Page 1

301EM

MODULE D’EXPANSION

EXPANSION MODULE

Manuel d’utilisateur

User Manual

Page 2

Page 3

Gas Detection Device

301EM

User Manual

ERP 512720

2/09

Page 4

Page 5

Notices and Trademarks

Copyright by Honeywell International Inc.

Release 512720 February 2009

While this information is presented in good faith and believed to be accurate,

Honeywell disclaims the implied warranties of merchantability for a particular

purpose and makes no express warranties except as may be stated in its written

agreement with and for its customers.

In no event is Honeywell liable to anyone for any indirect, special or consequential

damages. The information and specifications in this document are subject to

change without notice.

Honeywell Analytics

4005 Matte Blvd, Unit G

Brossard, Quebec, Canada, J4Y 2P4

301EM User Manual iii

Page 6

Page 7

Symbol Definitions

The following table lists the symbols used in this document to denote

certain conditions:

Symbol Definition

ATTENTI ON: Identifies information that requires

special consideration

TIP: Identifies advice or hints for the user, often

in terms of performing a task

REFERENCE _ INTERNAL: Identifies an

additional source of information within the

bookset.

Indicates a situation which, if not avoided, may

CAUTION

result in equipment or work (data) on the system

being damaged or lost, or may result in the

inability to properly operate the process.

CAUTION: Indicates a potentially hazardous

situation which, if not avoided, may result in minor

or moderate injury. It may also be used to alert

against unsafe practices.

CAUTION: Symbol on the equipment refers the

user to the product manual for additional

information. The symbol appears next to required

information in the manual.

WARNING: Indicates a potentially hazardous

situation which, if not avoided, could result in

serious injury or death.

WARNING symbol on the equipment refers the

user to the product manual for additional

information. The symbol appears next to required

information in the manual.

301EM User Manual v

Page 8

Page 9

Contents

INTRODUCTION ..............................................................9

Description ............................................................................................... 9

Intended Use ............................................................................................9

Unpacking ................................................................................................ 9

INSTALLATION INSTRUCTIONS .................................10

Installation Guidelines .......................................................................10

Wall Mount Installation ......................................................................10

Recommended Sensor Installation Heights ...........................................11

Determining the Number of Transmitters ..........................................12

Range and Alarm Levels ........................................................................13

Installing Optional Remote Sensors .......................................................14

WIRING DETAILS ..........................................................16

System Wiring ...................................................................................16

Power Connections ................................................................................17

Connecting sensors to transmitter .........................................................18

Communication to Controller .................................................................19

Relay Outputs ........................................................................................19

24 Vdc Output ........................................................................................20

4-20 mA Configuration ...........................................................................20

4-20 Output Configuration ......................................................................22

CALIBRATION / PROGRAMMING ................................ 27

User Interface ....................................................................................27

Operating Mode .....................................................................................27

Pushbutton Definitions ...........................................................................28

Programming the Unit ........................................................................29

Accessing the Programming Menus ..................................................30

Setting the Unit’s Address .................................................................31

Configuring a Sensor .........................................................................32

Changer the Sensor Address .................................................................32

Adding a new Sensor .............................................................................33

Removing a Sensor ...............................................................................34

301EM User Manual vii

Page 10

Adding Remote Panels ......................................................................34

Using the Service Menu ....................................................................35

Using the SetEvent Menu ..................................................................36

Changing Event Configurations .............................................................37

Using the SetRelay Menu ..................................................................40

Deactivating the Buzzer .....................................................................41

Configuring the Unit’s Alarms ............................................................42

Setting the Unit’s Analog Outputs ......................................................43

Calibrating the Unit ............................................................................44

Connecting the Hardware ......................................................................44

Adjusting the Zero (If Required) .............................................................45

Calibrating the Sensor ...........................................................................46

301EM Specifications ......................................................................48

301IRFS Specifications .....................................................................49

Maintenance ......................................................................................51

Replacement Parts ................................................................................51

Cleaning .................................................................................................51

APPENDIX A ..................................................................52

Available Pre-programmed configurations ........................................52

Type 1 CND (B-52 Canadian Standard for R123) .................................52

Type 2 CND (B-52 Canadian Standard for other Refrigerants) .............52

Type 3 US (ASHRAE 15 Standard for Refrigerants) .............................53

Type 4 (Default configuration - other than B-52 and ASHRAE 15) ........54

LIMITED WARRANTY ................................................... 55

Limited Warranty ....................................................................................55

Re-Stocking Policy .................................................................................55

Exclusions ..............................................................................................56

Warranty Limitation and Exclusion .........................................................56

Disclaimer of Unstated Warranties ........................................................57

Limitation of Liability ...............................................................................57

viii 301EM User Manual

Page 11

Introduction

Introduction

Description

Honeywell introduces a breakthrough innovation in refrigerant, toxic and

combustible gas monitoring as part of our continued commitment to

cutting-edge technology and customer satisfaction.

The result of extensive research and design, the 301EM uses the latest in

infrared technology. The 301EM can have up to 20 sensors connected to

allow for accurate monitoring of even the lowest gas concentration.

The 301EM (with an LCD display and keypad) can be installed in a

location separate from the detection area, making it safer to monitor gas

readings.

The 301EM also offers 4-20mA outputs, relay outputs, Modbus

communication, audible alarm options and is compatible with our 301C

controller.

Intended Use

The availability and costs associated with refrigerant gases make

monitoring a necessity for managing equipment rooms. A Honeywell

refrigerant detector provides early warning of refrigerant leaks, which

enhancing the refrigerant conservation strategy by monitoring

equipement room refrigerant gas concentrations. Toxic and combustible

sensors can be linked to the 301EM, allowing it to meet the broadest

range of customer requirements. The 301EM Expansion Module has

been carefully designed with several factory programmed configurations

that meet or exceed ASHRAE B-52 or 15-2201 standards.

Unpacking

After opening the package, remove the equipment and components.

Please make sure that all the items described on the order form or bill of

lading are actually in the box and are undamaged.

301EM User Manual 9

Page 12

Installation Instructions

Installation Guidelines

Installation Instructions

Installation Guidelines

These guidelines must be strictly observed to ensure that the equipment

will work properly. If they are not applied, Honeywell will not recognize any

liability in case of improper operation:

Make sure to locate all units easily accessible for proper service.

• Avoid any location where units could be subject to vibrations.

• Avoid any location close to any electromagnetic interference.

• Avoid any location where there are large temperature swings.

• Verify local requirements and existing regulations which may affect

the choice of location.

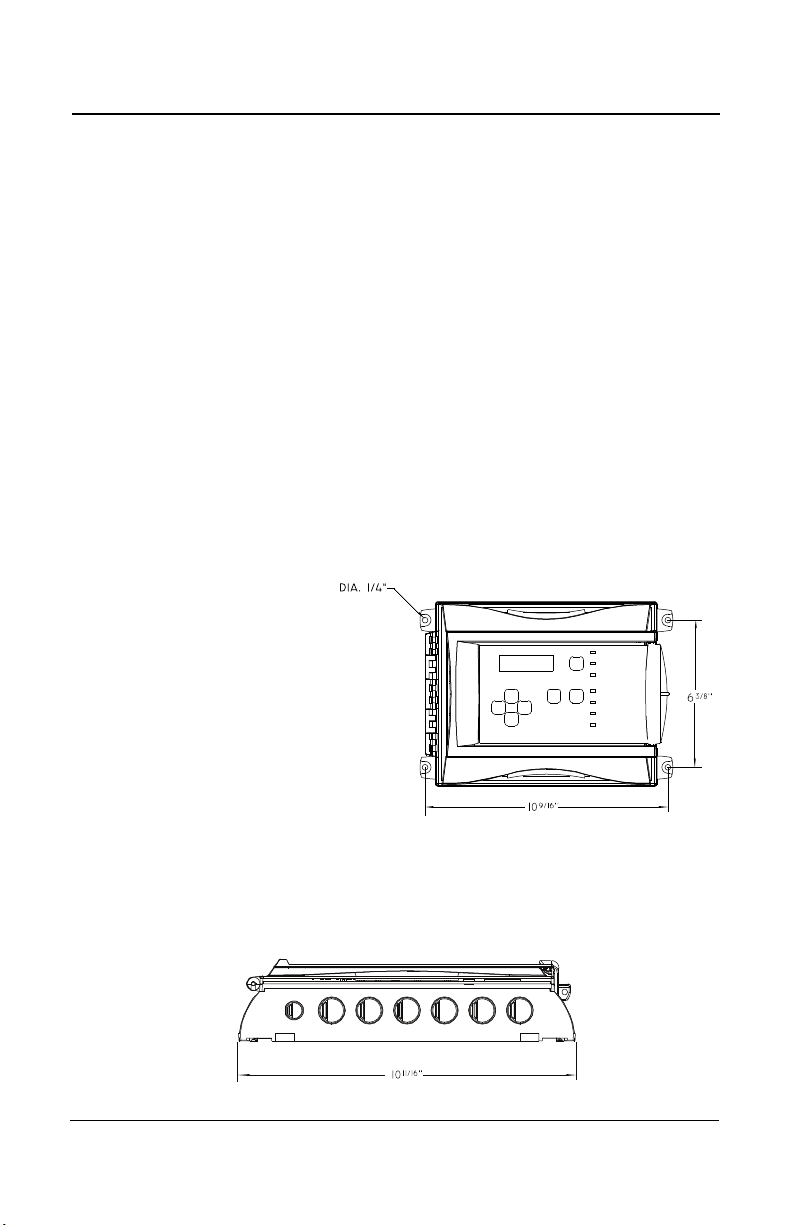

Wall Mount Installation

We recommend installing the

monitor at a height of 1.5 m

(4.9 ft) from the ground (eye

level).

• Mark two holes 162mm (6

3/8”) apart in height

• Mark two holes268.3mm

(10 9/16”) apart in width

• Drill 6.35mm (1/4”) holes

and prepare as necessary

• Mount unit with appropriate screws

Remember to pass all wiring through knock-outs at base of unit, using the

appropriate conduit.

10 301EM User Manual

Page 13

Installation Instructions

Wall Mount Installation

Recommended Sensor Installation Heights

The installation heights recommended represent general guidelines.

Always confirm with local laws and regulations before proceeding, as

these take precedence over manufacturer's recommendations.

Detected Gas

CO Carbon Monoxide 0.968 1 - 1.5 m (3 - 5 ft.) from floor

*NO2 Nitrogen Dioxide 1.58 (cold) 30 cm -1 m (1-3 ft.) from ceiling

H2 Hydrogen 0.07 30 cm (1 ft.) from ceiling

CL2 Chlorine 2.50 30 cm (1 ft.) from floor

H2S Hydrogen Sulfide 1.19 30 cm (1 ft.) from floor

O2 Oxygen 1.43 1 - 1.5 m (3 - 5 ft.) from floor

HCL Hydrogen Chloride 1.30 30 cm (1 ft.) from floor

HCN Hydrogen Cyanide 0.932 30 cm (1 ft.) from ceiling

ETO Ethylene Oxide 1.50 30 cm (1 ft.) from floor

SO2 Sulfur Dioxide 2.25 30 cm (1 ft.) from floor

R11 Refrigerants 5.04 30 cm (1 ft.) from floor

R12 Refrigerants 4.20 30 cm (1 ft.) from floor

R13B1 Refrigerants 5.14 30 cm (1 ft.) from floor

R114 Refrigerants 5.9 30 cm (1 ft.) from floor

R22 Refrigerants 3.11 30 cm (1 ft.) from floor

R123 Refrigerants 5.27 30 cm (1 ft.) from floor

R125 Refrigerants 4.14 30 cm (1 ft.) from floor

R134A Refrigerants 3.52 30 cm (1 ft.) from floor

R227 Refrigerants 5.90 30 cm (1 ft.) from floor

R245A Refrigerants 30 cm (1 ft.) from floor

R404A Refrigerants 3.43 30 cm (1 ft.) from floor

R407C Refrigerants 3.0 30 cm (1 ft.) from floor

R410A Refrigerants 3.0 30 cm (1 ft.) from floor

R507 Refrigerants 3.43 30 cm (1 ft.) from floor

R508b Refrigerants 30 cm (1 ft.) from floor

COMB Most combustibles are heavier than air, with the exception of methane,

hydrogen,ethylene and acetylene. Sensors for gases that are heavier than

air should be installed approximately 30 cm (1 foot) from the floor. For

combustibles that are lighter than air, sensors should be installed 30 cm (1

foot) from the ceiling, close to the potential leak source.

Relative Density

(air = 1)

Installation Height

* May differ in certain applications. Hot NO2 from exhaust systems is lighter than ambient air.

301EM User Manual 11

Page 14

Installation Instructions

Determining the Number of Transmitters

Determining the Number of Transmitters

The number of units required to protect an area is determined by the

unit’s detection radius, which depends on the type of gas detected, as

shown in the following table.

