Page 1

Honeywell Process Solutions

Profibus-DP(Pnet) Module

2MLL-PMEB/PSRA/PSEA

User's Guide

R240

January 2018

Release 240

Honeywell

Page 2

Notices and Trademarks

Copyright 2019 by Honeywell International

Sárl. Release 240 January 2019

While this information is presented in good faith and believed to be accurate, Honeywell disclaims

the implied warranties of merchantability and fitness for a particular purpose and makes no

express warranties except as may be stated in its written agreement with and for its customers.

In no event is Honeywell liable to anyone for any indirect, special or consequential damages. The

information and specifications in this document are subject to change without notice.

Honeywell, PlantScape, Experion PKS, and TotalPlant are registered trademarks of Honeywell

International Inc.

Other brand or product names are trademarks of their respective owners.

Honeywell Process Solutions

1860 W. Rose Garden Lane

Phoenix, AZ 85027 USA

1-800 822-7673

ii Fast Ethernet Module 2MLL-EFMTB/EFMFB User's Guide R240

Honeywell

January 2018

Page 3

Revision History

Version Date Remark Page

V 1.0 ’06.02 First Edition -

V1.1 ’07.10 2MLI-CPUU added -

V 2.0 ’10.08 2MLR CPU added -

Ch. 11 Compliance with EMC Specification added -

2MLL-PMEC added -

PROFICON configuration tool added -

Automatic Network Scan modified Ch.9.1.1

2MLL-PSRA added Ch.1.3.3

V 2.1 ’11.05 How to enable link through flag added Ch.5.2.3

V 2.2 ’11.06

V2.3 ’14.11 SoftMaster V4.0 UI Updated -

V2.4 ’16.03

Performance specifications added

- Max. number of modules per node : 24 Modules

Add 2MLL-PMEB

- PROFIBUS DPv1 setting

- P2P communication setting

- SoftMaster UI updated (2MLL-PMEB contents, P2P

settings)

Ch.2.2

-

Page 4

About User’s Manual

Thanks for purchasing ML PLC of Honeywell

Before use, make sure to carefully read and understand the User’s Manual about the functions, performances, installation and

programming of the product you purchased in order for correct use and importantly, let the end user and maintenance

administrator to be provided with the User’s Manual.

The User’s Manual describes the product. If necessary, you may refer to the following description and order accordingly. In

addition, you may connect our website (www.honeywellprocess,com/) and download the information as a PDF file.

Relevant User’s Manuals

Tit le Desc rip tio n

SOFTMASTER software user manual describing online function

SOFTMASTER User’s Manual

SOFTMASTER User’s Manual

(for 2MLI, 2MLR)

2MLK/MLM/MLC Instructions &

Programming User’s Manual

2MLI/2MLR/MLI Instructions &

Programming User’s Manual

2MLK CPU User’s Manual

(2MLK-CPUA/CPUE/CPUH/CPUS/CPUU)

2MLI CPU User’s Manual

(2MLI-CPUU)

such as programming, print, monitoring, debugging by using

2MLK, ML50 CPU

SOFTMASTER software user manual describing online function

such as programming, print, monitoring, debugging by using

2MLI, 2MLR CPU

User’s manual for programming to explain how to use

instructions that are used PLC system with 2MLK, MLM/MLC

CPU.

User’s manual for programming to explain how to use

instructions that are used PLC system with 2MLI, 2MLR, MLI

CPU.

2MLK-CPUA/CPUE/CPUH/CPUS/CPUU user manual

describing about 2MLK CPU module, power module, base, IO

module, specification o f e xtension cable and system

configuration, EMC standard

2MLI-CPUU user manual describing about 2MLI CPU module,

power module, base, IO module, specification of extension cable

and system configuration, EMC standard

2MLR redundant series User’s

Manual

N Configurator User’s Manual

Current user manual is written based on the following version.

Related OS version list

Model O/S vers ion

2MLK-CPUH, CPUS, CPUA, CPUE V2.0

2MLI-CPUU, CPUH V2.0

SOFTMASTER V4.2

2MLR-CPUH/F, CPUH/T V1.0

1 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEB User’s Guide

Honeywell

2MLR-CPUU user manual describing about 2MLR CPU module,

power module, extension drive, base, IO module, specification of

extension cable and system configuration, EMC standard

User’s manual for Pnet, Dnet configuration tool, N Configurator

R240

January2019

Page 5

◎ Contents ◎

Chapter 1 Introduction

Chapter 2 Specifications

Chapter 3 Installation and Test Operation

1.1 Introduction -------------------------------------------------------------------------------------------------------- 1-1

1.2 Characteristics ---------------------------------------------------------------------------------------------------- 1-1

1.3 Product Configuration ---------------------------------------------------------------- --------------------------- 1-2

1.3.1 Model Name ------------------------------------------------------------------------------------------------ 1-2

1.3.2 Available number by CPU ------------------------------------------------------------------------------- 1-2

1.3.3 Slave Device ----------------------------------------------------------------------------------------------- 1-3

1.4 Software ------------------------------------------------------------------------------------------------------------- 1-4

1.4.1 Check list for the software ------------------------------------------------------------------------------ 1-4

1.4.2 SOFTMASTER -------------------------------------------------------------------------------------------- 1-5

1.4.3 Checking the version ------------------------------------------------------------------------------------- 1-5

2.1 General Specifications ------------------------------------------------------------------------------------------ 2-1

2.2 Performance Specifications ----------------------------------------------------------------------------------- 2-2

2.3 Structure & Characteristics ------------------------------------------------------------------------------------ 2-3

2.3.1 Structure of Pnet I/F module -------------------------------------------------------------------------- 2-3

2.4 Cable Specifications --------------------------------------------------------------------------------------------- 2-6

2.4.1 Cable specifications of Belden network ------------------------------------------------------------- 2-6

3.1 Precautions for Installation ------------------------------------------------------------------------------------ 3-1

3.1.1 Precautions for Installation --------------------------------------------------------------------------- 3-1

3.2 From Setting to Operation ------------------------------------------------------------------------------------- 3-2

3.3 Installation of the product -------------------------------------------------------------------------------------- 3-3

3.3.1 Installation of 2MLL-PMEA --------------------------------------------------------------------------- 3-3

3.4 Test Operation ---------------------------------------------------------------------------------------------------- 3-6

3.4.1 Precautions for system configuration ------------------------------------------------------------- 3-6

1 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 6

Chapter 4 System Configuration

Chapter 5 Communication Program

Chapter 6 SyCon Setting

4.1 System Configuration of Network ---------------------------------------------------------------------------- 4-1

4.1.1 ML200 Pnet + Smart I/O ----------------------------------------------------------------------------- 4-1

4.1.2 ML200 Pnet + Composite System ----------------------------------------------------------------- 4-2

5.1 Communication Program --------------------------------------------------------------------------------------- 5-1

5.1.1 Type of communication program ------------------------------------------------------------------- 5-1

5.2 SOFTMASTER --------------------------------------------------------------------------------------------------- 5-2

5.2.1 Setting PLC type ----------------------------------------------------------------------------------------- 5-2

5.2.2 Registration of the communication module ------------------------------------------------------- 5-4

5.2.3 Uploading High Speed Link parameter and setup ----------------------------------------------- 5-8

5.2.4 Setting P2P Parameter ---------------------------------------------------------------- ---------------- 5-1 1

6.1 Introduction -------------------------------------------------------------------------------------------------------- 6-1

6.1.1 Main functions ------------------------------------------------------------------------------------------ 6-1

6.1.2 Characteristics ------------------------------------------------------------------------------------------ 6-1

6.2 Installation --------------------------------------------------------------------------------------------------------- 6-1

6.2.1 System requirements --------------------------------------------------------------------------------- 6-1

6.2.2 Software installation ----------------------------------------------------------------------------------- 6-2

6.3 Communication settings in SyCon -------------------------------- ------------------------------------------- 6-8

6.3.1 Initial screen --------------------------------------------------------------------------------------------- 6-8

6.3.2 Composition of menu --------------------------------------------------------------------------------- 6-9

6.3.3 New file ------------------------------------------------------------------------------------------------ -- 6-1 1

6.3.4 Master selection --------------------------------------------------------------------------------------- 6-12

6.3.5 Slave selection ----------------------------------------------------------------------------------------- 6-15

6.3.6 Bus parameter ----------------------------------------------------------------------------------------- 6-17

6.4 On-line Function ------------------------------------------------------------------------------------------------- 6-18

6.4.1 Introduction --------------------------------------------------------------------------------------------- 6-18

6.4.2 Online to the CIF -------------------------------------------------------------------------------------- 6-18

6.4.3 Automatic network scan ----------------------------------------------------------------------------- 6-18

6.4.4 Start/Stop communication --------------------------------------------------------------------------- 6-20

6.4.5 Debug mode -------------------------------------------------------------------------------------------- 6-20

6.4.6 Diagnostic functions ---------------------------------------------------------------------------------- 6-20

2 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 7

Chapter 7 N Configurator Setting

Chapter 8 High-speed Link

7.1 Introduction -------------------------------------------------------------------------------------------------------- 7-1

7.1.1 Main functions ------------------------------------------------------------------------------------------ 7-1

7.1.2 Characteristics ------------------------------------------------------------------------------------------ 7-1

7.2 Installation --------------------------------------------------------------------------------------------------------- 7-2

7.2.1 System requirements --------------------------------------------------------------------------------- 7-2

7.2.2 How to install Program --------------------------------------------------------------------------------- 7-2

7.3 Start PROFICON -------------------------------------------------------------------------------------------------- 7-3

7.3.1 Screen composition ------------------------------------------------------------------------------------- 7-3

7.3.2 Menu composition --------------------------------------------------------------------------------------- 7-4

7.3.3 New Project(New File) -------------------------------------------------------------------------------- 7-10

7.4 Network composition through PROFICON ----------------------------------------------------------------- 7-11

7.4.1 Master composition ------------------------------------------------------------------------------------ 7-11

7.4.2 Slave composition -------------------------------------------------------------------------------------- 7-13

7.4.3 Bus parameter ------------------------------------------------------------------------------------------- 7-16

7.5 Download and upload Network Configuration ------------------------------------------------------------- 7-17

7.5.1 Download Network Settings ------------------------------------------------------------------------- 7-17

7.5.2 Upload Network Settings ----------------------------------------------------------------------------- 7-19

7.6 Diagnosis function -------------------------------- ---------------------------------------------------------------- 7-20

7.6.1 Start / Stop Communication -------------------------------------------------------------------------- 7-20

7.6.2 Debug mode (Start/Stop Debug Mode, Device Diagnostics) -------------------------------- 7-20

7.6.3 Live List --------------------------------------------------------------------------------------------------- 7-22

7.6.4 Automatic Network Scan ------------------------------------------------------------------------------ 7-23

7.6.5 I/O Data Monitoring ------------------------------------------------------------------------------------ 7-24

7.6.6 Disconnection Report ---------------------------------------------------------------------------------- 7-25

7.6.7 Master information (Device Information) ---------------------------------------------------------- 7-25

7.6.8 Master reset (Firmware Reset) ---------------------------------------------------------------------- 7-25

8.1 Introduction -------------------------------------------------------------------------------------------------------- 8-1

8.2 Process of High-speed Link Send/Receive Data --------------------------------------------------------- 8-2

8.3 Operation Sequence of High-speed Link ------------------------------------------------------------------- 8-3

8.4 High Speed Link Parameter Setting--------------------------------------------------------------------------- 8-4

8.5 High-speed Link Information --------------------------------------------------------------------------------- 8-10

8.5.1 Monitor of High-speed link information ---------------------------------------------------------- 8-12

3 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 8

Chapter 9 P2P

Chapter 10 Program Example

Chapter 11 Troubleshooting

Chapter 12 Compliance with EMC Specifications

9.1 Introduction -------------------------------------------------------------------------------------------------------- 9-1

9.2 Process of P2P Read/Write Data ---------------------------------------------------------------------------- 9-2

9.3 Operation Sequence of P2P ---------------------------------------------------------------------------------- 9-3

9.4 P2P Parameter Setting ------------------------------------------------------------------------------------------- 9-4

9.5 P2P Informatio-n ------------------------------------------------------------------------------------------------- 9-9

10.1 Example of Communication with PMEA ----------------------------------------------------------------- 10-1

10.1.1 SyCon settings --------------------------------------------------------------------------------------- 10-1

10.1.2 SOFTMASTER settings ---------------------------------------------------------------------------- 10-9

10.2 Example of Communication with PMEA --------------------------------------------------------------- 10-14

10.2.1 PROFICON settings ------------------------------------------------------------------------------ 10-14

10.2.2 SOFTMASTER settings -------------------------------------------------------------------------- 10-23

11.1 Symptoms and Management by LED Status ----------------------------------------------------------- 11-1

11.2 System Diagnosis of SOFTMASTER -------------------------------- ------------------------------------- 11-2

11.2.1 Information on communication module --------------------------------------------------------- 11-2

11.2.2 High-speed link --------------------------------------------------------------------------------------- 11-3

11.2.3 Log ------------------------------------------------------------------------------------------------------ 11-3

11.2.4 Auto-scan ---------------------------------------------------------------------------------------------- 11-4

11.3 Diagnosis of Communication Module through SOFTMASTER ------------------------------------- 11-5

11.4 Troubleshooting ------------------------------------------------------------------------------------------------ 11-6

