Honeywell 7800 Owner's Manual

7800 SERIES EC7895A, RM7895A

GENERAL

The Yamatake Honeywell EC7895A and RM7895 is a microprocessor

based integrated burner control for automatically fired gas, oil, or

combination fuel single burner applications. The RM7895 consists of

the Relay Module. Subbase, Amplifier and Purge Card. Options

include Keyboard Display Module, Personal Computer Interface,

DATA CONTROLBUS MODULE™, Remote Display Module, and

COMBUSTION SYSTEM MANAGER™ Software.

The EC7895 and RM7895 are programmed to provide a level of

safety, functional capability and features beyond the capacity of

conventional controls.

Functions provided by the EC7895 and RM7895 include automatic

burner sequencing, flame supervision, system status indication,

system or self-diagnostics and troubleshooting.

Relay Module

PRODUCT DATA

• Dependable, long-term operation provided by microcomputer

technology.

• First-out annunciation and system diagnostics provided by a 2

row by 20 column Vacuum Fluorescent Display (VFD) located

on the optional Keyboard Display Module.

• Five (LEDs) for sequence information.

• Interchangeable plug-in flame amplifiers.

• Local or remote annunciation of EC7895 and RM7895

operation and fault information.

• Nonvolatile memory; EC7895 and RM7895 retain history files

and sequencing status after loss of power.

• Remote reset (optional).

• Report generation (optional).

• Selectable recycle or lockout on loss of airflow.

• Selectable recycle or lockout on loss of flame.

• Shutter drive output.

• Burner controller data (optional):

— Flame signal strength.

— Hold status.

— Lockout/alarm status.

— Sequence status.

— Sequence time.

—Total cycles of operation.

—Total hours of operation.

—Fault history providing for the six most recent faults:

• Cycles of operation at the time of the fault.

•Fault message and code.

• Hours of operation at the time of the fault.

• Sequence status at the time of the fault.

• Sequence time at the time of the fault.

— Diagnostic information:

•Device type.

• Flame amplifier type.

• Flame failure response time.

• Manufacturing code.

• On/Off status of all digital inputs and outputs.

• Selected prepurge time.

• Software revision and version of EC7895 and RM7895

and optional Keyboard Display Module.

• Status of configuration jumpers.

Contents

FEATURES

• Safety features:

— Airflow switch check.

— Closed loop logic test.

— Dynamic AMPLI-CHECK®.

— Dynamic input check.

— Dynamic safety relay test.

— Dynamic self-check logic.

— Internal hardware status monitoring.

—Tamper resistant timing and logic.

• Access for external electrical voltage checks.

• Application flexibility.

• Communication interface capability.

Copyright © 1996 Honeywell Inc. • All Rights Reserved

General ......................................................................................... 1

Features ........................................................................................ 1

Specifications ................................................................................ 2

Ordering Information ..................................................................... 2

Principal Technical Features ......................................................... 8

Safety Provisions .......................................................................... 8

Installation ..................................................................................... 9

Wiring ............................................................................................ 11

Assembly ...................................................................................... 14

Operation ...................................................................................... 17

Checkout ....................................................................................... 20

Troubleshooting ............................................................................ 26

X-XX UL

65-0205

7800 SERIES EC7895A, RM7895A RELAY MODULE

SPECIFICATIONS

Model:

RM7895A

Electrical Ratings, see Table 1A:

Voltage and Frequency: 100 Vac (+10/-15%), 50 or 60 Hz

(+/- 10%).

1

Power Dissipation: RM7895: 10W maximum.

Maximum Total Connected Load: 2000 VA.

Fusing Total Connected Load: 20A maximum, type FRN or

equivalent.

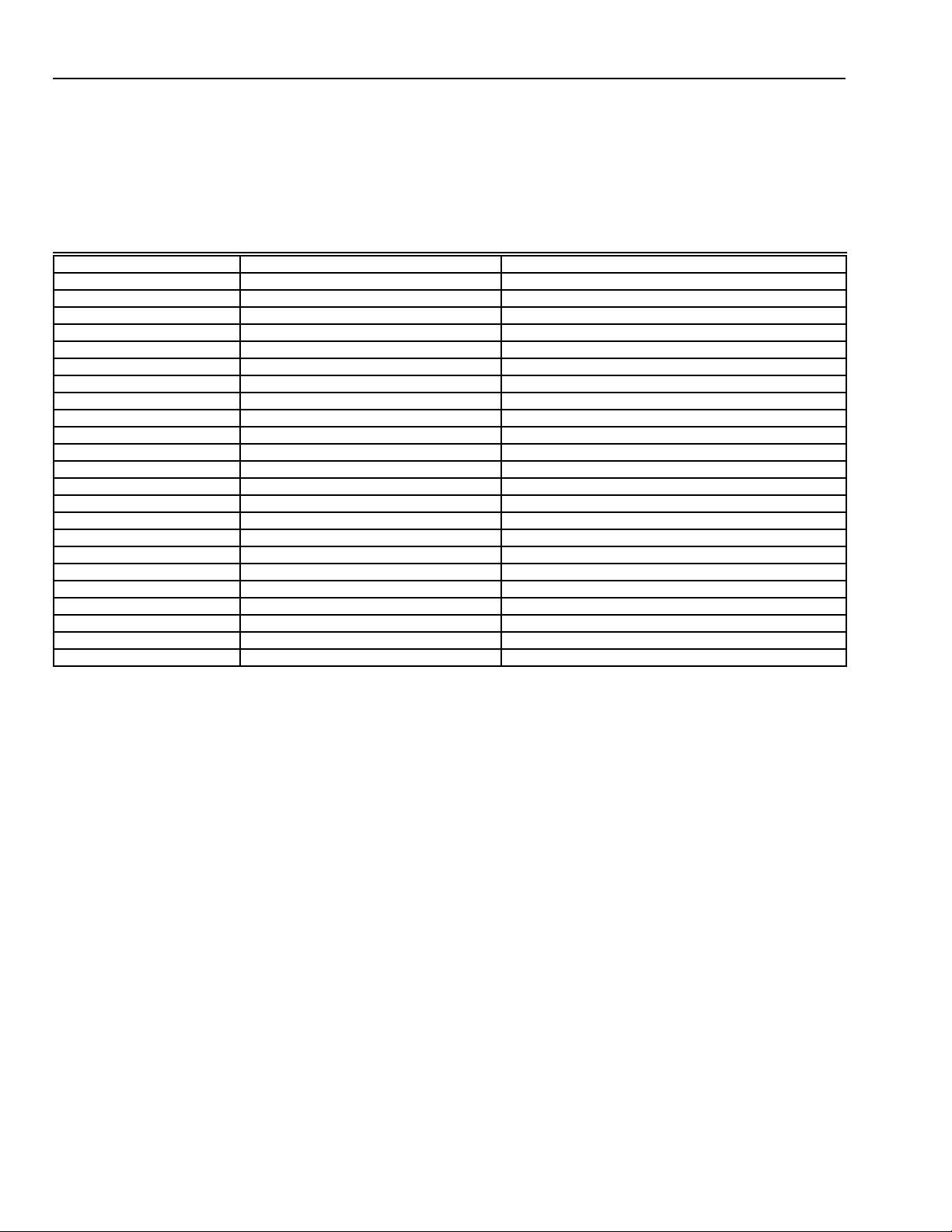

Table 1A. RM7895A Terminal Ratings.

