Page 1

INSTALLATION MANUAL

KN 62/62A/64

DISTANCE MEASURING

MANUAL NUMBER 006-00144-0007

REVISION 7 November, 2004

EQUIPMENT

Page 2

WARNING

Prior to the export of this document, review for export license requirement is needed.

COPYRIGHT NOTIC E

©1979, 2000, 2004 Honeywell International Inc.

REPRODUCTION OF THIS PUBLICATION OR ANY PORTION THEREOF BY ANY MEANS

WITHOUT THE EXPRESS WRITTEN PERMISSION OF HONEYWELL IS PROHIBITED,

EXCEPT TO THE EXTENT REQUIRED FOR INSTALLATION OR MAINTENANCE OF THE

RECIPIENT'S EQUIPMENT. FOR FURTHER INFORMATION CONTACT THE MANAGER,

TECHNICAL PUBLICATIONS, HONEYWELL, ONE TECHNOLOGY CENTER, 23500 WEST

105TH STREET OLATHE KS 66061 TELEPHONE: (913) 782-0400.

Page 3

BENDIX/KING KN 62/62A/64

REVISION HISTORY

KN 62/62A/64 Installation Manual

Part Number: 006-00144-0007

For each revision, Add, delete or replace pages as indicated.

REVISION: 7, November, 2004

ITEM ACTION

All pages Remove and Replace

Rev 7, November/2004 00144I06.TDC Page R-1

Page 4

BENDIX/KING KN 62/62A/64

THIS PAGE RESERVED

Rev 7, November/2004 00144I06.TDC Page R-2

Page 5

BENDIX/KING KN 62/62A/64

SECTION I

GENERAL INFORMATION

1.1 INTRODUCTION..........................................................................................1-1

1.2 EQUIPMENT DESCRIPTION ......................................................................1-1

1.3 TECHNICAL CHARACTERISTIC ................................................................1-1

1.3.1 DME CHANNEL SOURCES ........................................................................1-3

1.3.2 UNIT RESONANT FREQUENCY ................................................................1-5

1.4 UNITS AND ACCESSORIES.......................................................................1-5

1.4.1 KN 62 DME ..................................................................................................1-5

1.4.2 KN62A..........................................................................................................1-5

1.4.3 KN 64 DME ..................................................................................................1-5

1.4.4 KN 62/62A/64 INSTALLATION KIT ..............................................................1-6

1.5 LICENSE REQUIREMENTS........................................................................1-6

SECTION II

INSTALLATION

2.1 GENERAL INFORMATION ..........................................................................2-1

2.1.1 KN 62A.........................................................................................................2-1

2.1.2 KN 62 AND KN 64........................................................................................2-1

2.2 UNPACKING AND INSPECTING EQUIPMENT ..........................................2-1

2.3 EQUIPMENT INSTALLATION......................................................................2-1

2.3.1 AVIONICS COOLING REQUIREMENTS FOR PANEL

MOUNTED EQUIPMENT.............................................................................2-1

2.3.2 KN 62/62A/64 INSTALLATION.....................................................................2-2

2.3.3 MOLEX CONNECTOR ASSEMBLY.............................................................2-3

2.3.4 DME ANTENNA INSTALLATION .................................................................2-3

SECTION III

OPERATION

3.1 GENERAL....................................................................................................3-1

Rev 7, November/2004 00144I06.TDC Page TOC-1

Page 6

BENDIX/KING KN 62/62A/64

LIST OF FIGURES

FIGURE 1-1 KN 62/62A/64 CRITICAL FREQUENCIES....................................1-5

FIGURE 2-1 MOLEX TERMINALS AND TOOLS...............................................2-5

FIGURE 2-2 KN 62/62A/64 PIN FUNCTION .....................................................2-8

FIGURE 2-3 ANTENNA CABLE ASSEMBLY.....................................................2-11

FIGURE 2-4 KN 62/62A/64 INTERCONNECT ..................................................2-13

FIGURE 2-5 KN 62/62A/64 TO NARCO NAV 122 INTERCONNECT ...............2-15

FIGURE 2-6 DUAL SLIP CODE CONTROL UNIT INTERCONNECT ...............2-17

FIGURE 2-7 DUAL BCD CONTROL UNIT INTERCONNECT...........................2-19

FIGURE 2-8 DUAL 2X5 CONTROL UNIT INTERCONNECT............................2-21

FIGURE 2-9 SLIP CODE AND 2X5 CONTROL UNIT INTERCONNECT..........2-23

FIGURE 2-10 SLIP CODE AND BCD CONTROL UNIT INTERCONNECT.........2-25

FIGURE 2-11 2X5 AND BCD CONTROL UNIT INTERCONNECT .....................2-27

FIGURE 2-12 NAV 1 - NAV 2 CHANNELING OF A KN 62/62A/64 FROM

2 KX 155/165’S .............................................................................2-29

