Page 1

Modutrol Motor M7484A

The M7484A is a low voltage, reversing proportional modutrol motor used to drive a fuel

valve and combustion air damper as commanded

by the BCS 7700.

BCS 7700

■ Electronic, vibration resistant drive circuit.

■ Requires 24 Vac power supply.

■ Die-cast aluminum case.

■ Feedback potentiometer circuit provides position

indication input to the BCS 7700.

■ Motor stroke is fixed 90˚, 30 second timing.

■ Low and High Fire position proving feedback

potentiometer circuit.

■ 150 lb.-in. torque.

■ Accessories include weather proofing kit.

CONTENTS

Specifications ................................................2

Ordering Information.................................... 2

Installation .................................................... 4

Operation and Checkout ...............................6

T.M. • Rev. 7-92 • © Honeywell Inc. 1992 • Form Number 63-2273—1

Page 2

M7484A

SPECIFICATIONS • ORDERING INFORMATION

Internal

Electronic Internal

Drive Auxiliary

Model Timing Circuit Switch

M7484A1010 30 sec Yes No

CRANKSHAFT: Double ended, 3/8 inch square.

STROKE: 90˚ fixed.

TORQUE: 150 lb.-in.

Timing Normal

[Nominal] Running Breakaway

90° Stroke Torque Torque

30 sec 150 lb.-in. 300 lb.-in.

a

Maximum torque available to overcome occasional

large loads such as seized damper or valve. MUST NOT

BE USED CONTINUOUSLY AT THIS RATING.

DEADWEIGHT LOAD ON SHAFT:

Power End: 200 lb. [91 kg] maximum.

Auxiliary End: 200 lb. [45 kg] maximum.

ELECTRICAL RATINGS:

Terminal Description Rating

G Common

(Negative Supply)

Y • Power Supply from 8.0V

BCS 7700 +/- 0.050 Vdc

• Overvoltage 9.0 Vdc

continuous maximum

T Signal to BCS 7700 1.5-5.5 Vdc

1 Modutrol Motor closed 24 Vac

2 Modutrol Motor open 50/60 Hz

3 Modutrol Motor common

Current Draw: 0.8A at 24 Vac.

Power Consumption: 18W.

Specif ications

ENVIRONMENTAL RATINGS:

Ambient Temperature:

Operating: 32° F to 150° F.

Storage: -30° F to 150° F.

Humidity:

Operating: 85% RH continuous, noncondensing.

Vibration: Continuous 0.5G environment.

Dimensions: See Fig. 1.

ACCESSORIES:

DHE-94 Explosion-proof Housing— encloses motor

for use in explosive atmospheres. Not for use with

Q601 and Q455 Linkage. Requires 7617DM Coupling and 220738A Adapter Bracket.

a

Q607 Auxiliary Switch—controls auxiliary equipment

as a function of motor position. (Requires use of

220738A Adapter Bracket.)

Q605 Damper Linkage—connects motor to damper;

includes motor crank arm.

Q601 Linkage—connects motor to water or steam

valve.

Q618 Linkage—connects motor to water or steam

valve.

Q100 Linkage—connects motor to butterfly valve.

(Requires use of 220738A Adapter Bracket.)

Q181A Auxiliary Potentiometer—used to control aux-

iliary motor.

4074ERU Weatherproofing Kit—weatherproofs the

motor.

7617ADW Motor Crank Arm—included with Q605

but not with motor.

220741A Screw Terminal Adapter—used to convert

motor quick-connect terminals to screw terminals.

220738A Adapter Bracket—adjusts shaft height of

M7484A to match M741B.

Ordering Inf ormation

When purchasing replacement and modernization products from your wholesaler or your distributor, refer to the price sheets for

complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or phone:

1. Your local Honeywell Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Satisfaction

Honeywell Inc., 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386 (612) 542-7500

In Canada—Honeywell Limited/Honeywell Limitee, 740 Ellesmere Road, Scarborough, Ontario M1P 2V9 International Sales

and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany, Japan,

Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

2

Page 3

Fig. 1—M7484A dimensions in in. [mm].

4.88

124]

5.5

[140]

M7484A

SPECIFICATIONS

WIRING

BOX

BASE

MOTOR

AUXILARY

END

ADAPTER

BRACKET

.27

.50

[7]

.60 [15]

.96

[24]

4.06 [103]

1.5 [38]

7.3 [185]

[13]

2.4 [61]

.80

[20]

1.47 [37]

.76 [19]

POWER

END

2.59

[66]

5.39

[137]

.75

[19]

6.45

[164]

2.50 [64]

1.25 [32]

.15

[4]

1.75

[44]

M2616

3 63-2273—1

Page 4

M7484A

INSTALLATION

WHEN INSTALLING THIS PRODUCT…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

CAUTION

!

