Page 1

Granit™ 1280i

Industrial Full Range Laser Scanner

User’s Guide

Page 2

Disclaimer

Honeywell International Inc. (“HII”) reserves the right to make changes in specifications and other information contained in this

document without prior notice, and the reader should in all cases consult HII to determine whether any such changes have been

made. The information in this publication does not represent a commitment on the part of HII.

HII shall not be liable for technical or editorial errors or omissions contained herein; nor for incidental or consequential damages

resulting from the furnishing, performance, or use of this material. HII disclaims all responsibility for the selection and use of

software and/or hardware to achieve intended results.

This document contains proprietary information that is protected by copyright. All rights are reserved. No part of this document

may be photocopied, reproduced, or translated into another language without the prior written consent of HII.

2014 Honeywell International Inc. All rights reserved.

Web Address:

Microsoft® Windows®, Windows NT®, Windows 2000, Windows ME, Windows XP, and the Windows logo are trademarks or

registered trademarks of Microsoft Corporation.

Other product names or marks mentioned in this document may be trademarks or registered trademarks of other companies

and are the property of their respective owners.

www.honeywellaidc.com

Page 3

Product Agency Compliance - Granit 1280i

TÜV Rheinland

C

US

TÜV Rheinland

C

US

USA

FCC Part 15 Subpart B Class B

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital device pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio or television technician for help.

If necessary, the user should consult the dealer or an experienced radio/television technician for additional suggestions.

The user may find the following booklet helpful: “Something About Interference.” This is available at FCC local regional

offices. Honeywell is not responsible for any radio or television interference caused by unauthorized modifications of this

equipment or the substitution or attachment of connecting cables and equipment other than those specified by Honeywell.

The correction is the responsibility of the user.

Use only shielded data cables with this system. This unit has been tested with cables less than 3 meters. Cables greater

than 3 meters may not meet class B performance.

Caution: Any changes or modifications made to this equipment not expressly approved by Honeywell may void the FCC

authorization to operate this equipment.

TÜV-R Statement

TÜV R listed: UL 60950-1, Second Edition and CSA C22.2 No.60950-1-07, Second Edition.

Canada

Industry Canada ICES-003

This Class B digital apparatus complies with Canadian ICES-003. Operation is subject to the following conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesired operation.

Conformité à la règlementation canadienne

Cet appareil numérique de la Classe A est conforme à la norme NMB-003 du Canada. Son fonctionnement est assujetti

aux conditions suivantes :

1. Cet appareil ne doit pas causer de brouillage préjudiciable.

2. Cet appareil doit pouvoir accepter tout brouillage reçu, y compris le brouillage pouvant causer un fonctionnement

indésirable.

TÜV-R Statement

TÜV R listed: UL 60950-1, Second Edition and CSA C22.2 No.60950-1-07, Second Edition.

Page 4

Europe

The CE marking indicates compliance with the following directives:

• 2004/108/EC EMC

• 2011/65/EU RoHS (Recast)

In addition, complies to 2006/95/EC Low Voltage Directive, when shipped with recommended power supply. European

contact:

Hand Held Products Europe B.V.

Nijverheidsweg 9-13

5627 BT Eindhoven

The Netherlands

Honeywell International Inc. shall not be liable for use of our product with equipment (i.e., power supplies, personal computers, etc.) that is not CE marked and does not comply with the Low Voltage Directive.

Honeywell Scanning & Mobility Product Environmental Information

Refer to www.honeywellaidc.com/environmental for the RoHS / REACH / WEEE information.

Australia/NZ

C-Tick Statement

Conforms to AS/NZS 3548 EMC requirement

Mexico

Conforms to NOM-019.

Japan

VCCI: V-3, Technical Requirements, Class B ITE.

この装置は、 ク ラ ス B 情報技術装置です。 この装置は、 家庭環境で使用

する こ と を目的 と し てい ま すが、 この装置が ラ ジ オやテ レ ビ ジ ョ ン受信機に

近接し て使用 さ れる と 、 受信障害を引き 起こ す こ と があ り ます。

取扱説明書に従 っ て 正 し い取 り 扱い を し て下 さ い。 VCCI–B

South Korea

This product meets Korean agency approval.

이 기기는 가정용 (B 급 ) 전자파적합기기로서 주로 가정에서 사용하는 것을 목적으로 하며 ,

모든 지역에서 사용할 수 있습니다 .

Taiwan

If the following label is attached to your product, the product meets Taiwan agency approval:

BSMI Standard: CNS13438, CNS14336

依據標準 : CNS13438, CNS14336

Page 5

Russia

LASER LIGHT - DO NOT STARE INTO BEAM. CLASS 2 LASER PRODUCT.

RAYONNEMENT LASER NE PAS REGARDER DANS LE FAISCEAU. APPAREIL À

LASER DE CLASSE 2. MAX. 1mW :630-680 nm. IEC 60825-1: 2007. Complies with

21 CFR 1040.10 and 1040.11 except for deviations pursuant To Laser Notice No. 50,

dated June 24, 2007.

!

Customs Union approval

International

CB Scheme

Certified to CB Scheme IEC 60950-1, Second Edition.

Laser Safety Statement

If the following label is attached to your product, it indicates the product contains a laser engine or laser aimer:

This device has been tested in accordance with and complies with IEC60825-1 ed2 (2007). Complies with 21 CFR

1040.10 and 1040.11, except for deviations pursuant to Laser Notice No. 50, dated June 24, 2007.

LASER LIGHT, DO NOT STARE INTO BEAM, CLASS 2 LASER PRODUCT, 1.0 mW MAX OUTPUT: 650nM.

Caution: Use of controls or adjustments or performance of procedures other than those specified herein may

result in hazardous radiation exposure.

Patents

For patent information, please refer to www.hsmpats.com.

Solids and Water Protection

The Granit 1280i has a rating of IP65, totally protected against dust and protected against low pressure water jets.

Warning

To reduce the possibility of heat-related injuries, avoid touching sections of the scanner that feel warm.

Page 6

Required Safety Labels

Granit 1280i Scanner

Part Number, Serial

Number and Revision

Information location

Compliance

label location

Laser Label location

Laser Output

Page 7

Table of Contents

Chapter 1 - Getting Started

About This Manual ...............................................................................................................1-1

Unpacking Your Device .......................................................................................................1-1

Connecting the Device.........................................................................................................1-1

Reading Techniques ............................................................................................................1-2

Cyber Security Settings .......................................................................................................1-2

Setting Custom Defaults ......................................................................................................1-2

Resetting the Custom Defaults ............................................................................................1-2

Chapter 2 - Programming the Interface

Introduction ..........................................................................................................................2-1

Programming the Interface - Plug and Play .........................................................................2-1

RS232 Serial Port ................................................................................................................2-1

OPOS Mode...................................................................................................................2-1

Verifone

Gilbarco

Honeywell Bioptic Aux Port Configuration ...........................................................................2-2

Datalogic™ Magellan

NCR Bioptic Aux Port Configuration ....................................................................................2-3

Wincor Nixdorf Terminal Default Settings ............................................................................2-3

Wincor Nixdorf Beetle™ Terminal Default Settings .............................................................2-3

RS232 Modifiers ..................................................................................................................2-4

NCR Modifiers......................................................................................................................2-9

Scanner to Bioptic Communication....................................................................................2-10

®

Ruby Terminal Default Settings...........................................................................2-2

®

Terminal Default Settings ....................................................................................2-2

®

Aux Port Configuration....................................................................2-2

RS232 Baud Rate ..........................................................................................................2-4

RS232 Word Length: Data Bits, Stop Bits, and Parity ...................................................2-5

RS232 Handshaking ......................................................................................................2-6

RS232 Timeout ..............................................................................................................2-7

XON/XOFF.....................................................................................................................2-7

ACK/NAK .......................................................................................................................2-7

Communication Timeout ................................................................................................2-7

NAK Retries ...................................................................................................................2-8

Support BEL/CAN in ACK/NAK......................................................................................2-8

RS232 Defaults..............................................................................................................2-9

NCR ACK/NAK...............................................................................................................2-9

Block Check Character ..................................................................................................2-9

NCR Prefix .....................................................................................................................2-9

NCR Suffix ...................................................................................................................2-10

NCR Prefix/Suffix .........................................................................................................2-10

NCR NOF (Not-on-File) Error.......................................................................................2-10

Scanner-Bioptic Packet Mode......................................................................................2-11

Chapter 3 - Input/Output Settings

Power Save Mode................................................................................................................3-1

Power Up Beeper.................................................................................................................3-1

i

Page 8

Beep on BEL Character.......................................................................................................3-2

Good Read and Error Indicators..........................................................................................3-2

Beeper – Good Read.....................................................................................................3-2

Beeper Volume – Good Read........................................................................................3-2

Beeper Pitch – Good Read............................................................................................ 3-3

Beeper - Transmit Order................................................................................................3-3

Vibrate – Good Read..................................................................................................... 3-3

Beeper Pitch – Error ...................................................................................................... 3-4

Beeper Duration – Good Read ...................................................................................... 3-4

Number of Beeps – Good Read ....................................................................................3-5

Number of Beeps – Error............................................................................................... 3-5

Beeper Volume Max ...................................................................................................... 3-5

Laser Aimer ......................................................................................................................... 3-5

Laser Aimer - Scanning Pattern.....................................................................................3-5

Laser Aimer - Scanning Duration...................................................................................3-6

Laser Aimer - Good Read Pattern .................................................................................3-6

Laser Aimer - Good Read Duration ...............................................................................3-7

Aimer Delay ...................................................................................................................3-7

LED Indicators .....................................................................................................................3-8

LED Settings.................................................................................................................. 3-8

Good Read Delay ..........................................................................................................3-9

User-Specified Good Read Delay..................................................................................3-9

Out-Of-Stand Settings .........................................................................................................3-9

Out-of-Stand Defaults.................................................................................................... 3-9

Presentation Mode.......................................................................................................3-10

Manual Activation Mode ..............................................................................................3-10

End Manual Activation After Good Read..................................................................... 3-10

Manual Activation Laser Timeout - Trigger Settings.................................................... 3-11

Reread Delay.....................................................................................................................3-11

User-Specified Reread Delay ...................................................................................... 3-11

CodeGate

®

........................................................................................................................3-12

Character Activation Mode ................................................................................................3-12

Activation Character .................................................................................................... 3-12

End Character Activation After Good Read................................................................. 3-13

Character Activation Timeout ......................................................................................3-13

Character Deactivation Mode ............................................................................................3-13

Deactivation Character ................................................................................................ 3-14

Centering...........................................................................................................................3-14

Blinky Mode .......................................................................................................................3-15

Laser Scan Angle ..............................................................................................................3-15

Decode Security ................................................................................................................3-16

Continuous Scan Mode .....................................................................................................3-16

ii

Page 9

Output Sequence Overview...............................................................................................3-16

Output Sequence Editor ..............................................................................................3-16

To Add an Output Sequence .......................................................................................3-16

Other Programming Selections....................................................................................3-17

Output Sequence Editor ..............................................................................................3-18

Sequence Timeout.......................................................................................................3-18

Sequence Match Beeper .............................................................................................3-18

Partial Sequence .........................................................................................................3-19

Require Output Sequence ...........................................................................................3-19

No Read ............................................................................................................................3-20

Chapter 4 - Data Editing

Prefix/Suffix Overview .........................................................................................................4-1

To Add a Prefix or Suffix:............................................................................................... 4-1

To Clear One or All Prefixes or Suffixes........................................................................ 4-2

To Add a Carriage Return Suffix to All Symbologies..................................................... 4-2

Prefix Selections..................................................................................................................4-2

Suffix Selections..................................................................................................................4-2

Function Code Transmit ......................................................................................................4-3

Communication Check Character........................................................................................ 4-3

Intercharacter, Interfunction, and Intermessage Delays......................................................4-3

Intercharacter Delay ......................................................................................................4-4

User Specified Intercharacter Delay.............................................................................. 4-4

Interfunction Delay.........................................................................................................4-4

Intermessage Delay....................................................................................................... 4-5

Chapter 5 - Data Formatting

Data Format Editor Introduction .......................................................................................... 5-1

Add a Data Format ..............................................................................................................5-1

Other Programming Selections......................................................................................5-2

Terminal ID Table................................................................................................................5-3

Data Format Editor Commands...........................................................................................5-3

Move Commands...........................................................................................................5-6

Search Commands........................................................................................................ 5-7

Miscellaneous Commands.............................................................................................5-9

Data Formatter ..................................................................................................................5-11

Data Format Non-Match Error Tone............................................................................ 5-12

Primary/Alternate Data Formats........................................................................................5-12

Single Scan Data Format Change............................................................................... 5-13

Chapter 6 - Symbologies

All Symbologies...................................................................................................................6-1

Message Length Description...............................................................................................6-1

Codabar...............................................................................................................................6-2

Codabar Concatenation................................................................................................. 6-3

iii

Page 10

Code 39 ...............................................................................................................................6-5

Code 32 Pharmaceutical (PARAF)................................................................................ 6-6

Full ASCII....................................................................................................................... 6-7

Code 39 Code Page ...................................................................................................... 6-7

Interleaved 2 of 5.................................................................................................................6-8

Matrix 2 of 5.........................................................................................................................6-9

NEC 2 of 5.........................................................................................................................6-11

Code 93 .............................................................................................................................6-12

Code 93 Code Page .................................................................................................... 6-13

Straight 2 of 5 Industrial (three-bar start/stop)...................................................................6-14

Straight 2 of 5 IATA (two-bar start/stop)............................................................................6-15

Code 11 .............................................................................................................................6-16

Code 128...........................................................................................................................6-17

ISBT 128 Concatenation..............................................................................................6-18

GS1-128 ............................................................................................................................ 6-23

Telepen..............................................................................................................................6-24

UPC-A ...............................................................................................................................6-25

UPC-A/EAN-13

with Extended Coupon Code .......................................................................................... 6-28

UPC-A/Code 128 Coupon Code Output...................................................................... 6-28

UPC-A Number System 5 Addenda Required............................................................. 6-29

Coupon GS1 DataBar Output...................................................................................... 6-30

UPC-E0 .............................................................................................................................6-31

EAN/JAN-13 ......................................................................................................................6-34

Convert UPC-A to EAN-13 ..........................................................................................6-34

ISBN Translate ............................................................................................................6-40

ISSN Translate ............................................................................................................6-41

EAN/JAN-8 ........................................................................................................................ 6-42

MSI .................................................................................................................................... 6-44

Plessey Code ....................................................................................................................6-46

GS1 DataBar Omnidirectional ...........................................................................................6-47

GS1 DataBar Limited.........................................................................................................6-48

GS1 DataBar Expanded....................................................................................................6-49

Trioptic Code ..................................................................................................................... 6-50

GS1 Emulation ..................................................................................................................6-50

China Post (Hong Kong 2 of 5)..........................................................................................6-51

Chapter 7 - Utilities

To Add a Test Code I.D. Prefix to All Symbologies.............................................................7-1

Show Software Revision......................................................................................................7-1

Show Data Format...............................................................................................................7-1

Test Menu............................................................................................................................7-1

TotalFreedom ...................................................................................................................... 7-1

Application Plug-Ins (Apps) .................................................................................................7-2

EZConfig-Scanning Introduction..........................................................................................7-2

Installing EZConfig-Scanning from the Web.................................................................. 7-3

Resetting the Factory Defaults ............................................................................................7-3

iv

Page 11

Chapter 8 - Serial Programming Commands

Conventions.........................................................................................................................8-1

Menu Command Syntax......................................................................................................8-1

Query Commands ...............................................................................................................8-1

Responses..................................................................................................................... 8-2

Serial Trigger Commands....................................................................................................8-3

Read Time-Out .............................................................................................................. 8-3

Resetting the Custom Defaults............................................................................................8-3

Menu Commands ................................................................................................................ 8-4

Chapter 9 - Product Specifications

Granit 1280i Industrial Corded Scanner Product Specifications.......................................... 9-1

Depth of Field Charts...........................................................................................................9-2

Typical Performance .....................................................................................................9-2

Guaranteed Performance ............................................................................................9-2

....................................................................................................................................... 9-3

Standard Connector Pinouts ...............................................................................................9-4

Serial Output.................................................................................................................. 9-4

Chapter 10 - Maintenance

Repairs .............................................................................................................................. 10-1

Maintenance......................................................................................................................10-1

Cleaning the Scanner ..................................................................................................10-1

Cleaning the Window................................................................................................... 10-1

Inspecting Cords and Connectors ...............................................................................10-1

Replacing Cables ..............................................................................................................10-1

Replacing an Interface Cable ......................................................................................10-2

Troubleshooting.................................................................................................................10-2

Chapter 11 - Customer Support

Technical Assistance.........................................................................................................11-1

Product Service and Repair...............................................................................................11-1

Appendix A - Reference Charts

Symbology Charts ...............................................................................................................A-1

Linear Symbologies .......................................................................................................A-1

Postal Symbologies .......................................................................................................A-2

ASCII Conversion Chart (Code Page 1252)........................................................................A-2

Lower ASCII Reference Table.............................................................................................A-3

ISO 2022/ISO 646 Character Replacements ......................................................................A-7

Unicode Key Maps ..............................................................................................................A-9

v

Page 12

vi

Page 13

1

Getting Started

About This Manual

This User’s Guide provides installation and programming instructions for the Granit 1280i corded industrial scanners. Product

specifications, dimensions, warranty, and customer support information are also included.