Gas Detected

CO Carbon monoxide 15 m (50 ft)

NO2 Nitrogen dioxide 15 m (50 ft)

Others 7 m (23 ft)

Surveillance

Radius

Area Covered

2

707 m

(7610 ft2)

2

707 m

(7610 ft2)

154 m2 (1658 ft2)

12 301EM User Manual

Page 15

Installation Instructions

Determining the Number of Transmitters

Range and Alarm Levels

Gas Detected Range Alarm A Alarm B Alarm C

CL2 Chlorine 0-15 ppm 0.5 ppm 1 ppm 13,5 ppm

CO Carbon monoxide 0-250 ppm 25 ppm 200 ppm 225 ppm

2S Hydrogen sulfide 0-50 ppm 10 ppm 15 ppm 45 ppm

H

2 Nitrogen dioxide 0-10 ppm 0.72 ppm 2 ppm 9 ppm

NO

O

2 Oxygen 0-25% Vol. 19.5% Vol. 22% Vol. 22,5% Vol.

SO2 Sulfur dioxide 0-10 ppm 2 ppm 5 ppm 9 ppm

R-123 Refrigerant 0-1000 ppm 50 ppm 500 ppm 900 ppm

R-11 Refrigerant 0-1000 ppm 250 ppm 500 ppm 900 ppm

R-12 Refrigerant 0-1000 ppm 250 ppm 500 ppm 900 ppm

R13B1 Refrigerant 0-1000 ppm 250 ppm 500 ppm 900 ppm

R114 Refrigerant 0-1000 ppm 250 ppm 500 ppm 900 ppm

R-22 Refrigerant 0-1000 ppm 250 ppm 500 ppm 900 ppm

R-125 Refrigerant 0-1000 ppm 250 ppm 500 ppm 900 ppm

R134A Refrigerant 0-1000 ppm 250 ppm 500 ppm 900 ppm

R227 Refrigerant 0-1000 ppm 250 ppm 500 ppm 900 ppm

R245A Refrigerant 0-1000 ppm 250 ppm 500 ppm 900 ppm

R404A Refrigerant 0-1000 ppm 250 ppm 500 ppm 900 ppm

R407C Refrigerant 0-1000 ppm 250 ppm 500 ppm 900 ppm

R410A Refrigerant 0-1000 ppm 250 ppm 500 ppm 900 ppm

R507 Refrigerant 0-1000 ppm 250 ppm 500 ppm 900 ppm

R508b Refrigerant 0-1000 ppm 250 ppm 500 ppm 900 ppm

Comb Combustibles 0-100% LEL 25% LEL 50% LEL 90% LEL

A different alarm level may have been programmed in order to satisfy the

constraints of a particular application.

Deadband and Accuracy

(Refrigerant detection)

The deadband is the area of signal or detection range where no action

occurs. The IRF deadband is 20 ppm.

301EM User Manual 13

Page 16

Installation Instructions

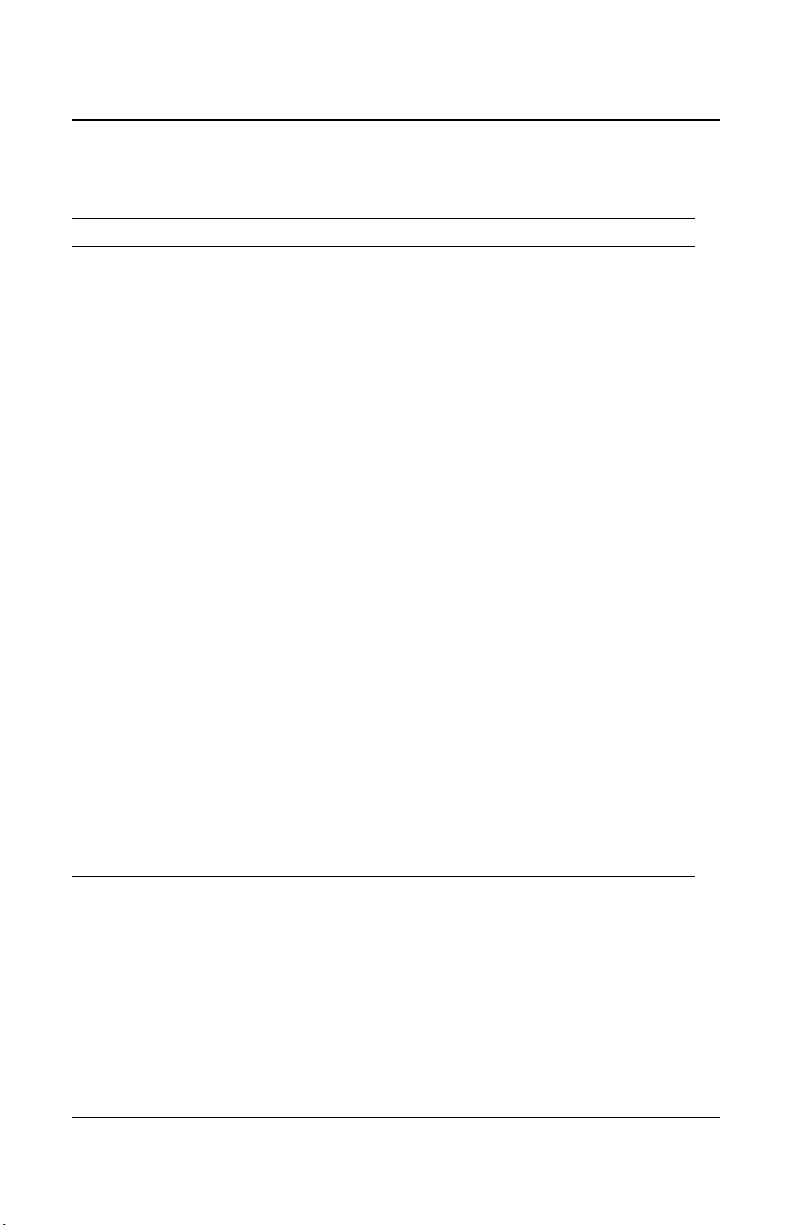

A

(white)

Power Comm.

sensor #5

sensor #6

sensor #7

sensor #8

External

Power

Supply

To next

sensors

B

(green)

V+ (red)

V- (black)

HPTV5DC8,

Input: 115 VAC 1A,

Output: 4.0A@6 and

12VDC, 2.5A@

24VDC

From

301EM

Determining the Number of Transmitters

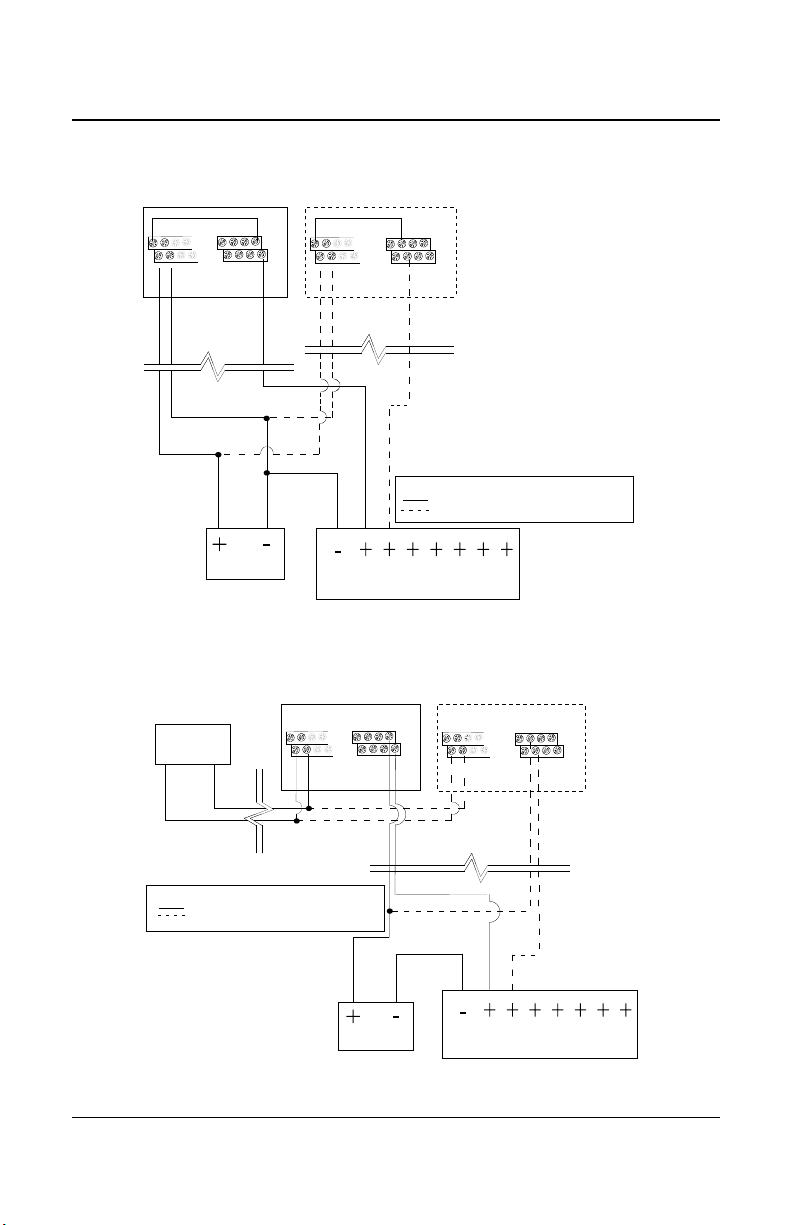

Installing Optional Remote Sensors

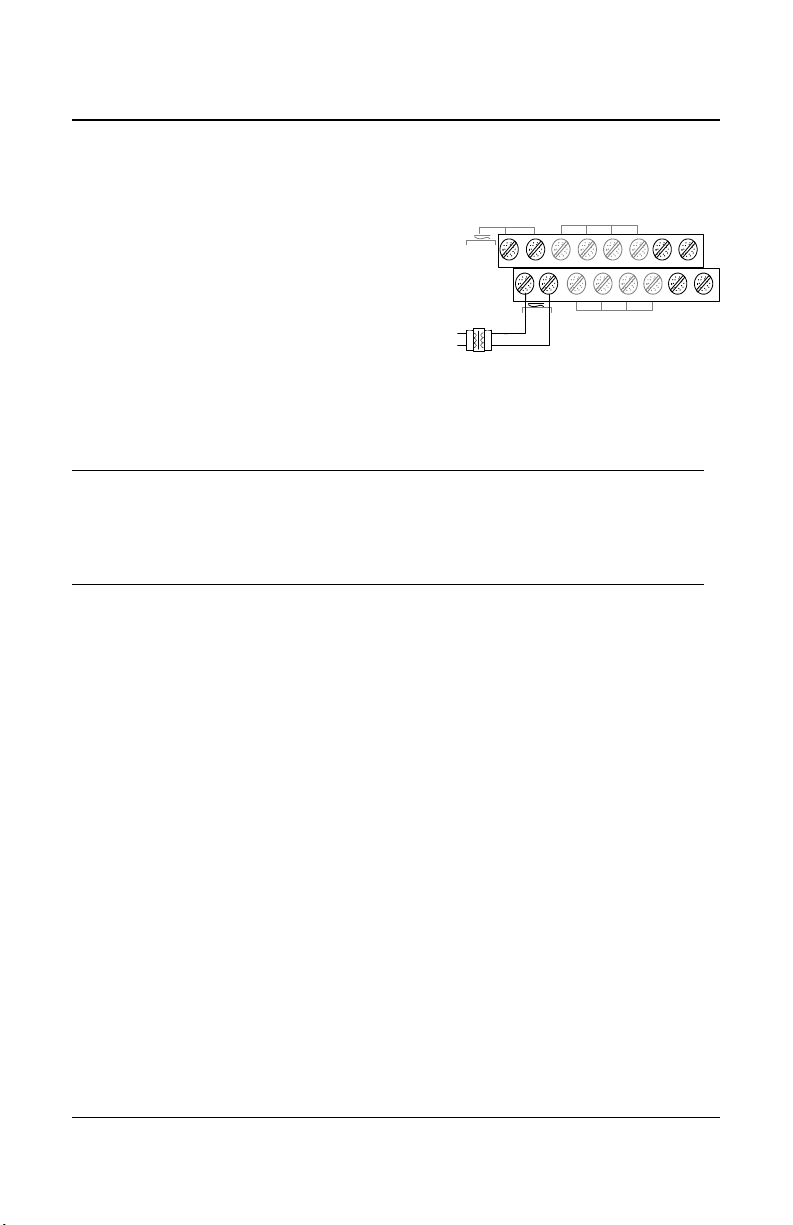

301IRFS Sensor

The refrigerant sensor should be installed at the recommended height,

which is 30 cm (1 foot) from the floor.

Communication cables should be 2-24

AWG, twisted and shielded (Belden 9841

or equivalent), which should be connected

in a daisy chain from the 301EM (as

shown).

Power cables should be 14 AWG cable,

maximum length of 60 m (200 ft). The first

four sensor power cables may be wired

directly to the 301EM. Additional sensors

require an external power supply (one per

group of four sensors, to a maximum of 20

sensors in total), using the same rated

cable as units wired to the 301EM.

