Honeywell AGF1 User Manual

AGF1

WASTE GAS TEMPERATURE SENSOR

PRODUCT DATA

FEATURES

The waste gas temperature sensor AGF1 is suitable for

measuring waste gas in the flue gas pipe.#

The measured waste gas temperature can for instance be

used for the following functions:

• Monitoring of waste gas temperature

• Determining switching on/off times of the burner

• Determining fuel consumption

• Calculating waste gas loss from the heat generator

• Metering the running time of the burner

In order to find out which of the above functions are possible,

consult the instructions of the controller to which the waste

gas sensor is connected.

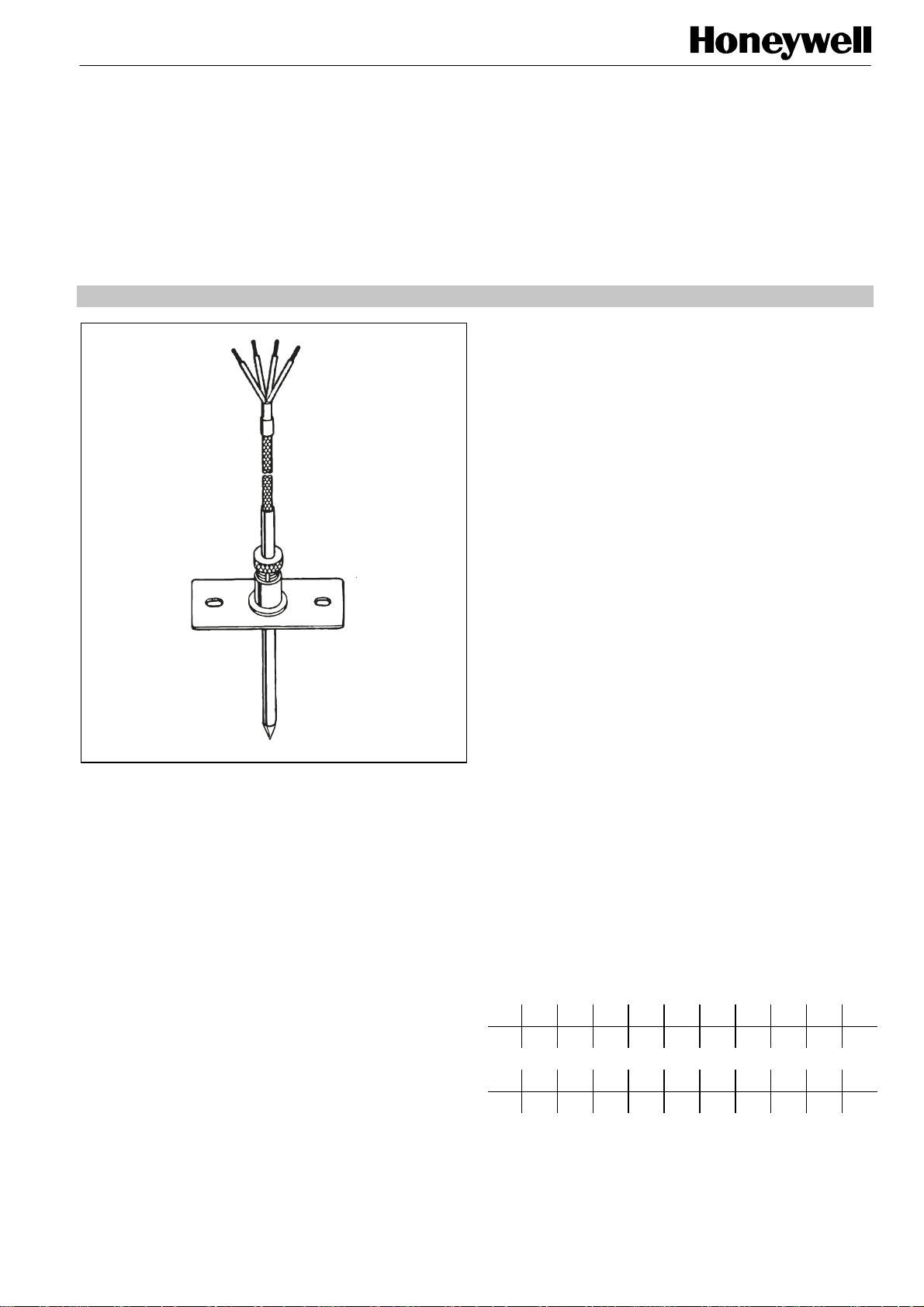

The AGF 1 is designed as a conduit sensor to measure the

waste gas temperature.

SPECIFICATION

Temperature measurement

and range of application 0...320 °C

Sensor element PT 1000 (1000 Ω at 0 °C)

Construction Rod sensor with fitting for

Dimensions Sensor shaft ∅ 5 mm

Max. cable length 100 m at ∅ 1.5 mm²

The resistance of the waste gas temperature sensor AGF 1

depends on the temperature (according to DIN 43 760):

