Page 1

Burner Control System

BCS 3600

CONTENTS

Safety ........................................1

General Information

Receiving and Inspection

Installation

Adjustment

.....................................2

....................................2

Final Checkout

Panel Operation

Assistance in the event of malfunction

Human Machine Interface (HMI) Screens

Control motor slidewire calibration

UDC3200 Series Controller

Temperature controller configuration record sheet

High Temperature Limit

Exhaust Fan Flow Limit Switch Installation

Stack Thermocouple Installation

Material thermocouple installation

Recommended spare parts

Converting units

..............................1

.........................2

.................................3

................................3

................4

..............4

...................5

........................6

.......7

...........................8

.............9

...................10

..................11

.......................12

...............................12

OPERATING INSTRUCTIONS

Edition 11.19· ·

SAFETY

32-00248

WARNING

– This equipment is potentially dangerous with the possibility of

serious personal injury and property damage. Hauck Manufacturing Company recommends the use of flame supervisory

equipment and fuel safety shutoff valves. Furthermore, Hauck

urges rigid adherence to National Fire Protection Association

(NFPA) standards and insurance underwriter’s requirements.

Operation and regular preventative maintenance of this

equipment should be performed only by properly trained and

qualified personnel. Annual review and upgrading of safety

equipment is recommended.

– These instructions are intended for use only by experienced,

qualified combustion start-up personnel.

– Adjustment of this equipment and its components, by

unqualified personnel, can result in fire, explosion, severe

personal injury, or even death.

GENERAL INFORMATION

The Hauck Burner Control System (BCS) provides burner management and temperature control of a single pilot ignited burner firing

on gas, oil or liquid propane (LP). The spark ignited, gas fired pilot is

interrupted after the main burner flame has been established. Flame

supervision is provided by a Honeywell RM7890A1056 flame relay

combined with a R7849A1023 amplifier module and one or two

C7027A1049 UV scanners.

A Programmable Logic Controller (PLC) supervises burner operation

and is coupled to a Human Machine Interface (HMI) to provide the

operator with system status and fault annunciation.

A Honeywell UDC3200 series microprocessor based instrument is

provided for temperature control. The controller is electronically linked

to the burner control motor to automatically adjust the burner firing

rate and maintain process temperature near the controller’s setpoint.

The Temperature Controller’s thermocouple senses the temperature

of the material or exhaust gases as it exits the dryer, depending on

where it’s positioned. The controller generates a position proportional

output based on the difference between the setpoint and the process

temperature input.

The control MODE selector switch enables the operator to assign

control of the burner. The center, LOW FIRE, position of this switch is

used to hold the burner at low fire. The right, MAN (manual) position

enables the operator to increase (INC) or decrease (DEC) the burner

position via the MANUAL switch. The left, AUTO position uses the

Temperature Controller to operate the burner.

GB – www.docuthek.com

Page 2

The limit contact of the High Temp Limit instrument is used to shut

1

2

3

down the burner if the preset high temperature limit is exceeded.

An alarm contact is also used to alert the Operator when the stack

temperature nears the limit setting. Refer to HIGH TEMPERATURE

LIMIT for entering the desired alarm setpoints.

High temperature limits will not prevent baghouse fires. They will,

when properly installed and adjusted shut off the burner when the

limit’s temperature setpoint is exceeded. Outside factors such as

chemicals, bag contamination or other ignition sources are beyond

the control of the burner management system.

CAUTION

– The HIGH TEMP LIMIT setpoint is factory set at 400°F

(204°C). If the system is equipped with a fabric dust collector

(baghouse), consult the manufacturer for recommended

baghouse temperature limitations.

Part designations

1 UDC3200 Temperature Controller

2 High Temperature Limit

3 Human Machine Interface (HMI) Screens

RECEIVING AND INSPECTION

Upon receipt, check each item on the bill of lading and/or invoice to

determine that all equipment has been received. Examine all parts to

determine if there has been any damage in shipment. If equipment is

to be stored prior to installation, provide a dry storage area.

INSTALLATION

➔

For optimum use of the BCS panel, it is suggested that the drawings provided by Hauck be referred to for limit switch and valve

installation and wiring. In the event that a recommended switch or

valve is not used, it may be necessary to connect jumper wire(s)

between appropriate terminals in the control panel or burner

junction box. Such determination remains the responsibility of the

Customer, based upon his application, accepted safe installation

and operating procedures, and any applicable insurance guidelines

or governmental regulations.