Honeywell bar code scanners are factory programmed for the most common terminal and communications settings. If you need

to change these settings, programming is accomplished by scanning the bar codes in this guide.

An asterisk (*) next to an option indicates the default setting.

Unpacking Your Device

After you open the shipping carton containing the product, take the following steps:

• Check for damage during shipment. Report damage immediately to the carrier who delivered the carton.

• Make sure the items in the carton match your order.

• Save the shipping container for later storage or shipping.

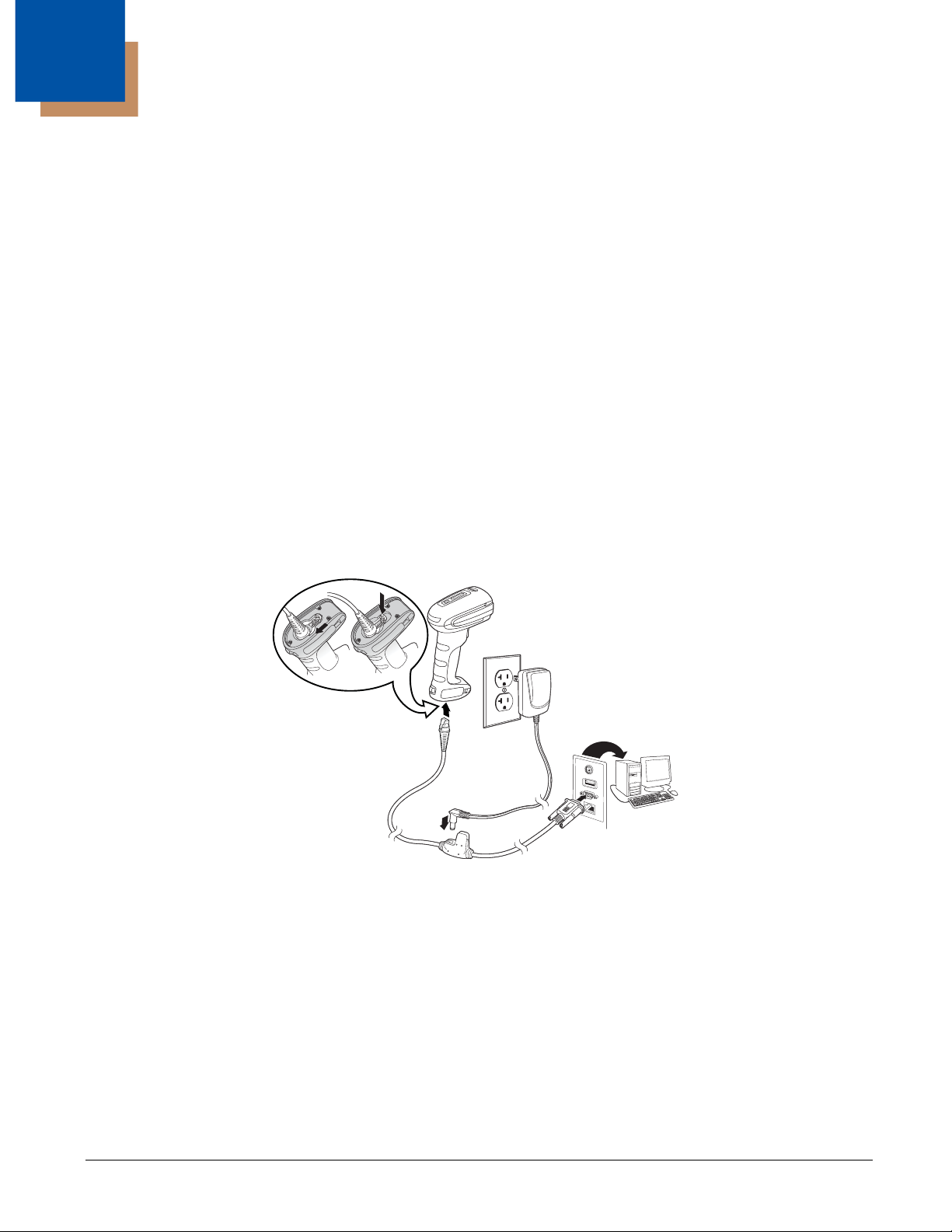

Connecting the Device

1. Turn off power to the terminal/computer.

2. Connect the appropriate interface cable to the scanner.

Note: For the scanner to work properly, you must have the correct cable for your type of terminal/computer.

3. Make sure the cable is pushed tightly into the scanner. Loosen the locking plate and slide it over the base of the cable

connector to lock the cable in place. Tighten the screw.

4. Plug the serial connector into the serial port on your computer. Tighten the two screws to secure the connector to the port.

5. Once the scanner has been fully connected, power up the computer.

6. Plug in the AC adapter, if applicable.

This interface programs 9600 baud, 8 data bits, no parity, and 1 stop bit.

1 - 1

Page 14

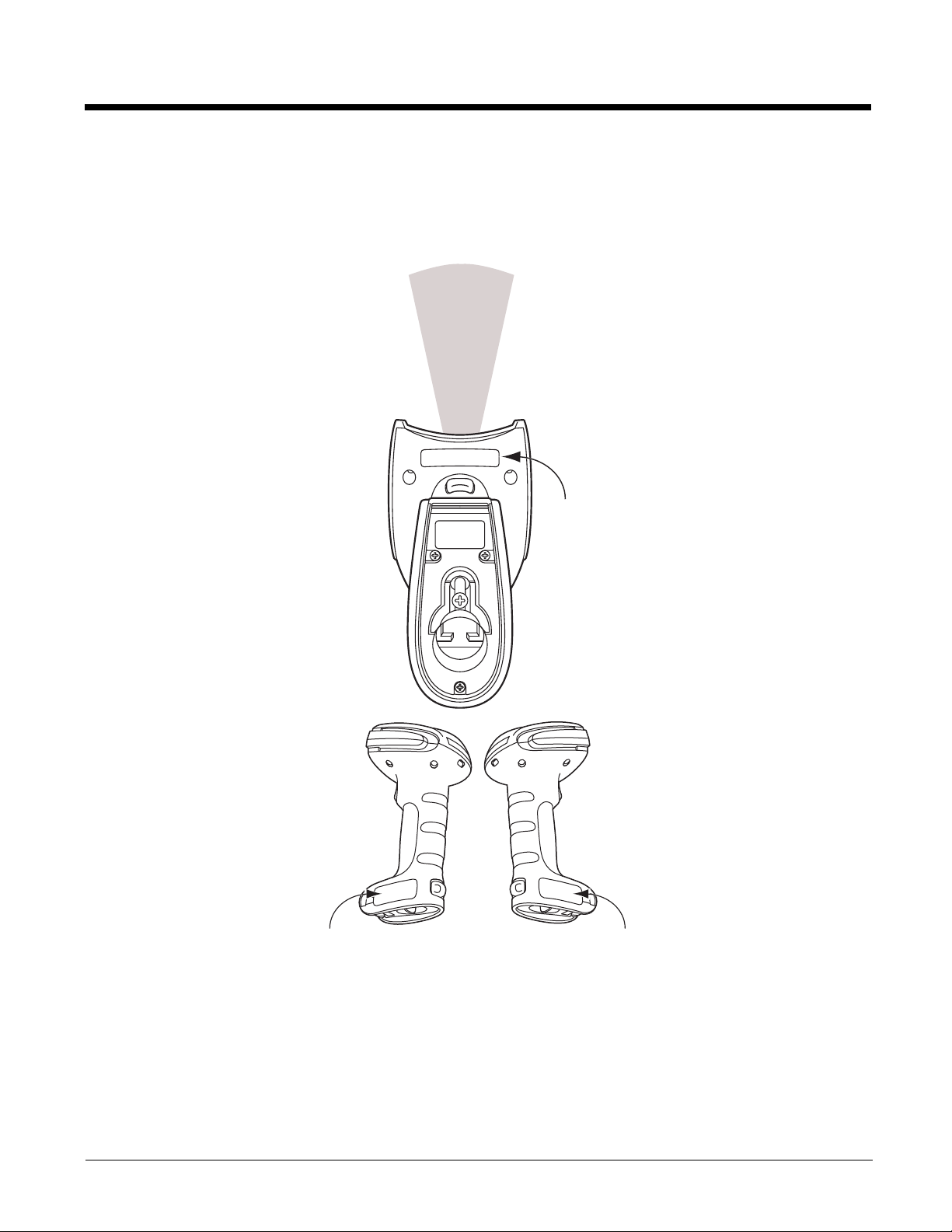

Reading Techniques

Set Custom Defaults

Save Custom Defaults

Activate Custom Defaults

The Granit 1280i scanner has a bright red scanning line that corresponds to the scanner’s horizontal field of view.

The scanning line is smaller when the scanner is closer to the code and larger when it is farther from the code. Symbologies

with smaller bars or elements (mil size) should be read closer to the unit. Symbologies with larger bars or elements (mil size)

should be read farther from the unit. To read single or multiple symbols (on a page or on an object), hold the scanner at an

appropriate distance from the target, pull the trigger, and center the scanning line on the symbol. If the code being scanned is

highly reflective (e.g., laminated), it may be necessary to tilt the code up 15° to 18° to prevent unwanted reflection.

Cyber Security Settings

Honeywell scanners have additional settings aimed at preventing cyber attacks. You may want to restrict the ability to program

your device with menu codes or serial commands, or you may want to disable firmware upgrades to your device. Honeywell’s

Cyber Security settings allow you to secure your device by restricting these features. Please contact the nearest technical support office (see Technical Assistance on page 11-1) for further information.