°C 0 20 50 100 110 120 130 140 150 160

1000 1078 1194 1385 1423 1461 1498 1536 1573 1610

Ω

°C 170 180 190 200 210 220 230 250 300 320

(short-time upper limit 400 °C)

according to DIN 43 760

mounting on waste gas pipe

Length 180 mm

Length of terminal cable 1 m

1648 1685 1722 1758 1795 1832 1868 1941 2120 2191

Ω

EN3R-1104 GE51 R0897

AGF1

A

d

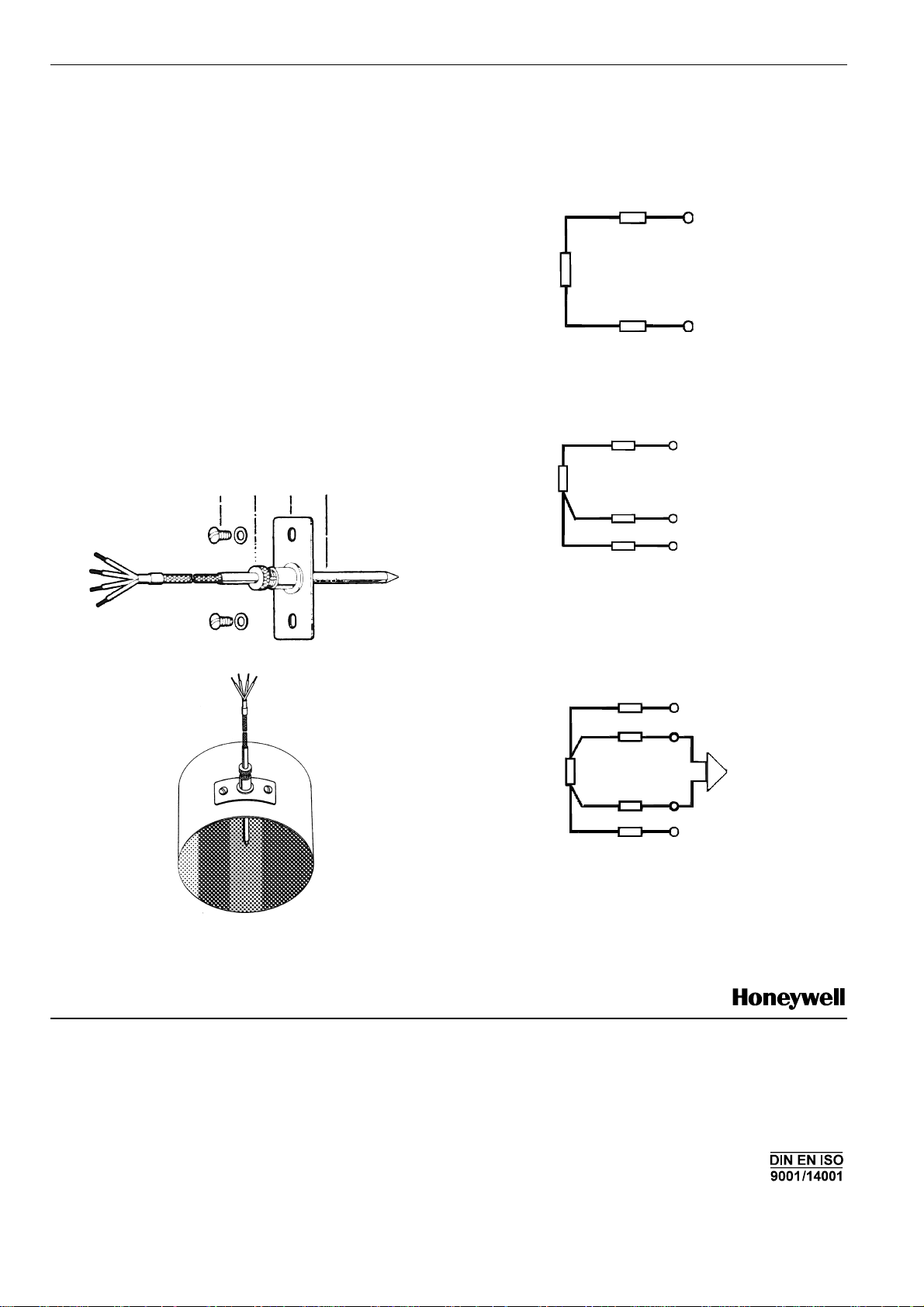

MOUNTING

1. Loosen locking screw B and pull out the sensor element D

from the guiding pipe.

2. Drill a 10 mm Þ hole at the position chosen on the gas

pipe. Take care that the hole for the sensor element is

near the heat generator (ca. 10 – 40 cm behind supports

for the boiler waste gas).

3. Fit the plate C of the waste pipe so that it lies on the pipe.

4. Mark and drill the holes 3.0 mm Þ for the screws supplied.

5. Insert the sensor element into the guiding pipe.

6. Adjustment

The measurement of the waste gas temperature must be

carried out in the core of the waste gas stream (hottest

zone). Furthermore, it must be ensured that the swirling of

waste gas in the pipe has taken place. By inserting the

sensor elelment D at various depths and by repeated

measuring of the waste gas temperature, the hottest zone

will be found. The temperatures can be read in the display

on the digital controller (see instructions).

7. When then hottest zone has been found, the sensor shaft

is fixed into position by tightening the locking screw B.

ABCD

ELECTRICAL CONNECTION

There is a three-prong connection in the controller.

The wiring of the temperature sensor has to be in accordance

with the overall wiring circuit diagram.

red

RL

GF 1

white

white

re

red

RL

power supply

+

white

Advantage: only two cables

Disadvantage: the cable resistance RL distorts the

measurement.

Three cable connection

red

AGF 1

Advantage: the cable resistance is taken into account by

the electronic evaluation and there is no

distorbtion in the measurement.

Disadvantage: three cables are necessary and all must have

the same resistance.

Four cable connection

AGF 1

white

white

Advantage: the cable resistance has no bearing on the

results due to the electronic compensation

(current demand and high ohmic voltage

level). The measurement is not distorted and

the cables can have different resistances.

Disadvantage: four cables are necessary

Home and Building Control Products

Honeywell AG

Böblinger Straβe 17

D-71101 Schönaich

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://europe.hbc.honeywell.com

Subject to change without notice. Printed in Germany Manufacturing location certified to

EN3R-1104 GE51 R0897

measurement

-

Loading...

Loading...