➔

Locate the tabletop panel on a firm support in an area that is

protected from the weather and free from vibration. The drop-in

version is designed to install in an existing enclosure. Reference

the panel assembly drawings for mounting dimensions and required cutouts.

WARNING

– A ground wire is also required between the burner junction

box and the control panel terminal strip.

3

Determine the burner control motor type and install one of the

following jumpers:

a. From fuse 5 to Ground for a sinking type motor, Barber-Cole-

man EA57 medium torque.

b. From fuse 5 to 7A for a sourcing type motor, Barber-Coleman

EA71 or EA73 high torque.

➔ If the burner control motor needs to be driven open until purge

time is completed the control needs to be configured. See page

2 (Adjustment) for instructions.

4

Wire the fuel valves, valve position limit switches and fuel pressure

limit switches as shown on the external component wiring diagram.

5

Install the exhaust fan flow limit switch in the dryer exhaust duct

as shown in page 9 (Exhaust Fan Flow Limit Switch Installation) . Wire the normally open contact of the exhaust flow limit to

the appropriate terminals in either the burner junction box or the

BCS control panel.

6

Install a limit switch on the exhaust damper set to close when the

damper is greater than 50% open.

7

Install the stack temperature thermocouple in the dryer exhaust

duct to sense exhaust gas temperature. See page 10 (Stack

Thermocouple Installation) for installation instructions.

8

Install a Hauck Rapid Response material temperature thermocouple in the material discharge chute to sense the temperature

of the material leaving the dryer. See page 11 (Material thermocouple installation) for recommended installation.

9

Connect the thermocouples to the appropriate terminals in the

BCS control panel using thermocouple cable of the same type

as the Material and Stack thermocouples.

10

Install the pilot (if applicable) and main flame scanner(s) on the

burner and wire them to the appropriate terminals in the burner

junction box. Reference burner instructions for scanner installation

details.

11

Refer to the external component wiring diagram for interconnection between the burner junction box and the BCS panel terminal

strips.

ADJUSTMENT

1

Set the purge timer for the required purge time and whether the

control motor needs to be open during the purge cycle.

a

With the control power ON push the F4 (SETUP) button on the

HMI.

WARNING

– Operating specifications of 32 to 130°F (0 to 54°C), 30 to

95% relative humidity (non-condensing) should be considered

in selecting a suitable location for the control panel.

1

Provide 120Vac single phase grounded neutral power to the

burner control panel. It is recommended that the customer provide

a master disconnect switch to interrupt power service to the

panel. Maintain polarity as indicated on the drawings provided

when connecting the main power source to the panel.

2

Install a heavy gauge (No. 12 AWG minimum) ground wire between

the panel ground connector and "Earth" ground.

b

Push the SERVICE button on the HMI screen.

2

BCS 3600 · Edition 11.19 · EN

Page 3

c

Enter the service password using the keypad on the HMI.

WARNING

– Before igniting the burner, the dryer must be purged to remove

possible accumulation of combustible gases. A minimum of

four complete air changes must be supplied. Multiply the total

system volume (dryer, baghouse and exhaust ducts) in cubic

feet by four. Divide this value by the low fire air flow in cubic

feet per minute. The result will be the required purge time in

minutes

2

Perform the fuel motor calibration procedure described in page

5 (Control motor slidewire calibration).

➔ Recalibrate annually or whenever a control motor is serviced or

replaced.

3

Verify that all low fire limit switch contacts are closed when the

burner is at 0% and open when the burner leaves low fire. Reference the burner operating instructions for switch adjustment.

4

Verify that all purge permissive contacts are closed after the burner control motor drives open for purge (Sealed-in burners only).

FINAL CHECKOUT

1

Ensure sure that all equipment and components have been installed in accordance with the manufacturer's instructions.

2

Verify all wiring and tighten connections.

3

Confirm all linkage adjustments and insure that control arms and

linkage rods are tight.

4

Clean all traps and filters.

5

Check all fuel and air supply lines for leaks.

6

Verify all pressure settings.

d

Enter the amount of time needed to complete the purge cycle,

in seconds, into the purge timer window by selecting the PURGE

TIMER field and entering the time using the keypad on the HMI.

e

If the control motor needs to be open during the purge cycle turn

on the HIGH FIRE PURGE by touch the switch symbol.

f

Push the MAIN soft key to exit the SERVICE screen.

BCS 3600 · Edition 11.19 · EN

PANEL OPERATION

1

Open applicable manual shutoff valves to supply air and fuel to

the system.