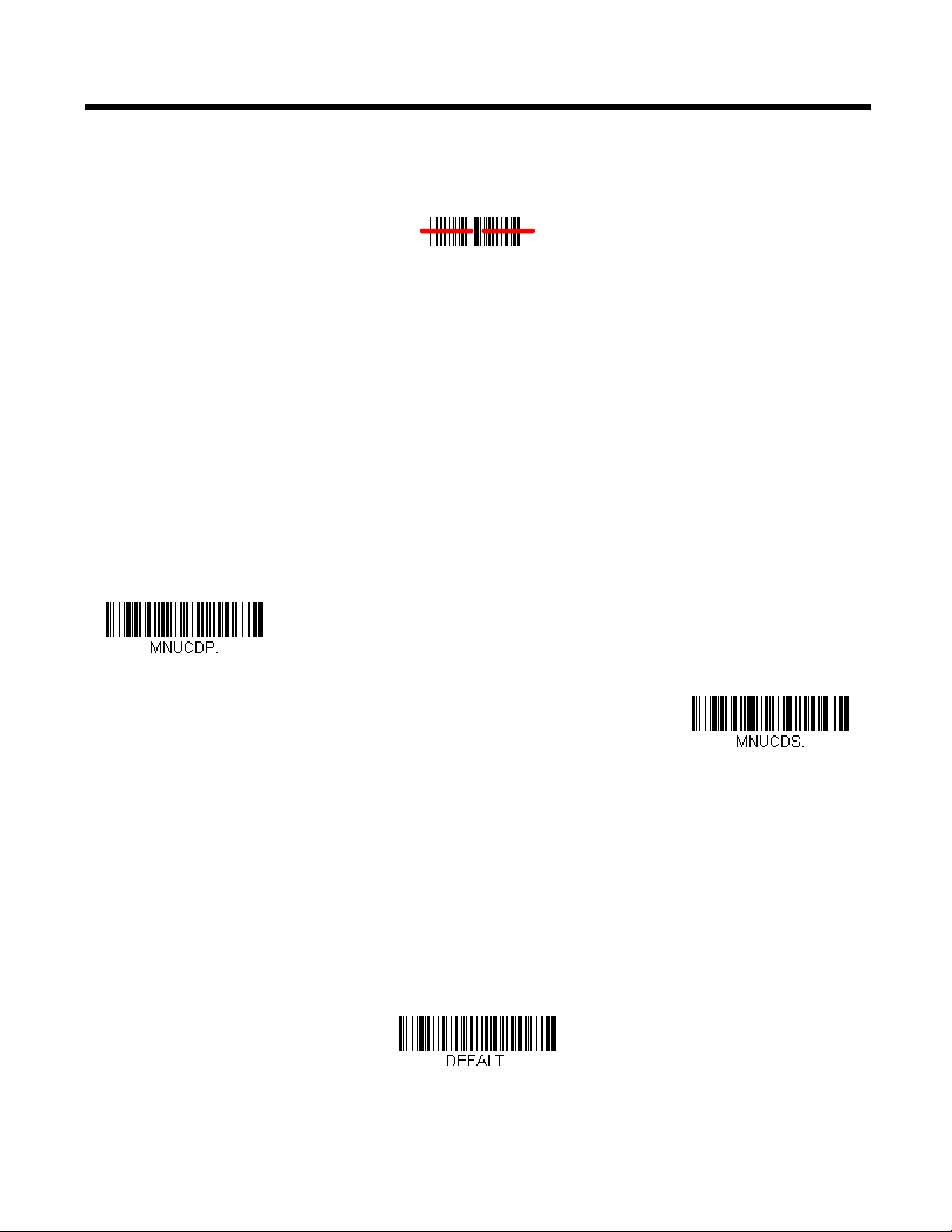

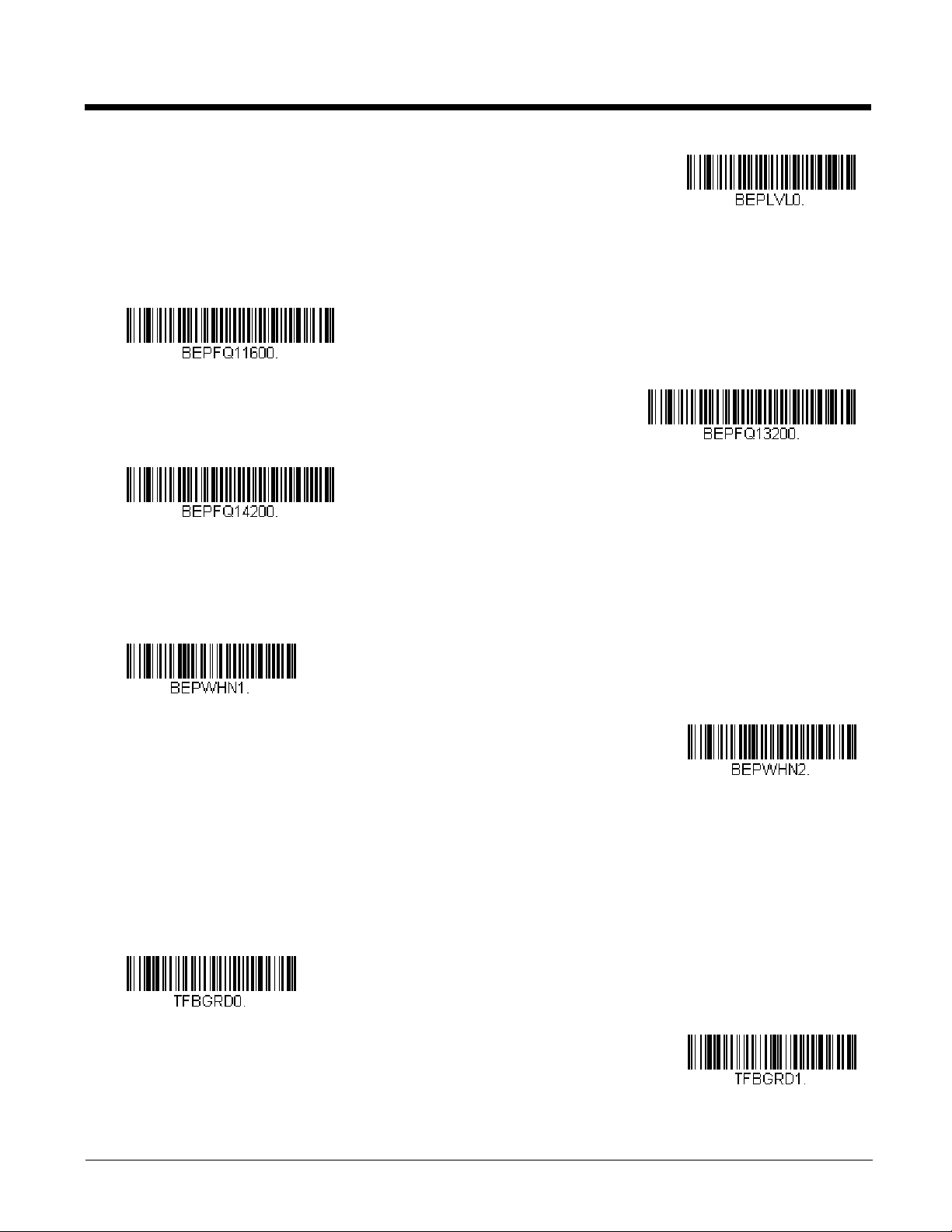

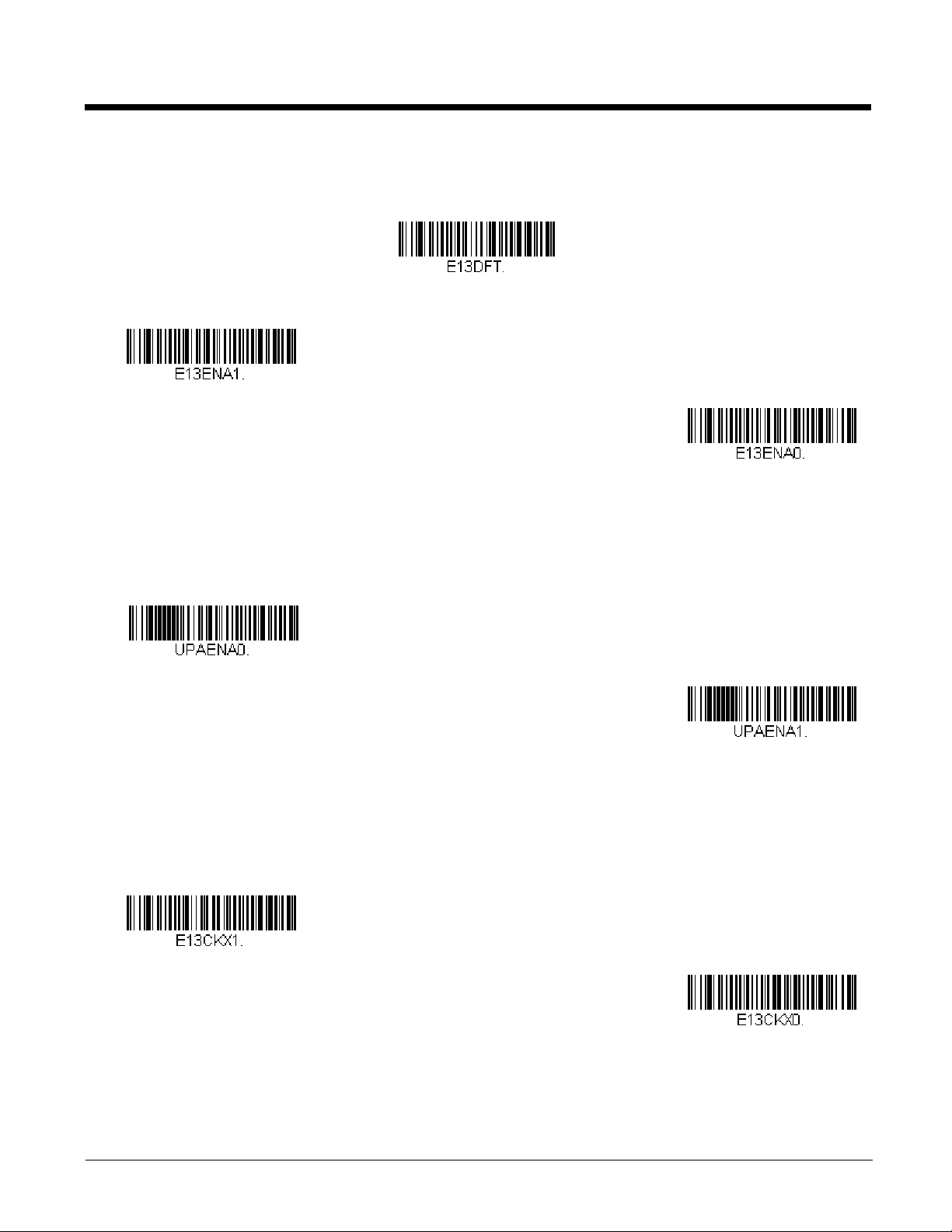

Setting Custom Defaults

You have the ability to create a set of menu commands as your own, custom defaults. To do so, scan the Set Custom Defaults

bar code below before scanning the menu commands for your custom defaults. If a menu command requires scanning numeric

codes from the back cover, then a Save code, that entire sequence will be saved to your custom defaults. When you have

entered all the commands you want to save for your custom defaults, scan the Save Custom Defaults bar code.

You may have a series of custom settings and want to correct a single setting. To do so, just scan the new setting to overwrite

the old one. For example, if you had previously saved the setting for Beeper Volume at Low to your custom defaults, and decide

you want the beeper volume set to High, just scan the Set Custom Defaults bar code, then scan the Beeper Volume High

menu code, and then Save Custom Defaults. The rest of the custom defaults will remain, but the beeper volume setting will be

updated.

Resetting the Custom Defaults

If you want the custom default settings restored to your scanner, scan the Activate Custom Defaults bar code below. This is

the recommended default bar code for most users. It resets the scanner to the custom default settings. If there are no custom

defaults, it will reset the scanner to the factory default settings. Any settings that have not been specified through the custom

defaults will be defaulted to the factory default settings.

1 - 2

Page 15

2

RS232 Interface

OPOS Mode

Programming the Interface

Introduction

This chapter describes how to program your system for the desired interface.

Programming the Interface - Plug and Play

Plug and Play bar codes provide instant scanner set up for commonly used interfaces.

Note: After you scan one of the codes, power cycle the host terminal to have the interface in effect.

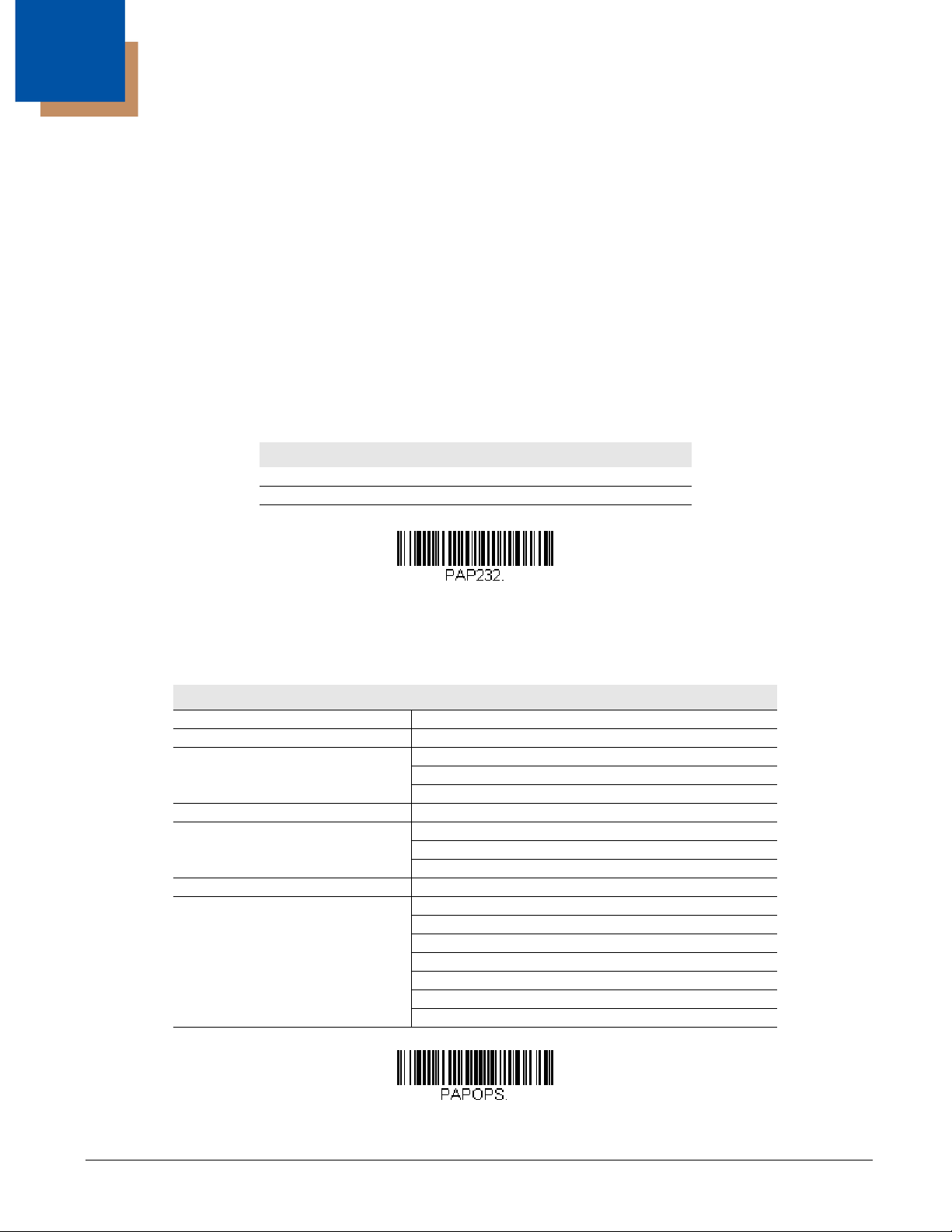

RS232 Serial Port

The RS232 Interface bar code is used when connecting to the serial port of a PC or terminal. The following RS232 Interface

bar code also programs a carriage return (CR) and a line feed (LF) suffix, baud rate, and data format as indicated below. It also

changes the trigger mode to manual.

Option Setting

Baud Rate 9600 bps

Data Format 8 data bits, no parity bit, 1 stop bit

OPOS Mode

The following bar code configures your engine for OPOS (OLE for Retail Point of Sale) by modifying the following OPOSrelated settings:

Option Setting

Interface RS232

Baud Rate 38400

RS232 Handshaking Flow Control, No Timeout

XON/XOFF Off

ACK/NAK Off

Data Bits, Stop Bits, and Parity 8 Data, 1 Stop, Parity None

Prefix/Suffix

Intercharacter Delay Off

Symbologies Enable UPC-A with check digit and number system

Clear All Prefixes and Suffixes

Add Code ID and AIM ID Prefix

Add CR Suffix

Enable UPC-E0 with check digit

Enable EAN/JAN-8 with check digit

Enable EAN/JAN-13 with check digit

Enable Code 128

Enable Code 39

Enable OPOS with automatic disable off

2 - 1

Page 16

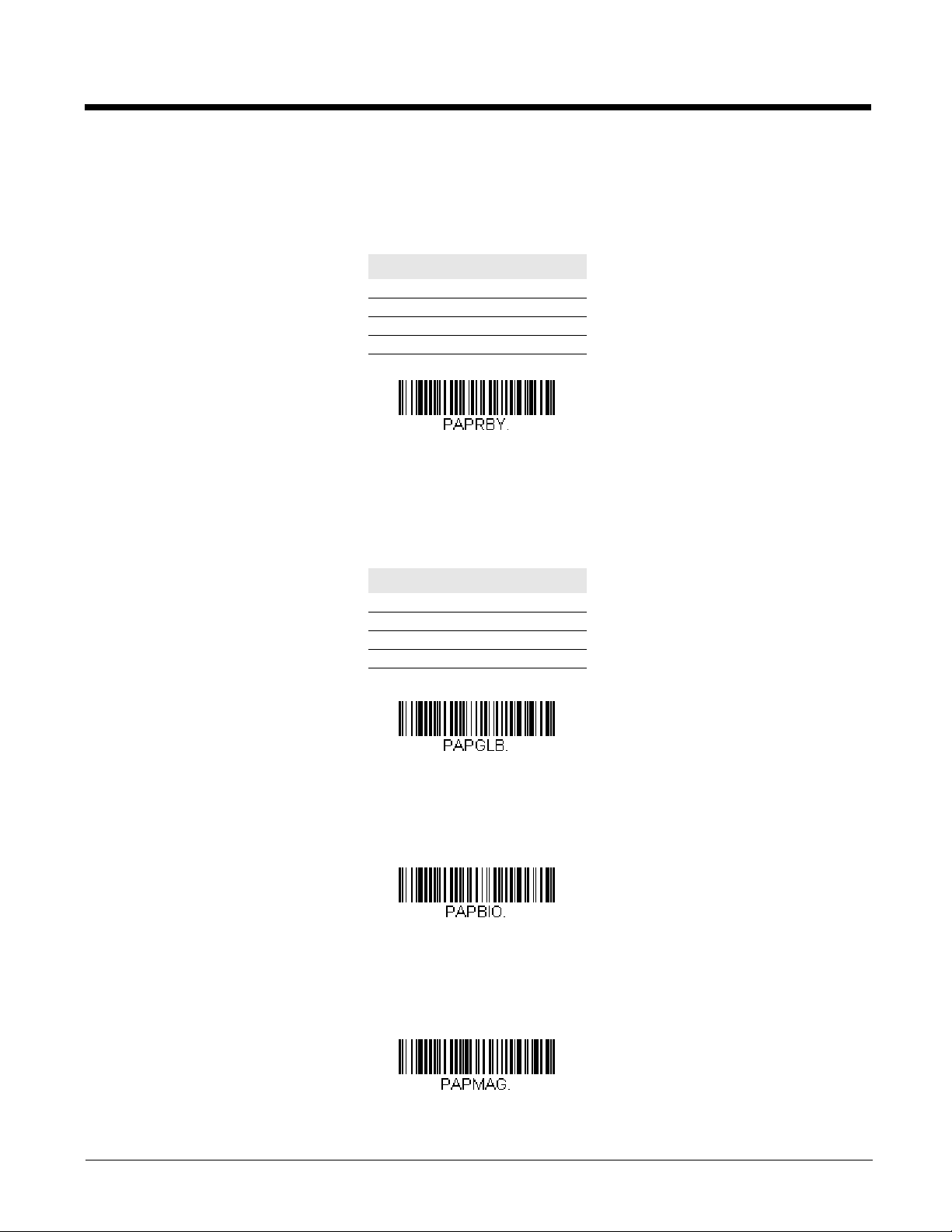

Verifone® Ruby Terminal Default Settings

Verifone Ruby Settings

Gilbarco Settings

Honeywell Bioptic Settings

Datalogic Magellan Settings

Scan the following Plug and Play code to program the scanner for a Verifone Ruby terminal. This bar code sets the baud rate to

1200 bps and the data format to 8 data bits, no parity bit, 1 stop bit. It also adds a line feed (LF) suffix and programs the following prefixes for each symbology:

Symbology Prefix

UPC-A A

UPC-E A

EAN-8 FF

EAN-13 F

Gilbarco® Terminal Default Settings

Scan the following Plug and Play code to program the scanner for a Gilbarco terminal. This bar code sets the baud rate to 2400

bps and the data format to 7 data bits, even parity, 2 stop bits. It also adds a carriage return (CR) suffix and programs the following prefixes for each symbology:

Symbology Prefix

UPC-A A

UPC-E E0

EAN-8 FF

EAN-13 F

Honeywell Bioptic Aux Port Configuration

Scan the following Plug and Play code to program the scanner for a Honeywell bioptic scanner auxiliary port configuration. This

bar code sets the baud rate to 38400 bps and the data format to 8 data bits, no parity, 1 stop bit.

Datalogic™ Magellan® Aux Port Configuration

Scan the following Plug and Play code to program the scanner for a Datalogic Magellan auxiliary port configuration. This bar

code sets the baud rate to 9600 bps and the data format to 8 data bits, no parity, 1 stop bit.

