Thank you for purchasing a Honda generator.

This manual describes operation and maintenance of the Honda EB12D

Generator. All information in this publication is based on the latest product

information available at the time of printing. Honda Motor Co., Ltd,

reserves the right to make changes at any time without notice and without

incurring any obligation.

No part of this publication may be reproduced without written permission.

This manual is a permanent part of the generator, and it must stay with the

generator if resold.

The Honda EB12D generator is not factory equipped with a spark arrester.

In some areas, it is illegal to operate an engine without a USDA-qualified

spark arrester. Check local laws and regulations before operating. An op-

tional spark arrester is available from an authorized Honda generator

dealer.

READ THIS OWNER’S MANUAL CAREFULLY. Pay special attention to

these symbols and any instructions that follow:

m

m -Indicates a strong possibility that serious injury or death

m

m -Indicates that equipment or property damage can result if in-

NOTE: Gives helpful information.

Honda generators are designed to give safe and dependable service if

operated according to instructions. Operating this generator requires

special effort on your part to ensure your safety of others. Using this

generator for a purpose not intended’ may cause injury or property

damage.

m

damage. Read and understand the owner’s manual before operating this

generator.

If a problem should arise, or if you have any questions about the generator,

see an authorized Honda generator dealer.

-Indicates serious injury or death WILL result if instructions

are not followed.

could result if instructions are not followed.

-Indicates a possibility that minor injury can result if instructions are not followed.

structions are not followed.

Careless operation or misuse may cause injury or property

HONDA MOTOR CO., LTD. 1990, ALL RIGHTS RESERVED

1

CONTENTS

1. SAFETY INFORMATION

2. COMPONENT IDENTIFICATION

3. CONTROLS

Engine switch

Circuit breaker

Circuit protector

Ground Fault Circuit Interrupter (GFCI) Receptacle

Fuel meter

Hour meter

Indicator lights

4. PRE-OPERATION CHECKS

Maintenance cover opening and closing

Engine oil

Fuel

Coolant

Fuel filter

Battery

Indicator lights

5. STARTING AND STOPPING THE ENGINE

Starting the engine

Stopping the engine

6. GENERATOR USE

7. MAINTENANCE .................................................................

Tool kit

Maintenance schedule

Engine oil change

Air cleaner

Fuel filter

Battery

Fuse replacement

8. TRANSPORTING AND STORAGE

9. TROUBLESHOOTING

10. SPECIFICATIONS

11. WIRING DIAGRAM

12. WARRANTY SERVICE

.......................................................................

..................................................................

.................................................................

...............................................................

.......................................................................

......................................................................

.................................................................

........................................................................

...............................................................................

..........................................................................

........................................................................

...........................................................................

.................................................................

...........................................................................

.......................................................................

........................................................................

...........................................................................

......................................................

............................................

...................................................

................................

...............................

...........................................................

..........................................................

..............................................................

.......................................................

..............................................................

.............................................................

..........................................

..........................................................

...............................................................

.............................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.................

3

5

7

7

8

8

9

10

10

11

13

13

14

15

17

18

::

21

21

24

26

32

32

33

34

35

37

38

40

41

43

44

45

46

2

I. SAFETY INFORMATION

SAFETY INFORMATION

For your safety and the safety of others, pay special attention to these

precautions:

Operator Responsibility

l

Know how to stop the generator quickly in case of emergency. Understand the use of all generator controls, output receptacles, and

connections.

l

Be sure that anyone who operates the generator receives proper in-

struction. Do not let children operate the generator without parental

supervision.

Electric Shock Hazards

l

The generator produces enough electric power to cause a serious shock

or electrocution if misused.

l

Using a generator or electrical appliance in wet conditions, such as rain

or snow, or near a pool or sprinkler system, or when your hands are

wet, could result in electrocution. Keep the generator dry.

l

If the generator is stored outdoors, unprotected from the weather,

check the Ground Fault Circuit Interrupter (GFCI) receptacle, and all

other electrical components on the control panel, before each use.

Moisture or ice can cause a malfunction or short circuit in electrical

components which could result in electrocution.

l

Do not connect to a building’s electrical system unless an isolation

switch has been installed by a qualified electrician.

Fire and Burn Hazards

l

The exhaust system gets hot enough to ignite some materials.

- Keep the generator at least 1 meter (3 feet) away from buildings and

other equipment during operation.

- Keep flammable materials away. from the generator.

l

The muffler becomes very hot during operation and remains hot for

while after stopping the engine. Be careful not to touch the muffler

while it is hot. Let the engine cool before storing the generator indoors.

l

Diesel fuel is flammable, and fuel vapor can explode. Refuel in a well

ventilated area with the engine stopped. Keep flames and sparks away,

and do not smoke in the area.

l

Diesel fuel may spill and ignite if the generator is tilted or overturned.

Place the generator on a firm, level surface. Avoid loose sand or snow.

Carbon Monoxide Hazards

l

Exhaust contains poisonous carbon monoxide, a colorless and odorless

gas. Breathing exhaust can cause loss of consciousness and may lead

to death.

l

If you run the generator in an area that is confined, or even partially

enclosed, the air you breathe could contain a dangerous amount of exhaust gas. To keep exhaust gas from building up, provide adequate

ventilation.

3

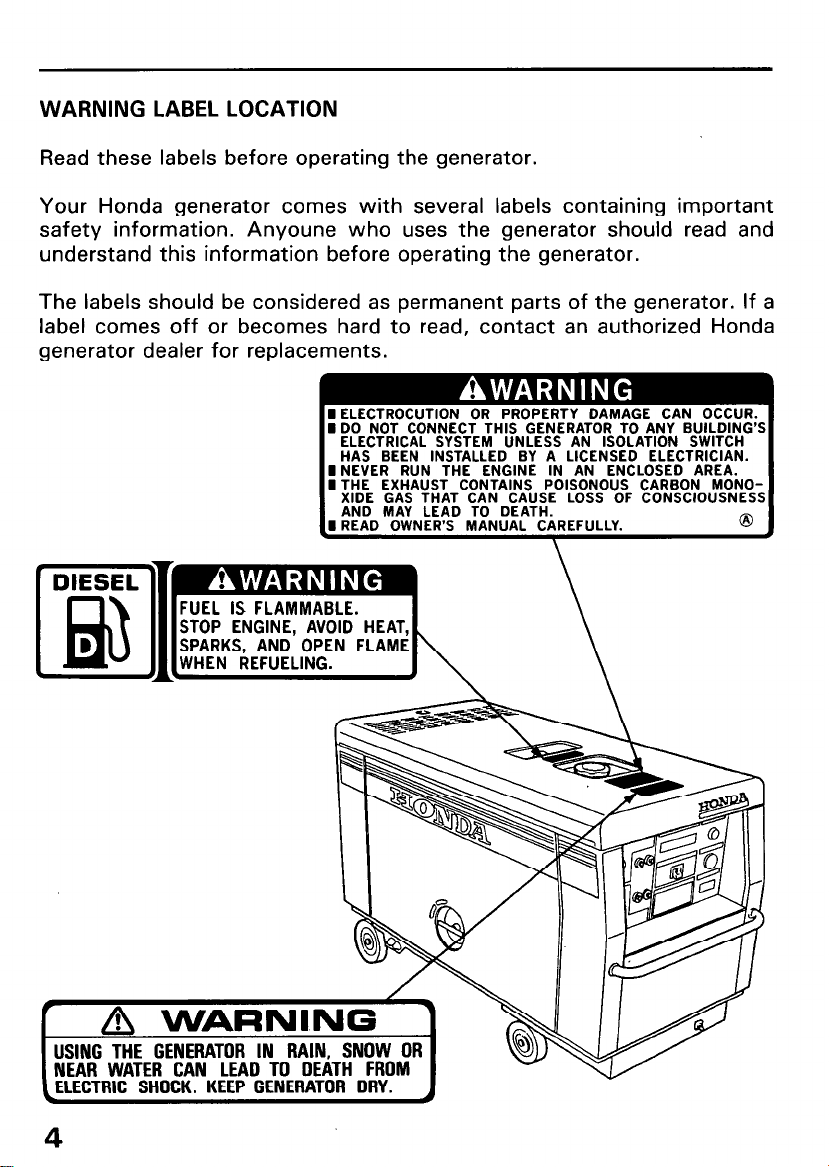

WARNING LABEL LOCATION

Read these labels before operating the generator.

Your Honda generator comes with several labels containing important

safety information. Anyoune who uses the generator should read and

understand this information before operating the generator.

The labels should be considered as permanent parts of the generator. If a

label comes off or becomes hard to read, contact an authorized Honda

generator dealer for replacements.

I ELECTROCUTION OR PROPERTY DAMAGE CAN OCCUR.

I DO NOT CONNECT THIS GENERATOR TO ANY BUILDING’S

ELECTRICAL SYSTEM UNLESS AN ISOLATION SWITCH

HAS BEEN INSTALLED BY A LICENSED ELECTRICIAN.

INEVER RUN THE ENGINE IN AN ENCLOSED AREA.

lTHE EXHAUST CONTAINS POISONOUS CARBON MONO-

XIDE GAS THAT CAN CAUSE LOSS OF CONSCIOUSNESS

AND MAY LEAD TO DEATH.

