m

misused. Do not expose the generator/welder to moisture, rain or snow.

Do not let the gelierator/welder get wet, and do not operate it with wet

hands.

The generator/welder is a potential source of electrical shock if

Thank you for purchasing a Honda generator/welder.

This manual covers the operation and maintenance of EW140 and EW171

generator/welders. All information in this publication is based on the latest

product information available at the time of printing.

The illustrations in this manual are based on the EW 171 generator/welder.

Honda Motor Co., Ltd. reserves the right to make changes at any time

without notice and without incurring any obligation.

No part of this publication may be reproduced without written permission.

This manual should be considered a permanent part of the

generator/welder and should remain with the generator/welder if it is

resold.

This generator/welder is equipped with a U.S.D.A. qualified spark arrester

which requires periodic maintenance to ensure its effectiveness. It is illegal in some areas to operate an engine without a spark arrester; check

local laws and regulations.

ADANGER: Indicates severe personal injury or death will result if instructions are not followed.

m Indicates a strong possibility of severe personal injury or loss of

life if instructions are not followed.

CAUTION: Indicates a possibility of personal injury or equipment damage

if instructions are not followed.

NOTE: Gives helpful information.

If a problem should arise, or if you have any questions about your

generator/welder, consult an authorized Honda dealer.

l

Welding is potentially a very hazardous activity. It should only be attempted by a trained welder with a thorough knowledge of proper

welding techniques and safety procedures.

l

Honda generator/welders are designed to give safe operation and

dependable service if operated according to instructions. Read and

understand this Owner’s Manual before operating the’

generator/welder. Failure to do so could result in personal injury or

equipment damage.

1

CONTENTS

CONTENTS

1. GENERATOR/WELDER SAFETY

2. COMPONENT IDENTIFICATION

3. PRE-OPERATION CHECK

.......................................................

4. STARTING THE ENGINE ................

5. GENERATOR/WELDER OPERATION

6. STOPPING THE ENGINE

l

High altitude operation ...........

7. MAINTENANCE

...................................................................

........................................................

8. TRANSPORTING/STORAGE

9. TROUBLESHOOTING

10. SPECIFICATIONS

11. WIRING DIAGRAM

............................................................

.................................................................

.............................................

..............................................

..............................................

. .......................................

............

..‘..........................................

...................................................

12. 4-WHEEL KIT INSTALLATION (optional parts)

13. WARRANTY SERVICE

...........................................................

...........................

.

..i

...............

...........................

3

7

9

13

17

26

27

28

37

39

41

42

43

44

1. GENERATOR/WELDER SAFETY

TO ENSURE SAFE OPERATION -

Place the generator/welder on a firm, level surface; avoid loose sand or

snow. If the generator/welder is tilted or overturned, fuel spillage and a

fire may result.

To prevent fire hazards and to provide adequate ventilation, keep the

generator/welder at least 1 meter (3 feet) away from buildings and

other equipment during operation. Do not place flammable objects

close to the generator/welder.

Children and pets must be kept away from the area of operation due to

a possibility of electric shock or burns from hot components.

Know how to stop the generator/welder quickly, and understand the

operation of all the controls. Never permit anyone to operate the

generator/welder without proper instruction.

The generator/welder is a potential source of electrical shock if misus-

ed. Do not expose the generator/welder to moisture, rain or snow. Do

not let the generator/welder get wet, and do not operate it with wet

hands.

Use adequate eye protection. Eye protection is of the utmost impor-

tance, not only for the operator, but also for any other personnel in the

vicinity while welding is being done. Eye hazards include arc’ glare,

reflected glare, stray flashes, sparks, and flying bits of molten metal.

Looking at a welding arc with unprotected eyes may produce severe

pain and even temporary blindness.

Use a helmet or hand-held shield with a #IO or darker filter lens.

Filter lenses eliminate the harmful effects of infrared and ultraviolet

radiation frop the arc and reduce the glare from the arc light as well.

Wear protective clothing such as leather gloves, cap, sleeves, jacket,

apron, and high-top safety shoes. All outer clothing m&t be free of oil

and grease.