Terminal No. Description Ratings

G Flame Sensor Ground

Earth G Earth Ground

2

L2(N) Line Voltage Common

3 Alarm 100 Vac, 1A pilot duty.

4 Burner Motor 100 Vac, 9.8 AFL, 58.8 ALR (inrush).

5 Line Voltage Supply (L1) 100 Vac (+10/-15%), 50 or 60 Hz (+/- 10%).

3,4

6 Burner Controller and Limits 100 Vac, 1 mA.

7 Airflow Interlock 100 Vac, 9A.

8 Pilot Valve/Ignition 100 Vac, 4.5A ignition and 50VA pilot duty.

9 Main Fuel Valve 100 Vac, 2A pilot duty.

10 Ignition 100 Vac, 4.5A ignition.

5

4

4

F(11) Flame Sensor 60 to 220 Vac, current limited.

12 Unused

13 Unused

14 Unused

15 Unused

16 Unused

17 Unused

18 Unused

19 Unused

20 Unused

21 Unused

22 Shutter 100 Vac, 0.5A

1

Range of allowable operating frequency: 45 to 66 Hz.

2

The 7895 must have an earth ground providing a connection between the subbase and the control panel or the equipment.

The earth ground wire must be capable of conducting the current to blow the 20A fuse (or breaker) in event of an internal short

circuit. The 7895 needs a low impedance ground connection to the equipment frame which, in turn, needs a low impedance

connection to earth ground. For a ground path to be low impedance at RF frequencies, the connection must be made with

minimum length conductors that have maximum surface areas. Wide straps or brackets rather than leadwires are preferred.

Be careful to verify that mechanically tightened joints along the ground path, such as pipe or conduit threads or surfaces held

together with fasteners, are free of nonconductive coatings and are protected against mating surface corrosion.

3

2000 VA maximum connected load to 7895 Assembly.

4

Can also be 100 Vac, 1A pilot duty.

5

Can also be 65 VA pilot duty with motorized valve, 1150 VA inrush, 460 VA open, 250 VA hold.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Relations

Honeywell, 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

65-0205

2

7800 SERIES EC7895A, RM7895A RELAY MODULE

Model:

EC7895

Electrical Ratings, see Table 1B:

Voltage and Frequency: 200 Vac (+10/-15%), 50 or 60 Hz

(+/- 10%).

1

Power Dissipation: EC7895: 10W maximum.

Maximum Total Connected Load: 2000 VA.

Fusing Total Connected Load: 20A maximum, type FRN or

equivalent.

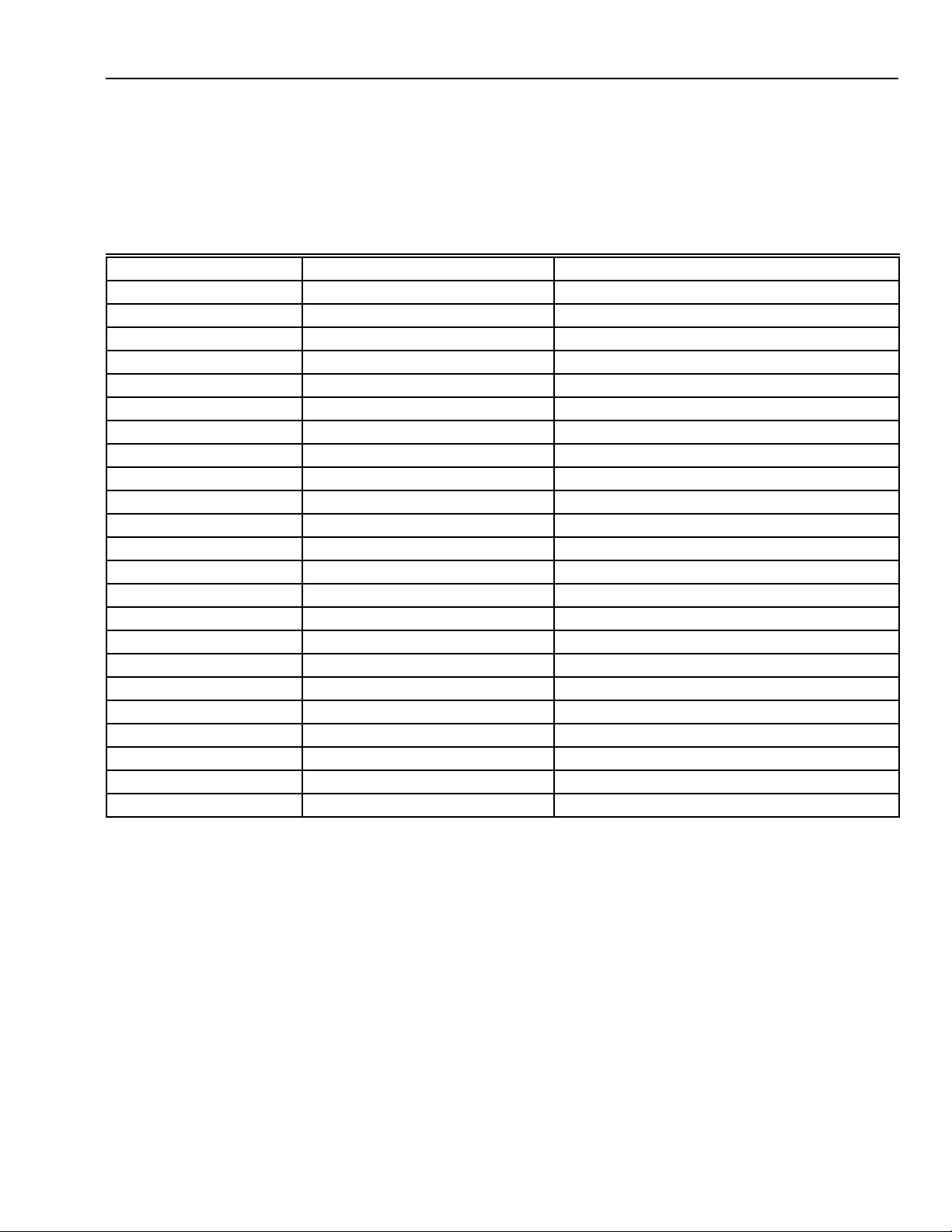

Table 1B. EC7895A Terminal Ratings.

