Page 1

Series 3000 MkII and MkIII

2-wire loop powered toxic and

Oxygen gas detector for use in

potentially explosive atmospheres

- explosion proof and intrinsically

safe versions

Page 2

Series 3000 MkII

and MkIII

Reliable detection

• Proven electrochemical

sensing technology

• Uses Surecell™ electrochemical cells,

ideal for hot and humid environments

• Long-life sensing elements

• Patented ‘Reflex’ sensing element

verification diagnostics

Reduced installation costs

• Integral surface mounting lugs

• Optional horizontal or vertical pipe

mounting bracket

• Flameproof transmitter allows field

wiring to be run along with other

non-IS instruments

• Plug-in sensor removes wiring

• Can be retrofitted in place of Series 2000

Reduced commissioning costs

• Sensor recognition feature auto

configures transmitter

• Non-intrusive configuration

• Plug and play factory configured sensors

Reduced maintenance costs

• IS sensor connection permits hot swap,

reducing downtime

• User programmable calibration

frequency

• Integral fault diagnostic software

• Menu/icon driven calibration

procedure

Regulatory compliance

• European (ATEX)

• US (UL)

• Canadian (c-UL)

• South America (Inmetro)

• International (IECEx)

Range of optional accessories

• Remote sensor mounting kit

• Duct mounting kit (for H2, CO

and H2S only)

• Calibration cup to apply test gas

• Collecting cone

Typical applications

• Exploration and drilling platform

• Production platforms

• Onshore oil and gas terminals

• Refineries and chemical plants

• Power plants

• Waste water facilities

• Utilities

The Series 3000 range of transmitters provide

comprehensive monitoring of toxic and Oxygen gas

hazards in potentially explosive atmospheres. Suitable

for mounting both indoors and out, they are available in

two versions and offer excellent versatility. The MkII is

contained in a flameproof housing, has an intrinsically safe

sensor connection and is for use in predominantly Zone 1

applications. However with the use of the optional remote

mounting kit the sensor of the MkII can be mounted in a

Zone 0 environment. The MkIII is for use with a separate

suitable IS barrier allowing the complete transmitter to be

used in Zone 0 applications.

These low powered gas detectors all feature a loop

powered 4-20 mA connection, making them ideal for

both new and retrofit installations. Users can configure

the detector through the use of the easy to read LCD

and intuitive interface while fault diagnostic software

and a programmable calibration period greatly simplify

maintenance procedures.

The intrinsically safe smart sensors are

supplied pre-configured and can be ‘hot

swapped’ without having to remove power to

the detector, saving time and money during

commissioning and routine servicing. A remote

sensor mounting kit is available that allows the

sensor to be mounted up to 15m (50ft) from

the transmitter, making it ideal for operation in

areas that are difficult to access.

Series 3000 is supplied with all necessary

accessories for easy installation. The detector

can be wall mounted using the integral

mounting lugs or pipe mounted (horizontal or

vertical) using the optional pipe mounting kit.

Electrical installation is made using the

2 x M20 cable entries (ATEX/IECEx version) or

2 x ¾”NPT conduit entries (UL/c-UL versions).

A suitable blanking plug is also supplied to

seal any unused entries. A weatherproof cap

is included for use in the harshest outdoor

conditions.