14 301EM User Manual

Page 17

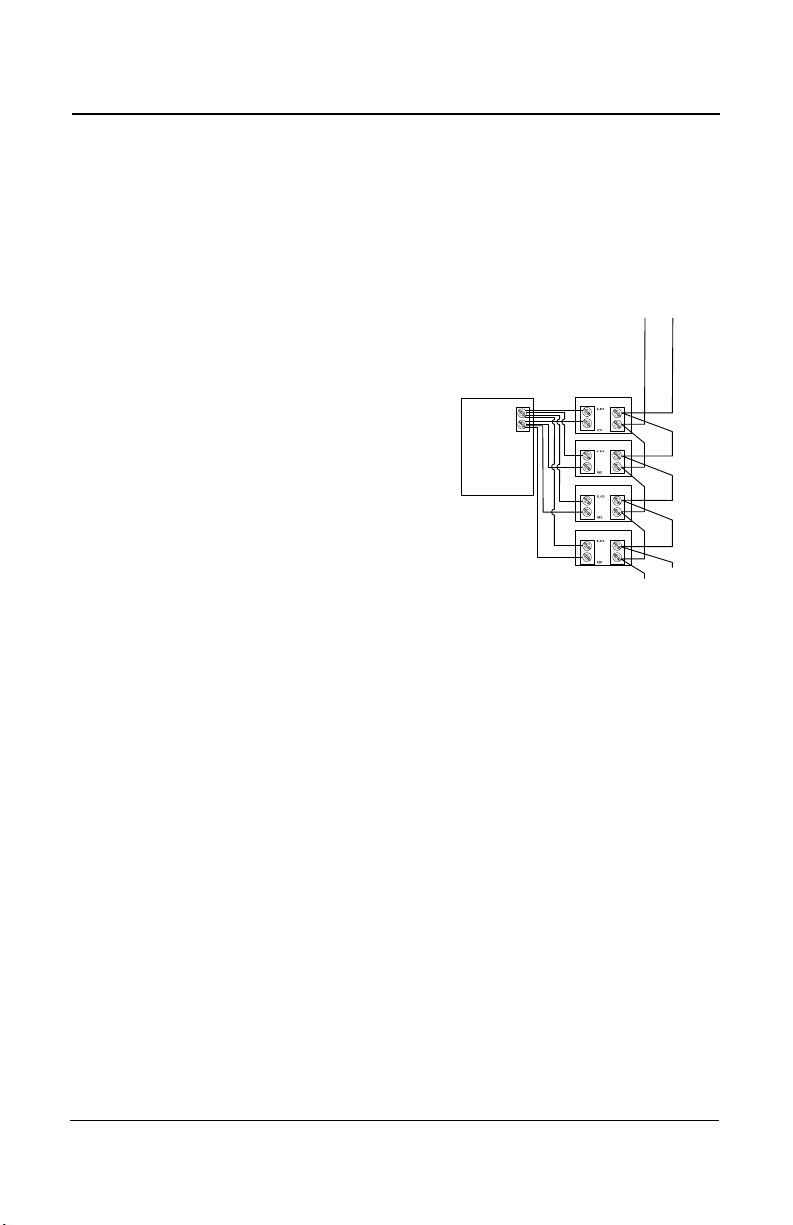

Installation Instructions

Monitor

Shielding must be grounded at the terminal

This housing not included

Calibration tubing

Thread dimension

3/4

Determining the Number of Transmitters

S301D2 Remote Sensor

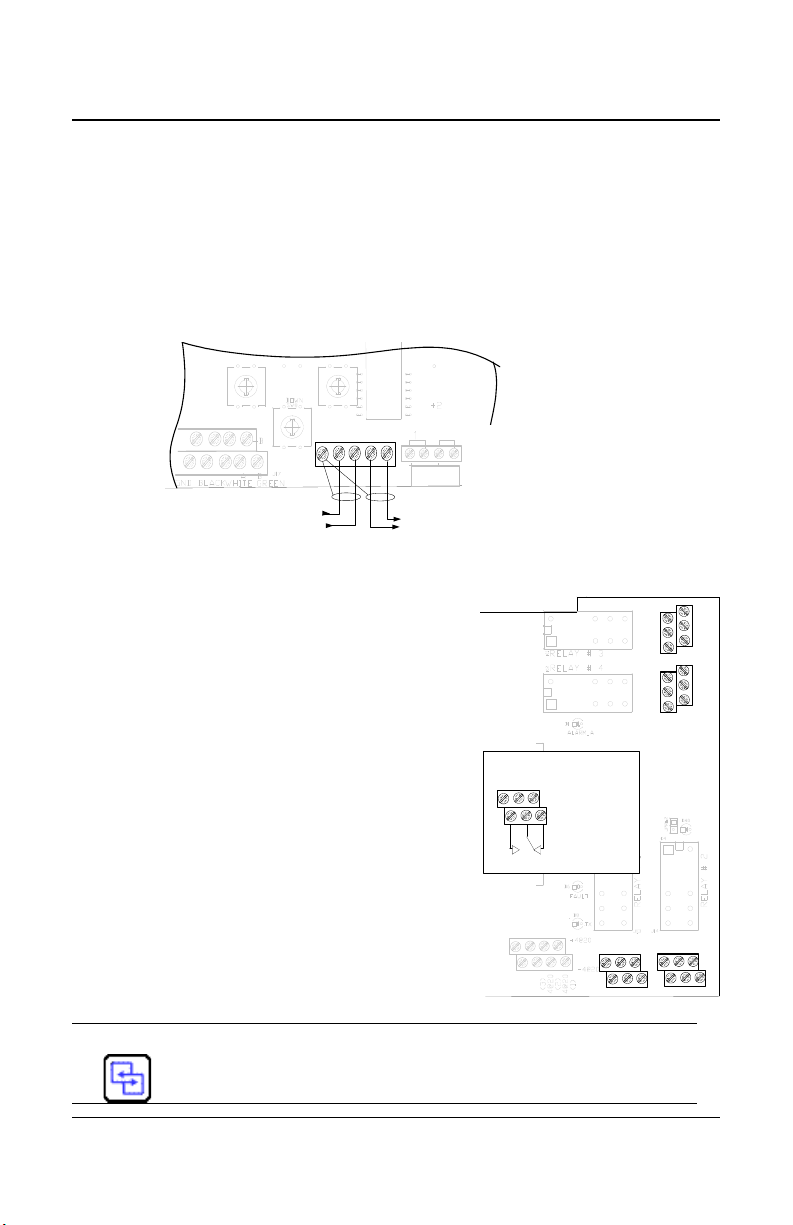

The drawing below illustrates the connection for a 301D2 sensor with the

D2RS-PC option.

Communication: Use 224 AWG, twisted and

shielded cable (Belden

9841 or equivalent)

Power: Use 2-18 AWG

cable, maximum length of

160 m (500 ft).

301EM User Manual 15

Page 18

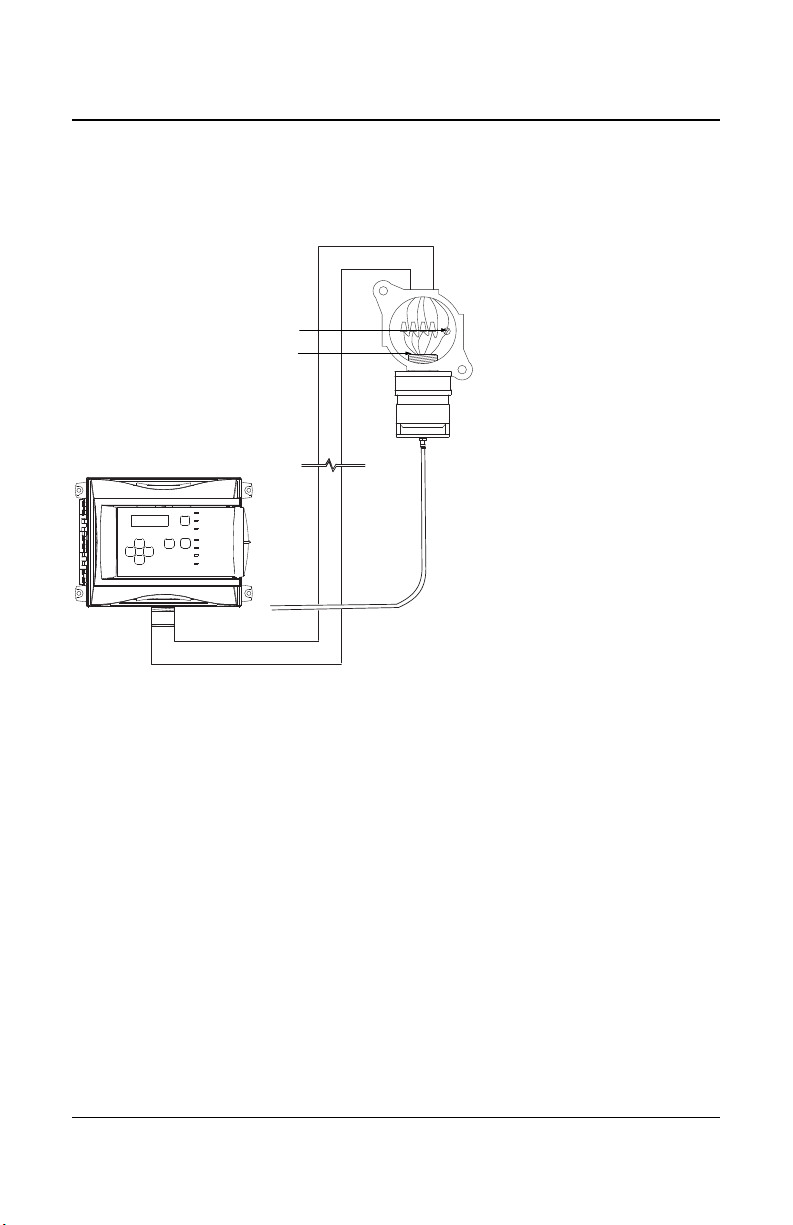

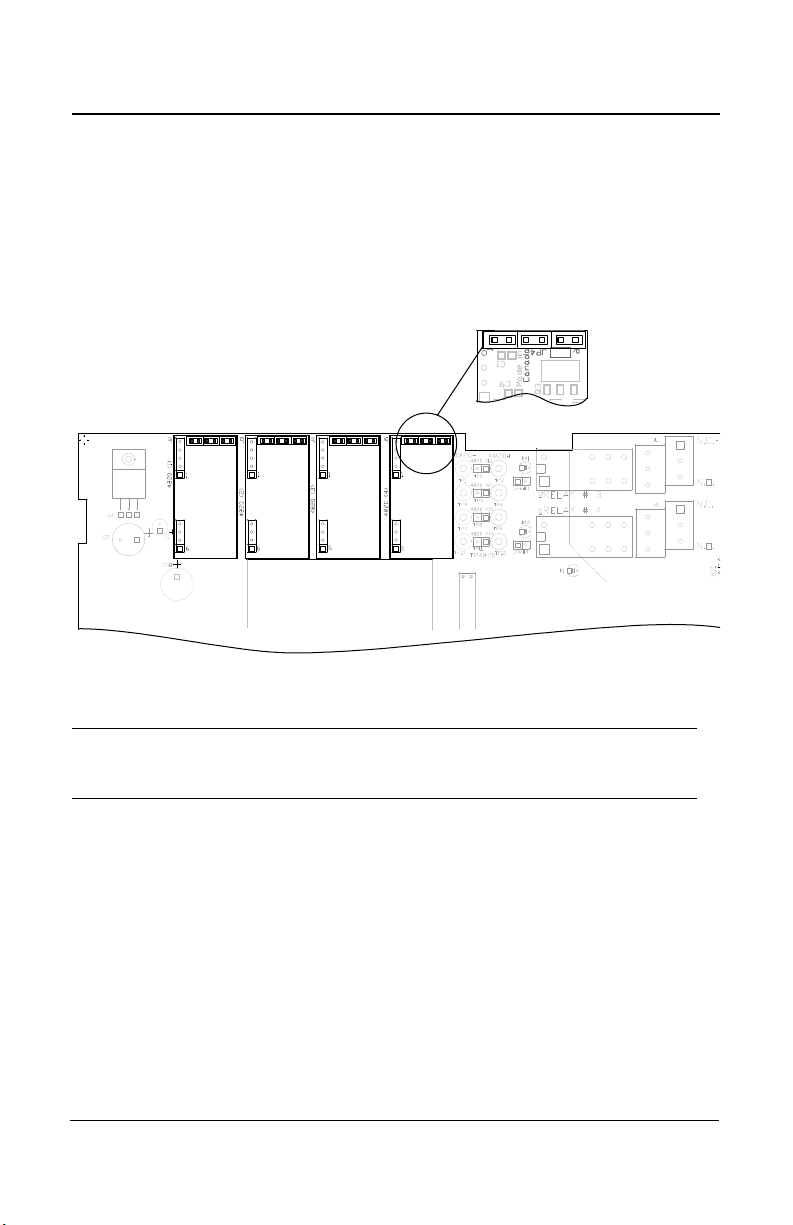

WIRING DETAILS

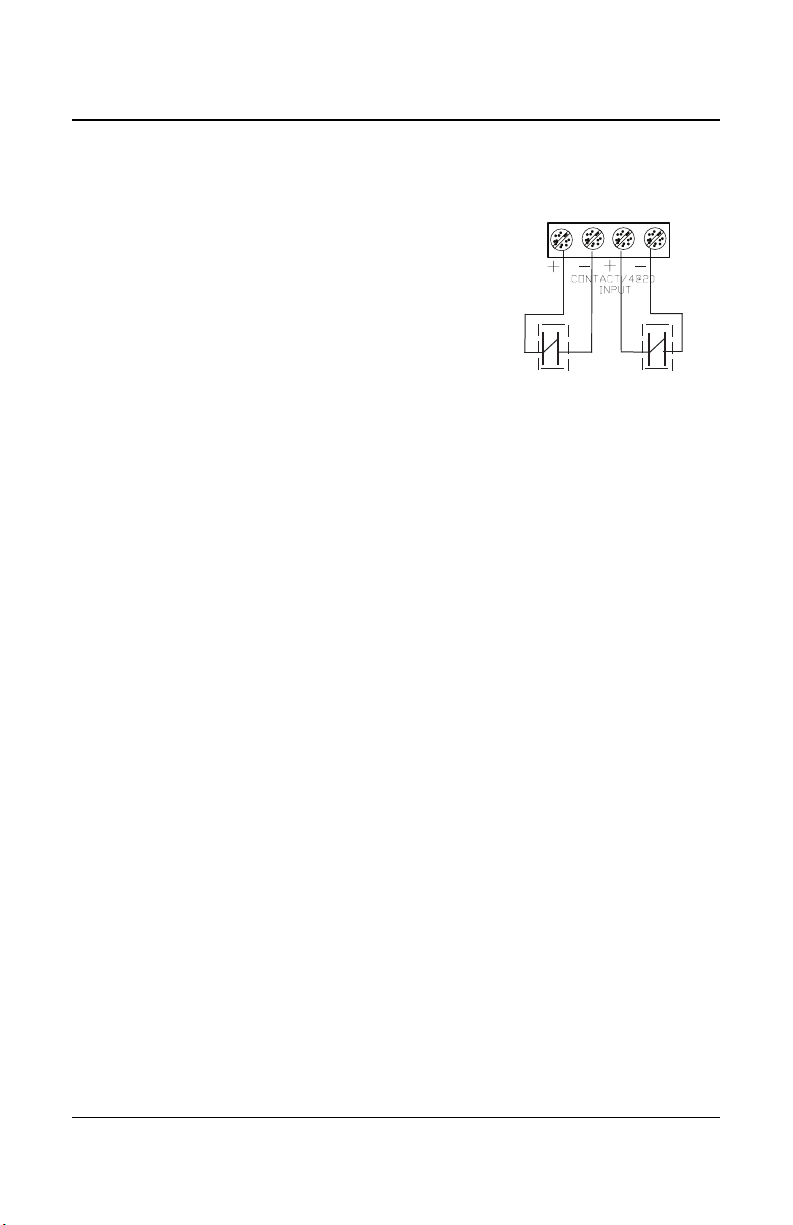

Contact

input

LCD screen

J8 J9

EOL Positions

Disabled

R

RC

GND BLACK WHITE

GREEN

ABAB

A

B

SHIELD

+-+-

J10

J1

6

J17

OUT #1

OUT #2

OUT #3

4@20

(4)

4@20

(3)

4@20

(2)

4@20

(1)

+ 4@20

- 4@20

N.O. N.C. N.O. N.C.