Terminal No. Description Ratings

G Flame Sensor Ground

Earth G Earth Ground

2

L2 (N) Line Voltage Common

3 Alarm 200 Vac, 1A pilot duty.

4 Burner Motor 200 Vac, 4A at pF = 0.5, 20A inrush

5 Line Voltage Supply (L1) 200 Vac (+10/-15%), 50 or 60 Hz (+/- 10%).

4

3,4

6 Burner Controller and Limits 200 Vac, 1 mA.

7 Airflow Interlock 200 Vac, 9A.

8 Pilot Valve/Ignition 200 Vac, 4A at pF = 0.5, 20A inrush

9 Main Fuel Valve 200 Vac, 4A at pF = 0.5, 20A inrush

10 Ignition 200 Vac, 4A at pF = 0.5, 20A inrush

4

4

4

F(11) Flame Sensor 60 to 220 Vac, current limited.

12 Unused

13 Unused

14 Unused

15 Unused

16 Unused

17 Unused

18 Unused

19 Unused

20 Unused

21 Unused

22 Shutter 200 Vac, 0.5A

1

Range of allowable operating frequency 45 through 66 Hz.

2

The EC7895 must have an earth ground providing a connection between the subbase and the control panel or the equipment.

The earth ground wire must be capable of conducting the current to blow the 20A fuse (or breaker) in event of an internal short

circuit. The RM7895 needs a low impedance ground connection to the equipment frame which, in turn, needs a low

impedance connection to earth ground. For a ground path to be low impedance at RF frequencies, the connection must be

made with minimum length conductors that have maximum surface areas. Wide straps or brackets rather than leadwires are

preferred. Be careful to verify that mechanically tightened joints along the ground path, such as pipe or conduit threads or

surfaces held together with fasteners, are free of nonconductive coatings and are protected against mating surface corrosion.

3

2000 VA maximum connected load to EC7895 Assembly.

4

Total load current excluding burner/boiler motor and firing rate outputs cannot exceed 5A, 25A inrush.

3

65-0205

7800 SERIES EC7895A, RM7895A RELAY MODULE

Environmental Ratings:

Ambient Temperature:

Weight:

RM7895 with Dust Cover: 1 pound 15 ounces, unpacked.

Operating: -40° F to 140° F.

Storage: -60° F to 150° F.

Humidity: 85% RH continuous, noncondensing.

Vibration: 0.5G environment.

IMPORTANT

Flame Detection System available for use with

EC7895 and RM7895. To select your Plug-in Flame

Signal Amplifier and applicable Flame Detector, see

Dimensions:

Ta ble 2 and Fig. 3 through 5.

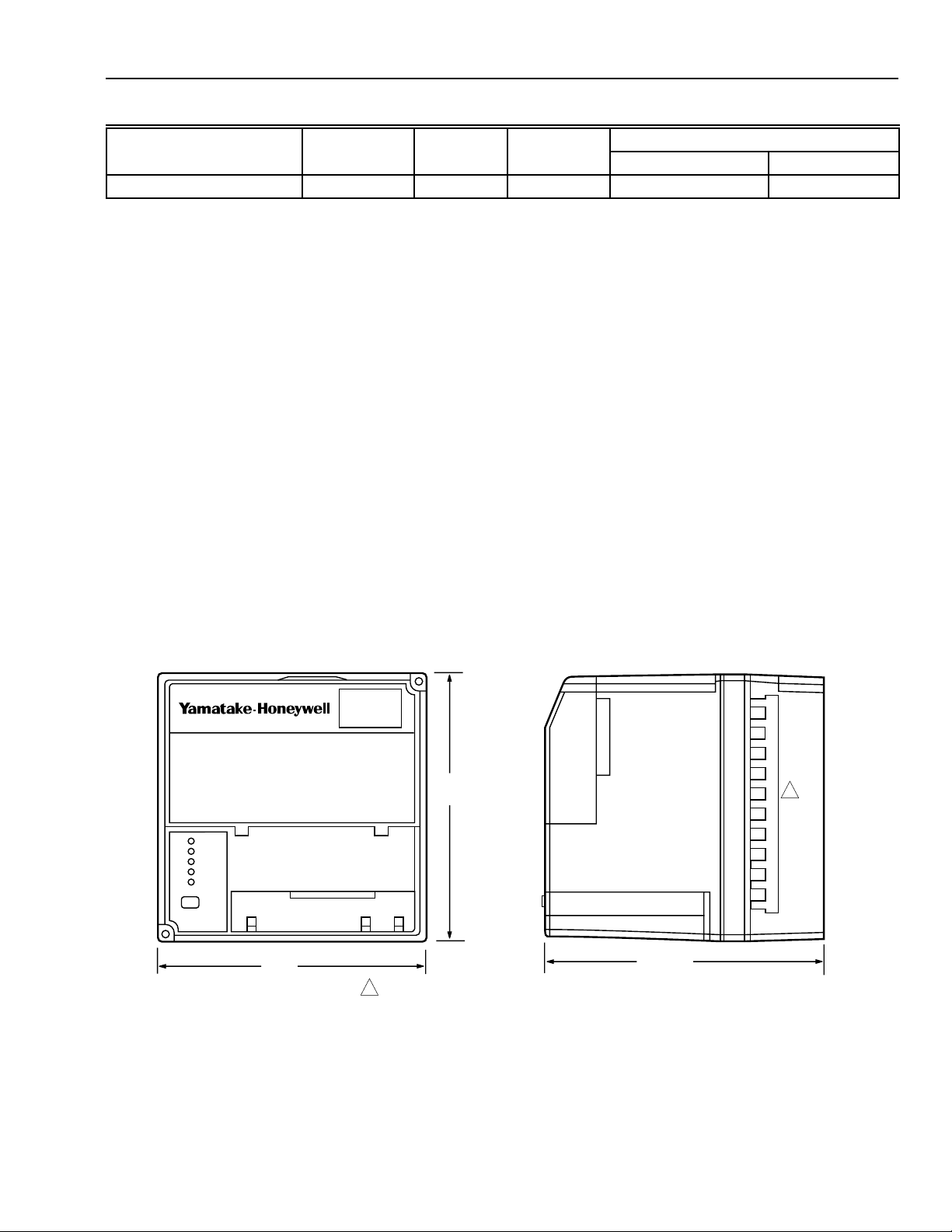

Refer to Fig. 1 and 2.