11.4.1 SyCon abnormal connection ---------------------------------------------------------------------- 11-6

11.4.2 SOFTMASTER abnormal connection ---------------------------------------------------------- 11-7

11.4.3 Abnormal connection with slave module ------------------------------------------------------- 11-8

12.1 Requirements Complying with EMC Specifications ---------------------------------------------------- 12-1

12.1.1 EMC specifications ----------------------------------------------------------------------------------- 12-1

12.1.2 Panel ----------------------------------------------------------------------------------------------------- 12-2

12.1.3 Cable ----------------------------------------------------------------------------------------------------- 12-3

12.2 Requirements Complying with Low Voltage Direction ------------------------------------------------ 12-4

12.2.1 Specifications applicable to ML200 series ------------------------------------------------------ 12-4

12.2.2 Selection of ML200 series PLC -------------------------------------------------------------------- 12-4

4 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 9

Appendix

A.1 Terminology ------------------------------------------------------------------------------------------------------- A-1

A.2 List of Flags ------------------------------------------------------------------------------------------------------- A-3

A.2.1 High-speed link flags ------------------------------------------------------------------------------------ A-3

A.2.2 Link devices (N) ------------------------------------------------------------------------------------------ A-6

A.3 Dimensions -------------------------------------------------------------------------------------------------------- A-8

5 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 10

Chapter 1 Introduction

1.1 Introduction

1.2 Characteristics

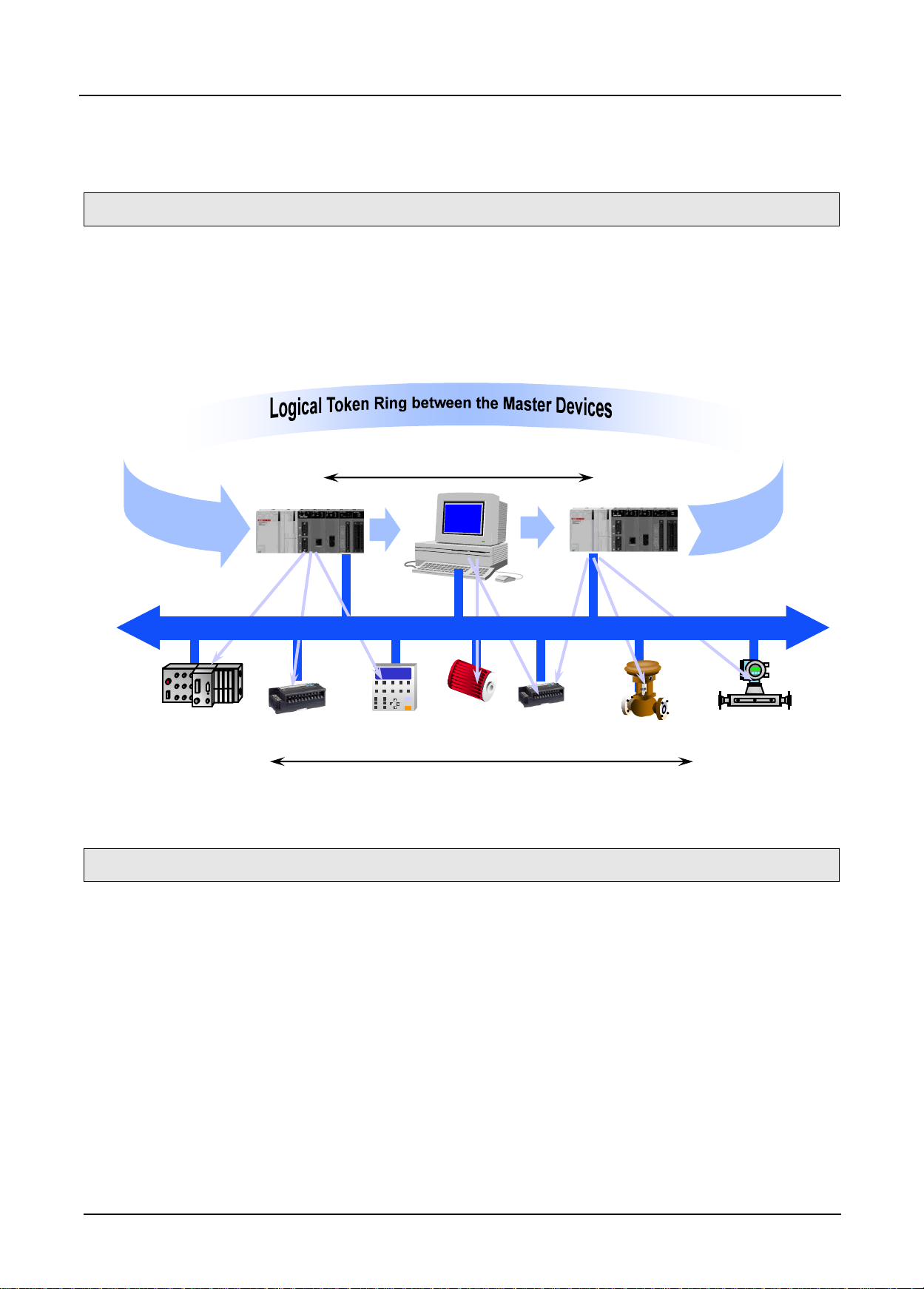

Active Stations, Master Devices

PC

Passive Stations (Slave Devices) are polled

PROFIBUS

Chapter 1 Introduction

This user’s manual is to describe Profibus-DP (Decentralized Peripherals) Master I/F module (hereinafter

referred to as Pnet I/F module) among communication modules of ML200 PLC system.

Profibus-DP is specified in IEC Fieldbus Standard IEC 1158.

In this communication, Token Ring is used to control the communication and to configure the network easily.

Pnet I/F module is a module to control the field bus with Twisted Shielded Pair Copper Cable applied.

ML200 Pnet I/F module has the characteristics as follows;

▶ Conforms to the international standard of EN 50170

▶ Supports Auto Baud Rate Detect

▶ Supports Sync/Freeze mode

▶ Max. input data : 244 Bytes/Slave

▶ Max. output data: 244 Bytes/Slave

▶ Max. data size : 244 Bytes/Slave, 10 kbyte/Master

▶ Communication speed : 9.6k, 19.2k, 31.25k, 45.45k, 93.7k, 187.5k, 500k, 1.5M, 3M, 6M, 12M

1 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 11

Chapter 1 Introduction

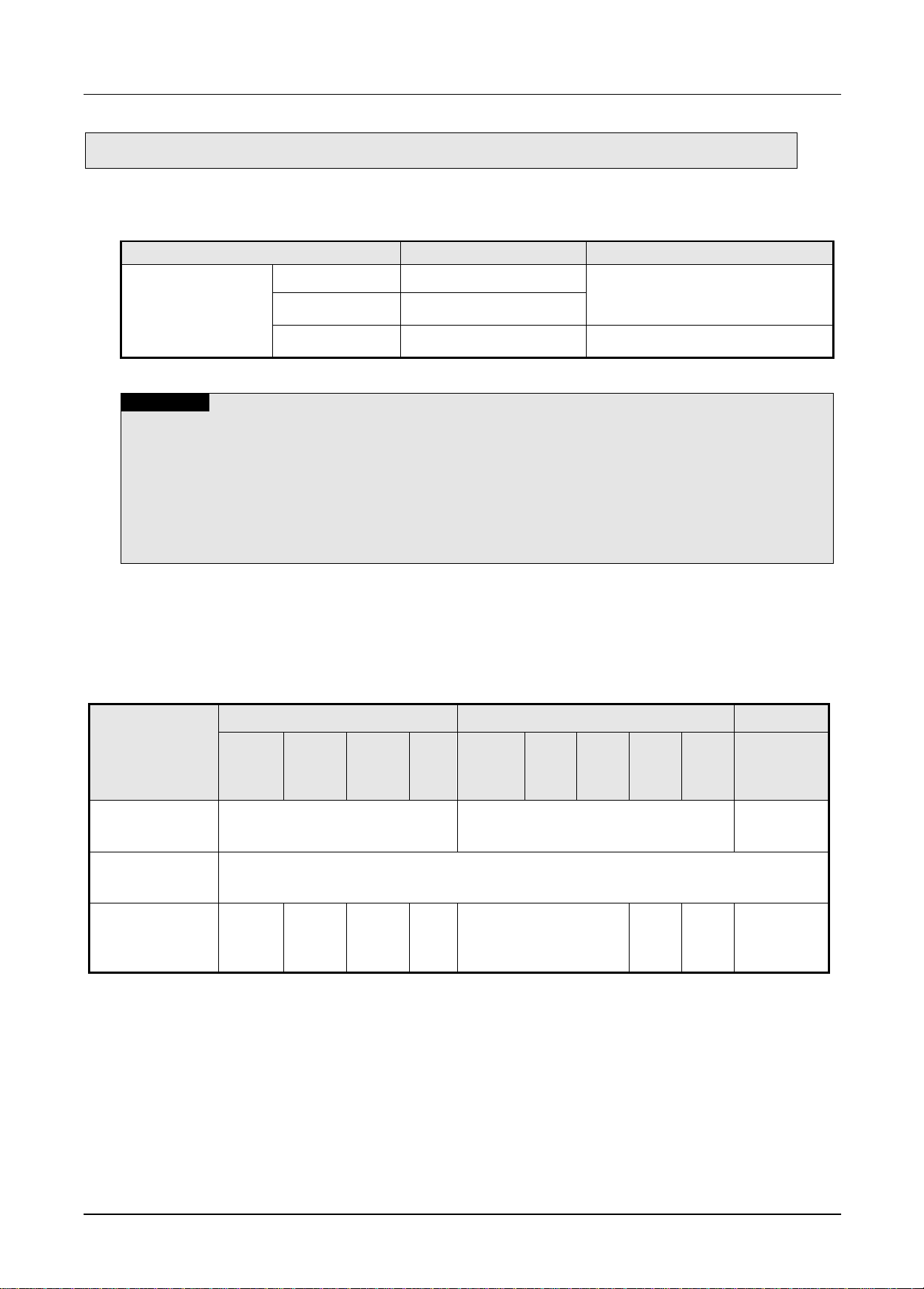

1.3 Product Configuration

Model

Contents

Remark

2MLK/2MLI/2MLR

2MLL-PMEA

Profibus-DP Master

Supports DP-V0

2MLL-PMEC

Profibus-DP Master

2MLL-PMEB

Profibus-DP Master

Supports DP-V1

Note

(1) ML200 Pnet supports only Profibus-DP. FMS, PA are not supported and protocol conversion is

available by the coupler

(2) Support of the DP version

1) DP-V0: Periodical data exchange between the PLC and the slave device

(Node diagnosis, module status, specific channel diagnosis)

2) DP-V1: Asynchronous data exchange between the PC or PLC and the slave device, integration of

EDD and FDT, fail-safe communication, alarm

3) DP-V2: supports broadcast, clock synchronization and time stamp, HART, upload/download,

redundancy

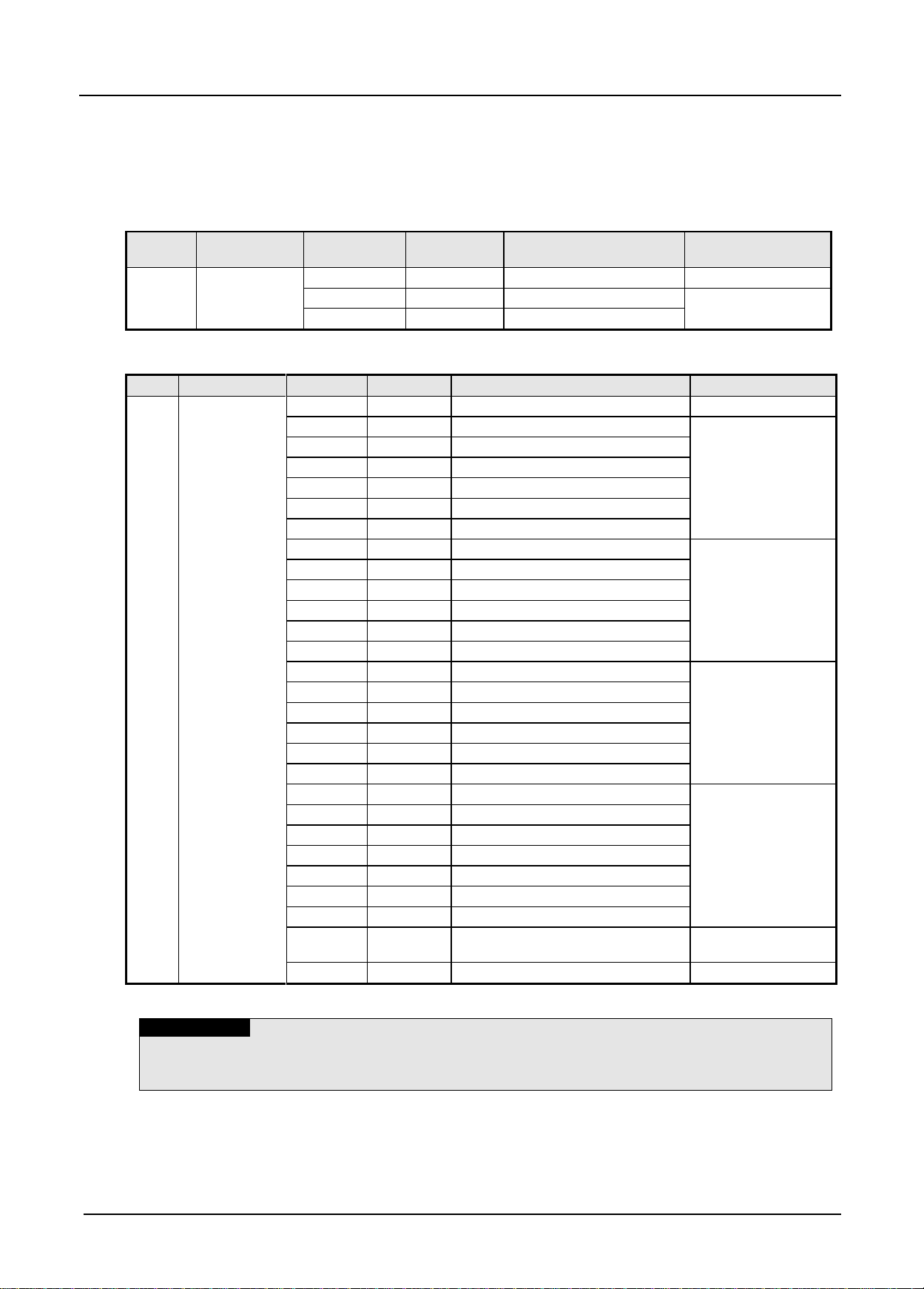

Item

2MLK

2MLI

2MLR

2MLKCPUH

/CPUU

2MLK-

CPUA

/CPUS

2MLK-

CPUE

2MLI-

CPUU

2MLI-

CPUH

2MLI-

CPUS

2MLI-

CPUE

2MLR-

CPUH/T

2MLR-

CPUH/F

The number of the

module using High

Speed Link (Max.)

