Page 1

AGA

Burner control unit BCU 370

Technical Information · GB

6 Edition 01.19

• For modulating, forced draught burners for gas of unlimited

capacity in intermittent or continuous operation

• Control of fan and butterfly valve

• Simple system set-up thanks to optional tightness control and

integrated ignition unit

• Easy start-up and maintenance thanks to Manual operating mode

• Optionally available with integrated fieldbus interface for simple

wiring

Page 2

Contents

Burner control unit BCU 370 ........................1

Contents ............................................2

1 Application ........................................4

1.1 Applications example ..............................6

1.1.1 Modulating-controlled forced draught burner........6

1.1.2 Modulating-controlled forced draught burner with

tightness control ............................................6

1.1.3 Modulating-controlled forced draught burner with

pilot burner and tightness control ..........................7

1.1.4 Controlling the BCU via

PROFIBUS DP ...............................................8

1.1.5 Controlling the BCU and the butterfly valve via

PROFIBUS DP ...............................................8

2 Certification .......................................9

3 Function ......................................... 10

3.1 Connection diagrams .............................10

3.1.1 BCU 370 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1.2 BCU 370 with actuator IC 20........................ 14

3.1.3 Capacit y control by adjusting the valve between

the Open position and a separate Min position........... 15

3.1.4 BCU 370..B1 with PROFIBUS DP ...................16

3.1.5 Assignment of connection terminals ................17

3.2 BCU 370 program sequence .....................19

3.2.1 Normal start-up ..................................... 19

3.2.2 Quick start, butterfly valve waits in the Ignition

position.....................................................21

3.2.3 Quick start, butterfly valve waits in the Closed

position....................................................23

3.2.4 Start-up without pre-purge, butterfly valve waits

in the Closed position ..................................... 25

3.2.5 Controlled air flow ....................................27

3.3 Tightness control .................................28

3.3.1 Program sequence ..................................30

3.4 PROFIBUS DP ....................................32

3.4.1 Safety-related control signals.......................32

3.4.2 BCSoft ...............................................33

3.4.3 Configuration, master-slave procedure .............33

3.4.4 Addressing...........................................33

3.4.5 Network technology .................................34

3.4.6 Configuration........................................34

3.4.7 Bus communication .................................34

3.5 Program status ...................................36

3.6 Fault message (blinking)..........................37

3.6.1 Reaction to process faults ..........................38

4 Parameters ...................................... 40

4.1 Scanning the parameters .........................42

4.2 Flame control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.2.1 Burner flame signal.................................. 42

4.2.2 Burner switch-off threshold......................... 42

4.2.3 UVS check (1× in 24 hours) ..........................43

4.3 Behaviour during star t-up ....................... 44

4.3.1 Minimum burner pause time tBP ....................44

4.3.2 Burner start-up attempts ...........................44

4.3.3 Switch-on delay time t

4.3.4 Pre-ignition time t

st

4.3.5 1

t

SA1

4.3.6 1

4.3.7 2

4.3.8 2

safety time on start-up, burner/pilot burner

........................................................46

st

flame proving period, burner/pilot burner t

nd

safety time on start-up, main burner t

nd

flame proving period, main burner t

.............................45

E

................................45

VZ

FS1

.......47

SA2

.........47

FS2

..46

4.4 Behaviour during operation...................... 48

4.4.1 Minimum operating time tB .........................48

4.4.2 Controller enable signal delay time t

4.4.3 Safety time during operation t

SB

.............48

RF

...................48

4.4.4 Restart after flame failure during operation ........49

4.4.5 Last fault signal .....................................49

4.4.6 V2 during burner operation .........................50

4.5 Monitoring/tightness control ....................51

4.5.1 Min. gas pressure monitoring ........................51

4.5.2 Digital input function.................................51

4.5.3 Air monitoring during pre-purge .................... 52

4.5.4 Air monitoring during operation.....................53

4.5.5 Tightness controll, test period t

...................54

P

BCU 370 · Edition 01.19 2

= To be continued

▼

Page 3

4.6 Air control .........................................56

4.6.1 Valve control .........................................56

4.6.2 Pre-purge............................................56

4.6.3 Quick start starts in... .................................57

4.6.4 Pre-purge time t

4.6.5 Post-purge time t

4.6.6 Fan run-up time t

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

PV

.................................59

PN

.................................60

GV

4.7 Control using PROFIBUS DP .....................61

4.7.1 Bus control activation ................................61

4.7.2 Bus control limitation.................................61

4.8 Manual mode .....................................63

4.8.1 Operating time in Manual mode ....................63

4.9 Fault messages ...................................64

4.9.1 The last 10 fault messages..........................64

4.10 Password ........................................64

4.10.1 User-defined password . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5 Selection ........................................ 65

5.1 Type code .........................................65

6 Project planning information .................... 66

6.1 Cable selection .................................. 66

6.1.1 Ionization cable......................................66

6.1.2 UV cable .............................................66

6.1.3 Ignition cable ........................................66

6.2 Fan control........................................67

6.3 Controlling the butterfly valve ....................67

6.4 Safety interlock (limits) ...........................67

6.5 Too many remote resets ..........................67

6.6 Protecting the ignition unit from overload ...... 68

6.7 Wiring ............................................ 68

6.7.1 Single-electrode operation with external ignition

unit.........................................................68

6.8 BCU switched off ................................ 68

6.9 Note on EC type-examination or CSA and FM

approval ...............................................69

6.10 Contact fuses ...................................69

6.11 Installation ......................................69

6.12 Protective circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

6.13 BCSoft...........................................69

7 Flame control ..................................... 70

7.1 ...with flame rod....................................70

7.2 ...with UV sensor ...................................70

8 Accessories.......................................71

8.1 High-voltage cable ...............................71

8.2 BCSoft ............................................71

8.2.1 Opto-adapter PCO 200 ..............................71

8.3 Radio interference suppressed terminal boots...71

8.4 Connection kit BCU 370..........................71

8.5 Set of stickers BCU 370...........................71

8.6 GSD master data file for BCU 370..B1 ............72

9 Technical data ....................................73

9.1 PROFIBUS DP ....................................74

9.2 Operating controls and dimensions ..............75

9.3 Converting units ..................................76

10 Legend ..........................................77

11 Glossary .........................................78

11.1 Safety shut-down ................................78

11.2 Fault lock-out....................................78

11.3 Warning signal ...................................78

11.4 Timeout 25 s/250 s .............................78

12 Annex .......................................... 79

12.1 Status and fault messages for PROFIBUS DP ..79

Feedback ...........................................82

Contact.............................................82

BCU 370 · Edition 01.19 3

= To be continued

▼

Page 4

Application

BCU 370

1 Application

The BCU 370 burner control unit controls, ignites and

monitors industrial forced draught burners of unlimited

capacity in intermittent or continuous operation.

It can be used for directly ignited forced draught burn-

ers or forced draught burners ignited with pilot burner.

The BCU 370 activates the fan and sets the connected

butterfly valve to Pre-purge and Ignition position. After

pre-purge and burner start, the enable signal is issued

to an external controller which positions the butterfly

valve in accordance with the capacit y demand. Post-

purge occurs after the end of burner operation. The

burner control unit BCU 370 monitors the gas and air

pressure. An optionally integrated tightness control

BCU 370 · Edition 01.19 4

Lower section Upper section

function checks the valves with an external gas pres-

sure switch.

Programmability by means of the optical interface and

BCSoft PC software guarantees optimum adaptation to

the relevant application. Adjustable start-up attempts

and automatic restart which can be activated ensure

the high flexibility of the burner equipment.

The quick-start option allows standard-compliant star t-

up of the forced draught burner without pre-purge

after controlled shut-down. This avoids unnecessary

admission of air into the combustion chamber. The heat

output is available as quickly as possible after a temperature demand.

▼

Page 5

Application

The program status, the unit parameters and the level

of the flame signal can be read directly from the BCU.

An integrated Manual mode allows manual start of the

burner and setting of the butterfly valve position inde-

pendently of the central control system. The BCSoft

operator-control and setting software provides a pow-

erful tool for commissioning and servicing.

To reduce the installation and wiring costs, Honeywell

Kromschröder offers an optional Profibus DP interface

to transfer the activation signals and feedbacks.