2

Twist to release the EMERGENCY STOP button and verify that

the FUEL selector switch is in the desired position.

a

The Temperature Controller, High Temperature Limit and flame

relay will perform their self-test procedures.

b

The burner control motor will drive to its low fire position.

c

The RESET indicator will come on.

d

A “BURNER STOPPED” message will appear

3

Start the combustion air and exhaust fans and all other equipment

required for plant operation. After all safety limits have closed, a

“PRESS RESET TO START PURGE” message will appear.

4

Place the control MODE selector in the desired position and

verify setpoints of both the Temperature Controller and High Temperature Limit(s).

5

Momentarily press the RESET button to initiate the system purge

sequence.

a

Run Relay, CR102, will be energized.

b

The RESET indicator will go out.

c

If HIGH FIRE PURGE was setup in the SERVICE screen the burner control motor will drive open to prepare for system purge and

a “WAITING FOR PURGE LIMITS” message may appear (Sealedin burners only).

6

Provided that all purge permissive contacts are closed:

a

The Purge Timer will begin its timed delay, and a “PURGING …

SECONDS” message will appear.

7

After the purge delay, has been completed:

a

The PURGE COMPLETE relay, CR228, will be energized.

b

The burner control motor will drive closed to prepare for pilot

ignition (Sealed-in burners only).

c

A “WAITING FOR LOW FIRE LIMITS” message may appear.

8

When the motor has reached its low fire start position and the

burner low fire limit switches have closed:

a

“READY to START” will be displayed.

b

The START pushbutton will flash indicating that the burner is ready

to start.

9

Momentarily press the START pushbutton to begin the burner

ignition sequence

3

Page 4

a

Start Relay, CR320, will be energized.

b

The RM7890A flame relay will be energized and perform its safe

start check.

c

“IGNITING PILOT” will be displayed and the ignition transformer

and pilot solenoid valves will be energized.

10

If a satisfactory pilot flame is detected by the UV scanner:

a

Flame signal strength will be displayed on the HMI

b

A “PILOT ON” message will appear.

c

The ignition transformer will be de-energized.

d

Power will be supplied to the main fuel valves.

e

“MAIN VALVES ON” followed by “MAIN FLAME TRIAL” will be

displayed as the flame relay performs a 10 second main flame

trial for ignition.

11

After the ignition trial, has completed, the pilot solenoids will be

de-energized and the pilot will go out.

12

When a 10 second internal timer has been completed:

a

The pilot scanner will be de-energized, (If applicable).

b

The burner control motor will be released from low fire, and respond to the motor positioning outputs of the temperature controller.

13

Start material flow to the dryer. Use the ▲ and ▼ keys of the

Temperature Controller to manually control the burner firing rate,

or press the MANUAL/AUTO key on the controller to begin automatic temperature control.

➔ The center, LOW FIRE, position of the MODE switch will return

the burner to its low fire position.

➔

In the event of a Temperature Controller failure, the MAN. (MANUAL) position of the control MODE selector will enable the Operator

to increase (INC) or decrease (DEC) the burner via the MANUAL

INC/DEC switch.

14

To terminate burner operation, press the STOP pushbutton.

a

Run Relay, CR102, will be de-energized and the RESET indicator

will come on.

b

Purge Complete relay, CR228, and Start Relay, CR320, will be

de-energized and a “BURNER STOPPED” message will appear.

c

The Honeywell RM7890 flame relay will be de-energized.

d

All fuel valves will be de-energized.

e

The burner control motor will drive closed.

ASSISTANCE IN THE EVENT OF MALFUNCTION

?

No power to instruments or indicators.

• Check for 120Vac between L1 and L2. Reset circuit breaker.

?

“WAITING FOR PURGE LIMITS”

• Check purge limits series: 120Vac on terminals 19, 24C,

24B, 24A and 24.

?

“WAITING FOR LOW FIRE LIMITS”

• Check low fire series: 120Vac on terminals 19, 21B, 21A and

21.

?

"IGNITION FAILURE RESET REQUIRED”

• Verify operation of pilot solenoids and ignition transformer.

Check pilot adjustment and fuel supply.

• Check for 120Vac on terminals 8 and 9.

• Replace flame relay.

?

FLAME RELAY FAULT RESET REQUIRED

• Verify pilot and main burner setup.

• Clean UV scanner lens and verify operation.

?