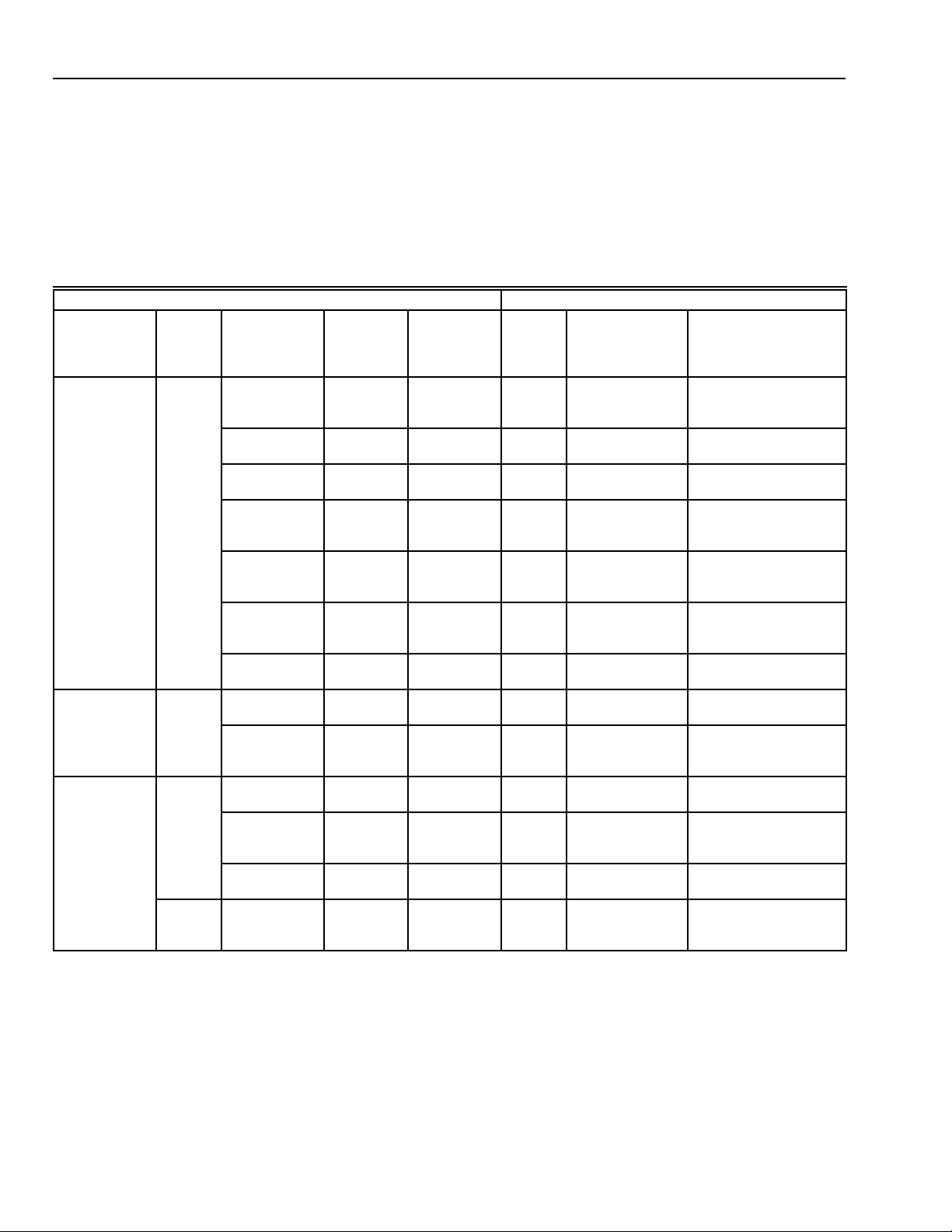

Table 2. Flame detection systems (Figs. 3, 4, 5).

Plug-in Flame Signal Amplifiers Applicable Flame Detectors

Flame

Failure

Type Color

Checking Model

Rectification Green No R7847A .8 or 3 sec Gas Rectifying Flame

Self-

Response

Time Fuel Type Models

C7004, C7007, C7011

Rod Holders

a

Complete Assemblies:

C7008, C7009, Q179.

No R7847A .8 or 3 sec Oil Rectifying

Photocell

No R7847A 3 sec Gas,

Oil, Coal

Dynamic

R7847B

d

.8 or 3 sec Gas Rectifying Flame

AMPLI-

Ultraviolet

(Purple Peeper)

Rod Holders

CHECK®

Dynamic

AMPLI-

R7847B

d

.8 or 3 sec Oil Rectifying

Photocell

C7003, C7010, C7013,

b

C7014

C7012A,C.

C7004, C7007, C7011

a

Complete Assemblies:

C7008, C7009, Q179.

C7003, C7010, C7013,

b

C7014

c

CHECK®

Dynamic

AMPLI-

R7847B

d

3 sec Gas,

Oil, Coal

Ultraviolet

(Purple Peeper)

C7012A,C.

c

CHECK®

Dynamic

R7847C

Self-Check

Infrared Red No R7848A 3 sec Gas,

Dynamic

R7848B

AMPLI-

e

3 sec Gas,

d

3 sec Gas,

Oil, Coal

Oil, Coal

Oil, Coal

Ultraviolet

(Purple Peeper)

Infrared

(Lead Sulfide)

Infrared

(Lead Sulfide)

C7012E,F.

C7015

C7015

CHECK®

Ultraviolet Purple No R7849A .8 or 3 sec Gas, Oil Ultraviolet

(MiniPeeper)

Dynamic

AMPLI-

R7849B

d

.8 or 3 sec Gas, Oil Ultraviolet

(MiniPeeper)

C7027, C7035,

c

C7044.

C7027, C7035,

c

C7044.

