HONDA GENERATOR/WELDER

OWNER’S MANUAL

1 HONDA MOTOR CO., LTD. 1983

Thank you for purchasing a Honda generator/welder.

This manual covers operation and maintenance of the EW170 Generator/

welder. All information in this publication is based on the latest product

information available at the time of approval for printing.

Honda Motor Co., Ltd. reserves the right to make changes at any time without

notice and without incurring any obligation.

No part of this publication may be reproduced without written permission.

This manual should be considered a permanent part of the welder and should

remain with the welder if it is sold.

Pay special attention to statements preceded by the following words:

B Indicates a strong possibility of severe personal injury or loss of

life if instructions are not followed.

CAUTION: Indicates a possibility of personal injury or equipment damage if

instructions are not followed.

NOTE: Gives helpful information.

If a problem should arise, or if you have any questions about this product,

consult an authorized Honda dealer.

B Welding is potentially a very hazardous activity.

It should only be attempted by a trained welder with a thorough knowledge

of proper welding techniques and safety procedures.

This Honda product is designed to give safe and dependable service if operated

according to instructions. Read and understand the owner’s Manual before

operating this product. Failure to do,so could result in personal injury or

equipment damage.

,

CONTENTS

CONTENTS

1. GENERATOR/WELDER SAFETY

2. COMPONENT IDENTIFICATION

3. PRE-OPERATION CHECK

4. .STARTING THE ENGINE .................................

5. OPERATION

6. STOPPING THE ENGINE .................................. 21

7. MAINTENANCE., .......................................

8. TRANSPORTING/STORAGE .............................. 30

9. TROUBLESHOOTING

10. SPECIFICATIONS

11. WIRINGDIAGRAM ......................................

12. HANGER KIT INSTALLATION

13. WARRANTY SERVICE

............................................ 14

....................................... 35

.................................

.....................................

...................................

...........................

............................

............................

3

5

7

11

23

32

36

37

38

2

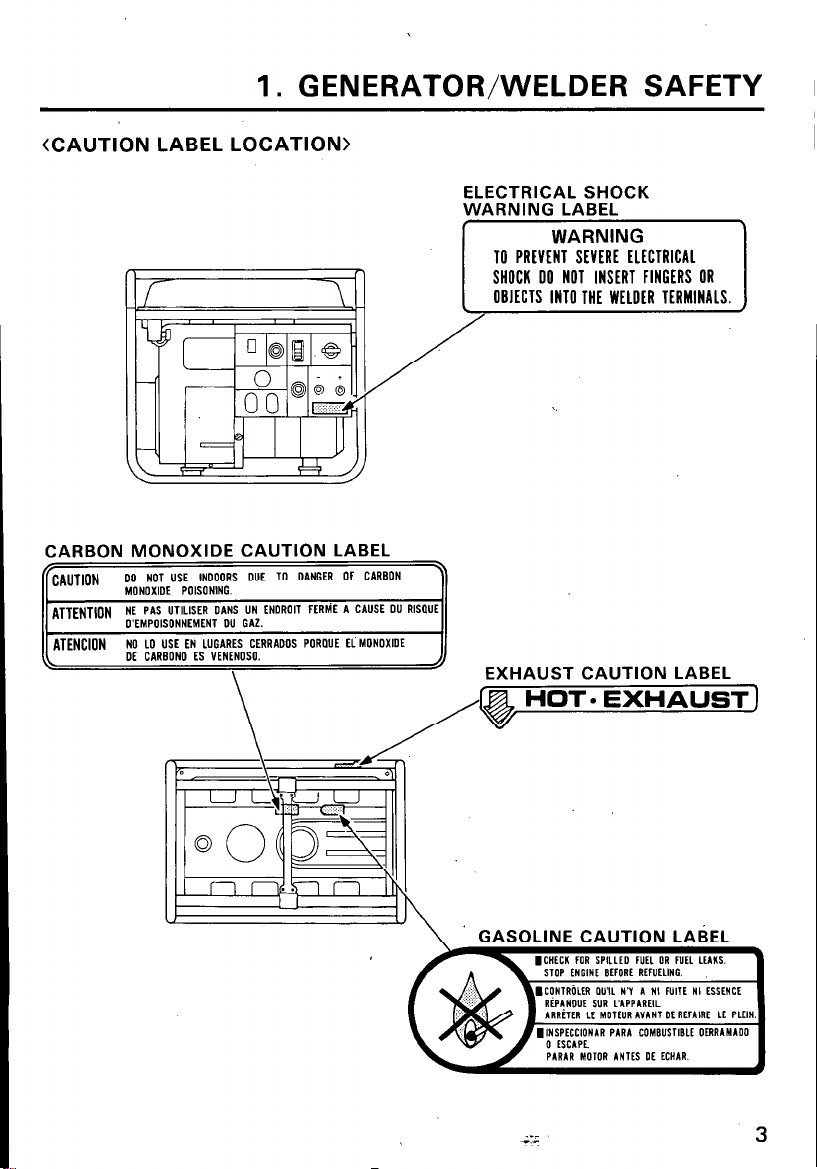

1. GENERATOR/WELDER SAFETY

(CAUTION LABEL LOCATION>

CARBON MONOXIDE CAUTION LABEL

DO NOT USE INOOOAS OUE TO DANGER Of CARBON

;; ~“,,“,“,‘,,‘rs’UyC:NREENSOS POROUE EL MONOXIOE

ELECTRICAL SHOCK

WARNING LABEL

OBJECTS INTO THE WELDER TERMINALS.

EXHAUST CAUTION LABEL

HOT. EXHAUST]

’

~CHECK fOR SPILLED fW OR fML LEAKS.

STOP fNGlNt BffORE MfULLING.

IINSPECCIONAR PARA COMBUSTIBLI OIRRAMAOO

TO ENSURE SAFE OPERATION -

0 The Generator/welder is a potential source of deadly electrical shocks when

misused; do not operate in rain or snow or any other wet conditions.

l

Place the generator/welder at least lm (3 ft.) away from buildings or other

equipment when operating.

l

Operate the generator/welder on a level surface.