Page 3

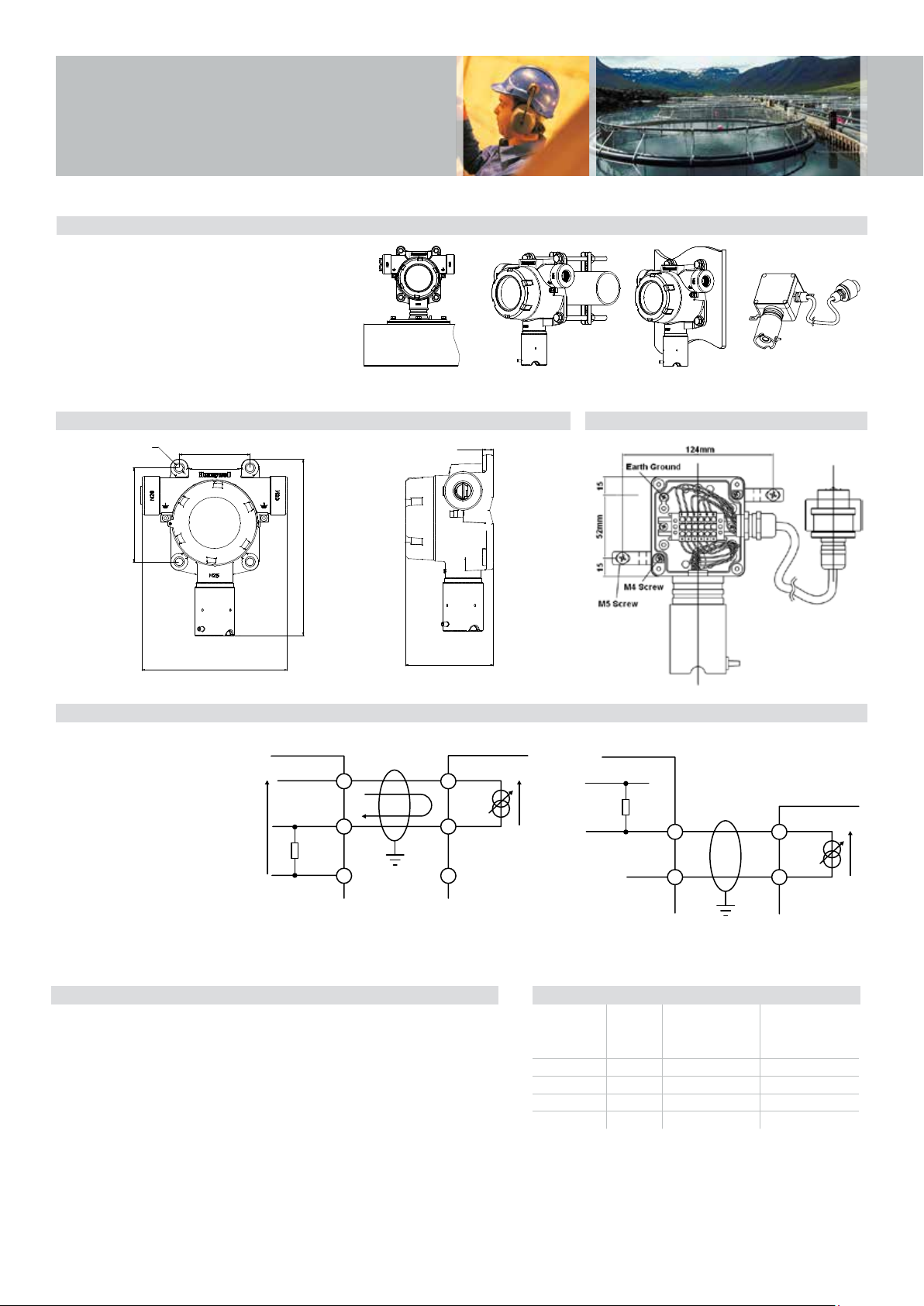

Installation

Controller Detector

V

Mechanical Installation Options

Series 3000 MkII and MkIII are designed for use

in potentially explosive atmospheres. As such,

installation should follow national guidelines

using suitable mechanically protected cable and

glands (M20 or ¾” NPT) or conduit (¾” NPT).

Use 0.5mm

cross sectional area cable as needed to ensure

minimum operating voltage at the detector,

depending on installed cable length. Various

accessories are available for different applications.

2

(20AWG) to 2.0mm2 (~14AWG)

Pipe Mounting Wall MountDuct Mount

Remote Mounting

Dimensions

Ø8.5

80

106

164

Wiring Schematics Series 3000 MkII

Detector supply V

• 17Vdc (min) to 32Vdc (max)

Maximum detector signal I

• 22mA (over range)

d

m

Cable resistance Rc

• Subject to cable type

Load resistor of control panel R

• Assumed 33Ω (min) or 250Ω (max)

• Subject to controller manufacturer

Controller supply voltage V

• Subject to controller manufacturer

• Assumed nominal of 24Vdc

c

Remote Mounting Arrangement

12

201

Note: All dimensions

99

Controller

R

+VE

c

L

Signal Signal

R

L

-VE

c

1

I

m

2

3

+VE

1

V

d

Signal

2

3

+VE

R

L

V

c

-VE -VE

R

c

1

I

m

2

in mm (1" = 25.4mm)

Detector

+VE

1

2

V

d

Typical Maximum Installed Cable Lengths Series 3000 MkII

The maximum cable length between a controller and detector is dependent upon:

• The minimum guaranteed supply voltage to the detector at

the controller (V

• The minimum operating voltage of the detector (V

).