CHECK®

Dynamic

Self-Check

Blue Dynamic

Self-Check

R7861A 3 sec Gas,

f

g

R7886A

e

3 sec Gas,

Oil, Coal

Oil, Coal

Ultraviolet C7061

Ultraviolet

C7076

(Adjustable

Sensitivity)

a

Order flame rod separately; see holder Instructions.

b

Use

only

c

The C7012A,C, C7027, C7035 and C7044 Flame Detectors should be used only on burners that cycle on-off at least once

Honeywell Photocell, part no. 38316.

every twenty-four hours. Appliances with burners that remain on continuously for twenty-four hours or longer should use the

C7012E,F Flame Detector with the R7847C Amplifier or the C7076A,D Flame Detector with the R7886A Amplifier or the C7061

Flame detector with the R7861 Amplifier as the ultraviolet flame detection system.

d

Circuitry tests the flame signal amplifier at least 12 times a minute during burner operation and shuts down the burner if the

amplifier fails.

e

Circuitry tests all electronic components in the flame detection system (amplifier and detector) 12 times a minute during burner

operation and shuts down the burner if the detection system fails.

f

When R7861 is used with EC7895, the application requires a step down transformer. See Fig. 14.

g

Use with RM7895A only.

65-0205

4

7800 SERIES EC7895A, RM7895A RELAY MODULE

Sequence Timing For Normal Operation:

Flame Establishing Period

Device Initiate Standby Purge Pilot Main

EC7895A/RM7895A 10 sec. * ** 4 or 10 sec. No

*STANDBY and RUN can be an infinite time period.

** PURGE is determined by the ST7800A Purge Card selected.

Approval Bodies:

RM7895A:

Underwriters Laboratories Inc. listed: File no. MP268,

Guide no. MCCZ.

Factory Mutual approved.

EC7895A:

Factory Mutual approved.

Mounting:

Q7800A for panel mount or Q7800B for wall or burner mount.

Required Components:

Plug-in Flame Signal Amplifier, see Table 2.

Plug-in Purge Timer Cards: Selectable ST7800A, two

seconds to 30 minutes.

Q7800A or Q7800B.

BURNER

CONTROL

Accessories:

Optional:

Network Interface Unit,

Part No. Q7700A1014, 120V 50/60 Hz

Part No. Q7700B1004, 100V to 200V 50/60 Hz

Network Interface ControlBus Module,

Part No. QS7800A1001.

COMBUSTION SYSTEM MANAGER™,

Part No. ZM7850A1001.

ControlBus 5-Wire Electrical Connector,

Part No. 203541.

DATA CONTROLBUS MODULE™,

Part No. S7810A1009.

Dust Cover, Part No. 221729A.

Flame Simulators:

UV Flame Simulator, Part No. 203659.

Rectification Simulator, Part No. 123514A.

Keyboard Display Module, Part No. S7800A1001,

English.

Keyboard Display Module, Part No. S7800A1118,

Japanese.

Remote Display Mounting Bracket, Part No. 203765.

Remote Display Power Supply, Part No. 203968A Plug-in.

Remote Reset Module, Part No. 57820A1007.

Sixty-inch Extension Cable Assembly, Part No. 221818A.

POWER

PILOT

FLAME

MAIN

ALARM

RESET

5 (127)

5

(127)

REMOVE ONLY FOR TERMINAL TEST ACCESS.

1

5-1/4

(133)

1

M11135

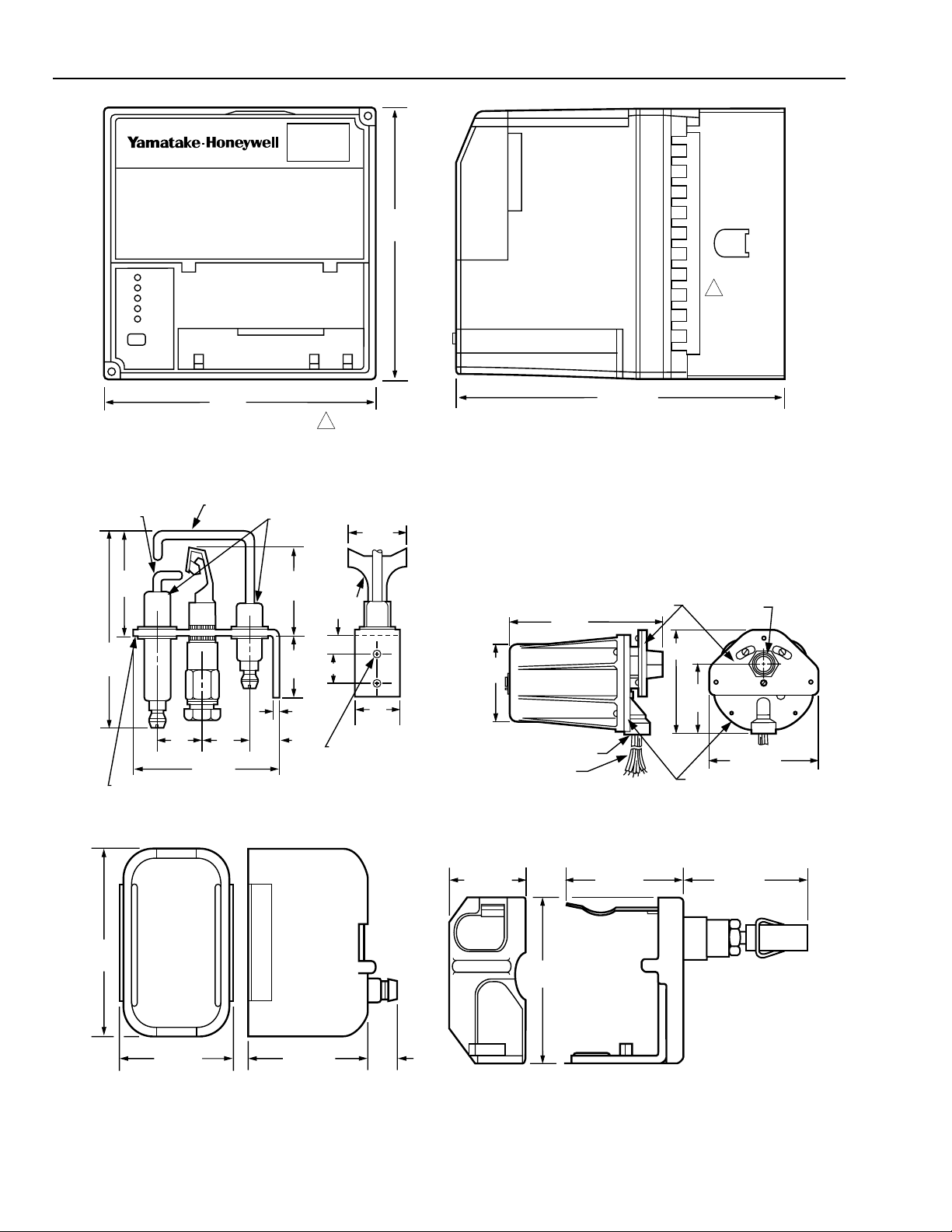

Fig. 1. Mounting dimensions of EC7895/RM7895 Relay Module and Q7800A Subbase in in. (mm).