If it is tilted, fuel spillage may result.

l

Exhaust gas contains poisonous carbon monoxide. Welding vapor is also

harmful to your health. Be sure to provide adequate ventilation. Never

operate the generator or perform welding in an enclosed area.

l

Know how to stop the-welder quickly and understand operation of-all the

controls. Never permit anyone to operate the welder without proper in-

structions.

l

Keep children and pets away from the welder when it is in ‘operation.

l

Keep away from rotating parts while the engine is running.

l

Use adequate eye protection. Eye protection is of the utmost importance,

not only for the operator but also for any other personnel in the vicinity

while welding is being done.

l

Looking at a welding arc with unprotected eyes may produce severe pain

and even temporary blindness.

9 Eye hazards include stray flashes, reflected glare, sparks, and flying bits of

molten metal.

0 Be sure to use a helmet or hand-held shield with a #lO or darker filter lens.

Filter lenses eliminate the harmful effects of infrared and ultraviolet radiation from the arc as well as reduce the glare from the arc light.

l

Wear protective clothing such as leather gloves, cap, sleeves, jacket, apron,

and high-top safety shoes. All outer clothing must be free of oil and grease.

FACE SHIELD GLOVES SAFETY SHOES

4

APRON

FUEL H

VALVE

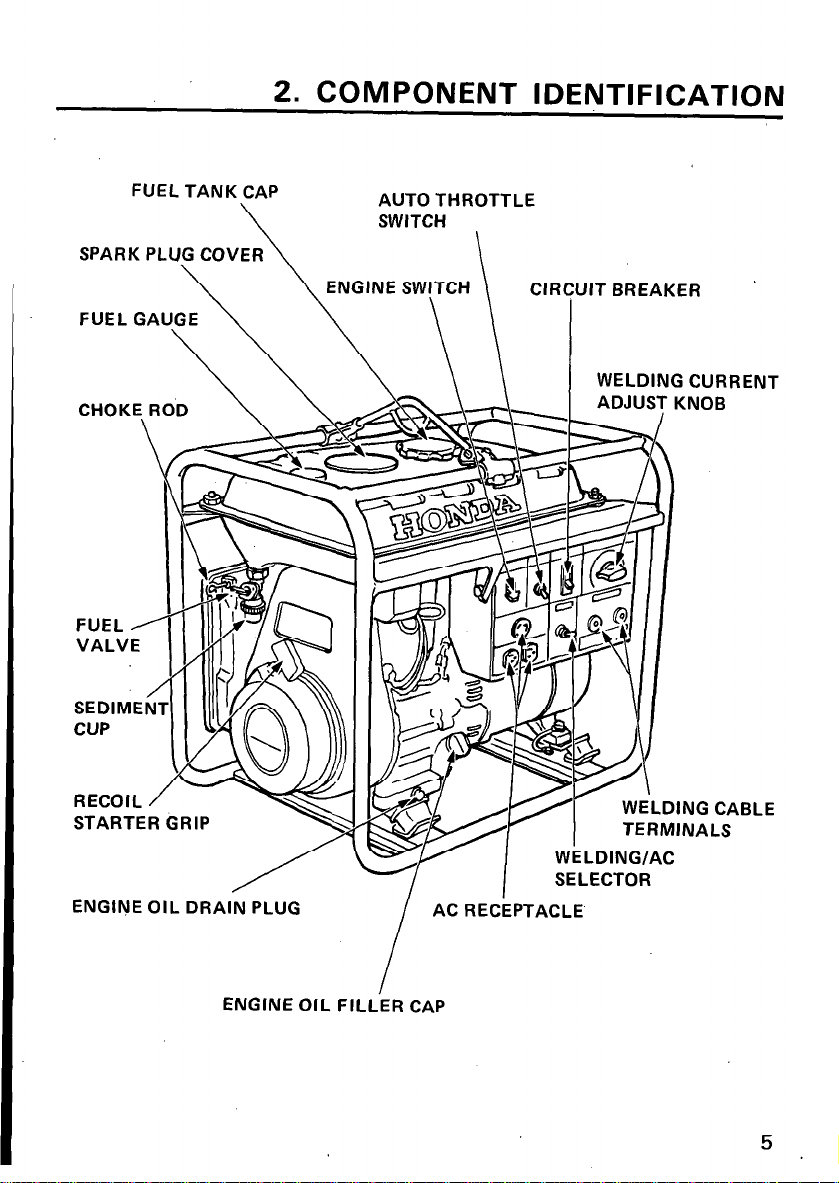

2. COMPONENT IDENTIFICATION

SEDIMEI;

