BACnet® Fixed Function Thermostat

MERCURY NOTICE

CAUTION

FOR FAN COIL/HEAT PUMP/CONVENTIONAL SYSTEMS

INSTALLATION INSTRUCTIONS

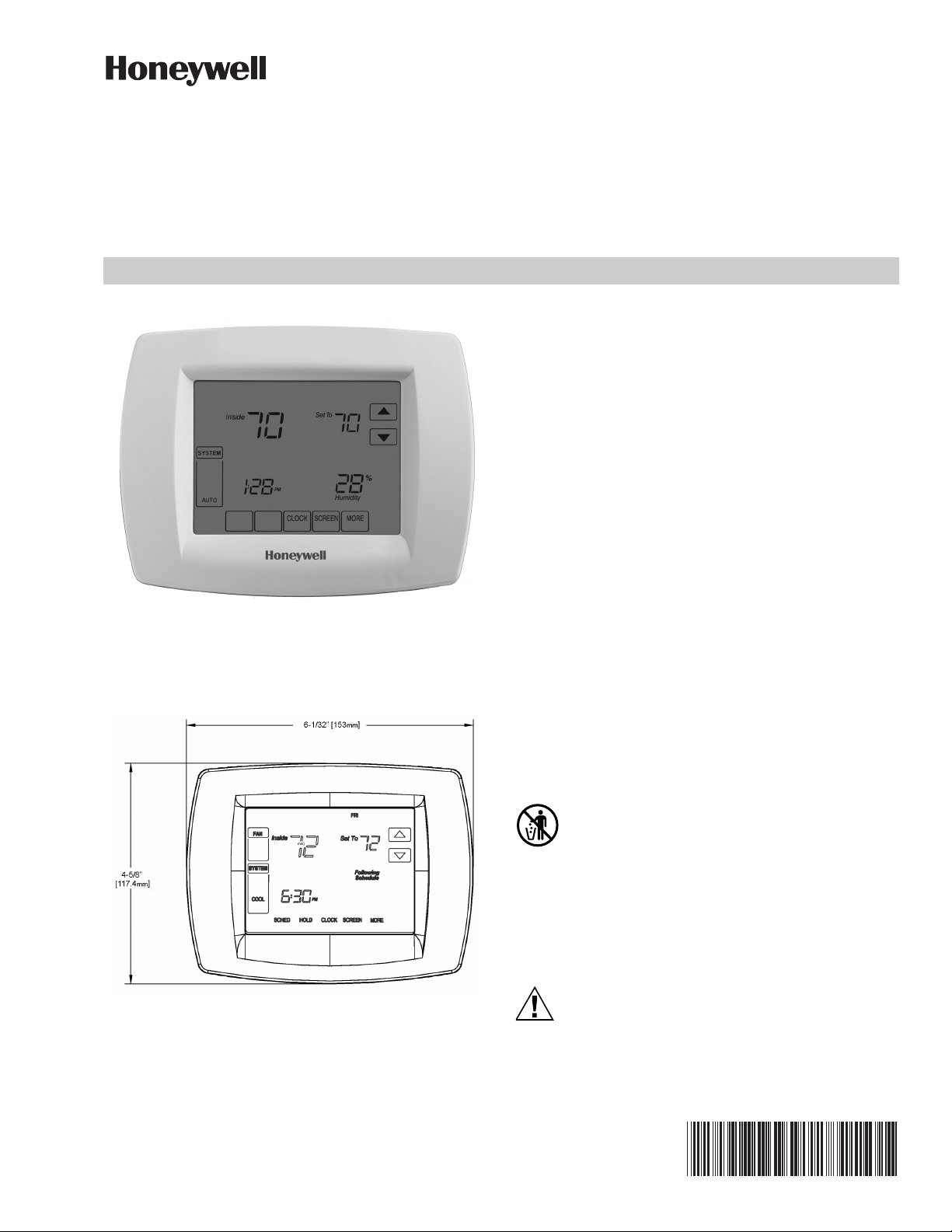

APPLICATION

Honeywell’s BACnet® Fixed Function Thermostat, BACnet

FF, is a configurable device with 19 pre-loaded

applications. The thermostat is a communicating,

intelligent sensor-controller combination with built-in

temperature and humidity sensors used to control

systems such as roof top units, fan-coil units and heat

pumps. The thermostat communicates over an MS/TP

LAN so it operates as a fully-functioning BACnet

controller and easily integrates with the building

automation system. The two available models are

TB3026B and TB3026B-W, which includes a wireless

sensor option.

INSTALLATION

Dimensions

The Fixed Function Thermostat consists of a mounting

plate and a circuit board with a plastic cover.

Fig. 1. Fixed Function Thermostat dimensions.

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a

hazardous condition.

2. Check ratings given in instructions and on the

product to ensure the product is suitable for the

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

If this control is replacing a control that contains

mercury in a sealed tube, do not place your old

control in the trash. Dispose of properly.

Contact your local waste management authority

for instructions regarding recycling and the proper

disposal of an old control. If you have questions,

contact Honeywell Customer Care Center.