12

12

12

The number of the

module using P2P

(Max.)

2MLL-PMEA/C: Not supported

2MLL-PMEB: 8

The number of

available

expansion base

(Max.)

7 3

1 7 3 1 31

1.3.1 Model Name

This describes on the product configuration of the ML200 Pnet I/F module.

1.3.2 Available number by CPU

You can mount up to 12 Pnet I/F module. If possible, mount the module in the basic base for best

performance of the communication module. The following table indicates the available service type by the

CPU. When configuring the system, apply this considering the number of the communication module.

2 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 12

Chapter 1 Introduction

Item

Connection

cable

Model

Product code

contents

Remark

Master

module

Twisted pair

(Electricity)

2MLL-PMEA

47200001

Profibus DPv0

Sycon

2MLL-PMEC

47200103

Profibus DPv0

ProfiCon

2MLL-PMEB

47200180

Profibus DPv1

Item

Connection cable

Model

Product code

contents

Remark

Slave

module

Twisted pair

(electricity)

MPL-D22A

47060007

DC input 16 points

Fixed type, 9-pin

communication

connector

MPL-D24A

47060009

DC input 32 points

MPL-TR2A

47060008

TR output 16 (0.1A, Sink)

MPL-TR4A

47060010

TR output 32 (0.1A, Sink)

MPL-RY2A

47060011

Relay output 16

MPL-DT4A

47060012

DC input 16/ TR output 16

MPL-D22C

47060046

DC input 16

Removable type, 9-pin

communication

connector

MPL-D24C

47060047

DC input 32

MPL-TR2C

47060048

TR output 16 (0.5A, Source)

MPL-TR4C

47060049

TR output 32 (0.5A, Source)

MPL-RY2C

47060051

Relay output 16

MPL-DT4C

47060050

DC input16/ TR output 16

MPL-TR2B

47060059

TR output 16 (0.5A, Source)

Fixed type, 9-pin

communication

connector

MPL-TR4B

47060058

TR output 32 (0.5A, Source)

MPL-DT4B

47060060

DC input16/ TR output 16

MPL-TR2A1

47060084

TR output 16 (0.5A, Sink)

MPL-TR4A1

47060076

TR output 32(0.5A, Sink)

MPL-DT4A1

47060078

DC input 16/ TR output 16

MPL-TR2C1

47060085

TR output 16 (0.5A, Sink)

Removable type, 9-pin

communication

connector

MPL-TR4C1

47060077

TR output 32 (0.5A, Sink)

MPL-DT4C1

47060079

DC input 16/ TR output 16

MPL-AV8C

47060123

Analog voltage input, 8 channels

MPL-AC8C

47060124

Analog current input 8 channels

MPL-DV4C

47060125

Analog voltage output, 8

MPL-DC4C

47060126

Analog current output, 8

MPL-BSSA

47060130

Expansion type Pnet I/F module

Module for expansion

type Pnet I/F module

2MLL-PSRA

47200128

Pnet Remote I/F module

Remote I/F module

Note

1) Fixed type: The product whose I/O terminal block is fixed at the module

2) Removable type: The product whose I/O terminal block can be removed

1.3.3 Slave Device

The Pnet I/F module can be connected with Smart I/O series and available product list is as follows.

(1) Master module

(2) Slave module

[Table1.3.1] Pnet I/F module product list (Smart I/O)

3 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 13

Chapter 1 Introduction

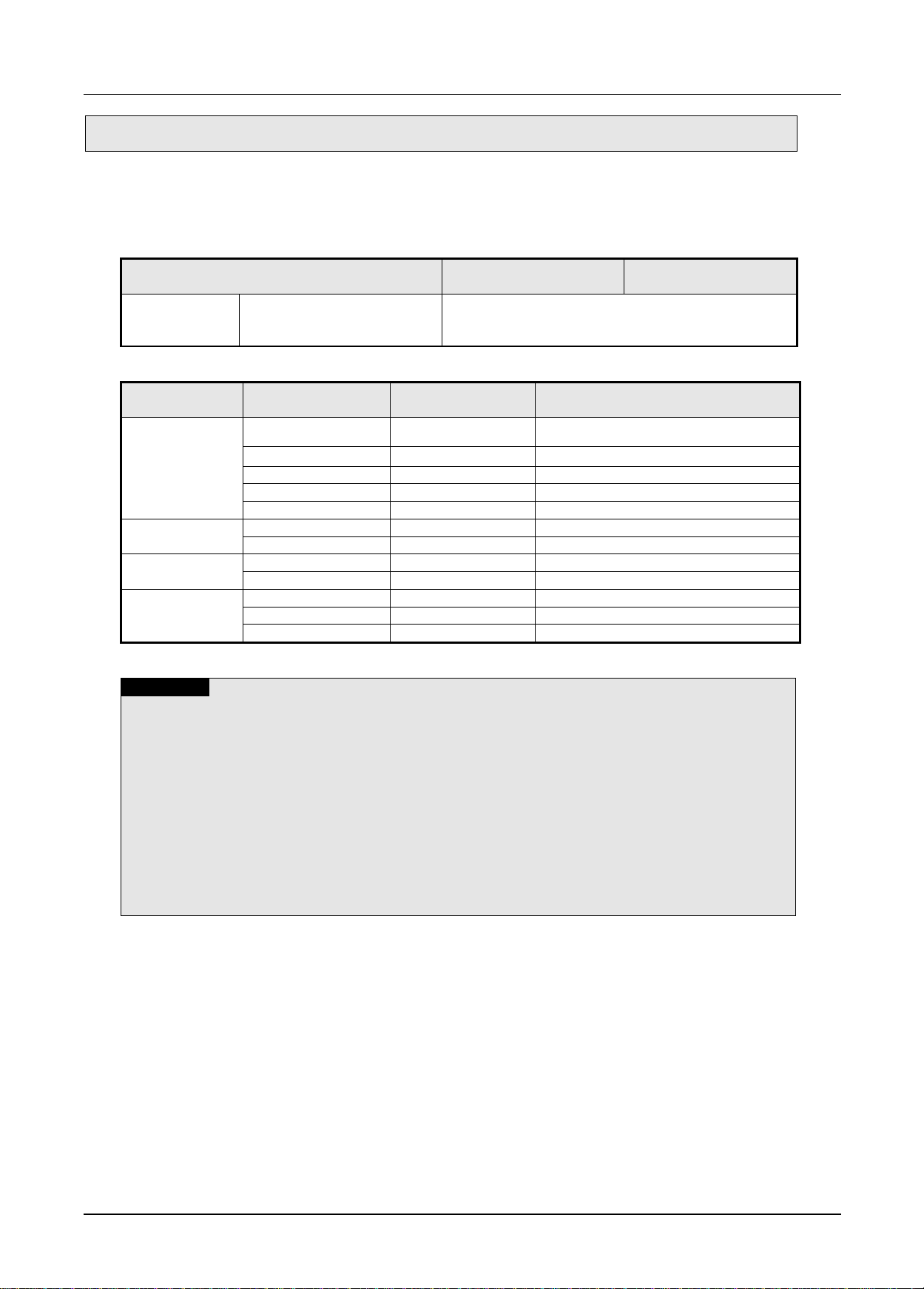

1.4 Software

Item

Programming tool

Communication

configuration tool

2MLL-PMEA

2MLL-PMEC

2MLL-PMEB

Profibus-DP master module

SOFTMASTER

Item

Model

Available version

(recommended)

Remark

2MLK series

2MLK-CPUH

V2.0

2MLK-CPUS

V2.0

2MLK-CPUA

V2.0

2MLK-CPUE

V2.0

2MLK-CPUU

V1.0

2MLI series

2MLI-CPUH

V1.0

2MLI-CPUU

V1.0

2MLR series

2MLR-CPUH/T

V1.0

2MLR-XPUH/F

V1.0

Software

SOFTMASTER

V4.2

SyCon

V2.0

Configuration tool for 2MLL-PMEA

N Configurator

V3.1.x or later

Configuration tool for 2MLL-PMEB/C

Note

(1) You can download the above software from our web site. In case Internet is available, visit the

nearest distributor and get the installation CD.

Web site address: http://www.lsis.com/

(2) You can program the SOFTMASTER through the RS-232C port and USB of the CPU module. For

the cable, refer to wiring diagram of the CPU module.

(3) You can configure the network system by SyCon through the “Config” port of the 2MLL-PMEA.

Only 9-pin serial port is available and simultaneous connection with SOFTMASTER is not

available.

(4) You can set the parameter by N Configurator for 2MLL-PMEB/C through the USB port of the CPU

module and connection with SOFTMASTER is available.

(5) In case you use the product other than available version, some function may not work properly. If

possible, use the recommended version and check the compatibility.

This describes on the software tool for the Pnet I/F module. For programming and application, refer to the

followings

1.4.1 Check list for the software

(1) Software list

(2) Selecting the CPU (Version) to use the Pnet I/F module

4 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 14

Chapter 1 Introduction

1.4.2 SOFTMASTER

SOFTMASTER is software tool dedicated for the communication module including Pnet I/F module.

Setting the basic parameter, writing the frame and network diagnosis are available for the

communication module. Fore more detail, refer to Ch5. SOFTMASTER.

The following figure is an initial screen of the SOFTMASTER

[Figure 1.4.1] SOFTMASTER initial screen

1.4.3 Checking the version

Before using the Pnet I/F module, check the version of the module

(1) Check through the SOFTMASTER

This is method reading the communication module information through online connection

If it is under normal interface with the CPU, you can get the information as follows.

a) Execute the SOFTMASTER

b) Connect to the CPU through “Connect” on the “Online” menu.

c) After connection, execute [Online]-[Communication module setting]-[System Diagnosis]

d) In the “System Diagnosis” screen, select “Module Information” by double-clicking the

communication module and pop-up window

e) Software information appears at the right-bottom.

5 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 15

Chapter 1 Introduction

[Figure 1.4.2] Checking the version of the module through the SOFTMASTER

(2) Check through the case label of the product

The module information is attached at the external case every communication modules

In case online connection is not available, take a module apart and check the label in the module case.

6 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 16

Chapter 2 Specifications

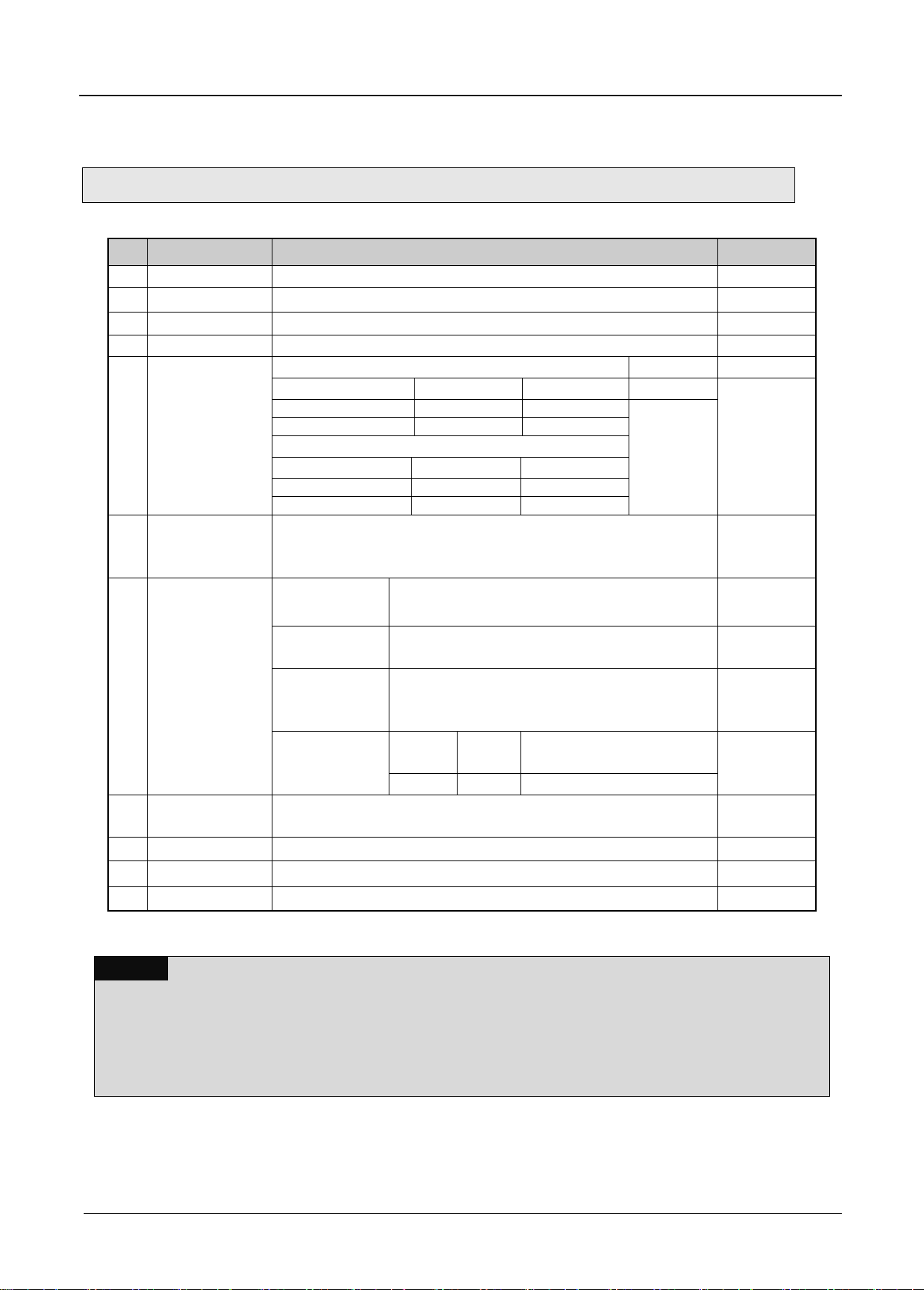

2.1 General Specifications

No.