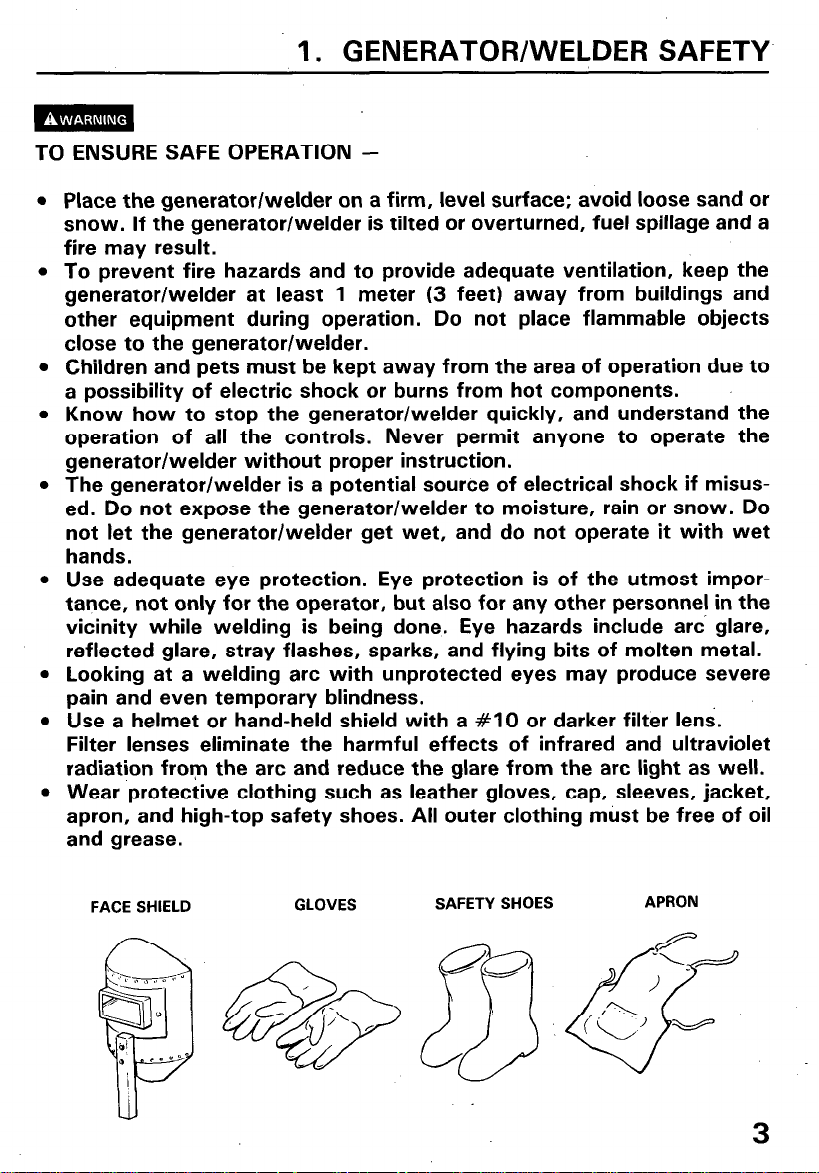

FACE SHIELD

GLOVES

SAFETY SHOES

APRON

Gasoline is extremely flammable and is explosive under certain

conditioris.

Refuel in a well-ventilated area with the engine stopped. Do not smoke

or allow flames or sparks in the refueling area or where gasoline is

stored.

Do not overfill the fuel tank. After refueling, make sure the ta,nk cap is

closed properly and securely.

Be careful.not to spill fuel when refueling. Fuel vapor or spilled fuel may

ignite. If any fuel is spilled, make sure the area is dry before starting the

engine.

Never run the engine in an enclosed or confined area. Exhaust contains

poisonous carbon monoxide gas; exposure may cause loss of consciousness and may lead to death.

Provide adequate ventilation when welding; welding vapors are harmful

to your health.

The muffler becomes very hot during dperation and remains sufficiently

hot to inflict burns if touched, even after shutting off the engine. To prevent severe burns or fire hazards, let the engine cool before transporting

the generator/welder or storing it indoors.

Connections for standby power to a building’s electrical system must be

made by a qualified electrician and must comply with all applicable laws

and electrical codes. Improper connections can allow electrical current

from the generator to backfeed into the utility lines. Such backfeed may

electrocute utility company workers or others who contact the lines during a power outage, and when utility power is restored, the generator

may explode, burn, or cause fires in the building’s electrical system.

CAUTION: Equipment damage and corrosion from sand, dirt, and water

may occur if the generator is overturned or sinks into’s soft surface.