I READ OWNER’S MANUAL CAREFULLY.

\

@

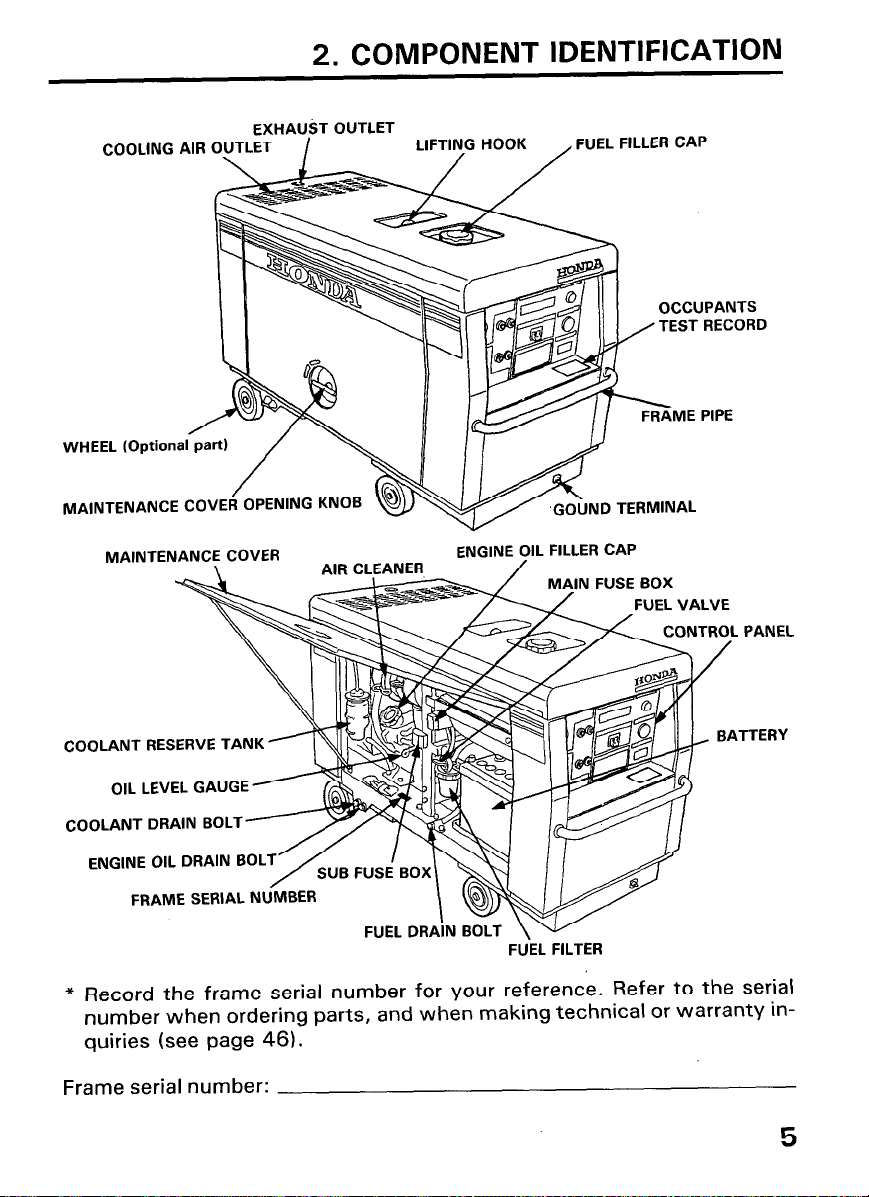

2. COMPONENT IDENTIFICATION

COOLING AIR OLJTLET

MAINTENANCE COVE

MAINTENANCE COVER

EXHAUST OUTLET

/ LIFTIYG HOOK

, FUEL FILLER CAP

TEST RECORD

ENGINE OIL FILLER CAP

PANEL

OOLANT RESERVE TANK

OIL LEVEL GAUG

)OLANT DRAIN

ENGINE OIL DRAIN BOLT

FRAME SERIAL NLkMBER

BOL

I 68%

FUEL DRAIN BOLT

\w ’

d

FUEL FILTER

L

TTERY

* Record the frame serial number for your reference. Refer to the serial

number when ordering parts, and when making technical or warranty inquiries (see page 46).

Frame serial number:

5

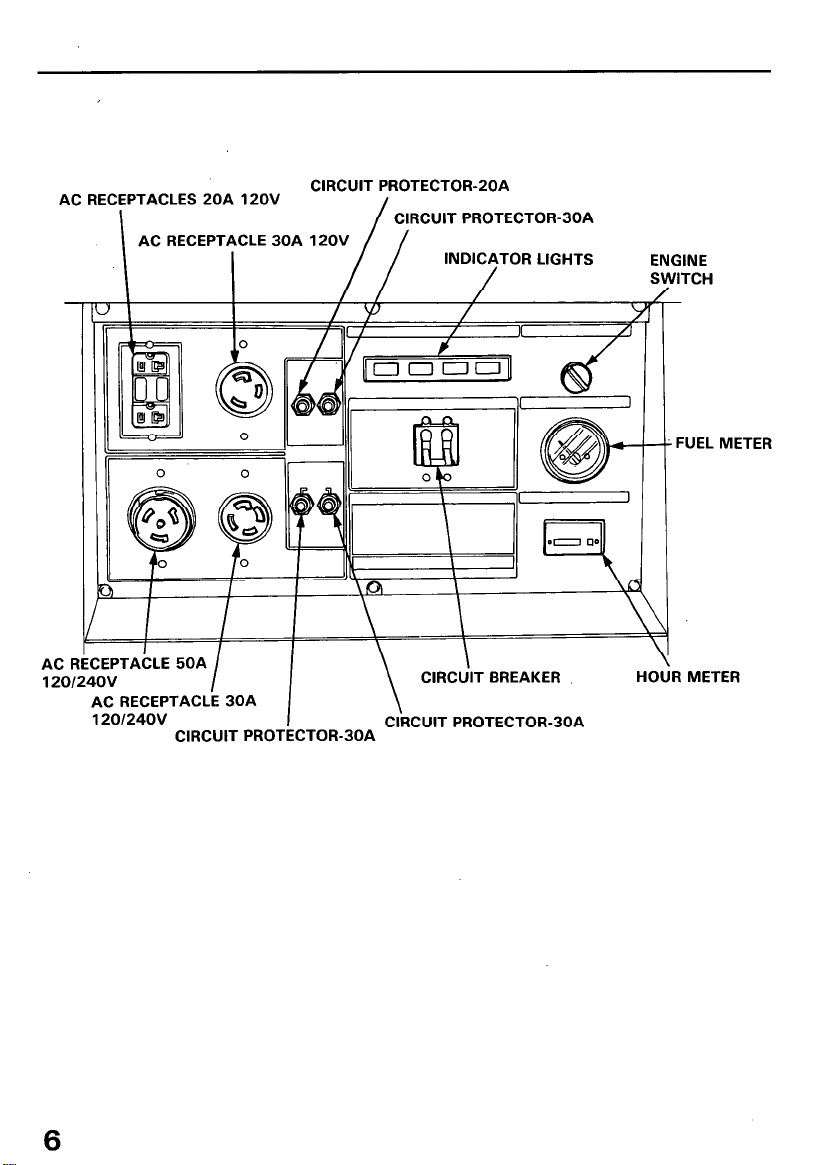

AC RECEPTACLES 20A 120V

AC RECEPTACLE 30A 12OV

I

AC I

1201

TACLE 50A

I24OV

AC RECEPTACLk 30A

120124OV

I

I

CIRCUIT PROTECTOR-BOA

CIRCUIT PROTECTOR-2OA

I

/

CIRCUIT PROTECTOR-30A

INDICATOR LIGHTS

CIRdIT BREAKER

\

\

CIRCUIT PROTECTOR-30A

ENGINE

sv

/

VITCH

/

,

: FUEL METER

a

\

IU iR METER

6

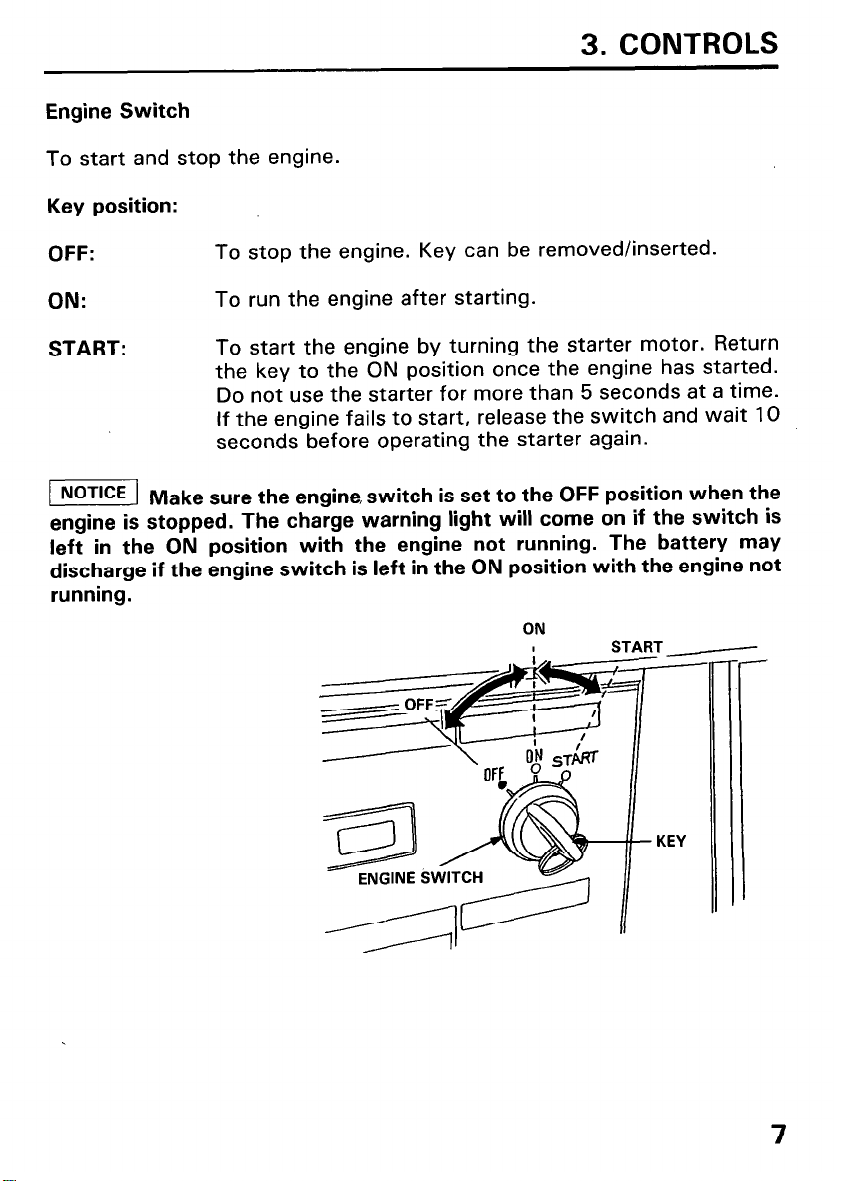

Engine Switch

To start and stop the engine.

Key position:

3. CONTROLS

OFF:

ON:

START: To start the engine by turning the starter motor. Return

w Make sure the engine, switch is set to the OFF position when the

engine is stopped. The charge warning light will come on if the switch is

left in the ON position with the engine not running. The battery may

discharge if the engine switch is left in the ON position with the engine not

running.

To stop the engine. Key can be removed/inserted.

To run the engine after starting.

the key to the ON position once the engine has started.

Do not use the starter for more than 5 seconds at a time.

If the engine fails to start, release the switch and wait 10

seconds before operating the starter again.

ON

KEY

7

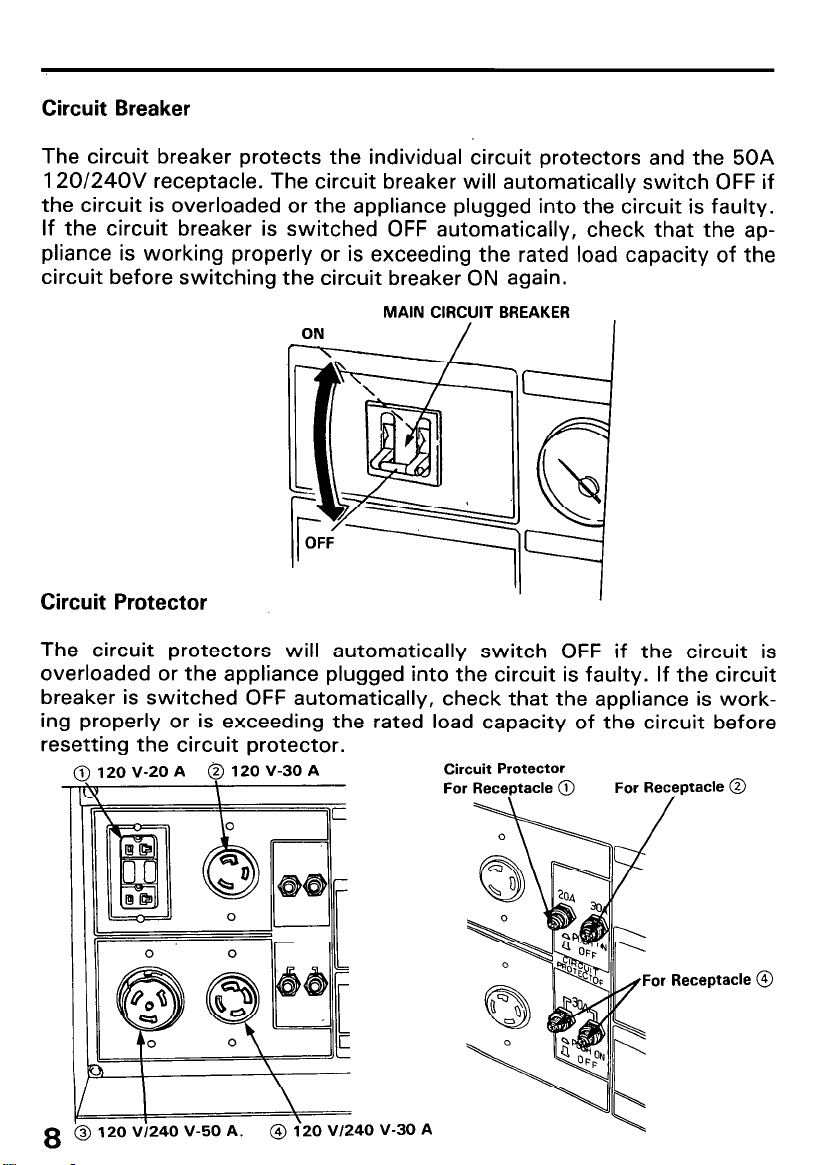

Circuit Breaker

The circuit breaker protects the individual circuit protectors and the 50A

120/24OV receptacle. The circuit breaker will automatically switch OFF if

the circuit is overloaded or the appliance plugged into the circuit is faulty.

If the circuit breaker is switched OFF automatically, check that the appliance is working properly or is exceeding the rated load capacity of the

circuit before switching the circuit breaker ON again.

MAIN CIRCUIT BREAKER

Circuit Protector

The circuit protectors will automatically switch OFF if the circuit is

overloaded or the appliance plugged into the circuit is faulty. If the circuit

breaker is switched OFF automatically, check that the appliance is working properly or is exceeding the rated load capacity of the circuit before

resetting the circuit protector.

@12OV-20A @lZOV-30A

q.

\

I K-

Circuit Protector

For Receptacle @

For Receptacle @

/

8 ‘oVv)240 V-50 A.

@ i20 VI240 V-30 A

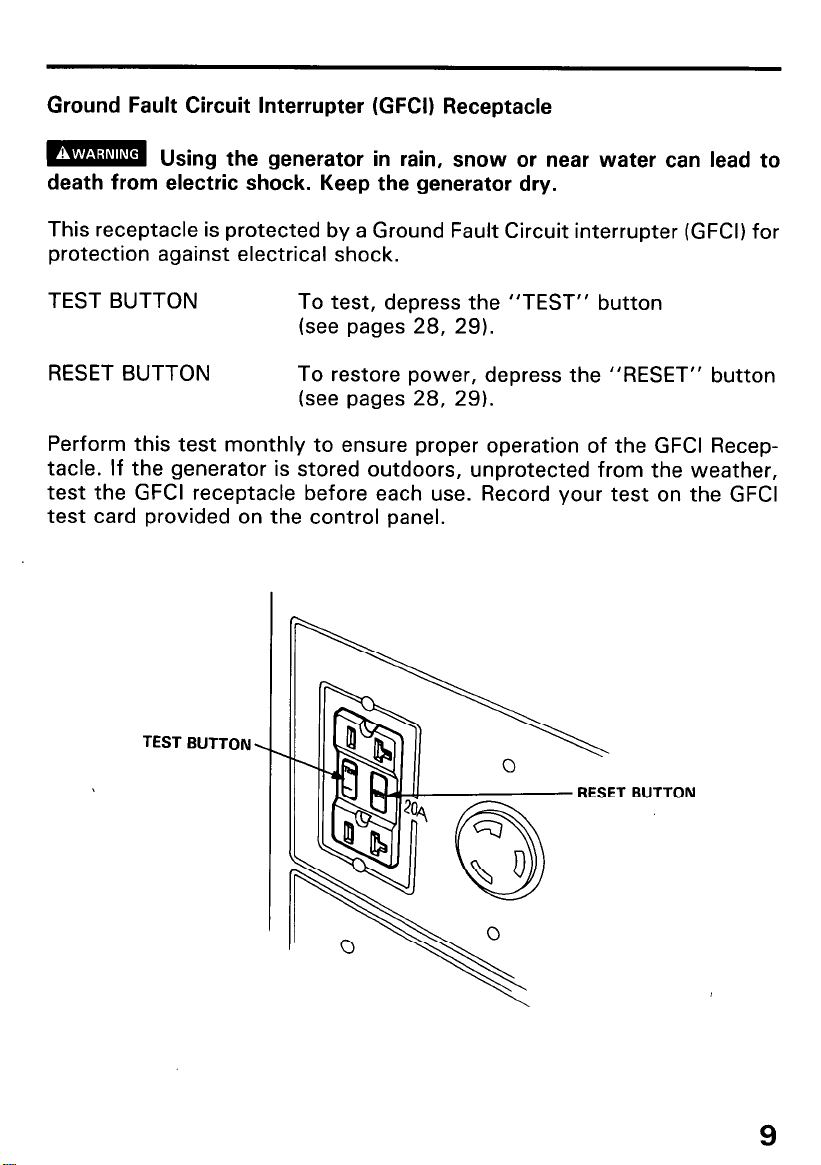

Ground Fault Circuit Interrupter (GFCI) Receptacle

m Using the generator in rain, snow or near water can lead to

death from electric shock. Keep the generator dry.