CUP

RECOIL,

STARTEI

ENGINE OIL DRAIN PLUG

ENGINE OIL FILLER CAP

AC RECiPTACLE

I

I

5

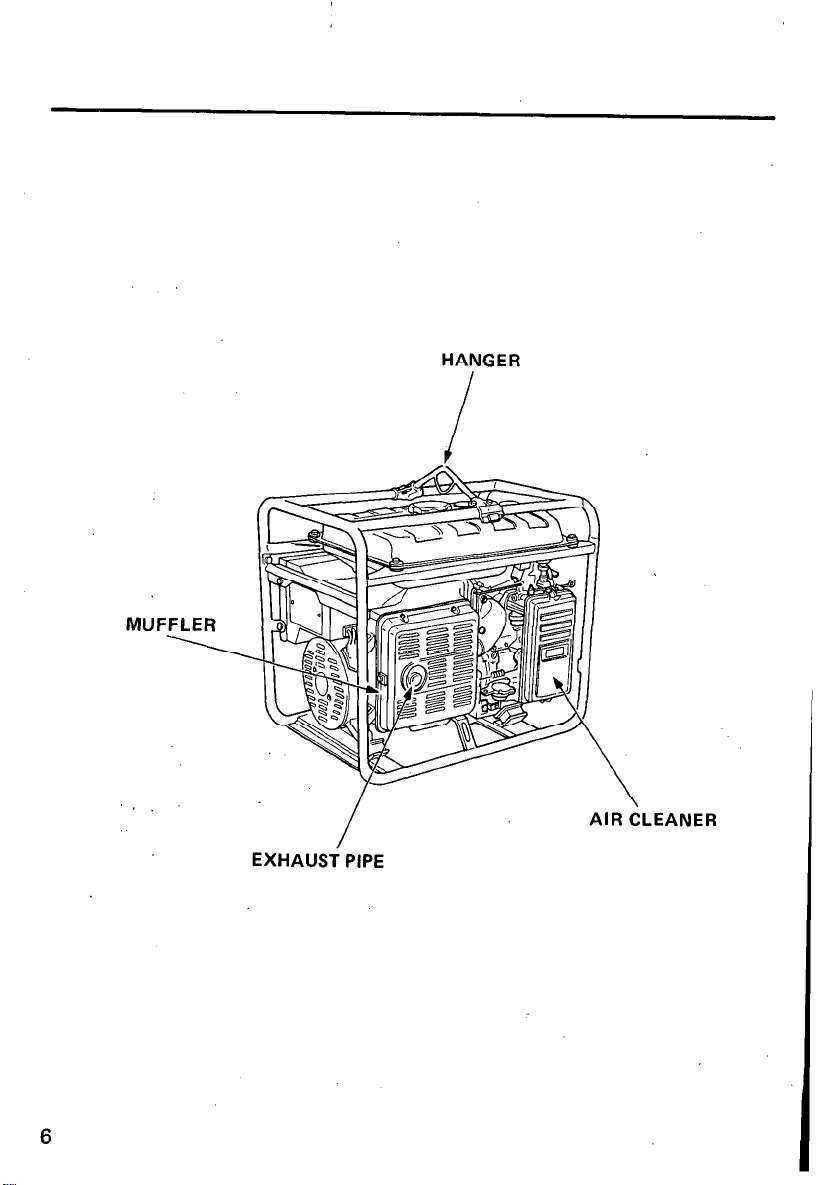

MU

HANGER

/

6

/

AIR CLEANER

EXHAUST PIPE

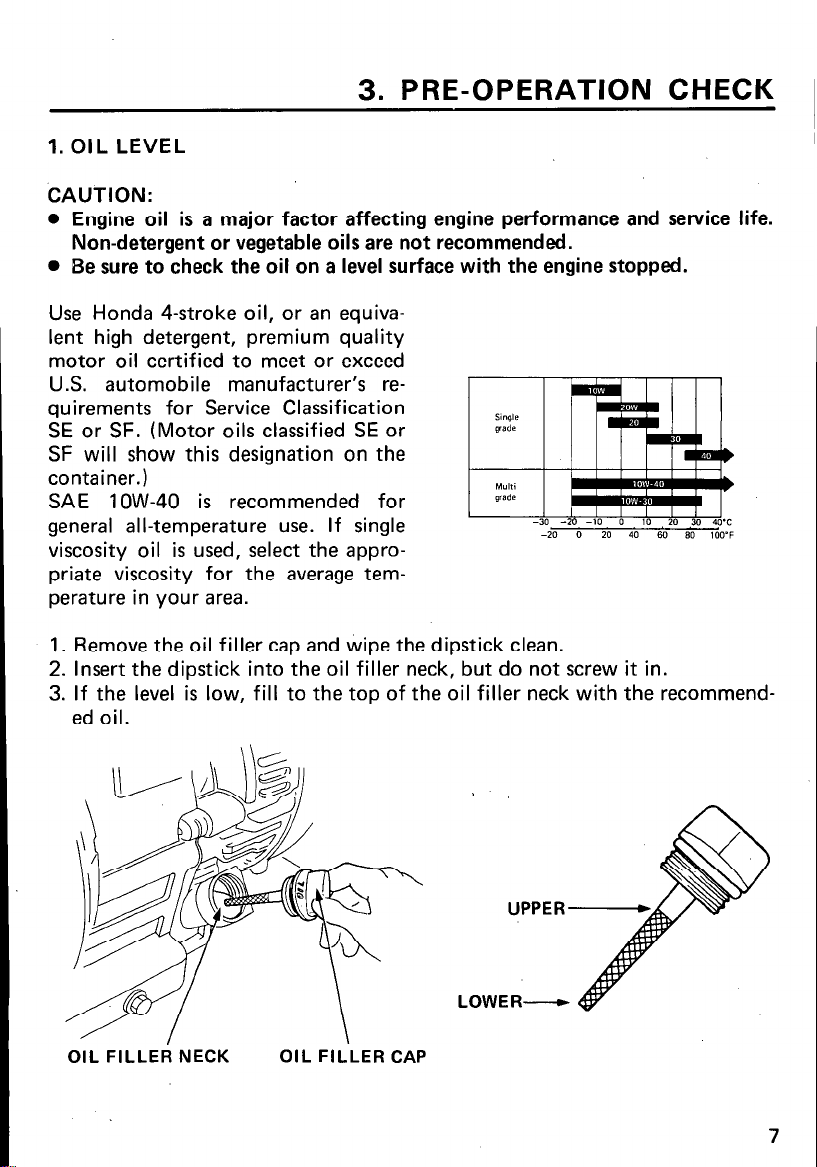

3. PRE-OPERATION CHECK

1. OIL LEVEL

CAUTION:

l

Engine oil is a major factor affecting engine performance and service life.

Non-detergent or vegetable oils are not recommended.

l

Be sure to check the oil on a level surface with the engine stopped.

Use Honda 4-stroke oil, or an equivalent high detergent, premium quality

motor oil certified to meet or exceed

U.S. automobile manufacturer’s re-

quirements for Service Classification

SE or SF. (Motor oils classified SE or

SF will show this designation on the

container.)

SAE low-40 is recommended for

general all-temperature use. If single

viscosity oil is used, select the appropriate viscosity for the average temperature in your area.

1. Remove the oil filler cap and wipe the dipstick clean.

2. Insert the dipstick into the oil filler neck, but do not screw it in.

3. If the level is low, fill to the top of the oil filler neck with the recommended oil.

‘/ I \

OIL FILLER NECK

OIL FILLER CAP

’