N.O.

N.C.

N.O.

N.C.

J6

J1

+VDC RED

V+

V+ V-

V-

24 IN

24

IN

DOWN

SW8

ESC

SW6

UP

SW2

ENTER

SW7

SW3

FAN

SW4

RESET

SILENCE

SW1

Sensor #1 IRF

ABV+ V-

Terminal J17

see page 20 for complete sensor wiring details

J13 J14

Terminals J8, J9

see pages 22, 25 and 27

for complete 4-20 wiring

details

Terminals J13, J14, J1, J6

See page 21 for complete

relay wiring instructions

Terminal J10

Used for communication

connections to a control

unit (such as 301C)

Terminal J16

Used (normally) to

connect a breakglass

switch (see page 23)

Sensor #2 GasPoint2

System Wiring

WIRING DETAILS

System Wiring

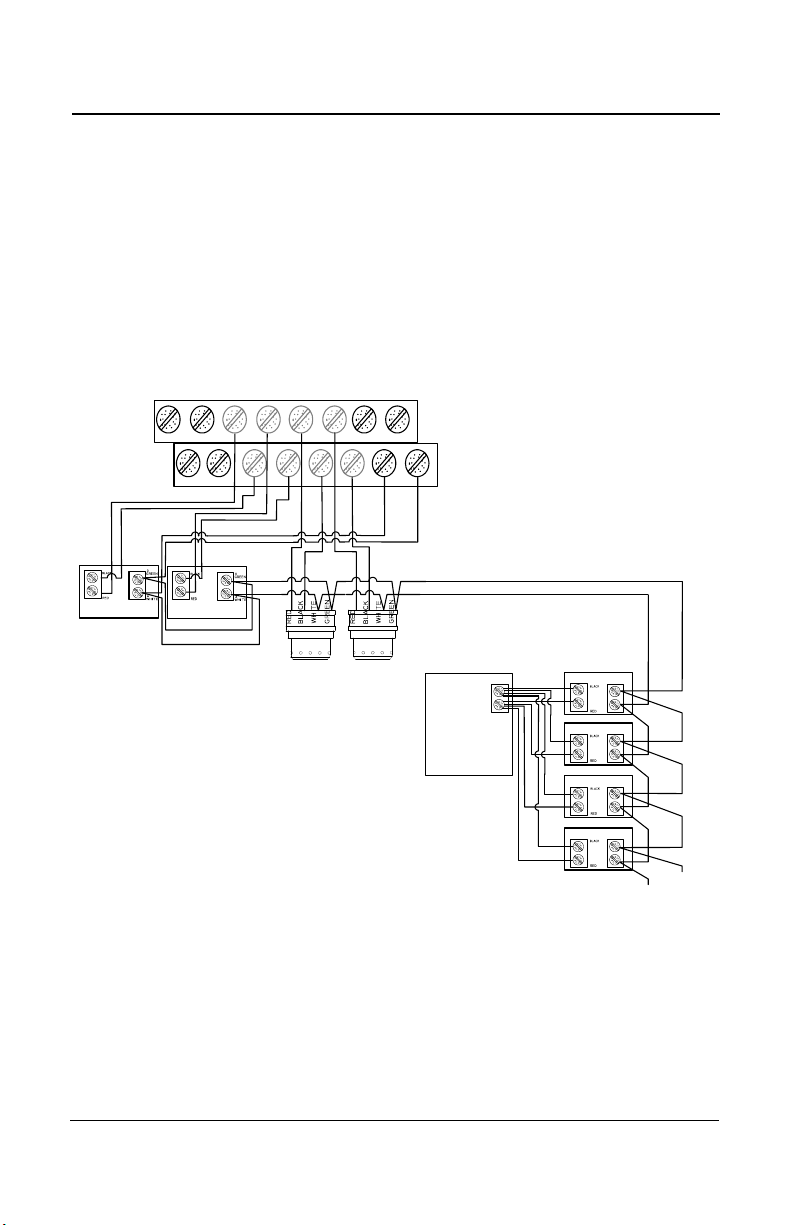

Both GasPoint II (301D2) and IRFS sensors can be linked to the 301EM

system. The drawing below illustrates an overview of PCB terminal

wiring.

.

16 301EM User Manual

Page 19

Power Connections

+VDC RED

V+ V-

24

IN

24

IN

The power requirement range is 22-27

Vac, 29-38 Vdc, 2.0 A max. The polarity is

not important. The system must be

grounded on the transformer.

A dedicated circuit-breaker must be

used.

Separate power supplies must be

provided for each group of 4 sensors

The 301EM requires a 100VA transformer that must be

installed near the unit to prevent voltage loss. If there is no

CAUTION

transformer, or if the transformer capacity is insufficient, 24

Vdc outputs will not have sufficient power, which will have an

impact on RFS/RFSA and other device options.

WIRING DETAILS

System Wiring

301EM User Manual 17

Page 20

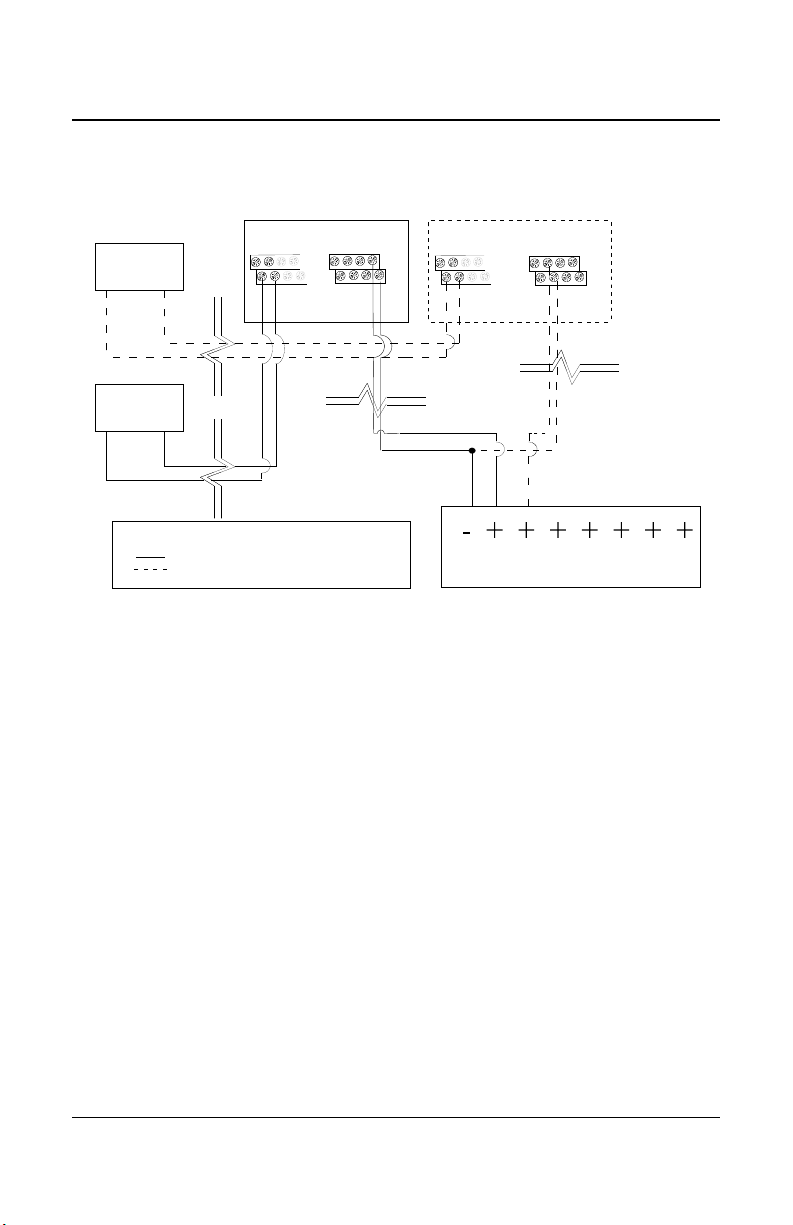

WIRING DETAILS

GND

BLACK

WHITE

GREEN

A

B

J17

+VDC RED

V+

V-

24

IN

sensor #3

S

e

n

s

o

r

#

1

S

e

n

s

o

r

#

2

S

e

n

s

o

r

#

3

S

e

n

s

o

r

#

4

A

(white)

Power Comm.

sensor #5

sensor #6

sensor #7

sensor #8

External

Power

Supply

To next

sensors

sensor #1

sensor #4

POWER:

Maximum 4 power

connections direct to unit.

Additional power sources

required for every group of 4

sensors.

COMMUNICATION:

Communication must be

connected in daisy chain

configuration.

B

(green)

V+ (red)

V- (black)

A

sensor #2

HPTV5DC8,

Input: 115 VAC 1A,

Output: 4.0A@6 and

12VDC, 2.5A@ 24VDC

System Wiring

Connecting sensors to transmitter

Connect the sensor to the transmitter as shown in the diagram below. The

maximum distance between sensor and power supply is 200 ft. (60 m) for

refrigerant and 500 ft. (160 m) for toxic and combustible gases. Color

coding (black, red, green, white) must be respected.

The first four sensors can be connected directly to the 301EM. Additional

sensors must have external power supplies (T300VA, 120/24Vac-300VA

Transformer) for every group of 4 sensors and communication must be in

daisy-chain connection

Note: Use 2-18 AWG wire gauge for toxic and explosives sensor power

wiring. Use 14 AWG wire gauge for refrigerant sensor power

wiring.

18 301EM User Manual

Page 21

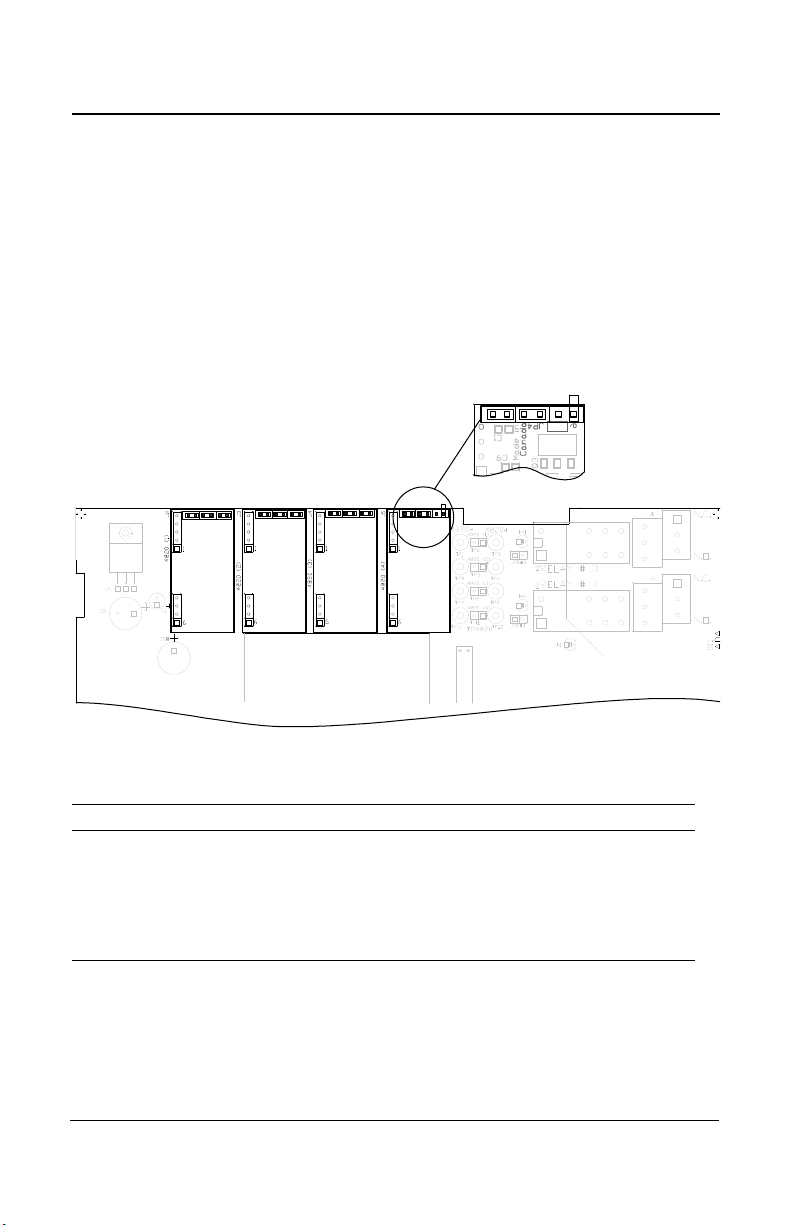

WIRING DETAILS

Previous

Next

Contact

input

J16

Communication Wire Gauge:

2-24 AWG (Belden 9841)

Twisted and shielded cable

2000 feet (600 m) per channel

T-tap: 65 feet (20 m) / T-tap

130 feet (40 m) total

COMMUNICATION

SHIELD A B A B

J10

N.O. N.C.