5

65-0205

7800 SERIES EC7895A, RM7895A RELAY MODULE

BURNER

CONTROL

5

(127)

POWER

PILOT

FLAME

MAIN

ALARM

RESET

1

IGNITION

ELECTRODE

(Q179C ONLY)

1-21/32

(42)

3-1/8

(79)

BRACKET

5 (127)

REMOVE ONLY FOR TERMINAL TEST ACCESS.

1

6-3/32 (155)

M11134

Fig. 2. Mounting dimensions of EC7895/RM7895 Relay Module and Q7800B Subbase in in. (mm).

25/32

(20)

FLAME ROD

25/32

(20)

2-25/32

(62)

Q179

CERAMIC

INSULATORS

1-13/32

(36)

TARGET

1-1/16

1/2 (13)

(27)

3/32 (2)

17/32

(14)

3/8 (10)

THREADED

MOUNTING

HOLES (2)–

10-32 UNF

1 (25)

11/16

(18)

M1983

3-3/4

(95)

7-7/32

(183)

1/2–14 NPSM

LEADWIRES

MOUNTING FLANGE

C7012A,C,E,F

5-1/8 (130)

3-7/16

(87)

FACEPLATE

3/4–14 NPT

5-1/4 (133)

M1962A

65-0205

(51)

13/16 (21)

2

1-3/4

(45)

1-1/4 (32)

1-5/16 (33)

5/16

(8)

C7013A C7014A

1-1/4 (32)

1-3/8 (35)

M1847

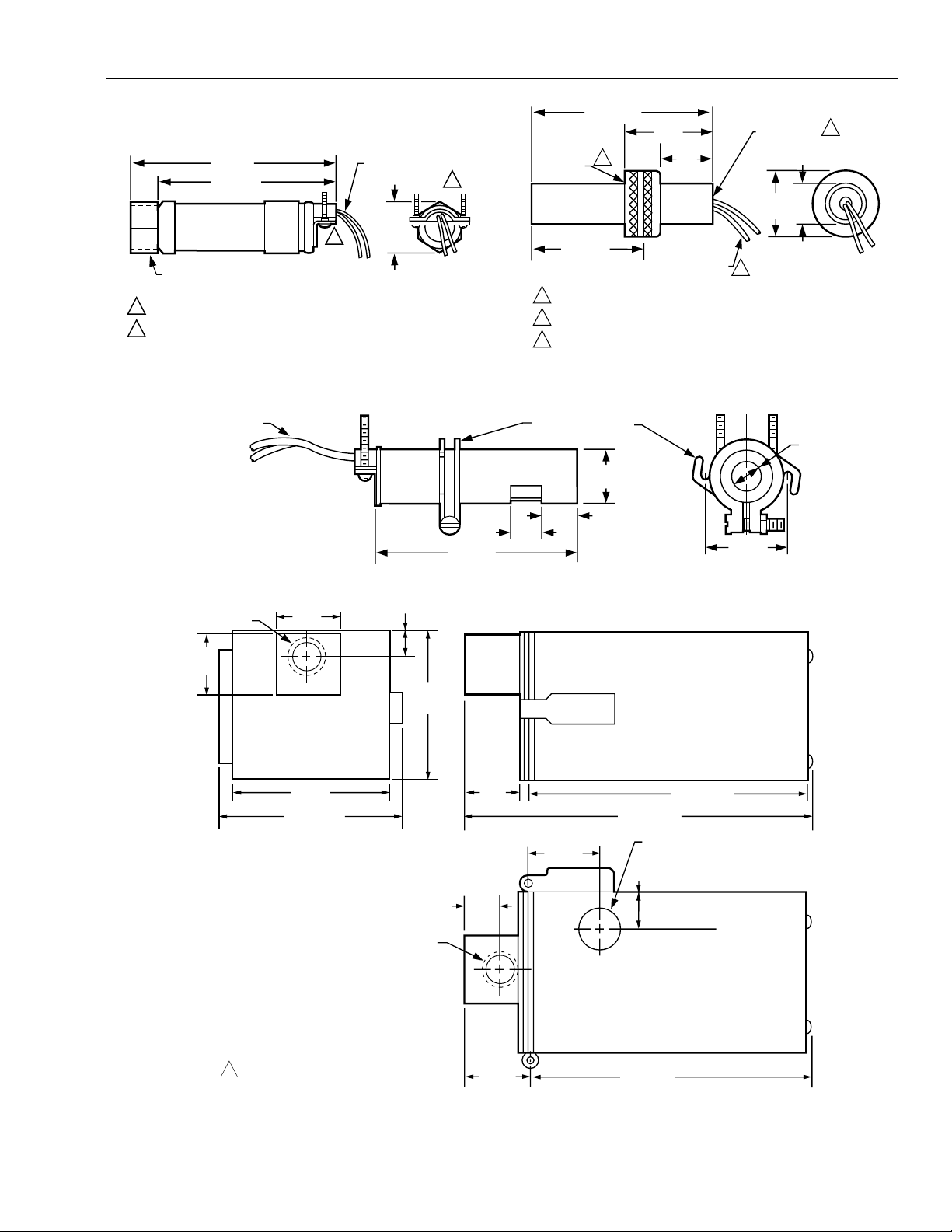

Fig. 3. Rectification detectors.

6

7800 SERIES EC7895A, RM7895A RELAY MODULE

1/2-14 NPSM

INTERNAL THREADS

2

2 (51)

COLLAR WITH

1–11-1/2 NPSM

INTERNAL

THREADS

1

1

DIN APPROVED C7035A1064 HAS 1-11 BSP.P1 INTERNAL THREADS.

DIN APPROVED C7035A1064 HAS 1/2-14 BSP-F INTERNAL THREADS.

MODEL AVAILABLE WITH 12 FOOT [3.66 METER] LEADWIRES.

2

3

INSERTION DEPTH

6 FOOT

[1.83 METER]

LEADWIRES (2)

3

M1945A

2-5/8 (67)

1-1/2

(38)

31/32

(25)

4-1/8 (105)

1-3/16

(30)

4 (102)

3-1/2 (89)

COLLAR WITH 1/2-14 NPSM

INTERNAL THREADS

1

MODEL AVAILABLE WITH 24 FOOT (7.32 METER) LEADWIRES.