UPPER

LOWER-

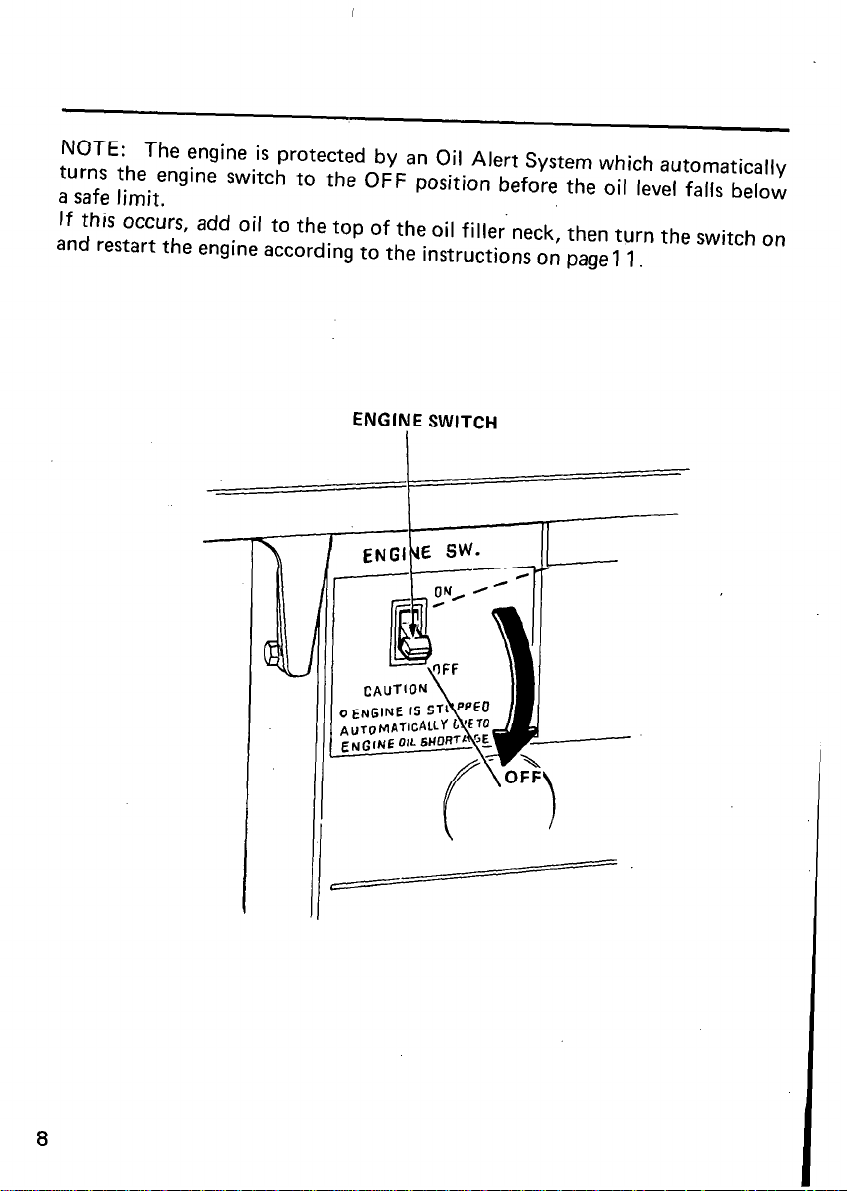

NOTE: The engine is protected by an Oil Alert System which automatically

turns the engine switch to the OFF position before the oil level falls below

a safe limit.

If this occurs, add oil to the top of the oil filler’neck then turn the switch on

and restart the engine according to the instructions on page 1 1.

ENGINE SWITCH

8

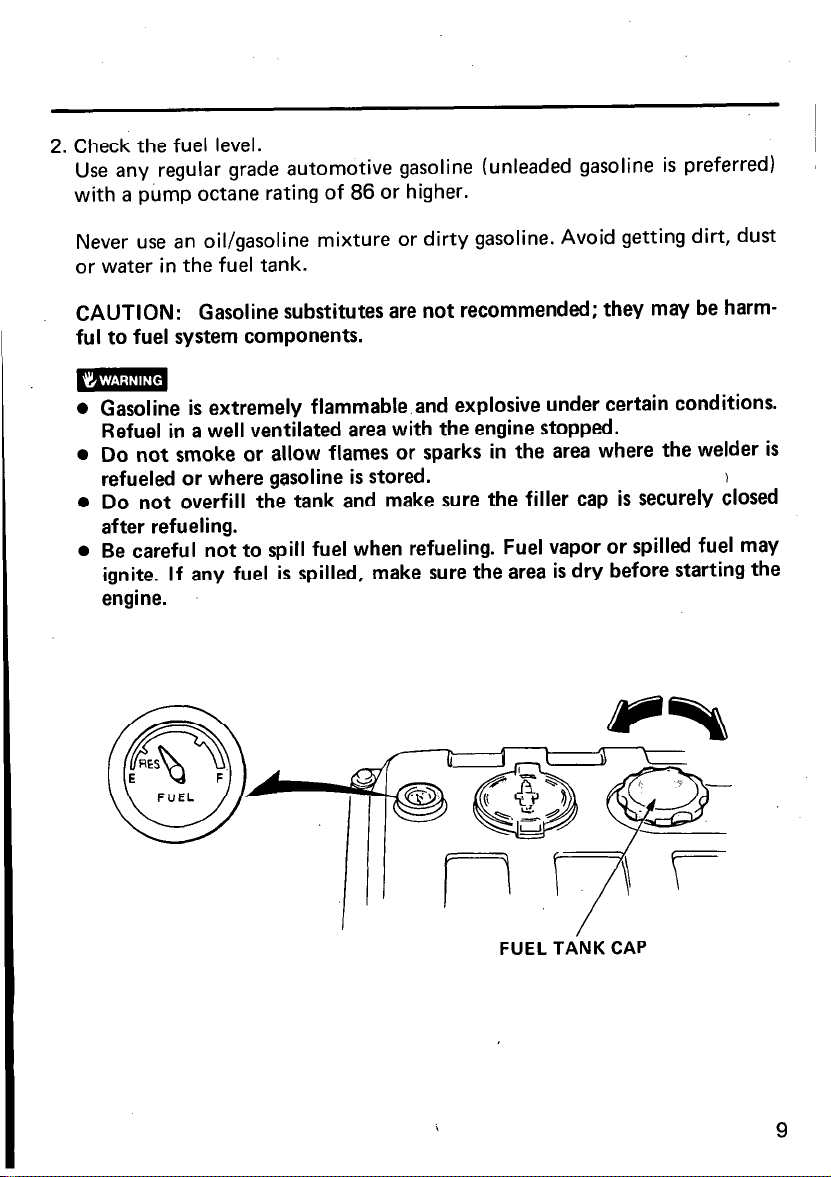

2.

Check the fuel level.

Use any regular grade automotive gasoline (unleaded gasoline is preferred)

with a pump octane rating of 86 or higher.

Never use an oil/gasoline mixture or dirty gasoline. Avoid getting dirt, dust

or water in the fuel tank.

CAUTION: Gasoline substitutes are not recommended; they may be harmful to fuel system components.