This receptacle is protected by a Ground Fault Circuit interrupter (GFCI) for

protection against electrical shock.

TEST BUTTON

To test, depress the “TEST” button

(see pages 28, 29).

RESET BUTTON

To restore power, depress the “RESET” button

(see pages 28, 29).

Perform this test monthly to ensure proper operation of the GFCI Receptacle. If the generator is stored outdoors, unprotected from the weather,

test the GFCI receptacle before each use. Record your test on the GFCI

test card provided on the control panel.

TEST

BUTTON

BUTTON

9

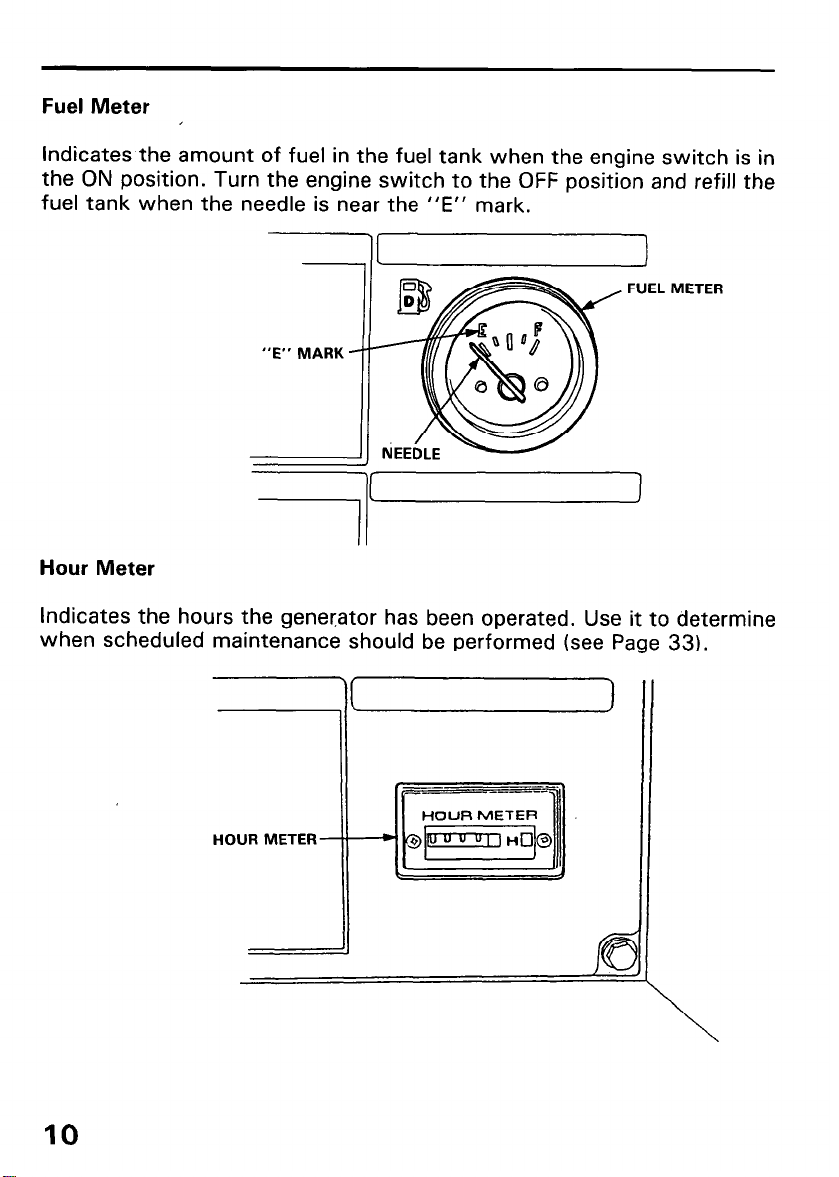

Fuel Meter

Indicates the amount of fuel in the fuel tank when the engine switch is in

the ON position. Turn the engine

fuel tank when the needle is near the “E” mark.

switch to the OFF position and refill the

FUEL METER

I

71

Hour Meter

Indicates the hours the gener,ator has been operated. Use it to determine

when scheduled maintenance should be performed (see Page 33).

10

HOUR METER

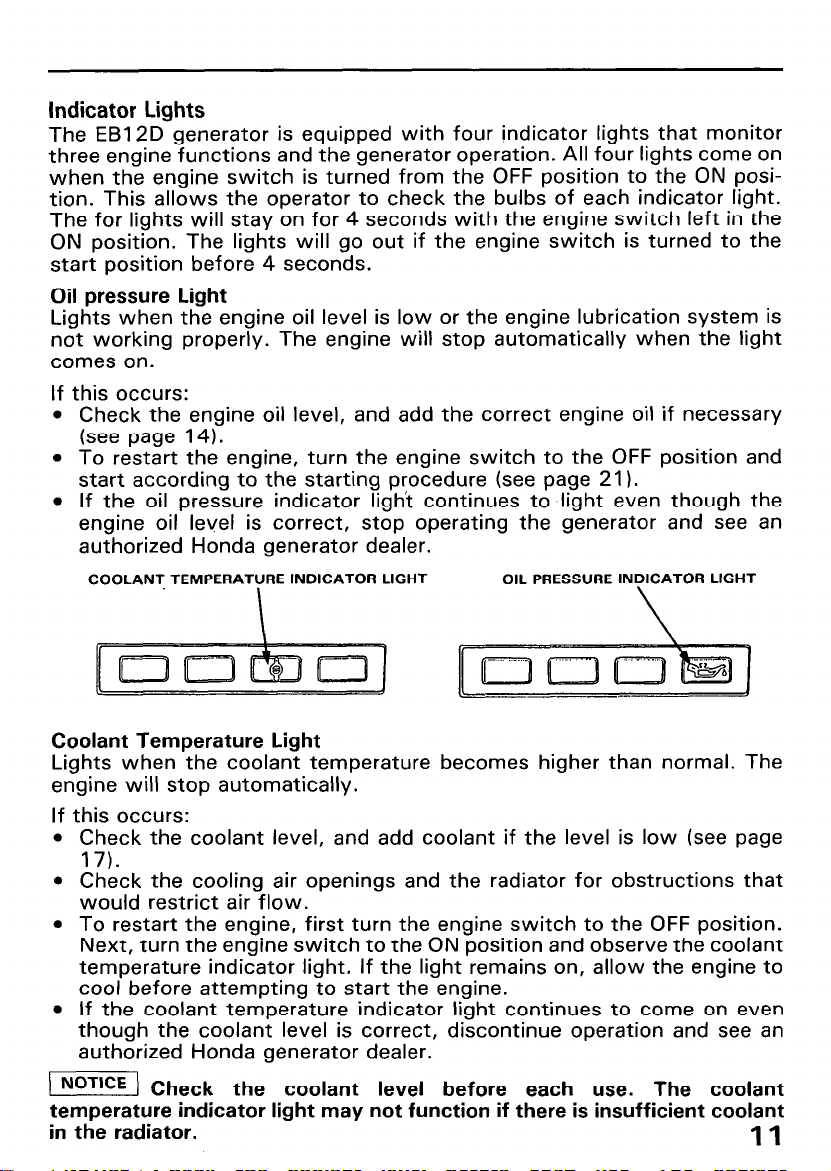

Indicator Lights

The EB12D generator is equipped with four indicator lights that monitor

three engine functions and the generator operation. All four lights come on

when the engine switch is turned from the OFF position to the ON posi-

tion. This allows the operator to check the bulbs of each indicator light.

The for lights will stay on for 4 seconds with the engine switch left in the

ON position. The lights will go out if the engine switch is turned to the

start position before 4 seconds.

Oil pressure Light

Lights when the engine oil level is low or the engine lubrication system is

not working properly. The engine will stop automatically when the light

comes on.

If this occurs:

l Check the engine oil level, and add the correct engine oil if necessary

(see page 14).

l To restart the engine, turn the engine switch to the OFF position and

start according to the starting procedure (see page 21 I.

l If the oil pressure indicator light continues to light even though the

engine oil level is correct, stop operating the generator and see an

authorized Honda generator dealer.

COOLANT TEMPERATURE INDICATOR LIGHT

OIL PRESSURE INDICATOR LIGHT

Coolant Temperature Light

Lights when the coolant temperature becomes higher than normal. The

engine will stop automatically.

If this occurs:

l Check the coolant level, and add coolant if the level is low (see page

17).

l Check the cooling air openings and the radiator for obstructions that

would restrict air flow.

l To restart the engine, first turn the engine switch to the OFF position.