1. Disconnect power supply before beginning

installation to prevent electric shock or equipment damage. More than one disconnect may

be required to be opened to remove all power.

2. Do not attempt to turn the motor shaft by hand

or with a wrench. Damage to the gear train

will result.

LOCATION

Install the motor in any location except where acid

fumes or other deteriorating vapors might attack the metal

parts, or in atmospheres of escaping gas or other explosive

vapors. The M7484A is rated for temperatures between

32°F to150° F. If located outdoors, use weatherproofing

kit; see Accessories section.

Allow enough clearance for installing accessories and

servicing the motor when selecting a location. See Fig. 1.

MOUNTING

Always install the motor with the crankshaft horizontal. Mounting flanges extending from the bottom of the

motor housing are drilled for 1/4 in. machine screws or

bolts.

The M7484A is shipped from the factory in the closed

position, which is the limit of counterclockwise rotation as

viewed from the power end of the motor, see Fig. 2.

Fig. 2—Motor shaft position at rotational limits

as viewed from the power end of the motor.

VERTICAL

REFERENCE

45°

FULL

CLOSED

90°

FULL

OPEN

90 DEGREE STROKE

E2390

Installation

INSTALLING LINKAGES

A crank arm is not included with the motor.

In general, check the following points of operation

when installing a motor and linkage:

1. Adjust linkages for valves and louver type dampers

adjust so that the damper or valve moves through only the

maximum required distance when the motor moves through

its full stroke.

2. Stop the motor at the end of its stroke by using

internal travel limit switch; do not stall the motor by using

the damper or valve. CAUTION: The motor will be

damaged if it is not permitted to complete its full stroke.

3. For any installation, do not exceed the motor ratings.

WIRING

Disconnect power supply before wiring to prevent

electrical shock or equipment damage. More than one

disconnect may be required to be opened to remove all

power.

1. Be sure all wiring agrees with applicable codes,

ordinances, and regulations.

2. Make sure that the voltage and frequency stamped

on the motor correspond to the characteristics of the power

supply.