Items

Specification

Reference

1

Ambient Temp.

0 ~ 55 C

2

Storag e T em p.

25 ~ 70 C

3

Ambient humidity

5 ~ 95%RH (Non-condensing)

4

Storage humidity

5 ~ 95%RH (Non-condensing)

5

Vibration Immunity

Occasional vibration

-

Frequency

Acceleration

Pulse width

Times

IEC61131-2

5≤f< 8.4 ㎐

-

3.5mm

10 times

each

direction (X,Y

and Z)

8.4≤f≤150 ㎐

9.8 ㎨(1G)

-

Continuous vibration

Frequency

Acceleration

Pulse width

5≤f< 8.4 ㎐

-

1.75mm

8.4≤f≤150 ㎐

4.9 ㎨(0.5G)

-

6

Shocks Immunity

P eak acceleration : 147 m/s2(15G)

D uration : 11ms

P ulse wave type : Half-sine (3 times each direction per each axis)

IEC61131-2

7

Noise Immunity

Square wave

impulse noise

AC : ±1,500V

DC : ±900V

LSIS internal

test spec.

Electrostatic

discharge

Voltage: 4kV (Contact discharge)

IEC61131-2

IEC61000-4-2

Radiated

electromagnetic

field noise

8 0 ~ 1 0 00 MHz, 10V/m

IEC61131-2,

IEC61000-4-3

Fast transient

/Burst noise

Classific

ation

Power

supply

Digital/Analog Input/Output,

Communication Interface

IEC61131-2

IEC61000-4-4

Voltage

2kV

1kV

8

Operation

ambience

Free from corrosive gases and excessive dust

9

Altitude

Less than 2,000m

1 0

Pollution degree

Less than 2

1 1

Cooling method

Air-cooling

Note

1) IEC (International Electrotechnical Commission):

An international nongovern ment al or ganiz ation which promotes internationally cooperat e d st andar diz ation in

electric/electronic field, publishes international standards and manages applicable estimation system related with.

2) Pollution degree:

An index indicating pollution degree of the operating environment which decides insulation performance of the devices.

For instance, Pollution degree 2 indicates the state generally t hat only non-conductive pollution occurs. However, this

state contains temporary conduction due to dew produced.

General specifications of ML200 series are as specified below in Table 2.1.

Chapter 2 Specifications

Table 2.1 General Specifications

1 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 17

Chapter 2 Specifications

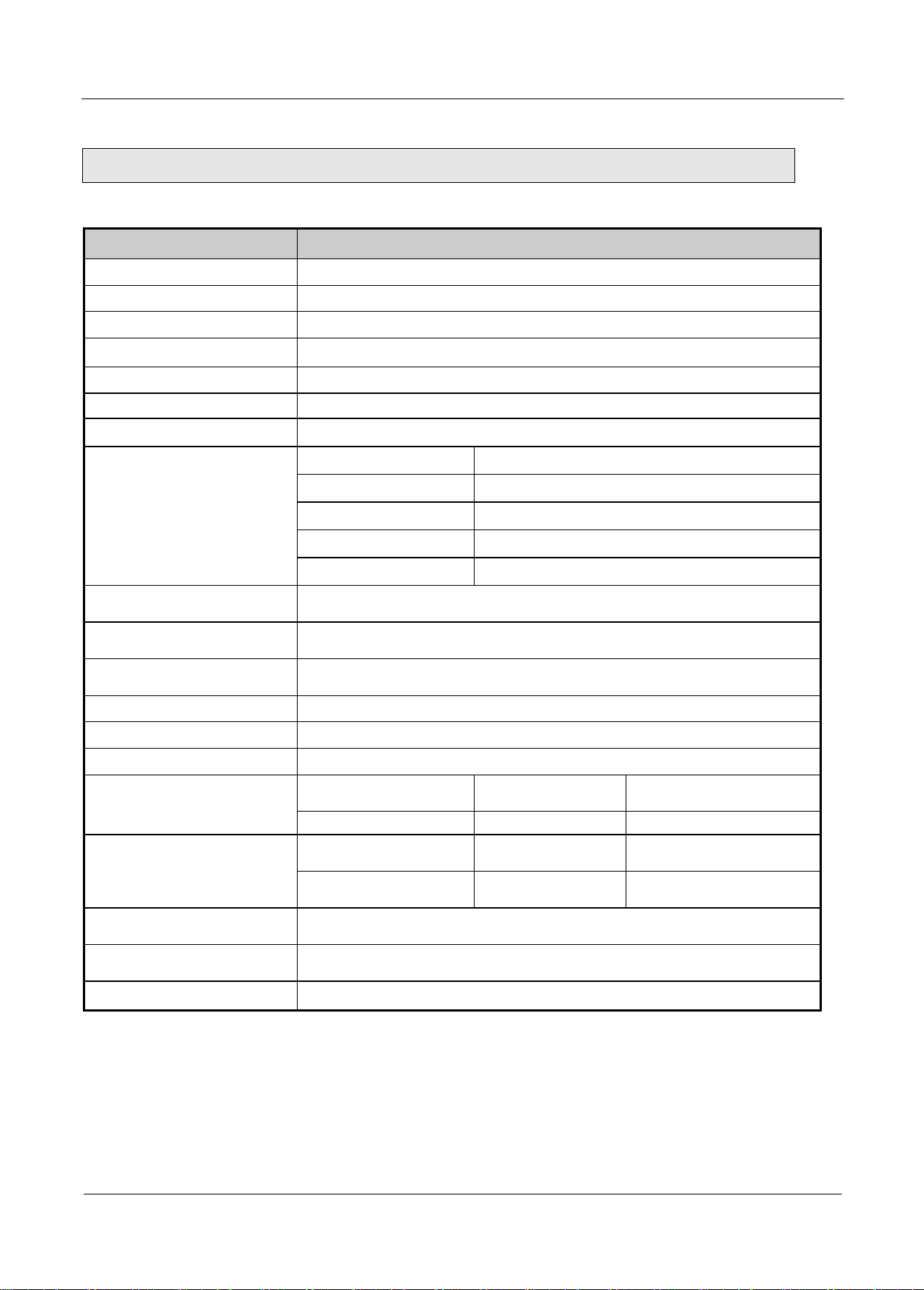

2.2 Performance Specifications

Item

Details

Module Type

Master

Network Type

Profibus-DP

Standard

EN50170/DIN19245

Interface

RS-485 (Electric)

Transmission Route

Bus type

Modulation Type

NRZ

MAC

Local Token Ring

Max. Distance &

Transmission Speed

Distance (m)

Transmission Speed (bps)

1,200

9.6k, 19.2k, 31.25k, 45.45k, 93.75k, 187.5k

400

500k

200

1.5M

100

3M/6M/12M

Max. number of stations per

network

126

Max. number of stations per

segment

32 (including master & repeater)

Max. number of modules per

node

24 modules

Cable used

Electric-twist shielded pair cable

Max. communication size

10 KBytes

Max. size per slave

244 bytes

Max. number of units to be

installed

2MLK-CPUH

2MLI-CPUH

2MLK-CPUS,

CPUA, CPUE

2MLR-CPUH/T, CPUH/F,

CPUH/S

24

24

24

Installation Position

2MLK-CPUH/2MLI-

CPUU

2MLK-CPUS,

CPUA, CPUE

2MLR-CPUH/T, CPUH/F,

CPUH/S

Basic base ~ expansion

stage 7

Basic base ~

expansion stage 3

Stage 31

Communication Parameters

to set

SoftMaster , SyCon (2MLL-PMEA Dedicated Configuration Tool)

N Configurator (2MLL-PMEB/C Dedicated Configuration Tool)

Internal-consumed current

(mA)

550(2MLL-PMEA), 450(2MLL-PMEC), 500(2MLL-PMEB)

Weight (g)

114(2MLL-PMEA), 112(2MLL-PMEC), 88(2MLL-PMEB)

Performance specifications of Pnet I/F module are as described below.

[Table 2.2] Performance Specifications

2 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 18

2.3 Structure & Characteristics

LED

Status

LED description

RUN

On

Normal

Completion of initialization

Off

Error

Occurrence of error

I/F

Blink

Normal

Normal status of CPU module and interface

Off

Error

Error of CPU module and interface

HS

On

Normal

Service is normal status when High-speed link is enabled

Blink

Stand by

Communication break status between Pnet I/F module and slave when

downloading by Sycon

Off

Error

High-speed link service error occurred when High-speed link is enabled

P-RUN

Blink

Stop

Stop status of communication status between Pnet I/F module and slave

module

On

Run

Run status of Communication between Pnet I/F module and slave

module

STAT

On

Normal

Normal status of High-speed link communication

Off

Error

Abnormal status of Master module

ERR

On

Error

It needs to check the slave module

Off

Normal

Normal status

◀

LED

display

◀

Connection area of Sycon Configuration Tool

◀

Connection area of communication cable

◀

Designation area

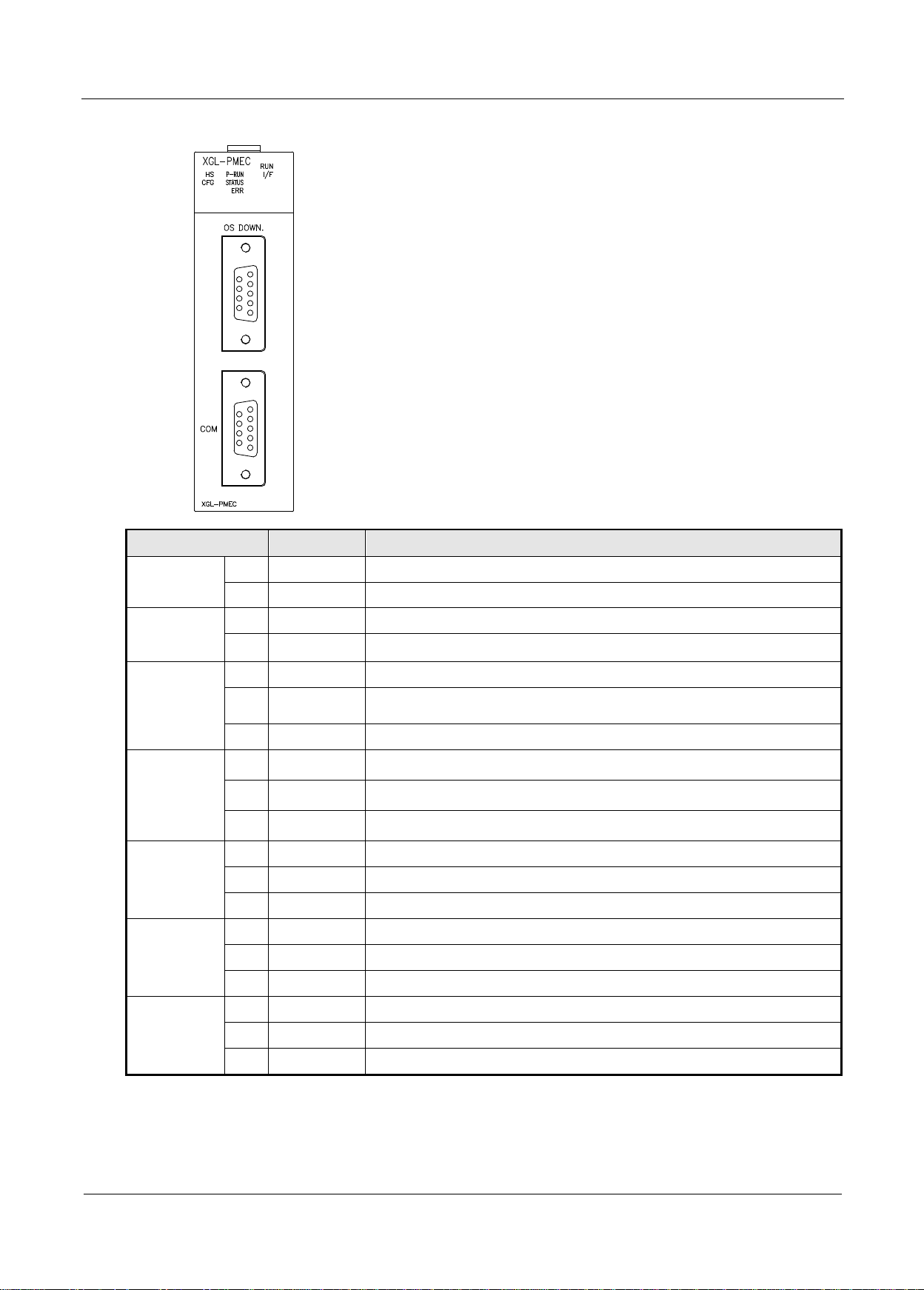

2.3.1 Structure of Pnet I/F module

(1) Structure of 2MLL-PMEA

Chapter 2 Specifications

[Table 2.3.1] LED display of 2MLL-PMEA

3 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 19

Chapter 2 Specifications

LED

Status

LED description

RUN

On

Normal

Completion of initialization

Off

Error

Occurrence of error

I/F

Blink

Normal

Normal status of CPU module and interface

Off

Error

Error of CPU module and interface

HS

On

Normal

Service is normal status when High-speed link enabled

Blink

Stand by

Communication break status between Pnet I/F module and slave when

downloading by N Configurator

Off

Error

High-speed link service error occurred when High-speed link is enabled

P-RUN

On

Under

communication

Normal communication between the Pnet I/F module and slave

Blink

Under

communication

Clear communication between the Pnet I/F module and slave (I/O data 0)

On

Communication

stop

Communication stop status between the Pnet I/F module and slave

STATUS

On

Error

System error

Blink

Auto-scan

System auto-scan mode

Off

Normal

System normal

ERR

On

Error

Bus error (line short, different communication speed, and etc.)