Next, turn the engine switch to the ON position and observe the coolant

temperature indicator light. If the light remains on, allow the engine to

cool before attempting to start the engine.

l If the coolant temperature indicator light continues to come on even

though the coolant level is correct, discontinue operation and see an

authorized Honda generator dealer.

NoT’CE Check the coolant level before each use. The coolant

temperature indicator light may not function if there is insufficient coolant

in the radiator.

11

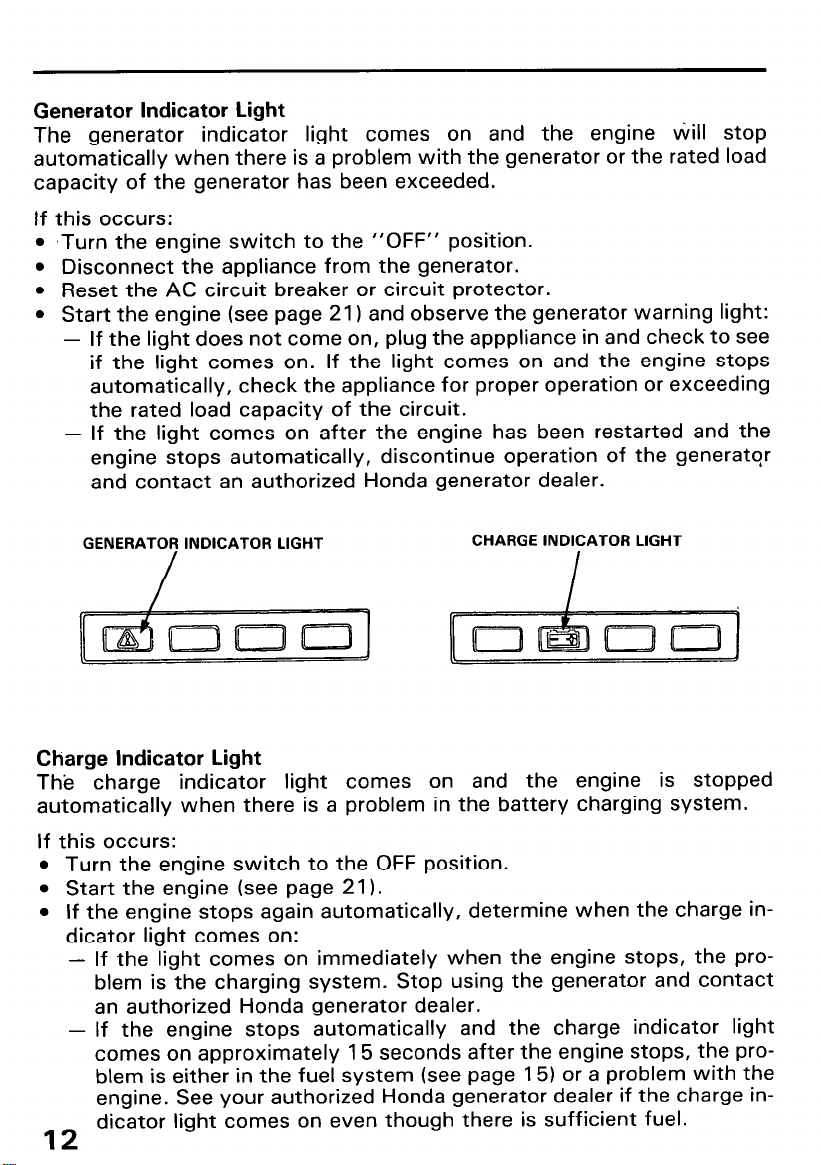

Generator Indicator Light

The generator indicator light comes on and the engine Will stop

automatically when there is a problem with the generator or the rated load

capacity of the generator has been exceeded.

If this occurs:

l

,Turn the engine switch to the “OFF” position.

l

Disconnect the appliance from the generator.

l

Reset the AC circuit breaker or circuit protector.

l

Start the engine (see page 21) and observe the generator warning light:

-

If the light does not come on, plug the apppliance in and check to see

if the light comes on. If the light comes on and the engine stops

automatically, check the appliance for proper operation or exceeding

the rated load capacity of the circuit.

-

If the light comes on after the engine has been restarted and the

engine stops automatically, discontinue operation of the generator

and contact an authorized Honda generator dealer.

GENERATOR INDICATOR LIGHT

CHARGE INDICATOR LIGHT

Charge Indicator Light

The charge indicator light comes on and the engine is stopped

automatically when there is a problem in the battery charging system.

If this occurs:

l

Turn the engine switch to the OFF position.

l

Start the engine (see page 21).

l

If the engine stops again automatically, determine when the charge in-

dicator light comes on:

-

If the light comes on immediately when the engine stops, the problem is the charging system. Stop using the generator and contact

an authorized Honda generator dealer.

-

If the engine stops automatically and the charge indicator light

comes on approximately 15 seconds after the engine stops, the problem is either in the fuel system (see page 15) or a problem with the

engine. See your authorized Honda generator dealer if the charge in-

dicator light comes on even though there is sufficient fuel.

12

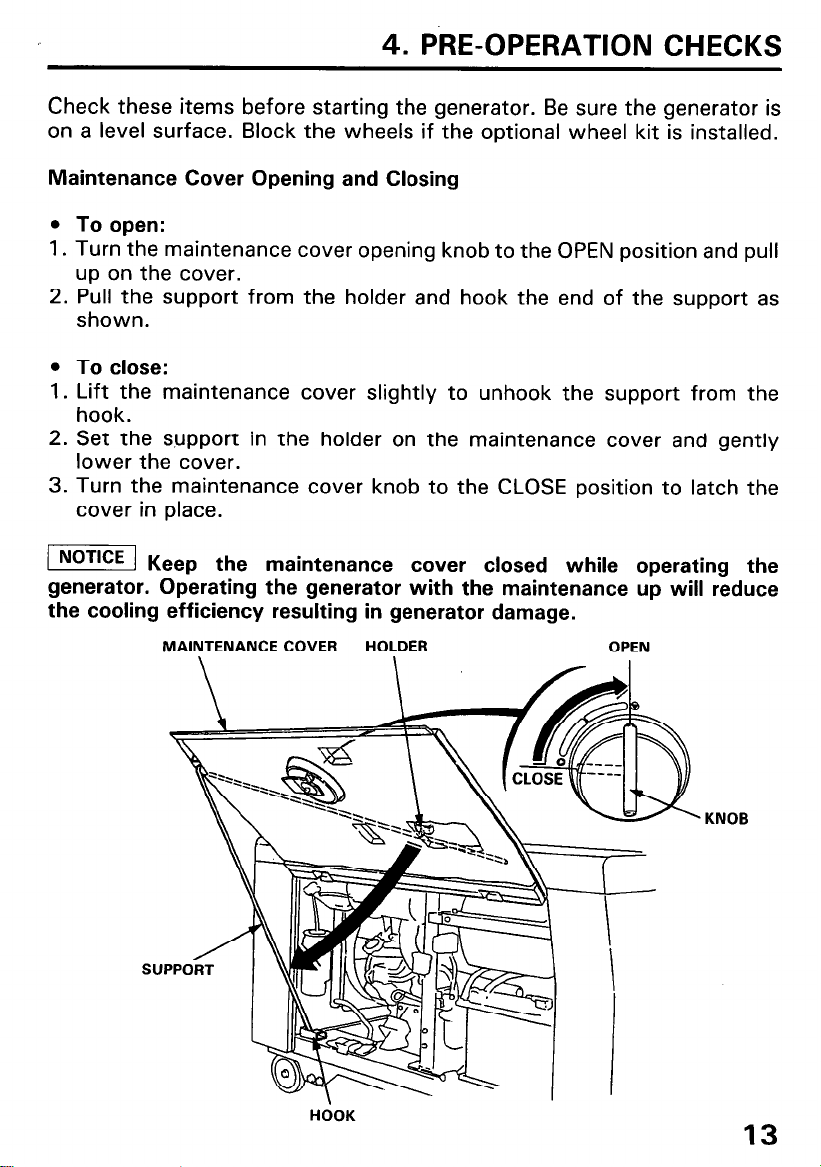

4. PRE-OPERATION CHECKS

Check these items before starting the generator. Be sure the generator is

on a level surface. Block the wheels if the optional wheel kit is installed.

Maintenance Cover Opening and Closing

l

To open:

1. Turn the maintenance cover opening knob to the OPEN position and pull

up on the cover.

2. Pull the support from the holder and hook the end of the support as

shown.

l

To close:

1. Lift the maintenance cover slightly to unhook the support from the

hook.

2. Set the support in the holder on the maintenance cover and gently

lower the cover.

3. Turn the maintenance cover knob to the CLOSE position to latch the

cover in place.

( Ke

ep the maintenance cover closed while operating the

generator. Operating the generator with the maintenance up will reduce

the cooling efficiency resulting in generator damage.