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

31-00093-03

BACNET® FIXED FUNCTION THERMOSTAT

CAUTION

4 FEET

(1.2 METERS)

YES

NO

NO

NO

M36229

20

19

18

17

16

15

14

13

12

11

M36230

10

9

8

7

6

5

4

3

BO-5

BO-4

BO-3

BO-2

GND

AO-0

COM

AO-1

MS TP

+

MS TP

–

24VAC = HOT

RELAY

24VAC

BO-0

BO-1

GND = NEUTRAL

AI/BI-0

COM

AI/BI-1

COM

AI/BI-2

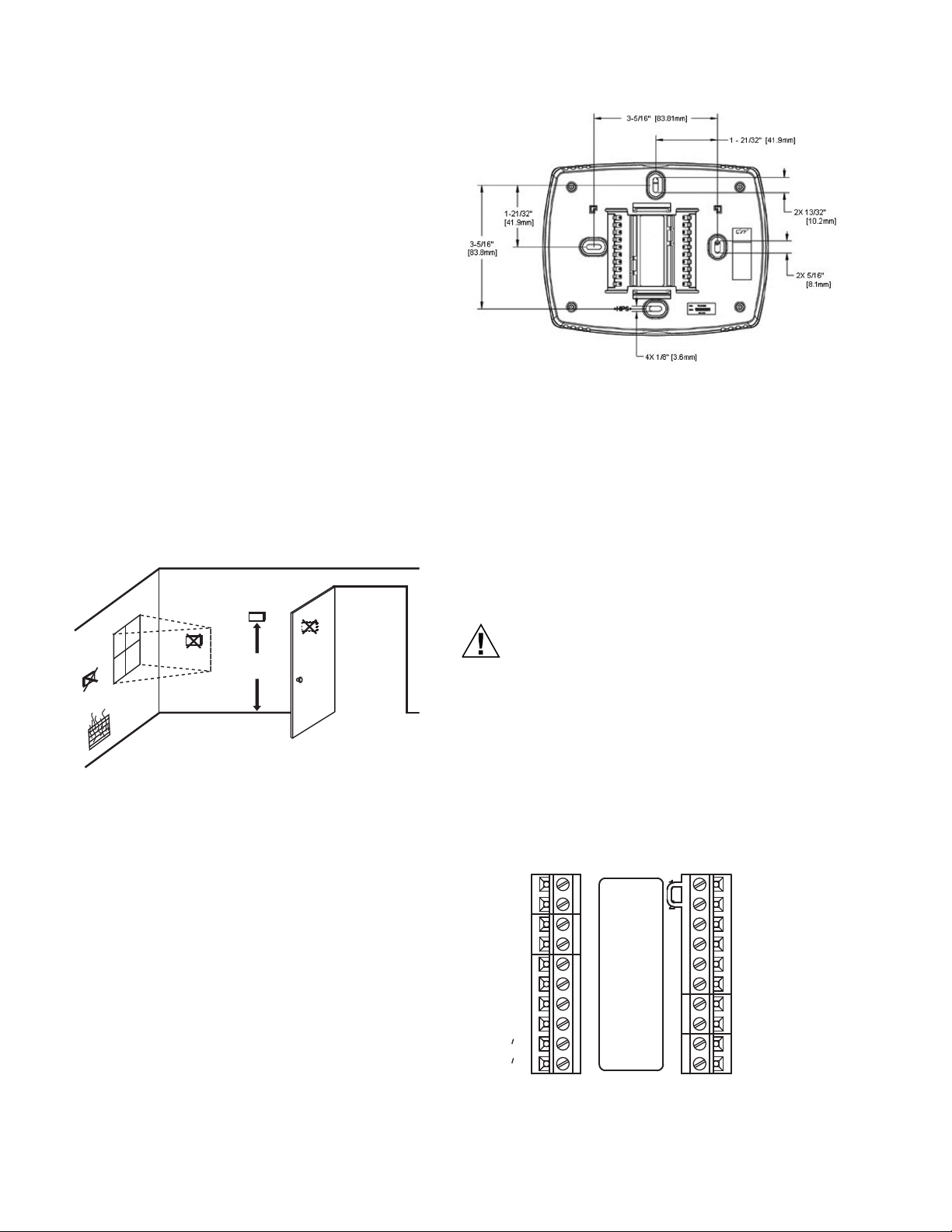

Location

Do not install the thermostat where it can be affected by:

— drafts or dead spots behind doors and in corners.

— hot or cold air from ducts.

— radiant heat from sun or appliances.

— concealed pipes and chimneys.

— unheated (uncooled) areas such as an outside wall

behind the thermostat.

IMPORTANT

To avoid electrical interference, which can cause

erratic performances, keep wiring runs as short as

possible and do not run thermostat wires adjacent

to the line voltage electrical distribution systems.

Use shielded cable. The cable shield must be

grounded only at the controlled equipment case.