2 - 2

Page 17

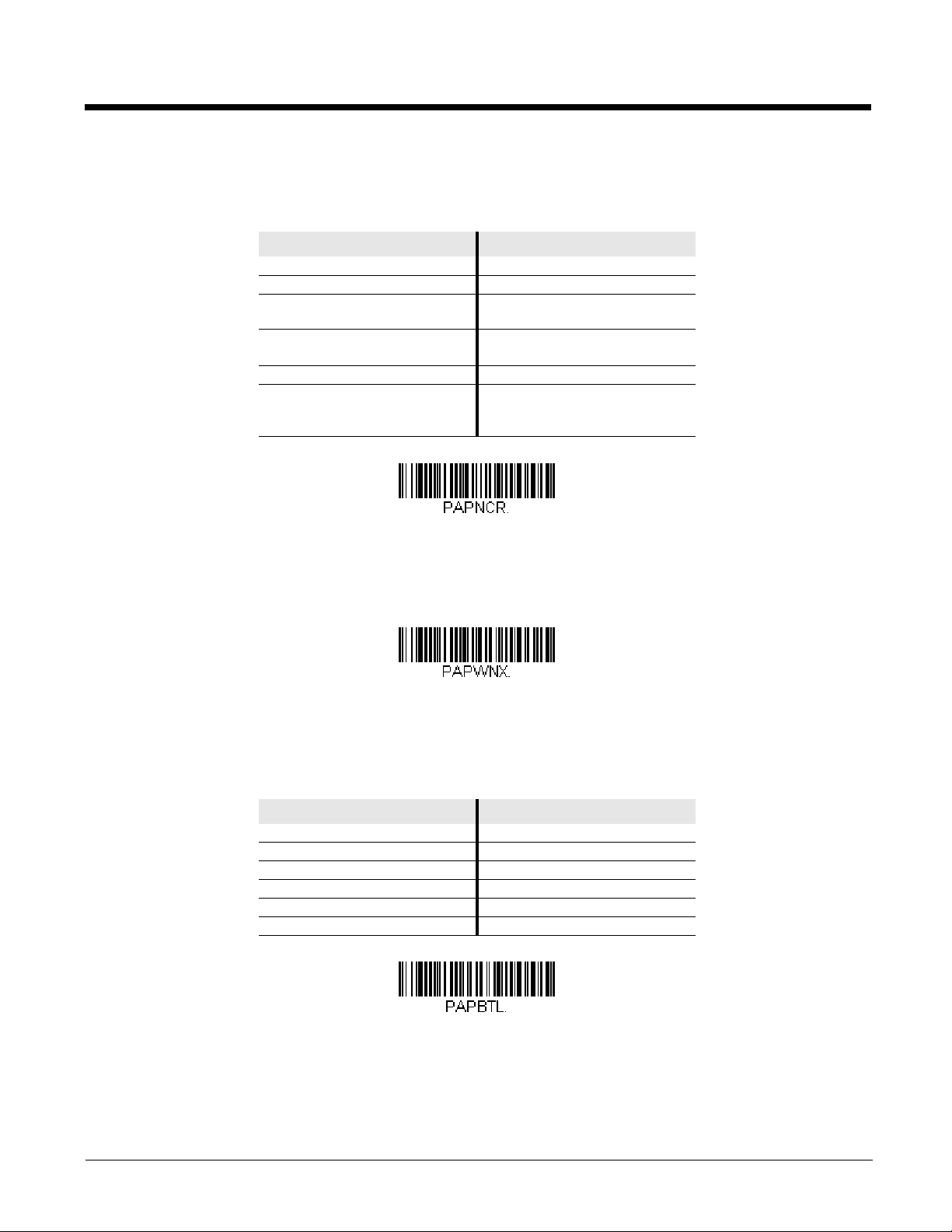

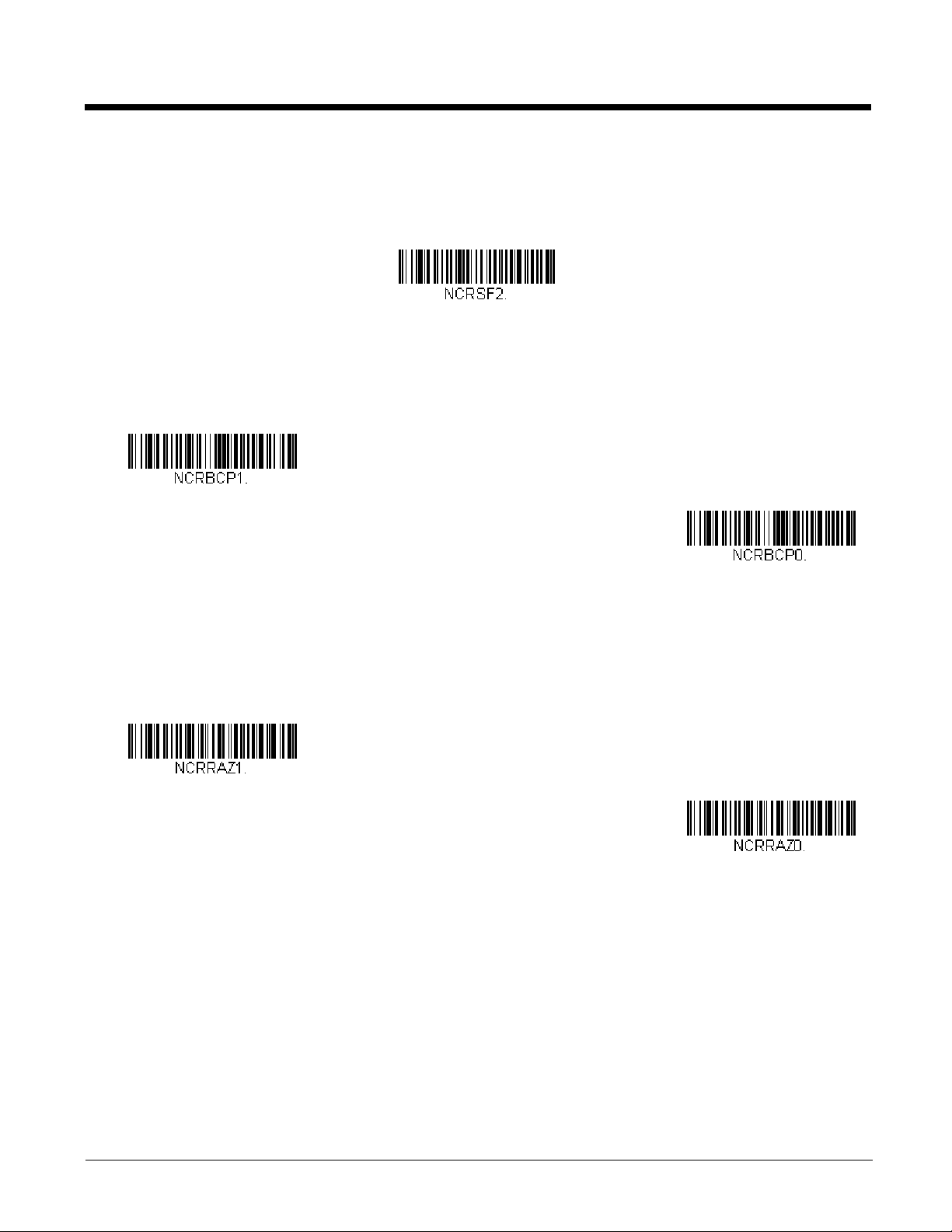

NCR Bioptic Aux Port Configuration

NCR Bioptic Settings

Wincor Nixdorf Terminal Settings

Wincor Nixdorf Beetle Settings

Scan the following Plug and Play code to program the scanner for an NCR bioptic scanner auxiliary port configuration. The following prefixes are programmed for each symbology:

Symbology Prefix Symbology Prefix

UPC-A A Interleaved 2 of 5 b

UPC-E E0 Code 128 f

GS1 DataBar

Omnidirecitonal

EAN-8 FF GS1 DataBar

Expanded

EAN-13 F Codabar N

Code 39 a Code 32

Pharmaceutical

(PARAF)

r

r

a

Wincor Nixdorf Terminal Default Settings

Scan the following Plug and Play code to program the scanner for a Wincor Nixdorf terminal. This bar code sets the baud rate

to 9600 bps and the data format to 8 data bits, no parity, 1 stop bit.

Wincor Nixdorf Beetle™ Terminal Default Settings

Scan the following Plug and Play code to program the scanner for a Wincor Nixdorf Beetle terminal. The following prefixes are

programmed for each symbology:

Symbology Prefix Symbology Prefix

Code 128 K EAN-13 A

Code 93 L GS1-128 P

Codabar N Interleaved 2 of 5 I

UPC-A A0 Plessey O

UPC-E C Straight 2 of 5 IATA H

EAN-8 B All other bar codes M

2 - 3

Page 18

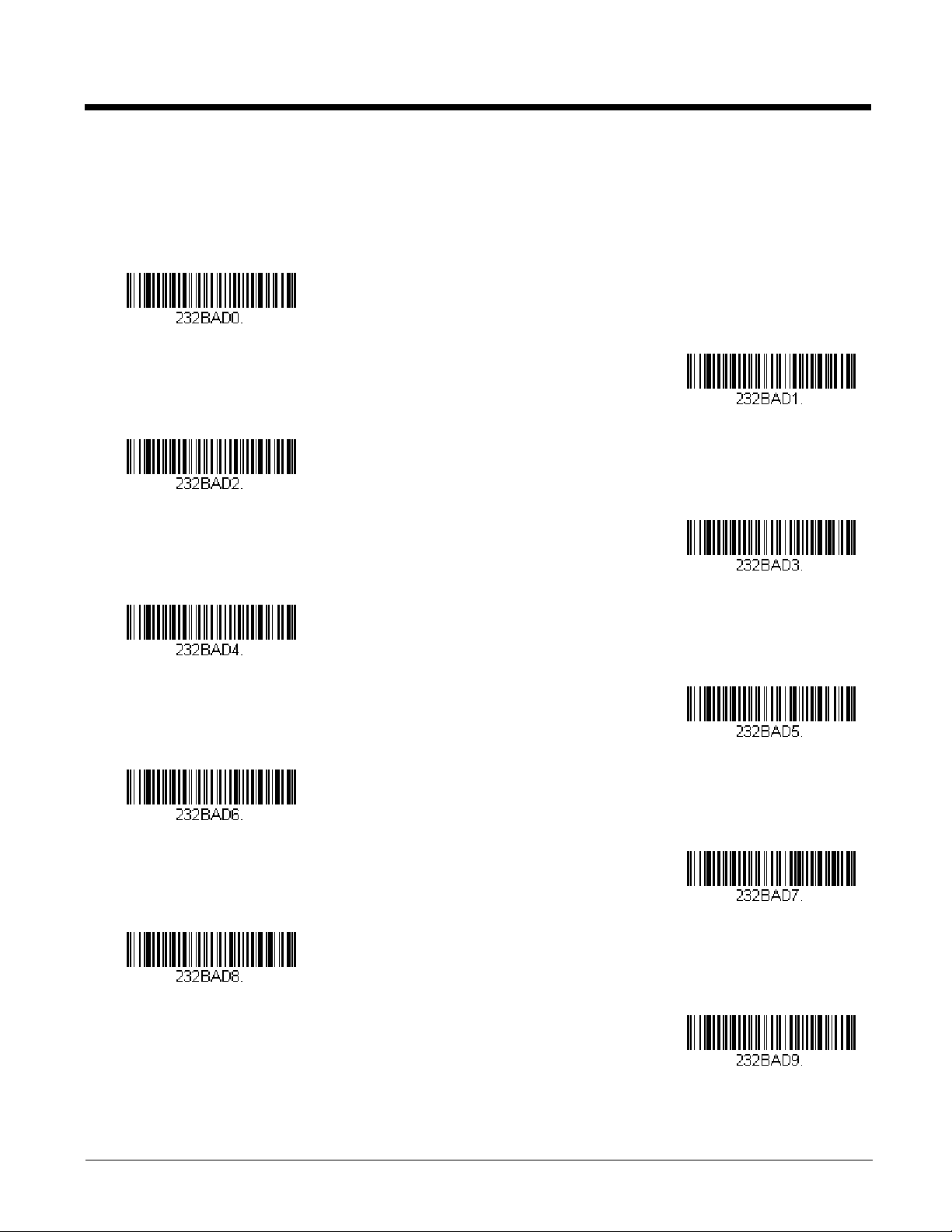

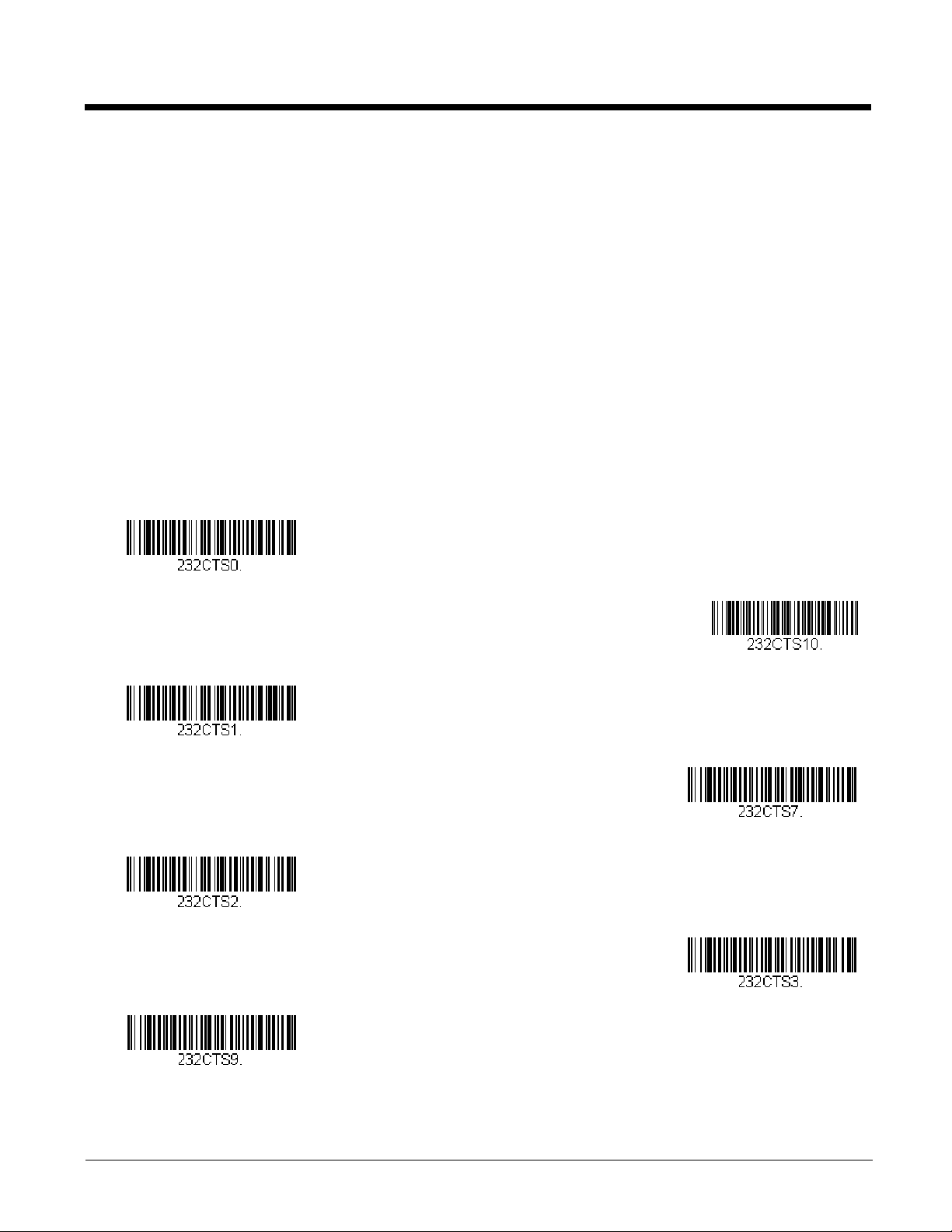

RS232 Modifiers

300

600

1200

2400

4800

* 9600

19200

38400

57,600

115,200

RS232 Baud Rate

Baud Rate sends the data from the scanner to the terminal at the specified rate. The host terminal must be set for the

same baud rate as the scanner. Default = 9600.