MAINTENANCE COVER

HOLDER OPEN

KNOB

HOOK

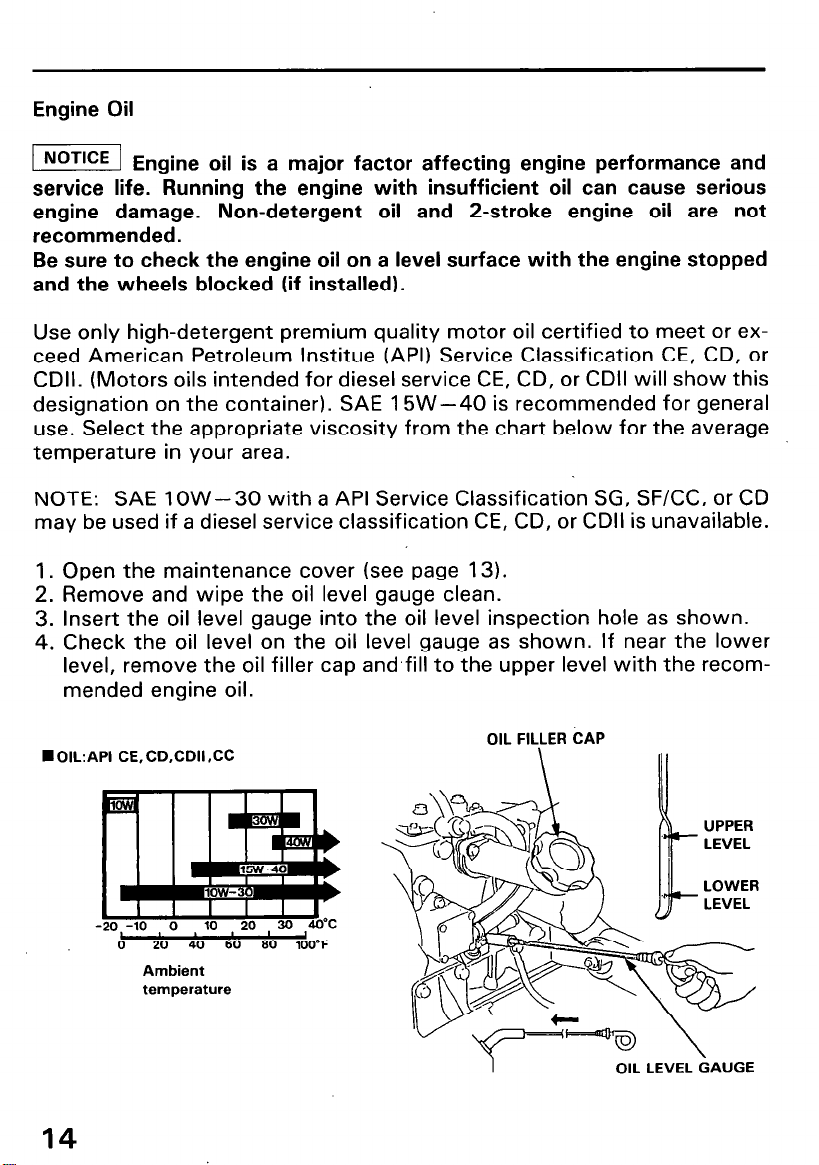

Engine Oil

-1 En

gine oil is a major factor affecting engine performance and

service life. Running the engine with insufficient oil can cause serious

engine damage. Non-detergent oil and 2-stroke engine oil are not

recommended.

Be sure to check the engine oil on a level surface with the engine stopped

and the wheels blocked (if installed).

Use only high-detergent premium quality motor oil certified to meet or exceed American Petroleum lnstitue (API) Service Classification CE, CD, or

CDII. (Motors oils intended for diesel service CE, CD, or CDII will show this

designation on the container). SAE 15W-40 is recommended for general

use. Select the appropriate viscosity from the chart below for the average

temperature in your area.

NOTE: SAE low-30 with a API Service Classification SG, SF/CC, or CD

may be used if a diesel service classification CE, CD, or CDII is unavailable.

1. Open the maintenance cover (see page 13).

2. Remove and wipe the oil level gauge clean.

3. Insert the oil level gauge into the oil level inspection hole as shown.

4. Check the oil level on the oil level gauge as shown. If near the lower

level, remove the oil filler cap and,fill to the upper level with the recommended engine oil.

n

OIL:API CE, CD,CDII SC

0

20 40 60 00 100°F

Ambient

temperature

14

OIL FILLER CAP

1

OIL LEVEL GAUGE

Fuel

Fuel tank capacity: 38 lit. (IO US gal, 8.4 Imp. gal1

Turn the engine switch ON and check the fuel meter.

Refill the tank to the upper level if necessary. Do not fill the fuel tank above

the upper level mark.

Use ONLY clean high-quality fuel.

Recommended fuel specifications: ASTM D-975-l -D/2-D

Use No. 2-D fuel at temperatures above 20°F (-7OC)

Use No. 1-D fuel at temperatures below 20°F (-7OC)

Use No. 1 -D fuel for all temperatures at altitudes above 5000 ft (1500 m).

Diesel fuel with a cetane rating as low as 40 may be used, but a cetane

rating of 45 is recommended.

Do not use contaminated diesel fuel.

Do not mix different grades of diesel fuels.

Avoid getting dirt, dust or water in the fuel tank.

After refueling, be sure to tighten the fuel tank cap securely.

l

Diesel fuel is flammable and explosive under certain conditions. Refuel

in a well ventilated area with the engine stopped.

l

Do not smoke or allow flames or sparks in the area where the engine is

refueled or where diesel fuel is stored.

l

Do not overfill the tank, and make sure the filler cap is securely closed

after refueling.

l

Be careful not to spill fuel when refueling. Spilled fuel vapor may ignite.

If fuel is spilled, make sure the area is dry before starting the engine.

l

Use diesel fuel only. Do not use gasoline, kerosene or any other fuel

oils. Do not mix gasoline with diesel fuel.

UPPER LEVEL

ON

--ENGINE

FUEL

15

NOTE:

l

Depending on the season and the ambient temperature, a different

grade of diesel fuel should be used. If a summer grade fuel is used in the

winter, the summer fuel may freeze preventing the engine from starting. Winter grade fuel is used in the summer could result in a lack of

engine power. Be sure to use the proper grade of diesel fuel which complies with the ambient temperature.

l

Keep the fuel tank filled in the winter. Water can accumulate from condensation if the tank is kept only partially filled. Refill the fuel tank after

each use.

l

Check the fuel filter before each use for water and contaminates. Service the fuel filter if any contaminates are found (see page 18).

Air Bleeding

The generator is equipped with an automatic air bleeding system in the

event the engine is run out of fuel. Refill the tank (see page 15). Make sure

that fuel is supplied to the fuel filter, then start the engine (see page 21).

NOTE: Light blue exhaust will be seen and the engine speed may fluctuate as air bleeding is occuring. This is normal. Run the engine without a

load until the engine speed stabilizes and the exhaust smoke clears.

16

Coolant

1.

Open the maintenance cover (see page 13).

2.

Check the coolant level in the reserve tank when the engine is at normal

operating temperature.

If the level is near the MIN level, add coolant to bring it up to the MAX

level (see page 18 for coolant recommendation).

MAX (UPPER

MIN (LOWER

LEVEL)

I

LEVEL)

TANK

3. If there is no coolant in the reserve tank, the cooling system should be

checked for leaks and repaired if necessary. Coolant must then be add-

ed to the radiator and reserve tank.

m

The coolant is hot and under pressure and sever scalding

could result. Never remove the radiator cap when the engine is hot.

Wait until the engine is cool, then turn the radiator cap

counterclockwise until it stops.

DO NOT PRESS DOWN WHILE

TURNING THE CAP. After any remaining pressure has been relieved,

remove the cap

by pressing down and again turning it

counterclockwise. Add enough coolant to fill the radiator, and reinstall

the cap. Be sure to tighten it securely. Fill the reserve tank up to the

MAX level with the engine cold. Recheck the reserve tank once the

engine reaches normal operating temperature.

17

Coolant Recommendation

Use high quality ethylene glycol antifreeze that is specifically formulated

for use in aluminum engines. Mix the antifreeze with low-mineral drinking

water or distilled water.

A 50/50 mixture of ethylene glycol antifreeze and water is recommended

for most temperature and provides good corrosion brotection. A higher

concentration of antifreeze decrease cooling efficiency and is recommended only if additional protection against freezing is needed. A concentration

of less than 40% antifreeze will not provide proper corrosion protection.

[ NOTICE ] Th

cause corrosion damage that will shorten the life of the engine.

Fuel Filter

1. Open the maintenance cover (see page 13).

2. Inspect the fuel filter for dirt, water, or other contaminates and clean

the fuel filter if necessary (see page 37).

e use of unsuitable antifreeze, hard water, or salt water will

FUEL STRAINER

18

STRAINEi ELEMENT

Battery

The electrolyte level must be kept between the UPPER and LOWER level

marks. If the electrolyte level is near the LOWER level, remove the battery

filler caps and carefully add distilled water to the upper level line (see page

38).

UPPER LEVEL

LOWER LEVEL

m

or skin causes burns. Wear protective clothing and use eye protection

when working near the battery.

POISON-KEEP OUT OF REACH OF CHILDREN

EMERGENCY PROCEDURES:

Eyes

Skin -Remove contaminated clothing. Flush skin with large

If swallowed -Drink water or milk and call your poison control center or a

The battery contains corrosive sulfuric acid. Contact with eyes

-Flush with water from a cup or other container for at least

15 minutes. Call a physician immediately.

quantities of water. Call a physician.

physician immediately.