N.O. N.C.

N.O.

N.C.

N.O.

N.C.

RELAY OUTPUTS

3+5

4+6

1+3

2+4

Normally

open

Normally

closed

5

31

642

System Wiring

Communication to Controller

Terminal J10 is for communication connections from the 301EM to the

301C Controller. The cables must be grounded using the shield terminal.

The network can be up to 2000 ft. (609 m) per channel. The length of a Ttap can be a maximum of 65 feet (20 m). A maximum of 130 ft. (40 m) for

all the T-taps must be respected.This diagram illustrates network

communication wiring on terminal J10; wires come in from a previous

device and go out to the next device.

Relay Outputs

The relay outputs will withstand up to 5 amps

at 30 Vdc or 250 Vac (resistive load only).

They can be used to activate horns, strobes,

etc. Refer to the drawing for proper wiring.

Failsafe Relay Outputs

When power is applied to the 301EM, these

relays are also powered up. The devices

connected to these outputs will be triggered

when power is cut, which allows detection of

power failures or interruptions.

The 301EM is factory configured in Normal

mode, which means that the relay outputs

are not in failsafe mode.

See the APPENDIX section for more details about B-52 and

ASHRAE 15 standard configurations.

301EM User Manual 19

Page 22

WIRING DETAILS

Contact

input

J8 J9

RFS

RFSA

System Wiring

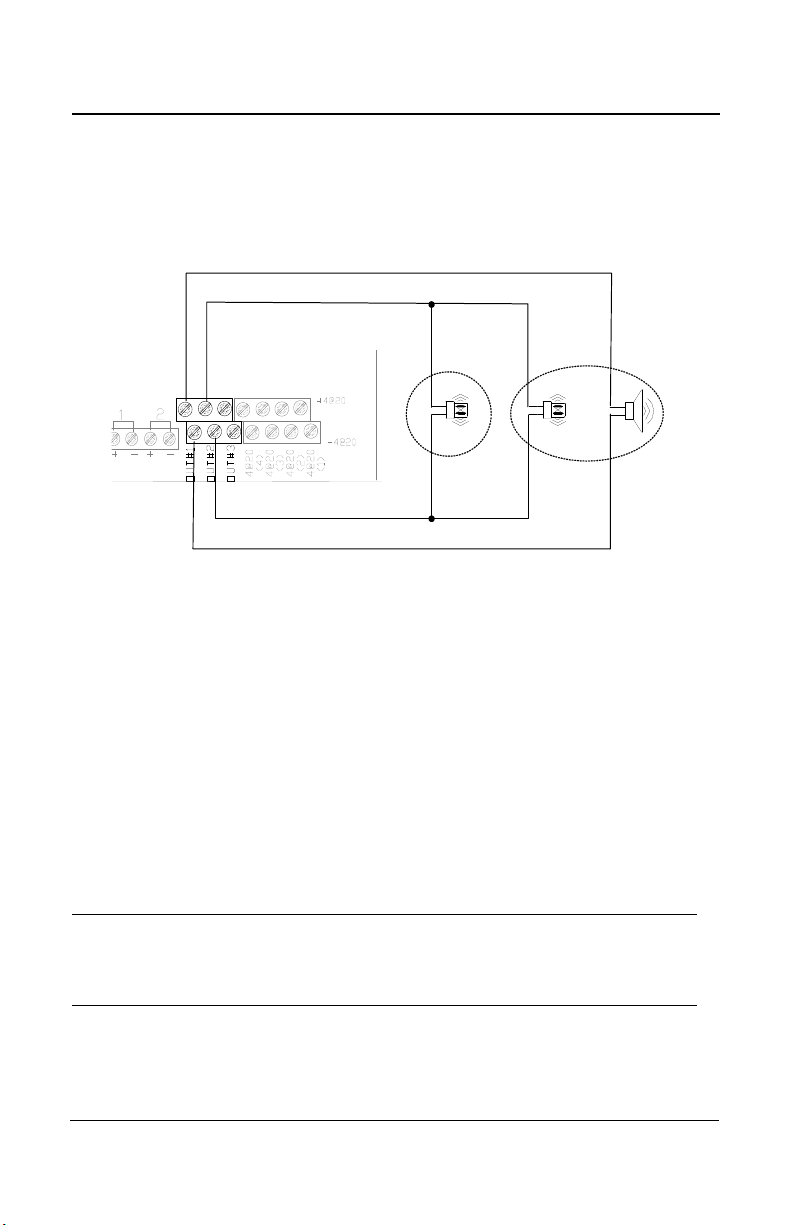

24 Vdc Output

The three 24 Vdc / 250 mA outputs are provided to activate DC horn,

strobe, etc.

Note: Terminal connectors labeled OUT #1 and OUT #2 must be

dedicated to RFSA use only, if applicable.

Terminal connector labeled OUT #3 must be used for RFS only, if

applicable.

RFS: Optional built-in stobe

RFSA: Optional built-in stobe and horn

4-20 mA Configuration

Output 4-20 mA, J9

The 4-20 mA output option will provide a real time analog readout of the

gas concentration read by the 301EM for each of its sensors. It can be

connected to a third party controller, DDC, BMS, etc.

Polarity must be observed.

CAUTION

20 301EM User Manual

Do not apply electrical power to the 301EM until all

connections are made. Significant damage can result from

incorrect wiring.

Page 23

Contact Input, J16

Contact 1

Contact 2

J16

The contact input is mainly used to connect a

manual break glass switch to comply with the

mechanical code. It is also possible to

connect a third break glass switch in series if

needed.

The drawing illustrates the ASHRAE 15

configuration where:

Contact 1 = Electrical shut down (ASHRAE 15

config.)

Contact 2 = Fan activation (ASHRAE 15 config.)

WIRING DETAILS

System Wiring

301EM User Manual 21

Page 24

WIRING DETAILS

System Wiring

4-20 Output Configuration

4-20 mA Current Sourcing Output Configuration

The transmitter supplies the loop current. The maximum impedance

supported by the loop is 400 ohms. Set jumpers on JP4 at 1-2, 3-4 and 5-

6.

A dedicated power supply must be used with each 301EM.

CAUTION

22 301EM User Manual

Considerable damage may occur if this condition is not strictly

followed.

Page 25

Current Sourcing Output Configuration

DDC SYSTEM

24 VAC

24 VAC

24 VAC

24 VAC

4-20 mA

4-20 mA

- MORE THAN ONE TRANSMITTER CONNECTED

- ONE TRANSMITTER CONNECTED

LEGEND

TRANSMITTER 1

TRANSMITTER X

J9 J9J16J16

V+

V-

V+

V-

+4@20

-4@20

+4@20

-4@20

Sensor #1

Sensor #2

Sensor #3

Sensor #4

Sensor #1

Sensor #2

Sensor #3

Sensor #4

WIRING DETAILS

System Wiring

301EM User Manual 23

Page 26

WIRING DETAILS

System Wiring

Output Loop-Powered Operation

(Factory Setting)

The 4-20 mA output is factory set for loop-powered operation and

requires a power source of 12 Vdc to 30 Vdc. The overall impedance

depends on the voltage supplied at the 4-20 mA loop. Set jumpers on

JP4 at 2-3, 4-5 and 6 for this type of configuration.

Permitted Impedance in the 4-20 mA Loop

Voltage Source Applied Total Impedance

12 Vdc 400 Ohms

16 Vdc 600 Ohms

20 Vdc 800 Ohms

24 Vdc 1,000 Ohms

30 Vdc 1,300 Ohms

24 301EM User Manual

Page 27

3 Wire Configuration

DDC SYSTEM

24 VDC

24 VAC 24 VAC 4-20 mA4-20 mA

MORE THAN ONE TRANSMITTER CONNECTED

ONE TRANSMITTER CONNECTED

LEGEND

TRANSMITTER 1

TRANSMITTER X

J9 J9J16J16

V+

V-

V+

V-

+4@20

-4@20

+4@20

-4@20

Sensor #1

Sensor #2

Sensor #3

Sensor #4

Sensor #1

Sensor #2

Sensor #3

Sensor #4

DDC SYSTEM

24 VDC

24 VAC 24 VAC 4-20 mA4-20 mA

- MORE THAN ONE TRANSMITTER CONNECTED

- ONE TRANSMITTER CONNECTED

LEGEND

TRANSMITTER 1

TRANSMITTER X

24 VAC

J9 J9J16J16

V+

V-

V+

V-

+4@20

-4@20

+4@20

-4@20

Sensor #1

Sensor #2

Sensor #3

Sensor #4

Sensor #1

Sensor #2

Sensor #3

Sensor #4

4 Wire Configuration

WIRING DETAILS

System Wiring

301EM User Manual 25

Page 28

Page 29

Programming and Calibration

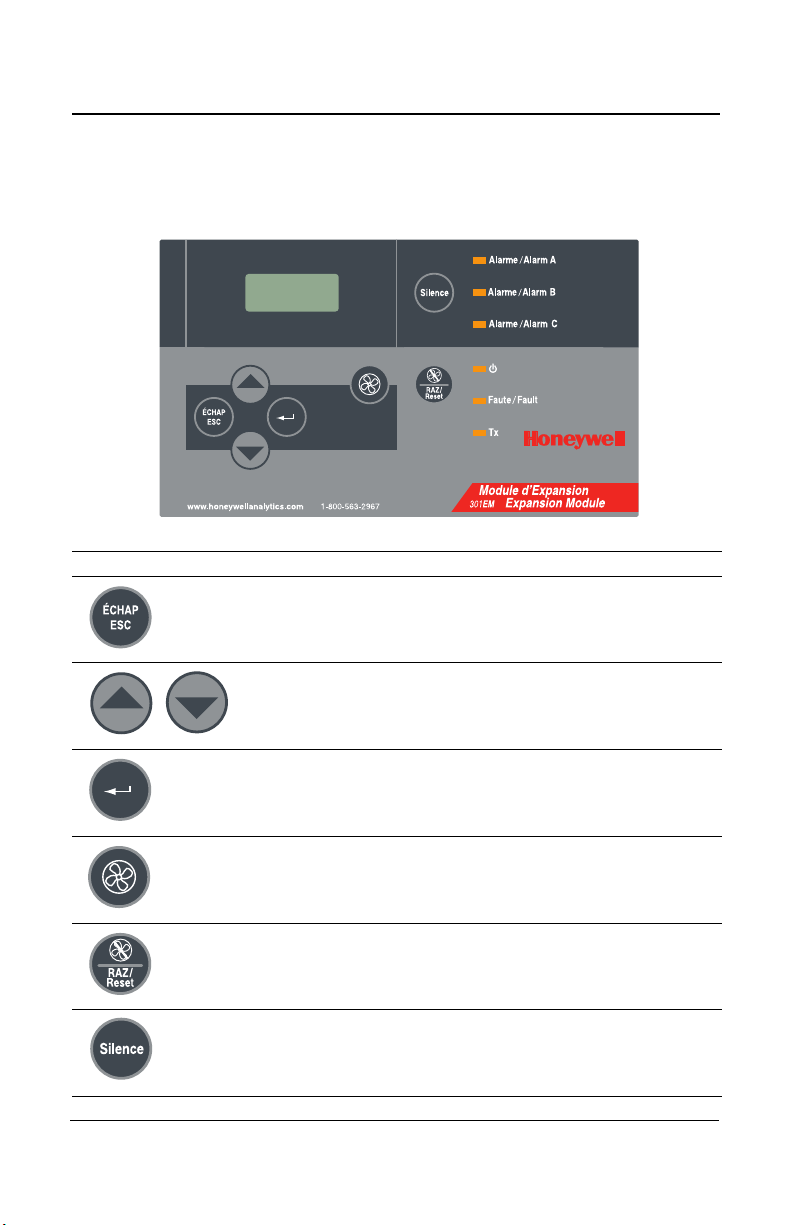

User Interface

Programming and Calibration

User Interface

When power is initially applied, the unit’s LCD screen will display the

product’s name and firmware version.

Operating Mode

Normal Mode When the 301EM is in Normal mode, no user

intervention is required. The display will scroll to

display (gas and concentration) readings from up to 20

sensors. The Tx LED will blink when there is a

transmission on the communication channel (if the unit

is connected to a controller)

Alarm Mode Red LEDs light according to the alarm level detected

(Alarm A, B or C). If the unit is equipped with a horn or

strobe, these will also be activated with the

corresponding alarm.

Fault Mode If a sensor has communication problems, the yellow

Fault LED lights. This LED will also light when the

service alarm is activated.

Programming The programming mode is password protected.

Mode Only qualified technicians should access this mode.

The enter key provides access to programming and

confirms an entry, while the arrow keys allow

technicians to increase or decrease values and scroll

throughout the menus.

301EM User Manual 27

Page 30

Programming and Calibration

User Interface

Pushbutton Definitions

The 301EM has “pushbuttons” that serve as an interface to the unit’s

programming functions. Below is a description for each button’s function:

Key Description

Used to exit the menus or cancel an input. Also used to

stop the alternating reading between the connected

sensors.