FIGURE 2-13 KN 62/62A/64 OUTLINE AND MOUNTING DRAWING................2-31

FIGURE 2-14 KN 62/62A/64 INSTALLATION DRAWING....................................2-33

FIGURE 2-15 KN 62/62A/64 INSTALLATION DRAWING....................................2-35

FIGURE 2-16 KN 60 ANTENNA INSTALLATION DRAWING ..............................2-37

FIGURE 2-17 KN 61 ANTENNA INSTALLATION DRAWING ..............................2-39

FIGURE 2-18 030-00005-0000 CONNECTOR ASSEMBLY................................2-43

FIGURE 3-1 KN 62/62A/64 FREQUENCY MODE.............................................3-2

FIGURE 3-2 KN 62/62A/64 GROUND SPEED/TIME-TO-STATION MODE.......3-2

FIGURE 3-3 KN 62/62A/64 REMOTE MODE....................................................3-3

Rev 7, November/2004 00144I06.TDC Page TOC-2

Page 7

BENDIX/KING KN 62/62A/64

LIST OF TABLES

TABLE 1-1 SHIFTED BCD DME CHANNELING CODES...............................1-3

TABLE 1-2 2X5 DME CHANNELING CODES.................................................1-4

TABLE 1-3 SLIP CODE DME CHANNELING CODES....................................1-4

TABLE 1-4 KN 62/62A/64 INSTALLATION KIT................................................1-6

TABLE 2-1 KN 62/62A/64 PIN FUNCTION LIST.............................................2-9

Rev 7, November/2004 00144I06.TDC Page TOC-3

Page 8

BENDIX/KING KN 62/62A/64

Rev 7, November/2004 00144I06.TDC Page TOC-4

Page 9

BENDIX/KING KN 62/62A/64

SECTION I

GENERAL INFORMATION

1.1 INTRODUCTION

This manual contains information relative to the physical, mechanical, and electrical characteristics and installation procedures for the KN 62/62A/64 DME. The KN 64 has lower output power

than the KN 62/62A. The KN 64 is not TSO’ed.

1.2 EQUIPMENT DESCRIPTION

The KN 62/62A/64 is a panel mounted, 200 channel DME employing th e latest state of the art so lid-state transmitter and large scale integrated circuit (LSI) technology. All tuning is done electronically using a single crystal, digital, frequency synthesizer. The unit has a gas discharge display

that simultaneously indicates range, speed, and time-to-station or range and frequency. An automatic dimming circuit adjusts the brightness of the display to compensate for changes in ambient

light level.

,

Range, speed, and time-to-station are measured digitally, using two LSI

are employed in the digital frequency synthesizer and display circuitry.

The KN 62/62A/64 can be channeled internally using its own frequency selection knobs or externally from any of the common NAV receiver codes.

s. Two other LSI circuits

The KN 62/62A/64 is an extremely compact DME requiring only 1. 3 inches of panel height. It can

be operated with any DC input from 11 to 33 volts. Power consumption is only 15 watts at any

input voltage; thus, forced air cooling is

not required.

1.3 TECHNICAL CHARACTERISTICS

SPECIFICATION CHARACTERISTIC

TSO COMPLIANCE (KN 62A only): F.A.A. TSO C66a

KA 60 Antenna: FAA TSO C66a and TSO C74c

KA 61 Antenna: FAA TSO C66c, C74c, C112, C118, C147

RTCA DO-160 Environmental

Categories

KN 62A: /A1B1/A/PKS/XXXXXXZBBBA

KA 60: /D2/A/JY/XXXXXXXXXXX

RTCA DO-160D Environmental

Categories

KA 61: [D2X]ACB[SCMYL,RG]XRFXX-

SXXXXXXX[XXXX][2A]AX

CHANNELS: 200 channels

ELECTRICAL: A. All solid state transmitter

Rev 7, November/2004 00144I06.TDC Page 1-1

B. Electronically tuned by single crystal, digital,

frequency synthesizer

C. Range, speed, and time-to-station measured

digitally, using large scale integrated circuits

Page 10

BENDIX/KING KN 62/62A/64

SPECIFICATION CHARACTERISTIC

D. Gas discharge display

OUTPUT POWER: 50 watts peak, pulsed power minimum (35 watts,

KN 64)

100 watts nominal (50 watts, KN 64)

MAXIMUM DISPLAY RANGE:* 389 nautical miles

PANEL HEIGHT: 1.3 inches (3.30 cm) maximum

ACQUISITION SENSITIVITY: -82dBm minimum, -87dBm nominal

(-78dBm minimum, -87dBm nominal, KN 64)

NOTE

*THE MAXIMUM RANGE AT WHICH THE DME

WILL LOCK UP IS DETERMINED BY ALTITUDE

AND GROUND STATION OUTPUT POWER AND

SENSITIVITY.

SPECIFICATION CHARACTERISTIC

RANGE ACCURACY:*

GROUND SPEED ACCURACY:

TIME-TO-STATION ACCURACY:

SEARCH TIME: 1.0 second nominal

MEMORY TIME: 11 to 15 seconds

AUDIO OUTPUT (IDENT): Level adjustable up to 15mW INTO 600 OHM

MAXIMUM ALTITUDE: 50,000 feet

KN 62/62A/64 OVERALL DIMENSIONS (in-

cluding mounting rack and connectors)

.1 NAUTICAL MILES OR ± .14%, WHICH-

±

EVER IS GREATER, FROM 0 TO 99.9 NAUTICAL MILES

1 NAUTICAL MILE FROM 100 TO 389

±

NAUTICAL MILES

1 KNOT OR ± 1%, WHICHEVER IS

±

GREATER FROM 0 TO 999 KNOTS

1 MINUTE FROM 0 TO 99 MINUTES

±

LOAD, nominally set for 2mW

LENGTH 12.258 INCHES (31.135 cm)

