Honda XL200 2001-2016 Service Manual

SERVICE INFORMATION 16-1

TROUBLESHOOTING 16-2

CDI SYSTEM INSPECTION 16-3

IGNITION COIL 16-3

PULSE GENERATOR 16-4

EXCITER COIL 16-5

IGNITION TIMING 16-6

SERVICE INFORMATION

GENERAL

t

h

• When checking the ignition system, always follow steps in the troubleshooting flow chart (page 16-2).

• The CDI unit may be damaged if dropped. Also, if the connector is disconnected when current is present, the excessive

voltage may damage the unit. Always turn off the ignition switch before servicing.

• Ignition timing cannot be adjusted since the CDI unit is non-adjustable. If ignition timing is incorrect, check the system

components and replace any faulty parts.

• A faulty ignition system is often related to poorly connected or corroded connectors. Check those connections before

proceeding.

• Use spark plug of the correct heat range. Using spark plug with an incorrect heat range can damage the engine.

• For stator removal and installation, see section 9.

• Some electrical components may be damaged if terminals or connectors are connected or disconnected while the ignition

switch is ON and current is present.

• If the engine must be running to do some work, make sure the area is well-ventilated. Never run the engine in an enclosed

area.

• The exhaust contains poisonous carbon monoxide gas that may cause loose of consciousness and may lead to death.