4

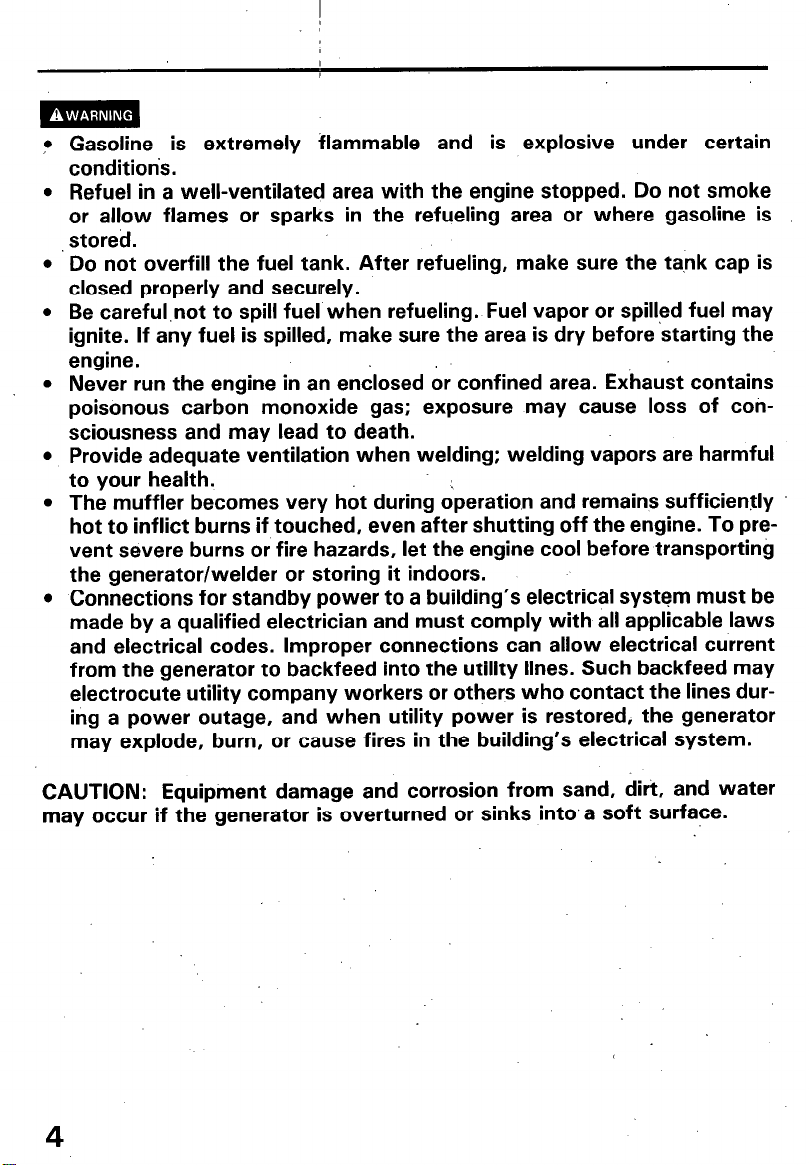

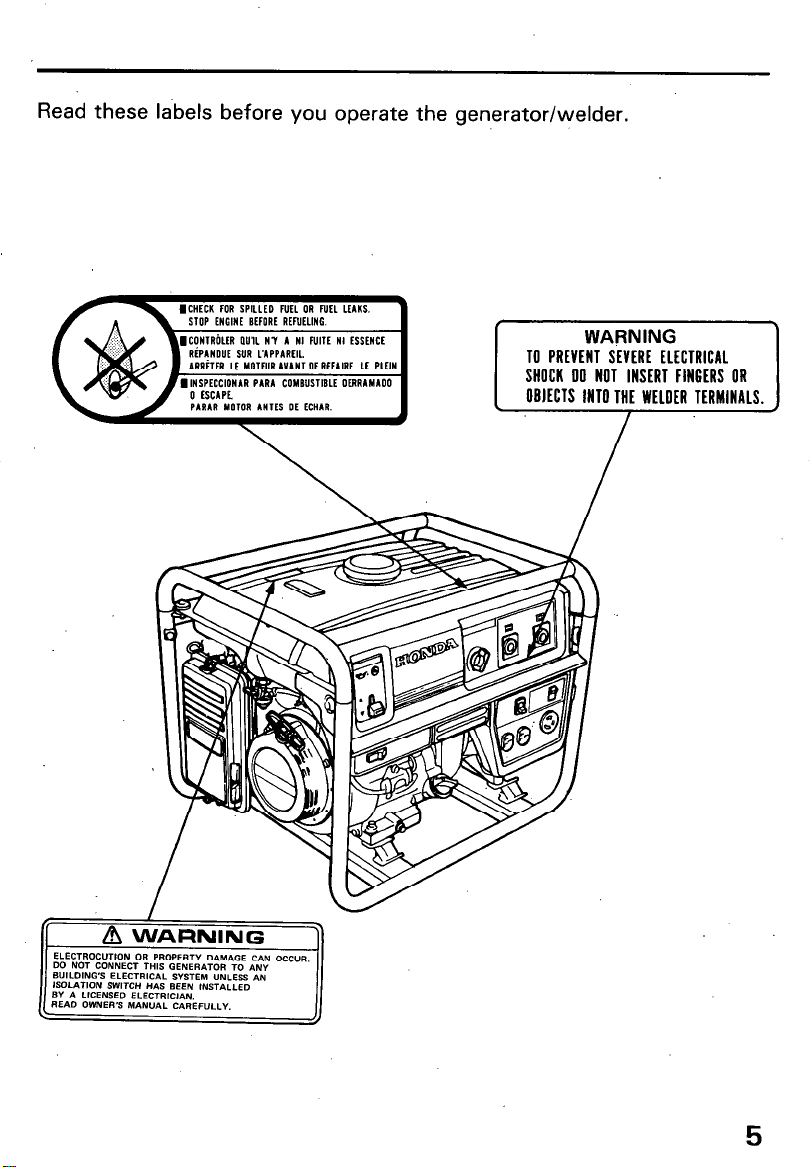

Read these labels before you operate the generator/welder.