WHEN USED TO SENSE ROOM TEMPERATURE

Install the thermostat about 4 ft. (1.2m) above the floor in

an area with good air circulation at average temperature.

(See Fig. 2.) Confirm mounting height meets Americans

with Disabilities Act requirements.

WHEN NOT USED TO SENSE ROOM TEMPERATURE

When using the remote-mounted temperature (and

humidity) sensor(s) to sense ambient conditions, install

the thermostat in an area that is accessible for setting and

adjusting the temperature and settings.

Fig. 3. Wallplate dimensions.

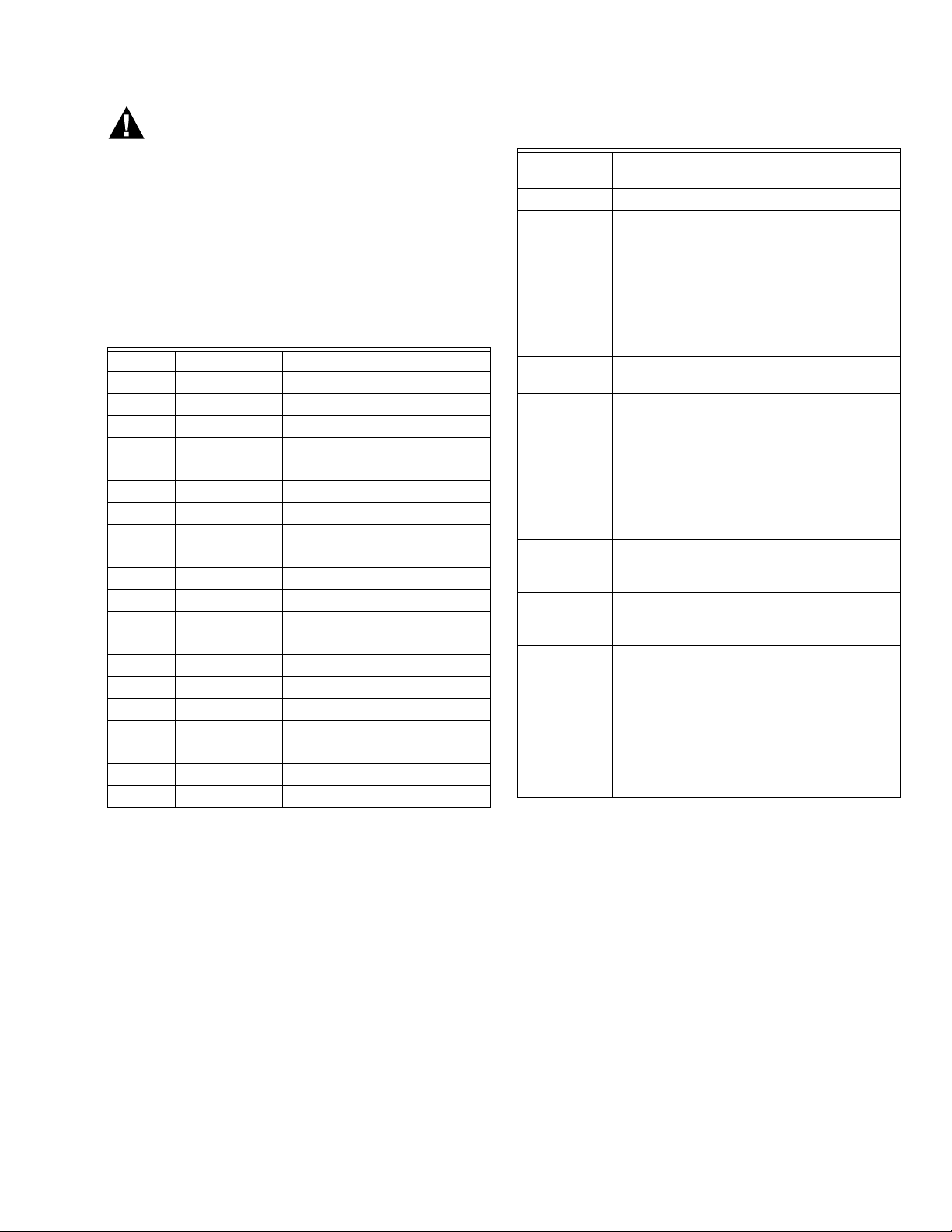

Wiring the Wallplate

IMPORTANT

All wiring must comply with local electrical codes

and ordinances.

NOTE: Maximum (and recommended) wire size is 18-

gauge. Do not use wire smaller than 22-gauge.

Follow equipment manufacturer wiring instructions when

available. A letter code is located near each terminal for

identification.

Power must not be connected while wiring.

Wiring a unit that is powered may result in

electrical shock and/or equipment damage.

Mounting Wallplate

The thermostat can be mounted horizontally on the wall or

on a 4 in. x 2 in. (101.6 mm x 50.8 mm) wiring box.

1.

2. Use a pencil to mark the mounting holes (see Fig. 3).

3.

4. Pull the wires through the wiring opening, and posi-

5. Insert the screws into the holes and tighten.

31-00093—03 2

Fig. 2. Typical location of thermostat

or remote-mounted sensor.