C

• The maximum current draw of the detector (I

• The input impedance of the controller (R

• The resistance of the cable (R

Using the example values, the table opposite shows typical cable lengths.

For a specific application, the cable manufacturer’s resistance data for a specific cable type

must be used.

A cable length calculation formula can be found in the product technical manual.

Series 3000 MkII Maximum Cable Length shown in km (mi)

Cable Size Cable

2

0.5mm

)

d

)

m

)

L

)

C

(20AWG*) 36.8 (59.2) 3.9 (2.4) 0.9 (0.6)

2

(17AWG*) 19.5 (31.4) 7.3 (4.5) 1.7 (1.1)

1.0mm

2

(16AWG*) 12.7 (20.4) 11.2 (7.0) 2.7 (1.7)

1.5mm

2

(14AWG*) 10.1 (16.3) 14.1 (8.8) 3.4 (2.1)

2.0mm

*Nearest equivalent

Resistance

Ω/km

R

c

(Ω/mi)

Cable distance km

(mi) where the Input

Impedance

= 33Ω

R

L

Cable distance km (mi)

where the Input

Impedance

= 250Ω

R

L

Page 4

Installation

Wiring Schematics Series 3000 MkIII

Signal

Controller

+VE

R

L

1 1

-VE -VE

2 2

Simple Zener Barrier

or Isolator

B

A

R

R

I

E

R

Controller

Detector

+VE

+VE

R

L

Earth

3

1 1

Signal

2

-VE

3

4

Dual Zener Barrier

or ‘Mirror’ Isolator

Single Barrier Schematic Dual Barrier Schematic

Series 3000 MkIII Cable Length Suggested barriers and isolators Series 3000 MkIII

The limiting factors in calculating maximum cable lengths when using barriers

and isolators are the total capacitance and inductance. Barriers and isolators

have a fixed amount of capacitance and inductance that can be connected to

their outputs. The cable between the field device and barrier/isolator will have

a value for capacitance and inductance per metre or kilometre that will be

available from the manufacturer or supplier.

To calculate the maximum cable lengths, calculate the total capacitance

and inductance for the length of cable, add any capacitance or inductance

due to the field device (in the case of Series 3000 MkIII capacitance and

inductance = 0). The resulting totals should not be greater than the value

shown for the barrier or isolator.

Listed below are some suggested barriers and isolators for use with

Series 3000 MkIII.

MTL7728+ (single channel zener barrier)

MTL7787+ (2-channel zener barrier)

MTL5042 (Galvanic Isolator)

Pepperl+Fuchs KFD2-STC4-EX1 (Galvanic Isolator)

Note: It is up to the user to ensure that the barrier or isolator used is suitable for

their application.

2

3

Detector

+VE

Signal

Electrical Connections

Terminal Detector Controller

Number Terminal Connection

1 + +VE

2 - Signal

Page 5

Technical Summary

Series 3000 MkII and MkIII Detector

Use Rugged and reliable gas detector for the protection of personnel from toxic and Oxygen gas hazards. MkII version

suitable for use in Zone 1, 2, 21 or 22 hazardous areas and North American Class I and II Division 1 or 2 areas.

MkIII version suitable for use in Zone 0, 1, 2, 20, 21 or 22 applications.