5

NO LO USE EN LUGARES CERRAOOS POROUE ELMONOXIOE

\ I

6

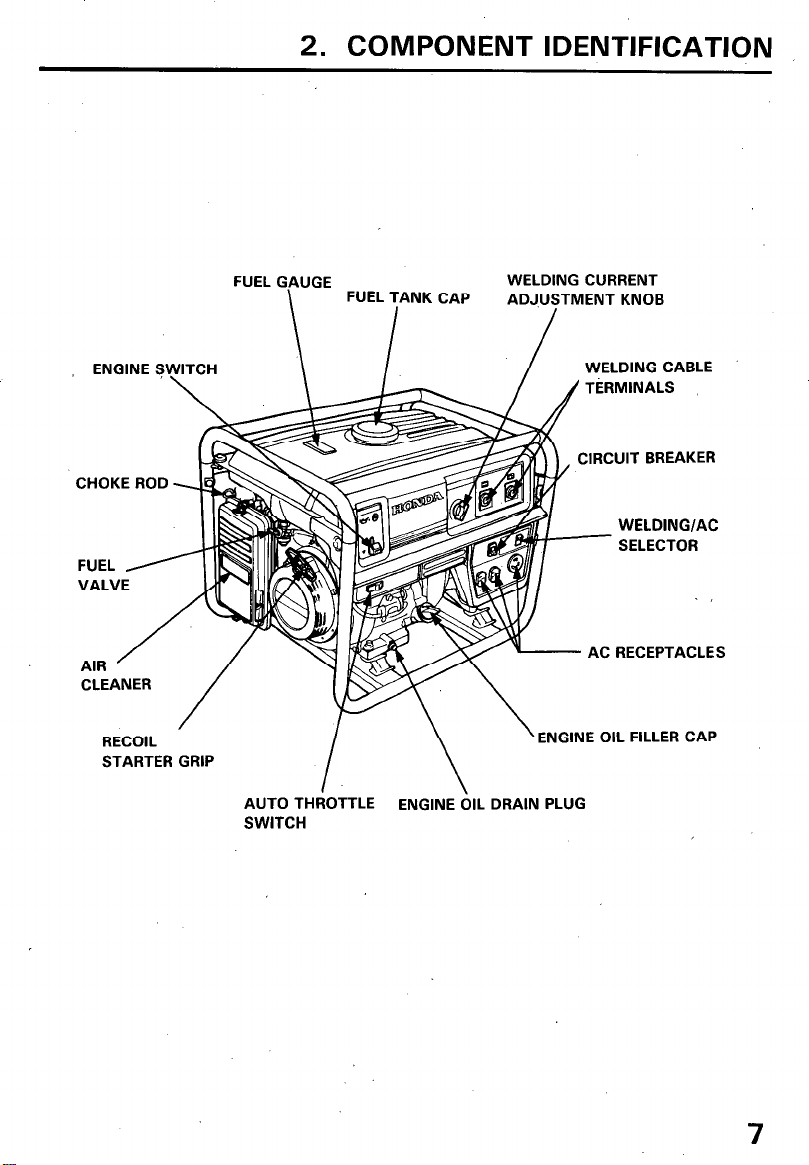

2. COMPONENT IDENTIFICATION

ENGINE 9WlTCH

\ \

AIR ’