0 Gasoline is extremely flammable.and explosive under certain conditions.

Refuel in a well ventilated area with the engine stopped.

l

Do not smoke or allow flames or sparks in the area where the welder is

refueled or where gasoline is stored.

l

Do not overfill the tank and make sure the filler cap is securely closed

after refueling.

l

Be careful not to spill fuel when refueling. Fuel vapor or spilled fuel may

ignite. If any fuel is spilled, make sure the area is dry before starting the

engine.

FUEL TANK CAP

9

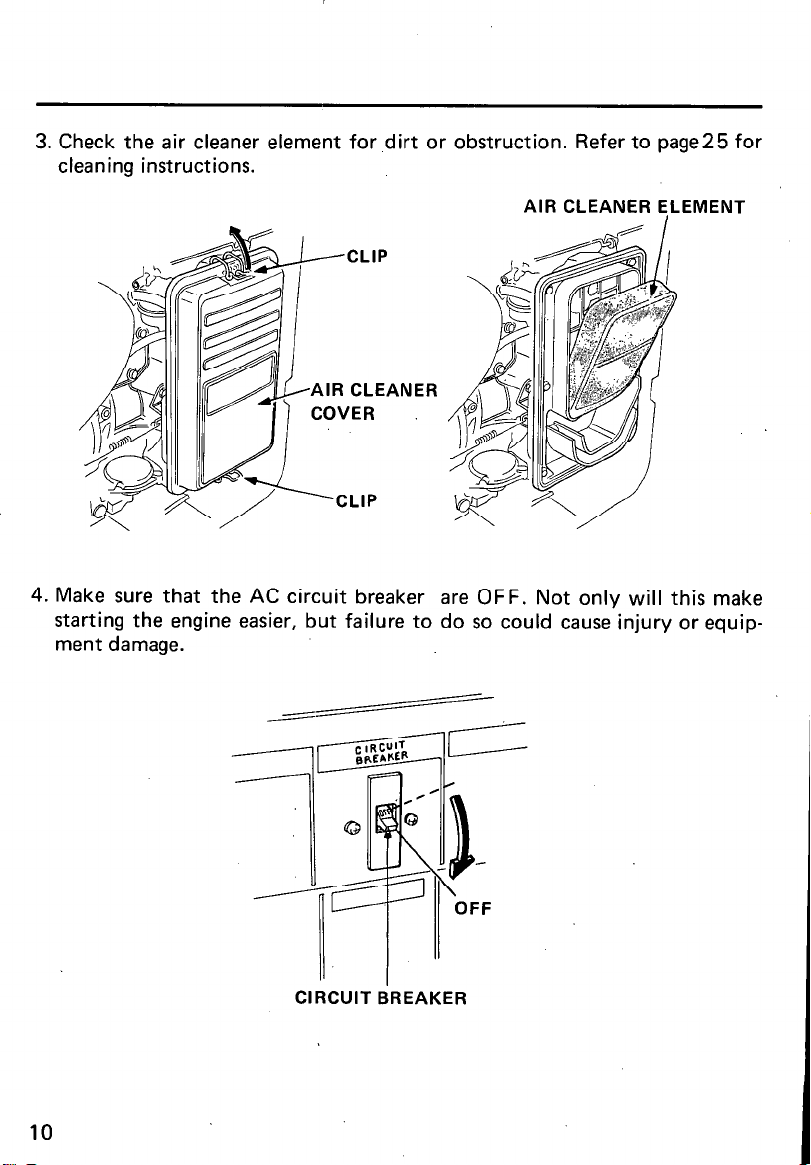

3. Check the air cleaner element for dirt or obstruction. Refer to page25 for

cleaning instructions.

AIR CLEANER ELEMENT

% \

CLIP

4. Make sure that the AC circuit breaker are OFF. Not only will this make

starting the engine easier, but failure to do so could cause injury or equipment damage.

CIRCUIT BREAKER

10

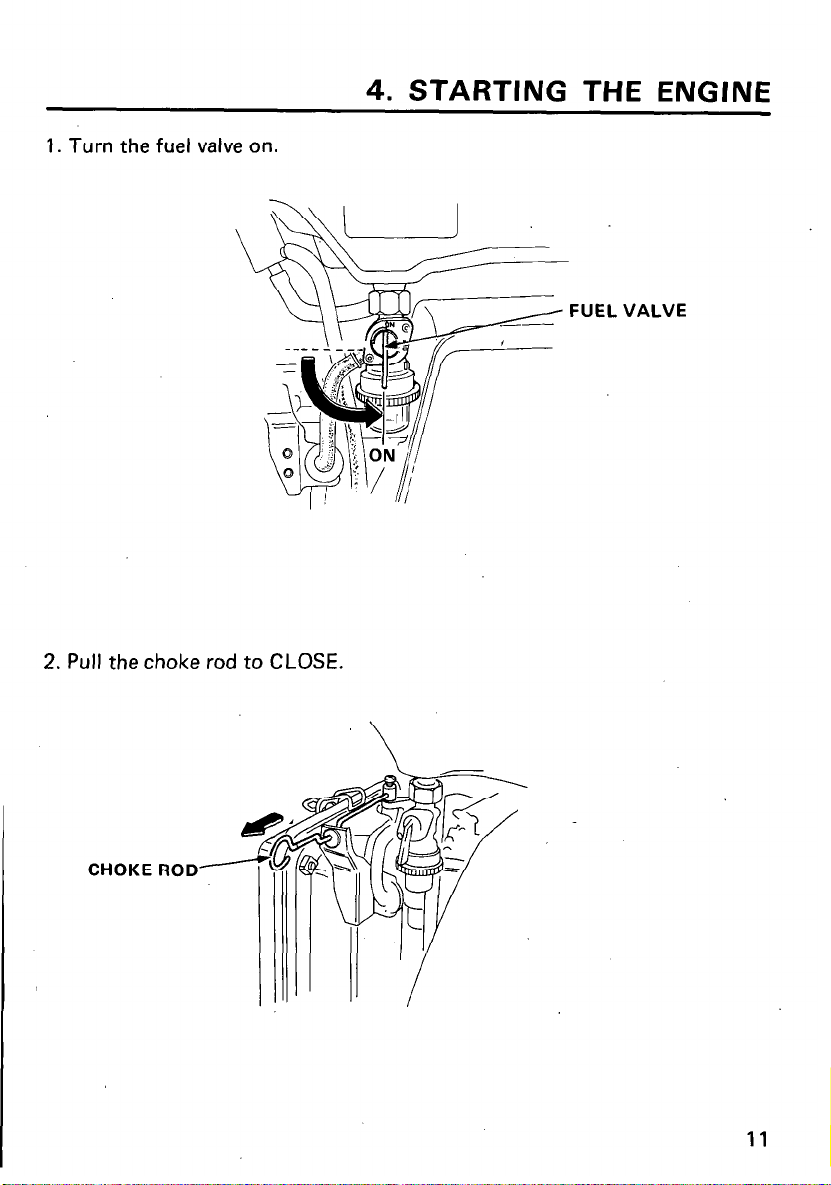

1. Turn the fuel valve on.

2. Pull the choke rod to CLOSE.

4. STARTING THE ENGINE

FUEL

VALVE

CHOKE ROD

11

3. Turn the engine switch on.

ENGINE SWITCH

4. Turn the auto-throttle switch off.

AUTO THROTTLE SWITCH

NOTE: More warm-up time will be required if the auto-throttle is left on.