BCU 370 · Edition 01.19 5

Page 6

Application

L1

L1

21

24

23

22

DG

DG

21

24

23

22

DG

DG

BCU 370..I1

9 3

7

min

DL

VG

BCU 370..I1..D3

9 3

7

min

DL

VG

1.1 Applications example

25

28

26

20

19

90° ➔ 0

4

V1

VG..L

DG

DG

VG..L

VG..L

IC 20

11

11

IC 20

DL

4

4

V1

V1

DG

DG

pu/2

pu/2

DL

0 ➔ 90°

5293130 32

V2

M

BVA

0 ➔ 90°

29 3130

5 32

5

V2

V2

M

B VA

GIK

90° ➔ 0

GIK

18

17

13

UVS

25

28

26

20

19

18

17

13

UVS

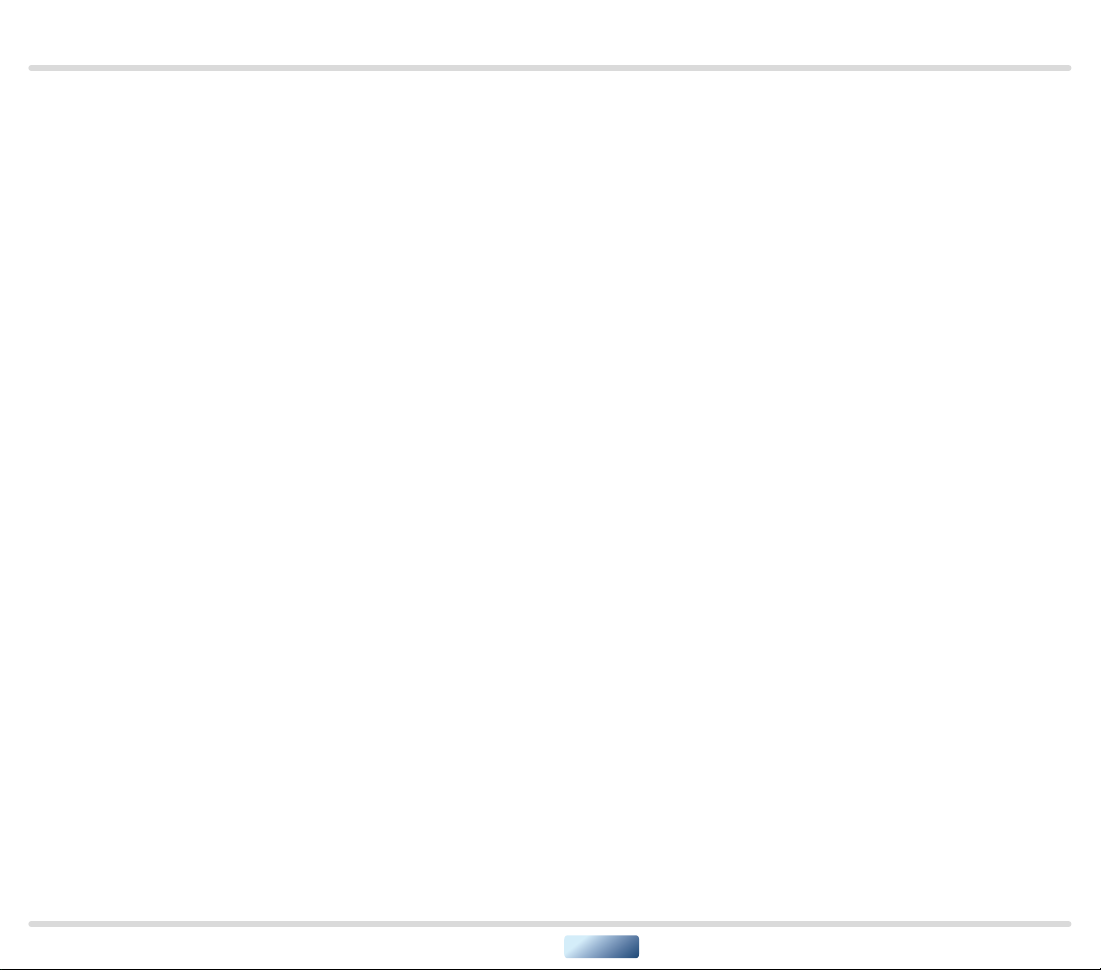

1.1.1

Modulating-controlled forced

draught burner

The BCU 370 controls the fan and

moves the butterfly valve to prepurge and ignition position. It issues

the enable signal to the control system after start-up of the burner.

Modulating-controlled forced

1.1.2

draught burner with tightness

control

In addition to controlling the forced

draught burner, the burner control

unit also monitors the fail-safe

function of the two solenoid valves

for gas via the gas pressure switch

DG which is set to pu/2.

Parameter 27 = 1: V2 is “ON” during

burner operation.

BCU 370 · Edition 01.19 6

Page 7

Application

L1

21

24

23

22

DG

DG

BCU 370..D3

9 3

7

min

DL

VG

V1 V2

DL

45

DG

pu/2

11

DG

VG..L

VG

IC 20

BVA

90° ➔ 0

0 ➔ 90°

29 3130

632

V3

M

GIK

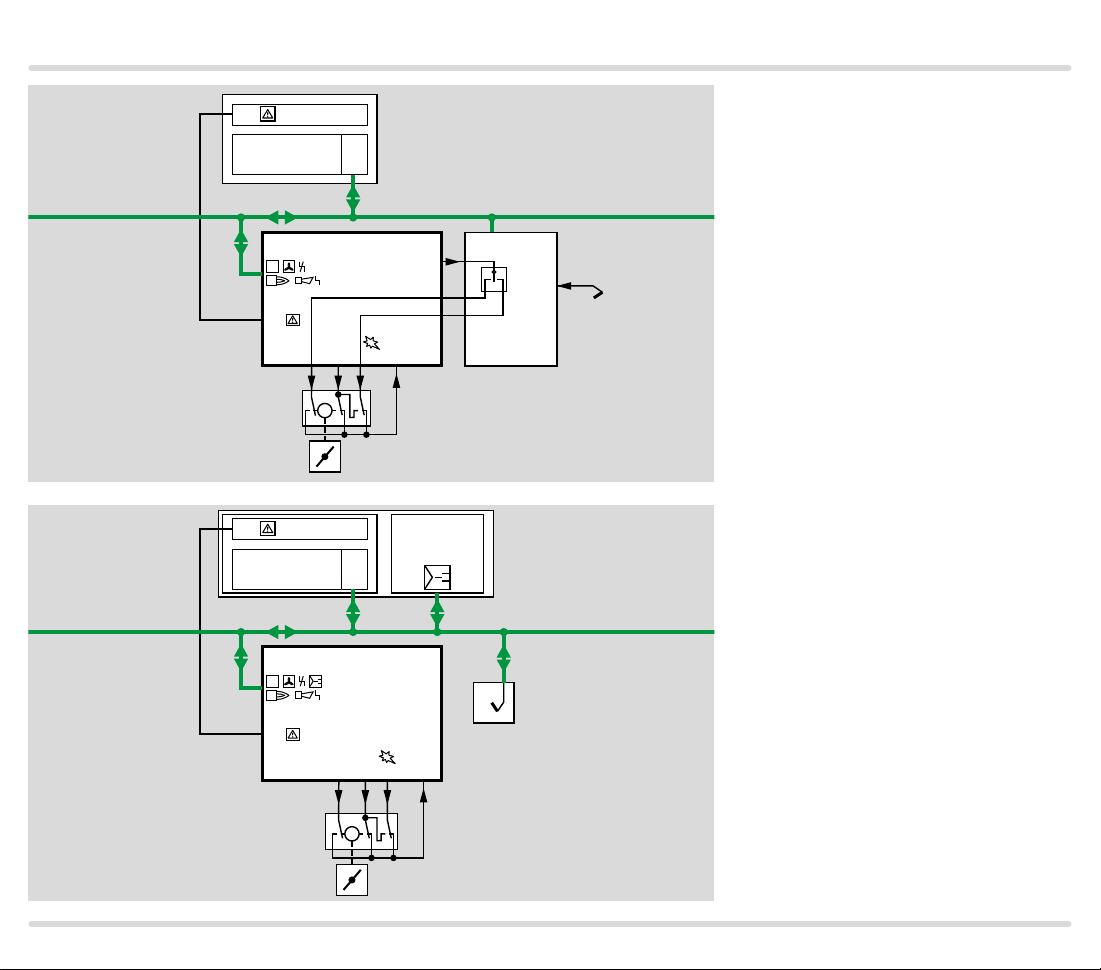

1.1.3

25

28

26

20

19

18

17

13

Modulating-controlled forced draught burner with pilot burner and tightness control

A pilot burner ignites the main burner and is switched off during the

main burner’s safety time.

Parameter 27 = 0: V2 is “OFF”, i.e. interrupted pilot burner, during burner

operation.

UVS

BCU 370 · Edition 01.19 7

Page 8

Application

L1,

PLC

BCU 370..B1

ϑ

L1,

L1,

PLC

Profibus DP

BCU 370..B1-3

ϑ

L1,

0 ➔ 90°

29 31 3230

M

3PS

29 30 31

BUS

90° ➔ 0

BUS

0 ➔ 90°

Profibus DP

Temperature

controller

90° ➔ 0

25

28

26

32

3PS

Temperature

controller

ϑ

1.1.4 Controlling the BCU via PROFIBUS DP

The BCU 370..B1 issues the enable

signal to the temperature controller

for capacity control. The temperature controller then controls the

butterfly valve directly.

ϑ

1.1.5 Controlling the BCU and the

butterfly valve via PROFIBUS DP

The BCU 370..B13 receives posi-

tioning information for the butterfly

valve from the temperature controller via the PROFIBUS DP and activates the butterfly valve following

controller enable.

M

BCU 370 · Edition 01.19 8

Page 9

Certification

2 Certification

Certificates – see ww w.docuthek.com

EU certified pursuant to

Directive:

– Low Voltage Directive (2014/35/EU),

– EMC Directive (2014/30/EU).

Regulation:

– Gas Appliances Regulation (EU) 2016/426

FM approved

Factory Mutual Research Class: 7611 “Combustion

Safeguards and Flame Sensing Systems”. Suitable for

applications pursuant to NFPA 86.

www.approvalguide.com

ANSI/CSA approved

UL listed

USA and Canada

Underwriters Laboratories – UL 372 “Primary Safety

Controls for Gas and Oil-fired Appliances”.

ww w.ul.com ➔ Tools (at the bottom of the page) ➔ Online Certifications Directory

AGA approved

AGA

Australian Gas Association, Approval No.: 6880

http://ww w.aga.asn.au/product _directory

Eurasian Customs Union

The product BCU 370 meets the technical specifica-

tions of the Eurasian Customs Union.

American National Standards Institute/Canadian

Standards Association – Class number: 333501 and

333581.

BCU 370 · Edition 01.19 9

Page 10

Function

BCU 370..I1

F1

F3

l v1 v2s1v3 cc

31 2 4 5 6 7 8 9 10 11 12 13 14 15 16 1917 18 20 21 22 23 24 25 26 27 28 29 30 31 32

V1 C S1 S L A Z M V2 V3 R

C

V1

V2

DL DG

V3

ppp

minDGmax

230V~

PE N

Z

I

3 Function

3.1 Connection diagrams

3.1.1 BCU 370

The drawing shows the BCU 370..I1 with integrated

ignition unit, ionization control and double-electrode

operation.

For cable selection and wiring, see page 66 (Project

planning information).

90° ➔ 0

0 ➔ 90°

r

r1 s

max. 1 A,

max. 1 A,

253 V

253 V

M

3PS

ϑ

For the explanation of symbols, see page 77 (Legend).