Blink

Error

There is disconnection during communicating with the slave module

Off

Normal

Normal status

CFG

On

Error

There is no Configuration Setting in the Pnet I/F module

Blink

Normal

Downloading or uploading the Configuration Setting

Off

Normal

A Pnet I/F module is configured normally

◀

LED

display

◀

Firmware Download Port

◀

Connection area of communication cable

◀

Designation area

(2) Structure of 2MLL-PMEC

[Table 2.3.2] LED Display of 2MLL-PMEC

4 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 20

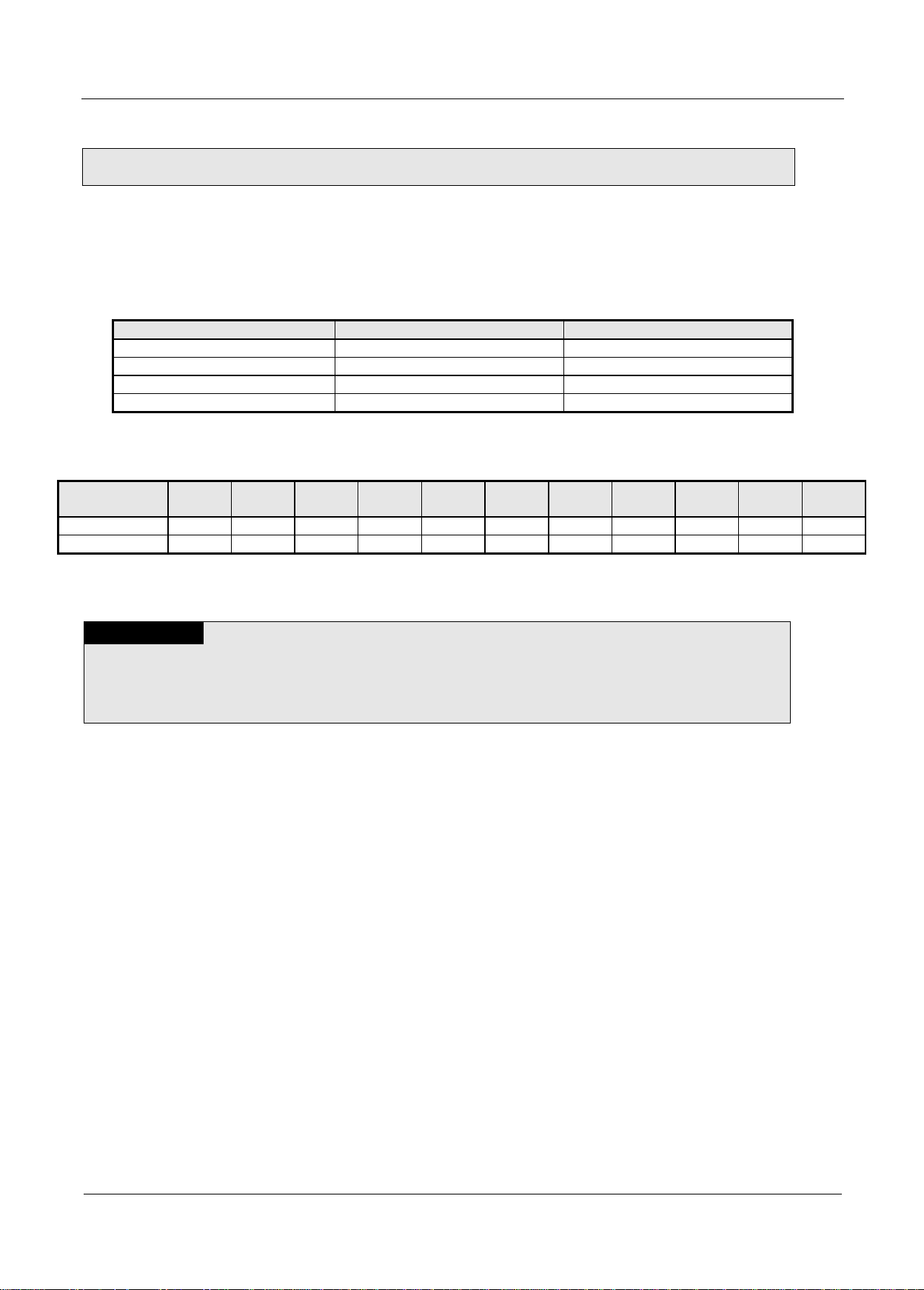

(3) Structure of 2MLL-PMEB

LED

Status

LED description

RUN

On

Normal

Initialize complete and normal operation

Off

Error

Fatal error

I/F

Blink

Normal

Normal in interface status with CPU

Off

Error

Error in interface status with CPU

HS

On

Normal

Normal HS link communication status

Blink

Standby

Stop communication status/downloading Parameter in HS link enable

Off

Error

HS Link service disable status

P2P

On

Normal

Normal P2P communication status

Blink

Standby

Stop communication status/downloading Parameter in P2P enable

Off

Error

P2P disable status

P-RUN

On

Normal

Normal communication

Off

Error

Communication is stopped

STATUS

On

Error

System error

Off

Normal

Normal communication

ERR

On

Error

All slaves are eliminated

Blink

Error

Some slaves are eliminated

Off

Normal

Normal

CFG

On

Error

No network configuration for Profibus-DP Master module

Blink

Standby

Downloading or uploading configuration parameter to Master module

Off

Normal

Network configuration is installed successfully

◀

Designation area

◀

LED Display

◀

Connection area of communication cable

Chapter 2 Specifications

[Table 2.3.3] LED display of 2MLL-PMEB

5 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 21

Chapter 2 Specifications

2.4 Cable Specifications

Cable characteristic

Type A

Type B

Impedance

135~160Ω(freq. 3~20MHz)

100~130Ω(freq. > 100kHz)

Capacity

< 30 pF/m

< 60 pF/m

Resistance

< 110 Ω

-

Conductor Area

> 0.34 mm2 (22 AWG)

> 0.22 mm2 (24 AWG)

Baud Rate

(Kbit/s)

9.6

19.2

31.25

45.45

93.75

187.5

500

1500

3000

6000

12000

Cable Type A

1200

1200

1200

1200

1200

1200

400

200

100

100

100

Cable Type B

1200

1200

1200

1200

1200

600

200

70 - -

-

Remark

1) The profibus standard defines two types of bus cables, but it is usually recommended to use a

type. Please contact the cable manufacturer for details.

2) Awg is a numbering scheme that indicates the size of the wire.

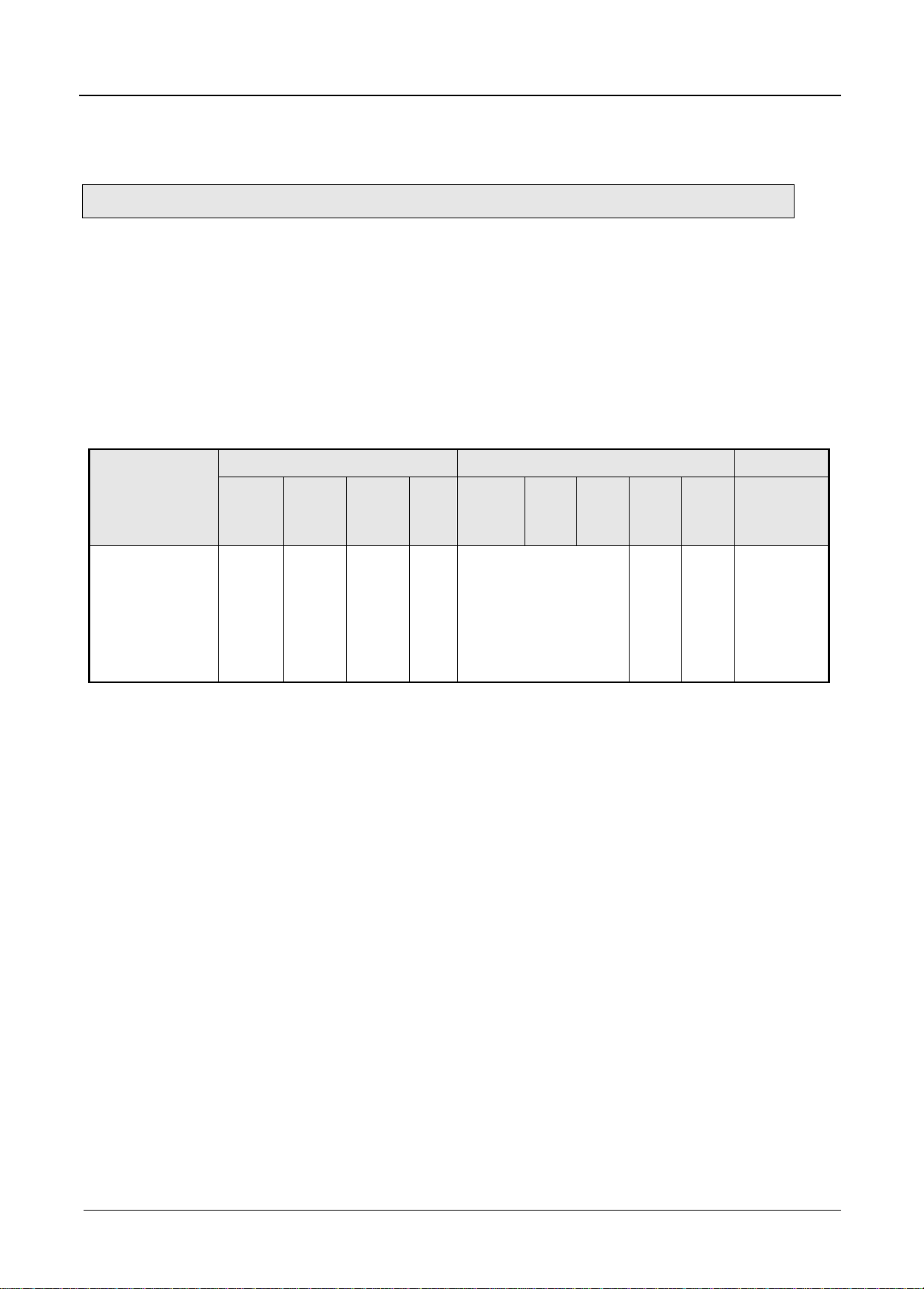

2.4.1 Cable Specifications

The cable uses shielded twisted-pair wires. Table 2.4.1 and Table 2.4.2 show the maximum

transmission distance according to cable type and speed cable type.

[Table 2.4.1] Cable specification

[Table 2.4.2] Communication distance by cable and baud rate

6 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

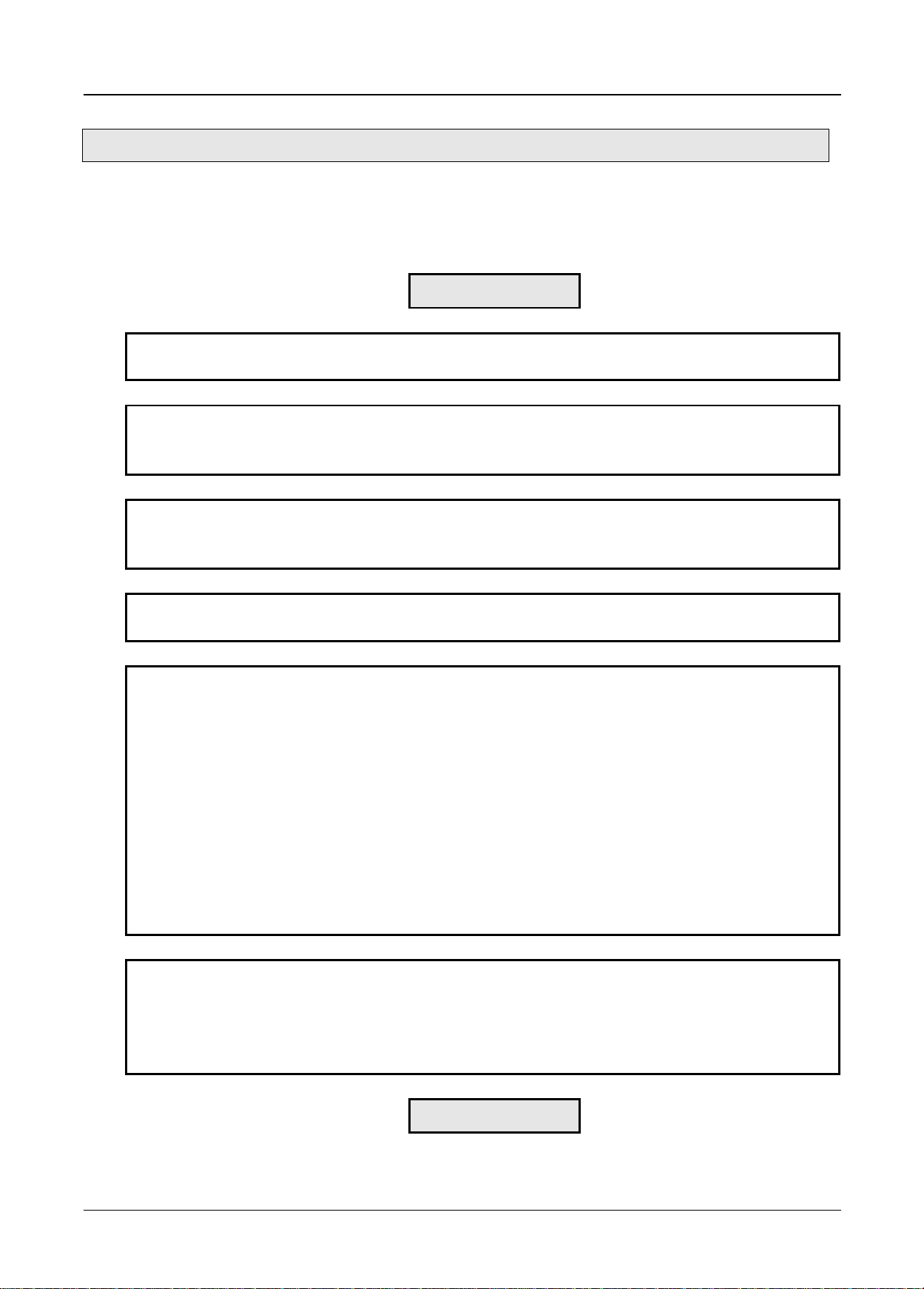

Page 22

3.1 Precautions for Installation

Item

2MLK

2MLI

2MLR

2MLKCPUH

/CPUU

2MLK-

CPUA

/CPUS

/CPUSN

2MLK-

CPUHN

/CPUUN

2MLK-

CPUE

2MLI-

CPUUN

2MLI-

CPUU

2MLI-

CPUH

2MLI-

CPUS

2MLI-

CPUE

2MLRCPUH/T,

CPUH/F,

CPUH/S

Number of

available

expansion base

(max.)