Used to scroll through the sensor data displays or through

menus or to change a specific value.

Serves as an “enter” key and is used to access a

programming field or to confirm a specific value.

Fan start switch (For B-52 or ASHRAE 15 programming).

See the Events table

Used to reset all outputs after system returns to normal

operating mode (linked to the Reset function in the Events

menu).

Turns off the buzzer and horns

28 301EM User Manual

Page 31

Programming and Calibration

Programming the Unit

Programming the Unit

The 301EM is equipped with a programming menu that allows users to

modify certain parameters and to calibrate the unit.

Menu Option Description

Password Provides password restricted access to programming

menus

Set Adr. Lets users select a specific address for the device

Mem SD Inactive option: Reserved for technicians’ use only

Sensor Lets users add or remove a sensor

Set #RP Lets users add up to ten 301EMRP units

Service Lets users specify different Service alarm settings

SetEvent Lets users configure specific events for some or all sensor

types

SetRelay Lets users specify whether a relay will be set to failsafe

Buzzer Lets users activate or deactivate the silence button

Set Alr Lets users set specific minimum and maximum alarm levels

(for alarms A, B and C)

SetAnOut Lets users adjust the 4-20 outputs

Set Zero Lets users adjust the sensor zero

Set Span Lets users calibrate each sensor

Quit Lets users exit the programming menus

301EM User Manual 29

Page 32

Programming and Calibration

PASSWORD

A

A

Accessing the Programming Menus

Accessing the Programming Menus

Acces to the 301EM’s programming is password protected for security

reasons. The password is “VA”.

• Press the enter key to access the programming menus. The

PASSWORD screen is displayed

• The first letter is underlined. Press the up or down arrow to change

the letter until V is displayed

• Press Enter to confirm. The next letter is underlined. Press the up or

down arrow until A is displayed

• Press Enter to confirm the password and access the menus

30 301EM User Manual

Page 33

Programming and Calibration

Menu

Set Adr.

Set ADR

M001 V01

Setting the Unit’s Address

Setting the Unit’s Address

The 301EM is shipped with the default address set to 1. If you are using

the unit in a network, this menu lets you select a specific address,

according to your network configuration.

• Access the menu and use the arrows to scroll to the Set Adr. menu

and press enter to select

• The Set Adr. menu is displayed. Use the arrows to change the

address and press enter when the desired address (Modbus

addresses M001 to M254 and Vulbus addresses V01 to V30) is

displayed.

• The screen returns to the main menu

Make certain that no two devices share an address as this

may result in network conflicts

301EM User Manual 31

Page 34

Programming and Calibration

Menu

Sensor

Sensor

Chg Adr.

NO2 #1

SD #1

Configuring a Sensor

Configuring a Sensor

The Sensor menu option allows users to add a new sensor, to scan for

new sensors or to remove a sensor. Access the menu and use the arrows

to scroll to the Sensor menu and press enter to select.

There are now 4 possible actions available: NewSens?, Chg Adr., Scan

SD, Disable. Use the arrows to scroll up or down through these options

and press enter to select.

Note: The NewSens? menu is reserved for and should only be used

by qualified technicians.

Changer the Sensor Address

This menu lets users change the sensor’s address (position) in the

301EM. Pay special attention when changing a sensor’s address that you

do not change to an address that is already in use as this will replace the

existing sensor.

• Scroll to the Chg Adr. menu and press enter to select.

• The screen displays the sensor gas type, sensor # and its address.

Use the arrows to scroll through the sensors until the desired sensor

is displayed.

32 301EM User Manual

Page 35

Programming and Calibration

NO2 #1

For #2 ?

Sensor

Scan SD

Scan sd

sd3 164

Configuring a Sensor

• Press enter to select the sensor. The screen displays the sensor gas

type and its address. Use the arrows to scroll to the address desired

(between 1 and 20) and press enter to confirm.

The sensor’s address has been changed.

Adding a new Sensor

This menu lets users add new sensors (to expand the network or to

replace an expired sensor).

When adding new sensors, it is important to add one sensor

at a time to ensure proper address assignment.

• Scroll to the Scan SD menu option and press enter to select.

The device searches for any new sensor and assigns the new sensor the

first available address. The screen displays a wait message while the

device searches for the sensor.

When the device has found the sensor, it displays the sensor device

address (its position in the 301EM) and its firmware version.

301EM User Manual 33

Page 36

Programming and Calibration

Sensor

Disable?

Menu

Set #RP

Set #RP

0 EMRP

Adding Remote Panels

Removing a Sensor

This menu lets users remove a sensor from the 301EM.

• Scroll to the Disable? menu option and press enter to select.

Adding Remote Panels

The Set #RP menu lets users add up to 10 remote panels (301EMRP) to

the 301EM’s network.

• Scroll to the Set #RP menu option and press enter to select.

• In the Set #RP screen, use the arrows to scroll the the desired

number (since you can add up to ten remote panels you can select a

number between 1 and 10) and press enter to select.

Once entered into the 301EM’s network, the remote panels will display or

announce the status of the 301EM’s sensors.

34 301EM User Manual

Page 37

Programming and Calibration

Menu

Service

Service

Set Act

Set Time

12 Month

Using the Service Menu

Using the Service Menu

The Service menu allows users to configure several service related

options, such as when and how to activate service alarms. Service alarms

are used to signal when a sensor needs to be replaced or calibrated.

This menu contains two options: Set Act and Set Time.

The Set Act menu lets users select the action that will be taken. Available

options are: Fault, OFF or Visual

Fault: A service alarm will be activated whenever there is a fault

status

OFF: No service alarm will be triggered at any time (factory default

setting)

Visual: Only a visual service alarm will be activated

The Set Time menu lets users configure a specific deadline at which a

service alarm will be activated.

Use the arrows to scroll between 12 to 24 months to trigger a service

alarm after the specified number of months in service. Select the Reset

option to turn off the Service alarm for a period of 100 days (after the

alarm was triggered).

301EM User Manual 35

Page 38

Programming and Calibration

Menu

SetEvent

SetEvent

Type1CND

Using the SetEvent Menu

Using the SetEvent Menu

Although the 301EM is fully configured with specific event configurations

(see the tables in Appendix A for details on available configurations), it is

nonetheless possible to modify events to suit different applications.

• Scroll to the SetEvent menu and press enter to select.

If this is the initial setup and no previous events have been configured,

you must select the event configuration (Type) from the menu (see the

tables in Appendix A for details).

• Use the arrows to scroll through the options and press enter to select.

The available options (described in greater detail in Appendix A) are:

Type1 CND, Type2 CND, Type3 US, Type # 4 and OTHER.

Note: Selecting the “OTHER” event type creates an event with all fields

and events blank. Therefore, no events will appear when pressing

the arrows. Events must be created before they appear in the scroll

list.

Once the configuration type has been selected, it can no

longer be changed without erasing ALL events and

reconfiguring the system anew. Consult the tables in

Appendix A to make certain that the appropriate event

configuration is selected.

36 301EM User Manual

Page 39

Programming and Calibration

Type1CND

Event# 1

Event# 1

SD All

EraseALL

No?

Using the SetEvent Menu

Changing Event Configurations

The various event menus allow users to modify standard configurations or

to create completely customized event configurations, based on their

needs. Each event menu provides a set of four options, which also

contain a subset of options, as described below.

The first screen that appears is the main event screen. Press enter to

select the event displayed or use the arrows to scroll through the event

numbers to select a specific event.

The first event screen lets users specify which sensors will be linked to

the event. The screen displays SD All (the default value). Press enter to

enable the field and use the arrows to scroll through the available options.

When the desired option is displayed press enter to select.

SD All: Applies the event action to all sensors

SD #1: (through SD #4) Applies the event action to only the selected

sensor

ManSW#1:(through ManSW#2) Applies the event action to the selected

switch

SD #---: Displays the EraseALL screen. When “Yes?” is

selected from the Event #1 menu, all

configuration data for events will be erased.

Note that when “SD #---” is selected at any other event

number, the EraseALL screen does not appear and only the

data for the active event number will be erased (and events

will change numbers, moving up one).

When you have selected the option and pressed enter, the field is

disabled and you can proceed to the next screen. Use the arrows to

move ahead one screen.

301EM User Manual 37

Page 40

Programming and Calibration

Event# 1

= ALRA

EraseALL

No?

Using the SetEvent Menu

The second event screen lets users specify what will trigger an event. The

screen displays ALRA (the default value).

• Press enter to enable the field and use the arrows to scroll through

the options:

= ALRA: (through ALRC) Links the event to Alarm A, B or C

= Fault: Links the event to a fault condition

= ALL: Links the event to all conditions (alarm and fault)

= ---: Displays the EraseALL screen. When “Yes?” is

selected from the Event #1 menu, all configuration

data for events will be erased.

Note that when “---” is selected at any other event number, the

EraseALL screen does not appear and the data for the active

event number will be erased (and events will change numbers,

moving up one).

If ManSW#1(or #2) was selected at the previous step this

screen will only have 2 options: Open or Closed.

Set to Open if the output is set to Normally Closed, or to

Closed if the output is set Normally Open.

When you have selected the option and pressed enter, the field is

disabled and you can proceed to the next screen. Use the arrows to

move ahead one screen.

38 301EM User Manual

Page 41

Programming and Calibration

Event# 1

REL #1

EraseALL

No?

Event# 1

RESET N?

Using the SetEvent Menu

The third event screen lets users specify the actions linked to the event.

The screen displays REL #1 (the default value).

• Press enter to enable the field and use the arrows to scroll through

the options:

REL #1: (through REL #4)Triggers the devices connected to the

selected relay

OUT #1: (through OUT #3)Triggers the devices connected to the

selected Output

BUZZER: Triggers the audible alarm for this event

---: Displays the EraseALL screen. When “Yes?” is

selected from the Event #1 menu, all configuration

data for events will be erased.

Note that when “---” is selected at any other event number, the

EraseALL screen does not appear and the data for the active

event number will be erased (and events will change numbers,

moving up one).

When you have selected the option and pressed enter, the field is

disabled and you can proceed to the next screen. Use the arrows to

move ahead one screen.

The final screen, RESET, lets users specify that an event will remain

active, even after it has returned to normal.

• Press enter to enable the field and use the arrows to scroll to Y?.

• Press enter once again to activate the Reset function.

Note: The Reset key on the front panel lets you deactivate the event

301EM User Manual 39

Page 42

Programming and Calibration

Menu

SetRelay

Using the SetRelay Menu

Using the SetRelay Menu

The SetRelay menu lets users specify whether the the relay for the event

will be in failsafe mode and whether the Silence button on the user

interface (front of housing) will be enabled for this event.

Press enter to select the menu and use the arrows to scroll through the

options:

FAILSAFE? Puts the relay in Failsafe mode (the default setting is no

failsafe).

Silence Enables the Silence button function of the user

interface for this event.

When you have selected the option and pressed enter, the field is

disabled and you can proceed to the next screen. Use the arrows to

move to the next menu.

40 301EM User Manual

Page 43

Programming and Calibration

Menu

Buzzer

Silence

Yes?

Key Beep

No?

Deactivating the Buzzer

Deactivating the Buzzer

The 301EM is shipped with the buzzer function activated by default. This

menu lets you activate or deactivate the Silence button on the keypad and

to silence or activate the key beep function.

• Access the menu and use the arrows to scroll to the Buzzer menu

and press enter to select. The display moves to the next screen.

•The Silence screen displays Yes?, press enter to select (or scroll to

No? to disable the Silence button). The keypad Silence button is

enabled; when the buzzer sounds, pressing the silence button will

turn the buzzer off.

• The next screen, Key Beep, allows you to activate a sound for any

key activation. Use the arrows to display either Yes or No and press

enter to confirm.

• The screen returns to the main menu

301EM User Manual 41

Page 44

Programming and Calibration

Menu

Set Alr

H2S #1

SD #1

H2S #1

Min AlrA

Min AlrA

9.0 PPM

Configuring the Unit’s Alarms

Configuring the Unit’s Alarms

Although the 301EM is shipped with the default alarm settings, this menu

allows you to set specific minimum and maximum levels for alarms A, B

and C.

• Access the menu and use the arrows to scroll to the Set Alr. menu

and press enter to select

• The menu displays the first sensor’s information screen. Use the up or

down arrows to scroll between sensors and press enter when the

desired sensor is displayed.

• The next six screens let you modify both the minimum and maximum

alarm setting for all alarm levels (A, B, C). Use the arrows to scroll

and press enter to select the desired alarm.

• In the selected alarm screen, use the arrows to increase or decrease

the value and press enter to confirm the desired value.

• The screen returns to the first sensor menu

Repeat these steps for each alarm level to modify.

42 301EM User Manual

Page 45

Programming and Calibration

Menu

SetAnOut

SetAnOut

Set Min 1

Set Min1

AdjAnOut

Set Min1

*WAIT*

Setting the Unit’s Analog Outputs

Setting the Unit’s Analog Outputs

This menu lets you adjust each of the four analog outputs, minimum and

maximum (e.g. the 4 and the 20).

Note that this menu does not display how the output is being

adjusted. The Output must be connected (to an ammeter or

to the DDC) for readings to be viewed.

• Access the menu and use the arrows to scroll to the SetAnOut. menu

and press enter to select.

•The SetAnOut menu is displayed. In this menu, you can scroll to

select the output (from Min 1 to Min 4 and Max 1 to Max 4) and press

enter to select.

•The AdjAnOut screen appears. Press on the up arrow to increase

the analog output value or the down arrow to decrease (the 301EM’s

screen does not change or display any changes; the value will only be

visible on the connected meter).