WIDTH: 6.312 inches (16.032 cm)

HEIGHT: 1.300 inches ( 3.302 cm)

WEIGHT: 2.6 LBS (1.18 KG) nominal

Rev 7, November/2004 00144I06.TDC Page 1-2

Page 11

BENDIX/KING KN 62/62A/64

POWER REQUIREMENTS: 11-33VDC at 15 watts

066-1068-04 AND 066-1088-01 ONLY

BACKLIGHTING: NOMINAL 14VDC AT 2 WATTS

NOMINAL 28VDC AT 2 WATTS

CHANNELING SOURCES: a. Internal

b. External control head providing shifted

BCD code such as KFS 560B.

c. External control head providing ARINC 2 x

5 code such as KX 170 and KFS 560B.

d. External control head providing slip code

such as KX 170A, KX 170B, KX 175A, and KX

175B.

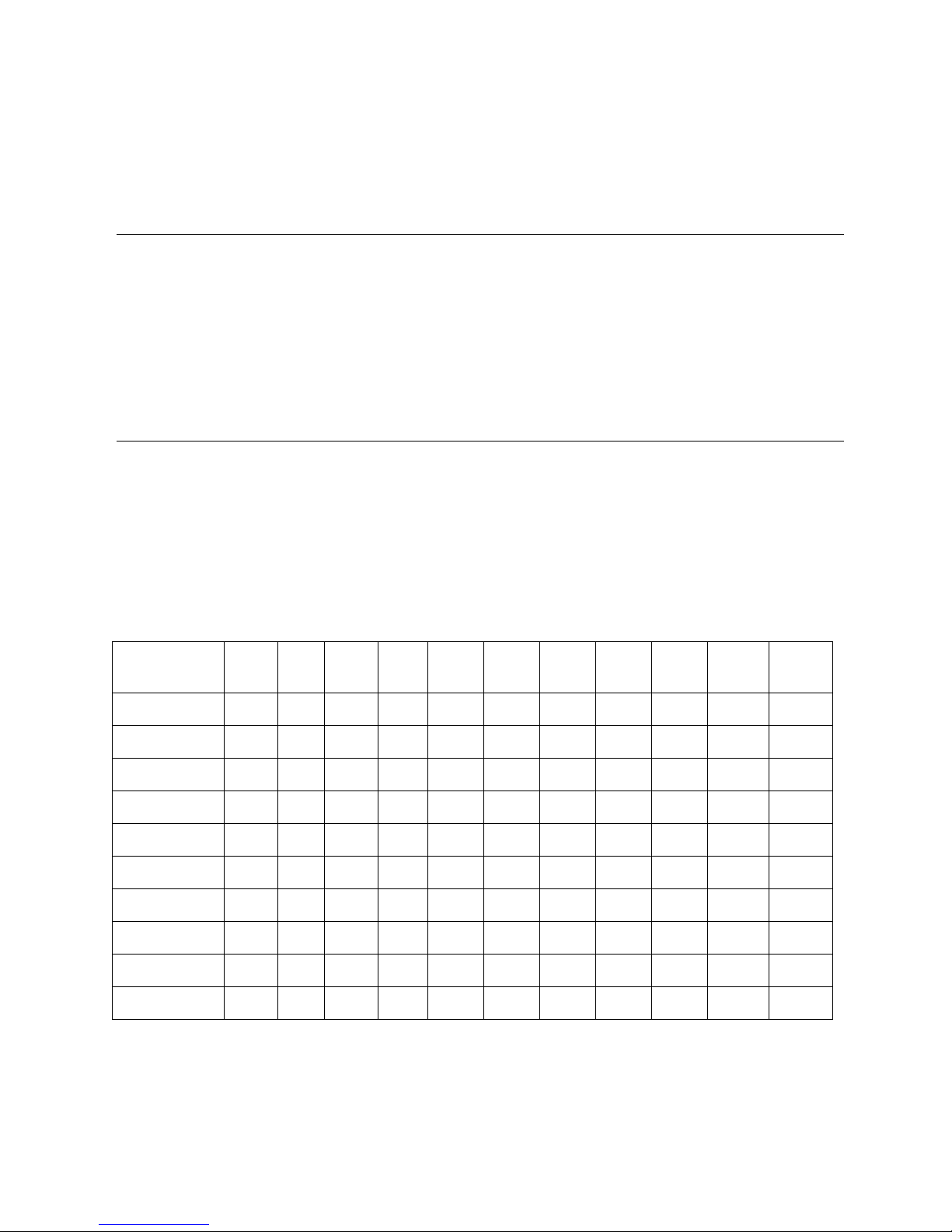

1.3.1 DME CHANNEL SOURCES

The KN 62/62A/64 can be channeled by the internal channeling tunning knobs or it may be chan-

neled by an external source. The KN 62/62A/64 will accept external channeling in the form of

Shifted BCD, ARINC 2X5, or Bendix/King Slip code. The tunning logic for each of the three types

of channeling is given in tables 1-1, 1-2, and 1-3.