“EXHAUST FAN FAULT”

• Monitor module 1 input 2. Check exhaust flow switch (terminal 12) and exhaust fan interlock (terminal 13)

?

“COMBUSTION AIR FAULT”

• Monitor module 1 input 3. Check combustion air interlock

(terminal 14) and air pressure switch (terminal 16)

?

“LOW GAS PRESSURE”

• Monitor module 1 input 4. Verify that the manual gas valve is

open and that the low gas pressure switch is made (120Vac

on terminal16A)

?

“HIGH GAS PRESSURE”

• Monitor module 1 input 7 and the high gas pressure switch is

made (120Vac on terminal18)

?

“OIL PRESSURE FAULT”

• Monitor module 1 input 5. Verify that the manual valve is

open and that the low and high pressure switches are made

(120Vac on terminal17A)

?

“ATOMIZING AIR FAULT”

• Monitor module 1 input 6. Verify that compressed air is available and that the supply pressure switch is made (120Vac on

terminal17C)

?

“OIL TEMPERATURE FAULT”

• Monitor module 1 input 7. For heavy oil systems, verify that

oil heater is operating and that both the low and high oil

temperature switches are made (120Vac on terminal18)

?

“COMPRESSED AIR FAULT”

• Monitor module 2 input 3. For oil firing with compressed air

atomization, the compressed air pressure switch must close

within 5 seconds after the compressed air solenoid is energized (120Vac on terminal 30A)

?

“HIGH LIMIT FAULT”

• Monitor module 2 input 2. (120Vac on terminal 26) Observe

the display and OUT indicator of the High Temp Limit instrument. “OPEN” indicates an open TC or broken wire. The

instrument must be manually reset by pressing the RESET

key.

?

“STACK TEMP NEAR LIMIT”

• Warns the Operator that the High Limit instrument is nearing

the High Limit setpoint (factory set at 380 F). Manually decrease the burner firing rate or increase material feed rate to

avoid burner shutdown.

?

PURGE TIMER NOT SET

• Warns the operator that the internal purge timer has not

been set in the PLC.