▼

L1 (L1)

N (L2)

PE

BCU 370 · Edition 01.19 10

Page 11

Function

13 14 15 16 PE

3

2

UVS

1

BCU 370..I1 for 120 V and 230 V, UV control

BCU 370..I2

N13 14 15 16 PE

3

2

UVS

1

Z Z

BCU 370..I2 for 230 V, ignition by electrode to electrode

BCU 370..I3 for 120 V, ignition by electrode to electrode

BCU 370..I3

N13 14 15 16 PE

with centre tap for secondary grounding

▼

3

2

UVS

1

BCU 370 · Edition 01.19 11

Z Z

Page 12

Function

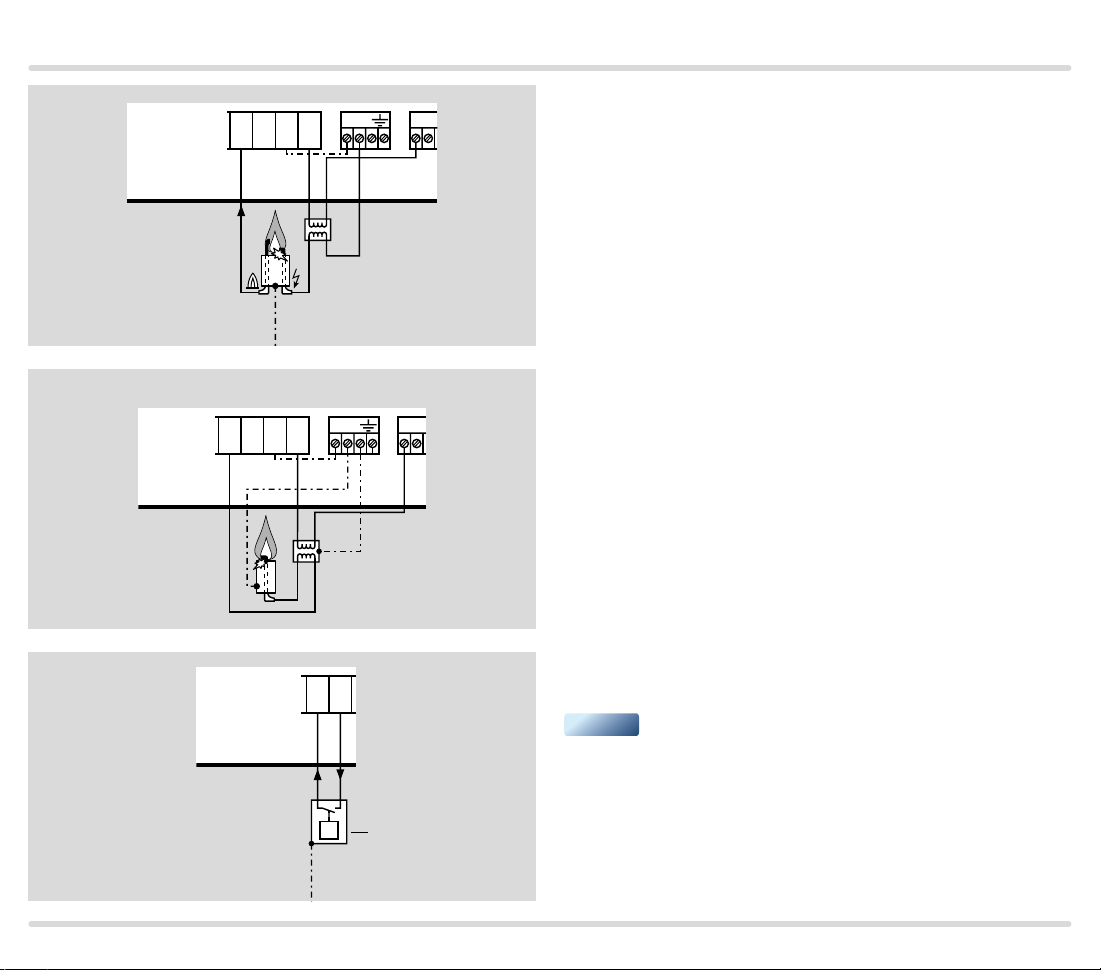

BCU 370

BCU 370

BCU 370 with external ignition transformer, e.g. TZI or

N13 14 15 16 PE

Z

I

TGI

BCU 370 with single-electrode operation, which requires an external ignition transformer TZI or TGI

N13 14 15 16 PE

BCU 370..D3, gas pressure switch DG for tightness

BCU 370..D3

11 12

control

▼

p

e

p

2

DG

BCU 370 · Edition 01.19 12

Page 13

Function

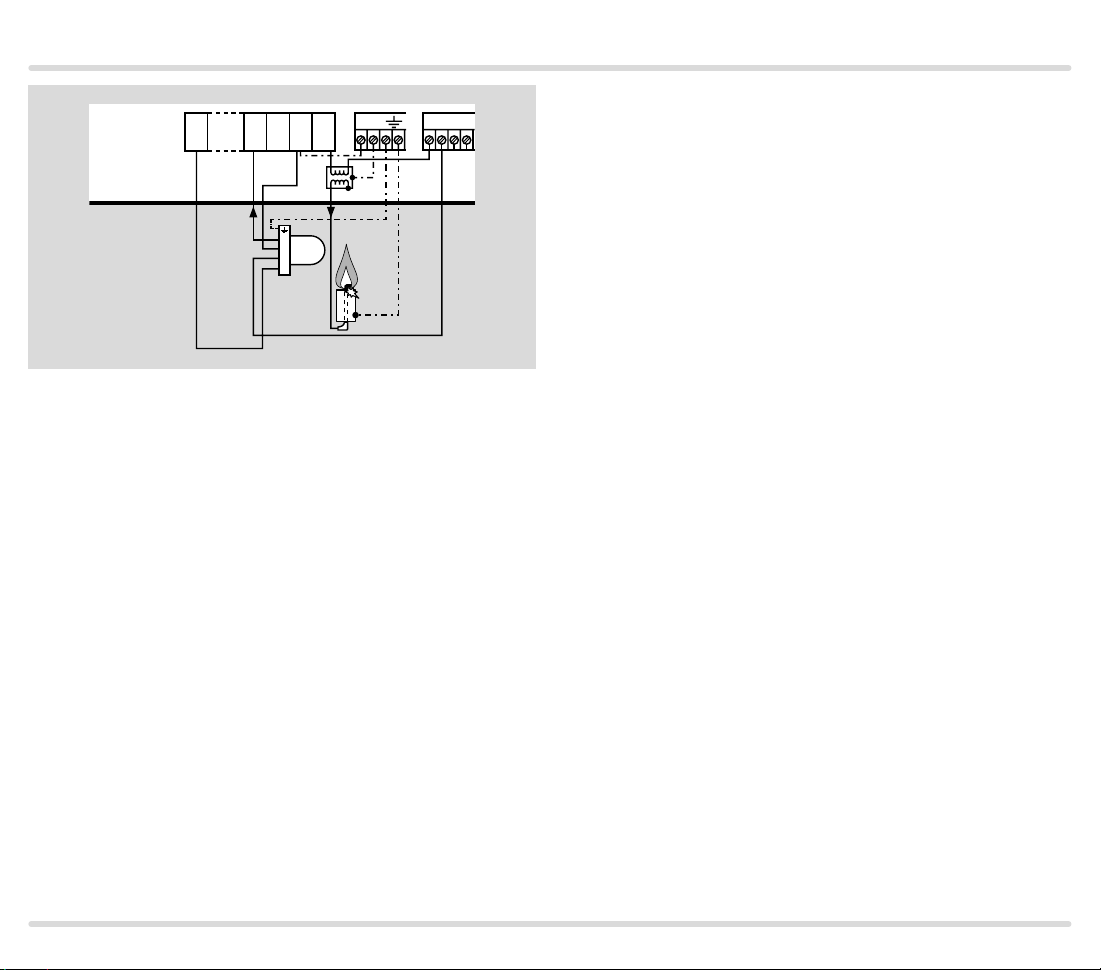

BCU 370..U1

131141516 PE N

4

3

UVC 1

2

1

BCU 370..U1 with UV flame detector UVC 1 for continuous operation

Use 5-core connection cable including a PE wire and

complying with local regulations.

The UVC 1 is grounded using a PE wire connection

which is galvanically connected to the housing.

BCU 370 · Edition 01.19 13

Page 14

Function

BCU 370

90° ➔ 0

0 ➔ 90°

r

25 26 27 28 29 30 31 32

3PS

0

90°

16

3.1.2 BCU 370 with actuator IC 20

The “closed contact” (90° ➔ 0) of the external three-

point step controller (3PS) can be connected to terminal 26 or 27.

Terminal 26: the controller operates between the open

and ignition positions.

Terminal 27: the controller operates between the open

and closed positions.

L1 (L1)

N (L2)

PE

90° ➔ 0

0 ➔ 90°

321

674812 1115 13

S11

PE

IC 20

S10

S1S2

S3 S4

M

BCU 370 · Edition 01.19 14

Page 15

Function

90° ➔ 0

0 ➔ 90°

r

25 26 27 28 29 30 31 32

3.1.3 Capacity control by adjusting the valve between the Open position and a separate Min position

This connection is used if the valve position to be ap-

proached is below the Ignition position.

Standard wiring of BCU 370 and BCU 370..B1 without

three-point step control function

Valve position Activation of terminal

Upper end position Open 28

Lower end position Closed 27

Lower end position Min Via separate limit switch

Lower end position Ignition 26

–+

3PS

BCU 370 · Edition 01.19 15

M

Min

Page 16

Function

BCU 370..I1..B1

F1

F3

l v1 v2s1v3 cc

31 2 4 5 6 7 8 9 10 11 12 13 14 15 16 24 25 26 27 28 29 30 31 32

V1 C S1 S L A Z M V2 V3 R

C

V1

V2

DL DG

V3

ppp

minDGmax

r

230V~

PE N

Z

I

3PS

BCU 370..B1

ON

OFF

2B 2A 1B 1A

0 ➔ 90°

M

90° ➔ 0

L1 (L1)

N (L2)

PE

PROFIBUS-DP

3.1.4 BCU 370..B1 with PROFIBUS DP

Function, see page 32 (PROFIBUS DP)

For cable selection and wiring, see page 66 (Project

planning information).