• When the desired output value is reached, press enter to confirm.

The screen displays *WAIT* while the unit is reinitialized.

• The screen returns to the main menu.

Repeat these steps for each output to adjust.

301EM User Manual 43

Page 46

Programming and Calibration

or

17 Liter

Span

Calibration

Gas Cylinder

103 Liter

Span

Calibration

Gas Cylinder

Refrigerant sensor calibration

Calibrating the Unit

Calibrating the Unit

Honeywell provides its customers with specialized gas detection

equipment. Beyond the warranty period, the systems must be maintained

and calibrated on a regular basis (normally twice a year).

If unit span or zero cannot be adjusted, the sensor may be approaching

its end-of-life and must be replaced. Keep an operation log of all

maintenance, calibrations and alarm events.

The unit requires warm-up time before being put into service and

calibrated. The warm-up time required depends on the type of sensor,

however a standard minimum of fifteen (15) minutes is recommended.

Connecting the Hardware

1. Plug the calibration adaptor onto the gas sensor inlet.

2. Screw the regulator to the appropriate calibration gas cylinder (for

either span or zero adjustment) and set the flow rate (see Table I on

page 47).

3. Connect the tubing to the regulator outlet and to the calibration

adaptor or to calibration port.

44 301EM User Manual

Page 47

Programming and Calibration

PASSWORD

A

A

Menu

Set Zero

H2S #1

SD #1

H2S #1

GoCalib?

Menu

*Quit*

Calibrating the Unit

Adjusting the Zero (If Required)

When the unit displays 0 %/ppm in an area with no presence of the target

gas, proceed to “Calbibrating the Sensor” on the following page.

To adjust the zero, inject zero gas (nitrogen) at the specified flow rate.

The gas must be allowed to flow into the unit for a minimum of 2.5 minutes

before beginning and then throughout the adjustment.

1. Press enter to access the programming menu.

Since the menus are password protected you

must first enter the password in the PASSWORD

screen

2. Use the up or down button to change each letter

until VA is displayed. Press enter after each letter

to confirm and to access the menus.

3. Use the up or down arrow to scroll to the Set Zero

menu screen and press enter to select.

4. Use the up or down arrow to select the sensor to

be calibrated and press enter to select.

5. Press enter again when the screen displays

GoCalib to start the zero adjustment

6. The Wait screen is displayed throughout the

adjustment and the menu returns to the main

menu screen when the adjustment is complete.

7. Use the up or down arrow to scroll to the Quit

menu and press enter to exit the programming

menus.

301EM User Manual 45

Page 48

Programming and Calibration

PASSWORD

A

A

Menu

Set Span

H2S #1

SD #1

SetGas

25.0 PPM

Menu

*Quit*

Calibrating the Unit

Calibrating the Sensor

To calibrate the sensor, inject the calibration gas at the specified flow rate.

The gas must be allowed to flow into the unit for a minimum of 2.5 minutes

before beginning and then throughout the calibration.

1. Press enter to access the programming menu.

Since the menus are password protected you

must first enter the password in the PASSWORD

screen

2. Use the up or down button to change each letter until VA is displayed.

Press enter after each letter to confirm and to access the menus.

3. Use the up or down arrow to scroll to the Set Span

menu screen and press enter to select.

4. Use the up or down arrow to select the sensor to

be calibrated and press enter to select.

5. The next screen, SetGas, allows users to specify

a calibration gas value. Use the up or down arrow

to increase or decrease the value and press enter

to confirm.

6. Press enter again when the screen displays

GoCalib to start the calibration

7. The gas concentration is displayed throughout the

calibration and the menu returns to the main

menu screen when the adjustment is complete.

8. Use the up or down arrow until the Quit menu is

displayed and press enter to exit the programming

menus.

46 301EM User Manual

Page 49

Programming and Calibration

Calibrating the Unit

Table I - Calibration Information

Gas Scale Warm-up Flow Rate Notes

Combustible 0 - 102% LEL 15 min. 500 ml/min 1% Volume CH4 =

20% LEL CH4.

CL2 0 - 15.3 ppm 15 min. 500 ml/min

CO 0 - 255 ppm N/A 500 ml/min

H2S 0 - 51.0 ppm 15 min. 500 ml/min

* HF 0 - 10.2 ppm 15 min. 500 ml/min Nitrogen dioxide is

a surrogate gas for

HF

NO2 0 - 10.2 ppm 15 min. 500 ml/min

O2 0 - 25.5% N/A 500 ml/min

SO2 0 -10.2 ppm 15 min. 500 ml/min

Refrigerant

Rxxx

0 - 1000 ppm 15 min 100 ml/min Replace the xxx by

the required

refrigerant

* Discontinued products: Only existing sensors will be supported.

301EM User Manual 47

Page 50

Programming and Calibration

301EM Specifications

301EM Specifications

Power 22-27 Vac, 50/60 Hz

29-38Vdc, 2 A@ 29 Vdc

Standard Outputs: 4 DPDT relays

3 Outputs at 24 Vdc @ 250 mA each

Optional Outputs: 4-20 mA for each sensor

Communication RS-485: Modbus or Vulbus

Audible Alarm: 65 dBA @ 1 m (3 ft)

Display : Backlit LCD

Visual Indicators: Green LED: Normal operation

Red LEDs: Alarm A, B and C

Yellow LED: Fault/service alarm

Amber LED: Tx (Activated in network mode)

Length of lines: Up to 2000 feet (609 m) between 301EM

and controller

T-tap: 65 ft. (20 m) maximum per t-tap, to a

total of 130 ft. (40 m)

Relay Output Rating: 5A, 30Vdc or 250Vac (resistive load)

Circuit Protection: Long Time-Lag Polyswitch Type TT

Overvoltage Category: II

Operating Environment: Indoor Use

Operating Temperature Range: 0 to 40°C (32°F to 100°F)

Operating Humidity Range: 0 to 95% RH (non-condensing)

Operating Altitude: Up to 3000m (9843 feet)

Enclosure: NEMA 4X ABS - Polycarbonate indoor

Pollution Degree: 2

Size (HxWxD): 20.3 x 28 x 7 cm

7.99” x 11.02” x 2.76”

Weight: 1.02 kg (2.26 lbs)

Certifications ANSI/UL 61010-1

CAN/CSA C22.2 No. 61010-1

Optional Horn: 105dBA, 4-28V, 2800Hz (RFSA)

Min. Voltage 80 dB(A) min. @ 2 ft and 6 Vdc

Max Voltage 90 dB(A) min. @ 2 ft and 28

Vdc

Optional Strobe: STAS flashing LED

48 301EM User Manual

Page 51

Programming and Calibration

301IRFS Specifications

301IRFS Specifications

Gases Detected: R11, R12, R13B1, R22, R114, R123,

R125, R134a, R227, R245A, R404A,

R407C, R410A, R507, R508b

Sensor power requirements: 8.5 - 12.5 Vdc, 1A@10 Vdc Maximum

Sensing Technology: Infrared sensor

Measurement Range: 0-1000 ppm

Resolution: 1 ppm

Deadband: 20 ppm

Accuracy: ±10ppm à 50 ppm / ±40ppm à 500 ppm

Response Time (T90): 60 seconds

Warmup time 15 minutes

Operating Environment: Indoor Use

Operating Temperature Range: 0 to 40°C (32°F to 100°F)

Operating Humidity Range: 0 to 95% RH (non-condensing)

Enclosure: ABS - Polycarbonate

Size (HxWxD): 10.2 x 28 x 6.3 cm

4.02” x 11.02” x 2.48”

Weight: 0.603 kg (2.33 lbs)

The 301EM sensor LED has 2 functions. If the sensor is working properly,

the LED will blink according to the sensor addresses on the 301EM. In

that case, the LED will blink as shown:

Address 1 = The LED blinks 2 times during 2,8 seconds

Address 2 = The LED blinks 3 times during 2,8 seconds

Address 3 = The LED blinks 4 times during 2,8 seconds

Address 4 = The LED blinks 5 times during 2,8 seconds

Addresses 5 to 20 = The LED blinks once during 2,8 seconds

If the sensor is connected to a 301IRF, the LED will be on during 0,2

seconds and off during 2,6 seconds (blinking). If the sensor has a

problem (failsense), the LED will remain on.

301EM User Manual 49

Page 52

Programming and Calibration

301IRFS Specifications

301D2 Sensor Specifications

Sensing technology: Electrochemical (toxic)

Catalytic combustion (combustible)

Diffusion fuel cell (oxygen)

Sensor power requirements:

Length of lines: Up to 160m (500 feet ) between 301EM

Operating Temperature Range: Toxic: -40 to 40°C (-40°F to 100°F)

Operating Humidity Range: 0% to 95% RH, non-condensing

Operating Altitude: Up to 3000m (9843 feet )

Enclosure: Class 1, Division 1, Groups B, C, D

Toxic: 7 - 9 Vdc, 25mA@ 8 Vdc

Combustible : 7 - 9 Vdc, 100mA@ 8 Vdc

and sensor (toxic and combustible)

Combustible: -40 to 50°C (-40°F to 112°F)

50 301EM User Manual

Page 53

Programming and Calibration

Maintenance

Maintenance

The 301EM requires no maintenance. Transmitters, however, require

regular inspection and calibration.

Replacement Parts

LED replacement instructions for RFS or RFSA option:

• Turn the cap until the diamond shape aligns with the triangle outline

shape

• Pull off the cap

• Use the insertion tool to remove the LED;

• Use the insertion tool to put in the new LED;

• Put the cap back on (press down firmly)

• Turn the cap until the diamond is aligned with the white triangle

shape.

Due to the continuous evolution of our products, please contact our

service department for ordering parts or for more details.

Technical Support Line: 1-800-563-2967

Cleaning

Clean the exterior with a soft, damp cloth. Do not use solvents, soaps or

polishers.

301EM User Manual 51

Page 54

APPENDIX A

Available Pre-programmed configurations

APPENDIX A

Available Pre-programmed configurations

Type 1 CND (B-52 Canadian Standard for R123)

SetEvent Input Status Output Reset Silence

Event # 1 SD All Alr A Relay #1 Yes No

Event # 2 SD All Alr A Relay #4 Yes No

Event # 3 SD All Alr A Out 1 Yes Yes

Event # 4 SD All Alr A Out 2 Yes No

Event # 5 SD All Alr A Out 3 Yes No

Event # 6 SD All Alr A Buzzer Yes Yes

Event # 7 SD All Alr A Relay #2 Yes Yes

Event # 8 SD All Alr A Relay #3 Yes No

Event # 9 SD All Fault Relay #3 Yes No

Event #10 SD All Alr B Relay #1 No No

Event #11 SD All Alr C Relay #1 No No

Type 2 CND (B-52 Canadian Standard for other Refrigerants)

Event Input Status Output Reset Silence

Event # 1 SD All Alr A Relay #1 Yes No

Event # 2 SD All Alr A Out 1 Yes Yes

Event # 3 SD All Alr A Out 2 Yes No

Event # 4 SD All Alr A Out 3 Yes No

Event # 5 SD All Alr A Buzzer Yes Yes

Event # 6 SD All Alr A Relay #2 Yes Yes

Event # 7 SD All Alr B Relay #4 Yes No

Event # 8 SD All Alr A Relay #3 Yes No

Event # 9 SD All Fault Relay #3 Yes No

Event #10 SD All Alr C Relay #1 No No

52 301EM User Manual

Page 55

APPENDIX A

Available Pre-programmed configurations

Type 3 US (ASHRAE 15 Standard for Refrigerants)

Event Input Status Output Reset Silence

Event # 1 SD All Alr A Relay #1 Yes No

Event # 2 SD All Alr A Out 1 Yes Yes

Event # 3 SD All Alr A Out 2 Yes No

Event # 4 SD All Alr A Out 3 Yes No

Event # 5 SD All Alr A Buzzer Yes Yes

Event # 6 SD All Alr A Relay #2 Yes Yes

Event # 7 SD All Alr B Relay #4 No No

Event # 8 SD All Alr A Relay #3 Yes No

Event # 9 SD All Fault Relay #3 No No

Event #10 ManSw #1* Open Relay #1 Yes No

Event #11 ManSw #1* Open Relay #4 Yes No

Event #12 ManSw #1* Open Out 1 Yes Yes

Event #13 ManSw #1* Open Out 2 Yes No

Event #14 ManSw #1* Open Out 3 Yes No

Event #15 ManSw #1* Open Buzzer Yes Yes

Event #16 ManSw #1* Open Relay #2 Yes Yes

Event #17 ManSw #1* Open Relay #3 Yes No

Event #18 SD All Alr C Relay #1 No No

Event #19 ManSw #2** Open Relay #1 No No

*Mansw #1 Trigger an electrical shut down.

**ManSw #2 Trigger relay #1.

301EM User Manual 53

Page 56

APPENDIX A

Available Pre-programmed configurations

Type 4 (Default configuration - other than B-52 and ASHRAE 15)

Event Input Status Output Reset Silence

Event # 1 SD All Alr A Relay #1 No No

Event # 2 SD All Alr B Relay #2 No Yes

Event # 3 SD All Alr C Relay #3 No No

Event # 4 SD All Fault Relay #4 No No

Event # 5 SD All Alr B Out 1 No Yes

Event # 6 SD All Alr A Out 2 No No

Event # 7 SD All Alr C Out 3 No No

Event # 8 SD All Alr B Buzzer No Yes

54 301EM User Manual

Page 57

Limited Warranty

Limited Warranty

Limited Warranty

Honeywell Analytics, Inc. warrants to the original purchaser and/or

ultimate customer ("Purchaser") of Vulcain products ("Product") that if any

part thereof proves to be defective in material or workmanship within

twelve (12) months, such defective part will be repaired or replaced, free

of charge, at Honeywell Analytics' discretion if shipped prepaid to

Honeywell Analytics at 4005 Matte Blvd., Unit G, Brossard, Quebec,

Canada, J4Y 2P4, in a package equal to or in the original container. The

Product will be returned freight prepaid and repaired or replaced if it is

determined by Honeywell Analytics that the part failed due to defective

materials or workmanship. The repair or replacement of any such

defective part shall be Honeywell Analytics' sole and exclusive

responsibility and liability under this limited warranty.