CLEANER

RECOIL

STARTER GRIP

/

FUEL GAUGE

\ FUEL jANK CAP ADJ;;ETMENT KNOB

AUTO THdOTTLE

SWITCH

ENGINE OIL DRAIN PLUG

WELDING CURRENT

- AC RECEPTACLES

ENGINE OIL FILLER CAP

CIRCUIT BREAKER

WELDING/AC

SELECTOR

7

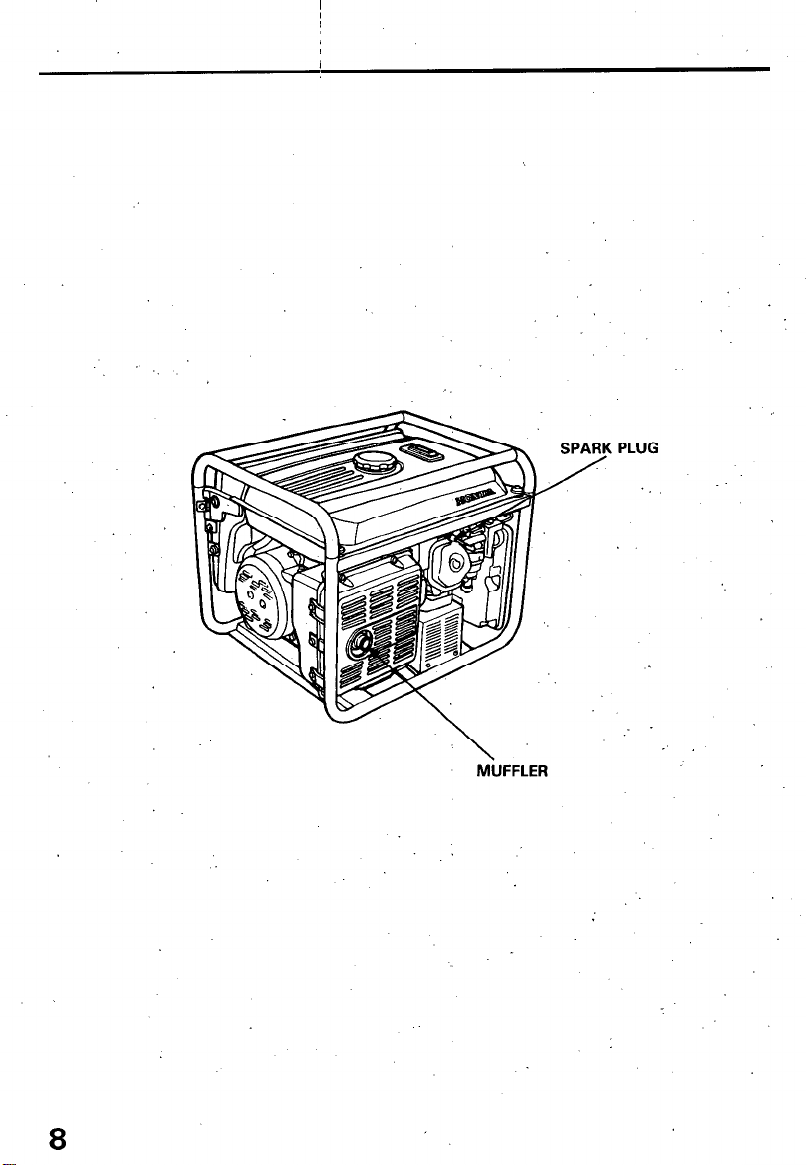

SPARK PLUG

‘_

8

3. PRE-OPERATION CHECK

Check the generator/welder on a level surface with the engine stopped.

Engine Oil

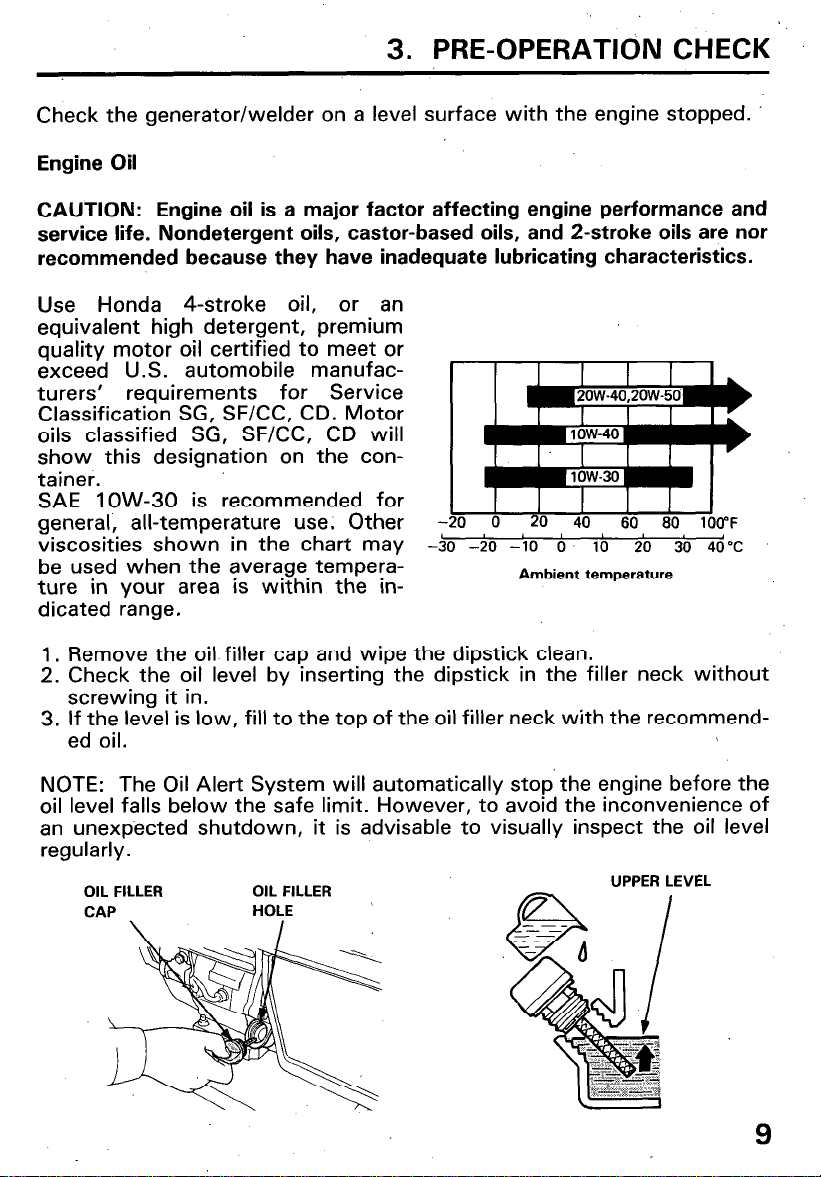

CAUTION: Engine oil is a major factor affecting engine performance and

service life. Nondetergent oils, castor-based oils, and 2-stroke oils are nor

recommended because they have inadequate lubricating characteristics.