2 - 4

Page 19

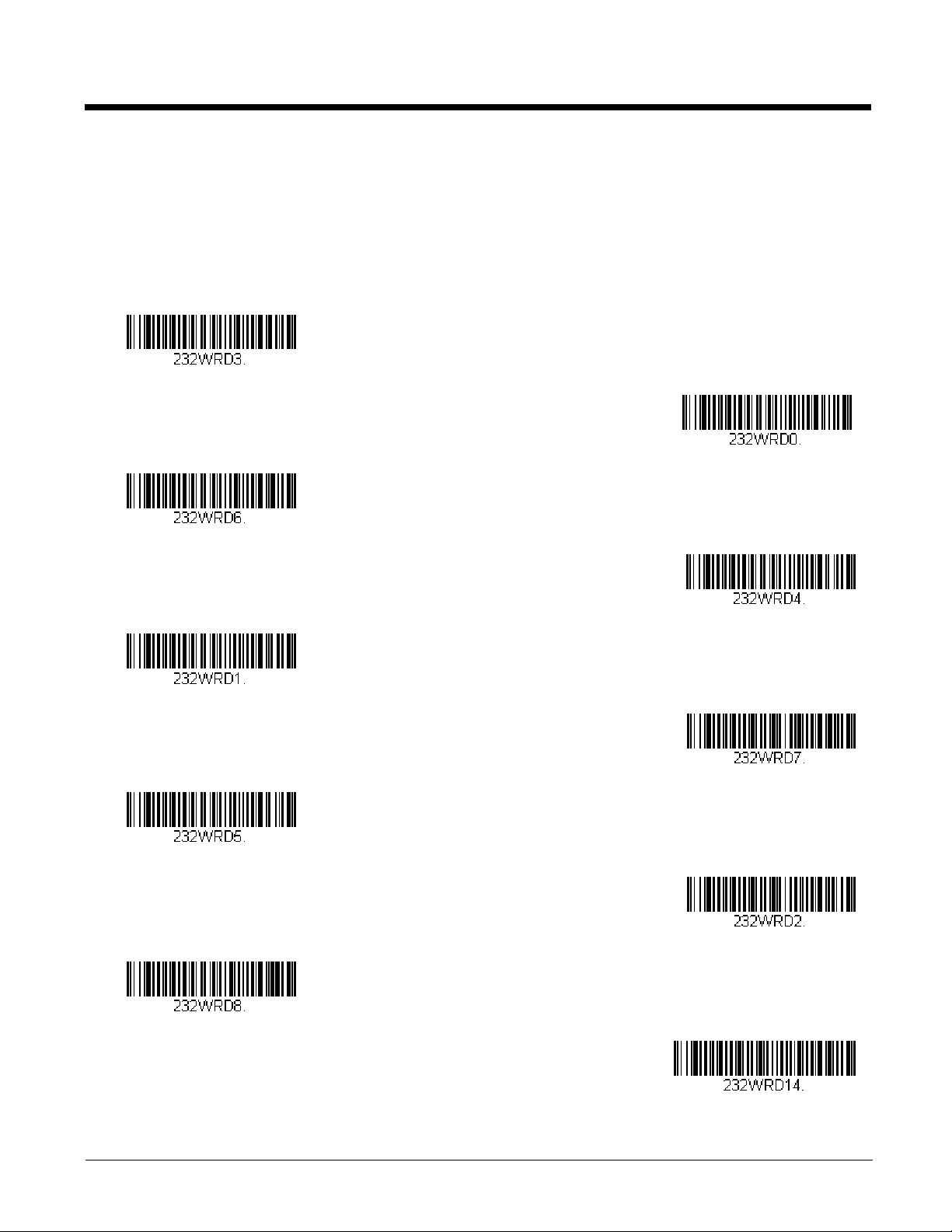

RS232 Word Length: Data Bits, Stop Bits, and Parity

7 Data, 1 Stop, Parity Even

7 Data, 1 Stop, Parity None

7 Data, 1 Stop, Parity Odd

7 Data, 2 Stop, Parity Even

7 Data, 2 Stop Parity None

7 Data, 2 Stop, Parity Odd

8 Data, 1 Stop, Parity Even

* 8 Data, 1 Stop, Parity None

8 Data, 1 Stop, Parity Odd

8 Data, 1 Stop, Parity Mark

Data Bits sets the word length at 7 or 8 bits of data per character. If an application requires only ASCII Hex characters 0

through 7F decimal (text, digits, and punctuation), select 7 data bits. For applications that require use of the full ASCII set,

select 8 data bits per character. Default = 8.

Stop Bits sets the stop bits at 1 or 2. Default = 1.

Parity provides a means of checking character bit patterns for validity.

Default = None.

2 - 5

Page 20

RS232 Handshaking

* RTS/CTS Off

* RTS/CTS Off, RTS

Inactive

Flow Control, No Timeout

Character-Based Flow Control,

No Timeout

Two-Direction Flow Control

Flow Control with Timeout

Character-Based Flow Control

with Timeout

RS232 Handshaking allows control of data transmission from the scanner using software commands from the host device.

RTS/CTS Off: RTS/CTS is turned off so no data flow control is used, but RTS is still active.

RTS/CTS Off, RTS Inactive: RTS/CTS is turned off so no data flow control is used and RTS is inactive.

Flow Control, No Timeout: The scanner asserts RTS when it has data to send, and will wait indefinitely for CTS to be

asserted by the host.

Character-Based Flow Control, No Timeout: The scanner asserts RTS when it has a character to send, and will wait

indefinitely for CTS to be asserted by the host

Two-Direction Flow Control: The scanner asserts RTS when it is OK for the host to transmit. The host asserts CTS

when it is OK for the device to transmit.

Flow Control with Timeout: The scanner asserts RTS when it has data to send and waits for a delay (see RS232

Timeout on page 2-7) for CTS to be asserted by the host. If the delay time expires and CTS is not asserted, the device

transmit buffer is cleared and scanning may resume.

Character-Based Flow Control with Timeout: The scanner asserts RTS when it has a character to send and waits for a

delay (see RS232 Timeout on page 2-7) for CTS to be asserted by the host. If the delay time expires and CTS is not

asserted, the device transmit buffer is cleared and scanning may resume.

Default = RTS/CTS Off.

2 - 6

Page 21

RS232 Timeout

RS232 Timeout

XON/XOFF On

* XON/XOFF Off

ACK/NAK On

* ACK/NAK Off

Communication Timeout

When using Flow Control with Timeout, you must program the length of the delay you want to wait for CTS from the host.

Set the length (in milliseconds) for a timeout by scanning the bar code below, then setting the timeout (from 1-65535 milliseconds) by scanning digits from the inside back cover, then scanning Save.

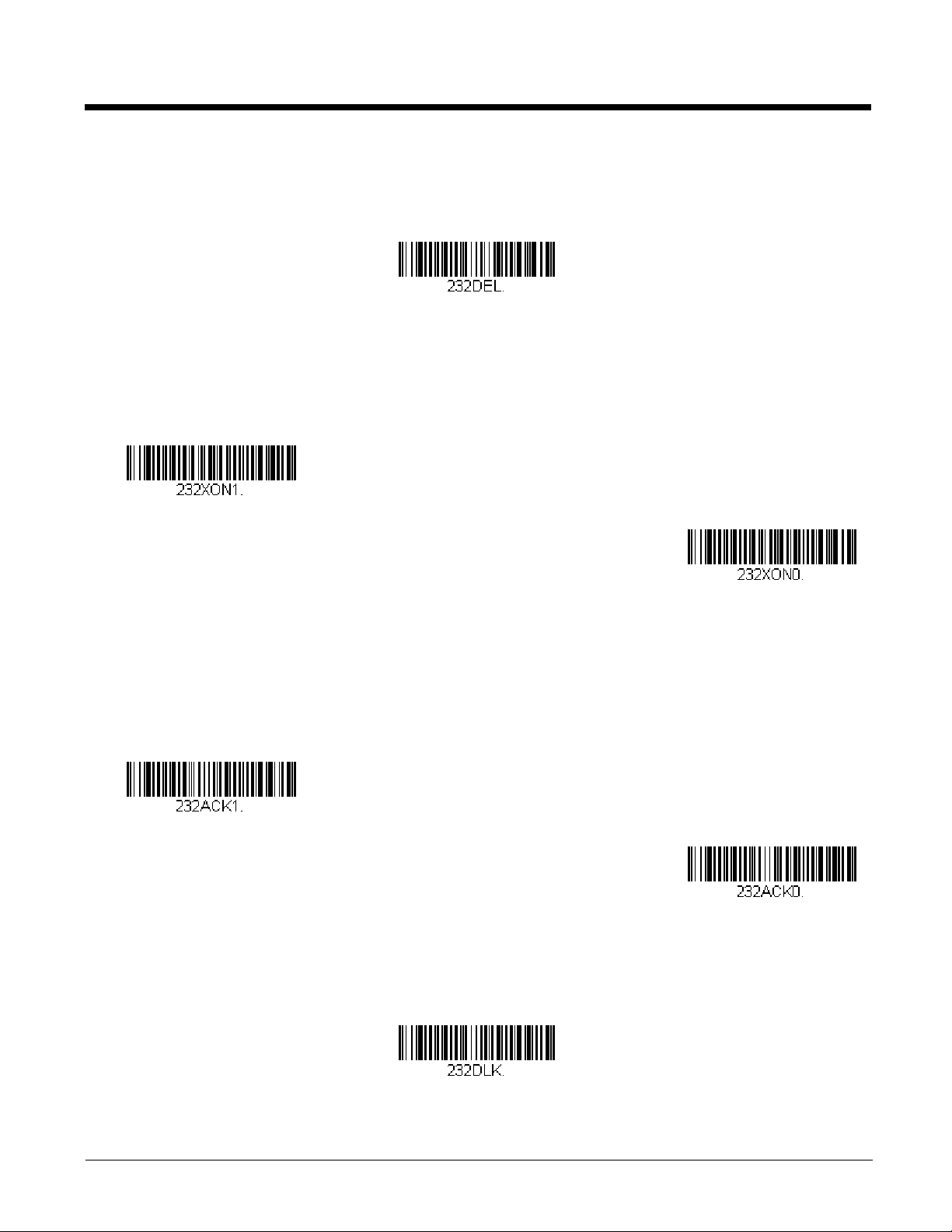

XON/XOFF

Standard ASCII control characters can be used to tell the scanner to start sending data (XON/XOFF On) or to stop sending

data (XON/XOFF Off). When the host sends the XOFF character (DC3, hex 13) to the scanner, data transmission stops.

To resume transmission, the host sends the XON character (DC1, hex 11). Data transmission continues where it left off

when XOFF was sent. Default = XON/XOFF Off.

ACK/NAK

After transmitting data, the scanner waits for an ACK character (hex 06) or a NAK character (hex 15) response from the

host. If ACK is received, the communications cycle is completed and the scanner looks for more bar codes. If NAK is

received, the last set of bar code data is retransmitted and the scanner waits for ACK/NAK again. Turn on the ACK/NAK

protocol by scanning the ACK/NAK On bar code below. To turn off the protocol, scan ACK/NAK Off. Default = ACK/NAK

Off.

Communication Timeout

This allows you to set the length (in milliseconds) for a timeout for the host ACK/NAK response. Scan the bar code below,

then set the timeout (from 1-65535 milliseconds) by scanning digits from the Programming Chart, then scanning Save.

Default = 2000 ms.

2 - 7

Page 22

Timeout Retries

Timeout Retries

O

f

f

* On

NAK Retries

BEL/CAN On

* BEL/CAN Off

This setting limits the number of Communication Timeout retries. If the Timeout Retries is set to 0, the transmission is

terminated after the initial Communication Timeout. Scan the bar code below, then set the number of retries (from 0-

255) by scanning digits from the Programming Chart, then scanning Save. (5 is the recommended setting.) Default =

0.

Communication Timeout Beeper

This selection programs the scanner to issue an error beep when a communication timeout has occurred. The error

beep sound is programmed using Number of Beeps – Error (page 3-5). Default = On.

NAK Retries

This selection limits the number of NAK retries that can occur in ACK/NAK mode. Scan the bar code below, then set the

number of retries (from 0-255) by scanning digits from the Programming Chart, then scanning Save. (5 is the recommended setting.) Default = 0, or disabled.

Support BEL/CAN in ACK/NAK

This protocol responds to <BEL> and <CAN> commands when in ACK/NAK mode. The scanner sounds an error tone

when a <BEL> command is sent from the host. <CAN> terminates the transmission. Default = BEL/CAN Off.

2 - 8

Page 23

RS232 Defaults

RS232 Defaults

* NCR ACK/NAK Off

NCR ACK/NAK On

* Transmit

Don’t Transmit

NCR Prefix

If you want the custom RS232 default settings restored to your scanner, scan the RS232 Defaults bar code below. This

resets the scanner to the custom default settings (see Setting Custom Defaults on page 1-2). If there are no custom

defaults, it will reset the scanner to the factory default settings. Any settings that have not been specified through the custom defaults will be restored to the factory default settings.

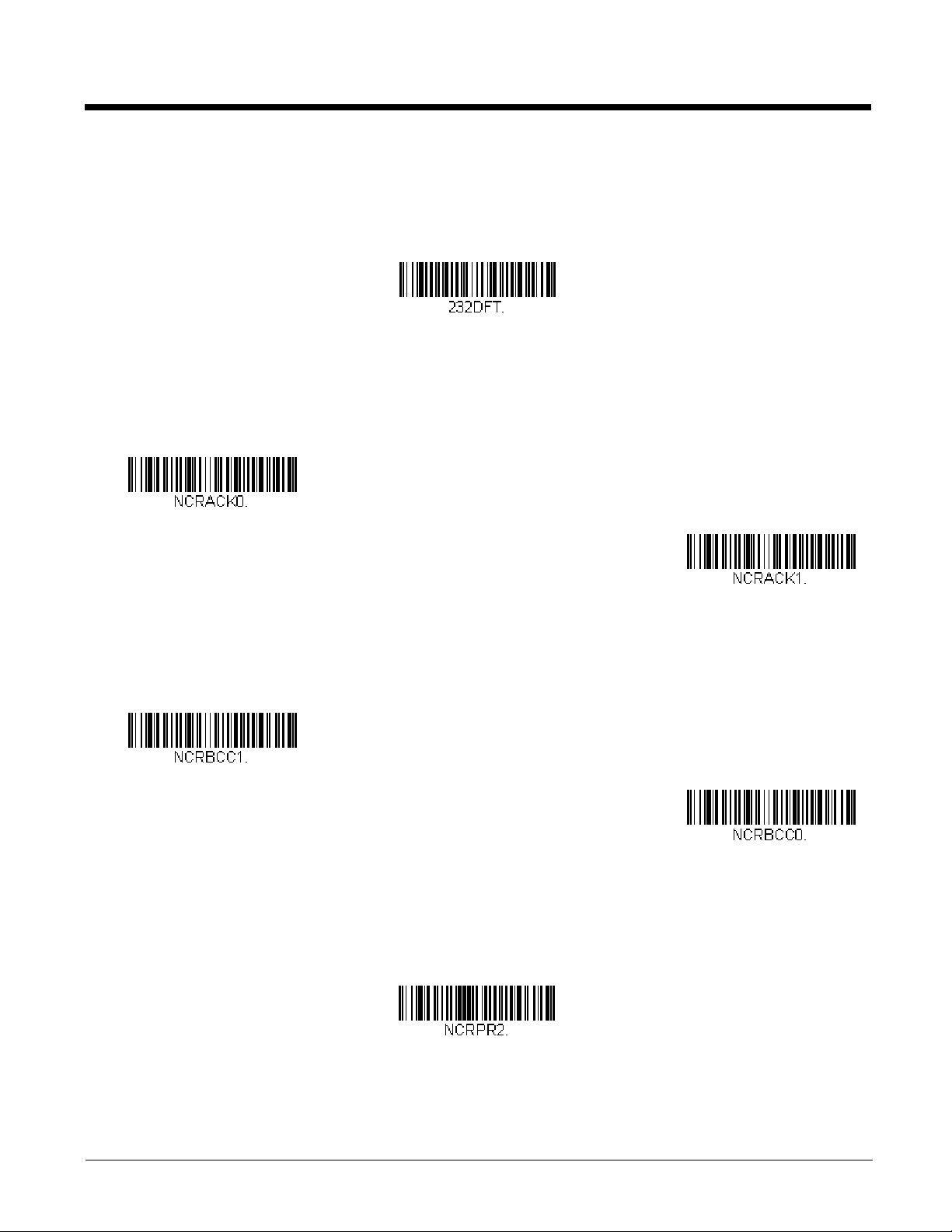

NCR Modifiers

NCR ACK/NAK

This is an NCR communication protocol for ACK/NAK processing. Default = NCR ACK/NAK Off.