For the explanation of symbols, see page 77 (Legend).

BCU 370 · Edition 01.19 16

Page 17

Function

3.1.5 Assignment of connection terminals

Terminal Type Designation Function

1, 2 V AC input Supply voltage

3 V AC output Fan Connection for fan control

4

5 Gas valve V2 Connection of phase for gas valve V2

6 Gas valve V3 Connection of phase for gas valve V3

7

9 Minimum gas pressure Connection for pressure switch to monitor the minimum gas pressure

11 Maximum gas pressure Connection for pressure switch to monitor the maximum gas pressure

8, 10 and

12

Safety circuit

output

Inputs for

pressure switches

V AC outputs Mains supply Phase for pressure switch mains supply

13

14 Supply voltage to UV sensor Output for supply voltage to UV sensor

15 Burner ground Burner ground input for UV sensor

Flame control

Gas valve V1 Connection of phase for gas valve V1

Minimum air pressure Connection for pressure switch to monitor the minimum air pressure

Flame amplifier input Input for flame amplifier

16 Ignition transformer output Output for (external) ignition transformer

17, 18

19, 20

1) 2)

21

1) 2)

22

1) 2)

23

1) 2)

Floating contact

1) 2)

V AC input

Signalling contact for operating

signals

Signalling contact for faults Contact between terminals 19 and 20 closes in the event of a BCU fault signal

Start-up signal Signal applied: BCU start; no signal: BCU stop

Controlled air flow

Remote reset Input for external signal (button) to reset the unit af ter a fault lock-out

24 Controller enable/emergency stop Connection for higher-level safety devices and interlocks (e.g. emergency stop)

25

26

27

28

2)

2)

2)

2)

Connection for

external threepoint step

controller

Controller enable

Y (to ignition position) Connection for the signal to activate the ignition position

Y (to min. position) Connection for the signal to activate the position for minimum capacity

Y+ (to max. position) Connection for the signal to activate the position for maximum capacity

Voltage to operate the BCU,

1 = phase (L1), 2 = neutral conductor (N)

Contact between terminals 17 and 18 closes once the operating signal has been

received from the burner

Signal applied: fan is started to supply air to the combustion chamber for cooling, for

example. Only functional in standby. The function is deactivated as soon as a signal is

received at terminal 1 (BCU star t).

Output signal for controller enable for the three-point step controller. The actuator can

be set to various positions.

▼

BCU 370 · Edition 01.19 17

Page 18

Function

Terminal Type Designation Function

29, 30

and 31

32 Safety circuit input

1)

BCU..B1: not fitted/non-functional

2)

BCU..B13: not fitted/non-functional

V AC output Capacity control Connection for capacity control using an actuator

Feedback from actuator/

frequency converter

Connection for the position feedback signal from the actuator

BCU 370 · Edition 01.19 18

Page 19

Function

3.2 BCU 370 program sequence

Switch on BCU 370

In the event of fault signal: reset

00

H0

H0

01

A1

P1

A2

03

04

05

Start-up position/standby

Start-up with ϑ signal

Switch-on delay time t

Fan run up time t

Butterfly valve moves to Open position

Pre-purge time t

Butterfly valve moves to Ignition position

Pre-ignition time t

Ignition activated

Safety time t

burner/pilot burner (P12),

Flame proving period t

running for burner/pilot burner (P13)

PV

SA1

V1 and V2 open

running (P22)

E

(P20)

GV

running (P18)

running (P21)

VZ

running for

FS1

3.2.1 Normal start-up

If a fault from the preceding operating cycle is still being signalled after

switching on, it will be necessary

to reset this first. Once the startup signal (ϑ) has been applied, the

switch-on delay tE starts to elapse.

During the fan run-up time t

GV

which follows, the fan starts with

the butterfly valve being closed. The

butterfly valve then moves from the

Closed to the Open position. After

pre-purge, it moves back to the Ignition position.

The running times depend on the

respective actuator. The BCU waits

for actuator feedback before continuing the program sequence.

Now the BCU activates pre-ignition

t

and then opens valves V1 and

VZ

V2 for the pilot burner. The ignition

time tZ is constant.

After the flame proving period for

the pilot burner t

to ignite the main burner.

, valve V3 opens

FS1

▼

BCU 370 · Edition 01.19 19

Page 20

04

05

03

Flame proving period t

FS1

running for burner/pilot burner (P13)

Safety time t

SA1

running for

burner/pilot burner (P12),

V1 and V2 open

Pre-ignition time t

VZ

running (P21)

Ignition activated

Function

06

07

H8

08

08

P9

A0

Safety time t

Controller enabler signal delay time t

Butterfly valve moves to Closed position

SA2

If parameter P27 = 0:

V2 is switched off

Flame proving period t

running for main burner (P15)

Controller enable signal

Controlled shut-down

Post-purge time t

running for main burner (P14),

V3 opens

FS2

(P29)

RF

via ϑ signal

running (P19)

PN

If parameter 27 = 0, V2 closes at the

end of the main burner safety time

t

. The pilot burner is switched off.

SA2

Then the flame proving period for

the main burner t

and the con-

FS2

troller enable signal delay time tRF

start to elapse. Af terwards, the BCU

issues the enable signal to the controller.

If there is no pilot burner, program

steps

06

and

07

will be omitted.

As soon as the start-up signal (ϑ) is

switched off, post-purge starts. The

butterfly valve moves to the Ignition position during this time, then

to the Closed position. Next, the

BCU rests in the start-up position/

standby.

00

BCU 370 · Edition 01.19 20

Start-up position/standby

Page 21

Function

00

H0

H0

01

02

03

04

05

06

Start-up position/standby

Start-up with ϑ signal

Switch-on delay time t

Fan run up time tGV (P20)

Waiting time t

Pre-ignition time t

Ignition activated

Safety time t

burner/pilot burner (P12),

V1 and V2 open

Flame proving period t

running for burner/pilot burner (P13)

Safety time t

running for main burner (P14),

SA2

V3 opens

running (P22)

E

running (P21)

VZ

running for

SA1

3.2.2 Quick start, butterfly valve

waits in the Ignition position

Parameter 06 = 0, parameter 28 = 0

Quick start is the same as normal

start, except that pre-purge is

dispensed with. The burner starts

quicker. This results in improved

control quality, since there is no

dead time, the energy is used better

and no cold air is fed to the combustion chamber.

The BCU 370 only carries out a

W

quick start if the last shut-down

was a controlled shut-down. No

more than 24 hours may have

elapsed and the BCU must have

been switched on.

In contrast to the “normal start-up”,

in the case of a quick start, program

A1

FS1

steps

ted.

P1

,

and

A2

will be omit-

If there is no pilot burner, program

steps

06

und

07

will also be omit-

ted.

If parameter P27 = 0:

V2 is switched off

BCU 370 · Edition 01.19 21

▼

Page 22

05

06

04

03

Flame proving period t

FS1

running for burner/pilot burner (P13)

Safety time t

SA2

running for main burner (P14),

V3 opens

If parameter P27 = 0:

V2 is switched off

Safety time t

SA1

running for

burner/pilot burner (P12),

V1 and V2 open

Pre-ignition time t

VZ

running (P21)

Ignition activated

Function

07

H8

08

Controller enabler signal delay time t

Flame proving period t

running for main burner (P15)

Controller enable signal

After controlled shut-down, the

post-purge time tPN starts to elapse

FS2

and then the butterfly valve moves

to the Ignition position in preparation for the next start.

(P29)

RF

NOTE: Quick start is not allowed for

units with FM or CSA approval.

08

P9

A1

A2

00

BCU 370 · Edition 01.19 22

Butterfly valve moves to Open position

Butterfly valve moves to Ignition position

Controlled shut-down

via ϑ signal

Post-purge time t

Start-up position/standby

PN

running (P19)

Page 23

Function

00

H0

H0

A1

A2

01

02

03

04

05

Start-up position/standby

Start-up with ϑ signal

Switch-on delay time tE running (P22)

Butterfly valve moves to Open position

Butterfly valve moves to Ignition position

Fan run up time t

Waiting time t

Pre-ignition time t

Ignition activated

Safety time t

for burner/pilot burner (P12),

V1 and V2 open

Flame proving period t

running for burner/pilot burner (P13)

(P20)

GV

W

running (P21)

VZ

running

SA1

FS1

3.2.3 Quick start, butterfly valve

waits in the Closed position

Parameter 06 = 0, parameter 28 = 1

Pre-purge will also be omitted for

this type of quick start. To prevent

cold air from entering the combustion chamber while the BCU is in

start-up position/standby, the butterfly valve waits in the Closed position.

The BCU 370 only carries out a

quick start if the last shut-down

was a controlled shut-down. No

more than 24 hours may have

elapsed and the BCU must have

been switched on.

After the switch-on delay time t

,

E

the butterfly valve moves to the Ignition position. The Ignition position

is always approached from the top.

Therefore, the butterfly valve moves

to the Open position first.

▼

BCU 370 · Edition 01.19 23

Page 24

05

04

03

Flame proving period t

FS1

running for burner/pilot burner (P13)

Safety time t

SA1

running

for burner/pilot burner (P12),

V1 and V2 open

Pre-ignition time t

VZ

running (P21)

Ignition activated

Function

06

07

H8

08

08

P9

Safety time t

Controller enabler signal delay time t

Post-purge time t

SA2

If parameter P27 = 0:

V2 is switched off

Flame proving period t

running for main burner (P15)

Controller enable signal

Controlled shut-down

running for main burner (P14),

V3 opens

FS2

(P29)

RF

via ϑ signal

running (P19)

PN

If there is no pilot burner, program

steps

06

and

07

will be omitted.