Use Honda 4-stroke oil, or an

equivalent high detergent, premium

quality motor oil certified to meet or

exceed U.S. automobile manufacturers’

Classification SG, SF/CC, CD. Motor

oils classified SG, SF/CC, CD will

show this designation on the container.

SAE low-30 is recommended for

general, all-temperature use. Other

viscosities shown in the chart may

be used when the average temperature in your area is within the in-

dicated range.

requirements for Service

,

-30 -20

-10 0 10 20

Ambient temperature

30 40°C

1. Remove the oil filler cap and wipe

2. Check the oil level by inserting the dipstick in the filler neck without

the dipstick clean.

_

. .

screwing it in.

3. If the level is low, fill to the top of the oil filler neck with the recommended oil.

NOTE: The Oil Alert System will automatically stop the engine before the

oil level falls below the safe limit. However, to avoid the inconvenience of

an unexpected shutdown, it is advisable to visually inspect the oil level

regularly.

OIL FILLER OIL FILLER

CAP

HOLE

UPPER LEVEL

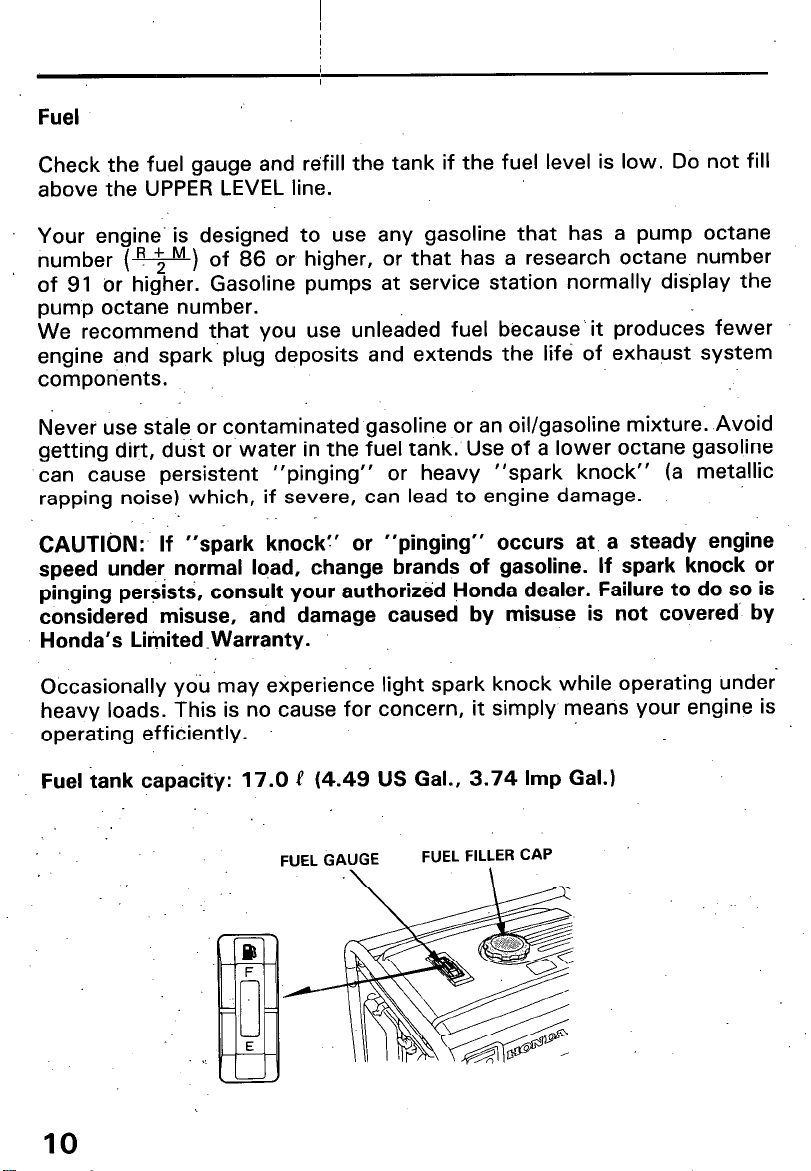

Fuel

Check the fuel gauge and refill the tank if the fuel level is low. Do not fill

above the UPPER LEVEL line.

