Page 1

301C

Gas detection network controller

offering safety, energy efficiency,

and ease of installation

Page 2

The 301C Controller continuously monitors

and controls toxic, combustible, and

refrigerant gases as well as oxygen.

Rely on the 301C for safety, energy

efficiency, and easy installation of your

gas detection network.

Using an addressable RS-485 communication protocol, the 301C uses

daisy chain wiring to connect up to 96 transmitters in three loops.

This simplies installation, in turn lowering costs. The 301C’s powerful

zoning, voting, and averaging abilities signicantly reduce operational

and maintenance costs. And what’s more, the newly updated 301C cuts

commissioning time and hassle.

Flexible Logic Capabilities Reduce Operational Costs

Choose the 301C as the centerpiece for building a gas detection network

compliant with the industry’s most demanding safety and energy guidelines,

such as California Title 24 Part 6. The 301C controller offers automatic

sensor identication and unique zoning capabilities which permit the

grouping of multiple sensor readings. Readings from transmitters in a given

zone can be evaluated via averaging or voting. For example, voting can be

used to activate fans only when one-third of the sensors in a zone report

gas. This can avoid an excessive response to a single car idling. Time delays

can be congured at the leading edge of a gas response (to prevent false

alarms) or on the trailing edge (to reduce power cycling of a fan.) Outlier

detection can be used to identify when a single sensor reading is higher

than others. Responses can also be made conditional on time of day, day of

week, or other external input. This exibility can precisely match the needs of

each installation, thus saving energy and extending equipment life.

User Friendly

• Zero maintenance

• Automatic quick self-test and warm-up

• Continuous alphanumeric display

Inexpensive, Reliable and

Energy Efficient

• Low installation costs

• Allows for up to 126 zoning groups which can

save energy and extend fan and relay life

• Manages up to 180 events with

programmable latching alarms

• California Title 24 network option

Flexible Operation

• BACnet/IP available

• Interchangeable transmitters able to detect

different gases

• Expands to handle up to 96 transmitters or

relay modules

• Programmable time delays

• Integrated time clock enables scheduling of

system operations

Safety Measures

• Full array of visual indicators and integrated

65dBA alarm levels

• Fully programmable relays (can be set as

fail-safe or not)

Beneficial Options

• Available in a heavy duty industrial housing

(model number 96D)

• Datalogging option

BACnet is a registered trademark of ASHRAE. ASHRAE does not

endorse, approve or test products for compliance with ASHRAE

standards. Compliance of listed products to the requirements of

ASHRAE Standard 135 is the responsibility of BACnet International (BI).

BTL is a registered trademark of BI.”

Find out more

www.honeywellanalytics.com

Contact Honeywell Analytics:

Honeywell Analytics Inc.

405 Barclay Blvd.

Lincolnshire, IL USA 60069

Tel: 847.955.8200

Toll free: 800.538.0363

Fax: 847.955.8210

haservice@honeywell.com

www.honeywell.com

Please Note:

While every effort has been made to ensure accuracy in this publication, no responsibility can be accepted for errors or omissions.

Data may change, as well as legislation, and you are strongly advised to obtain copies of the most recently issued regulations,

standards, and guidelines. This publication is not intended to form the basis of a contract.

DS01005_v7 7/15

© 2015 Honeywell Analytics

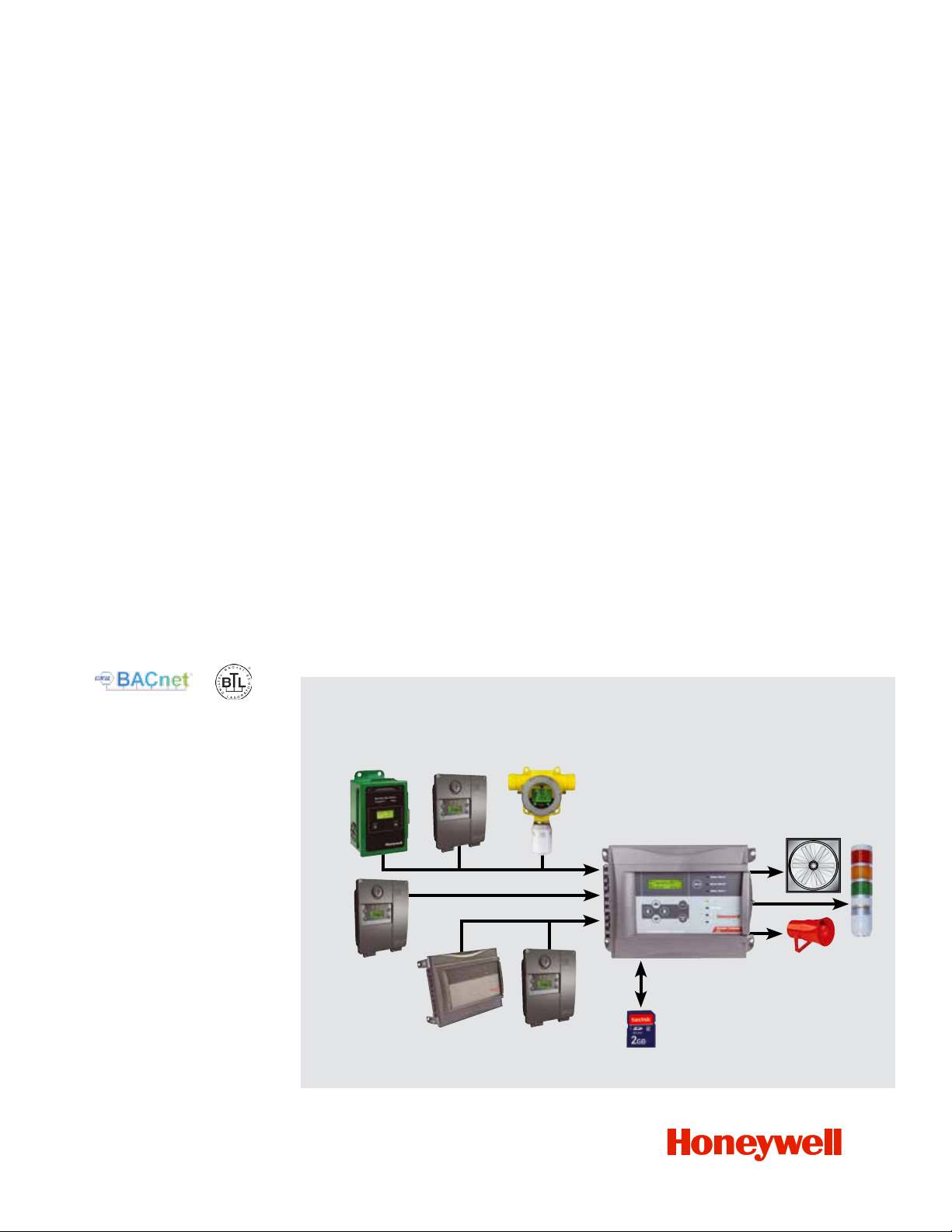

The 301C Controller: Centerpiece of a Complete

Gas Detection Network for the Intelligent Building

EC-FX-NH3 E3Point Sensepoint XCD

3

Point

E

Connect up to 96 transmitters on RS485 networks.

Optional BTL-listed BACnet/IP interface

provides all concentrations and relay drives.

301C

Four freely-programmable

5 Amp DPDT relay ouputs.

Optional datalogger

3

E

Point301R8

stores events, gas

concentration levels and

system configurations.

Loading...

Loading...