XL200

16. IGNITION SYSTEM

16-1

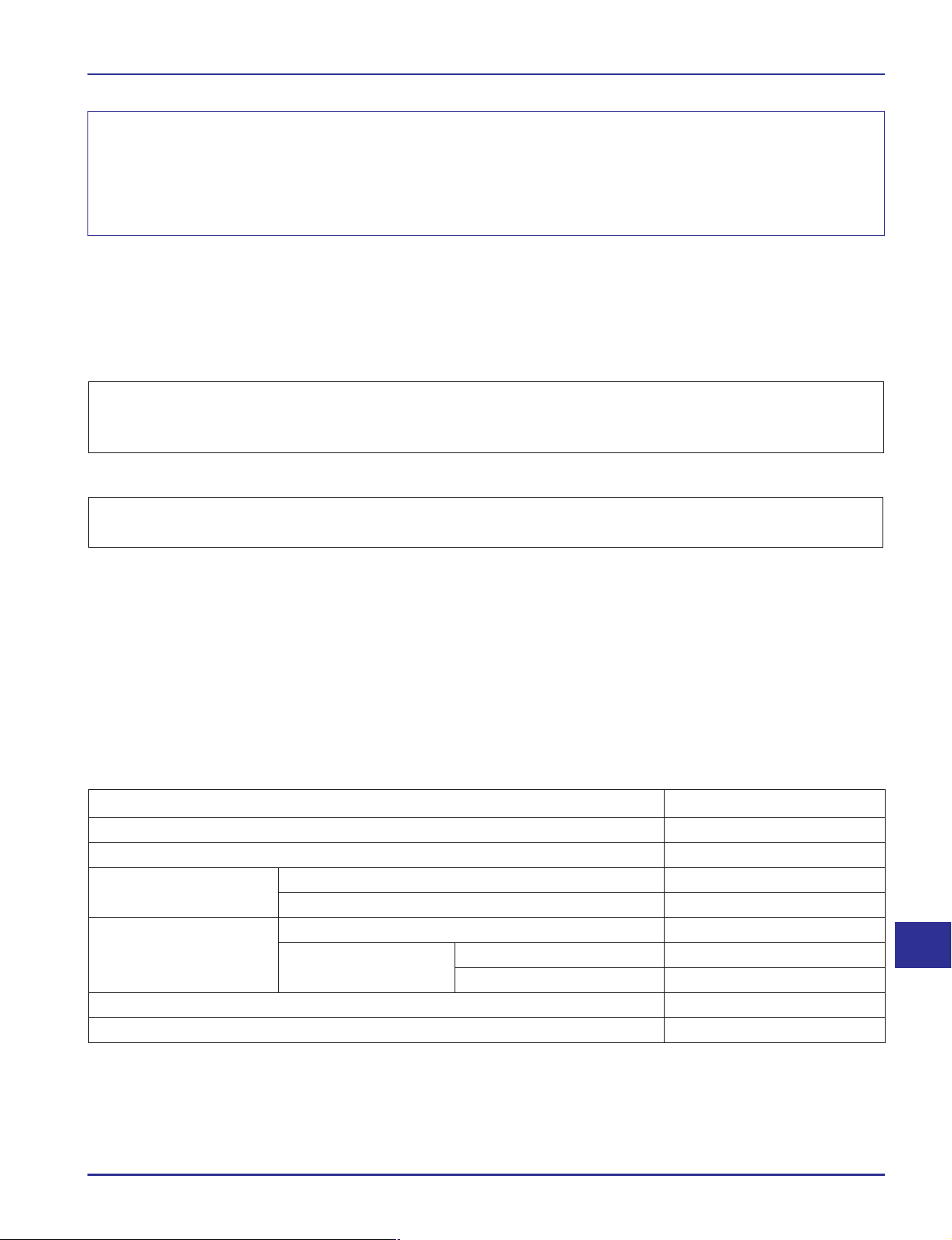

ITEM STANDARD

Spark plug

DP8EA-9(NGK) X24EP-U9 (DENSO)

Spark plug gap 0,8—0,9 mm (0.031 - 0.035 in)

Ignition timing “F” mark 15° BTDC a 1300 rpm

Full advance 32° BTDC a 5.500 rpm

Ignition coil Primary coil resistance 0,4—0,6

(20°C/68°F)

Secondary coil without plug cap 10,8—16,2k

resistance

with plug cap 15—22k

Exciter coil resistance 100-300 (20°C/68°F)