12

5. Pull the starter grip until compression is felt, then pull briskly.

NOTE: Do not allow the starter grip to snap back. Return it slowly by

hand.

STARTER GRIP

6. Push the choke rod to OPEN as the engine warms up.

CHOKE ROD-

13

5. OPERATION

Auto-throttle system

With the switch in the AUTO position, engine speed is automatically reduced

to an idle when all loads are turned off or disconnected. When appliances are

turned on or reconnected, the engine resumes the rated speed. At OFF, the

auto-throttle system does not operate.

NOTE:

l

AUTO is recommended to minimize fuel consumption.

l

The auto-throttle system will not respond to electrical loads of less than 1

ampere.

l

The system is not effective for use with appliance that require only mo-

mentary power. To avoid extended warm-up periods, keep the switch OFF

until the engine reaches operating temperature.

l

AC applications

m To prevent electrical shock from faulty appliances, the genera-

tor should be grounded. Connect a length of heavy wire between the

ground terminal and the ground source.

CAUTION:

l

Limit operation requiring maximum power (4.0 kVA) to 30 minutes.

The total wattage of all appliances connected must be considered.

l

Do not exceed the current limit specified for any one receptacle.

l

Connections for emergency power to household circuits must be made

by a qualified electrician and must comply with all applicable laws and

electrical codes. Improper installation may result in personal injury or

damage to equipment or property.

NOTE: Single phase electric motors whose capacities are up to 750W can

be operated. Motors which require heavy starting current may not be used.

1.4

1. Turn the AC/DC (Weld) selector to the AC position.

CAUTION: AC voltage is present at the AC receptacles at all times regard-

iess

of the position of the AC/DC (WELD) selector. However, when this

selector is in the DC (WELD) position, the AC voltage fluctuates considerably.

Under no circumstances should any type of electrical appliance be plugged

into any of the AC receptacles when the selector is in the DC (WELD) position.

.

2. Plug the appliance into the proper receptacle.

3. Turn on the appropriate AC circuit breaker.

The appliance may now be turned on.

15

l

Welding

m Welding is potentially a very hazardous activity. It should only

be attempted by a trained welder with a thorough knowledge of proper

welding techniques and safety procedures. Be sure to read and follow the

safety rules on pages 3 and 4 of this manual.

1. Put the Engine Switch in the OFF position. Turn the AC circuit breaker.

off and remove any plugs from the AC receptacles.

CAUTION: Voltage is present at the welding terminals whenever the

engine-is running regardless of the position of the AC/DC (WELD) selector.

16

2. Connect the welding cables to the welder’s DC terminals.

CAUTION: Failure to use the proper gauge cable may lead to painful

burns and/or damage to equipment. See table on page 20.

TERMINALS

3. Start the engine, and when it has warmed up fully, turn the Auto-Throttle

Switch to the AUTO position.

17

4. Turn the AC/DC (WELD) selector to the DC (WELD) position.

CAUTION:

0 To avoid accidental arcing, one cable end should be firmly attached to

the object to be welded and the electrode holder at the end of the other

cable should be held in the operator’s hand when the DC (WELD) selector is turned on.

0 AC voltage is present at the AC receptacles at all times regardless of the

position of the AC/DC (WELD) selector. However, when this selector is

in the DC (WELD) position, the AC voltage is unregulated. Under no

circumstances should any type of electrical appliance be plugged into

any of the AC receptacles when the selector is in the DC (WELD) position.

18

5. Set the current adjuster knob to the proper current level for the job being

done.

19

WELDING CABLE SELECTION

When choosing welding cable, it is best to allow a comfortable safety margin.

The cable’s length, gauge (diameter), and material all combine to determine

how much current it can safely carry. The table below gives the current carrying capacity of various lengths and gauges of standard copper welding cable.

I

CABLE CAB L,E

GAUGE

1 .644

2 .604

* Lengths given are for the combined length of the positive and negative

cables.

CAUTION: An undersize cable will offer unacceptably high resistance to

current flow from the welder. This will lead to poor quality welds and will

shorten the life of the generator/welder.

OPERATING RATE

The welder should not be operated continuously at high current settings. Th,e

proportion of welding time to “rest” time is called the Operating Rate. For

example: The welder’s Operating Rate at 1.10 Amps is 70%. This means that

in a given 10 minutes period actual welding can be performed for a total of

7 minutes. Use the table below to determine the Operating Rate for other

current settings.

I

DIA.

I

O-50 FT. 50-100 FT. loo-250 FT.

CURRENT CAPACITY AMPERES

250 200

200 195

LENGTH IN FEET*

170

150

I

Current

Rate 20%

20

170A

150A

30%

130A

50%

IlOA

70% 100%

Below 90A

1. <AC APPLICATION>

Turn the appliance switch off and the

ClRCUli BREAKER

2. <WELDING>

Stop welding or cutting.

Turn the engine switch off.

6. STOPPING THE ENGINE

AC

circuit breaker off.

21

3. Turn the fuel valve off.

22

7. MAINTENANCE

The purpose of the maintenance and adjustment schedule is to keep the generator/welder in the best operating condition.

Inspect or service as scheduled in the table on the next page.

m Shut off the engine before performing any maintenance. If the

engine must be run, make sure the area is well ventilated. The exhaust contains poisonous carbon monoxide gas.

CAUTION: Use only genuine HONDA parts or their equivalent. The use of

replacement parts which are not of equivalent quality

erator/welder.