TABLE 1-1 SHIFTED BCD DME CHANNELING CODES

Frequency

Mhz

108 0000.0X0000.X01

109 0001.1X0001.X50

110 0010.2X0010

111 0011.3X0011

112 0100.4X0100

113 0101.5X0101

114 0110.6X0110

115 0111.7X0111

M8 M4 M2 M1 .X

Mhz

K800K400K200K100.XX

Mhz

K50

116 1000.8X1000

117 1001.9X1001

0 = Connected to Remote Control Common

1 = Open

Rev 7, November/2004 00144I06.TDC Page 1-3

Page 12

BENDIX/KING KN 62/62A/64

TABLE 1-2 2 x 5 DME CHANNELING CODES

Frequency Mhz

MA ME MC MD X

Mhz

KA KE KC KD .XX

Mhz

K5

0

108 0110.0X1011.X01

109 0011.1X0111.X50

110 1011.2X0101

111 0111.3X1101

112 0101.4X1110

113 1101.5X1100

114 1110.6X1001

115 1100.7X1010

116 1001.8X0110

117 1010.9X0011

0 = Connected to Remote Control Common

1 = Open

TABLE 1-3 SLIP CODE DME CHANNELING CODES

Frequency Mhz

108 1101.0X0011.X01

109 1110.1X0001.X50

110 0111.2X0000

111 0011.3X1000

112 0001.4X1100

113 1000.5X0110

114 0100.6X1011

115 1010.7X1101

116 0101.8X1110

117 0010.9X0111

0 = Connected to Remote Control Common

1 = Open

M0 M1 M2 M3 .X

Mhz

K0 K1 K2 K3 .XX

Mhz

K50

Rev 7, November/2004 00144I06.TDC Page 1-4

Page 13

BENDIX/KING KN 62/62A/64

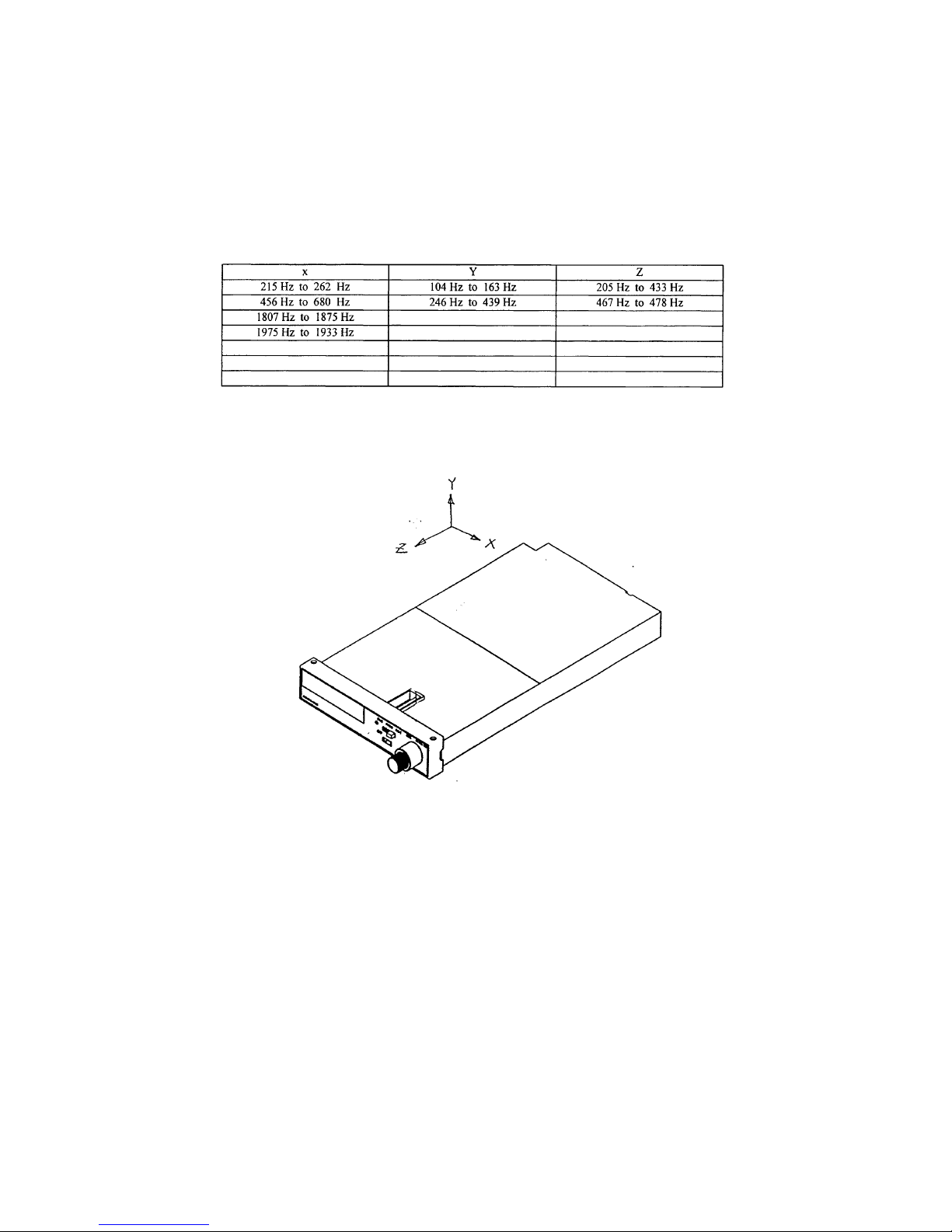

1.3.2 UNIT RESONANT FREQUENCIES

The following critical frequencies are mechanical resonance of the unit under test that have peak

acceleration amplitude greater than twice the input acceleration amplitude. There were no observed changes in performance of the unit under test.