Pulse generator resistance (20°C/68°F) 293—358

SPECIFICATION

16

XL200

IGNITION SYSTEM

16-0

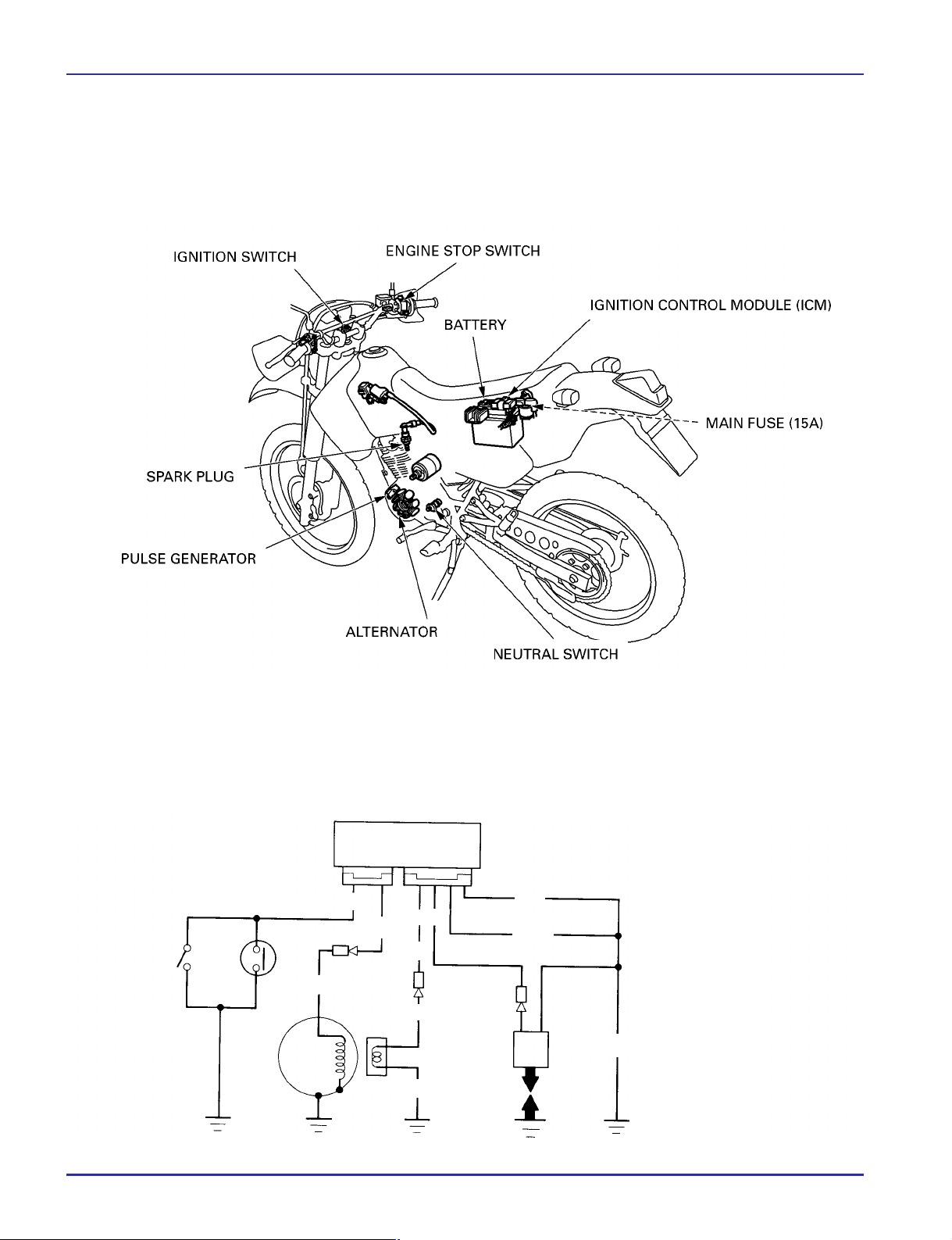

(5) CDI UNIT

(2) ENGINE STOP SWITCH

B/W

B/R

B/R

L/Y

L/Y

B/Y

G

G/W

(3) IGNITION COIL

(9) PULSE

GENERATOR

(1) IGNITION

SWITCH

(8) ALTERNATOR (10) SPARK PLUG

B…BLACK

R…RED

L…BLUE

Y…YELLOW

W…WHITE

G…GREEN

XL200

16-2

TROUBLESHOOTING

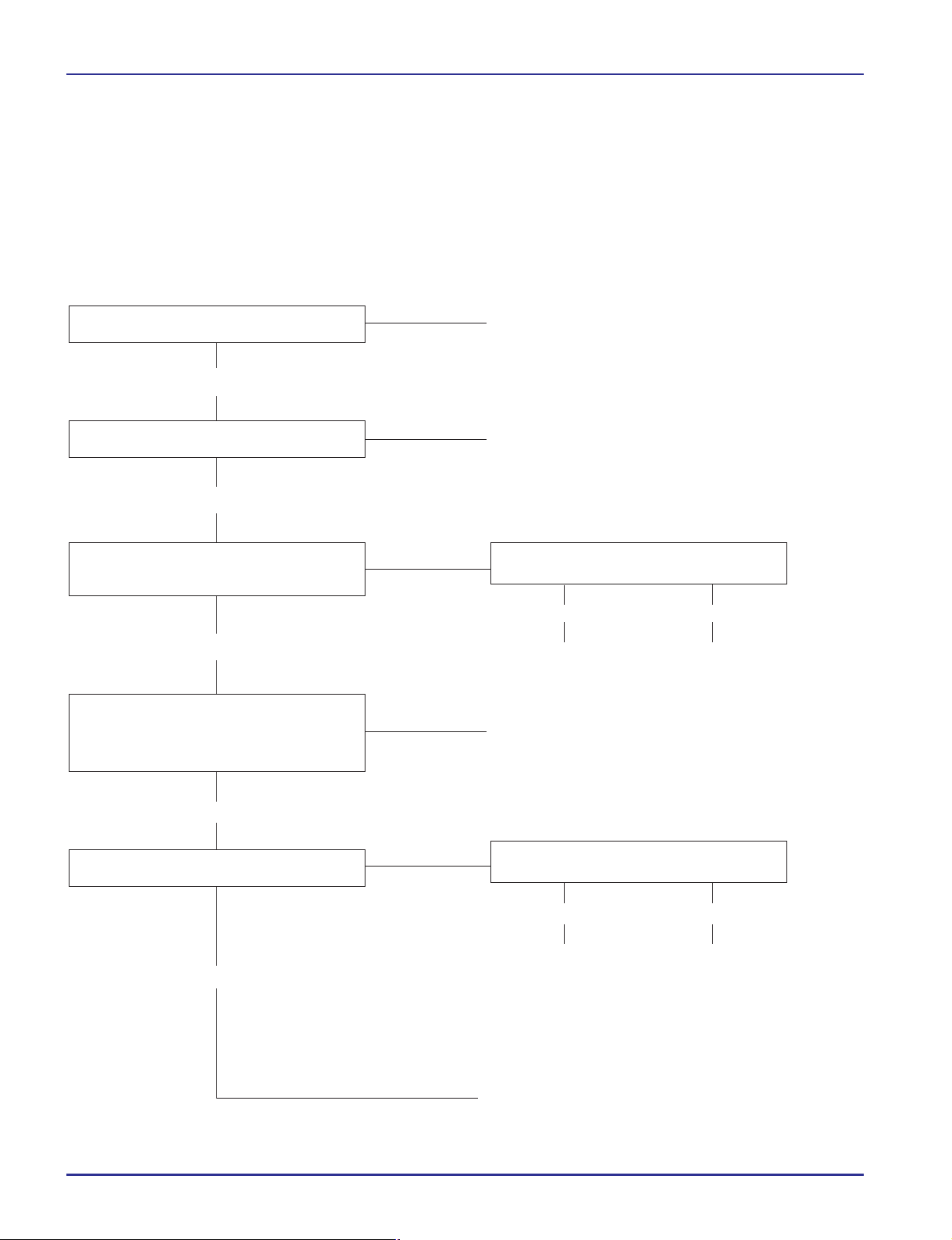

• Inspect the followings before diagnosing the system.

– Faulty spark plug.

– Loose spark plug cap or spark plug wire connections.

– Water got into the spark plug cap (Leaking the ignition coil secondary voltage).

• Temporarily exchange the ignition coil with the other good one and perform spark test. If there is spark, the exchanged

ignition coil is faulty.

Weak or no spark at plug

IGNITION SYSTEM

Check the ignition secondary coil

resistance (page 16-3).

Normal

Abnormal

Abnormal

Abnormal

Normal Abnormal

Abnormal

Check the CDI unit connectors for loose or

poorly contact.

Normal

Check the ignition coil resistance at the CDI

unit 4P connector (page 16-3).

Normal

Measure voltage between Black/White and

Green terminals of CDI unit.

Continuity should exist with ignition switch

“ON”.

Normal

Check the pulse generator resistance at the

CDI unit 4P connector.

• Faulty ignition coil

• Faulty spark plug wire

• Loose or poorly contact connectors

• Check the ignition coil.

Abnormal

Normal Abnormal

• Check the pulse generator.

• Open or short circuit

in wire harness

• Faulty ignition switch

• Open or short circuit in wire harness

• Faulty ignition coil

• Open or short circuit

in wire harness

• Loose or poorly

contact connectors

• Faulty CDI unit.

• Faulty pulse

generator

Normal

Loading...

Loading...