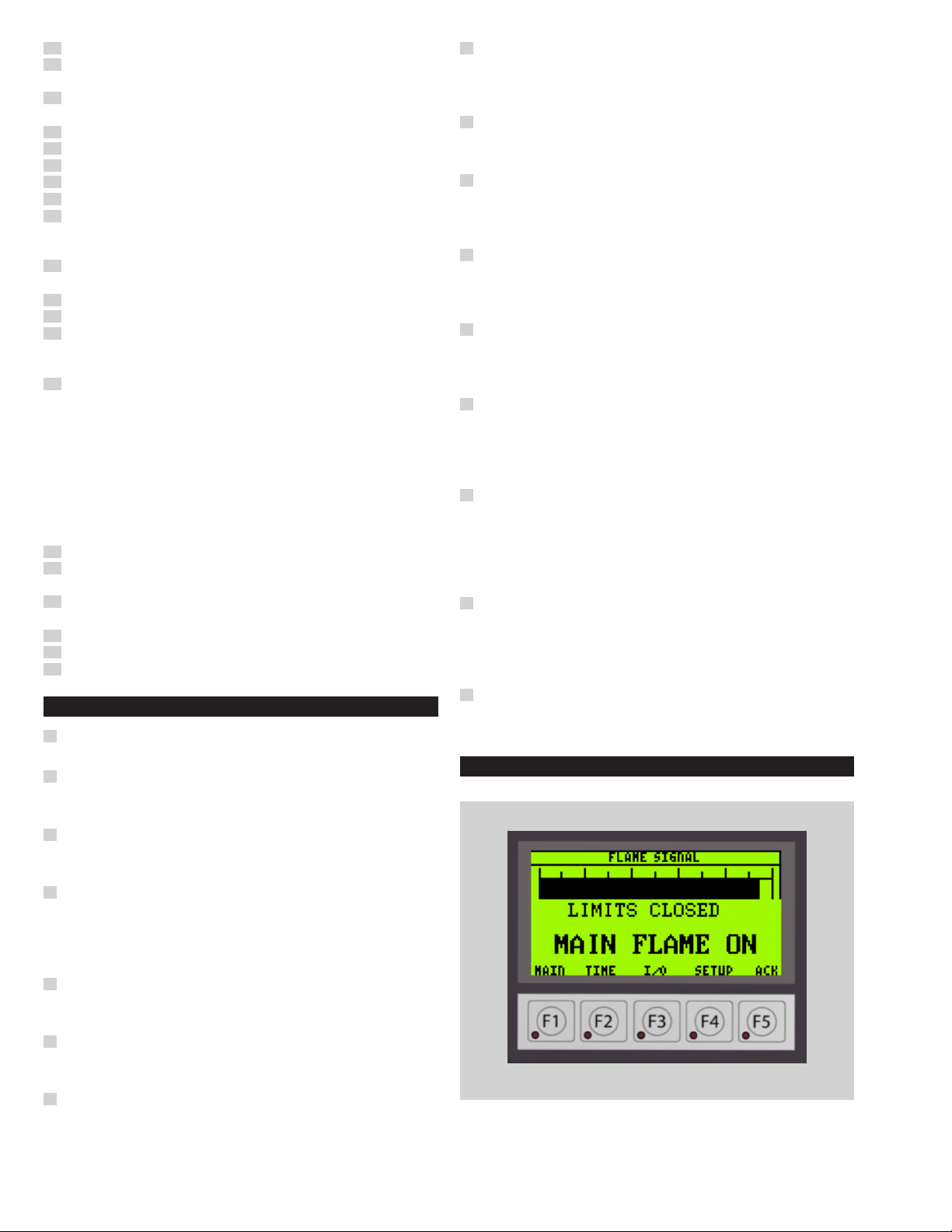

HUMAN MACHINE INTERFACE (HMI) SCREENS

Main

F1 Displays limits and system status along with flame signal strength.

BCS 3600 · Edition 11.19 · EN

4

Page 5

Time

ACK

F2 Displays resettable and accumulated firing time.

Input/Output

F3 Displays input and output status of the CPU module. Touch the

MODULE 1 and MODULE 2 buttons to display their input status

Setup

F5 key mimics the function of the alarm silence button. It also displays the alarm status message along with related troubleshooting

information.

CONTROL MOTOR SLIDEWIRE CALIBRATION

➔

The burner control motor incorporates a position feedback slidewire. A signal from the Temperature Controller is connected to

the slidewire in order to generate position feedback signal for

the control panel.

➔

The following calibration procedure must be performed before

operating the burner for the first time

➔

RECALIBRATE ANNUALLY OR WHENEVER A CONTROL

MOTOR, SLIDEWIRE OR TEMPERATURE CONTROLLER

IS SERVICED OR REPLACED.

1

Place the MODE selector in the AUTO position.

2

Press the F4 key to enter the SETUP screen.

F4 Enables contrast adjustment, Backlight color selection and Screen

Saver delay time.

Note: 0 = Screen Saver Disabled

BCS 3600 · Edition 11.19 · EN

Setup

3

The press the SERVICE soft key on the HMI and enter the password using the keypad screen to get to the SERVICE screen.

5

Page 6

Keypad

3200

SP 3200

DI

8

Wait for the zero value to stop changing and confirm that the

motor is in its low fire position then press [FUNCTION] again to

advance to SPAN VAL. The control motor will drive open and the

upper display value should increase. If it is necessary to reverse

control motor operation, interchange 2 and 3 and 7 and 8 on the

control motor terminal strip.

9

After the feedback value, has stopped increasing, confirm that

the motor has reached its high fire position then press [FUNCTION]

followed by [LOWER DISPLAY] to complete the calibration sequence.

10

Once the motor calibration is completed turn off the calibration

mode by selecting the MTR_CA soft key again.

UDC3200 SERIES CONTROLLER

➔ The Honeywell UDC3200 series controller has been configured

at the factory with parameters which generally produce accurate

temperature control.

➔ Before making any field adjustments, other then as noted in this

instruction sheet, please contact the Hauck service department.

Operator Interface

➔

This section describes the function of the various displays and keys

➔ Examples are given for changing the controller setpoint and op-

erating the burner in MANUAL.

➔

Detailed information is given in the vendor literature supplied with

the control panel.

Service

Motor calibration

4

5

6

7

Select the MTR_CA soft key on the HMI, this will enable the

burner control motor to be driven by the Honeywell Temperature

Controller without having to fire the burner.

Enter the calibration mode on the Temperature Controller by

pressing the [SETUP] key until the display reads CALIB POSITION.

Press the [FUNCTION] key to display DISABLE POS PROP then

press the ▲ key to change the upper display DO AUTO.

Press [FUNCTION] to begin motor calibration. The lower display

will read ZERO VAL while the upper display will show the slidewire

feedback value.