Block Check Character

When this selection is set to Transmit, the NCR Block Check Character (BCC) is expected with incoming messages and

transmitted with outgoing messages. Default = Transmit.

NCR Prefix

This selection allows you to program an NCR-specific prefix. Refer to the ASCII Conversion Chart (Code Page

1252), page A-2 to find the hex equivalent for the characters you want for the NCR prefix (typically, 02 for STX). Scan the

bar code below, then set the hex number (from 0-FF) by scanning digits from the Programming Chart, then scanning Save.

Default = 0.

2 - 9

Page 24

NCR Suffix

NCR Suffix

Transmit

* Don’t Transmit

On

* Off

This selection allows you to program an NCR-specific suffix. Refer to the ASCII Conversion Chart (Code Page 1252), page

A-2 to find the hex equivalent for the characters you want for the NCR suffix (typically, 03 for ETX). Scan the bar code

below, then set the hex number (from 0-FF) by scanning digits from the Programming Chart, then scanning Save. Default

= 0.

NCR Prefix/Suffix

When set to Tra ns mit, both the NCR prefix and suffix are transmitted with bar codes. Usually, prefixes and suffixes are

programmed using the Data Editing selections (see Data Editing beginning on page 4-1), however, the following commands

override any other prefix/suffix settings. Default = Don’t Transmit.

NCR NOF (Not-on-File) Error

A scanner receives an NOF (Not on File) command from the POS whenever it cannot cross-reference the bar code to a

price parameter. When set to On, the error tone sounds (set via Number of Beeps – Error, page 3-5) for an NOF, and dis-

ables the scanner while the cashier looks up the price manually. When set to Off, no sound is emitted for an NOF. Default

= Off.

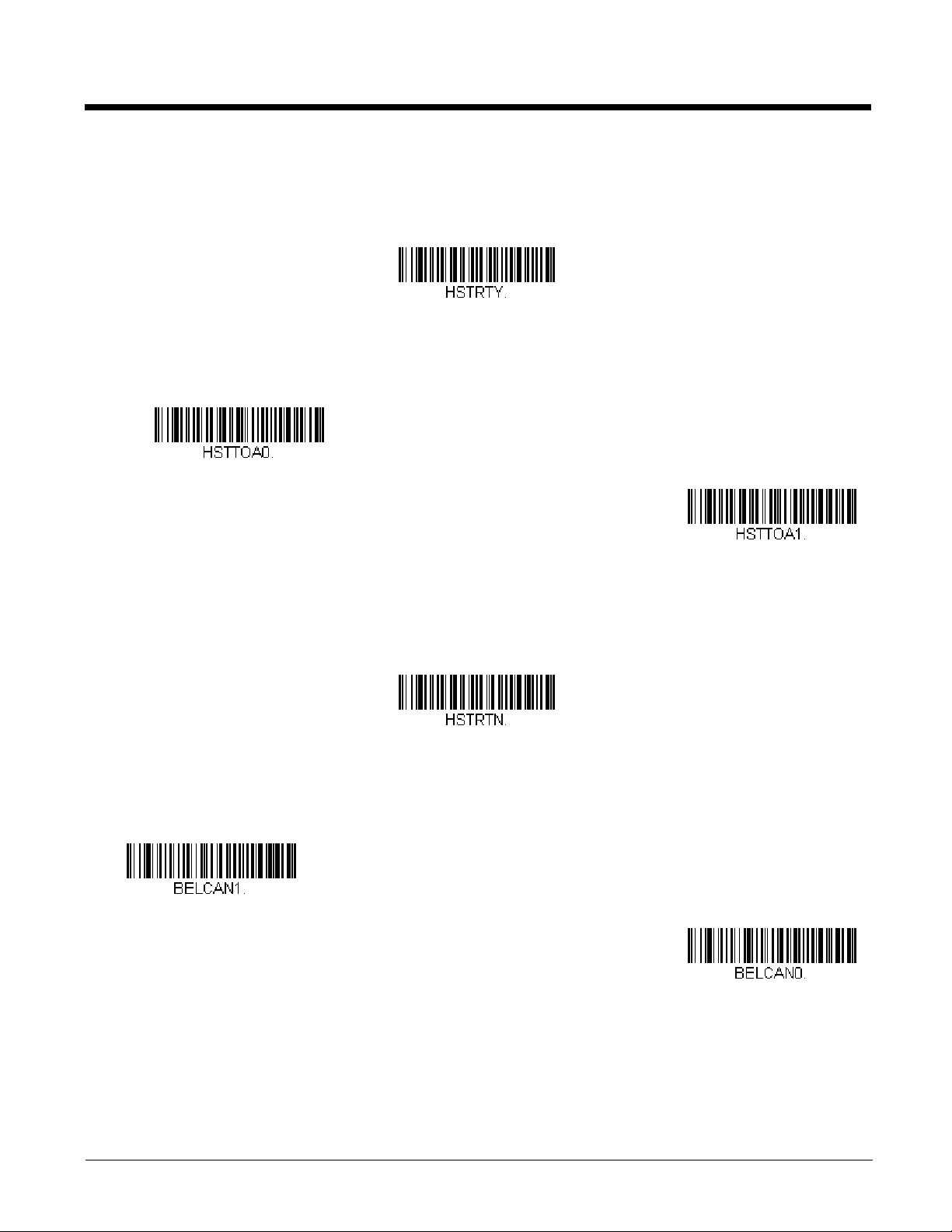

Scanner to Bioptic Communication

The following settings are used to set up communication between Honeywell scanners and bioptic scanners.

Note: The scanner’s baud rate must be set to 38400 and the RS232 timeout must be set to 3000 in order to communicate with

a bioptic scanner. See "RS232 Modifiers" on page 2-4, and RS232 Timeout on page 2-7 for further information.

2 - 10

Page 25

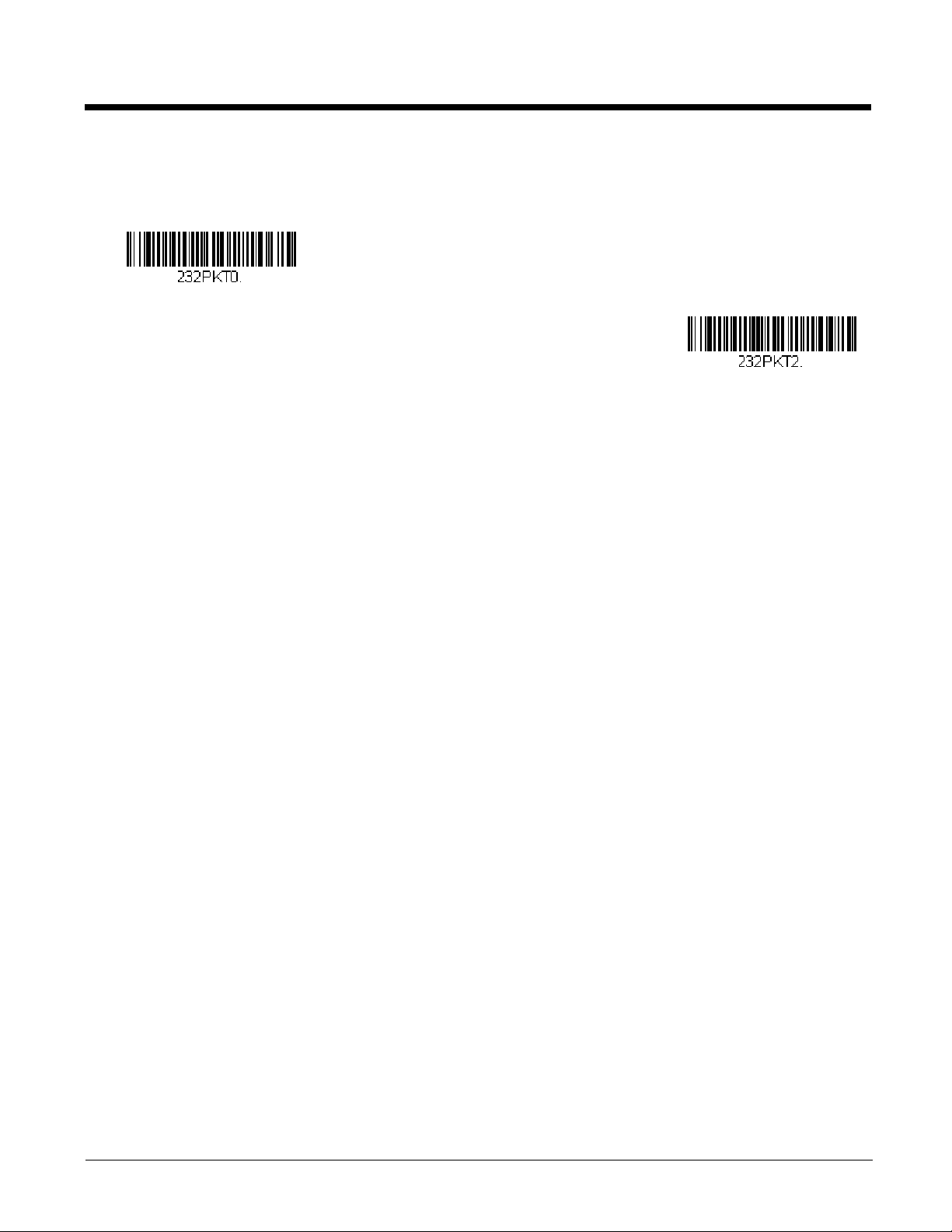

Scanner-Bioptic Packet Mode

* Packet Mode Off

Packet Mode On

Packet Mode On must be scanned to set the scanner’s format so it is compatible with a bioptic scanner. Default = Packet

Mode Off.

2 - 11

Page 26

2 - 12

Page 27

3

* Off

Sleep Mode Only

Hibernate Mode

Power Save Mode Timeout

Power Up Beeper Off -

Scanner

Input/Output Settings

Power Save Mode

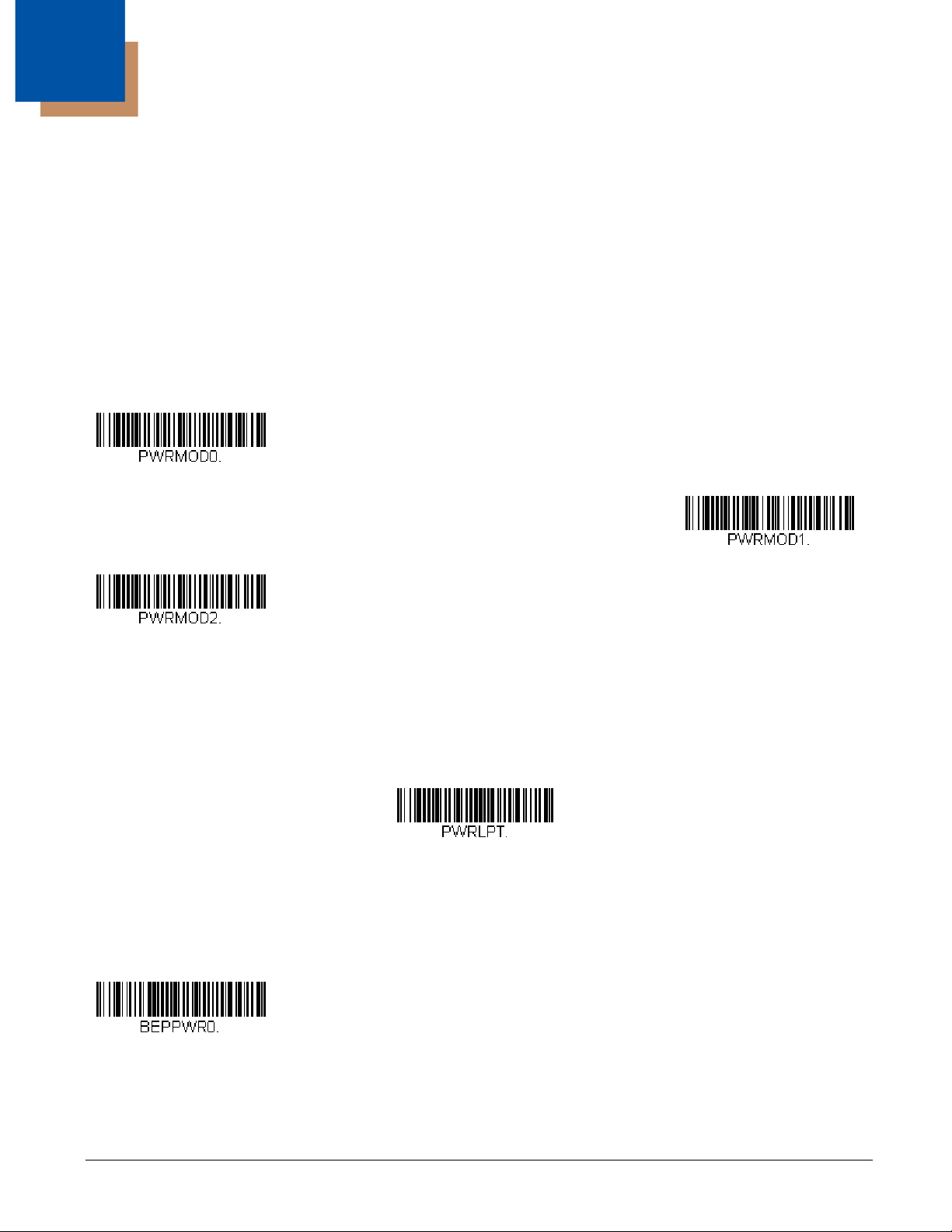

Power Save Mode allows you to automatically set the conditions under which the scanner idles, sleeps, and wakes up. When

Off is selected, no power saving is used and the scanner remains powered on until the trigger is pressed.

When Sleep Mode is selected, the scanner goes into sleep mode (powered off) after the time interval set using Power Save

Mode Timeout (page 3-1), during which there is no activity. This provides significant power savings over the Off setting.

When Hibernate Mode is selected, the scanner goes into idle mode after the time interval set using Power Save Mode Timeout

(page 3-1), during which there is no activity. After the same time interval has elapsed with no activity while the scanner is in idle

mode, the scanner goes into sleep mode (powered off). This provides additional power savings over the Sleep Mode setting,

but the scanner takes longer to wake up.

Default = Off.

Power Save Mode Timeout

Use this selection to set a timeout (in seconds) for the scanner when using Power Save Mode. When this time has

elapsed with no activity, the scanner will enter the Power Save Mode selected. After scanning the Power Save Mode

Timeout bar code, set the timeout duration (from 0-65535 seconds) by scanning digits on the Programming Chart

inside the back cover, then scanning Save. Default = 600 seconds.

Power Up Beeper

The scanner can be programmed to beep when it’s powered up. Scan the Off bar code(s) if you don’t want a power up beep.

Default = Power Up Beeper On - Scanner.

