Honda CG125 (1976-1991) User Manual [ru]

Honda

CG125

Owners

Workshop

Manual

by Pete

with an additional Chapter on the

Shoemark

1985

on models

by Jeremy Churchill

Models covered

CG125. 124cc. June 1976 to May 1978

CG125K1.

CG125-B. 124cc. March 1981 to March 1982

CG125-C.

CG125-E. 124cc. November 1984 to April 1985

CG125(BR)-E/F. 124cc. April 1985 to April 1988

CG125(BR)-J. 124cc. April 1988 to September 1991

CG125(BR)-K. 124cc. September 1991 on

ISBN

©

Haynes

All rights reserved. No part of this book may be reproduced or transmitted in

any form or by any means, electronic or mechanical, including photocopying,

recording or by any information storage or retrieval system, without permission

in writing from the copyright holder.

Printed in the USA

124cc. May 1978 to March 1981

124cc. March

1 85010 918 4

Publishing 1994

(433-4T9)

1982

to November

1984

Haynes Publishing

Sparkford Nr Yeovil

Somerset BA22 7JJ England

Haynes Publications,

861

Lawrence Drive

Newbury

California 91320 USA

Park

Inc

British Library

A catalogue record for this book is available

from the British Library

CataloGuing

in Publication Data

~

Acknowledgements

Our thanks are due to APS Motorcycles of Wells (formerly

Fran

Ridewood

CSM of Taunton, who supplied the machines featured in this

manual.

& Co), Paul Branson Motorcycles of Yeovil, and

About this manual

The author of this manual has the conviction that the only

way in which a meaningful and easy to follow text can be

written is first to do the work himself, under conditions similar

to those found in the average household. As a result, the hands

seen in the photographs are those of the author. Even the

machines are not new: examples that have covered a considerable mileage were selected so that the conditions encountered

would be typical of those found by the average owner.

Unless specially mentioned, and therefore considered

essential, Honda service tools have not been used. There is

invariably some alternative means of slackening or removing

some vital component when service tools are not available and

risk of damage has to be avoided at all costs.

Each of the six Chapters is divided into numbered Sections.

Within the Sections are numbered paragraphs. In consequence,

cross reference throughout this manual is both straightforward

and logical. When a reference is made 'See Section 5.12' it

means Section 5, paragraph

Chapter were meant, the text would read 'See Chapter 2,

12

in the same Chapter. If another

We would also like to thank the Avon Rubber Company, who

kindly supplied information and technical assistance on tyre

fitting; NGK Spark Plugs (UK) Ltd for information on spark plug

maintenance and electrode conditions and Renold Limited for

advice on chain care and renewal.

Section 5.12'. All photographs are captioned with a

Section/paragraph number to which they refer and are always

relevant to the Chapter text adjacent.

Figure numbers (usually line illustrations) appear in

numerical order, within a given Chapter. Fig.

to the first figure in Chapter

descriptions of the machines and their component parts refer to

the right and left of a given machine when the rider is seated

normally.

Motorcycle manufacturers continually make changes to

specifications and recommendations, and these, when notified,

are incorporated into our manuals at the earliest opportunity.

We take great pride in the accuracy of information given in

this manual, but motorcycle manufacturers make alterations and

design changes during the production run of a particular

motorcycle of which they do not inform us. No liability can be

accepted by the authors or publishers for loss, damage or injury

caused by any errors in, or omissions from, the information given.

1.

1.1

Left-hand and right-hand

therefore refers

Contents

Page

Acknowledgements

About this manual

Introduction to the Honda

CG125

Model dimensions and weight

Ordering spare parts

Safety first!