Head 1 Head 2

Upper display with 4 larger

digits shows Process Variabble

value (normal operation) and

special annunciator features.

During Configuration, the

upper display provides

guidance for the operator

through prompts (7 -

characters)

During normal operation, the

lower display shows key-

selected operation parameters

such as Output, Setpoints,

Inputs, Deviation, active

Tuniung Parameter Set, Timer

Status, or minutes remaining in

a setpoint ramp (4 digits).

During configuration, the lower

display provides guidance for

the operator through prompts.

ALM

6

Indicated alarm 1 and/or alarm

2 conditions exists.

Indicates digital input 1 and/or

2 on.

BCS 3600 · Edition 11.19 · EN

Page 7

Head 1 Head 2

OUT

MAN

A

SP

Indicates control relay 1 and/or

ForC

or

Keys and functions

Changing the setpoints

1

Press the [LOWER DISPLAY] key until SP and the current setpoint

appears in the lower display.

2

Press and hold the ▲ key to increase the set point value. To make

changes more quickly, press the ▼ key while holding ▲ key. This

will shift the changing digit one place to the left.

3

To decrease the set point value, reverse the above procedure.

Adjusting the burner firing rate in the manual mode

1

Press the [AUTO/MANUAL] key to place the Controller in the

Manual Mode. The MAN indicator will come on and the lower

display will automatically change to show % OUT.

2

Press and hold the ▲ key to increase % Output value. To make

changes more quickly press the ▼ key while holding ▲ key. This

will shift the changing digit one place to the left.

3

To decrease the % Output value, reverse the above procedure.

Indicated either degrees

Fahrenheit or Centigrade.

Indicates either Manuel or Auto

Indicates local setpoints #1.

Also, a bar is lighted when the

setpoint being used is shown

Selects functions within each

configuration groups.

Returns controller to normal

display from Set Up mode.

Toggles various operating

parameters for display.

Increases setpoints or output

configuration values or

configuration mode groups.

Selects Manual or Auto mode.

Hold key down to cycle

through configured setpoints.

Enables Run/Hold of the SP

ramp or program plus timer

Decreases setpoint or output

configuration values or

configuration mode groups.

NEMA 4x and IP66 screw

attachment (each corner).

2 on.

mode.

on the lower display.

configuration group

Scrolls through the

value. Increases the

changes functions in

Infrared tranceiver

start.

value. Decreases the

changes functions in

TEMPERATURE CONTROLLER CONFIGURATION

RECORD SHEET

SET UP

GROUP

TUNING

SP RAMP

ACCUTUNE

ALGORITHM

OUT ALG

INPUT 1

INPUT 2 IN 2 TYPE SLIDEW

CONTROL

CONTROL

cont.

COM

ALARMS

DISPLAY

LOWER

DISPLAY

(FUNNCTION)