Maintenance Schedule

REGULAR SERVICE

may damage the gen-

Perform at every indi-

cated month or oper-

ating hour interval,

Engine oil Check Level

Change

Air cleaner Check

element

Spark plug

Spark arrester Clean

Fuel filter

Valve clearance

Combustion chamber

Fuel tank Clean

Fuel line Check

(Replace, if necessary)

._.^.

dote (I ): Service more trequently when used in dusty areas.

(2): These items should be serviced by an authorized Honda dealer, unless the owner

Clean

Clean-Adjust

Clean

Check-Adjust

Clean-Lap valves

has the proper tools and is mechanically proficient. See the Honda Shop Manual.

Daily

First

month

20°i rs.

0

Clean every 100 operating hours

Every

3 months

6O’Ars.

Every

6 months

1 OCZlrs.

Every

year

3OCZlrs.

23

Tool kit

The tools supplied are necessary for performing some periodic maintenance,

simple adjustments and repairs.

Always keep the tool kit with the generator/welder.

Changing oil

Drain the oil while the engine is still warm to assure rapid and complete draining.

1. Remove the drain plug and filler cap, and drain the oil. Retighten the drain

plug securely.

2. Refill with the recommended oil (see page 7) and check the level.

24

DRAIN

I L FILLER CAP

Air cleaner service

A dirty air cleaner will restrict air flow to the carburetor. To prevent carbure,

tor malfunction, service the air cleaner regularly. Service more frequently

when operating the generator/welder in extremely dusty areas.

-N

cleaner element. A fire or explosion could result.

CAUTION: Never run the engine without the air cleaner. Rapid engine wear

will result.

1.

Unsnap the clips, remove the air cleaner cover and remove the element.

ever use gasoline or low flash point solvents for cleaning the air

1 EMENT

2. Wash the element in a non-flammable or high flash point solvent and allow

it to dry.

3. Soak the element in clean engine oil and squeeze out the excess oil.

4. Reinstall the air cleaner element and the cover.

t

ELEMENT

25

Sediment cup service

The sediment cup prevents dirt or water which may be in the fuel tank from

entering the carburetor. If the engine has not been run for a long time, the

cup should be cleaned.

1. Turn the fuel valve OFF. Remove the sediment cup.

2. Clean the cup thoroughly.

3. Reassemble. Do not’ damage the rubber gasket.

B After installing the sediment cup, check for fuel leaks and make

sure the area is dry before starting the engine.

UEL VALVE

26

SEDli’lENT CUP

Spark plug service

Recommended spark plug: BR-4HS(NGK)

W14FR-U(ND)

To ensure proper engine operation, the spark plug must be properly gapped

and free of deposits.

1. Remove the spark plug cover.

2. Clean any dirt from around the spark plug base.

3. Remove the spark plug cap.

~

SPARK PLUG COVER

PLUG’CAP

27

4. Use the wrench supplied in the tool kit to remove the spark plug.

5. Visually inspect the spark plug. Discard it if the insulator is cracked or

chipped.

6. Measure the plug gap with a feeler gauge.

The gap should be 0.6-0.7 mm (0.024-0.028 in):Correct as necessary by

carefully bending the side electrode.

7. Attach the plug washer. Thread the plug in by hand to prevent cross-

threading.

8. Tighten a new spark plug l/2 turn with the wrench to compress the washer.

If you are reusing a plug, it should only take l/8-1/4 turn after the plug

seats.

CAUTION:

l

The spark plug must be securely tightened. An improperly tightened plug

can become very hot and possibly damage the engine.

l

Never use a spark plug with an improper heat range.

28

PLUG ~VRENCH

PLUG,GAP

0.6-0.7

(0.024-0.028

mm

in)

Spark arrester maintenance

w If the engine has been running, the muffler will be very hot. Allow

it to cool before proceeding.

CAUTION: The spark arrester must be serviced every 100 operating hours to

maintain its efficiency.

1. Loosen the bolts and nuts and remove the muffler.

2. Loosen two 8 mm bolts to remove the exhaust pipe.

3. Check the muffler exhaust port for carbon deposits; clean if necessary.

4. Remove the spark arrester from the muffler.

Clean the screen with a wire brush, and inspect it for damage. Replace if

necessary .

5. Install the spark arrester in the muffler.

Install the muffler and gasket and tighten the bolts and nuts securely.

MUFFLER PROTiCiOR

\/

6mm BOLTS

NUTS

EXHAUST PIPE

I

8 mm BOLTS

29

8. TRANSPORTING/STORAGE

m When transporting the generator/welder, turn the engine switch

OFF and ‘keep the unit level to prevent fuel spillage. Fuel vapor or spilled fuel

may ignite.

Before storing the unit for an extended period:

1. Be sure the storage area is free of excessive humidity and dust.

2. Drain the fuel a. With the fuel valve OFF, remove and empty the sediment cup.

b. Turn the fuel valve ON and drain the gasoline in the fuel tank into a

suitable container.

c. Replace the sediment cup and tighten securely.

FUEL VALVE

\ /

30

d. Drain the carburetor by loosening the drain screw. Drain the gasoline

KDRAiNSCREW

into a suitable container.

I------

e. Pull the starter grip until resistance is felt; the piston is coming up on its

compression stroke. At this position, the exhaust and intake valves are

closed, and this will help protect the engine from corrosion.

STARTER GRIP

f. Change the engine oil if the unit is to be stored for more than 1 year.

.31

,,..‘.

.’

9. TROUBLESHOOTING

The chart that follows relates various generator/welder troubles to their possible ,causes and corrections. Many of the troubles listed are closely related,

and elimination of one may eliminate others. Before taking the unit to your

Honda Dealer, perform the following steps.

----------------__---------

w When the engine will not start:

Is the correct starting procedure being used?

Check the following :

l

Fuel valve position

0 Engine switch position

0 Choke rod position

0 Starter grip operation

I I

Is there enough’fuel in the fuel tank?

Is gasoline reaching the carburetor?

To check, loosen the drain screw with the fuel valve on.

m If any fuel is spilled, make sure the area is dry before testing the spark plug or starting the engine. Fuel vapor or spilled fuel

may ignite.

32

J

Is there enough bil in the crankcase?

l

The oil alert system prevents the engine from being started if the

level of oil in the crankcase falls below prescribed level:

Is the spark plug wet or fouled?

0 Clean the spark plug.

0 Check the plug gap and adjust.

Is there spark at the spark plug?

1) Remove the spark plug cap. Clean any dirt from around the spark

plug base, and remove the spark plug.

2) Install the spark plug in the plug cap.