As soon as the start-up signal (ϑ) is

switched off, post-purge starts. The

butterfly valve moves to the Ignition position during this time, then

to the Closed position. Next, the

BCU rests in the start-up position/

standby.

NOTE: Quick start is not allowed for

units with FM or CSA approval.

A0

00

BCU 370 · Edition 01.19 24

Butterfly valve moves to Closed position

Start-up position/standby

Page 25

Function

00

H0

H0

A1

A2

01

02

03

04

05

Switch on BCU 370

In the event of fault signal: reset

Start-up position/standby

Start-up with ϑ signal

Switch-on delay time t

Butterfly valve moves to Open position

Butterfly valve moves to Ignition position

Fan run up time t

Waiting time t

Pre-ignition time t

Ignition activated

Safety time t

burner/pilot burner (P12),

V1 and V2 open

Flame proving period t

running for burner/pilot burner (P13)

running (P22)

E

GV

W

running (P21d

VZ

running for

SA1

(P20)

FS1

3.2.4 Start-up without pre-purge,

butterfly valve waits in the Closed

position

Parameter 18 = 0, parameter 28 = 1

If a fault from the preceding operating cycle is still being signalled after

switching on, it will be necessary

to reset this first. Once the startup signal (ϑ) has been applied, the

switch-on delay t

starts to elapse.

E

Afterwards, the butterfly valve

moves from the Closed to the Open

position and then to the Ignition position. During the fan run-up time

t

which follows, the fan starts

GV

with the butterfly valve being set to

Ignition position.

After the waiting time t

, the BCU

W

activates pre-ignition tVZ and then

opens valves V1 and V2 for the

pilot burner. The ignition time tZ is

constant. After the flame proving

period for the pilot burner t

FS1

, valve

V3 opens to ignite the main burner.

▼

BCU 370 · Edition 01.19 25

Page 26

04

05

03

Flame proving period t

FS1

running for burner/pilot burner (P13)

Safety time t

SA1

running for

burner/pilot burner (P12),

V1 and V2 open

Pre-ignition time t

VZ

running (P21d

Ignition activated

Function

06

07

H8

08

08

P9

A0

00

Safety time t

Controller enabler signal delay time t

Butterfly valve moves to Closed position

SA2

If parameter P27 = 0:

V2 is switched off

Flame proving period t

running for main burner (P15)

Controller enable signal

Controlled shut-down

Post-purge time t

Start-up position/standby

running for main burner (P14),

V3 opens

FS2

(P29)

RF

via ϑ signal

running (P19)

PN

If parameter 27 = 0, V2 closes at the

end of the main burner safety time

t

. The pilot burner is switched off.

SA2

Then the flame proving period

for the main burner t

and the

FS2

controller enable signal delay time

tRF start to elapse. Af terwards, the

BCU issues the enable signal to the

controller. If there is no pilot burner,

program steps

06

and

07

will be

omitted.

As soon as the start-up signal (ϑ) is

switched off, post-purge starts. The

butterfly valve moves to the Ignition position during this time, then

to the Closed position. Next, the

BCU rests in the start-up position/

standby.

NOTE:

Quick start is not allowed for units

with FM or CSA approval.

BCU 370 · Edition 01.19 26

Page 27

Function

N

r

r1 s

1917 18 20 21 22 23 24 25 26 27 28 29 30 31 32

max. 1 A,

max. 1 A,

253 V

253 V

3PS

ϑ

0 ➔ 90°

M

3.2.5 Controlled air flow

The controlled air flow function is enabled when the

90° ➔ 0

controlled air flow input, terminal 22 or via Status and

fault messages for PROFIBUS DP, is activated. Cold air

is fed to the combustion chamber, e.g. for cooling.

Following the air pressure switch DL “no flow” state

check, the BCU 370 starts the fan and opens the butterfly valve to the Open position. The pressure switch

for air DL monitors the air pressure.

If the start-up signal (ϑ) is applied during controlled air

flow, the burner is started. If the elapsed controlled air

flow time is at least as long as the set pre-purge time,

the burner starts immediately after the Ignition position

L1 (L1)

N (L2)

PE

has been reached. If it is shorter, the total air volume is

supplied until the end of the pre-purge time.

Activation of the controlled air flow input is not required

for normal burner start.

Activation of the controlled air flow function during

burner operation will be ignored.

BCU 370 · Edition 01.19 27

Page 28

Function

L1

DG

BCU 370..I1..D3

21

24

23

22

9 3

DG

min

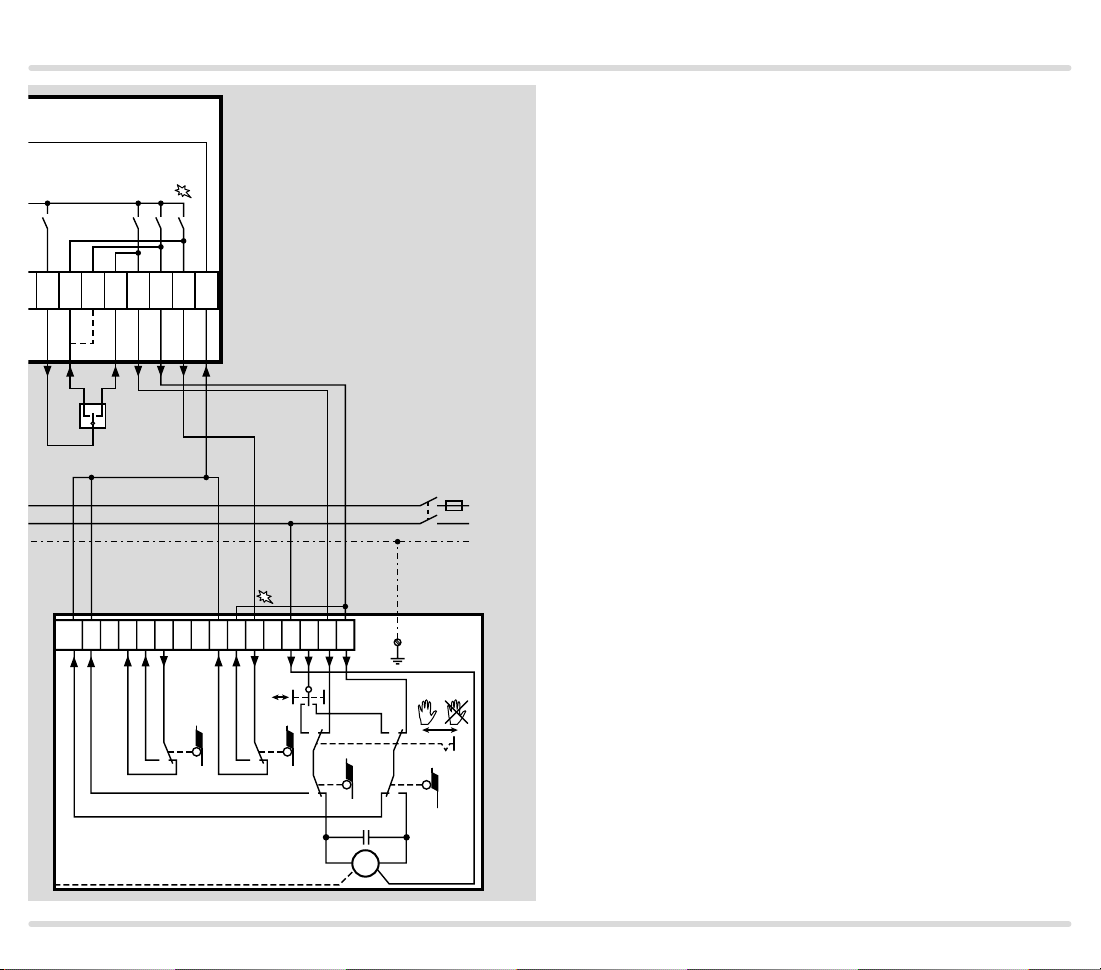

3.3 Tightness control

On BCU 370..D3, the tightness control monitors the fail-safe function

of the gas solenoid valves if parameter 24 is set to 3.

The aim of the tightness control is

to identify an inadmissible leak on

one of the gas solenoid valves and

25

28

26

20

19

90° ➔ 0

0 ➔ 90°

DL

VG

4

DG

pu/2

11

DG

VG..L

V1

DL

7

29 3130

5 32

V2

IC 20

B VA

GIK

M

18

17

13

UVS

to prevent burner start. The other

gas solenoid valve continues working properly and takes over the safe

shut-off of the gas supply.

The test takes place during pre-

purge. The fan runs and the air

pressure opens the air/gas ratio

control GIK.

In the case of quick start (parameter

06 = 0), the test takes place after

burner operation during post-purge.

The pre- and post-purge times (pa-

rameters 18 and 19) must be set so

that their duration is at least as long

as the test period t

.

P

▼

BCU 370 · Edition 01.19 28

Page 29

Function

L1

BCU 370..D3

21

24

23

22

9 3

DG

min

Downstream of the gas solenoid

valve V2 on the burner side, the pipe

to the burner must be open so that

the space between valves V1 and V2

can be vented.

The pressure switch DG moni-

tors the pressure between the two

25

28

26

20

19

90° ➔ 0

7

DL

45

V1 V2

11

DG

0 ➔ 90°

632

29 3130

V3

18

17

13

valves. It must be set to half of the

inlet pressure p

/2 in order to check

u

both valves with equal sensitivity.

In pilot/main burner systems with

three gas solenoid valves, V2 and

V3 are checked simultaneously.

DG

VG

DG

pu/2

VG..L

GIK

UVS

VG

M

DL

IC 20

BVA

BCU 370 · Edition 01.19 29

Page 30

Function

TEST

V2

V2

tL = 3 s

V2

t

M

pZ >

V1

OK

0 ➔ I

I ➔ 0

p

u

2

–

OK

3.3.1 Program sequence

The program flow chart explains the

process during the TEST phase.

V1 V2

After start-up the waiting time t

starts to elapse. Then either the left

W

or right path is executed.