PROP BD

RATE MIN

RESET RPM

SECURITY

LOCKOUT

AUTO MAN

RUN HOLD

SP SEL

SP RAMP

SP RATE

FUZZY

ACCUTUNE

CONT ALG

TIMER

IN ALG1

OUT ALG

MOTOR TI

IN 1 TYPE

IN 1 HIGH

IN 1 LOW

RATIO 1

BIAS IN 1

FILTER 1

BURNOUT 1

PV SOURCE

PID SETS

LSP'S

RSP SRC

SP TRACK

PWR MODE

SP HI LIMIT

SP LO LIMIT

ACTION

OUT RATE

OUT HI LIM

OUT LO LIM

I HI LIM

I LO LIM

DROPOFF

DEADBAND

FAILSAFE

FAILMODE

MAN OUT

AUTO OUT

PB OR GAIN

MIN OR RPM

COM ADDR

COMSTATE

IRENABLE

BAUD

TX DELAY

A1S1 TYPE

A1S2 TYPE

A2S1 TYPE

A2S2 TYPE

ALARM HYST

BLOCK

DIAGNOST

A1S1 VALUE

A2S1 VALUE

A2S2 VALUE

DECIMAL

TEMPUNIT

PWR FREQ

LANGUAGE

FACTORY

CONFIGURATION

15.00

0.00

1.00

0

NONE

ENABLE

DISABLE

ENABLE

DISABLE

DISABLE

DISABLE

DISABLE

PID A

DISABLE

NONE

POSITN

40

J TC L

550.0 F

20.00 F

1.000

0.0

1

UP

INPUT 1

1 ONLY

1 ONLY

NONE

NONE

MANUAL

550.0 F

20.00 F

REVERSE

DISABLE

100.0

0.0

100.0

0.0

0.0

2.0

0.0

NO LATCH

0.0

0.0

PB PCT

RPM

3

DISBALE

ENABLE

19200

1

NONE

NONE

NONE

NONE

0.1

DISABLE

DISABLE

Not Applicable

Not Applicable

Not Applicable

NONE

DEG F

60 HZ

ENGLISH

FINAL

SETTING

BCS 3600 · Edition 11.19 · EN

7

Page 8

HIGH TEMPERATURE LIMIT

The high temperature limit has been configured at the factory and

should not require any adjustments. The procedure for changing the

limit or alarm setpoint and a configuration record are given below.

Detailed information is given in the vendor literature supplied with

the control panel.

Changing the limit or alarm setpoint

1

Hold the SETUP key and press the ▲ key. The lower display will

show SLCT and the upper display will read OPTR.

2

Release the SETUP key and press the ▲ key until the upper

display reads SETP then press SETUP again to display the current

limit setpoint.

3

Use the ▲ or ▼ keys to change the setpoint.

4

Press SETUP to advance to PhA1 and again use the ▲ or ▼ keys

to change the alarm setpoint if desired.

5

Hold SETUP and press the ▲ key then release the SETUP key

and press the ▲ key until the upper display again reads OPTR;

then press SETUP to return to the operating (normal) display.

CONFIGURATION RECORD SHEET

➔ SLCT = CONF

➔ ULOC = 20

Lower Display

(Function)

INPT J.F

RUL 999.9

RLL -199.9

OFFS 0.0

CTRL HI

SPUL 999.9

SPLL -199.9

ALA1 P_HI

PHA1 380.0

AHY1 0.1

ALA2 PL_O

PLA2 -199.9

AHY2 0.1

USE2 A1_d

USE3 A2_d

DISP ENAB

CLOC 20

AHY2 0.1

AHY2 0.1

1

After completing Configuration, simultaneously press the ▲ and

SETUP keys. ConF will appear in the Upper Display.

2

Press the ▲ arrow key until the Upper Display reads SEtP then

press SETUP. ULoc will appear in the Lower Display.

3

Press the ▲ arrow until Upper Display reads 10.

4

Press SETUP to enter the set point mode.

Factory

Configuration

Final

Setting

5

Set the limit set point at 400 F and PhA1 at 380 F. All other settings

remain at their factory defaults.

Lower Display

(Function)

SP 400.0

HYSt 0.1

FiLt 2

PhA1 380.0

AHY1 0.1

PLA2 -199.9

AHY2 0.1

SLoc 10

8

Factory

Configuration

Final

Setting

BCS 3600 · Edition 11.19 · EN

Page 9

EXHAUST FAN FLOW LIMIT SWITCH INSTALLATION

Mount the exhaust fan flow switch in the dryer exhaust duct as

shown below.

1

Cut a 2" hole in the duct where the pitot tube will be located.

2

For "blind" applications, mark two of the holes using one half of

the mounting flange.

3

Reach through the 2" hole to hold the nuts in place to mount the

plate half. Use silicone sealant as a gasket. Tighten the nuts and

bolts securely. Insert the pitot approximately 12" into the duct

and hold in place.

4

Using the second half of the flange, tighten the 1/4-20 bolts to

hold the pitot in place.

BAG HOUSE

AIR FLOW DIRECTION

WARNING

– Do not fasten both halves of the flange. One side is left

unbolted for removal and cleaning of Pitot tube.

5

For other applications, weld the four duct mounting nuts to the

inside of the ductwork using the flange as a pattern.

6

Use silicone caulk as a gasket

7

Remote mount the pressure switch to a vibration and heat free

location. Connect the plastic tubing from the pitot to the switch

connecting the upstream side of the pitot to the bottom of the

switch and the downstream side of the pitot to the top side of

the switch. Wire switch per schematic

UPSTREAM

DOWNSTREAM

DOWNSTREAM

12“

UPSTREAM

PRESSURE

CONNECTION

PRESSURE

CONNECTION

STACK

1 1/2 DIA.

HOLE

DUCT CUTDOWN DETAIL

FOR SWITCH

ASSEMBLY MOUNTING

(4) 7/16 DIA.

HOLES EQ. SPACED

ON A 3“ DIA BC.

45°

BCS 3600 · Edition 11.19 · EN

9

Page 10

STACK THERMOCOUPLE INSTALLATION

➔ Install a Hauck stack temperature thermocouple in the dryer ex-

haust duct to sense exhaust gas temperatures.