3) Turn the engine switch on. Grounding the side electrode to the

stay, pull the recoil starter to see ,if sparks jump across the gap.

STARTER ,’

GRIP

GROUNDING

STAY

-A

ENGINE

0 If there are no sparks, replace the plug.

l

If a new plug produces no sparks or if there are sparks and the

engine still does not start, take the generator to the dealer.

33

n

When the welding arc is weak :

Is the cable size correct? (Page20)

l

Length

l

Gauge/Diameter

Is the proper electrode being used?

n

When there appears to be no electricity at the AC receptacles:

l

Are the circuit breakers tripped?

l

Is the

generator

l

Is the appliance in good operating condition?

over-loaded?

Disconnect the appliance from the generator and carefully inspect it and

its power cord for defects.

34

TYPE AND DIMENSIONS

Type

Overall length

Overall width

Overall height

Dry weight

ENGINE

Model

Type

Displacement

Bore x stroke

Rated output

Cooling system

Ignition system

Fuel tank capacity

Oil capacity

DC (WELDING) OUTPUTS

Generator

Phase

Rated current

Rated voltage

Welding current

Operating rate

Rated rpm

Electrode diameter

10. SPECIFICATIONS

Honda generator/welder EWl70

695 mm (27.4 in.)

465 mm (18.3 in.)

695 mm (27.4 in.)

104 kg (229 lb.)

G E400

4-stroke, side valve, 1 cylinder

406 cm3 (24.8 cu.in.1

86 x 70 mm (3.4 x 2.8 in.)

8.0 PS/3,600 rpm

Forced air cooling

Flywheel magneto

16.5 liters (4.3 US gal.)

1.2 liters (1.27 US qt.)

2-pole rotating field magnet

6-phase, semi-wave rectification

130A

26.5V

55-l 70A

50% / 130A

3,600 rpm

2.6-4.0 mm (0.1 O-O.1 6 in.)

AC OUTPUTS

Maximum output

Rated output

Rated voltage

Power factor

Phase

Frequency

4 kVA (4,OOOW)

4.0 kVA (4,000W)

12ov

1.0

Single

60 Hz

35

R/w

RESIST,

I

9

1

SWITCH

-I- AUTO-THROTTLE =

=

AC RECEPTACLES

ENGINE BLOCK

?k

12. HANGER KIT. INSTALLATION

8 x 16 mm FLANGED,BOLT

(4)

HAYGER

BRACKET

CAUTION:

0 Position the hanger at the generator’s balance point, midway between the

spark plug cover and the fuel tank cap.

l

Fit the end tabs of the hanger through the bracket slots, and bolt the

brackets to the hanger.

SPARK PLUG

COVER

FUEL TANK

CAP

\

I

\

HANGER

37

13. WARRANTY SERVICE

I

Owner Satisfaction

Your satisfaction and goodwill are important to your,dealer and to us.

Normally, any problems with the product will be handled by your dealer’s service department. Sometimes, however, despite the best intentionsof all concerned, misunderstandings can occur. If your problem

has not been handled to your satisfaction, we suggest you take the following action:

l

Discuss your problem with a member of dealership management. Of-

ten complaints can be quickly resolved at that level. If the problem

has already been reviewed with the Service Manager, contact the

owner of the dealership or the General Manager.

l

If your problem still has not been resolved to your satisfaction, con-

tact the Motorcycle and Power Products Customer Relations Depart-

ment at the regional office of American Honda Motor Co., Inc. in your

area. Regional office locations are shown on the following page. We

will need the following information in order to assist you:

-Your name, address, and telephone number

-Product model and serial number

-Date of purchase

-Dealer name and address

-Nature of the prob’lem

After reviewing all the facts involved, you will be advised of what action

can be taken. Please bear in mind that your problem will likely be re-

solved at the dealership,.using the dealer’s facilities, equipment, and

personnel, so it is very important that your initial contact be with the

dealer.

Your purchase of a Honda product is greatly appreciated by both the

dealer and American Honda Motor Co., Inc. We want to assist you in ev;

ery way possible to assure your complete satisfaction with your

purchase. ,.

38

Regional Office Locations

NORTHWEST REGIONAL OFFICE

(includes Alaska)

American Honda Motor Co., Inc.

Customer Relations Department

P.O. Box 30295

Portland. Oregon 97220

Telephone: (6031255-1186

.

WESTERN REGIONAL OFFICE

(includes Hawaii)

American Honda Motor Co.. Inc.

Customer Relations Department

P.O. Box 420

Gardena. California 90247

Telephone: (213) 6042524

MIDWEST REGIONAL OFFICE

American Honda Motor Co.. Inc.

Customer Relations Department

P.O. Box 22

Greendale. Wisconsin 53129

Telephone: (414) 421-9300

\

J-

SOUTHWEST REGIONAL OFFICE

American Honda Motor Co.. Inc.

Customer Relations Department

Irving. Texas 75062

Telephone: (2141 256.6663

. P.O. Box 5406

NORTHEAST REGIONAL OFFICE

American Honda Motor CO.. 1°C.

Customer Relations Department

P.O. Box 749

Moorertown. New Jersey 06057

Telephone: 1609) 776-l 100

\

SOUTHEAST REGIONAL OFFICE

Iincludes Puerto Rico1

n---:--.^ %nda Motor Co., Inc.

;;;::;;:;

. Relations Department

1600 Morrison Parkway

Alpharetta. Georgia 30201

Telephone: 14041 442.2000

39

Current customer service contact information:

United States, Puerto Rico, and U.S. Virgin Islands:

Honda Power Equipment dealership personnel are trained professionals. They should

be able to answer any question you may have. If you encounter a problem that your

dealer does not solve to your satisfaction, please discuss it with the dealership's

management. The Service Manager or General Manager can help. Almost all problems

are solved in this way.

If you are dissatisfied with the decision made by the dealership's management, contact

the Honda Power Equipment Customer Relations Office. You can write:

American Honda Motor Co., Inc.

Power Equipment Division

Customer Relations Office

4900 Marconi Drive

Alpharetta, GA 30005-8847

Or telephone: (770) 497-6400 M-F, 8:30 am - 7:00 pm EST

When you write or call, please provide the following information:

• Model and serial numbers

• Name of the dealer who sold the Honda power equipment to you

• Name and address of the dealer who services your equipment

• Date of purchase

• Your name, address, and telephone number

• A detailed description of the problem

MEMO

Loading...

Loading...