(Available to

equip

communication

module)

7 3 7

1 7 3 1 31

Chapter 3 Installation and Test Operation

Chapter 3 Installation and Test Operation

3.1.1 Precautions for Installation

For system configuration through Pnet I/F module, carefully make sure of the following items prior to

installation.

1) Check the basic factors necessary for system configuration to select an appropriate communication

module.

2) Select the exclusive Pnet cable to be used for this communication module.

3) Before the communication module is installed, check for any foreign material on the base connector the

module will be installed on and any damage on the connector pin of the module.

4) All the communication modules can be installed on the basic base ~ the expansion base. For the

number of available expansion base by CPU, refer to the following table.

5) For installation of the module, exactly insert the protuberant part at the bottom of the module with the

communication cable disconnected into the base groove and then apply enough strength until its top is

locked up with the locking device of the base. If the lock is not applied, it may cause an error on the

interface with CPU.

1 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 23

3.2 From Setting to Operation

Operation Sequence

Install Pnet I/F module on the base.

Check the applicable base/slot position for correct installation.

Configure the system between Pnet I/F module and slaves.

Use the exclusive Pnet cable for communication.

Set each slave’s station number

With power On, check the LED status of the communication module.

Check if the interface of the communication module is normal with CPU.(RUN: On, I/F: Blink, ERR:

Off)

Specify the configuration through SyCon or N Configurator.

Specify the module to be configured as Pnet I/F master module and download it.

Download High-speed link/P2P parameters.

Set how to connection with [Online] – [Connection]

[Online] – [Diagnosis] – [I/O information] – [I/O Sync.]

Open the [High-speed Link] block setting tab

Execute [Online] – [Communication module setting] – [Config. Upload] at [High-speed Link] block tab

Set the High-speed Link block parameters

Download the parameters with [Online] – [Write]

Execute [Online] – [Communication module setting] – [Enable Link]

Open [P2P] block setting tab

Set the P2P block parameters

Download the parameters with [Online] – [Write]

Execute [Online] – [Communication module setting] – [Enable Link]

Use system diagnosis function in SOFTMASTER to check the normal operation of the product.

Set how to connection with [Online] – [Connection]

Execute [Online] – [Communication module setting] – [System Diagnosis]

Open the [Status by service] window in [System Diagnosis]

Check the normal operation with P2P and High-speed Link service

Start Run

Chapter 3 Installation and Test Operation

The sequence of the product from installation to operation will be described below. After the product

installation is complete, install and configure the system to be operated as specified in the following

sequence.

2 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 24

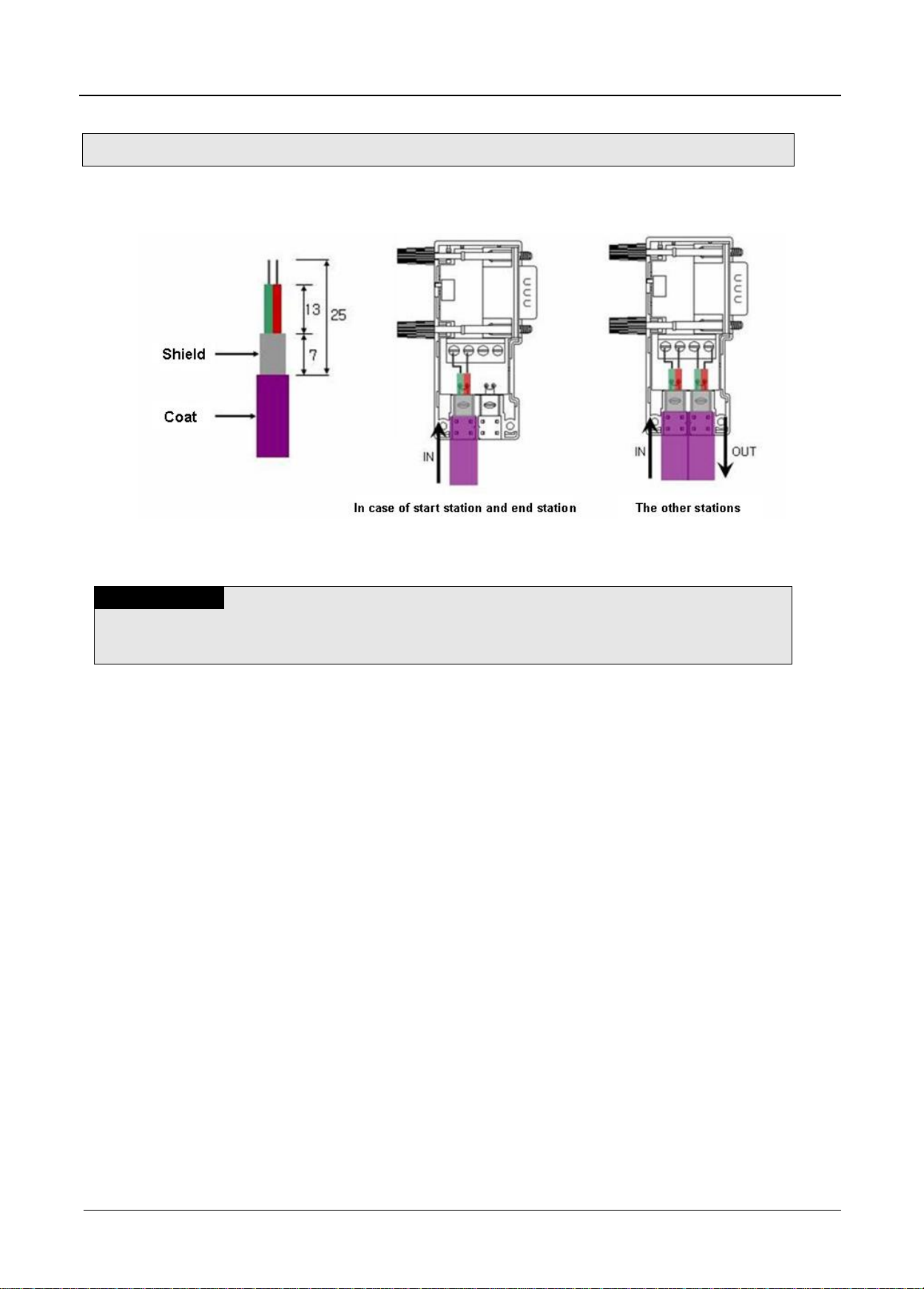

3.3 Installation of the cable

Remark

1) Installation length of Pnet cable depends on the communication speed. (Refer to [Table] 3.2)

3.3.1 Installation of 2MLL-PMEA/PMEB

Chapter 3 Installation and Test Operation

[Figure 3.3.1] The method of Pnet cable installation

1) How to install Pnet cable

(1) Use Profibus-DP cable.

(2) When slipping the coat of the cable, be careful not to let the shielded line escaped from PCB of

the connector.

(3) The number of stations to be installed shall be within 32 including master and repeater for 1

segment.

(4) The shielded line of the cable shall be in contact with the shielded area of the connector.

(5) The cable is generally recommended to be installed at the end of the slave, diverged from the

master.

(6) If the cable is used at the object car, use the extended line.

(7) Communication cable shall be installed at least 10cm away from the power supply cable.

(8) Check the cable connected with the connector if tightened well with terminal block.

(9) After the cable connected, measure the line resistance value on the master by means of digital

multi-meter. (If terminal resistance at the both ends of the cable is On, it will be generally 110Ω +

line resistance value + connector resistance value)

3 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 25

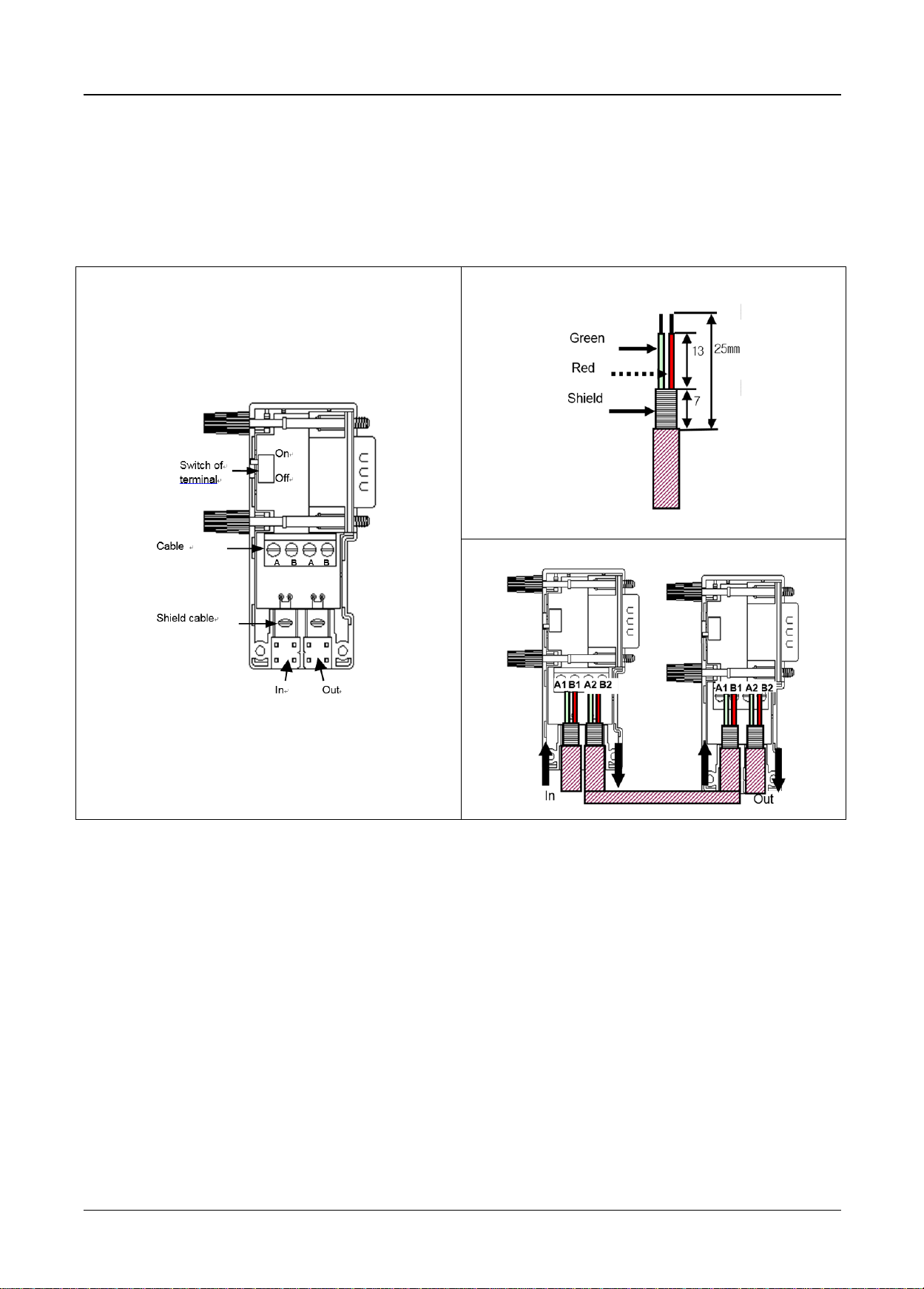

<Connector structure>

<Cable structure>

<Cable wiring method>

Chapter 3 Installation and Test Operation

2) Pnet Connector structure and wiring method

(1) Input Line: green line is connected to A1, red line is connected to B1

(2) Output line: green line is connected to A2, red line is connected to B2

(3) Connect shield to clamp of shield

(4) In case of installing the connector at terminal, install the cable at A1, B1

4 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 26

Remark

(1) Please refer to below for cable name and place of purchase.

1) Thomascable : Profibus-DP UNITRONIC-BUS L2/FIP/BUS Tel)043-217-8600

2) Belden cable : 3079A Tel)02-2202-2656

Chapter 3 Installation and Test Operation

3) Pnet termination

- Connector

<Terminal connection> <Branch connection>

4) General notices

(1) Termination treatment of vertical section is needed.