Detectable Gases

Gas Formula Selectable Full

Scale Range

Oxygen

Hydrogen Sulphide

Hydrogen Sulphide

Carbon Monoxide

Sulphur Dioxide

Ammonia*

Ammonia*

Chlorine

Chlorine Dioxide

Nitric Oxide

Nitrogen Dioxide

Hydrogen

Hydrogen

Hydrogen Chloride

Hydrogen Cyanide

Hydrogen Fluoride

Phosphine

Fluorine

Ozone

Ethylene Oxide

O

H

H

CO

SO

NH

NH

CI

CIO

N0

NO

H

H

HCI

HCN

HF

PH

F

O

ETO

2

S

2

S

2

25.0% / Vol only 25.0%Vol -30°C / -22°F 55°C / 131°F

10.0 to 50.0ppm 15.0ppm -40°C / -40°F 55°C / 131°F

50 to 500ppm 100ppm -40°C / -40°F 55°C / 131°F

100 to 500ppm 300ppm -40°C / -40°F 55°C / 131°F

2

3

3

2

2

5.0 to 20.0ppm 15.0ppm -40°C / -40°F 55°C / 131°F

50 to 200ppm 200ppm -20°C / -4°F 40°C / 104°F

200 to 1,000ppm 1,000ppm -20°C / -4°F 40°C / 104°F

5.0 to 20ppm 5.0ppm -10°C / 14°F 55°C / 131°F

1.00ppm only 1.00ppm -20°C / -4°F 55°C / 131°F

100ppm only 100ppm -20°C / -4°F 55°C / 131°F

2

2

2

5.0 to 50.0ppm 10ppm -20°C / -4°F 55°C / 131°F

1,000ppm only 1,000ppm -20°C / -4°F 55°C / 131°F

9,999ppm only 9,999ppm -20°C / -4°F 55°C / 131°F

10.0 to 20.0ppm 10ppm -20°C / -4°F 40°C / 104°F

30.0ppm only 30.0ppm -20°C / -4°F 55°C / 131°F

12.0ppm only 12.0ppm -20°C / -4°F 55°C / 131°F

3

2

3

1.2ppm only 1.2ppm -20°C / -4°F 40°C / 104°F

4.00ppm only 4.00ppm -20°C / -4°F 55°C / 131°F

0.400ppm only 0.400ppm -20°C / -4°F 55°C / 131°F

20.0 to 50.0ppm 25.0ppm -20°C / -4°F 55°C / 131°F

Electrical

Connections and Power MkII MkIII

2-wire loop powered

17Vdc (±10%) to 32Vdc (max)

22mA max. over range

Recommended Cable

Signal

2-wire with screen (90% coverage) or conduit

2

0.5mm

(20AWG) to 2.0mm2 (14AWG)

0-100% FSD 4-20mA

Fault = 3mA

Calibration due selectable off or 3mA

Max. over range 22mA

Inhibit (toxic sensors) = Selectable 3mA or 4mA

Inhibit (Oxygen sensors) = Selectable 3mA or 17.4mA

Construction

Material Transmitter: Epoxy painted aluminium alloy LM25 or 316 Stainless Steel, Sensor: 316 Stainless Steel with PTFE filter

Maximum Dimensions 164mm x 201mm x 99mm (6.4” x 7.9” x 3.9”)

Weight Aluminium alloy LM25: 1.7kg (3.75lbs.) Stainless Steel 316: 3.7kg (8.16lbs.)

Environmental

IP Rating IP66 (EN 60529), NEMA 4X

Certified Temperature ATEX/IECEX: -20°C to +55°C (-4°F to +131°F) (MkIII -40°C to +55°C (-40°F to +131°F))

UL/c-UL: -40°C to +55°C (-40°F to +131°F)

Operating Humidity Continuous 20-90% RH (non-condensing) Intermittent 0-99% RH (non-condensing)

Operating Pressure 90-110kPa

Storage Conditions 15°C to 30°C (59°F to 86°F), 30-70% RH (non-condensing)

Default Range Operating Temperature**

Min Max

1

2 wire loop powered

10Vdc (±10%) to 30Vdc (max)

22mA max. overrange

Entity parameters for Barrier Selection:

Vmax/Ui = 30Vdc

Imax/Ii = 125mA

Pmax/Pi = 1.2W

Li = 0mH

Ci = 0µF

*Suitable for applications without NH3

ambient background concentrations only.

**When operating in Hazardous Area

applications the detector must not be

operated outside the certified temperature

range. See Certification details for UL,

c-UL and ATEX/IECEx certified temperature

ranges.

1

+55°C / 131°F intermittent.