Position and level the wallplate (for appearance only).

Drill two pilot holes in the wall, on the marks. For drywall, drill 3/16-in. holes. For firmer material such as

plaster, drill 7/32-in. holes. Gently tap anchors (provided) into the pilot holes until flush with the wall.

tion the wallplate over the mounting holes.

1. Connect wires to the terminal blocks. See Fig. 4 for

terminal assignments and Table 1 for terminal

descriptions.

2. Securely tighten each screw.

3. Push excess wire back into the hole.

4. Plug the hole with non-flammable insulation to pre-

vent drafts from affecting the Fixed Function Thermostat.

5.

Check for loose or frayed wire that may cause a short.

Fig. 4. Fixed Function Thermostat terminal

assignments.

BACNET® FIXED FUNCTION THERMOSTAT

WARNING

Do not apply line voltage to source pins.

A jumper is pre-installed between pins 1 and 2. The

jumper supplies 24 VAC to BO-1, BO-3, and BO-4 relays. It

can be removed if those BOs are powered from an external

source. (Note: BO-0, BO-2, and BO-5 relays are powered

from terminal 1.)

See BACnet Fixed Function Thermostat System

Engineering Guide (31-00098) for typical wiring

examples.

Table 1. Terminal Identification.

Terminal Label Connection

1 24VAC 24 VAC Power

2 RELAY 24VAC 24 VAC Power

3 BO0 Relay Output

4 BO1 Relay Output

5 GND Ground

6 AI0 Universal Input

7 COM Common

8 AI1 Universal Input

9 COM Common

10 AI2 Universal Input

11 MS/TP - BACnet ® Communications

12 MS/TP + BACnet ® Communications

13 AO1 Analog Output

14 COM Common

15 AO0 Analog Output

16 GND Ground

17 BO2 Relay Output

18 BO3 Relay Output

19 BO4 Relay Output

20 BO5 Relay Output

Table 2. MS/TP LAN Facts.

Tra nsm ission

speed

Layout Bus (daisy chain).

Cabling BACnet specifies the following. Shielded,

Segment

length

Maximum

devices

overall

Maximum

devices per

segment

Repeaters Required when making runs longer than

Ter min ating

resistors

Shield

grounding

9.6, 19.2, 38.4, 76.8Kbps (configured at

global controller).

twisted-pair cabling with characteristic

impedance between 100 and 130W.

Distributed capacitance between

conductors must be less than 30 pF/foot

(100 pF/m). Distributed capacitance

between conductor and shield must be

less than 60 pF/foot (200 pF/m). Foil or

braided shield acceptable.

4000 ft. (1071 m.) per segment using

recommended wire.

Depends on classification of devices as

master or slave. Maximum number of

master devices is 128. Maximum number

of slave devices or devices overall (mixed

master and slave) is 255. This includes

BACnet FFs, BACnet global controllers (all

are considered masters) and any other

devices, regardless of their relative unit

loads.

Depends on relative unit load of devices

(see “Terminating MS/TP LAN Cabling” on

page 3).

4000 ft. Three repeaters maximum

between any two devices.

Matched resistors required at each end of

segment bus wired across (+) and (–). Use

matched precision resistors rated |

1/4 W ±1% / 80 - 130 Ohms.

Ground shield drain wire at single point

earth (panel) ground, not BACnet FF

ground. Tape off shield drain wire at other

end. Tie shield drain wire through at each

BACnet FF.

MS/TP LAN Wiring

The BACnet FF communicates on the site-wide BACnet

system over a twisted-pair MS/TP LAN, which uses the

EIA–485 signaling standard. The BACnet FFs are master

devices on the MS/TP LAN.

Each BACnet FF employs a high-quality EIA–485

transceiver and exerts 1/4 unit load on the MS/TP LAN.

Terminating MS/TP LAN Cabling

MS/TP terminations are located on the lower left of the

BACnet FF wallplate.

Maintain polarity of the MS/TP wire run throughout the

MS/TP LAN.

Grounding the MS/TP LAN Shield

Proper shield grounding of the MS/TP cabling can help

minimize the risk of communications problems and

damage to equipment because of transient voltage spikes

(for example, lightning strikes).

Follow these guidelines for grounding MS/TP cable

shields:

• Each MS/TP segment should have a single point of

shield ground, preferably as close to the middle of the

cabling run as possible.

• Do not ground the MS/TP shield using a BACnet FF

terminal.

3 31-00093—03

BACNET® FIXED FUNCTION THERMOSTAT

CAUTION

• Never ground both ends of a shield; differences in

potential between the grounds may induce current on

the shield, causing interference.

• At termination connecting points, tie the shield through

with a wire nut.

• At ungrounded, exposed shield points (the end of a

segment), tape back the shield to the wire jacket or, for

optimum transient shunting, use 100V gas discharge

tubes or 120V MOVs between shield and ground.