Figure 1-1 KN 62/62A/64 CRITICAL FREQUENCIES

1.4 UNITS AND ACCESSORIES

1.4.1 KN 62 DME

The KN 62 is available in only one version under P/N 066-1064-00.

1.4.2 KN 62A DME

The KN 62A is available in two versions, P/N 066-1068-01 and P/N 066-1068-04.

1.4.3 KN 64 DME

The KN 64 is available in two versions, P/N 066-1088-00 and 066-1088-01.

Rev 7, November/2004 00144I06.TDC Page 1-5

Page 14

BENDIX/KING KN 62/62A/64

1.4.4 KN 62/62A/64 INSTALLATION KIT

The KN 62/62A/64 installation kit, P/N 050-01611-XXXX is available in two versions. The -0000

and the -0001. The contents of the kit are listed below:

TABLE 1-4 KN 62/62A/64 INSTALLATION KIT

PART NUMBER

050-01611-xxxx

030-00005-0000 CONNECTOR, BNC UG 88C/U 1 0

030-00101-0002 PANEL MOUNT PLUG 1 1

030-01094-0053 CONNECTOR 1 1

030-01107-0022 CONNECTOR TERM 22T 1 1

089-02051-0024 NUT SPEED U 6-32 4 4

089-02353-0001 NUT CLIP 6-32 4 4

089-05903-0007 SCREW, PHP 4-40X7/16 2 2

089-06012-0008 Screw, FHP 6-32X1/2 4 4

089-08003-0034 WASHER, SPLIT LOCK #4 2 2

089-08168-0002 WASHER WAVE 1 1

089-08252-0030 WASHER 2 2

090-00019-0007 RING RETAINER .438 1 1

DESCRIPTION -0000

Rev. AA

-0001

Rev. AC

1.5 LICENSE REQUIREMENTS

NONE

Rev 7, November/2004 00144I06.TDC Page 1-6

Page 15

BENDIX/KING KN 62/62A/64

SECTION II

INSTALLATION

2.1 GENERAL INFORMATION

This section contains information relative to the installation and wiring of the KN 62/62A/64 DME.

A close adherence to methods and procedures discussed herein is required.

2.1.1 KN 62A ONLY

The conditions and tests required for TSO approval of this article are minimum performance stan-

dards. It is the responsibility of those desiring to install this article either on or within a specific

type or class of aircraft to determine that the aircraft installation conditions are within TSO standards. The article may be installed only if further evaluation by the applicant documents an acceptable installation and is approved by the Administrator.

2.1.2 KN 62 AND KN 64

The conditions and tests performed on this article are minimum performance standards. It is the

responsibility of those desiring to install this article either on or within a specifice type or class of

aircraft to determine that the aircraft installation conditions are within these perfomrance standards. The article may be installed only if further evaluation by the applicant documents an acceptable installation and is approved by the Administrator.

2.2 UNPACKING AND INSPECTING EQUIPMENT

Exercise extreme care when unpacking the equipment. Make a visual inspection of the unit for

evidence of damage incurred during shipment. If a claim for damage is to be made, save the shipping container to substantiate the claim. The claim should be promptly filed with the transpo rtation

company. It would be advisable to retain the container and packaging material after all equipment

has been removed in the event that equipment storage or reshipment should become necessary.

2.3 EQUIPMENT INSTALLATION

2.3.1 AVIONICS COOLING REQUIREMENTS FOR PANEL MOUNTED EQUIPMENT

The greatest single contributor to increased reliability of all modern day avionics is to limit the max-

imum operating temperature of the individual units. While modern day individual circuit designs

consume much less electrical energy, the watts per cubic inch dissipated within avionics units remains much the same due to high density packaging techniques utilized. Consequently, the importance of providing avionics stack cooling is still with us.

Rev 7, November/2004 00144I06.TDC Page 2-1

Page 16

BENDIX/KING KN 62/62A/64

While each individual unit may not require forced air cooling, the combined heat load of several

units operating in a typical avionics stack will significantly degrade the reliability of the avionics if

provisions for stack cooling are not incorporated in the initial installation. Recommendations on

stack cooling are contained in Bendix/King Installation Bulletin #55 and #143 revised. Failure to

provide stack cooling will certainly lead to increased avionics maintenance costs and may void the

Honeywell warranty.

2.3.2 KN 62/62A/64 INSTALLATION (FIGURES 2-1 THROUGH 2-18)

A. Plan a location on the aircraft panel that is clearly visible and within easy access of the pilot.

B. Avoid mounting the KN 62/62A/64 close to heater vents or other high heat sources.

C. Compass safe distance is 8 inches for worst case deflection of one degree.

D. Install the mounting rack in the aircraft using 6-32 x 1/2 flat head phillips screws (P/N 089-

06012-0008) and 6-32 clip nuts (P/N 089-02353-0001). The screws are inserted from the

inside through the holes in the sides of the mounting rack.

E. Connect the harness wires to the connector pins and insert the connector pins into the rear

of the Molex connector. See Section 2.3.3 and Figures 2-1 and 2-2.

F. Mount the Molex connector on the two hex spacers at the rear of the mounting rack. Use

two 4-40 x 7/16 pan head, phillips screws (P/N 089-05903-0007) and two #4 split lock washers (P/N 089-08003-0034). Orient the connector so the polarizer key is closer to the side

next to the antenna connector.