Page 6

Technical Summary

and Ordering Information

Certification

MkII MkIII

Transmitter:

UL/c-UL: Class I, Div. 1 & 2, Groups B, C & D;

Class II, Div. 1 Groups E, F & G, Class II, Div. 2, Groups

F & G; Class I, Zone 1, Group IIB + H2 Hazardous

Locations

II 2 (1) GD Ex d [ia IIC Ga] IIB + H2 T4 Gb

ATEX:

Ex t [ia IIIC Da] IIIB T135°C Db

IECEx: Ex d [ia IIC Ga] IIB + H2 T4 Gb Ex t [ia IIIC Da]

IIIB T135°C Db

Transmitter:

UL/cUL Class I, Divisions 1 & 2, Groups A, B, C & D;

Class II, Divisions 1 & 2, Groups E, F & G

II 1 (1) GD Ex ia IIC T4 Ga Ex ia IIIC T135°C Da

ATEX:

IECEx: Ex ia IIC T4 Ga Ex ia IIIC T135°C Da

Remote Sensor Accessory:

UL/c-UL: Class I, Division 1, Groups A, B, C and D

Class II, Divisions 1 and 2, Groups E, F and G

Class 1, Zone 0, Group IIC; Class II, Zone 20

II 1G D Ex ia IIC T4 Ga Ex ia IIIC T135°C Da

ATEX:

IECEx: Ex ia IIC T4 Ga Ex ia IIIC T135°C Da

Approvals CE compliant in accordance with: ATEX Directive 94/9/EC, EMC Directive 2004/108/EC, EN 50270

Ordering Information

Remote Sensor Accessory:

UL/c-UL = Class I, Div. 1, Groups A, B, C & D; Class II

Division 1 & 2, Groups E, F & G; Class 1, Zone 0, Group IIC;

Class II, Zone 20

II 1G D Ex ia IIC T4 Ga Ex ia IIIC T135°C Da

ATEX:

IECEx: Ex ia IIC T4 Ga Ex ia IIIC T135°C Da

A complete assembly consists of two parts, a transmitter and sensor which must be ordered separately.

• Transmitter PN#: Two certified versions are available:

- ATEX/IECEx approved version (Aluminium version part number S3KAL2, S3KAL3 Stainless Steel version part

number S3KAS2, S3KAS3)

- UL/CSA approved version (Aluminium version part number S3KUL2, S3KUL3, Stainless Steel version part

number S3KUS2, S3KUS3)

- Inmetro approved version (Aluminium version part number S3KNL2, S3KNL3, Stainless Steel version part

number S3KNS2, S3KNS3)

• Sensor PN#: All certified ATEX, IECEx, UL, CSA (c-UL) with two digits to specify gas type and range:

- e.g. S3KXXC1SS (C1 denotes Carbon Monoxide, with a default range of 0-300ppm and user configurable for

ranges from 0-100ppm to 0-500ppm (in 100ppm steps))

Transmitter

L - LM25 Aluminium

S - 316 Stainless Steel

Series 3000 Transmitter

S3KAL3

A - ATEX/IECEx approved

U - UL/c-UL approved

N - Inmetro approved

Sensor Part Numbers and Available Gases

S3KXSO1SS Oxygen (O

S3KXSC1SS Carbon Monoxide (CO) 0-300ppm (default) 0-100 to 0-500ppm selectable

S3KXSC2SS Carbon Monoxide (CO) 0-300ppm (default) 0-100 to 0-999ppm selectable

S3KXSH1SS Hydrogen Sulphide (H

S3KXSH2SS Hydrogen Sulphide (H

S3KXSL1SS Chlorine (CI

S3KXSS1SS Sulphur Dioxide (SO

S3KXSX1SS Chlorine Dioxide (CIO

) 0-25% Vol

2

S) 0-15ppm (default) 0-10 to 0-50ppm selectable

2

S) 0-100ppm (default) 0-50 to 0-500ppm selectable

2

) 0-5ppm (default) 0-5 to 0-20ppm selectable

2

) 0-15ppm (default) 0-5 to 0-20ppm selectable

2

) 0-1ppm only

2

2 - MkII version

3 - MkIII version

Page 7

Ordering Information Continued

Ordering Information Continued

S3KXSM1SS Nitrogen Monoxide (NO) 0-100ppm only

S3KXSN1SS Nitrogen Dioxide (NO

S3KXSG1SS Hydrogen (H

S3KXSG2SS Hydrogen (H2) 0-10,000 only

S3KXSR1SS Hydrogen Chloride (HCI) 0-10ppm (default) 0-10 to 0-20ppm selectable

S3KXSA1SS Ammonia (NH

S3KXSA2SS Ammonia (NH

S3KXSY1SS Hydrogen Cyanide (HCN) 0-30 ppm only

S3KXSF1SS Hydrogen Fluoride 0-12 ppm only

S3KXSP1SS Phosphine 0-1.2 ppm only

S3KXSU1SS Florine (F

S3KXSZ1SS Ozone (O

2

3

S3KXSE1SS Ethylene Oxide (ETO) 0-25.0ppm (default) 0-20.0 to 0-50.0ppm selectable

Shipping Details

Shipping carton dimensions 315mm (12.4”) (L) x 230mm (9.0”) (W) x 115mm (4.5”) (D)

Approximate weight Aluminium alloy LM25 : 1.7kg (3.75lbs.) Stainless Steel 316 : 3.7kg (8.16lbs.)

