Page 1

32003532-005

Dual Auxiliary Switch Package

INSTALLATION INSTRUCTIONS

APPLICATION

The Dual Auxiliary Switch Package contains two

independent 360 degree rotary switch cams for use in

conjunction with Direct Coupled Actuators (DCA). See

Table 1. It provides an on/off signal at two adjustable

points in the actuator stroke. This signal can be routed to

a controller or used to control equipment external to the

actuator (for example, electric reheat coils and fan). As

the device mounts over the DCA hub and setscrews, it

can be added to an already-installed DCA.

IMPORTANT

1. The 32003532-005 housing is made of a material designed to survive UL555(S) Smoke and

Fire Damper/Actuator testing.

2. Switches are not designed to function at the

extreme temperatures of the UL555(S) test for

extended periods.

Table 1. Switch and Actuator Compatibility.

Compatible Direct Coupled Actuator Models

ML4105 ML4202 ML8105 MS4209

ML4115 ML4302 ML8115 MS4309

ML4125 ML4702 ML8125 MS4709

ML4135 ML4802 ML8135 MS4809

ML8202 MS8209

ML8302 MS8309

Package Contents (see Fig. 1):

Self-tapping mounting screws (2).

Switch assembly.

1m, 6-conductor cable.

3/8 in. flexible conduit connector.

Mounting bracket.

Dimensions: See Fig. 2.

Conduit (not included): 3/8 in. flexible.

Electrical Switch Ratings: See Table 2.

Operating Temperature: -40 to 130°F (-40 to 54°C).

Switch Differential: Three angular degrees maximum.

Switching: Two single-pole, double-throw (spdt) micro

switches.

Ratings and Approvals:

Underwriters Laboratories Inc. Listed: File No. E4436.

UL94-5V Plenum rating.

NEMA2.

Cable: UL Style 1180 rated 300V, 200°C, 18 gauge.

Fig. 1. Auxiliary switch.

Table 2. Electrical Switch Ratings.

Vol tag e

(maximum)