3 - 1

Page 28

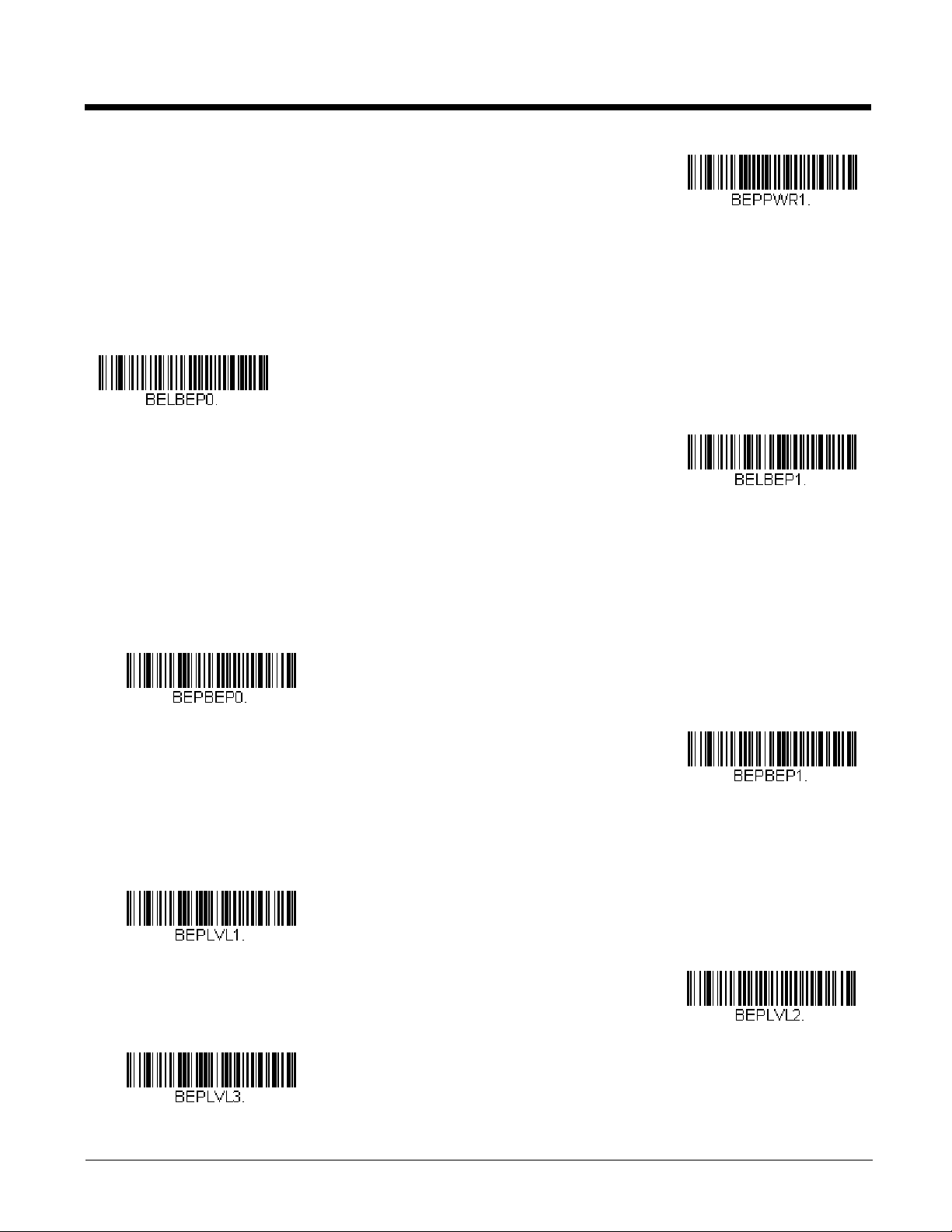

Beep on BEL Character

* Power Up Beeper On -

Scanner

*Beep on BEL Off

Beep on BEL On

Beeper - Good Read Off

* Beeper - Good Read On

Low

Medium

* High

You may wish to force the scanner to beep upon a command sent from the host. If you scan the Beep on BEL On bar code

below, the scanner will beep every time a BEL character is received from the host. Default = Beep on BEL Off.

Good Read and Error Indicators

Beeper – Good Read

The beeper may be programmed On or Off in response to a good read. Turning this option off only turns off the beeper

response to a good read indication. All error and menu beeps are still audible. Default = Beeper - Good Read On.

Beeper Volume – Good Read

The beeper volume codes modify the volume of the beep the scanner emits on a good read. Default = High.

3 - 2

Page 29

Beeper Pitch – Good Read

Off

Low (1600 Hz)

* Medium (3200 Hz)

High (4200 Hz)

* Before Transmission

After Transmission

Vibrate- Good Read Off

* Vibrate- Good Read On

The beeper pitch codes modify the pitch (frequency) of the beep the scanner emits on a good read. Default = Medium.

Beeper - Transmit Order

The beeper transmit order determines when the good read beep occurs. The scanner can be set to emit the good read

beep either before or after data transmission. Default = Before Transmission.

Vibrate – Good Read

The scanner vibrates once when a bar code is successfully read, and twice when a programming bar code is successfully

read. When a programming bar code is unsuccessful, the scanner emits one long vibration (2 times the Vibrate Duration

length). The trigger cannot be used again until the vibration has ended. Scan Vibrate - Good Read Off to keep the scanner from vibrating. This setting may be preferable if you need to scan multiple bar codes in succession and do not want to

wait till the vibration has ended. Default = Vibrate - Good Read On.

3 - 3

Page 30

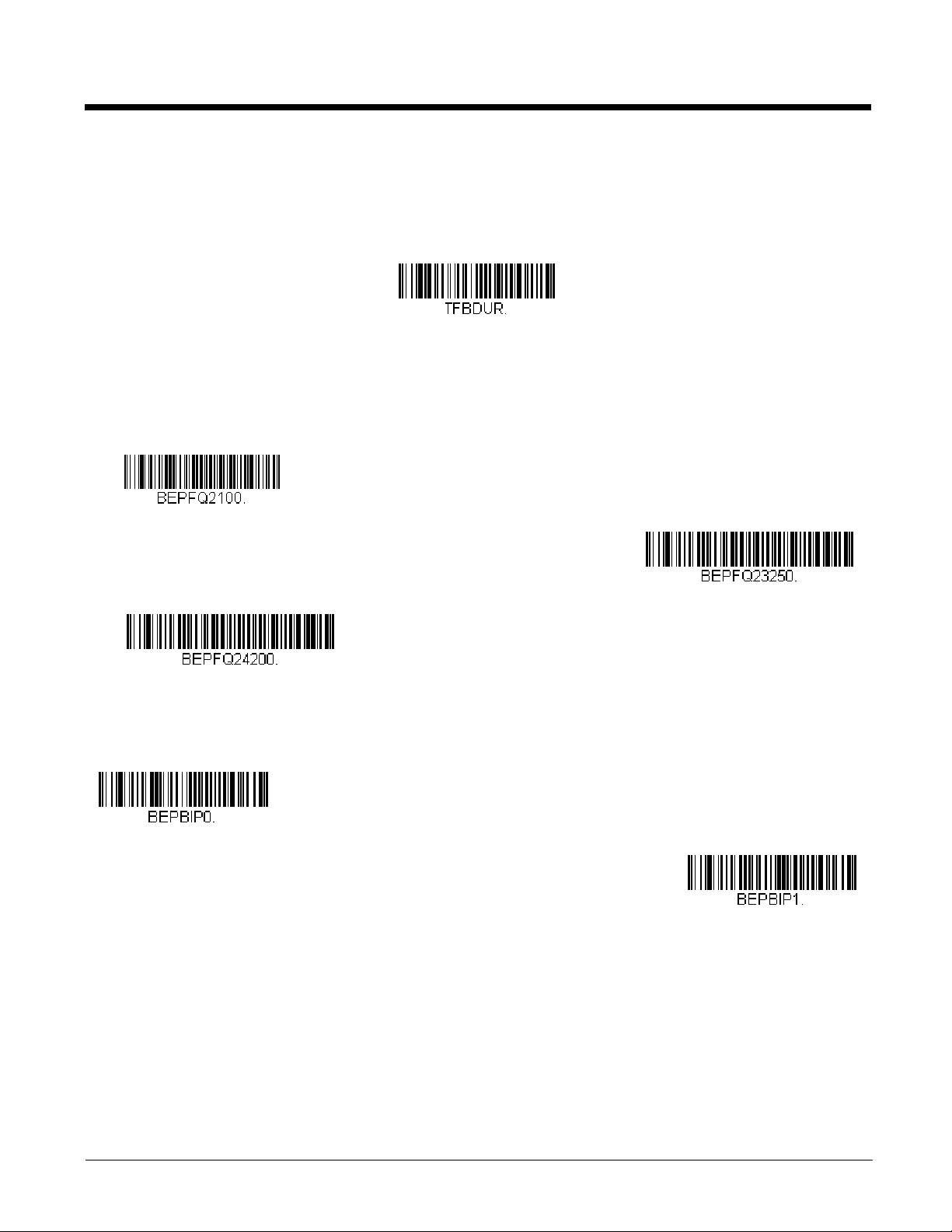

Vibrate Duration

Vibrate Duration

* Razz (100 Hz)

Medium (3250 Hz)

High (4200 Hz)

* Normal Beep

Short BeepShort Beep

If you want to set the length for the good read vibration, scan the bar code below, then set the duration (from 100 2,000 milliseconds) by scanning digits from the inside back cover, then scanning Save. If you need to scan multiple bar

codes in succession, you may wish to set a short duration time, since the trigger cannot be used until the vibration has

ended. Default = 300 ms.

Beeper Pitch – Error

The beeper pitch codes modify the pitch (frequency) of the sound the scanner emits when there is a bad read or error.

Default = Razz.

Beeper Duration – Good Read

The beeper duration codes modify the length of the beep the scanner emits on a good read. Default = Normal.

3 - 4

Page 31

Number of Beeps – Good Read

Number of Good Read Beeps/LED Flashes

Number of Error Beeps/LED Flashes

Beeper Volume Max

Laser Aimer - Scanning

Pattern Off

Laser Aimer - Scanning

Laser Dot

The number of beeps of a good read can be programmed from 1 - 9. The same number of beeps will be applied to the

beeper and LED in response to a good read. For example, if you program this option to have five beeps, there will be five

beeps and five LED flashes in response to a good read. The beeps and LED flashes are in sync with one another. To

change the number of beeps, scan the bar code below and then scan a digit (1-9) bar code and the Save bar code on the

Programming Chart inside the back cover of this manual. Default = 1.

Number of Beeps – Error

The number of beeps and LED flashes emitted by the scanner for a bad read or error can be programmed from 1 - 9. For

example, if you program this option to have five error beeps, there will be five error beeps and five LED flashes in response

to an error. To change the number of error beeps, scan the bar code below and then scan a digit (1-9) bar code and the

Save bar code on the Programming Chart inside the back cover of this manual. Default = 1.

Beeper Volume Max

Scan the following bar code to set all error and good read beeps to the maximum volume. This feature also sets the Beeper

Pitch – Good Read to the highest level.

Laser Aimer

Laser Aimer - Scanning Pattern

To set the laser light pattern that appears when scanning a bar code, you must first enter an aimer delay (see Aimer Delay

on page 3-7). Then scan one of the following bar codes to set a new scanning pattern.

Default = 10 Segment Line.

3 - 5

Page 32

Laser Aimer - Scanning Duration

Laser Aimer - Scanning

Blinking Dot

Laser Aimer - Scanning

3 Segment Line

Laser Aimer - Scanning

5 Segment Line

* Laser Aimer - Scanning

10 Segment Line

Laser Aimer - Scanning Duration

Laser Aimer - Good Read

Pattern Off

Laser Aimer - Good Read

3 Segment Line

Laser Aimer - Good Read

5 Segment Line

Use the Laser Aimer - Scanning Duration bar code to specify how long you want the Laser Aimer - Scanning Pattern to

remain on after the trigger is released. Scan the bar code below, then set the duration (from 0 - 65535 milliseconds) by

scanning digits from the inside back cover, then scanning Save. Default = 0 ms.

Laser Aimer - Good Read Pattern

Once a bar code has been successfully read, you may want the laser light to remain on, but to display a different pattern

than the scanning pattern. This gives the operator an additional visual indicator that the bar code was successfully read.

Scan one of the bar codes below to program your device for a Good Read Pattern. Default = 10 Segment Line.

3 - 6

Page 33

Laser Aimer - Good Read Duration

* Laser Aimer - Good Read

10 Segment Line

Laser Aimer - Good Read Duration

200 milliseconds

400 milliseconds

* Off (no delay)

Delay Duration

Use the Laser Aimer - Good Read Duration bar code to specify how long you want the Laser Aimer - Good Read Pattern

to remain on after a bar code has been successfully read. Scan the bar code below, then set the duration (from 0 - 65535

milliseconds) by scanning digits from the inside back cover, then scanning Save. Default = 0 ms.

Aimer Delay

The aimer delay allows a delay time for the operator to aim the scanner before the bar code is scanned. Use these codes

to set the time between when the trigger is pulled and when the bar code is scanned. During the delay time, the aiming

light will appear, but scanning will not begin until the delay time is over. Default = Off.

User-Specified Aimer Delay

If you want to set your own length for the duration of the delay, scan the bar code below, then set the time-out by scanning digits (0 - 4,000 ms) from the Programming Chart inside the back cover of this manual, then scan Save.

3 - 7

Page 34

LED Indicators

Red LED Off

Green LED Off

Red LED On with Good Scan

* Green LED On with Good Scan

* Red LED On with Laser

Green LED On with Laser

Red LED On when CodeGate

Disabled

Green LED On when CodeGate

Disabled

Red LED On with CTS

Green LED On with CTS

The green and red LEDs can be programmed to be On or Off and at different brightness levels to indicate various scanner

states. Use the following bar codes to program the LED indicators.

LED Settings

Default = Red LED On with Laser, Green LED On with Good Scan.

3 - 8

Page 35

Good Read Delay

* No Delay

Short Delay (500 ms)

Medium Delay (1,000 ms)

Long Delay (1,500 ms)

User-Specified Good Read Delay

Out-of-Stand Defaults

This sets the minimum amount of time before the scanner can read another bar code. Default = 0 ms (No Delay).

User-Specified Good Read Delay

If you want to set your own length for the good read delay, scan the bar code below, then set the delay (from 0 - 30,000 milliseconds) by scanning digits from the inside back cover, then scanning Save.

Out-Of-Stand Settings

The following settings program the scanner’s behavior when it is out of the stand, or hand-held.

Note: The Granit 1280i does not support In-Stand settings. It supports only the standard Honeywell Out-of-Stand settings.

Caution: When working with Out-of-Stand settings, enable the settings you want before disabling those you do not

want to use. If you disable settings first, you may program the scanner so it is unable to read bar codes. if

this happens, power cycle the scanner and scan the defaults bar code on page 1-2.

Out-of-Stand Defaults

If you want the Out-of-Stand default settings restored to your scanner, scan the Out-of-Stand Defaults bar code below.

This resets the scanner to the custom default settings (see Setting Custom Defaults on page 1-2). If there are no custom

defaults, it will reset the scanner to the factory default settings. Any settings that have not been specified through the custom defaults will be defaulted to the factory default settings.

3 - 9

Page 36

Presentation Mode

Presentation Mode Out-

of-Stand

Manual Activation Mode Off

Out-of-Stand

* Manual Activation Mode On

Out-of-Stand

Do Not End Manual Activation

After Good Read Out-of-Stand

* End Manual Activation After

Good Read Out-of-Stand

When the scanner is in Presentation Mode, it automatically detects bar codes, then scans and transmits the data. To set

the time period before the scanner can read the same bar code a second time use Reread Delay (page 3-11). To return to

trigger scanning, scan the Out-of-Stand Defaults bar code, above.

Manual Activation Mode

In Manual Activation Mode, you must press the trigger to scan a bar code. The scanner scans until a bar code is read, or

until the trigger is released. Default = Manual Activation On Out-of-Stand.

End Manual Activation After Good Read

After a bar code is successfully read, the laser can be programmed either to remain on and scanning, or to turn off. When

End Manual Activation After Good Read is enabled, the laser turns off and stops scanning after a good read. If you scan

Do Not End Manual Activation After Good Read, the laser remains on after a good read, but the trigger must be pressed

to scan the next bar code. Default = End Manual Activation After Good Read Out-of-Stand.

3 - 10

Page 37

Manual Activation Laser Timeout - Trigger Settings

Laser Timeout - Trigger Hold

Out-of-Stand

Laser Timeout - Trigger

Release Out-of-Stand

Short (500 ms)

* Medium (750 ms)

Long (1000 ms)

Extra Long (2000 ms)

User-Specified Reread Delay

You can set a timeout for the length of time the laser remains on and attempting to decode bar codes when the trigger is

held down, and after it is released. Set the length (in milliseconds) for a timeout by scanning one of the following bar codes,

then setting the timeout (from 1-65535 milliseconds) by scanning digits from the Programming Chart, then scanning Save.

Default = Trigger Hold Out-of-Stand 30,000 ms, Trigger Release Out-of-Stand 0.

Reread Delay

This sets the time period before the scanner can read the same bar code a second time. Setting a reread delay protects against

accidental rereads of the same bar code. Longer delays are effective in minimizing accidental rereads. Use shorter delays in

applications where repetitive bar code scanning is required. Reread Delay only works when in a Presentation Mode (see page

3-10). Default = Medium.

User-Specified Reread Delay

If you want to set your own length for the reread delay, scan the bar code below, then set the delay (from 0-30,000 milliseconds) by scanning digits from the inside back cover, then scanning Save.