G. Connect the antenna cable to the antenna connector (Figure 2-3).

H. Install the antenna connector in the mounting rack from the outside as shown in Figures 2-

14, 2-15. Secure connector in place with three washers and a retaining ring as shown in the

figure.

I. Install the KN 62/62A/64 into the mounting rack and secure by turning the hold down adjust-

ment screw (accessible through a hole in the front panel) clockwise with an allen hex

wrench until it is locked in place (Figure 2-13).

J. The audio output of the KN 62/62A/64 is set for approximately 2mW into 600 ohms at the

factory. If a different level is desired, readjust the audio level adjustment, accessible through

the top cover (Figure 2-13).

K. For 066-1068-04 and 066-1088-01 units with backlit Nomenclature refer to interconnect

drawings for interconnect to lighting buss.

L. When operating dual KN 62/62A/64’s, the respective DME’s will interfere with each other

when the NAV frequencies differ by 5.3 MHz (for example, 108.00 MHz and 113.3 MHz).

This interference results in premature flags or loss of ”lock-on”. Should this occur, one of

the KN 62/62A/64’ s shou ld be eithe r turned off or tuned to a different NAV frequency so that

the 5.3 MHz difference is eliminated.

Rev 7, November/2004 00144I06.TDC Page 2-2

Page 17

BENDIX/KING KN 62/62A/64

2.3.3 MOLEX CONNECTOR ASSEMBLY (FIGURE 2-1)

A. Solderless Contact Terminal Assembly using Molex Crimper

Refer to instructions in Section 2.3.3.

B. Solderless Contact Terminal Assembly using Pliers

1. Strip each wire 5/32” f or contact terminal (P/N 030-01107-0030). (The last two digits of

the contact terminal part number indicate the number of terminals furnished).

2. Tin the exposed conductor.

3. Using needle nose pliers, fold over each conductor tab in turn, onto the exposed conductor. When both tabs have been folded, firmly press the tabs against the conductor.

4. Repeat step 3 for insulator tabs.

5. Apply a small amount of solder (using minimum heat) to the conductor/tab connection

to assure a good electromechanical joint.

C. Contact Insertion into Molex Connector Housing

1. After the contact terminals have been installed on the wiring harness, the contact terminals can be inserted into the proper location in the connector housing (P/N 03001094-0053). The terminal cannot be inserted upside down. Be sure to push the terminal all the way in, until a click can be felt or heard.

2. The self-locking feature can be tested by gently pulling on the wire.

D. Extraction of Contact from Molex Connector

1. Slip the flat narrow blade of a Molex contact ejector tool, HT-1884 (P/N 047-05009-

0001) under the contact on the mating side of the connector. By turning the connector

upside down one can see the blade slide into the stop.

2. When the ejector is slid into place , the loc k ing k ey of the contact is raised, allowing the

contact to be removed by pulling moderately on the lead.

3. Neither the contact nor position is damaged by removing a contact; however, the contact should be checked visually before reinstalling in connector, to be certain that

retaining tab ”A” extends as shown (see Figure 2-1) for retention in connector.

2.3.4 DME ANTENNA INSTALLATION

2.3.4.1 General

a. The antenna should be well removed from any projections, the engine(s), and propeller(s).

It should also be well removed from landing gear doors, access doors, or other openings

which will break the ground plane for the antenna.

b. The antenna should be mounted on a bottom surface of the aircraft and in a v ertical position

when the aircraft is in level flight.

c. Avoid running other cables or wires near the antenna cable.

d. Avoid mounting the antenna within three (3) feet of the ADF sense antenna or any COMM

Rev 7, November/2004 00144I06.TDC Page 2-3

Page 18

BENDIX/KING KN 62/62A/64

antenna and six (6) feet from a transponder antenna.

e. Where practical, plan the antenna location to keep cable lengths as short as possible, and

avoid sharp bends in the cable to minimize the VSWR.

f. To prevent RF interference, the antenna must be physically mounted a minimum distance of

three feet from the KN 62/62A/64.

g. A back-up plate should be used for added strength on thin-skinned aircraft.

h. The antenna should be kept clean. If left dirty (oil covered) the range of the DME may be

affected.

i. On pressurized aircraft, the antenna should be sealed using RTV (P/N 016-01082-0000)

around the connector and mounting hardware.

j. All antennas should be sealed around the outside for moisture protection.

2.3.4.2 KA 60/61 Installation (Refer to Figure 2-16 and 2-17)

a. Peel the backing off the antenna template and apply template to the aircraft at the desired

mounting location.

b. Drill or cut the proper size holes for mounting the antenna, then remove the template.

c. Using the antenna as a stencil, draw a line around the base of the antenna that will come

into contact with the aircraft. Then carefully scrape off the paint within the stenciled area.