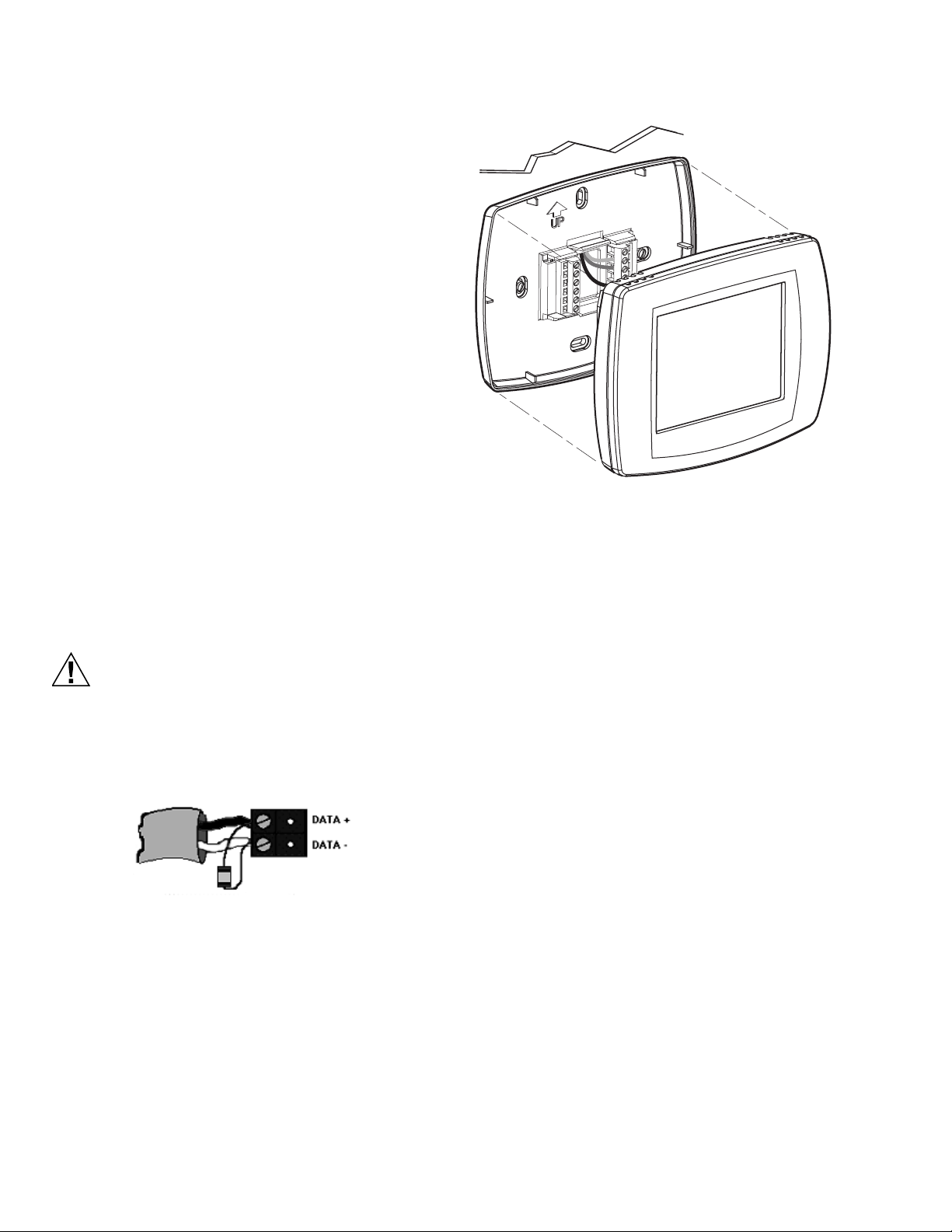

Terminating Resistors

Matched terminating resistors wired across MS/TP+ and

MS/TP– are required at the last device on each end of the

MS/TP segment for signal integrity (Fig. 5).

Optimum segment performance typically requires

“tuning,” a process by which the value of the terminating

resistors is selected based on the wave form of signals on

the segment. View wave forms using an industrial scope

meter. The goal is to have as square a wave form as

possible with an amplitude greater than 200 mV. Resistors

affect the wave form as follows:

• When the resistance value decreases, the amplitude of

the wave form decreases and becomes more square.

• When the resistance value increases, the amplitude of

the wave form increases and becomes less square.

WALL

INSTALLATION

REMOVE DURING

Fig. 6. Thermostat mounting.

M19919

Typically, precision resistors in the range 80-130 Ohms

(+1%) yield acceptable results. Ideally, the value of the

terminating resistors should match the rated

characteristic impedance of the installed cable. For

example, if the installed MS/TP cable has a listed

characteristic impedance of 100 Ohm, install 100 Ohm

matched precision resistors.

Do not mismatch terminating resistors.

Ensure that both resistors on a segment have the

same value.

NOTE: Typically, White is Data - and Black is Data +.

Fig. 5. Terminating resistor detail.

Mounting Thermostat to Wallplate

1. Align the terminal screw blocks with the pins on the

back of the thermostat.