3 - 11

Page 38

CodeGate

CodeGate Off

Out-of-Stand

* CodeGate On

Out-of-Stand

* Off

On

Activation Character

When CodeGate is On, the trigger is used to allow decoded data to be transmitted to the host system. The scanner remains on,

scanning and decoding bar codes, but the bar code data is not transmitted until the trigger is pressed. When CodeGate is Off,

bar code data is transmitted when it is decoded. Default = CodeGate On Out-of-Stand.

®

Character Activation Mode

You may use a character sent from the host to trigger the scanner to begin scanning. When the activation character is received,

the scanner continues scanning until either the Character Activation Timeout (page 3-13), the deactivation character is received

(see Deactivation Character on page 3-14), or a bar code is transmitted. Scan the following On bar code to use character activation, then use Activation Character (following) to select the character you will send from the host to start scanning. Default =

Off.

Activation Character

This sets the character used to trigger scanning when using Character Activation Mode. On the ASCII Conversion Chart

(Code Page 1252), page A-2, find the hex value that represents the character you want to use to trigger scanning. Scan

the following bar code, then use the Programming Chart to read the alphanumeric combination that represents that ASCII

character. Scan Save to finish. Default = 18 [CAN].

3 - 12

Page 39

End Character Activation After Good Read

Do Not End Character Activation

After Good Read

* End Character Activation After

Good Read

Character Activation Timeout

* Off

On

After a bar code is successfully detected and read from the scanner, the illumination can be programmed either to remain

on and scanning, or to turn off. When End Character Activation After Good Read is enabled, the illumination turns off

and stops scanning after a good read. If you scan Do Not End Character Activation After Good Read, the illumination

remains on after a good read. Default = End Character Activation After Good Read.

Character Activation Timeout

You can set a timeout for the length of time the illumination remains on and attempting to decode bar codes when using

Character Activation Mode. Set the length (in milliseconds) for a timeout by scanning the following bar code, then setting

the timeout (from 1-65,535 milliseconds) by scanning digits from the Programming Chart inside the back cover of this manual, then scanning Save. Default = 5000 ms.

Character Deactivation Mode

If you have sent a character from the host to trigger the scanner to begin scanning, you can also send a deactivation character

to stop scanning. Scan the following On bar code to use character deactivation, then use Deactivation Character (following) to

select the character you will send from the host to terminate scanning. Default = Off.

3 - 13

Page 40

Deactivation Character

Deactivation Character

0

Bar Code 1

Bar Code 2

10 20 30 40 50 60 70 80 90 100%

Centering On

* Centering Off

Left of Centering Window

This sets the character used to terminate scanning when using Character Deactivation Mode. On the ASCII Conversion

Chart (Code Page 1252), page A-2, find the hex value that represents the character you want to use to terminate scanning.

Scan the following bar code, then use the Programming Chart inside the back cover of this manual to read the alphanumeric combination that represents that ASCII character. Scan Save to finish. Default = 68 [h].

Centering

Use Centering to narrow the scanner’s field of view to make sure that when the scanner is hand-held, it reads only those bar

codes intended by the user. For instance, if multiple codes are placed closely together, centering will insure that only the

desired codes are read. (Centering can be used in conjunction with Centering, page 3-14, for the most error-free operation in

applications where multiple codes are spaced closely together. Using the Aimer Delay and Centering features, the scanner can

emulate the operation of older systems, such as linear laser bar code scanners.)

If a bar code is not touched by a predefined window, it will not be decoded or output by the scanner. If centering is turned on by

scanning Centering On, the scanner only reads codes that pass through the centering window you specify using the Left and

Right of Centering Window bar codes.

In the example below, the white box is the centering window. The centering window has been set to 20% left and 30% right.

Since Bar Code 1 passes through the centering window, it will be read. Bar Code 2 does not pass through the centering window, so it will not be read.

Note: A bar code needs only to be touched by the centering window in order to be read. It does not need to pass completely

through the centering window.

Scan Centering On, then scan one of the following bar codes to change the left or right of the centering window. Then scan the

percent you want to shift the centering window using digits on the inside back cover of this manual. Scan Save. Default Cen-

tering = 40% Left, 60% Right.

3 - 14

Page 41

Blinky Mode

Right of Centering Window

* Blinky Mode Off

Blinky Mode On

Blinky Always On/

Continuous

* Full Laser Beam Sweep

Reduced Laser Beam Sweep

Wide Laser Beam Sweep

When either Blinky Mode On or Blinky Always On/Continuous is scanned, the scanner blinks on and off at 50% duty cycle

(250 milliseconds on, then 250 milliseconds off.) Default = Blinky Mode Off.

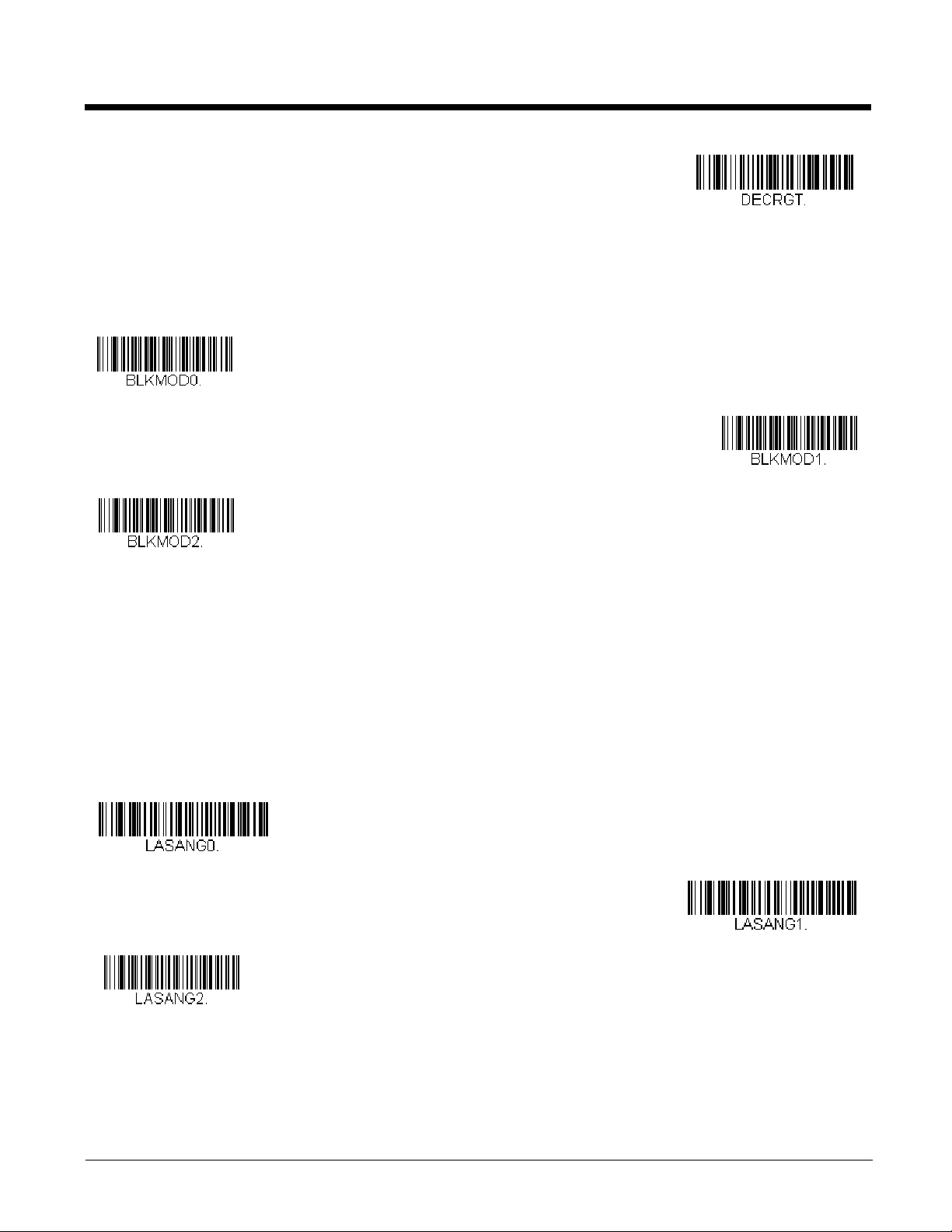

Laser Scan Angle

The laser scan angle can be set to several different widths in order to adjust to your particular scanning requirements.

Full Laser Beam Sweep: This is the default setting that produces a 13.5° laser beam.

Reduced Laser Beam Sweep: If you are aiming at a longer distance and the laser beam becomes too wide and touches adja-

cent bar codes, you may need to adjust the width of the beam. In this case, scan the Reduced Laser Beam Sweep bar code

below to narrow the laser beam.

Wide Laser Beam Sweep: If you have an exceptionally wide medium or high density bar code, you could use the wider sweep

so the laser beam encompasses all of the code.

Note: When using Wide Laser Beam Sweep, the depth of field is reduced.

3 - 15

Page 42

Decode Security

* Low

Low/Medium

Medium/High

High

Continuous Scan Mode

This selection allows you to adjust the decode security needed while scanning. For good quality codes, choose Low to achieve

fast scan speed. For codes prone to misreads, choose High. Default = Low.

Note: Increasing the security level may decrease the scan speed.

Continuous Scan Mode

This programs the engine to continuously scan and decode, with the laser and motor staying on.

Note: When operating in Continuous Scan Mode, the scanner’s upper operating temperature is 104°F (40°C).

Output Sequence Overview

Output Sequence Editor

This programming selection allows you to program the scanner to output data (when scanning more than one symbol) in

whatever order your application requires, regardless of the order in which the bar codes are scanned. Reading the Default

Sequence symbol programs the scanner to the Universal values, shown below. These are the defaults. Be certain you

want to delete or clear all formats before you read the Default Sequence symbol.

Note: To make Output Sequence Editor selections, you’ll need to know the code I.D., code length, and character match(es)

your application requires. Use the Alphanumeric symbols (inside back cover) to read these options. You must hold

the trigger while reading each bar code in the sequence.

To Add an Output Sequence

1. Scan the Enter Sequence symbol (see Require Output Sequence, page 3-19).

2. Code I.D.

On the Symbology Charts on page A-1, find the symbology to which you want to apply the output sequence format.

Locate the Hex value for that symbology and scan the 2 digit hex value from the Programming Chart (inside back

cover).

3. Length

Specify what length (up to 9999 characters) of data output will be acceptable for this symbology. Scan the four digit

data length from the Programming Chart. (Note: 50 characters is entered as 0050. 9999 is a universal number,

3 - 16

Page 43

indicating all lengths.) When calculating the length, you must count any programmed prefixes, suffixes, or formatted

A - Code 39

B - Code 128

C - Code 93

characters as part of the length (unless using 9999).

4. Character Match Sequences

On the ASCII Conversion Chart (Code Page 1252), page A-2, find the Hex value that represents the character(s) you

want to match. Use the Programming Chart to read the alphanumeric combination that represents the ASCII

characters. (99 is the Universal number, indicating all characters.)

5. End Output Sequence Editor

Scan F F to enter an Output Sequence for an additional symbology, or Save to save your entries.

Other Programming Selections

• Discard

This exits without saving any Output Sequence changes.

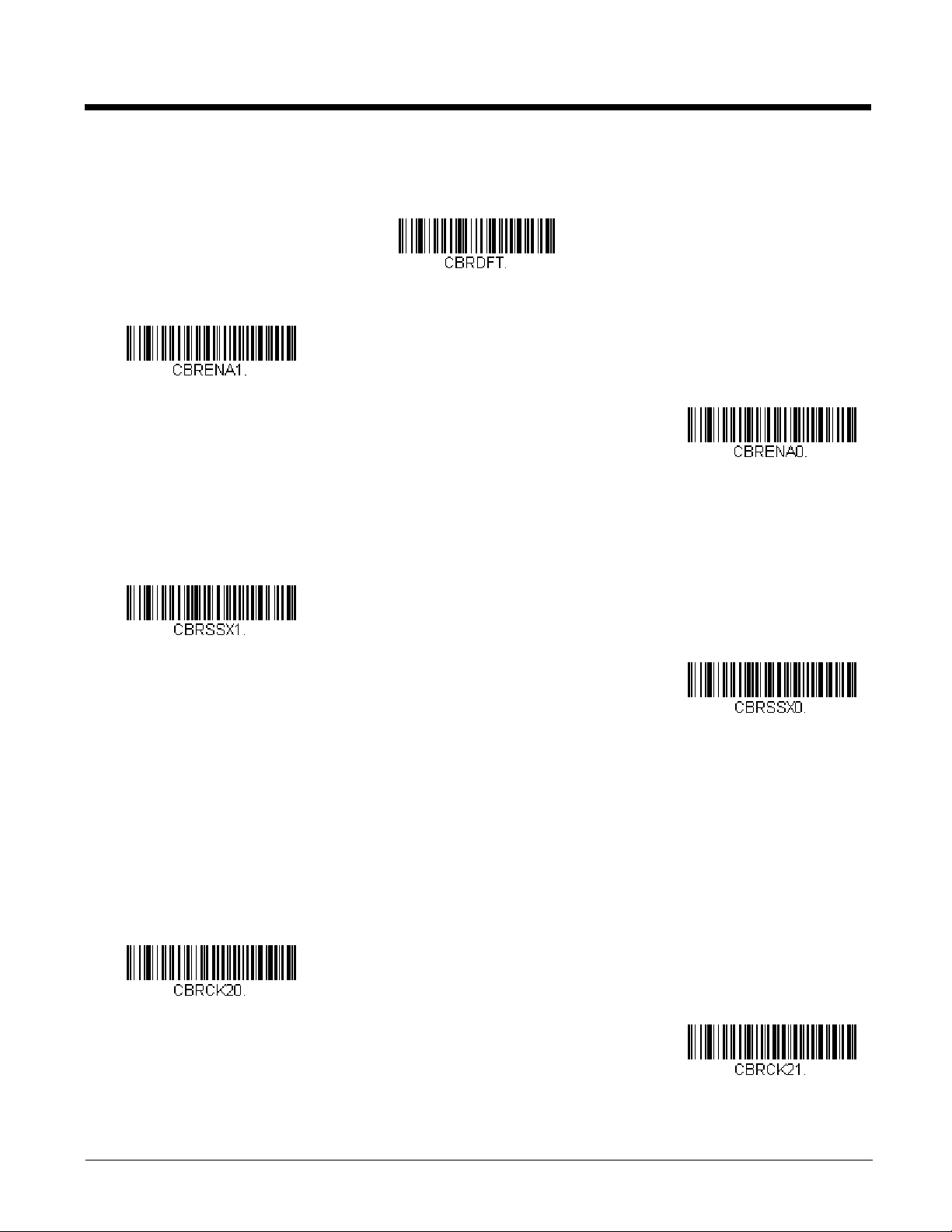

Output Sequence Example

In this example, you are scanning Code 93, Code 128, and Code 39 bar codes, but you want the scanner to output Code 39

1st, Code 128 2nd, and Code 93 3rd, as shown below.

Note: Code 93 must be enabled to use this example.

You would set up the sequence editor with the following command line:

SEQBLK62999941FF6A999942FF69999943FF

The breakdown of the command line is shown below:

SEQBLKsequence editor start command

62 code identifier for Code 39

9999 code length that must match for Code 39, 9999 = all lengths

41 start character match for Code 39, 41h = “A”

FF termination string for first code

6A code identifier for Code 128

9999 code length that must match for Code 128, 9999 = all lengths

42 start character match for Code 128, 42h = “B”

FF termination string for second code

69 code identifier for Code 93

9999 code length that must match for Code 93, 9999 = all lengths

43 start character match for Code 93, 43h = “C”

FF termination string for third code

To program the previous example using specific lengths, you would have to count any programmed prefixes, suffixes, or for-

matted characters as part of the length. If you use the example on page 3-17, but assume a <CR> suffix and specific code

lengths, you would use the following command line:

SEQBLK62001241FF6A001342FF69001243FF

3 - 17

Page 44

The breakdown of the command line is shown below:

Enter Sequence

Default Sequence

Sequence Timeout

Sequence Match Beeper Off

SEQBLKsequence editor start command

62 code identifier for Code 39

0012 A - Code 39 sample length (11) plus CR suffix (1) = 12

41 start character match for Code 39, 41h = “A”

FF termination string for first code

6A code identifier for Code 128

0013 B - Code 128 sample length (12) plus CR suffix (1) = 13

42 start character match for Code 128, 42h = “B”

FF termination string for second code

69 code identifier for Code 93

0012 C - Code 93 sample length (11) plus CR suffix (1) = 12

43 start character match for Code 93, 43h = “C”

FF termination string for third code