Optional Accessories

SPXCDMTBR Pipe Mounting Bracket

SPXCDSDP Sunshade/Deluge Protection

S3KCAL Calibration gas flow housing

S3KCC Collecting cone (for use when detecting Hydrogen gas only)

S3KDMK Duct mounting kit (for use when detecting O

S3KRMK ATEX/UL/c-UL approved remote sensor mounting kit (includes enclosure with sensor socket, 15m (50 feet)

of digital cable and glands, transmitter cable plug, mounting screws)

Calibration Gases Contact Honeywell Analytics representative

) 0-10 ppm (default) 0-5 to 0-50 ppm selectable

2

) 0-1000ppm only

2

) 0-200ppm (default) 0-50 to 0-200ppm selectable

3

) 0-1000ppm (default) 0-200 to 0-1,000ppm selectable

3

) 0-4.00ppm only

) 0-0.400ppm only

, CO, H2S or H2 gas)

2

Page 8

Honeywell Analytics Gas Detection

Honeywell Analytics is able to provide gas detection solutions to meet the requirements of all

applications and industries. Contact us in the following ways:

Headquarters

Europe, Middle East, Africa

Life Safety Distribution AG

Javastrasse 2

8604 Hegnau

Switzerland

Tel: +41 (0)44 943 4300

Fax: +41 (0)44 943 4398

gasdetection@honeywell.com

Customer Service:

Tel: 00800 333 222 44

Tel: +41 44 943 4380 (Alternative number)

Fax: 00800 333 222 55

Middle East Tel: +971 4 450 5800 (Fixed Gas Detection)

Middle East Tel: +971 4 450 5852 (Portable Gas Detection)

(Freephone number)

Technical Support Centres

Honeywell Analytics Ltd.

4 Stinsford Road

Nufeld Industrial Estate

Poole, Dorset, BH17 0RZ

United Kingdom

Tel: +44 (0) 1202 645 544

Fax: +44 (0) 1202 645 555

Honeywell Analytics

ZAC Athélia 4 - 375 avenue du Mistral

Bât B, Espace Mistral

13600 La Ciotat

France

Tel: +33 (0) 4 42 98 17 75

Fax : +33 (0) 4 42 71 97 05

Americas

Honeywell Analytics Distribution Inc.

405 Barclay Blvd.

Lincolnshire, IL 60069

USA

Tel: +1 847 955 8200

Toll free: +1 800 538 0363

Fax: +1 847 955 8210

detectgas@honeywell.com

Honeywell Analytics

Elsenheimerstrasse 43

80687 München

Germany

Tel: +49 89 791 92 20

Fax: +49 89 791 92 43

Asia Pacic

Honeywell Analytics

Asia Pacic

#701 Kolon Science Valley (1)

43 Digital-Ro 34-Gil, Guro-Gu

Seoul 152-729

Korea

Tel: +82 (0) 2 6909 0300

Fax: +82 (0) 2 2025 0388

India Tel: +91 124 4752700

analytics.ap@honeywell.com

Honeywell Analytics

P.O. Box-45595

6th Street

Musaffah Industrial Area

Abu Dhabi

UAE

Tel: +971 2 554 6672

Fax: +971 2 554 6672

EMEA: HAexpert@honeywell.com

US: ha.us.service@honeywell.com

AP: ha.ap.service@honeywell.com

www.honeywellanalytics.com

www.raesystems.com

Honeywell Analytics

Experts in Gas Detection

Please Note:

While every effort has been made to ensure accuracy in this publication, no responsibility can be accepted for errors or

omissions. Data may change, as well as legislation, and you are strongly advised to obtain copies of the most recently

issued regulations, standards, and guidelines. This publication is not intended to form the basis of a contract.

12113_H_Series 3000 MkII & MkIII_DS01057_V9_EMEA

05/15

© 2015 Honeywell Analytics

Loading...

Loading...