Routine maintenance

Quick glance maintenance adjustments and capacities

Recommended lubricants

Working conditions and tools

Chapter 1 Engine, clutch and gearbox

Chapter 2 Fuel system and lubrication

2

2

5

5

6

7

8

13

13

/

15

52

Chapter 3 Ignition system

Chapter 4 Frame and forks

Chapter 5 Wheels, brakes and tyres

Chapter 6 Electrical system

Chapter 7 The

1985

on models

Wiring diagrams

Conversion factors

Index

60

67

80

93

107

103, 124

125

126

I

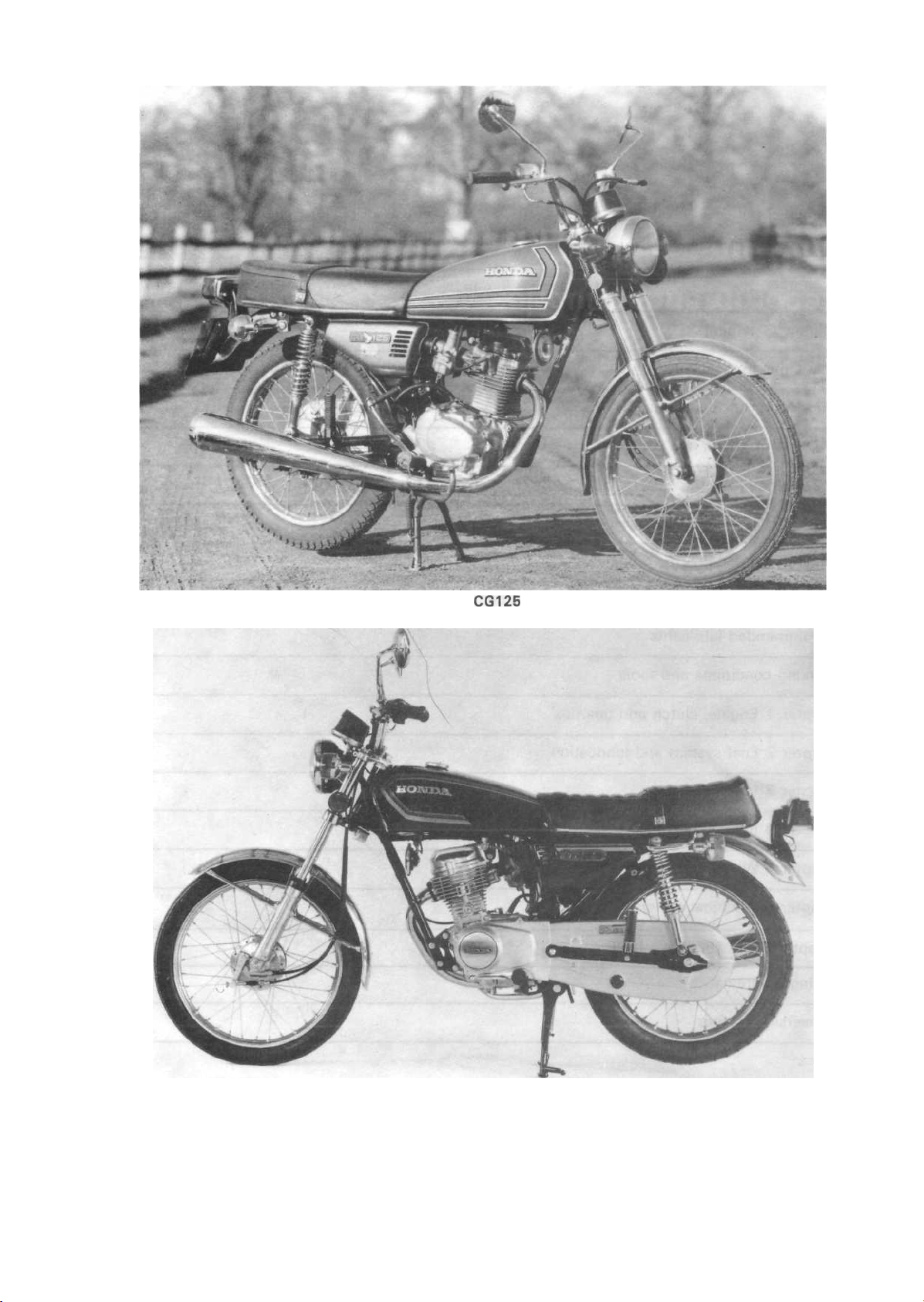

The Honda

CG125

model

The Honda CG125-C model

Introduction to the Honda

The

CG125

can be regarded in many ways as a utility version of the popular

CB1 25 with which it shares many features. The basic difference

between the two models is the

operated overhead valves in place of the more popular overhead

camshaft arrangement. The unit provides surprisingly brisk

performance coupled with good fuel economy. The machine in

general is functional and sensibly equipped, and does not suffer

the surfeit of gadgetry so often found on its contemporaries. Its

inherent simplicity makes it an ideal learner's or commuter's

mount, both in terms of ease of riding and in its ease of

maintenance. A noteworthy feature is the adoption of a full rear

chain enclosure. Although this is by no means a new idea,

having

with the changing dictates of fashion, it is, nevertheless, an

eminently sensible feature, greatly extending chain life.