+

START

t

W

p

pZ >

p

u

–

u

2

p

z

V1

OK

– If the interspace pressure p

greater than half of the inlet pressure pu/2 after the waiting time

tW, V2 is tight. V2 is opened for a

duration of 3 seconds to vent the

interspace. Then the measure-

is

Z

ment time tM starts to elapse. If

V1

0 ➔ I

no interspace pressure can be

measured after this time, V1 is

tL = 3 s

also tight. Both valves have thus

been checked.

V1

I ➔ 0

t

M

+

–

pZ >

p

u

2

+

V1 V2

V2

OK

– If no interspace pressure p

be measured after the waiting

time tW, V1 is tight. Then V1 is

opened for 3 seconds to fill the

space between the valves. Then

the measurement time tM starts

to elapse. If a pressure can be

can

Z

measured in the interspace after

this time, V2 is also tight. Both

valves have thus been checked.

▼

BCU 370 · Edition 01.19 30

Page 31

Function

TEST

V2

V2

0 ➔ I

tL = 3 s

V2

I ➔ 0

t

M

OK

+

START

t

W

p

pZ >

Leakage is indicated by

first valve and

37

36

for the

for the second.

V1 V2

p

u

–

u

2

p

z

V1

V1

0 ➔ I

tL = 3 s

V1

I ➔ 0

t

M

OK

pZ >

p

u

2

–

+

–

V1

OK

BCU 370 · Edition 01.19 31

V1 V2

V2

pZ >

p

u

2

+

OK

Page 32

Function

L1, N, PE

DI

SPS

PLC

API

PROFIBUS DP

BCU..B

BUS1– 6

BCU..B

BUS1– 6

3.4 PROFIBUS DP

The BCU..B1 features the same functions and perfor-

mance of a BCU® without a PROFIBUS connection.

PROFIBUS is a manufacturer-independent, open field-

P

BUS

1

bus standard for diverse applications.

PROFIBUS DP is a bus variant for communication between automation systems and distributed peripherals

at the field level, optimized for speed and low connection costs.

On PROFIBUS DP, the individual bus subscribers are

connected via a 2-core shielded cable as standard.

The bus system transfers the control signals for start-

ing, resetting and for controlling the air valve to purge

the furnace or kiln or for cooling in start-up position

and heating during operation from the control system

(PLC) to the BCU..B1. In the opposite direction, it sends

operating status, the level of the flame signal and the

current program status.

2

BCU..B

3.4.1 Safety-related control signals

Signals from the safety interlocks and digital input are

transferred independently of the bus communication

by separate cables. The air valve used to purge the fur-

BUS1– 6

nace or kiln can either be activated via the PROFIBUS

or via a separate cable to terminal 22. The purging pro-

3

cess must be monitored by further measures, e.g. flow

monitoring.

BCU 370 · Edition 01.19 32

Page 33

Function

3.4.2 BCSoft

The Windows software BCSoft allows extended access

to individual statistics, protocol functions, line recorders and the parameterization of the burner control unit

via an optical interface. Unit parameters which are not

relevant to safety can be set and adjusted to the specific application.

3.4.3 Configuration, master-slave procedure

PROFIBUS DP is structured as a master-slave system.

This allows mono-master or multi-master systems to be

implemented.

A distinction is made between three device types:

– DP Master Class 1 (DPM1)

DPM1 devices are central controllers which exchange

data with the distributed stations (slaves) on the basis of a defined cycle. This includes, for instance, the

PLC, PC, CNC or VME systems with which the PROFI

BUS DP is operated.

– DP Master Class 2 (DPM2)

DPM2 devices are programming, project planning or

operator-control devices. They are used for configuration and commissioning of the system or for system

operation and visualization in ongoing operation.

– DP slaves

The devices which transmit input information from

the periphery to the master and which issue output

information from the master to the peripher y are referred to as “slaves”.

This also includes the BCU..B1.

3.4.4 Addressing

A maximum of 126 units (masters and slaves) can be

connected to a PROFIBUS DP system. Each subscriber

is assigned an individual PROFIBUS address which can

be set between 0 and 126 using two code switches on

the BCU..B1 board.

BCU 370 · Edition 01.19 33

Page 34

Function

3.4.5 Network technology

All devices are connected in a bus structure (line). Up to

32 subscribers (masters or slaves) can be connected in

a single segment. The beginning and end of each segment is fitted with an active bus terminator. Both bus

terminators must have a permanent power supply to

ensure error-free operation. The power supply for the

bus terminator is provided by the BCU. The bus terminator can be connected in the bus connection plug.

If more than 32 subscribers are implemented or if there

is a need to expand the network area, repeaters (ampli-

fiers) must be used to link the individual bus segments.

3.4.6 Configuration

When planning a PROFIBUS DP system, unit-specific parameters of each subscriber are to be taken into account.

To allow for simple and standardized planning, the param

eters of the BCU..B1 have been summarized in a so-called

device master data file (GSD). The file structure is standardized so that it can be read by the planning devices of different manufacturers.

The GSD file can be downloaded from www.docuthek.

com, once you have registered. The steps required to copy

the file are described in the instructions for the automation system.

3.4.7 Bus communication

Input bytes (BCU ➔ master)

Bit Byte 0 Byte 1 Byte 2 Byte 3

0 Burner operation

1

2 Fault lock-out

3 Controlled air flow

4

5

6 ON

7 Manual mode

* Only on BCU 370..B13, three-point step control via PROFIBUS DP

Bit Byte 0

0 Reset

1 Start-up

2 Controlled air flow

3

4

5

6 Open*

7 Close*

* Only on BCU 370..B13, three-point step control via PROFIBUS DP

Open position

reached*

Closed position

reached*

Output by tes (master ➔ BCU)

Reserved

See table on page

for PROFIBUS DP)

79 (Status and fault messages

0–25.5 µA of the burner

▼

255 steps

BCU 370 · Edition 01.19 34

Page 35

Function

I/O bytes: the programmer can choose the data to be

transferred.

Inputs Outputs

BCU 370 Basic I/O 1 byte 1 byte

BCU 370 Standard I/O 4 bytes 1 byte

Baud rate: up to 1500 kbit/s.

The max. range per segment depends on the baud rate:

Baud rate [kbit/s] Range [m]

93.75 1200

18 7.5 1000

500 400

1500 200

The specified ranges can be increased by using repeat-

ers. No more than three repeaters should be connected

in series.

The specified ranges relate to bus cable type A (two-

core, shielded and twisted), e.g. Siemens, Order No.

6XV18300EH10, or

Lapp cable unitronic, Order No. 2170220T.

BCU 370 · Edition 01.19 35

Page 36

Function

3.5 Program status

Display Program status

00

A0

0

01

A1

1

P1

A2

02

03

04

05

06

07

H8

08

H0

C1

P9

In Manual mode, two dots blink on the display.

Start-up position/standby

Butterfly valve moves to Closed position

Air monitor "no flow" state check

Fan run-up time t

Butterfly valve moves to Open position

Air monitor operating position check

Pre-purge time t

Butterfly valve moves to Ignition position

Waiting time t

Pre-ignition time t

1st safety time on start-up t

1st flame proving period t

2nd safety time on start-up t

2nd flame proving period t

Controller enable signal delay time

Operation/Controller enable

Waits for switch-on delay or min. pause time

Controlled air flow

Post-purge time t

GV

PV

W

VZ

SA1

FS1

SA2

FS2

PN

BCU 370 · Edition 01.19 36

Page 37

Function

3.6 Fault message (blinking)

Fault message (blinking) Display Fault lock-out Safety shut-down Warning signal

Flame simulation

Start-up without flame signal

Flame failure during 1

Flame failure during 2

Flame failure during 2

Flame failure during operation

Too many remote resets

Safety interlock failure

Permanent remote reset

Timing cycle too short

DG

oscillating

min.

Bus module error

Bus fault

Open + Close set simultaneously

Fault Valve feedback

Tightne ss control: V1 leaking

Tightne ss control: V2/V3 leaking

Fault Air monitor break contact check

Fault Air monitor make contact check

Fault Air supply during pre-purge

Fault Air supply in program step X

Fault DG

Fault DG

Butterfly valve closed position not reached

Butterfly valve open position not reached

Butterfly valve ignition position not reached

in program step X

max.

in program step X

min.

st

flame proving period

nd

safety time

nd

flame proving period

01

04

05

06

07

08

10

50

52

53

55

E

P

56

35

36

37

0

1

P

X

X

X

A0

A1

A2

BCU 370 · Edition 01.19 37

Page 38

Function

3.6.1 Reaction to process faults

The BCU 370 reacts differently to process faults in different program steps. If, for example, the signal from air

1

pressure switch DL drops during pre-purge,

elapse. If the signal is not applied again, the BCU carries out three further start-up attempts.

Process fault BCU 370’s reaction

flashes on the display and a timeout time of 25 seconds starts to

Signal

(terminal)

DG

(11) drops

max.

DG

(9) drops

min.

DL (7) pending

Signal status During program step

not pending after t

not pending after t

not pending

drops

drops

drops

drops

drops

drops

drops

drops

drops

▼

SA1

SA2

All

XX

All except t

XX

t

04

SA1

t

06

SA2

"no flow" state check

0

Operating position check

1

Pre-purge time

P1

Valve moves to Ignition position

A2

Waiting time

02

Pre-ignition time

03

t

04

SA1

t

05

FS1

t

06

SA2

t

07

FS2

Controller enable waiting time

H8

SA1

+ t

SA2

Controlled shut-down

Timeout 25 s

Immediate fault lock-out

Safety shut-down

Start-up attempts1)Restart2)Fault message

4)

4)

4)

X

X

4

6

0

1

P

2

2

3

4

5

6

7

8

BCU 370 · Edition 01.19 38

Page 39

Function

Process fault BCU 370’s reaction

Signal

(terminal)

DL (7) drops

ϑ (21)

Safety interlock (24) drops

Flame (13) pending

1}

According to parameter 07. If the last start-up at tempt fails, a fault lock-out occurs.