2. Push the thermostat straight onto the wallplate.

NOTE: To remove the thermostat from the wall, first pull

out at the bottom of the thermostat; then remove

the top.

CONFIGURATION

Once the BACnet FF is mounted and wired, it can be

configured using the local touchscreen and a

configuration wizard using Niagara Framework® software.

When using the software, BACnet data is transmitted to

and from the device and building management system

using analog values (AVs) and binary values (BVs).

Listings of these AVs and BVs can be found in their

entirety in the BACnet Fixed Function Thermostat System

Engineering Guide (31-00098) and a limited listing can be

found on page 6.

Adjusting the Date and Time

When the controller is first powered up, the date and time

might need to be set. These are set at the factory, but the

on-board power supply may have run down. If this

happens, adjust the date and time.

TO ADJUST THE TIME

1. Touch Clock at the bottom of the screen.

2. Use the arrows to adjust the year, month, and day.

3. Press DONE.

4. Adjust the time and press DONE.

Setting the MAC Address and Device Instance

The MS/TP MAC address for each device must be set to a

unique value in the range of 0-127 on an MS/TP network

segment. The MAC address is set using the installer setup

menu through the device’s display. The factory default

MAC address is 0.

31-00093—03 4

BACNET® FIXED FUNCTION THERMOSTAT

E

MO

USASU

SYSTE

OFF

g

Schedule

de

Se

o

15

800

MAC ADDRESS

0

801

DEVICE INSTANCE NUMBER

00

802

18

803

76

804

M36231

The Device Instance Number must be unique across the

entire BACnet system network because it is used to

uniquely identify the BACnet devices. It may be used to

conveniently identify the BACnet device from other

devices during installation. The Device Instance Number

is set using the installer setup menu through the device’s

display or over the BACnet network. The Device Instance

Number can be changed by the user, which may be

necessary when integrating with a third party or when

attempting to replace an existing device and it is desired

to maintain the existing Device Instance Number. The

factory default Device Instance Number is 0009999 and

can range from 0-4194302.

NOTE: The device instance can also be set over the

BACnet network.

TO SET THE MAC ADDRESS AND DEVICE INSTANCE AT

THE DISPLAY

1. From the home screen, press SYSTEM (left side of

the screen). Five blank touch keys will appear at the

bottom of the screen.

2. Press and hold the two blank keys on either side of

the center key for approximately five seconds (see

Fig. 7).

T

Insi

t T

Followin

Fig. 8. ISU screen.

3. Use the down arrow next to the installer setup code

to advance to ISU code 800.

4. Use the up and down arrows next to the current setting to set ISU code 800 (MAC address) to a value

between 0 and 127.

NOTE: Set ISU code 801 (first digit of device

instance) to a value between 0 and 4.

DON

CANC

M19923

Fig. 7. Entering ISU mode.

The installer setup (ISU) screen appears. An ISU code is

displayed in the lower left. It is a four-digit code beginning

with zero. The current setting is displayed in the lower

right.

5. The device instance is set by entering values in four

separate ISU codes. See example on page 5.

6. Set ISU code 802 (second and third digits of device

instance) to a value between 00 and 99.

7. Set ISU code 803 (fourth and fifth digits of device

instance) to a value between 00 and 99.

8. Set ISU code 804 (sixth and seventh digits of device

instance) to a value between 0 and 99.

9. Press Done to exit installer setup.

For example, if the MAC address is 15 and the device

instance to 1876, use these settings:

Fig. 9. Setup codes and device configuration.

Installer Setup (ISU) Codes

Installer setup mode provides access to functions specific

to installation of a BACnet FF. Some BACnet FF

configuration parameters can be altered from the ISU

screens. The ISU parameters can also be accessed via

BACnet.

A password (PIN) can be required to access ISU mode by

setting AV-133 to a non-zero, four-digit number.

5 31-00093—03

BACNET® FIXED FUNCTION THERMOSTAT

For a complete application configuration guide, refer to

the BACnet Fixed Function Thermostat System

Engineering Guide (31-00098) and WEBs-AX

Configuration Guide (31-00097)

TO ACCESS THE ISU SCREENS

1. From the home screen, press SYSTEM (left side of

the screen). Five blank touch keys will appear at the

bottom of the screen.

2. Press and hold the two blank keys on either side of

the center key for approximately five seconds (see

Fig. 7).

3. If a password (PIN) code is required, use the top

arrows to select the first two digits of the code and

the bottom arrows to select the third and fourth digits of the code, and then press DONE.

The ISU screen appears.

4. Use the arrows to select parameters and values. See

Table 3 for details.

5. Press DONE.

NOTE: After five minutes of inactivity, the ISU

screen reverts to the main screen.

Table 3. ISU Parameters.