Your engine- is designed to use any gasoline that has a pump octane

number (y) of 86

or higher, or that has a research octane number

of 91 or higher. Gasoline pumps at service station normally diSplay the

pump octane number.

We recommend that you use unleaded fuel because‘it produces fewer

engine and spark’plug deposits and extends the life of exhaust system

components.

Never use stale or contaminated gasoline or an oil/gasoline mixture. Avoid

getting dirt, dust or water in the fuel tank. Use of a lower octane gasoline

can cause persistent “pinging” or heavy “spark knock” (a metallic

rapping

CAUTION: If “spark knock!’ or “pinging” occurs at a steady engine

speed under, normal Iqad, change brands of gasoline. If spark knock or

pinging persists, consult your authorized Honda dealer. Failure to do so is

considered misuse, and damage caused by misuse is not covered’ by

Honda’s LiMited -Warranty.

noise) which, if severe, can lead to engine damage.

Occasionally yoti’may experience light spark knock while operating under.

heavy loads. This is no cause for concern, it simply means your engine is

operating efficiently.

Fuel tank capacity: 17.0 0 (4.49 US Gal., 3.74 Imp Gal.)

FUEL GAUGE

FUEL FILLER CAP

10

l

Gasoline is extremely flammable and is explosive under certain condi-

tions.

l

Refuel in a well-ventilated area with the engine stopped. Do not smoke

or allow flames or sparks in the area where the engine is refueled or

where gasoline is stored.

l

Do not overfill the fuel tank (there should be no fuel in the filler neck).

After refueling, make sure the tank cap is closed properly and securely.

l

Be careful not to spill fuel when refueling. Spilled fuel or fuel vapor may

ignite. If any fuel is spilled, make sure the area is dry before starting the

engine.

l

Avoid repeated or prolonged contact with skin or breathing of vapor.

KEEP OUT OF REACH OF CHILDREN.

GASOLINES CONTAINING ALCOHOL

If you decide to use a gasoline containing alcohol (gasohol), be sure it’s

octane rating is at least as high as that recommended by Honda. There are

two types of “gasohol”: one containing ethanol, and the other containing

methanol. Do not use gasohol that contains more than 10% ethanol. Do

not use gasoline containing methanol (methyl or wood alcohol) that does

not also contain cosolvents and corrosion inhibitors for methanol. Never

use gasoline containing more than 5% methanol, even if it has cosolvents B

and corrosion inhibitors.

NOTE:

l

Fuel system damage or engine performance problems resulting from the

use of fuels that contain alcohol is not covered under the warranty.

Honda cannot endorse the use of fuels containing methanol since

evidence of their suitability,is as yet incomplete.

l

Before buying fuel from an unfamiliar station, try to find out if the fuel

contains alcohol, if it does, confirm the type and percentage of alcohol

used. If you notice any undesirable operating symptoms ,while using a

gasoline that contains alcohol, or one that you think contains alcohol,

switch to a gasoline that you know does not contain alcohol.

