Installation” on

page 2).

6) Reconnect the two air flow pickup tubes to the pressure

sensor (see section “Piping (AS- and NS-models)” on

page 5).

7) Replace the terminal blocks:

a) Insert each terminal block onto its alignment pins.

b) Press straight down to firmly seat it.

c) Repeat for each terminal block.

8) Restore power to the controller.

9) Perform procedure described in section “Checkout” on

page 14.

Controller Replacement (S-models)

To replace S-models, proceed as follows:

1) Remove all power from the controller.

2) Remove the terminal blocks (see section “Terminal Block

Removal”).

3) Remove the old controller from its mounting.

IMPORTANT

(IN THE CASE OF CONTROLLERS MOUNTED TO A DIN

RAIL):

1) Push straight up from the bottom to release the top

pins.

2) Rotate the top of the controller outwards to release

the bottom flex connectors (see Fig. 7).

4) Mount the new controller (see section “Installation” on

page 2).

5) Replace the terminal blocks:

a) Insert each terminal block onto its alignment pins.

b) Press straight down to firmly seat it.

c) Repeat for each terminal block.

6) Restore power to the controller.

7) Perform procedure described in section “Checkout” on

page 14.

BACnet® is a registered trademark of ASHRAE.

BTL® is a registered trademark of the BACnet International.

IAGARA FRAMEWORK® and the Niagara framework logo are

N

registered trademarks of Tridium, Inc.

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Rolle, Z.A. La Pièce 16, Switzerland by its Authorized Representative:

CentraLine

Honeywell GmbH

Böblinger Strasse 17

71101 Schönaich, Germany

Phone +49 (0) 7031 637 845

Fax +49 (0) 7031 637 740

info@centraline.com

www.centraline.com

Subject to change without notice

EN0Z-0959GE51 R0615

Loading...

Loading...