ISU Parameter Code Description Allowed Values

120 Year, first 2 digits 19-21

130 Year, second 2 digits 00-99 (00-54 if ISU 200=21)

140 Month 1-12

150 Day 1-31

160 Schedule format BV-133 0 – not programmable (BV-133=0) 4 – 7 day programmable (BV-133=1)

280 Backlight control BV-79 0 – on for 20 seconds after keypress

1 – low always on, bright after keypress

320 Swap English/Metric BV-69 1 – show opposite units to specified in DDC header

330 Daylight saving

AV-127

0 – off; no automatic adjustments

1 – pre 2007 scheme

2 – 2007 and later scheme

500 Filter change reminder

AV-124

0 – reminder not used

1 – 10 days

2 – 30 days

3 – 60 days

4 – 90 days

5 – 120 days

6 – 365 days

510 Hum pad change reminder

AV-125

0 – reminder not used

1 – 90 days

2 – 180 days

3 – 365 days

520 UV lamp change reminder

AV-126

540 Program periods

AV-129

640 Clock format

BV-83

670 Keypad lock

AV-128

0 – reminder not used

1 – 365 days

2 – Wake/Sleep

4 – Wake/Leave/Return/Sleep

12 – 12 hour (BV-83=0)

24 – 24 hour (BV-83=1)

0 – no lock

1 – access temperature settings only

2 – fully locked

700 Sensed room temperature offset (AV-138) -4 to +4 degrees F

701 Sensed room humidity offset (AV-139) -5% TO +5%

Humidity cannot be adjusted above 100% or below 0%.

702 Sensed outside air temperature offset (AV-140) -4 to +4 degrees F

703 Sensed outside humidity offset (AV-141) -5% TO +5%

Humidity cannot be adjusted above 100% or below 0%.

800 MS/TP MAC 0-127

31-00093—03 6

BACNET® FIXED FUNCTION THERMOSTAT

Table 3. ISU Parameters.

ISU Parameter Code Description Allowed Values

801 BACnet Device Instance - first digit 0-4

802 BACnet Device Instance second and third digits 00-99

803 BACnet Device Instance forth and fifth digits 00-99

804 BACnet Device Instance sixth and seventh digits 00-99

Pairing a Sensor to a Wireless BACnet FF (TB3026B-W Only)

BACnet FFs and sensors ship unpaired, verified by two

dashes in the Sensor Status field on the BACnet FF’s

Wireless Sensor Setup screen. To pair them, issue a pairing

command from the BACnet FF and then activate the

sensor.

Accessed from Field Service Mode (See “Field Service

Mode” on page 7), the BACnet FF’s Wireless Sensor Setup

Mode includes diagnostic screens for configuration and

checkout of associated sensors. With :UC displayed in

Field Service Mode, press the blank key (blank area) just to

the left of the blank center key, and then press the down

arrow key next to the :UC parameter.

Door/window sensors may be paired to any available

sensor number in the range 1-8. When cycling through

sensor numbers on the Wireless Sensor Setup screen,

unpaired sensor numbers show a status of --.

PIR sensors may be paired to any available sensor number

in the range 1-3.

NOTE: Pairing times out after 10 seconds of no

pairing activity.

5. Verify that the BACnet FF and sensor successfully

paired.

Paired = sensor status is displayed, replacing --.

Timed out = RESET is displayed and sensor status

is --.

Fig. 11. Door sensor number 1 paired and in closed

status.

TO ERASE SENSOR-TO-BACNET FF PAIRINGS

1. While viewing any sensor status screen while pairing

is not taking place, press the blank key to the left of

CANCEL.

2. Press the blank key to the right of DONE.

The sensor status field displays --, indicating

unpaired.

Fig. 10. Wireless Sensor Setup screen.

TO PAIR A SENSOR TO A BACNET FF

1. Make sure the battery is installed and activated in

the sensor.

2. If the sensor is a door/window switch, align the magnet so that the sensor is in the closed position. If the

sensor is a PIR sensor, cover the PIR.

IMPORTANT

Verify that the sliding door/window contact is

closed and cover all other PIRs to prevent interference during the pairing process.

3. On the BACnet FF select the sensor to pair and then

press Reset. The RESET key disappears and WAIT is

displayed indicating that the BACnet FF is waiting to

pair the sensor with the next device that receives a

radio signal.

4. Activate the sensor to be paired.

FIELD SERVICE MODE

Fixed Field Service Codes

Field service mode enables technicians to query and

command key operating variables in the BACnet FF while

at the BACnet FF touchscreen. A technician presses a

particular key sequence at the BACnet FF to enter field

service mode. In field service mode a technician uses the

left arrows to scroll through data codes and the right

arrows to change the value associated with a code.

The lower left of the LCD shows the two-digit data code

and the main area displays the data value. A pre-defined

list of data codes is available within the description of

each application. See BACnet Fixed Function Thermostat

System Engineering Guide (31-00098) for the complete

list of setup codes.

Users can be denied access to field service mode by

setting BV-68 to ON. A password can also be required to

enter field service mode by setting AV-132 to the desired

PIN.

Field service mode ends automatically if there is no key

activity for five minutes.