2}

According to parameter 08. If the restar t fails, a fault lock-out occurs.

3}

Safety time elapses completely.

4}

BCU restarts as soon as the signal is applied again.

5)

The program sequence is blocked.

6)

4) and 5)

Signal status During program step

Operation

08

drops

drops

drops

drops

pending

pending

pending

pending

not pending after t

drops

drops

drops

drops

drops

SA1

Controlled air flow

C1

All except t

XX

t

04

SA1

t

06

SA2

All

XX

"no flow" state check

0

Operating position check

1

Pre-purge time

P1

Valve moves to Ignition position

A2

Waiting time

02

t

04

SA1

t

05

FS1

t

06

SA2

t

07

FS2

Controller enable waiting time

H8

Operation

08

SA1

+ t

SA2

Controlled shut-down

Timeout 25 s

3)

3)

Immediate fault lock-out

Safety shut-down

6)

Start-up attempts1)Restart2)Fault message

8

P

50

01

01

01

01

01

04

05

06

07

08

08

BCU 370 · Edition 01.19 39

Page 40

Parameters

4 Parameters

Description Parameter Value range Default Adjustable1)

Burner flame signal 01

Burner switch-off threshold 02

Last fault signal 03 XX

Air monitoring during pre-purge 04 0 = Off; 1 = On 1

Air monitoring during operation 05 0 = Off; 1 = On 1

Pre-purge 06

Burner start-up attempts 07 1–4 1

Restart after flame failure during operation 08

Safety time during operation t

Minimum operating time t

Minimum burner pause time t

st

safety time on start-up, burner/pilot burner t

1

st

flame proving period, burner/pilot burner t

1

nd

safety time on start-up, main burner t

2

nd

flame proving period, main burner t

2

SB

B

BP

FS2

SA1

FS1

SA2

09 1; 2 s 1 s

10 0–250 s 0 s

11 0–250 s 0 s

12 2; 3; 5; 10 s 5 s

13 0; 2; 5; 10; 20 s 2 s

14 0; 2; 3; 5; 10 s 3 s

15 0; 2; 5; 10; 20 s 2 s

Operating time in Manual mode 16

UVS check (1× in 24 hours) 17 0 = Off; 1 = On 0

Pre-purge time t

Post-purge time t

Fan run-up time t

PV

PN

GV

18 0–250 s 30 s

19 0–250 s 0 s

20 0–25 s 2 s

0–25 µA

1–20 µA 1 µA

0 = Quick start;

1 = On each start-up

0 = Fault lock-out;

1 = Restart

0 = Unlimited;

1 = Limited to 5 minutes

v

1

0

1

▼

BCU 370 · Edition 01.19 40

Page 41

Parameters

Description Parameter Value range Default Adjustable1)

Pre-ignition time t

Switch-on delay time t

VZ

E

Min. gas pressure monitoring 23 0 = Of f; 1 = On 1

Digital input function 24

Valve control 25 0 = Of f; 1 = On 1

Tightne ss controll, test period t

P

V2 during burner operation 27 0 = Off; 1 = On 0

Quick start star ts in... 28

Controller enable signal delay time t

RF

User-defined password 30 0000–9999 XXXX

Bus control activation 31 0 = Of f; 1 = On 1

Bus control limitation 32

The last 10 fault messages 81–90 XX

1)

Adjustable using BCSoft soft ware and a PC opto-adapter. Changes using BCSoft must be verified by scanning the parameters using the

Reset/Information button.

2)

Will not be displayed.

= Adjustable

v = Depends on hardware configuration

21 0–5 s 1 s

22 0–250 s 0 s

0 = –

max.

10; 20;

10 s

26

1 = DG

3 = Tightne ss control

30–250 s

0 = Ignition position;

1 = Closed position

29

0; 10; 20;

30–250 s

0 s

0 = Closed position

1 = Low position

2 = Ignition position

1

v

v

0

2)

v

2

v

BCU 370 · Edition 01.19 41

Page 42

Parameters

4.1 Scanning the parameters

During operation, the 7-segment display shows the pro-

gram step/status.

In addition to the flame signal and the fault history, all

the parameters of the BCU can be scanned in numerical order by repeatedly pressing the Reset/Information

button (for 1 s).

The parameter display is ended 60 seconds after the

last time the button is pressed or by switching off the

BCU.

The BCU displays

The parameters cannot be scanned when the BCU is

switched off or when a fault or warning is displayed.

when the mains switch is off.

4.2 Flame control

The BCU is fitted with a flame amplifier which evaluates

whether an adequate flame signal is supplied by the

burner using a flame rod or UV sensor.

4.2.1 Burner flame signal

Parameter 01

Displays the flame signal in μA.

The BCU measures the flame signal and assesses

whether there is a flame on the basis of the switch-off

threshold.

4.2.2 Burner switch-off threshold

Parameter 02

The sensitivity at which the burner control unit detects

a flame can be set using parameter 02.

As soon as the measured flame signal falls below the

set value (2 to 20 µA), the BCU performs a fault lockout during start-up after the elapse of the safety time or

during operation after the elapse of the safety time during operation (parameter 19).

In the case of UV control, this value can be increased,

should the burner to be monitored be influenced by

other burners for example.

The measured flame signal of the system’s “own” burner

should be at least 3 µA (empirical value) higher than the

set switch-off threshold.

No switch-off threshold will be displayed on the BCU

370..U1 for use with UVC 1.

BCU 370 · Edition 01.19 42

Page 43

Parameters

4.2.3 UVS check (1× in 24 hours)

Parameter 17

Activates an automatic restart of the burner control unit

after 24 hours operating time.

For flame control using a UV sensor for intermittent op-

eration, parameter P17 = 1 must be set to force a restart

after 24 hours of operation to test the UV sensor.

Parameter 17 = 0: unlimited burner operation

Parameter 17 = 1: an automatic restart is activated

once every 24 hours. The restart begins with pre-purge

(parameter 06, “Pre-purge on each start-up” = 1) or

starting the burner in the Ignition position (parameter

06, “Pre-purge on each start-up” = 0).

The time starts each time the start-up signal (ϑ) is applied.

Since the BCU 370 interrupts burner operation autonomously after 24 hours, it is to be verified whether the

process allows for the resulting break in heat supply.

BCU 370 · Edition 01.19 43

Page 44

Parameters

4.3 Behaviour during start-up

4.3.1 Minimum burner pause time tBP

Parameter 11

Determines the minimum burner pause time.

To stabilize the burner operation, a minimum burner

pause time t

control system.

If the start-up signal (ϑ) drops after fan start or if a

safety shut-down occurs, a restart is suppressed for the

duration of the minimum burner pause time t

starts to elapse after expiry of the post-purge time tPN

(parameter 19).

4.3.2 Burner start-up attempts

Parameter 07

This defines the maximum number of possible start-up

attempts of the burner.

For burners which require several start-up attempts

due to longer pipes for example, the BCU can automatically carry out several start-up attempts.

Parameter 07 = 1: one start-up attempt

If a safety shut-down takes place during start-up, e.g.

on account of a flame signal failure, a fault lock-out occurs once the time t

and shows the cause of the fault.

Parameter 07 = 2 – 4: 2 – 4 start-up attempts

can be set independently of the central

BP

, which

BP

has elapsed. The display blinks

SA

If several start-up attempts are set at the works and if

the BCU performs a safety shut-down during start-up,

it closes the valves after the safety time t

has expired

SA

and attempts to start up again. Each start-up attempt

begins with pre-purge. Once the last programmed

start-up attempt has failed, the burner control unit performs a fault lock-out, in case no flame has formed. The

display blinks and shows the cause of the fault.

In accordance with EN 7462 and EN 676 a maximum

of four start-ups are permitted in specific cases if the

safety of the installation is not impaired. Please note

application standards.

NOTE: only 1 start-up attempt is possible for units with

FM or CSA approval.

BCU 370 · Edition 01.19 44

Page 45

Parameters

4.3.3 Switch-on delay time tE

Parameter 22

01

P1 A2

A1 08

t

t

E

GV

03 04

t

PV

t

t

Z1

VZ

t

SA1

06 H0 05 00

t

t

FS1

SA2

H8 07

t

t

FS2

RF

88

1

24

11 DG

9

DG

30

90° ➔ 0

29

0 ➔ 90°

31

32

7 DL

ϑ

21

3

16

13

4

5 V2

6 V3

17-18

19-20

V1

max.

min.

Determines the time between applying the start-up sig-

nal (ϑ) and initiating the burner start.

When several burners are activated simultaneously,

setting different switch-on delay times t

prevents the

E

fans from starting at the same time and reduces the

load on the power supply.

4.3.4 Pre-ignition time t

VZ

Parameter 21

01

P1 A2

A1 08

t

t

t

E

GV

03 04

t

PV

t

t

Z1

VZ

t

SA1

06 H0 05 00

t

t

FS1

SA2

H8 07

t

t

FS2

RF

The ignition unit is activated.

The ignition spark can stabilize in the air flow during the

pre-ignition time t

VZ

.

The valves are still closed during the pre-ignition time

t

. Following pre-ignition tVZ, the safety time t

VZ

starts to elapse. The valves are opened while the ignition unit continues to operate.

1

24

11 DG

9

30

29

31

32

7 DL

21

3

16

13

4

5 V2

6 V3

17-18

19-20

SA1

88

max.

DG

min.

90° ➔ 0

0 ➔ 90°

ϑ

V1

t

BCU 370 · Edition 01.19 45

Page 46

Parameters

4.3.5

1st safety time on start-up, burner/pilot burner t

Parameter 12

01

P1 A2

A1 08

t

t

E

GV

03 04

t

PV

t

t

Z1

VZ

t

SA1

The safety time on start-up t

06 H0 05 00

t

t

FS1

SA2

determines when the

SA1

H8 07

t

t

FS2

RF

pilot burner or burner valves will be closed in the event

of flame signal failure.