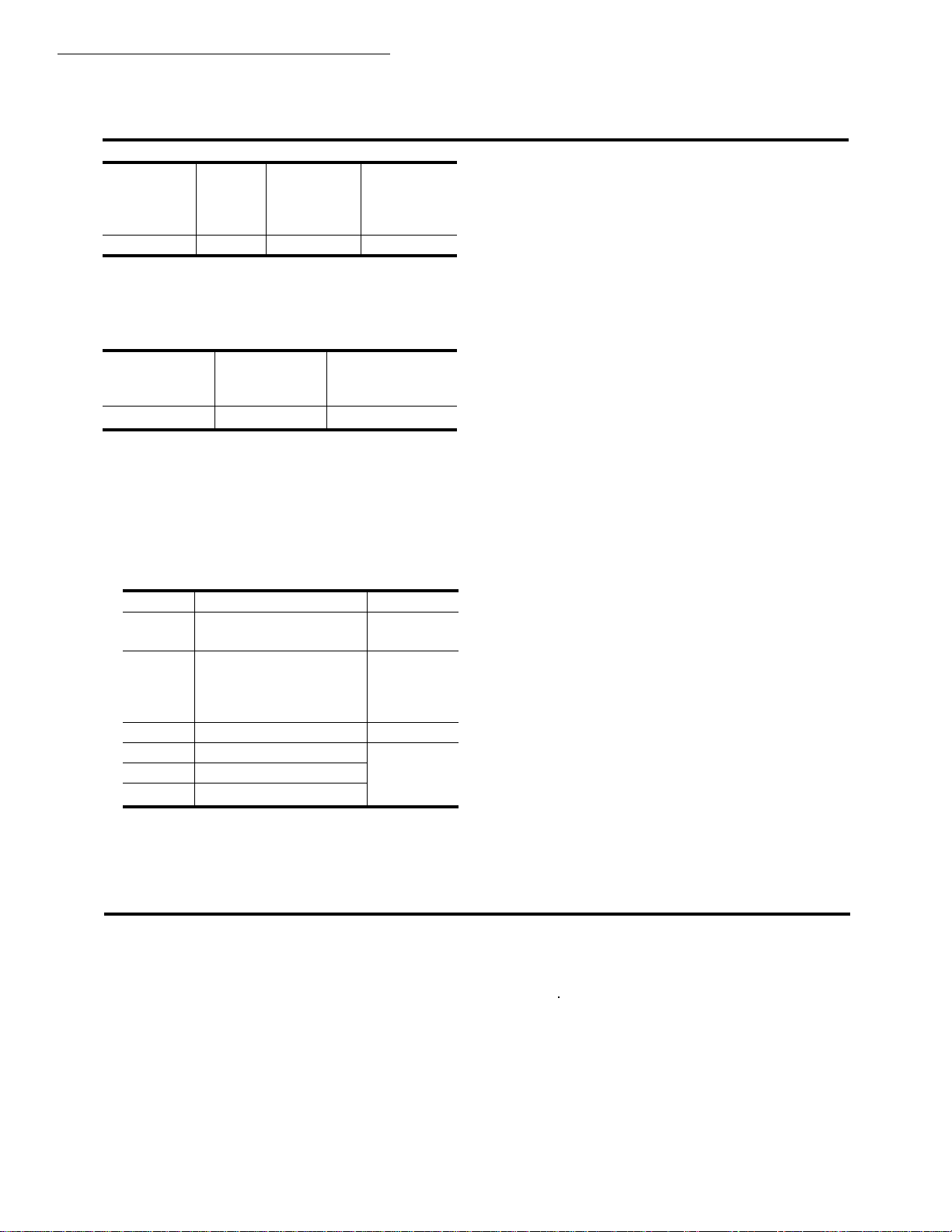

3. See Fig. 3 for the internal schematics and terminal

connections to the M7484A motor.

4. Use the recommended wire size and type:

• Terminals 1, 2, and 3 require No. 18 wire insulated

for voltages and temperatures encountered in the

application. Suggested conductor types include

TW[60C], THW [75C] and THHN [90C].

• Terminals G, T, and Y for the motor position indi-

cation circuit require a shielded three conductor

cable that is UL listed for temperatures and voltages

encountered in the application. Suggested cables

include Belden 9365 rated for 300V, 105° C or

Belden 8770 rated for 300V, 60° C.

5. Do not connect the shield to anything at the motor

end; tape the shield to avoid any unintended contact with

the motor housing. At the BCS 7700 end, ground the

shield to the control panel with as short as practical lead

wire length.

6. Do not route the feedback potentiometer circuit

leadwires in conduit with line voltage circuits.

7. Avoid routing the feedback potentiometer circuit

leadwires close to the ignition transformer leadwires.

8. Feedback potentiometer (low voltage) circuit leadwires can be routed outside of conduit if properly supported and protected from damage.

9. Maximum feedback potentiometer circuit leadwire

length of 100 feet.

10. Complete the required checkout as indicated in this

specification and return the system to normal operation.

4

Page 5

M7484A

INSTALLATION

Fig. 3—BCS 7700 internal block wiring diagram.

OIL

GAS

55

RELAY

DRIVE

CIRCUIT

RESET

PUSHBUTTON

RUN-TEST

SWITCH

A

B

RS485

C

L1

PREINGINTION

INTERLOCKS

BURNER

SWITCH

KEYBOARD AND DISPLAY

LIQUID CRYSTAL DISPLAY

A

B

RS485

C

50

51

OPTOISOLATOR

INPUTS

6K1

RECYCLE

LIMITS

52

53

11K1

54

56

10K1

DIGITAL

MONITOR

DIGITAL

MONITOR

MICROCOMPUTER

10K

11K

RELAY

DRIVE

CIRCUIT

5

7

6

KEYBOARD

OPTOISOLATOR

INPUTS

24VDC

OIL SELECT

GAS SELECT

MICROCOMPUTER

PROGRAM MODULE AND

CHASSIS MODULE INTERFACE

2K

3K

4K

6K

7K

8K

4

LOCKOUT

INTERLOCKS

ALARM

RELAY

INDICATES FEEDBACK SENSING TO

OPTOISOLATORS

OIL LINE

PURGE VALVE

ATOMIZING AIR

COMPRESSOR

MOTOR STARTER

TEMPERATURE

SENSOR

AMPLIFIER

SENSOR

POWER

SUPPLY

ANALOG

TO

DIGITAL

CONVERTOR

PLUG IN

9K

FLAME

AMPLIFIER

8

F1, 10A

120VAC

24VAC

L1

(HOT)

3

120 VAC

SAFETY

1K

RELAY

CIRCUIT

BURNER

MOTOR

STARTER

1K1 4K1

40VA

L2

SIGNAL

32

COMMON

33

SIGNAL

34

COMMON

35

POWER (RED)

36

SIGNAL (BLUE)

37

COMMON (BLACK)

38

POWER

39

SIGNAL

40

COMMON

41

POWER (RED)

42

SIGNAL (BLUE)

43

COMMON (BLACK)

44

POWER (RED)

45

SIGNAL (BLUE)

46

COMMON (BLACK)

47

FIRING

RATE

10

3K1

11

ATOMZING

AIR PROVING

SWITCH

2K1

12

WATER TEMP.

SENSOR / CONFIG. ANALOG

OIL TEMP.