7 31-00093—03

BACNET® FIXED FUNCTION THERMOSTAT

WARNING

DONE

CANCEL

TUE

PM

SYSTEM

OFF

COOL

CHANGE FILTER UV LAMP

Following

Schedule

Inside

M22766

Setting Field Service Codes

To set field service codes

1. From the home screen, press SYSTEM. Five blank

touch keys will appear at the bottom of the screen.

2. Press and hold the center bottom key for approximately five seconds (see Fig. 12).

Fig. 12. Entering Field Service mode.

3. The field service screen appears.

NOTE: If a password is required, use the top arrows

to select the first two digits of the code and

the bottom arrows to select the third and

fourth digits of the code, and then press

DONE.

4. Press the left up or down arrows until the desired

code appears.

5. Press the right up or down arrows to adjust the value

associated with the code.

6. Press the left up or down arrows to accept the

change and scroll to a different code.

7. Press DONE to exit field service mode.

TECHNICAL DATA

Power

24VAC power from a UL Listed Class-2 24VAC transformer

(not provided). The BACnet FF uses a half-wave rectifier

to convert the AC power supply to onboard power. This

enables multiple devices with half-wave power supplies

to be powered from a single, grounded transformer.

Max. Load = 89VA (all BOs ON).

If BO power jumper is not removed, then all BOs are pow-

ered from the controller’s transformer.

Minimum load includes controller and analog outputs at

full load (20mA into 500 Ohms).

All BOs are N.O. (Normally Open) contacts with a maxi-

mum switch rating of 24VAC @ 0.5A (12VA).

Maximum load assumes all 6 relay output loads are pow-

ered from the controller transformer and connected

loads are the maximum allowed (24VAC @ 0.5A). Actual

power requirements depend on connected loads.

Wireless Receiver (TB3026B-W only)

433.92 Mhz; range is 50 feet.

Inputs

3 universal inputs with 12-bit accuracy, providing con-

trolled voltage, current and resistive modes. Requires a

10k type 2 thermistor when using remote sensors.

Internal Sensors

1 internal temperature sensor, 0–120 deg. F (-17.8–48.9

deg. C); 1 internal humidity, 5–95% RH, non-condensing.

Relay Outputs

6 relay outputs; normally open contacts with a maximum

switch rating of 24VAC @ 0.5A (12VA). BO-0, BO-2 and

BO-5 are powered from the controller transformer. BO1, BO-3 and BO-4 are powered from control transformer through removable jumper, allowing these BOs

to be powered from a separate power source.

Universal Analog Outputs

2 outputs with 12-bit resolution. Each auto-detects for 0–

10VDC or 4–20mA. 4–20mA outputs are sourced by the

BACnet FF. Connected loads must return to the BACnet

FF ground. The BACnet FF automatically switches from

0–10V mode to 4–20mA current mode when it detects a

load value of less than 500 Ohms.

Processor & Memory

Powerful 32-bit processor with extensive flash memory

and RAM resources. Flash memory provides nonvolatile program and data storage, and allows for encrypted

updates to the program for future product enhancements.

Environmental

Residential, commercial and light-industrial environ-

ments. 0–120 deg. F (-17–49 deg. C). 0–95% RH, noncondensing.

Communications

BACnet MS/TP LAN up to 76.8Kbps.

Half wave devices and full wave devices must not

use the same AC transformer. You must maintain

wiring polarity. Failure to do so can result in

equipment damage.

If the HVAC equipment has an internal circuit

board that is powered by the same transformer that

will power the BACnet FF, verify that it is NOT full

wave.

Min. Load = 17VA (all BOs OFF).

31-00093—03 8

NOTE: MS/ TP is Master Slave/Token Passing.

Ratings

Listed Underwriters Laboratory for Open Energy Manage-

ment Equipment (PAZX) under the UL Standard for

Safety 916; listing includes both U.S. and Canadian

certification.

EMC Directive (European CE Mark) EN 60950

(TB30326B-W model only).

FCC Part 15, Class B.

BACNET® FIXED FUNCTION THERMOSTAT

Accessories

50037735-001 Wireless door/window sensor

50037736-001 Wireless passive infrared (PIR) motion

sensor.

More Information

To learn more about these products, visit

http://

• BACnet Fixed Function Thermostat Product Data

(Form No. 31-00096)

• BACnet Fixed Function Thermostat WEBs-AX

Configuration Wizard Guide (Form No. 31-00097)

• BACnet Fixed Function Thermostat System

Engineering Guide (Form No. 31-00098)

9 31-00093—03

BACNET® FIXED FUNCTION THERMOSTAT

31-00093—03 10

BACNET® FIXED FUNCTION THERMOSTAT

11 31-00093—03

BACNET® FIXED FUNCTION THERMOSTAT

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use or

modification to, the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against any

liability, cost, or damages, including attorneys’ fees, arising out of, or resulting from, any modification to the literature by you.

Automation and Control Solutions

Honeywell International Inc.

® U.S. Registered Trademark

© 2016 Honeywell International Inc.

31-00093—03 M.S. Rev. 07-16

Printed in United States

Loading...

Loading...