32003532-005 24 Vac

Class 2–

240 Vac

Resistive

Load

8A 2A

M22537

Inductive

Load

62-0212-01

Page 2

32003532-005 DUAL AUXILIARY SWITCH PACKAGE

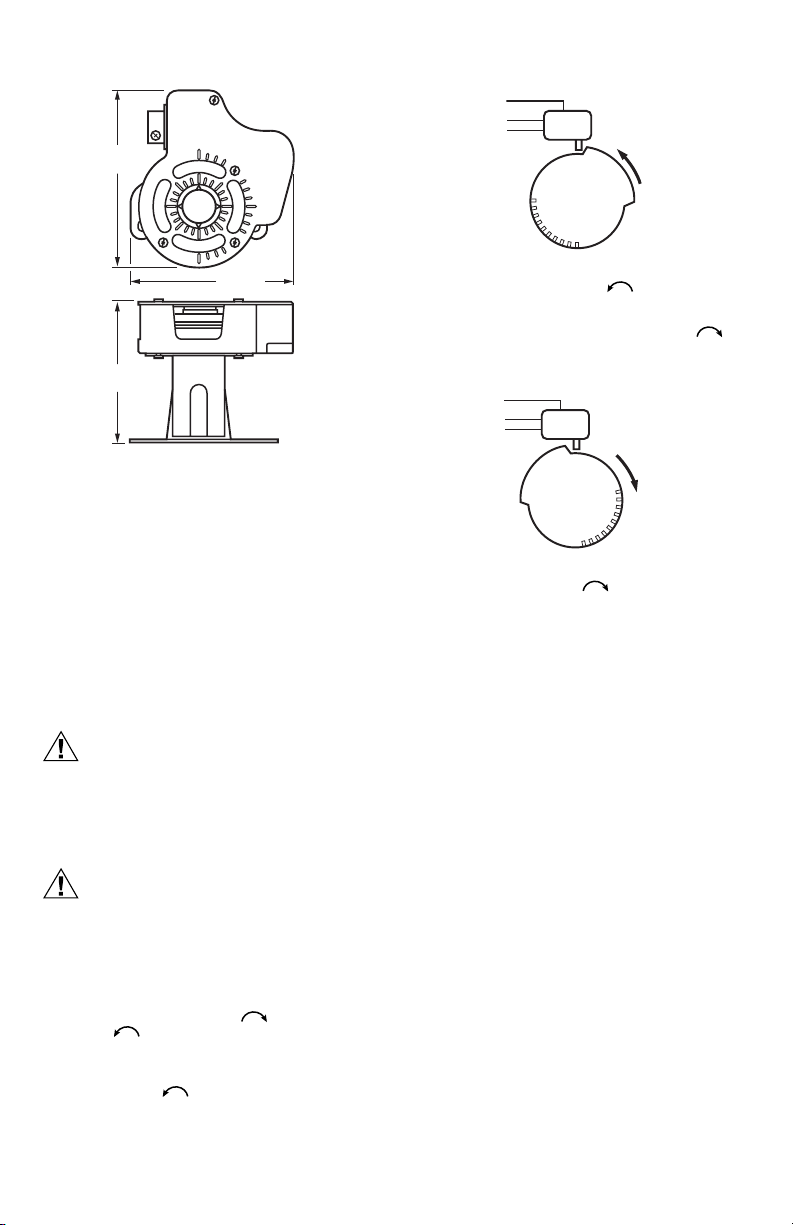

4

(102)

3-5/8 (92)

3

(76)

M17518

Fig. 2. Dimensions in in. (mm).

COM

NO

NC

CCW

M2160

Fig. 3. Switching configuration (top view)

for counterclockwise rotation.

Conversely, with the switch cam as shown in Fig. 4, the

normally closed contact opens during clockwise

rotation and the normally open switch closes.

COM

NO

NC

CW

INSTALLATION

When Installing this Product...

1. Read instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check ratings and descriptions given in

Specifications to make sure product is suitable for

your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

CAUTION

Electrical Shock or Equipment Damage

Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation and

always keep device assembled.

CAUTION

Actuator Damage Hazard.

Turning motor output hub by hand or wrench

can damage internal gears.

Forcibly turning the motor shaft damages the gear

train.

1. Determine desired switching action (if switch is to

energize during clockwise or counterclockwise rotation).

NOTE: With switch cam as shown in Fig. 3, the

normally closed contact opens during counterclockwise rotation and the normally open

switch closes.

M2161

Fig. 4. Switching configuration (top view)

for clockwise rotation.

NOTE: Switches can be set prior to installation on the

actuator if angular switch positions are known.

2. Align the switch hub with the set screws on the

actuator. See Fig. 5.

3. If the conduit location is not appropriate for your

application, adjust the bracket as follows:

a. Remove and set aside the four bracket screws.

b. Rotate the bracket 90, 180, or 270 degrees.

c. Replace the bracket screws.

4. Mount the switch on the actuator and tighten the

two screws.

5. Determine switch position settings based on the

angular indications molded into the housing.

NOTES:

— Interior angular indications appear in

15 degree increments (see Fig. 6).

— Exterior angular indications appear in

10 degree increments (see Fig. 6).

— Four 10 degree indications are not on the

cover (see Fig. 6).

6. Move each cam inside switch assembly to the

appropriate position. Remember the direction

of travel of the cam for switching purposes (see Fig.

3 and 4). Monitor the switch closure with an ohmmeter for a continuity check. See Table 3.

IMPORTANT

Make certain that the switch activates at the

desired degree of stroke.

62-0212—01 2

Page 3

32003532-005 DUAL AUXILIARY SWITCH PACKAGE

10°

M17520

Fig. 5. ML4125 DCA with Auxiliary Switch.

Table 3. Proper continuity measurements.

Switch Normally Open Normally Closed

Activated Zero ohms Infinite ohms

Not Activated Infinite ohms Zero ohms

15°

Fig. 6. Auxiliary switch angular indications.

Wiring

CAUTION

Electrical Shock or Equipment Damage

Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation and

always keep device assembled.

NOTE: See Table 4 for wiring information.

Table 4. Auxiliary Switch Wiring Connections.

Connection Upper Switch Lower Switch

Common Black/Red White/Red

Normally Closed Black/Yellow White/Yellow

Normally Open Black/Blue White/Blue

M17517

3 62-0212—01

Page 4

32003532-005 DUAL AUXILIARY SWITCH PACKAGE

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages

arising out of your use or modification to, the literature. You will defend and indemnify Honeywell,

its affiliates and subsidiaries, from and against any liability, cost, or damages, including attorneys’

fees, arising out of, or resulting from, any modification to the literature by you.

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

® U.S. Registered Trademark

© 2008 Honeywell International Inc.

62-0212—01 M.S. Rev. 06-08

Loading...

Loading...