19

Indicator lights

Turn the engine switch to the ON position and check to see if the indicator

lights come on. The indicator lights should go out after 4 seconds with the

engine switch in the ON position.

Return the engine switch to the OFF position.

If the indicator light(s) does not come on, or do not go out after 4 seconds

with the engine switch in the ON position, contact an authorized Honda

generator dealer.

20

ENGINE

INDICATOR LIGHTS

w

I

SWITCH

5. STARTING AND STOPPING THE ENGINE

Starting the engine

Before starting the engine disconnect any load from the AC receptacle.

1. Open the maintenance cover (see page 13) and turn the fuel valve to

the ON position.

ON

2. Close the maintenance cover (see page 13).

3. Turn the AC circuit breaker OFF.

AC CIRCUIT BREAKER

21

4. Insert the key and turn the engine switch to the ON position. If the ambient temperature is below freezing, wait for the indicator lights to go

OFF before turning the key to the start position. This allows the glows

plug to pre-heat the combustion chambers.

ON

5. Turn the engine switch to the START position and hold it there until the

engine starts.

/TiEiq Q)

erating the starter motor for more than 5 seconds can

damage the motor. If the engine fails to start, release the key,and wait at

least 10 seconds before operating the starter motor again.

. .

ENGINE SWITCH

22

6. After the engine starts, let the engine switch return to the ON position.

ON

7. Warm the engine for 2 or 3 minutes before applying a load to the

generator. Blue smoke might be emitted from the exhaust during the

warm-up. This is a normal occurrence.

piEiq pr

needed to warm-up the engine oil and properly lubricate internal engine

parts.

oper engine warm-up will stabiliie the engine speed. It also is

23

Stopping the engine

In an emergency:

Turn the engine switch to the OFF position.

-ENGINE SWITCH

In normal use:

1. Turn all electrical appliance’s connected to the generator OFF.

2. Turn the AC circuit breaker OFF.

24

AC CIRCUIT BREAKER

3. Turn the engine switch to the OFF position.

ENGINE SWITCH

4. Open the maintenance cover (see page 13) and turn the fuel valve to

the OFF position.

25

6. GENERATOR USE

1

!

Connections to a Building’s Electrical System

If the generator will be used as an alternative to utility company power, an

isolation switch must be installed to disconnect the utility lines from the

building when the generator is connected. Installation must be performed

by a qualified electrician and must comply with all applicable laws and

electrical codes.

m

allow electricity from the generator to backfeed into utility lines and may

cause serious injury or death to utility company workers or others who

contact the lines. Consult the utility company or a qualified electrician.

I] Im

electricity from the utility company to backfeed into the generator, which

will severely damage the generator and may cause a fire.

In some areas, generators are required by law to be registered with local

utility companies. Check local regulations for proper registration and use

procedures.

To ground the generator chassis, connect a length of heavy wire between

the ground terminal and an independant ground source. Consult a qualified

electrician for your particular application.

Improper connections to a building’s electrical system can

proper connections to a building’s electrical system can allow

26

GROUND

TERMINAL

AC Applications

Make sure all appliances are in good working order before connecting

them to the generator. If an appliance begins to operate abnormally,

becomes sluggish, or stops suddenly, turn it off immediately. Disconnect

the appliance, and determine whether the problem is the appliance, or the

rated load capacity of the generator has been exceeded.

m Substantial overloading of the generator will switch off the circuit breaker. Marginal overloading may not switch off the circuit breaker,

but will shorten the service life of the generator. Be sure that appliances do

not exceed the generator’s rated load capacity for more than 30 minutes

and that they never exceed the maximum load capacity.

Most appliance and power tool motors require more than the rated

operating current for start-up. To match appliance power needs to

generator capability, allow enough generator power reserve to accom-

modate motor start-up requirements.

An overload will trip (switch off) the circuit breaker. If this ,happens,

reduce the electrical load on the circuit. Wait a few minutes before resetting the circuit breaker.

27

Ground-Fault Circuit Interrupter (GFCI) Receptacle

m

death from electric shock. Keep the generator dry.

INSPECTION

Before each use:

If the generator is stored outdoors, unprotected from the weather, test the

GFCI receptacle before each use as described in the monthly inspection.

Monthly:

Under normal operating conditions, perform the GFCI test monthly.

Record your test on the GFCI test card provided on the control panel.

1.

Unplug all appliance’s from the GFCI receptacles.

2.

Start the engine.

Turn the circuit breaker ON.

3.

Using the generator in rain, or snow or near water can lead to

CIRCUIT BREAKER

4.

Press the TEST BUTTON

28

-The RESET BUTTON should extend

with a click.

-If the RESET BUTTON does not ex-

tend, contact an authorized Honda

generator dealer.

5. Press the RESET BUTTON

-The RESET BUTTON should be

flush with the test button.

-If the RESET BUTTON is not flush

with the TEST BUTTON, contact

an authorized Honda generator

dealer.

i

RESET BUTTON

6. When the RESET BUTTON extends during operation:

l

Unplug all appliance’s from the GFCI protected receptacle.

l

Press the RESET BUTTON.

IF THE GFCI CAN NOT BE RESET: The GFCI is faulty. Contact an autho-

rized Honda generator dealer.

IF THE GFCI RESETS PROPERLY:

Check the appliance or its cord.

29

Operation

1. Start the engine (see page 21).

2. Switch the AC circuit breaker ON.

CIRCUIT BREAKER

3. Plug the appliance into the appropriate AC receptacle.

30

How to use the receptacle

When two or more receptacles are used, refer to the table below and apply

the load to each receptacle equally to prevent overloading.

Voltage fluctuation can be prevented by applying the load equally to the

single phase receptacles.

Receotacle I 240

\

Case

usmg LLCU v only 4 I. I H Iwax., JU H Iwax.

Using both

and 240 V

120 V

50 A

41.7 A Total

Total 10

Total 20

Total 30

V

30 A

A

A

A

50 A

120v

30 A 20 A

Total

63.3 A

Total

43.3 A

Total

23.3 A

Max.

for both

When both 240 V and 120 V receptacles are use, be sure that the ampere

draw at each receptacle is less than the specified capacity and the total

ampere(s) are less that 83.4 amperes.

120V20A 120V30A

\ /

/

I llr

120 VI240 V 50 A

120 VI240 V 30 A

31

7. MAINTENANCE

!

Periodic maintenance and adjustment are necessary to keep the engine in

good operating condition. Service and inspect according to the

MAINTENANCE SCHEDULE.

m

To avoid carbon monoxide poisoning, shut off the engine

before performing any maintenance. If you run the engine in an area that is

confined, or even partially enclosed, the air you breathe could contain a

dangerous amount of exhaust gas. If the engine must be run for any

reason, be sure the area is well-ventilated.

To avoid serious burns, let the engine cool before performing

maintenance.

piEq us

e only genuine Honda parts or their equivalent for

maintenance and repair. Parts of lower quality may damage the engine.

Tool kit

The tools necessary for performing some of the periodic maintenance,

simple adjustments and repairs are supplied in the tool kit.

Always keep the tool kit with the generator.

32

v.

-CD

e= 1)

17 x 12 mm WRENCH

14 x 10 mm WRENCH

12 x 8 mm WRENCH

SCREW DRIVER

DRIVER GRIP

SPARE FUSE

(5 A, 10 A)

Maintenance Schedule

NOTE: (1) Service more frequently when used in dusty areas.

(2) These items should be serviced by an authorized HONDA generator dealer

unless the owner has the proper tools and is mechanically proficient. See the

Shop Manual.

(3) For professional commercial use log hours of operation to determine proper

maintenance intervals.

33

Engine oil change

Drain the oil while the engine is warm to assure complete and rapid

draining.

1. Open the maintenance cover (see page 13).

2. Remove the oil filler cap and drain plug to drain the oil.

3. After draining is complete, check that the sealing washer is in good

condition (replace if necessary), then retighten the drain bolt securely.

4. Refill with the recommended engine oil and check the oil level with the

oil level gauge (see page 14).

5. Install the oil filler cap.

6. Start the engine and allow it to warm to normal operating temperature.

Stop the engine and recheck the oil level with the oil level gauge (see

page 14). Add if necessary.

OIL FILLER CAP

GAUGE

ENGINE OIL CAPACITY: 4.8 lit. (5.0 US qt. 4.2 Imp qt)

Used motor oil may cause skin cancer if repeatedly left in contact with the

skin for prolonged periods. Although this is unlikely, unless you handle used oil on a daily basis, it is still advisable to thoroughly wash your hands

with soap and water as soon as possible after handling used oil.

NOTE:

Please dispose of used motor oil in a manner that doesn’t harm our environment. We suggest you take it in a sealed container to your local oil

reclamation station. Do not throw it in the trash or pour it on the ground or

down a drain.

34

Air cleaner

If you operate the generator in very dusty areas, check and replace the air

cleaner more often than specified in the MAINTENANCE SCHEDULE.

m Operating the engine without ttie air cleaner will cause rapid

engine wear.

i

1. Open the maintenance cover (see page 13).

,

2. Unhook the clips and remove the air cleaner cover and the inner cover.

AIR CLEANER COVER

INNER COVER

3. Remove the wing bolt and the air cleaner element.

NOTE: Do not clean the paper element. Replace it with a new one if it is

dirty.