Exhaust duct (Located before dry

dust collector & exhaust fan).

When two thermocouples are used with bacghouse

installation locate before and after baghouse.

1 – 3/8“ Dia.

1“ Pipe coupling

center over 1 – 3/8 dia.

hole and weld.

Drawing showing placement of thermocouple in exhaust duct.

➔

Thermocouple cables must be separated from AC power and

control wiring to avoid interference and nuisance shutdowns.

Observe polarity when making thermocouple connections. Regardless of TC type, the red wire is always negative.

ow

fl

ir

A

1/2“ Conduit

connection

Dryer stack

thermocouple assy.

10

BCS 3600 · Edition 11.19 · EN

Page 11

MATERIAL THERMOCOUPLE INSTALLATION

Brass adapter

➔ Install a Hauck Rapid Response Material Temperature Thermo-

couple in the material discharge chute to sense the temperature

of the material leaving the dryer.

Access door

15°

1“ Pipe coupling

(intalled by customer)

DAM

bushing

Thermocouple

Set-screw

F

l

ow

Discharge

chute

15“ REF

Drawing showing the placement of the thermocouple and "dam"

in the dryer discharge chute.

➔

A small clearance (1" maximum) should be provided under the

thermocouple so material will not be trapped between the thermocouple and the chute. Trapped material will cause a heat loss

path and the thermocouple will give erroneous readings.

➔

The thermocouple should make good contact with the material but

not be subject to severe abrasion caused by high velocities. If the

material is moving so fast that it bounces and leaves air adjacent

to the thermocouple, the temperature it senses will be lower than

the material. It may be necessary to place a dam in the chute so

that the thermocouple is in a relatively slow moving area next to

the dam. The dam must only be wide enough and high enough

to create a localized area of build-up where the material loses

velocity BUT DOES NOT STOP FLOWING. The thermocouple

must not be located in a stagnant zone or erroneous temperature

readings will result. Because of the large number of variables

involved, it is impossible to set down any exact size or location

of the dam that will always work. Field experimentation will be

neces¬sary if good results are to be obtained. It is advisable to

tack weld the dam in place so that it can be easily modified if it

fails to perform satisfactorily.

➔

During normal operation, the thermocouple should be rotated

once a month to expose a different area of its surface to the

abrasive forces of the material. This procedure will increase the

effective life of the thermocouple. If excessive wear occurs, a

protective tube may be added to shield the shaft in the region of

the high velocity flow

➔

Thermocouple cables must be separated from AC power and

control wiring to avoid interference and nuisance shutdowns.

Observe polarity when making thermocouple connections. Regardless of TC type, the red wire is always negative.

➔ Wire the thermocouple to the proper terminals in the panel.

10“

REF

BCS 3600 · Edition 11.19 · EN

11

Page 12

RECOMMENDED SPARE PARTS

PART NO. QTY DESCRIPTION

HK302263 1 Flame Relay RM7890A1056

14553 1 Flame Amp R7849A1023

16281 2

Honeywell UV Scanner

C7027A-1049

PRJ101034364 1 Honeywell UDC3200

HK402731 1 High Temperature Limit

101044055 1 Click Analog CPU C0-12ARE-D

101044056 1

101044057 1

Click 8 point AC Input Module

C0-08TR

Click 8 point Relay Output

Module C0-08NA

101033971 1 Click Power Supply C0-01AC

10049313 2

HK55167 5

HK43868 1

Relay, DPDT, Phoenix Contact,

PLC-RSC-120UC/21-21

Fuse, 7A, ¼ x 1-1/4, Littlefuse

type 313007

Stack Thermocouple, Hauck

TC200A-J

CONVERTING UNITS

see www.adlatus.org

FOR MORE INFORMATION

The Honeywell Thermal Solutions family of products includes Honeywell

Combustion Safety, Eclipse, Exothermics, Hauck, Kromschröder and

Maxon. To learn more about our products, visit

www.ThermalSolutions.honeywell.com or contact your Honeywell Sales

Engineer.

Honeywell Process Solutions

Honeywell Thermal Solutions (HTS)

1250 West Sam Houston Parkway

South Houston, TX 77042

ThermalSolutions.honeywell

© 2019 Honeywell

12

BCS 3600 · Edition 11.19 · EN

We reserve the right to make technical modifications in the interests of progress.

Loading...

Loading...