Re-Stocking Policy

The following re-stocking fees will apply when customers return products

for credit:

• 15% re-stocking fee will be applied if the product is returned within 1

month following the shipping date

• 30% re-stockingfee will be applied if the product is returned within 3

months following the shipping date

A full credit (less re-stocking fee) will only be issued if the product is in

perfect working condition. (If repairs are required on the returned product,

the cost of these repairs will be deducted from the credit to be issued.)

No credits will be issued beyond the three month period.

301EM User Manual 55

Page 58

Limited Warranty

Exclusions

a.If Gas sensors are part of the Product, the gas sensor is covered by

a twelve (12) month limited warranty of the manufacturer.

b.If gas sensors are covered by this limited warranty, the gas sensor

is subject to inspection by Honeywell Analytics for extended exposure

to excessive gas concentrations if a claim by the Purchaser is made

under this limited warranty. Should such inspection indicate that the

gas sensor has been expended rather than failed prematurely, this

limited warranty shall not apply to the Product.

c.This limited warranty does not cover consumable items, such as

batteries, or items subject to wear or periodic replacement, including

lamps, fuses, lves, nes, sensor elements, cartridges, or filter

elements.

Warranty Limitation and Exclusion

Honeywell Analytics will have no further obligation under this limited

warranty. All warranty obligations of Honeywell Analytics are

extinguishable if the Product has been subject to abuse, misuse,

negligence, or accident or if the Purchaser fails to perform any of the

duties set forth in this limited warranty or if the Product has not been

operated in accordance with instructions, or if the Product

serial number has been removed or altered.

301EM User Manual 56

Page 59

Limited Warranty

Disclaimer of Unstated Warranties

The warranty printed above is the only warranty applicable to this

purchase. All other warranties, express or implied, including, but not

limited to, the implied warranties of merchantability or fitness for a

particular purpose are hereby disclaimed.

Limitation of Liability

It is understood and agreed that Honeywell Analytics’ liability, whether in

contract, in tort, under any warranty, in negligence or otherwise shall not

exceed the amount of the purchase price paid by the purchaser for the

product and under no circumstances shall Honeywell Analytics be liable

for special, indirect, or consequential damages. The price stated for the

product is a consideration limiting honeywell analytics' liability. No action,

regardless of form, arising out of the transactions under this warranty may

be brought by the purchaser more than one year after the cause of

actions has occurred.

301EM User Manual 57

Page 60

Page 61

Dispositif de détection de gaz

301EM

Manuel d’utilisateur

ERP 512720

2/09

Page 62

Page 63

Avis et marques de commerce

Tous droits réservés par Honeywell International Inc.

Parution 512720 février 2009

Quoique cette information est présentée en bonne foi et est présumée exacte,

Honeywell décline la garantie tacite de la qualité marchande pour un emploi

particulier et offre aucune garantie exprès, à l’exception des conventions écrites

avec et pour ses clients.

Honeywell ne sera, sous aucune circonstance, responsable à qui que ce soit pour

des dommages spéciaux ou indirectes. Les informations et les spécifications

dans ce document sont susceptibles d’être modifiées sans préavis.

Honeywell Analytics

4005 Matte Blvd, Local G

Brossard, Québec, Canada, J4Y 2P4

Manuel de l’utilisateur 301EM iii

Page 64

Page 65

Définitions des symboles

Le tableau suivant contient la liste des symboles utilisés dans ce

document pour indiquer certaines conditions :

Symbole Définition

ATTENTI ON: Identifie une information demandant

une attention spéciale

Truc: Identifie un conseil ou un truc pour

l’utilisateur, souvent concernant une tâche

RÉFÉRENCE- INTERNE Indique une source

d’information supplémentaire à l’intérieur du

document.

Indique une situation à éviter pouvant entraîner des

ATTENTION

dommages au système ou la perte de travail

(documents) ou pouvant prévenir l’opération

normale du système.

ATTENTI ON : Indique une situation potentiellement

dangereuse qui peut entraîner des blessures

mineures ou modérées si pas évité. Peut

également signaler des actions dangereuses

ATTENTI ON: Un symbole sur l’équipement qui

réfère l’utilisateur à la documentation pour de plus

amples informations. Ce symbole apparaît à côté

des informations nécessaires dans le manuel.

AVERTISSEMENT : Indique une situation

potentiellement dangereuse qui peut entraîner des

blessures majeures ou la mort si pas évité.

AVERTISSEMENT Un symbole sur l’équipement

qui réfère l’utilisateur à la documentation pour de

plus amples informations. Ce symbole apparaît à

côté des informations nécessaires dans le manuel.

Manuel de l’utilisateur 301EM v

Page 66

Page 67

Table des matières

INTRODUCTION ...........................................................11

Description ........................................................................................11

Application visée ...............................................................................12

Déballage .........................................................................................12

INSTRUCTIONS D’INSTALLATION .............................13

Directives générales .............................................................................13

Installation murale ..................................................................................13

Hauteurs d’installation recommandées ..................................................14

Déterminer le nombre de transmetteurs ...........................................15

Plage de détection et niveaux d’alarmes ...........................................16

Installation des sondes à distances ..................................................17

DÉTAILS DE CONNEXION ...........................................19

Câblage du système ..........................................................................19

Connexion d’alimentation .......................................................................20

Connexion des sondes .........................................................................21

Communication ......................................................................................22

Sorties relais ..........................................................................................22

Sorties 24 Vcc ........................................................................................23

Configurations 4-20mA ..........................................................................23

Configuration sortie 4-20 mA .................................................................25

Manuel de l’utilisateur 301EM vii

Page 68

ÉTALONNAGE / PROGRAMMATION ...........................29

Interface usager ................................................................................29

Modes d’opération .................................................................................29

Description des touches .........................................................................30

Comment programmer l’unité ............................................................31

Comment accéder au menu de programmation ................................31

Comment désactiver l’alarme sonore ................................................32

Comment configurer l’adresse de l’unité ...........................................33

Comment configurer les alarmes .......................................................34

Comment configurer les sorties analogiques ....................................35

Comment étalonner l’unité .................................................................36

Brancher les régulateurs ........................................................................36

Étalonnage du zero (si requis) ...............................................................37

Étalonnage du gain ................................................................................38

Spécifications 301EM ........................................................................40

Spécifications sonde 301IRFS .........................................................41

Spécifications sonde 301D2 .............................................................42

Entretien ............................................................................................43

Pièces de remplacement ......................................................................43

Nettoyage ..............................................................................................43

ANNEXE ........................................................................44

Configurations pré-programmées disponibles ..................................44

GARANTIE LIMITÉE ......................................................47

Garantie limitée ......................................................................................47

Politique de Retour ................................................................................47

Exclusions ..............................................................................................47

Limitation et exclusion de la garantie .....................................................48

Dénégation de responsabilité d’autres garanties ...................................49

Limitation de responsabilité ...................................................................49

viii Manuel de l’utilisateur 301EM

Page 69

Introduction

INTRODUCTION

Description

À la recherche de technologies de pointe et de la satisfaction du client,

Honeywell présente une innovation dans le contrôle des gaz frigorigènes,

toxiques et explosifs.

Fruit de la recherche et d'une conception poussée, le 301EM utilise la

technologie infrarouge la plus avancée. Le 301EM peut gérer jusqu’à 20

détecteurs, ce qui permet la mesure précise d’infimes concentrations de

gaz. La sonde peut être placée à une distance allant jusqu'à 500 pi. de la

source d’alimentation pour le contrôle de gaz toxique et 200 pi. pour le

gaz frigorigène.

L'émetteur, équipé d'un affichage à CL rétroéclairé et d’un clavier de

touches, peut être installé à la hauteur des yeux dans un emplacement

différent de la zone de lecture des gaz frigorigènes. La surveillance se fait

donc d'un site sûr et éloigné.

Le 301EM offre également des sorties 4-20 mA et des relais, une

communication Modbus, des options d'alarmes sonores et il est

compatible avec notre contrôleur 301C.

Application visée

En raison de la disponibilité et des coûts croissants des gaz frigorigènes,

il devient nécessaire d’effectuer une surveillance accrue dans les salles

mécaniques. Le détecteur de frigorigène Honeywell fournit un

avertissement rapide lors de fuite de gaz et indique les concentrations de

gaz de la salle mécanique, ce qui permet d’améliorer la stratégie de

conservation du frigorigène. De plus, des sondes toxiques et

combustibles peuvent être jumelées au 301EM afin de rencontrer un plus

large éventail d’exigences pour la clientèle. Offert dans une configuration

spéciale, le module d'expansion 301EM a été soigneusement conçu pour

rencontrer et même dépasser les normes ASHRAE B-52 et 15-2201.

Déballage

Dès l’ouverture de l’emballage, assurez-vous que vous avez reçu

l’équipement et les composantes tels qu’indiqués sur le bon de

connaissement et que l’ensemble de la commande n’est pas

endommagé.

Manuel de l’utilisateur 301EM 9

Page 70

Instructions d’installation

Directives générales

INSTRUCTIONS D’INSTALLATION

Directives générales

Ces directives doivent être strictement respectées pour assurer le bon

fonctionnement de l’équipement. Si elles ne sont pas respectées,

Honeywell ne se tiendra aucunement responsable des incidents pouvant

en découller:

• Localiser chaque unité à un endroit facile d’accès pour un technicien.

• Éviter toute localisation des unités près des sources de vibrations.

• Évitez d’installer les unités près d’équipements émettant des

interférences électromagnétiques.

• Évitez les emplacements où la température change rapidement.

• Avant de débuter l’installation, vérifiez tous les codes, normes ou

législations pouvant affecter le choix de l’emplacement.

Installation murale

Nous recommandons d’installer

le moniteur à 1.5 m (4.9 pi) du

sol.

Mesurer les distances, tel

qu’indiqué :

• Distance en hauteur entre les

trous 162mm (6 3/8”)

• Distance en largeur entre les

trous 268.3mm

(10 9/16”)

• Perçer les trous 6.35mm (1/

4”) et fixer l’unité avec les vis

appropriées.

Le câblage de l’unité doit être enfiler dans les trous de pastilles

poinçonnées (knock-out) situés en dessous de l’unité.

10 Manuel de l’utilisateur 301EM

Page 71

Instructions d’installation

Directives générales

Hauteurs d’installation recommandées

Les hauteurs d'installation de détecteurs recommandées représentent des directives

générales. Toujours vérifier les normes et les lois locales avant de procéder à

l'installation. Celles-ci ont préséance sur les recommandations du fabricant.

Gaz Détectés Densité relative

CO Monoxyde de carbone 0.968 1-1.5 m (1-1.5 pi) du sol

NO2 Dioxyde d’azote 1.58 (froid)* 30 cm -1 m (1-3 pi) du plafond

H2 Hydrogène 0.07 30 cm (1 pi) du plafond

CL2 Chlore 2.50 30 cm (1 pi) du sol

H2S Sulfure d’hydrogène 1.19 30 cm (1 pi) du sol

O2 Oxygène 1.43 1 - 1.5 m (1 - 1.5 pi) du plancher

HCL Chlorure d’hydrogène 1.30 30 cm (1 pi) du sol

HCN Acide cyanidrique 0.932 30 cm (1 pi) du plafond

ETO Oxyde d’éthylène 1.50 30 cm (1 pi) du sol

SO2 Bioxyde de souffre 2.25 30 cm (1 pi) du sol

R11 Frigorigènes 5.04 30 cm (1 pi) du sol

R12 Frigorigènes 4.20 30 cm (1 pi) du sol

R13B1 Frigorigènes 5.14 30 cm (1 pi) du sol

R114 Frigorigènes 5.9 30 cm (1 pi) du sol

R22 Frigorigènes 3.11 30 cm (1 pi) du sol

R123 Frigorigènes 5.27 30 cm (1 pi) du sol

R125 Frigorigènes 4.14 30 cm (1 pi) du sol

R134A Frigorigènes 3.52 30 cm (1 pi) du sol

R227 Frigorigènes 5.90 30 cm (1 pi) du sol

R245A Frigorigènes

R404A Frigorigènes

R407C Frigorigènes

R410A Frigorigènes

R507 Frigorigènes

R508b Frigorigènes

La plupart des combustibles sont plus lourds que l’air, excepté le méthane,

l’hydrogène, l’éthylène et l’acétylène. Pour les gaz plus lourd que l’air, des

Comb

* Peut varier dans certaines applications. Le NO2 chaud sortant d’un dispositif d'échappement est plus

léger que l’air ambient.

capteurs devraient être installés à environ 30 cm du sol. Pour les

combustibles plus légers que l’air, des capteurs devraient être installés à

30 cm du plafond, près de la source potentielle de fuite.

(air = 1)

3.43

3.0

3.0

3.43

Manuel de l’utilisateur 301EM 11

Hauteur d’installation

30 cm (1 pi) du sol

30 cm (1 pi) du sol

30 cm (1 pi) du sol

30 cm (1 pi) du sol

30 cm (1 pi) du sol

30 cm (1 pi) du sol

Page 72

Instructions d’installation

Déterminer le nombre de transmetteurs

Déterminer le nombre de transmetteurs

Le nombre de transmetteurs est déterminé par le rayon de surveillance