Lightly sand the bare metal with fine sandpaper to insure removal of all paint and protective

coatings.

d. Sand the inside area of the aircraft where the backing plate will be located to remove the

chromate or other protective finish.

e. Apply Alumiprep No. 33 (P/N 016-01127-0000) following the directions on the container to

cleanse the metal of any residue.

f. Apply Alodine No. 1001 (P/N 016-01128-0000) following the directions on the container.

g. Rivet the backing plate (P/N 047-04570-0000) into place, if required.

h. Mount the antenna using #8 star washers (P/N 089-08017-0037) and 8-32 nuts (P/N 089-

02148-0032) included with the antenna.

i. RGU 400 or equivalent coaxial cable is normally used on installations having a cable run of

ten feet or less. For cable runs from ten to twenty feet, use RG 142B/U cable (P/N 024-

00002-0000).

j. Inspect coaxial cable connector for proper center contact, then fasten it securely to the

antenna.

Rev 7, November/2004 00144I06.TDC Page 2-4

Page 19

BENDIX/KING KN 62/62A/64

FIGURE 2-1 MOLEX TERMINALS AND TOOLS

Rev 7, November/2004 00144I06.TDC Page 2-5

(Sheet 1 of 3)

Page 20

BENDIX/KING KN 62/62A/64

FIGURE 2-1 MOLEX TERMINALS AND TOOLS

Rev 7, November/2004 00144I06.TDC Page 2-6

(Sheet 2 of 3)

Page 21

BENDIX/KING KN 62/62A/64

FIGURE 2-1 MOLEX TERMINALS AND TOOLS

Rev 7, November/2004 00144I06.TDC Page 2-7

(Sheet 3 of 3)

Page 22

BENDIX/KING KN 62/62A/64

FIGURE 2-2 KN 62/62A/64 PIN FUNCTION

Rev 7, November/2004 00144I06.TDC Page 2-8

Page 23

BENDIX/KING KN 62/62A/64

TABLE 2-1 KN 62/62A/64 PIN FUNCTION LIST

A --------------------- ! AUDIO LOW

B --------------------- ! AUDIO HI

C --------------------- DME COMMON

D --------------------- ! SLIP CODE SELECT

E --------------------- +14vdc LIGHT DIMMER

F --------------------- +28vdc LIGHT DIMMER SELECT

H <-- --------------------- K400/KE/K1 DME CHANNEL LINE

J --------------------- ! 2X5 CODE SELECT

K --------------------- ! 10 BIT FREQUENCY

L <-- --------------------- ! RNAV/CHAN REQ

M --------------------- BCD CODE SELECT

N <-- --------------------- DME REQUEST

P --------------------- RESERVED

R <-- --------------------- ALTITUDE REQUEST

S --------------------- GROUND

1 --------------------- A/C GROUND

2 --------------------- A/C POWER

3 --------------------- A/C POWER

4 <-- --------------------- K200/KC/K2 CHANNEL LINE

5 <-- --------------------- K50/K50/K50 CHANNEL LINE

6 <-- --------------------- K100/KD/K3 CHANNEL LINE

7 <-- --------------------- K800/KA/K0 CHANNEL LINE

8 <-- --------------------- M1/MD/D3 CHANNEL LINE

9 <-- --------------------- M2/MC/M2 CHANNEL LINE

10 --------------------- NO CONNECTION

11 <-- --------------------- M4/ME/M1 CHANNEL LINE

12 <-- --------------------- M8/MA/M0 CHANNEL LINE

13 <-- --------------------- DATA BUS

14 <-- --------------------- CLOCK BUS

15 --------------------- A/C GROUND

IN OUT

Rev 7, November/2004 00144I06.TDC Page 2-9

Page 24

BENDIX/KING KN 62/62A/64

Rev 7, November/2004 00144I06.TDC Page 2-10

Page 25

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-11

FIGURE 2-3 ANTENNA CABLE ASSEMBLY

(P/N 030-00101-0002, R-9)

Page 26

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-12

Page 27

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-13

FIGURE 2-4 KN 62/62A/64 INTERCONNECT

(Dwg. No. 155-01296-0000, R-8)

Page 28

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-14

Page 29

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-15

FIGURE 2-5 KN 62A/64 TO NARCO NAV 122 INTERCONNECT

(Dwg. No. 155-01339-0000, R-5)

Page 30

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-16

Page 31

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-17

FIGURE 2-6 DUAL SLIP CODE CONTROL UNIT INTERCONNECT

(Dwg. No. 155-01334-0000, R-5)

Page 32

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-18

Page 33

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-19

FIGURE 2-7 DUAL BCD CONTROL UNIT INTERCONNECT

(Dwg. No. 155-01335-0000, R-5)

Page 34

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-20

Page 35

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-21

FIGURE 2-8 DUAL 2 x 5 CONTROL UNIT INTERCONNECT

(Dwg. No. 155-01336-0000, R-5)

Page 36

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-22

Page 37

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-23

FIGURE 2-9 SLIP CODE AND 2 x 5 CONTROL UNIT INTERCONNECT

(Dwg. No. 155-01333-0000, R-5)

Page 38

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-24

Page 39

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-25

FIGURE 2-10 SLIP CODE AND BCD CONTROL UNIT INTERCONNECT

(Dwg. No. 155-01337-0000, R-5)

Page 40

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-26

Page 41

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-27

FIGURE 2-11 2 x 5 AND BCD CONTROL UNIT INTERCONNECT

(Dwg. No. 155-01338-0000, R-5)

Page 42

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-28

Page 43

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-29

FIGURE 2-12 NAV 1 - NAV 2 CHANNELING OF A KN 62/62A/64 FROM TWO KX 155/165’S

(Dwg. No. 696-3423-00, R-0)