SENSOR

STEAM

PRESSURE

SENSOR /

CONFIG.

ANALOG

OIL

PRESSURE

SENSOR

GAS

PRESSURE

SENSOR

24

25

26

27

28

29

1

30

31

IGNITION

TRANSFORMER

OIL MAIN

VALVE

16

GAS PRESSURE

SENSOR TEST VALVE

GAS MAIN

VALVE

FIRING RATE MOTOR

OPEN

3

CLOSE

PILOT

VALVE

EARTH GROUND

E

49

15

9K2

ALARM

14

L2

9K1

2

FLAME

DETECTOR

13

7K2

7K1

2

2

2

2

2

2

1

G

T

Y

20

8K2

19

8K1

18

23

22

21

1

WIRING SHOWN FOR INFRED FLAME DETECTOR FOR C7027

ULTRA VIOLET FLAME DETECTOR WIRE AS NOTED BELOW

– ULTRA VIOLETDECTECTOR BLUE LEAD - TERMINAL 31

– ULTRA VIOLET DETECTOR WHOTE LEAD - TERMINAL 30

THE ULTRA VIOLET FLAME DETECTOR WIRING IS POLARITY SENSITIVE,

REVERSING THE LEDS WIRES MAY DAMAGE THE SENSOR.

FOR ULTRA VIOLET C7012E,F WIRE AS NOTED BELOW:

– BLUE LEAD - TERMINAL 31 – YELLOW LEAD - TERMINAL 29

– WHITE LEAD - TERMINAL 27 – WHITE LEAD - L2

– BLACK LEAD - L1 – BLACK LEAD - L2

WIRE THESE TERMINALS WITH SHIEDLED CABLE PER SPECIFICATION. THE CABLE SHIELD

2

SHOULD NOT BE CONNECTED AT THE SENSOR END AND SHOULD BE TAPED TO AVOID

UNINTENTIONAL CONTACT. AT THE BOILER CONTROLLER END, THE SHIELD WIRES MUST BE

GROUNDED TO THE CONTROL PANEL WITH AS SHORT AS POSSIBLE A LEAD LENGTH.

5 63-2273—1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

3

AND OVERLOAD PROTECTION AS REQUIRED.

DO NOT CONNECT WIRES TO ANY UNUSED TERMINALS.

4

TERMINALS 9, 17, 21, 22, 23, 28, 48 ARE NOT USED.

POWER SUPPLY FOR SYSTEM SENSORS.

5

FIELD WIRING INTERNAL CIRCUITRY.

6

M580A

Page 6

M7484A

OPERATION AND CHECKOUT

Operation and Check out

OPERATION

The M7484A is a fixed 90° stroke nonspring return

motor. An internal sensing circuit incorporates a feedback

potentiometer in a bridge circuit. The feedback potentiometer circuit output is proportional to the mechanical

shaft position. An 8 Vdc power source from the BCS 7700

is required for circuit operation.

The M7484A is driven by applying 24 Vac to either the

open or closed motor coils. Position control is accom-

plished by using the BCS 7700 to monitor the feedback

potentiometer circuit and energize or de-energize the

drive coil(s) to achieve the required position.

CHECKOUT

After installation and linkage adjustment, check the

entire motor and control hookup to prove that:

— the motor properly operates the damper or valve.

— the motor properly responds to the BCS 7700.

Inspect the motor, linkage and valve or damper to

determine that all mechanical connections are correct and

secure. Be sure the pushrod does not extend more than a

few inches past the ball joints. Check to be sure there is

adequate clearance for the linkage to move through its

stroke without binding or striking other objects.

The M7484A is shipped in the fully closed position (the

limit of counterclockwise rotation as viewed from the

power end of the motor).

To check operation of the M7484A:

1. Place the BCS 7700 in Standby; open the Burner

Switch.

2. Place the RUN/TEST Switch in the TEST position.

3. Place the BCS 7700 in the Manual mode using the

AUTO/MANUAL key of the Keyboard and Display Module.

4. Place the cursor in the Keyboard and Display Module Liquid Crystal Display beneath % Rate, using the (<)

key.

5. Using the Keyboard and Display Module (+ or - )

keys, under manual control, drive the motor through its

entire stroke to assure the motor is responding to the BCS

7700 commands.

6. While manually adjusting the motor position, observe the position of the motor, as displayed on the

Keyboard and Display Module, to assure proper operation

of the feedback potentiometer circuit.

Home and Building Control Home and Building Control Helping You Control Your World

Honeywell Inc. Honeywell Limited—Honeywell Limitée

1985 Douglas Drive North 740 Ellesmere Road

Golden Valley, Minnesota 55422 Scarborough, Ontario

M1P 2V9

Printed in U.S.A.

QUALITY IS

KEY

Loading...

Loading...