11

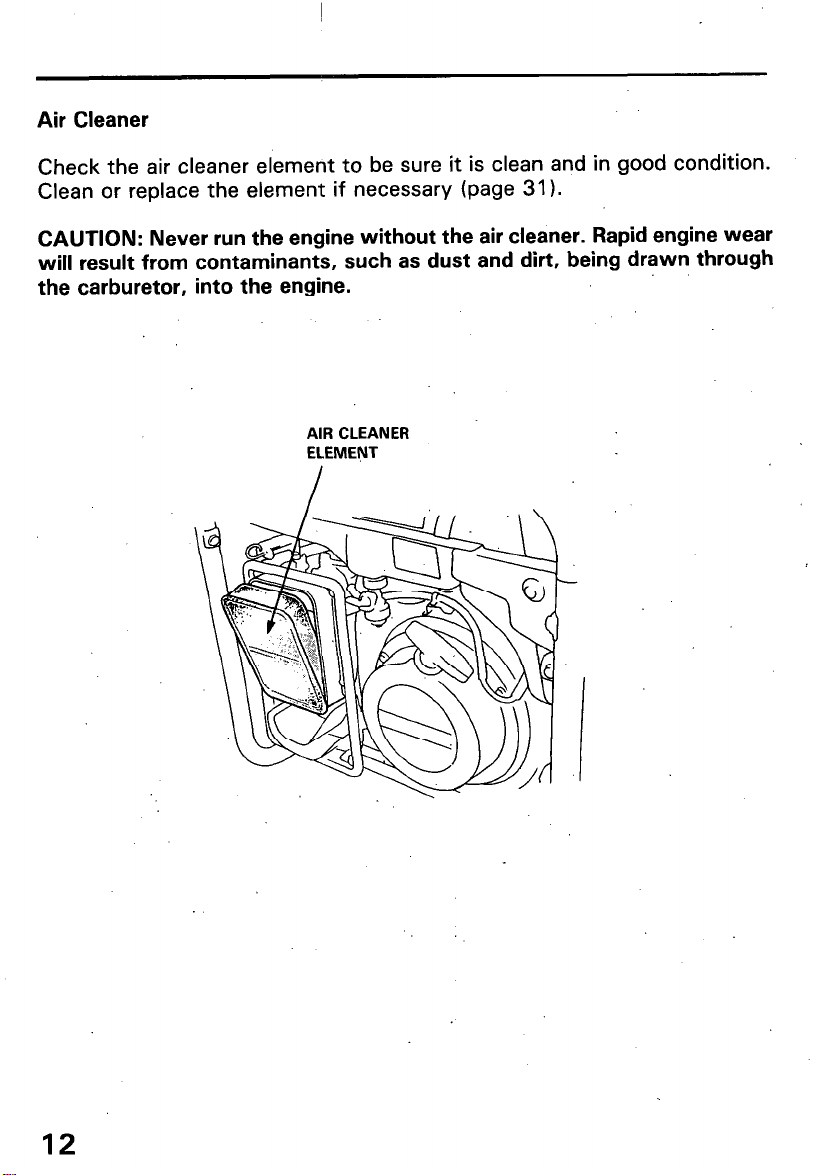

Air Cleaner

Check the air cleaner element to be sure it is clean and in good condition.

Clean or replace the element if necessary (page 31).

CAUTION: Never run the engine without the air cleaner. Rapid engine wear

will result from contaminants, such as dust and dirt, being drawn through

the carburetor, into the engine.

AIR CLEANER

ELEMENT

I

12

3. STARTING THE ENGINE

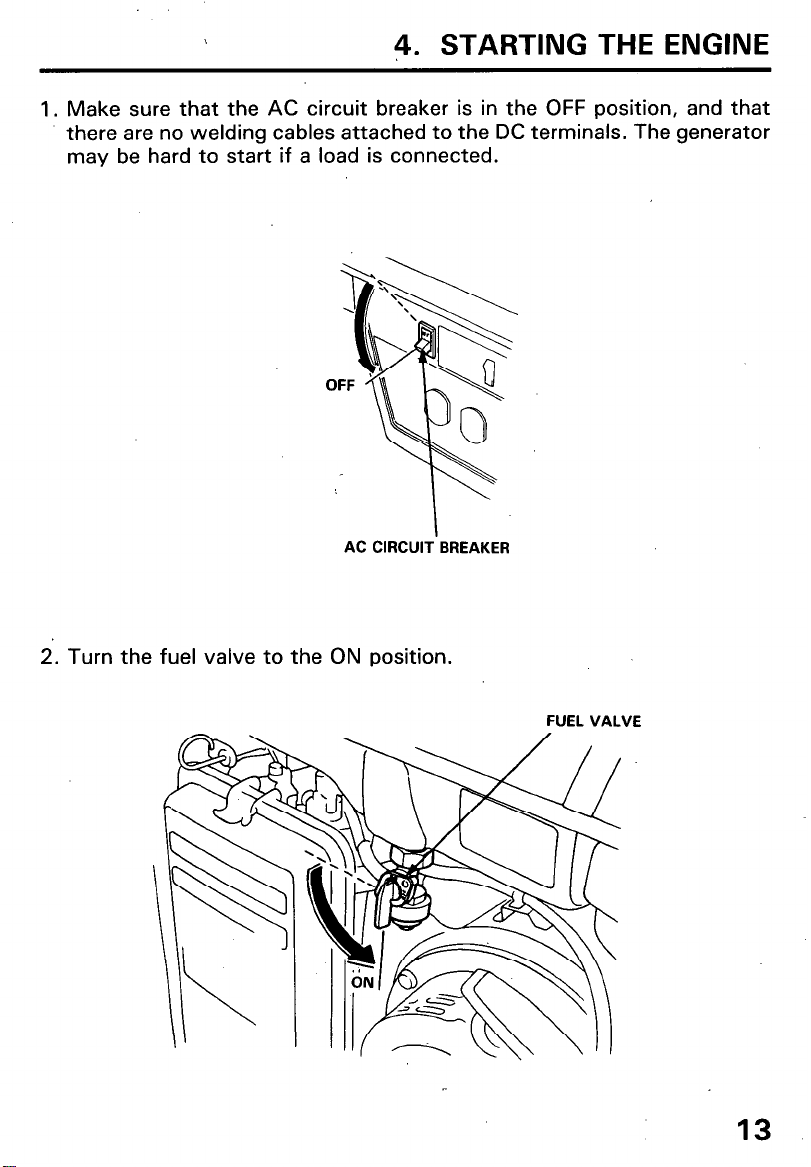

1. Make sure that the AC circuit breaker is in the OFF position, and that

there are no welding cables attached to the DC terminals. The generator

may be hard to start if a load is connected.

AC CIRCUIT BREAKER

2. Turn the fuel valve to the ON position.

FUEL VALVE

13