Page 44

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-30

Page 45

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-31

FIGURE 2-13 KN 62/62A/64 OUTLINE AND MOUNTING DRAWING

(Dwg. No. 155-05280-0000, R-AA)

Page 46

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-32

Page 47

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-33

FIGURE 2-14 KN 62/62A/64 INSTALLATION DRAWING

(Dwg. No. 155-05281-0000, R-4)

Page 48

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-34

Page 49

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-35

FIGURE 2-15 KN 62/62A/64 INSTALLATION DRAWING

(Dwg. No. 155-05281-0001, R-1)

Page 50

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-36

Page 51

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-37

FIGURE 2-16 KA 60 ANTENNA INSTALLATION DRAWING

(Dwg. No. 155-05289-0000, R-AB)

Page 52

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-38

Page 53

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-39

Figure 2-17 KA 61 Installation Drawing

(Page 1 of 2)

Page 54

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-40

Page 55

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-41

Figure 2-17 KA 61 Installation Drawing

(Page 2 of 2)

Page 56

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-42

Page 57

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-43

FIGURE 2-18 030-00005-0000 CONNECTOR ASSEMBLY

(Dwg. No. 155-05267-0000, R-0)

Page 58

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 2-44

Page 59

BENDIX/KING KN 62/62A/64

SECTION III

OPERATION

3.1 GENERAL

It is recommended that power to the KN 62/62A/64 be turned on only after engine start-up, as this

procedure increases the reliability of the solid state circuitry.

The KN 62/62A/64 front panel controls consist of an ON-OFF switch, a function switch, and frequency selection knobs (Figure 3-1). The function switch determines both the information displayed and the channeling source for the KN 62/62A/64. In Remote (RMT) mode, the KN 62/62A/

64 is channeled from an external control head, and the display shows range, speed, and t ime -tostation. In Frequency (FREQ) mode, the KN 62/62A/64 is channeled from its own frequency selection knobs, and the display shows range and frequency. In Ground Speed/Time-to-Station

(GS/T) mode, the KN 62/62A/64 holds the last internally selected frequency and displays range,

speed, and time-to-station.

The frequency hold feature in GS/T mode is necessary to prevent accidental rechanneling of the

DME when frequency is not being displayed. To prevent the unit from displaying false information,

the KN 62/62A/64 will display dashes and stay in ”search” whenever power is turned on or momentarily interrupted in GS/T mode. Normal operation is re-established by switching to FREQ or

RMT mode.

When the KN 62/62A/64 is locked to a ground station, range is displayed to the nearest 0.1 nautical mile from 0 to 99.9 nautical miles and to the nearest 1 nautical mile from 100 to 389 nautical

miles. Ground speed is displayed to the nearest knot from 0 to 999 knots. Time-to-station is displayed to the nearest minute from 0 to 99 minutes. The display also indicates 99 minutes for any

computed time- to-station greater than 99 minutes. When the KN 62/62A/64 is in search mode,

dashes are displayed instead of range, speed, and time-to-station. An automatic dimmin g circuit

adjusts the brightness of the display to compensate for changes in ambient light level. The dimming is controlled by a photocell mounted behind the front panel to the left of the display. Backlighting of nomenclature on 066-1068-04 and 066-1088-01 is connected and controlled directly by

aircraft dimming bus.

The audio output of the KN 62/62A/64 can be set as high as 15 milliwatts into 600 ohms using the

audio level adjustment accessible through the top cover. It is set for approximately 2mW output

at the factory. It is desirable to use the audio to identify the DME ground stations being received.

The effective range of the KN 62/62A/64 DME depends on many factors; most important being the

altitude of the aircraft. When the aircraft is on the ground, the KN 62/62A/64 usually will not re-

ceive DME stations due to line-of-sight signal limitations. Other contributing factors to the DME,s

effective range are the location and altitude of the ground transmitter, transmitter power output,

and the degree of maintenance of the ground facility. The distance measured by the KN 62/62A/

64 is slant-range distance (measured on a slant from aircraft to ground station) and should not be

confused with actual ground distance. The difference between ground distance and slant-range

distance is smallest at low altitude and long range. These distances may differ considerably when

in close proximity to a VOR/DME facility. However, if the range is three times the altitude or gre ater, this error is negligible. In order to obtain accurate ground speed and time-t o-station, the aircraft

must be tracking directly to or from the station.

Rev 6, May/2004 00144I06.TDC Page 3-1

Page 60

BENDIX/KING KN 62/62A/64

When operating dual KN 62/62A/64’s, the respective DME’s will interfere with each other when

the NAV frequencies differ by 5.3MHz (for example, 108.00MHz and 113.3MHz). This interference results in premature flags or loss of ”Lock-On”. Should this occur, one of the KN 62/62A/64’s

should be either turned off or tuned to a different NAV frequen cy so that the 5.3MHz difference is

eliminated.

FIGURE 3-1 KN 62/62A/64 frequency mode

FIGURE 3-2 KN 62/62A/64 ground speed/time-to-station mode

Rev 6, May/2004 00144I06.TDC Page 3-2

Page 61

BENDIX/KING KN 62/62A/64

FIGURE 3-3 KN 62/62A/64 remote mode

Rev 6, May/2004 00144I06.TDC Page 3-3

Page 62

BENDIX/KING KN 62/62A/64

Rev 6, May/2004 00144I06.TDC Page 3-4

Loading...

Loading...