V1 and V2 are opened and the ignition unit is activated

as the safety time t

starts to elapse. If no flame

SA1

signal is pending after elapse of the safety time t

the BCU performs a safety shut-down. The valves are

closed. The BCU carries out up to 3 further start-up attempts, depending on how parameter 07 “Burner startup attempts” has been set.

88

1

24

11 DG

9

DG

30

90° ➔ 0

29

0 ➔ 90°

31

32

7 DL

ϑ

21

3

16

13

4

5 V2

6 V3

17-18

19-20

SA1

V1

max.

min.

,

SA1

The setting of safety time t

is to be determined on

SA1

the basis of the burner capacity, the type of control and

the relevant application standard, e.g. EN 7462, EN

676, NFPA 85 or NFPA 86.

1st flame proving period, burner/pilot burner t

4.3.6

Parameter 13

01

P1 A2

A1 08

t

t

t

E

GV

03 04

t

PV

t

t

Z1

VZ

t

SA1

06 H0 05 00

t

t

FS1

SA2

H8 07

t

t

FS2

RF

Determines the flame proving period of the burner or

pilot burner.

This time elapses before the BCU starts the next pro-

gram step so as to give the flame time to stabilize.

The flame proving period t

safety time t

has expired.

SA1

starts to elapse once

FS1

88

1

24

11 DG

9

DG

30

90° ➔ 0

29

0 ➔ 90°

31

32

7 DL

ϑ

21

3

16

13

4

5 V2

6 V3

17-18

19-20

max.

min.

V1

FS1

t

BCU 370 · Edition 01.19 46

Page 47

Parameters

4.3.7 2nd safety time on start-up, main burner t

SA2

Parameter 14

01

P1 A2

A1 08

t

t

E

GV

03 04

t

PV

t

t

Z1

VZ

t

SA1

The safety time on start-up t

06 H0 05 00

t

t

FS1

SA2

determines when the

SA2

H8 07

t

t

FS2

RF

88

1

24

11 DG

9

DG

30

90° ➔ 0

29

0 ➔ 90°

31

32

7 DL

ϑ

21

3

16

13

4

5 V2

6 V3

17-18

19-20

V1

max.

min.

t

main burner valves will be closed in the event of flame

signal failure.

V3 is opened as the safety time t

One second before the end of the safety time t

starts to elapse.

SA2

SA2

, V2

is closed (parameter 27 = 0, “Interrupted pilot burner”)

or remains open (parameter 27 = 1, “Permanent pilot

burner”). If no flame signal is pending after elapse of

the safety time t

, the BCU performs a safety shut-

SA2

down. Valves V1, V2 and V3 are closed. The BCU carries

out up to 3 further start-up attempts, depending on

how parameter 07 “Burner start-up attempts” has been

set.

The setting of safety time t

is to be determined on

SA2

the basis of the burner capacity, the type of control and

the relevant application standard, e.g. EN 7462, EN

676, NFPA 85 or NFPA 86.

4.3.8 2

flame proving period, main burner t

FS2

nd

Parameter 15

01

P1 A2

A1 08

t

t

E

GV

03 04

t

PV

t

t

Z1

VZ

t

SA1

06 H0 05 00

t

t

FS1

SA2

H8 07

t

t

FS2

RF

88

1

24

11 DG

9

DG

30

90° ➔ 0

29

0 ➔ 90°

31

32

7 DL

ϑ

21

3

16

13

4

5 V2

6 V3

17-18

19-20

max.

min.

V1

t

Determines the flame proving period of the main burner

in pilot/main burner combinations.

This time elapses before the BCU starts the next pro-

gram step so as to give the flame time to stabilize.

The flame proving period t

safety time t

has expired.

SA2

starts to elapse once

FS2

BCU 370 · Edition 01.19 47

Page 48

Parameters

t

SA1

4.4 Behaviour during operation

4.4.1 Minimum operating time tB

Parameter 10

Defines the minimum burner operating time.

To stabilize the burner operation, a minimum operating

time can be set independently of the central control

system.

If the start-up signal (ϑ) drops once the first safety time

t

has started to elapse, the burner remains in opera-

SA1

tion for at least time tB. The minimum operating time

tB starts to elapse following controller enable. If the

start-up signal drops before the first safety time t

e.g. during pre-purge, the control unit reverts directly to

standby and the burner is not ignited.

4.4.2 Controller enable signal delay time t

RF

Parameter 29

01

P1 A2

A1 08

t

t

E

GV

03 04

t

PV

t

t

Z1

VZ

06 H0 05 00

t

t

FS1

SA2

H8 07

t

t

FS2

RF

SA1

88

1

24

11 DG

9

DG

30

90° ➔ 0

29

0 ➔ 90°

31

32

7 DL

ϑ

21

3

16

13

4

5 V2

6 V3

17-18

19-20

V1

max.

min.

,

t

Defines the time between start-up of the burner and

controller enable.

The controller enable signal delay time ensures a stable

combustion process, e.g. through uniform heating of

the entire combustion chamber.

The time t

after expiry of if

t

SA1

t

FS1

t

SA2

t

FS2

The BCU shows program status

starts to elapse

RF

t

= 0, t

t

t

SA2

FS2

SA2

SA2

= 0

= 0

> 0, t

= 0

FS1

> 0

FS1

t

> 0, t

FS1

H8

. After time tRF has elapsed,

the BCU closes the operation signalling contact (terminals

17/18) and activates controller enable (terminal 25).

4.4.3 Safety time during operation t

SB

Parameter 09

Defines the safety time during operation t

for valves

SB

V1, V2 and V3.

If there is a flame failure while the burner is operating, the

BCU closes the valves within the safety time during operation t

. The default in accordance with EN 298 is 1 s.

SB

The safety time during operation tSB can also be set to 2 s.

Prolonging the time increases the installation availability

in the case of brief-duration fades of the flame signal.

The safety time of the installation during operation (in-

cluding closing time of the valves) may not exceed 3 s in

accordance with EN 7462 or 4 s in accordance with NF

PA 85 and NFPA 86. Please note application standards.

BCU 370 · Edition 01.19 48

Page 49

Parameters

4.4.4 Restart after flame failure during operation

Parameter 08

Determines whether a restart will be attempted follow-

ing a safety shut-down during operation.

For burners with occasionally unstable flame signals

during operation, a one-off restart can be attempted.

Parameter 08 = 0: Off. A fault lock-out will occur in the

event of a flame failure during operation

In the event of an installation fault (e.g. flame failure or

air pressure failure), the burner control unit performs a

fault lock-out within the safety time during operation

t

. This involves disconnecting the power from the gas

SB

valves. The fault signalling contact closes, the display

blinks and shows the current program status, see page

79 (Status and fault messages for PROFIBUS DP).

Parameter 08 = 1: On. A restart will take place after a

flame failure during operation.

If the BCU detects an installation fault (e.g. flame failure) after the second flame proving period has elapsed,

the valves are closed and the operation signalling contact is opened within time t

. The burner control unit

SB

now attempts to restart the burner once. The restart

begins with pre-purge. For further restart attempts, the

burner must have been operational for at least 2 seconds.

If the burner does not function, a fault lock-out occurs.

The display blinks and shows the cause of the fault.

In accordance with EN 7462 and EN 676, a restart

may be attempted under certain conditions. The safety

of the system must not be impaired. Please note application standards.

4.4.5 Last fault signal

Parameter 03

The BCU shows the last fault message.

In order to analyze a burner system, the last fault message can be called up. In addition, parameters 81 to 90

show the last 10 messages. Extended diagnostics is

possible using the BCSoft software.

BCU 370 · Edition 01.19 49

Page 50

Parameters

4.4.6 V2 during burner operation

Parameter 27

Determines whether valve V2 is switched off 1 s before

the end of the second safety time t

On systems with pilot burners, the pilot burner can be

switched off once the main burner is operational.

Parameter 27 = 0: valve V2 is switched off 1 s before the

end of the second safety time t

SA2

this occurs at the end of the first flame proving period

t

or at the end of the first safety time t

FS1

This setting is required for pilot/main burner systems

where the pilot burner does not ignite the main burner

safely in each operating status.

Parameter 27 = 1: valve V2 remains open during the en-

tire burner operation. This setting is valid for directly ignited burners (t

= 0) and pilot/main burner systems

SA2

with permanent pilot burner.

SA2

. (If t

.

is set to 0,

SA2

SA1

if t

FS1

= 0).

BCU 370 · Edition 01.19 50

Page 51

Parameters

4.5 Monitoring/tightness control

4.5.1 Min. gas pressure monitoring

Parameter 23

Determines whether the minimum gas pressure DG

is monitored.

To ensure that there is adequate gas pressure on the

burner, the pressure can be monitored using the gas

pressure monitor DG

min.

.

Monitoring takes place in the start-up position/standby,

during burner start-up or during burner operation. If

the signal is not applied, a locking warning signal is

triggered and the display shows

X

, “Fault DG

program step X”. When the signal is applied again, the

BCU 370 attempts to restart the burner, provided the

start-up signal (ϑ) is applied.

The requirement for monitoring of the minimum gas

pressure is stipulated in the relevant application standard.

min

min.

. in

4.5.2 Digital input function

Parameter 24

Defines the function of the input on terminal 11.

Parameter 24 = 0: input has no function.

Parameter 24 = 1: monitoring of the maximum gas

pressure DG

max.

.

To ensure that the permissible gas pressure on the

burner is not exceeded, the pressure can be monitored

using the gas pressure monitor DG

max.

.

Monitoring takes place in the start-up position/standby,

during burner start-up or during burner operation. If

the signal is not applied, a fault lock-out occurs and the

display shows

X

, “Fault DG

in program step X”.

max.

Parameter 24 = 3: monitoring of the pressure switch

between V1 and V2/V3 for tightness control (only on

BCU..D3). See Function – Tightness control.

BCU 370 · Edition 01.19 51

Page 52

Parameters

4.5.3 Air monitoring during pre-purge

Parameter 04

This parameter is activated automatically if parameter