WING BOLT

35

4. Install the element, inner cover and air cleaner cover in the reverse order

of removal.

NOTE: Install the cover with the UP mark facing up and align the tabs of

the inner cover and the air cleaner cover with the cutout of the air cleaner

case.

5. Fasten the cover clips securely.

UP

AIR CLEANER COVER

/

CUTOUT

I

ELEMENT

36

Fuel filter

m

condition. Do not smoke or allow flames or sparks in the area.

1. Open the maintenance cover (see page 13).

2. Turn the fuel valve to the OFF position.

3. Loosen the ring nut and then remove the strainer cup, O-ring, spring and

element.

4. Inspect the fuel in the strainer cup for contaminates or water. Clean the

strainer cup thoroughly.

5. Install a new element using the spring, strainer cup, O-ring and ring nut.

Make sure that the O-ring is in good condition and is set properly on the

strainer cup.

6. After installing the strainer cup, turn the fuel valve to the ON position.

Check for fuel leaks. Make sure the area is dry before starting the

engine.

Diesel fuel is extremely flammable and explosive under certain

STRAINER CUP

FUEL VALVE

0-RIN

RlNk NUT

37

Battery

H Refilling battery fluid

If the generator is operated with insufficient battery electrolyte, sulfation

and battery plate damage will occur.

If rapid loss of electrolyte is experienced, or if your battery seems to be

weak, causing slow starting or other electrical problems, see

authorized Honda generator dealer.

Open the maintenance cover and check the electrolyte level in each battery cell. Fill the battery with distilled water to the upper level line. Never

overfill the battery.

your

p!q

or skin causes burns.

Wear protective clothing and use eye protection when working near the

battery.

POISON-KEEP OUT OF REACH OF CHILDREN

EMERGENCY PROCEDURES:

Eyes

Skin - Remove contaminated clothing. Flush skin with large

If swallowed - Drink water or milk and call your poison control center or

m

can explode the battery causing serious injury or bllndness.

Provide adequate ventilation.

Keep sparks and flames away.

Follow the above procedure carefully.

The battery contains corrosive sulfuric acid. Contact with eyes

- Flush with water from a cup or other container for at least

15 minutes. Call a physician immediately.

quantities of water. Call a physician.

a physician immediately.

Batteries produce explosive hydrogen gas. A spark or flame

38

UPPER LEVEL

LOWER LEVEL

n

Battery cleaning

If the battery terminals are contaminated or corroded, remove the battery

and clean the terminals.

Removal:

!

1. Remove the battery set plate.

2. Disconnect the negative (-1 battery cable first, then disconnect the

positive (+) battery cable.

3. Remove the battery.

4. Clean the terminals with a wire brush or sand paper. Clean the battery

with a solution of baking soda and warm water, taking care not to get

the solution of water in the battery cells. Dry the battery thoroughly.

5. Clean the battery cable ends with a wire brush or sand paper.

BATTERY SET PLATE

NEGATIVE (-1 TERMINAL

BATTERY

Installation:

1. Install the battery into the generator.

2. Connect the positive (+) battery cable first and tighten the nut securely.

Slide the battery ,boot over the positive (+I cable and terminal.

3. Connect the negative (-1 battery cable. Tighten the nut securely.

4. Coat the battery terminals and cable ends with clean grease.

5. Reinstall the battery set plate.

39

Fuse replacement

Turn the engine switch OFF and remove the key before checking or replacing fuses to prevent accidental short-circuiting.

To replace a sub fuse, pull the old fuse out of the clips with your fingers.

Push a new fuse into the clips.

If frequent fuse failure occurs, determine the cause and correct the pro-

blem before attempting to operate the generator.

If a main fuse is blown, see an authorized Honda generator dealer.

MAIN FUSE

1 NOTICE 1 Ne

SUB FUSE

ver use a fuse with a different rating from that specified.

5A

Serious damage to the electrical system or fire may result.

.

40

8. TRANSPORTING AND STORAGE

The engine becomes very hot during operation and remains hot for a while

after stopping. Allow the engine to cool before transporting or storing

indoors.

Transporting

I

i m

burns or fires. Let the engine cool before transporting or storing indoors.

+

When transporting the generator, turn the engine switch to the OFF position and keep the generator level to prevent fuel spillage.

Take care not to drop or strike the generator when transporting. Do not

place heavy objects on the generator.

Load and unload the generator in a level area. Use the lifting eye when lifting the generator. Do not use the frame pipes to lift the generator.

When maneuvering the generator on the ground, use the frame pipe op-

posite the control panel. When transporting the generator in a truck, tie

ropes to the frame pipes to secure the generator.

If a fork truck is used to lift the generator, insert the fork arms under the

positions marked with * and lift the generator.

On wheel equipped models; block the wheels securely.

Contact with a hot engine or exhaust system can cause serious

LIFTING EYE

FRAME PIPE

41

Before storing the generator for an extented period:

1. Be sure the storage area is free of excessive humidity and dust.

2. Clean the generator.

3. Check the generator according to the maintenance schedule (see page

33) and repair/replace any items as necessary.

4. Fill the fuel tank with fresh diesel fuel (see page 15).

5. Fully charge the battery. Recharge the battery once a month.

6. Cover the generator and place it in a well ventilated and dry area.

Before starting the engine after storage:

1. Change the engine oil (see page 34).

2. Fully charge the battery.

3. Remove the radiator cap and check the coolant level. Add as necessary

(see page 17).

4. Start the engine and allow it to warm to operating temperature before

applying a load to the generator.

42

10. SPECIFICATIONS

Dimensions

Model

Description

Length x Width x Height

Dry weight 340 kg (701 lb)

139Ox630x815mm

(54.7 x 24.8 x 32.1 in)

EBI 2D

ECD

Engine

Model GDI 100

Type

Displacement

[Bore x Stroke1

Rated output

Max. torque

Cooling system Liquid cooled

Combustion method

Fuel

Fuel tank capacity

Oil caoacitv

4 stroke OHC 3 cylinder water cooled diesel

I -

1061 cm3

[76 x 78 mm (3.0 x 3.1 in)1

20 PS/3,600 min-1 (rpm)

55.9 N.m (5.7 kg-m, 41.2 ft-lb)/

2,000 min-1 (rpm)

Direct injection

Diesel fuel

38 lit (IO US gal, 8.4 Imp gal)

4.8 lit (5.0 US at, 4.2 Imo at)

Generator

Type

Rated voltage

Rated frequency

Rated ampere

AC output 1 Rated output 1 10 kVA

Max output

Max ampere

Power factor

NOTE: Specifications are subject to change without notice.

I

I

AG

1201240 V

60 Hz

83.4 A/41.7 A

12 kVA

100 Al50 A

cos 0 = 1

44

I

I

I

1

3

Lsm-

, -ww-

-o-

I

--.““I

..I

___

12. WARRANTY SERVICE

Owner Satisfaction

Your satisfaction and goodwill are important to your dealer and to us. All

Honda warranty details are explained in the Distributor’s Limited Warranty. Normally, any problems concerning the product will be handled by your

dealer’s service department. If you have a warranty problem that has not

been handled to your satifsaction, we suggest you take the following

action:

l

Discuss your problem with a member of dealership management. Often

complaints can be quickly resolved at that level. If the problem has

already been reviewed with the Service Manager, contact the owner of

the dealership or the General Manager.

l

If your problem still has not been resolved to your satisfaction, contact:

American Honda Motor Co., Inc.

P.O. Box 100021

Duluth, Georgia 30136-9421

Telephone: (404) 497-6400

We will need the following information in order to assist you:

- Your name, address, and telephone number

- Product.model and serial number

- Date of purchase

- Dealer name and address

- Nature of the problem

After reviewing all the facts involved, you will be advised of what action

can be taken. Please bear in mind that your problem will likely be resolved

at the dealership, using the dealer’s facilities, equipment, and personnel,

so it is very important that your initial contact be with the dealer.

Your purchase of Honda product is greatly appreciated by both your dealer

and American Honda Motor Co., In. We want to assist you in every way

possible to assure your complete satisfaction with your purchase.

46

Current customer service contact information:

United States, Puerto Rico, and U.S. Virgin Islands:

Honda Power Equipment dealership personnel are trained professionals. They should

be able to answer any question you may have. If you encounter a problem that your

dealer does not solve to your satisfaction, please discuss it with the dealership's

management. The Service Manager or General Manager can help. Almost all problems

are solved in this way.

If you are dissatisfied with the decision made by the dealership's management, contact

the Honda Power Equipment Customer Relations Office. You can write:

American Honda Motor Co., Inc.

Power Equipment Division

Customer Relations Office

4900 Marconi Drive

Alpharetta, GA 30005-8847

Or telephone: (770) 497-6400 M-F, 8:30 am - 7:00 pm EST

When you write or call, please provide the following information:

• Model and serial numbers

• Name of the dealer who sold the Honda power equipment to you

• Name and address of the dealer who services your equipment

• Date of purchase

• Your name, address, and telephone number

• A detailed description of the problem

MEMO

47

MEMO

48

I

Loading...

Loading...