MODELS AVAILABLE WITH SPUD CONNECTOR (1/2-14 NPSM INTERNAL

2

THREADS) INSTEAD OF CLAMP TYPE CONNECTOR.

6 FOOT (1.83 METER)

LEADWIRES (2)

2

1-1/16

(27)

C7027

6 FOOT [1.83 METER]

LEADWIRES (2)

1 INCH NPT

2-1/4

(57)

1-1/16 (27)

1

M1943A

3-5/8 (92)

C7044

MOUNTING BRACKET

9/16

(14)

1/2

(13)

7/8

(22)

C7035

1-27/64

(36)

3/8

(10)

M1944A

2-1/4

(57)

ALLOW 9 INCHES (228 MILLIMETERS)

1

CLEARANCE TO SWING OUT THE DETECTOR

FOR LENS CLEANING OR SERVICING.

4 (102)

4-27/32 (123)

4

(102)

2-5/16

(58)

3/4 (19)

1-19/32

(41)

3/8 INCH NPT

2-11/16

(68)

C7076A

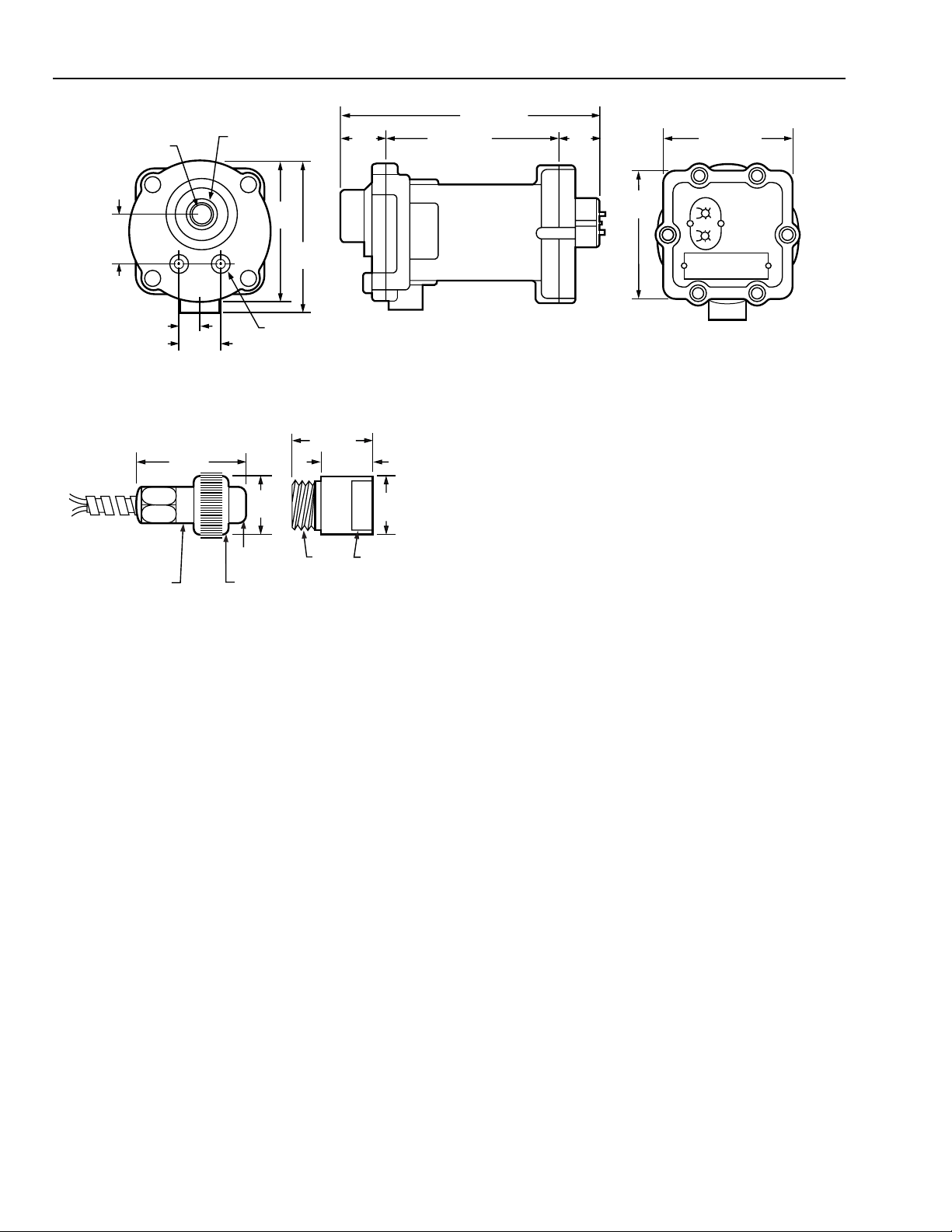

Fig. 4. Ultraviolet detectors in in. (mm).

7

1-13/32 (188)

10-9/32 (261)

7/8 (22) OPENING

FOR 1/2-INCH CONDUIT

29/32 (23)

7-5/8 (194)

M5083A

65-0205

7800 SERIES EC7895A, RM7895A RELAY MODULE

2-5/32

(55)

C7076D

15/16 [24] DIA.

2-1/2

(64)

1 (25)

2 (51)

1 INCH NPT

15/16–18 UNC

(2 EACH)

6-7/32

(158)

6-19/32

(168)

Fig. 4. Ultraviolet detectorsin in. (mm)

HEAT BLOCKCELL MOUNT

1-5/8 (41)

1-1/16 (27)

3/4-14

NPSM

1-1/4

(32)

3/4-14 NPSM

INTERNAL

THREADS

M1982A

2 LEADS IN A

48 INCH (1.2 METER)

FLEXIBLE CONDUIT

BUSHING WITH

MAGNIFYING LENS

2-3/4

(70)

1-1/4

(32)

APERTURE

COLLAR, 3/4-14 NPSM

INTERNAL THREADS

C7015

Fig. 5. Infrared detector in in. (mm).

PRINCIPAL TECHNICAL FEATURES

The EC7895 or RM7895 provides all customary flame

safeguard functions while providing significant advancements

in the areas of safety, annunciation and system diagnostics.

Safety Shutdown (Lockout) Occurs If:

1. Initiate Period

a. Purge card is not installed or removed.

b. Purge card is bad.

c. Configuration jumpers have been changed (after

200 hours).

d. AC line power errors occurred, see Operation.

e. Four minute INITIATE period was exceeded.

2. Standby Period

a. Flame signal is present after 40 seconds.

b. Ignition/pilot valve/intermittent pilot valve terminal

is energized.

c. Main valve terminal is energized.

d. Internal system fault occurred.

e. Purge card is not installed or removed.

f. Purge card is bad.