Despite remaining basically unchanged, the CG125 has

received several modifications and has been altered slightly in

appearance to keep up with its rivals. Five distinct versions have

appeared, with differences of varying significance, which are

identified (where applicable) in this Manual by their Honda

model code suffixes. Identification details, as available, are

given below with the approximate dates of import; note that the

latter need not necessarily coincide with the machine's date of

registration.

The

numbers CG125-1023061 to

not available. Identified by its shrouded, external spring, front

forks, this model Was imported from June

model first appeared in the UK in June 1976. It

CG125's

appeared and disappeared many times over the years

CG125

model (no identifying suffix) has the frame

1111090.

use of pushrod

Engine numbers are

1976

to May

1978.

CG125-1114636

It differed most noticeably from the

front forks with internal springs and exposed stanchions, and

was imported from May

CG125-1202755

CG125E-1374586.

only by its different paintwork and graphics and was imported

from March 1981 to March 1982.

CG125-1272831 to 1286692; its engine numbers start at

CG125E-1513928

indicator lamps, handlebar switches and the usual detail

changes to paintwork and graphics. This model is also fitted

with a higher compression engine and the (T)PFC carburettor

for greater fuel economy. Note also that the ignition switch is

combined in a new warning lamp cluster, mounted next to the

speedometer. Imported from March

CG 125-1288790

CG125E-1689761 to 1694851. Identical to the C model

except for detail changes to the graphics, this model was

imported from November

manufacture and are covered in Chapters 1 to 6. Later models

were manufactured in Brazil and known as the CG125(BR)

models; refer to Chapter 7 for further information.

CG125

The

CG125K1

The CG125-B model has the frame numbers

The CG125-C model has the frame numbers

The CG125-E model has the frame number

All the aforementioned models are of Japanese

model has the frame numbers

to

1162518.

to 1223689; its engine numbers start at

It

can be distinguished from the K1 model

on. Fitted with revised tail lamp, flashing

to 1293380 and the engine numbers

Engine numbers not available.

1978

1984

CG125

to March

1982

to April

model in having

1981.

to November

1985.

1984.

Model dimensions and weight

Overall length

Overall width

Overall height

Wheelbase

Seat height

Ground clearance

Dry weight

1840

mm (72.4 in)

735 mm (28.9 in)

1025 mm (40.4 in)

1200 mm (47.2 in)

755 mm (29.7 in)

135 mm (5.3 in)

95 kg (209

Ib)

Ordering spare parts

*

When ordering spare parts for the CG125 models, it is

advisable to deal direct with an official Honda agent, who will

be able to supply many of the items required ex-stock. It is

advisable to get acquainted with the local Honda agent, and to

rely on his advice when purchasing spares. He is in a better

position to specify exactly the parts required and to identify the

relevant spare part numbers so that there is less chance of the

wrong part being supplied by the manufacturer due to a vague

or incomplete description.