(2) In case that the distance is far between stations, it is possible to extend the segment through

repeater(max. 9 repeater, 10 segment), available to connect 32 stations per segment(include

repeater), max. 126 stations. (Repeater does not have station no.) The extended segment

having no station is available.

(3) Shield shall be connected to the housing of connector.

(4) Use the special connector having the inductor inside.

(5) Spur Line is not allowed to use.

(6) If the ground potential difference between stations is big, a great amount of current may flow

through the shield. In this case, install the cable to make the ground potential difference equal

separately. For high speed more than 1.5Mbps, special cares should be taken.

(7) In case of 12Mbps, keep the distance more than 1m between stations.

5) Termination treatment

(1) Each segment should do the termination treatment for both ends. If there are several segments,

it is required to do the termination treatment for each segment.

(2) Termination is available to turn on/off by the switch of special connector.

(3) If possible, install the master at the end of one side.

5 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 27

3.4 Test Operation

Chapter 3 Installation and Test Operation

Terminal resistance switch of Pnet cable shall be On. If the switch is not On, communication errors may

occur. Check LED operation status if normal with power on after communication cable is connected. If

normal, download the applicable program to PLC via SOFTMASTER so to execute the program.

3.4.1 Precautions for system configuration

1) Station No. of each slave shall be surely different from each other including this module. If connected

with the repeated station No., communication error may occur, leading to communication trouble.

High-speed link station No. of all stations also shall be different from each other to use High-speed

link service.

2) Use the communication cable as specified only. If not, serious error may occur to communication.

3) Check communication cable if disconnected or shorted prior to installation.

4) Tighten up communication cable connector until connected firmly. If cable connection is unstable, serious

error may occur to communication.

5) If remote communication cable is connected, keep the cable far away from power line or inductive noise.

6) Since the coaxial cable is not flexible, it is to be diverged min. 30cm away from the connector in

communication module. If the cable is bent at a right angle or transformed compulsorily, cable

disconnection or connector damage in communication module will be caused.

7) If LED operation is abnormal, refer to Chapter 10 Troubleshooting to check for causes and take actions

against. Contact service center if the error is as before.

6 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 28

Chapter 4 System Configuration

4.1 System Configuration of Network

Chapter 4 System Configuration

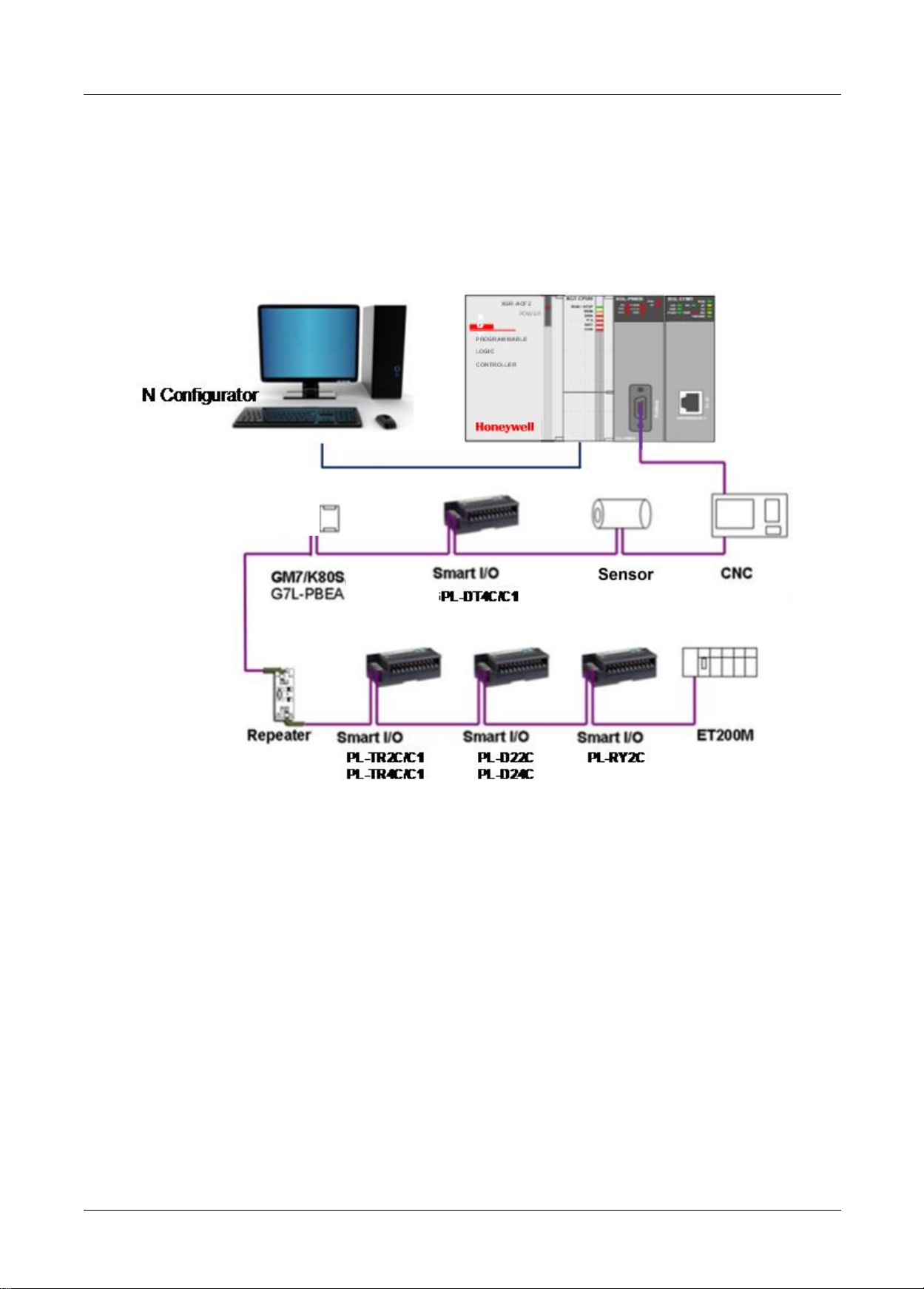

4.1.1 ML200 Pnet module and Smart I/O

Communication system of Pnet I/F modules is as shown below.

Set the Pnet I/F module as master in system and the others have to set as slave module.

To connect LS inverter, Pnet I/F option module have to install applicable product then it will be communicate.

[Figure 4.1] ML200 Pnet + Smart I/O diagram

1 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 29

Chapter 4 System Configuration

Sensor

4.1.2 ML200 Pnet + Composite System

If it is used with another company product, GSD file provided by the maker is needed. After GSD file is copied

to GSD folder of Pnet configuration software tool(SYCON, N Configurator) and then if you use Pnet

configuration software tool(SYCON, N Configurator), you can configure the slave modules in the network

automatically.

[Figure 4.1.2] ML200 Pnet + Composite system Diagram

2 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 30

Chapter 5 Communication Program

5.1 Communication Program

Note

(1) How to set SoftMaster is same though CPU type is different.

1) CPU type: 2MLI, 2MLK, 2MLR system common

(2) P2P communication is available with 2MLL-PMEB only that supports PROFIBUS DPv1.

Chapter 5 Communication Program

There is one communication function available in Pnet I/F module as described below.

5.1.1 Type of communication program

(1) High-speed link

High-speed link as a communication method between ML200 PLC communication module and slave

module is used to exchange data or information with destination station periodically for a specific time,

through which the changed data of self station or the destination station can be referred to periodically

for efficient application to the operation system and execution of communication is available only with

simple parameters setting.

How to set parameter is, download the configuration data to the communication module by means of

“Pnet configuration tool. And then upload the downloaded file in the SoftMaster. And then, specify the

self station area and destination station area for sending/receiving in the high speed link parameter.

Download the specified parameters and let the link enabled to execute High-speed link communication.

Data size is available from the min. 1 byte (16 points) to 244 bytes for the communication,

communication period from the min. 20 ms up to 10 sec. based on the communication details. It is easy

to use because communication with destination station is available only through simple parameters

setting. And it is also useful for periodic process of lots of data at a time thanks to high processing

speed of the internal data.

(2) P2P

P2P is the communication method between ML200 PLC communication module and slave module. It

can be used to read/write the data or information of slave at the point in time.

It can be effectively used to exchange the status information of other station or handle the alarm by

simple parameter settings.

How to set the parameter is as below,

1) In P2P parameter of SoftMaster, select data sending direction or alarm handling function.

2) Set slave’s station number and data address, ML200 PLC communication module address,

condition flag.

3) Download the P2P parameter and enable the link. Then P2P communication will be start.

Maximum 244 bytes sending and receiving data are available. It operates by condition flag that makes

it useful when user handle the temporary data.

(3) Configuration tool

In order to use a Pnet I/F module, you have to configure the system by ‘SyCon’ and ‘N

confugurator’ configuration tool and then download it to the Pnet I/F module

For detail on the setting method, refer to how to set the configuration tool

1 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 31

Chapter 5 Communication Program

5.2 SoftMaster pragram

In order to use Pnet I/F module, set High-speed link parameters (after SyCon/N Configurator Configuration is

uploaded) and then download the specified parameters onto CPU for application, which is available through

the SoftMaster.

5.2.1 Setting PLC type

To connect the SoftMaster to the PLC, you have to set the PLC type. Create the new project by selecting

[File] [New File]. On the new project menu, input the project name, project type and PLC type as shown

below

[Fig. 5.2.1] is initial screen of the SoftMaster

2 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

[Figure 5.2.1] initial screen of the SoftMaster

Page 32

Chapter 5 Communication Program

Items

Contents

Remark

Project name

Writing the project name in the SoftMaster software.

File location

Selecting the directory to save the project.

PLC Series

Selecting the PLC series (2MLK, ML50, 2MLI, 2MLR)

CPU kind

2MLK

2MLK-CPUA, CPUE, CPUH, CPUS, CPUU

ML50

ML50-MLMS, MLCH, MLIH, MLIE,

2MLI

2MLI-CPUU, CPUU/D, CPUH, CPUE, CPUS

2MLR

2MLR-CPUH/T, 2MLR-CPUH/F

Project comment

Writing the comment about the project.

[Figure 5.2.2] Creation of new project

There are 4 types of PLC (2MLK, ML50, 2MLI, and 2MLR). For detail on the CPU, refer to CPU

manual. Here we select 2MLK for example. After setting, menu of [Figure 5.2.3] appears

3 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 33

Chapter 5 Communication Program

[Figure 5.2.3] Initial menu of SoftMaster

5.2.2 Registration of the communication module

This describes on the basic setting needed for operation of Pnet I/F module

(1) Selection of the communication module

For the basic setting of the communication module in the SoftMaster, you have to register the

communication module at the applicable base, slot position of Standard setting window. You

can register the communication in the both ON/OFF status.

1) Registration in the offline status

If you want to register the communication without connection, select the base and slot of

standard setting window. Registration example of base 0, slot 2 is as follow.

a) Right click [Unspecified Network] in project tree and select

[Add Item] -> [Communication module]

4 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 34

Chapter 5 Communication Program

[Figure 5.2.4] Communication module menu selecting

b) Click [Add module] in [Select Communication Module] window.

[Figure 5.2.5] Add module

c) Select the type, base and slot in [Communication Module Settings] window.

[Figure 5.2.6] Communication module setting

5 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 35

Chapter 5 Communication Program

Classification Description

Communication

module setting

Type

Pnet I/F module

Base

Base no. of mounted module

Slot

Slot no. of mounted module

Pnet I/F module Off-line registration on base 0, slot 2 is as follow

[Table 5.2.1] Communication module setting contents

Registration PMEB module on base 0, slot 2

[Figure 5.2.7] Registration screen

6 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 36

Chapter 5 Communication Program

2) Registration in the online status

Connect to the ML200 CPU module. After connection, if you select [Online]-[Diagnosis]-[I/O

Information…], then click “I/O Sync], it searches all communication module and register them

automatically

* PLC should be STOP status for I/O Sync

[Figure 5.2.6] Read IO Information

In case Pnet is installed at the base 0, slot 10, it searches and registers as follows.

[Figure 5.2.7] Basic setting and Communication module Settings screen

7 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 37

Chapter 5 Communication Program

5.2.3 Uploading High Speed Link parameter and setup

(1) Screen of communication module specified

[Figure 5.2.9] Communication Module Settings

(2) Uploading a configuration tool (SyCon or N-Configurator)

With the mouse cursor positioned on “High-speed link1”, select [Online]-[Communication module

setting]-[Config. Upload (Dnet, Pnet)]

[Figure 5.2.10] Config data Upload from SyCon or N-Congurator

8 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 38

Chapter 5 Communication Program

Classification

Details

Master

Station No.

Display the Master station no.

Station No. *1

Setting range for the slave : 0 ~ 126

If identical station No. is set, communication will not be normal.

Mode *1

Sending: Transmission the data from master module to slave module.

Receiving: Transmission the data from slave module to master module.

Read area

(Master module

→

Slave module)

2MLK

Area to set the start address of device used for Sending.

Setting device : P, M, K, F, T, C, U, Z, L, N, D, R, ZR

2MLI

Area to set the start address of device used for Sending.

Setting device : A, M, I, Q, R, W, F, K, L, N, U

Save area

(Slave module

→

Master module)

2MLK

Area to set the start address of device used for Receiving.

Setting device : P, M, K, F, T, C, U, Z, L, N, D, R, ZR

2MLI

Area to set the start address of device used for Receiving.

Setting device : A, M, I, Q, R, W, F, K, L, N, U

Send data

Receive data

(Byte)

Display input/output points of slave module by the bytes.

- In case of I/O module of 8 bits or less, please s et 1 byte.