3. Prepurge Period

a. Airflow lockout feature is enabled and the airflow

switch does not close after ten seconds or within

the specified purge card timing.

b. Flame signal is detected after 30 seconds.

c. Ignition/pilot valve/intermittent pilot valve terminal

is energized.

11-13/16 (300)

7-13/16 (198)

1-27/32

(47)

5-13/16

(147)

5-13/16 (147)

M5084A

(Continued).

d. Main valve terminal is energized.

e. Internal system fault occurred.

f. Purge card is removed.

g. Purge card is bad.

4. Pilot Flame Establishing Period (PFEP)

a. Airflow lockout feature is enabled and the airflow

switch opens.

b. Ignition/pilot valve terminal is not energized.

c. No flame present at end of PFEP.

d. Main valve terminal is energized.

e. Internal system fault occurred.

f. Purge card is removed.

g. Purge card is bad.

5. Run Period

a. No flame present.

b. Airflow lockout feature is enabled and the airflow

switch opens.

c. Main valve terminal is not energized.

d. Internal system fault occurred.

e. Purge card is removed.

f. Purge card is bad.

SAFETY PROVISIONS

Internal Hardware Status Monitoring

The EC7895 or RM7895 checks the purge card for correct

parity to prevent purge timing shifts and circuitry failures. It

also analyzes the integrity of the configuration jumpers and

internal hardware. The POWER LED blinks every four

seconds, signifying an internal hardware check.

Closed Loop Logic Test

The test verifies the integrity of all safety critical loads,

terminals 8, 9, 10 and 21. If the loads are not energized

properly; i.e., the main valve terminal is powered during

PREPURGE, the EC7895 or RM7895 locks out on safety

shutdown. The EC7895 or RM7895 must react to input

changes but avoid the occurrence of

events. Signal conditioning is applied to line voltage inputs to

verify proper operation in the presence of

line noise such as transient high voltage spikes or short

periods of line dropout. Signal conditioning is tolerant of

synchronous noise (line noise events that occur at the same

time during each line cycle).

nuisance

normal

shutdown

electrical

65-0205

8

7800 SERIES EC7895A, RM7895A RELAY MODULE

Dynamic Ampli-Check

Dynamic AMPLI-CHECK® circuitry tests the flame signal

amplifier during burner operation and shuts down the EC7895

or RM7895 if the flame amplifier fails.

Dynamic Flame Amplifier and Shutter Check

Self-checking circuitry tests all electronic components in the

flame detection system and amplifier 10 to 12 times per

minute and shuts down the EC7895 or RM7895 if the

detection system fails.

Dynamic Input Check

All system input circuits are examined to assure that the

EC7895 or RM7895 is capable of recognizing the true status

of external controls, limits and interlocks. If any input fails this

test, a safety shutdown occurs and the fault is annunciated.

Dynamic Safety Relay Test

Checks the ability of the dynamic safety relay contact to open

and close. Verifies that the safety critical loads, terminals 8, 9,

10 and 21, can be de-energized, as required, by the Dynamic

Self-Check logic.

Dynamic Self-Check Safety Circuit

The microcomputer tests itself and related hardware, and at

the same time, the safety relay system tests the

microcomputer operation. If a microcomputer or safety relay

failure occurs and does not allow proper execution of the selfcheck routine, safety shutdown occurs and all safety critical

loads are de-energized.

Expanded Safe-Start Check

The conventional safe-start check, which prevents burner

start-up if flame is indicated at start-up, is expanded to

include a flame signal check during STANDBY, an airflow

switch check and a safety critical load check.

Off Cycle (Standby or Prepurge) Flame

Signal Check

The flame detection subsystem (flame detector and amplifier)

is monitored during STANDBY. If a flame simulating condition

or an actual flame exists, a system hold occurs and start-up is

prevented. If the flame signal exists at any time after the first

40 seconds of STANDBY, a safety shutdown occurs and is

annunciated. A shutter-check amplifier and self-checking

detector are energized for the first 40 seconds during

STANDBY and the last two seconds before exiting STANDBY.

If a flame exists, a safety shutdown occurs. An AMPLICHECK® Amplifier is energized continually through

STANDBY and PREPURGE to detect any possibility of a

runaway detector or a flame. If a flame exists, a safety

shutdown occurs. A standard amplifier is energized

continually through STANDBY and PREPURGE; if a flame

exists, a safety shutdown occurs.

®

Verified Spark Termination

The ignition terminal is monitored to assure early spark

termination (ten seconds ignition and pilot and ten seconds

pilot and main only

First-Out Annunciation AND Self-Diagnostics

Sequence Status Lights (LEDs)

indication of the program sequence: POWER, PILOT,

FLAME, MAIN and ALARM. The green POWER LED blinks

every four seconds, signifying that the RM7895 hardware is

running correctly.

Optional multi-function Keyboard Display Module

elapsed time during PREPURGE, PILOT IGN and MAIN IGN.

As an additional troubleshooting aid, it provides sequence

timing, diagnostic information and historical information when

a safety shutdown or hold or normal operation occurs.

First-out Annunciation

or identifies the cause of a failure to start or continue the

burner control sequence with text and numbered code via the

optional Keyboard Display Module. It monitors all field input

circuits, including the flame signal amplifier. The system

distinguishes 43 modes of failure and detects and

annunciates difficult-to-find intermittent failures.

Self-Diagnostics

the EC7895 or RM7895 to distinguish between field (external

device) and internal (system related) problems. Faults

associated within the flame detection subsystem, EC7895 or

RM7895 or Plug-in Purge Card are isolated and reported by

the optional Keyboard Display Module. See the 7800 SERIES

System Annunciation Diagnostics and Troubleshooting,

form 65-0118.

Airflow Switch Interlock

This interlock is typically connected to an airflow switch. The

Airflow Interlock (ILK) input must close ten seconds into

PREPURGE or within the specified purge card timing;

otherwise, a recycle to the beginning of PRE-PURGE or

lockout will occur, depending on how the airflow switch

selectable jumper is configured (see Table 3 in Operation

section).

INSTALLATION

).

provide positive visual

shows

reports the cause of a safety shutdown

add to the First-out Annunciation by allowing

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY, OR DEATH

To prevent possible hazardous burner operation,

verification of safety requirements must be performed

each time

a control is installed on a burner.

Tamper Resistant Timing and Logic

Safety and logic timings are inaccessible and cannot be

altered or defeated.

9

65-0205

Loading...

Loading...