(3) Screen after “SyCon Upload”

[Figures 5.2.11] Screen after SyCon uploaded

(4) High-speed link parameter settings

*1 : Area is not able to set

[Table 5.2.2] High-speed link Block Settings

9 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 39

Chapter 5 Communication Program

(5) High-speed link parameters download

[Figure 5.2.12] High-speed link parameters download

(6) Enabling the Link

[Figure 5.2.13] Link Enable of High-speed link parameters

10 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 40

Item

Description

P2P function

Write, read, diagnostic

Condition flag

Condition flag

Data type*1

Data type

No. of variable*1

No. of variable

Destination station

Check destination station

No. of destination

station

Destination station

Setting

Read area

Sending data area

Save area

Save area of receiving data

Data size

Sending/Receiving data size

5.2.4 P2P Parameter Setting

(1) The screen after communication module setting is as follow

Chapter 5 Communication Program

[Figure 5.2.14] The screen after communication module setting

(2) P2P parameter setting

*1 isn’t setting area.

[Table 5.2.15] P2P block setting

11 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 41

Chapter 5 Communication Program

(5) Download P2P parameter

[Figure 5.2.16] P2P parameter download

(6) Enable link

[Figure 5.2.17] Enable link P2P parameter

12 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 42

Chapter 5 Communication Program

Item

Version

SoftMaster

V3.61 or above

2MLR CPU

V1.91 or above

2MLI CPU

V3.4 or above

2MLK CPU

V3.7 or above

Flag

Data type

Device

Description

_HS_ENABLE_STATE

ARRAY[0..11] OF BOOL

%FX19040

HS link enable/disable current state

_HS_REQ

ARRAY[0..11] OF BOOL

%FX31520

HS link enable/disable request

_HS_REQ_NUM

ARRAY[0..11] OF BOOL

%FX31536

HS link enable/disable setting

_P2P_ENABLE_STATE

ARRAY[0..7] OF BOOL

%FX19072

P2P enable/disable current state

_P2P_REQ

ARRAY[0..7] OF BOOL

%FX31552

P2P enable/disable request

_P2P_REQ_NUM

ARRAY[0..7] OF BOOL

%FX31568

P2P enable/disable setting

Flag

Data type

Device

Description

_HS_ENABLE_STATE

ARRAY[0..11] OF BOOL

%FX15840

HS link enable/disable current state

_HS_REQ

ARRAY[0..11] OF BOOL

%FX16480

HS link enable/disable request

_HS_REQ_NUM

ARRAY[0..11] OF BOOL

%FX16496

HS link enable/disable setting

_P2P_ENABLE_STATE

ARRAY[0..7] OF BOOL

%FX15872

P2P enable/disable current state

_P2P_REQ

ARRAY[0..7] OF BOOL

%FX16512

P2P enable/disable request

_P2P_REQ_NUM

ARRAY[0..7] OF BOOL

%FX16528

P2P enable/disable setting

Flag

Data type

Device

Description

_HS1_ENABLE_STATE

BIT

F09600

HS link 1 enable/disable current state

_HS2_ENABLE_STATE

BIT

F09601

HS link 2 enable/disable current state

_HS3_ENABLE_STATE

BIT

F09602

HS link 3 enable/disable current state

_HS4_ENABLE_STATE

BIT

F09603

HS link 4 enable/disable current state

_HS5_ENABLE_STATE

BIT

F09604

HS link 5 enable/disable current state

_HS6_ENABLE_STATE

BIT

F09605

HS link 6 enable/disable current state

_HS7_ENABLE_STATE

BIT

F09606

HS link 7 enable/disable current state

_HS8_ENABLE_STATE

BIT

F09607

HS link 8 enable/disable current state

_HS9_ENABLE_STATE

BIT

F09608

HS link 9 enable/disable current state

_HS10_ENABLE_STATE

BIT

F09609

HS link 10 enable/disable current state

_HS11_ENABLE_STATE

BIT

F0960A

HS link 11 enable/disable current state

_HS12_ENABLE_STATE

BIT

F0960B

HS link 12 enable/disable current state

_HS1_REQ

BIT

F10300

HS link 1 enable/disable request

_HS2_REQ

BIT

F10301

HS link 2 enable/disable request

_HS3_REQ

BIT

F10302

HS link 3 enable/disable request

_HS4_REQ

BIT

F10303

HS link 4 enable/disable request

_HS5_REQ

BIT

F10304

HS link 5 enable/disable request

_HS6_REQ

BIT

F10305

HS link 6 enable/disable request

_HS7_REQ

BIT

F10306

HS link 7 enable/disable request

_HS8_REQ

BIT

F10307

HS link 8 enable/disable request

_HS9_REQ

BIT

F10308

HS link 9 enable/disable request

_HS10_REQ

BIT

F10309

HS link 10 enable/disable request

_HS11_REQ

BIT

F1030A

HS link 11 enable/disable request

_HS12_REQ

BIT

F1030B

HS link 12 enable/disable request

_HS1_REQ_NUM

BIT

F10310

HS link 1 enable/disable setting

_HS2_REQ_NUM

BIT

F10311

HS link 2 enable/disable setting

_HS3_REQ_NUM

BIT

F10312

HS link 3 enable/disable setting

_HS4_REQ_NUM

BIT

F10313

HS link 4 enable/disable setting

_HS5_REQ_NUM

BIT

F10314

HS link 5 enable/disable setting

* Enable Link through flag

It describes “Enable Link” method through flag. The following SoftMaster version, CPU OS version is needed.

Flag list related with “Enable Link”

-2MLR

-2MLI

-2MLK

13 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 43

Chapter 5 Communication Program

Flag

Data type

Device

Description

_HS6_REQ_NUM

BIT

F10315

HS link 6 enable/disable setting

_HS7_REQ_NUM

BIT

F10316

HS link 7 enable/disable setting

_HS8_REQ_NUM

BIT

F10317

HS link 8 enable/disable setting

_HS9_REQ_NUM

BIT

F10318

HS link 9 enable/disable setting

_HS10_REQ_NUM

BIT

F10319

HS link 10 enable/disable setting

_HS11_REQ_NUM

BIT

F1031A

HS link 11 enable/disable setting

_HS12_REQ_NUM

BIT

F1031B

HS link 12 enable/disable setting

_P2P1_ENABLE_STATE

BIT

F09620

P2P1 enable/disable current state

_P2P2_ENABLE_STATE

BIT

F09621

P2P2 enable/disable current state

_P2P3_ENABLE_STATE

BIT

F09622

P2P3 enable/disable current state

_P2P4_ENABLE_STATE

BIT

F09623

P2P4 enable/disable current state

_P2P5_ENABLE_STATE

BIT

F09624

P2P5 enable/disable current state

_P2P6_ENABLE_STATE

BIT

F09625

P2P6 enable/disable current state

_P2P7_ENABLE_STATE

BIT

F09626

P2P7 enable/disable current state

_P2P8_ENABLE_STATE

BIT

F09627

P2P8 enable/disable current state

_P2P1_REQ

BIT

F10320

P2P1 enable/disable request

_P2P2_REQ

BIT

F10321

P2P2 enable/disable request

_P2P3_REQ

BIT

F10322

P2P3 enable/disable request

_P2P4_REQ

BIT

F10323

P2P4 enable/disable request

_P2P5_REQ

BIT

F10324

P2P5 enable/disable request

_P2P6_REQ

BIT

F10325

P2P6 enable/disable request

_P2P7_REQ

BIT

F10326

P2P7 enable/disable request

_P2P8_REQ

BIT

F10327

P2P8 enable/disable request

_P2P1_REQ_NUM

BIT

F10330

P2P1 enable/disable setting

_P2P2_REQ_NUM

BIT

F10331

P2P2 enable/disable setting

_P2P3_REQ_NUM

BIT

F10332

P2P3 enable/disable setting

_P2P4_REQ_NUM

BIT

F10333

P2P4 enable/disable setting

_P2P5_REQ_NUM

BIT

F10334

P2P5 enable/disable setting

_P2P6_REQ_NUM

BIT

F10335

P2P6 enable/disable setting

_P2P7_REQ_NUM

BIT

F10336

P2P7 enable/disable setting

_P2P8_REQ_NUM

BIT

F10337

P2P8 enable/disable setting

▶ How to enable link

-HS link/P2P enable/disable setting flag ON HS link/P2P enable/disable request flag ON

▶ How to disable link

-HS link/P2P enable/disable setting flag OFF HS link/P2P enable/disable request flag ON

▶ You can monitor the Enable/Disable state of the each link through “enable/disable current states” flag.

14 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 44

Chapter 5 Communication Program

(7) Read

(a) Connect to CPU.

(b) After connected, select On-line and Read Parameter to display the screen as shown in [Figure.

5.2.16] and then, check the applicable parameters and click [OK].

[Figure 5.2.14] Read screen

(c) Reads previously specified values for the parameters checked.

(8) View Tree by Transmission/Reception

15 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 45

Chapter 5 Communication Program

16 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 46

6.1 Introduction

Function

Section

Details

Configuration

Communication type

Communication type and its details

Automatic network scan

Network scan

Diagnostic

Diagnostic function

Live List, Debugger, Global State Field

User data Send

I/O monitor, I/O monitor

Documentation

Print

Print out the Configuration

6.2 Installation

Chapter 6 SyCon Setting

6.1.1 Main functions

Chapter 6 SyCon Setting

6.1.2 Characteristics

SyCon is a Global Fieldbus Configurator.

SyCon executes the configuration through a standardized file.

SyCon has a diagnosis function.

6.2.1 System requirements

▪ PC 486 or higher

▪ Windows 95/98/ME/NT/2000/XP or later version

▪ Hard disc with 80MB or more

▪ CD ROM Drive

▪ RAM with 16MB or more

▪ Graphic Resolution: min. 800 x 600 pixel

▪ Windows 95: Service Pack 1 or higher

▪ Windows NT: Service Pack 3 or higher

1 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 47

Chapter 6 SyCon Setting

Select System

Installation

Select here

6.2.2 Software installation

1) After the CD is inserted into CD-ROM, Execute ‘Autorun.exe’.

2. Select ‘System installation’ and execute.

1) Do you want to install the System Configurator SyCon? Yes

2) Do you want to install the SyCon integrated OPC Server? No

3) Do you want to the Stand-Alone OPC Server/Busserver? No

4) Do you have a License code? Yes

5) Select Language

Next

2 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 48

Chapter 6 SyCon Setting

3. License Agreement

Select I agree

4. Program Registration

Input License code: F90BF4B3E874

Select ‘OK’

Select ‘Yes’.

3 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 49

Chapter 6 SyCon Setting

5. Configuration Setup

Select ‘Next’.

4 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 50

Chapter 6 SyCon Setting

Select the destination folder

to install

Display minimum Disk Space

required of PC

Select Network to install

1) Components

Select ‘Next’

2) Program Folder

Select ‘Next’

5 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 51

Chapter 6 SyCon Setting

3) Setup complete

6. Installed contents

1) Installed file

6 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 52

Chapter 6 SyCon Setting

2) Contents of Folder

- Destination: C:\Program Files\Honeywell\SyCon

3) GSD files for Profibus

- GSD files are generated as shown below.

7 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 53

Chapter 6 SyCon Setting

6.3 Communication Settings in SyCon

Menu

Icon

Status

Menu

Icon

Status

6.3.1 Initial screen

Network

Edit

8 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 54

Main

Submenu

Description

File

New

Make new file

Open

Open existed file

Close

Close the open file

Save

Save the open file

Save As

Saving the file as another name

Export

Export to Project

Copy

EDS

DBM

Import DBM extension file

PDD

Import PDD extension file

CSV

Import CSV extension file

GSD

DBM

Import DBM extension file

CSV

Import CSV extension file

Print…

Print

Print Preview

Preview of print

Print Setup…

Setup of print

Recent File

Display of recent file list

Exit

Exit SyCon

Editer

Cut

Cutting

Copy

copying

Paste

Pasting

Delete

Deleting

Replace

Replace

View

Device Table

Display of device name, ID and Type

Address Table

Display of slave module address and Size of

Input/Output

Logical Network View

-

Toolbars

Standard

Activate the basic menu

Fieldbus

Activate the Insert Icon on menu

Status Bar

Display the Status Bar on SyCon basic window

Insert

Master

Insert Master module

Device

Insert Slave module

6.3.2 Composition of menu

Chapter 6 SyCon Setting

9 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240

Honeywell January 2019

Page 55

Chapter 6 SyCon Setting

Main

Submenu

Description

Online

Download

Downloading SyCon settings file

Start Debug Mode

Display current connection status

Device Diagnostic

Information of diagnosis saved

Firmware Download

Downloading by Firmware

Firmware/Reset

Reset the Firmware

Extended Device Diagnostic

Function of diagnosis extended

Global State Field

Status of current communication and moue

Live List

Information and status of module per

station number

I/O Monitor

Display of I/O data

Message Monitor

Data analyzing between Master and Slave

Automatic Network Scan

Setting the network automatically

Get Device Attribute/

Set Device Attribute

-

Start Communication

Run the communication

Stop Communication

stop the communication

Device Info

Display of the day of manufacture and

Serial number

Activate Driver

To register the unregistered device

Read project Information

Information of project

Settings

Device Assignment

Setup the way of communication with Host

Bus Parameters

Setting of communication speed and

various parameter

Master Settings

Setting of master

Device Settings

-

Device Configuration

-

Auto Addressing

To allocate the address automatically

Project Information

Information of project

Path

The path of GSD setting file and project

Language

Language selection

Window

Cascade

Window array to cascade

Tile

Window array to tile

Help

Help Topics

Help view

About

Information of SyCon program

10 Pnet I/F Module 2MLL-PSRA, 2MLL-PMEA, 2MLL-PMEB User’s Guide R240