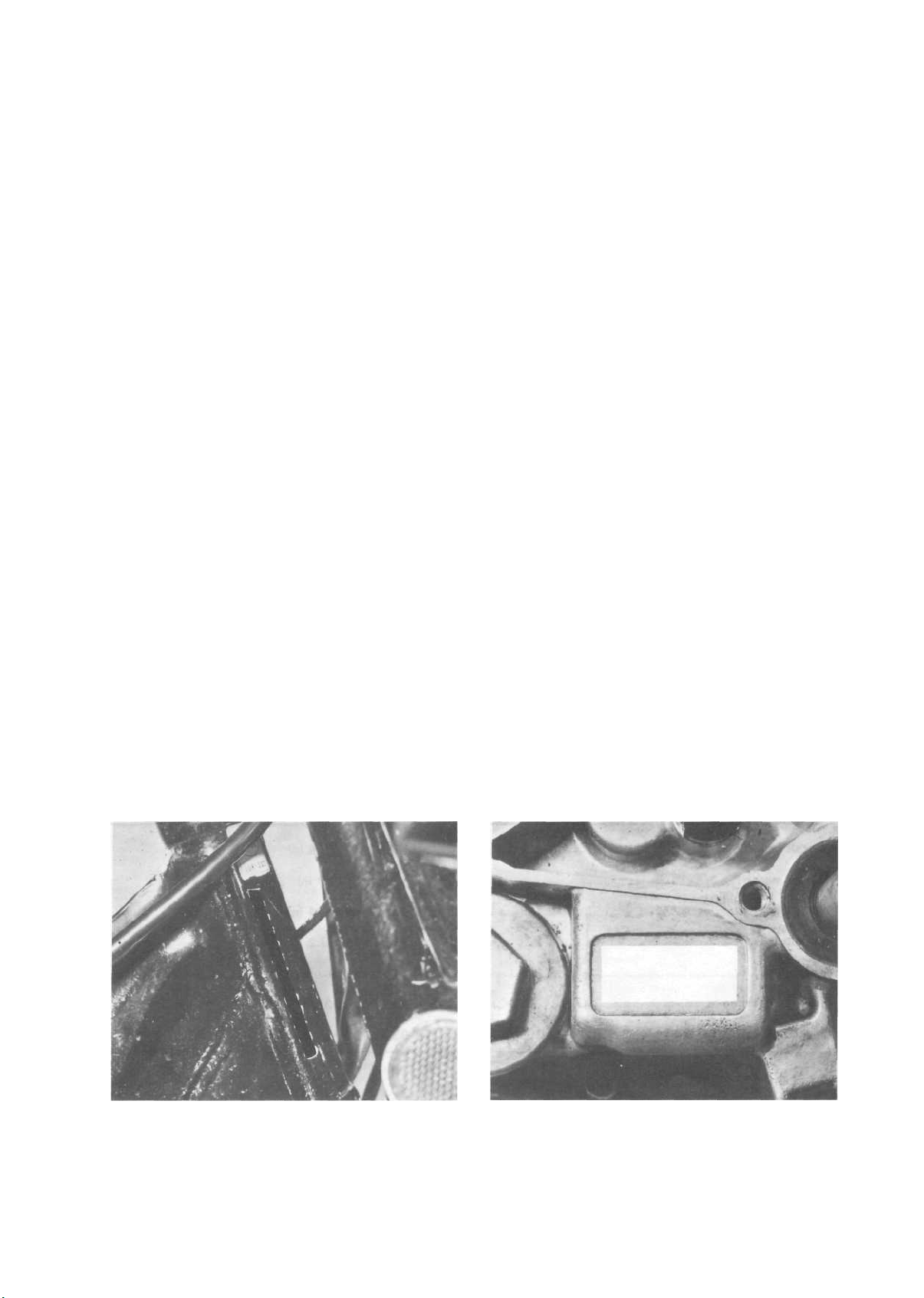

When ordering spares, always quote the frame and engine

numbers in full, together with any prefixes or suffixes in the

form of letters. The frame number is found stamped on the

right-hand side of the steering head, in line with the forks. The

engine number is stamped on the left-hand side of the

crankcase, immediately behind the oil strainer cap.

Use only parts of genuine Honda manufacture. A few

pattern parts are available, sometimes at a cheaper price, but

there is no guarantee that they will give such good service as

the originals they replace. Retain any worn or broken parts until

the replacements have been obtained; they are sometimes

needed as a pattern to help identify the correct replacement

when design changes have been made during a production run.

Some of the more expendable parts such as spark plugs,

bulbs, tyres, oils and greases etc., can be obtained from

accessory shops and motor factors, who have convenient

opening hours and can often be found not far from home. It is

also possible to obtain them on a Mail Order basis from a

number of specialists who advertise regularly in the motorcycle

magazines.

Frame number location

Engine number location

Safety first!

Professional motor mechanics are trained in safe working

procedures. However enthusiastic you may be about getting on

with the job in hand, do take the time to ensure that your safety

is not put at risk. A moments lack of attention can result in an

accident, as can failure to observe certain elementary

precautions.

There will always be new ways of having accidents, and the

following points do not pretend to be a comprehensive list of all

dangers; they are intended rather to make you aware of the

risks and to encourage a safety-conscious approach to all work

you carry out on your vehicle.

Essential DOs and

DON'T start the engine without first ascertaining that the

transmission is in neutral.

DON'T suddenly remove the filler cap from a hot cooling

system - cover it with a cloth and release the pressure gradually

first, or you may get scalded by escaping coolant.

DON'T attempt to drain oil until you are sure it has cooled

sufficiently to avoid scalding you.

DON'T grasp any part of the engine, exhaust or silencer without

first ascertaining that it is sufficiently cool to avoid burning you.

DON'T allow brake fluid or antifreeze to contact the machine's

paintwork or plastic components.

DON'T syphon toxic liquids such as fuel, brake fluid or

antifreeze by mouth, or allow them to remain on your skin.

DON'T inhale dust - it may be injurious to health (see Asbestos

heading).

DON'T allow any spilt oil or grease to remain on the floor —

wipe it up straight away, before someone slips on it.

DON'T use ill-fitting spanners or other tools which may slip and

cause injury.

DON'T attempt to lift a heavy component which may be

beyond your capability - get assistance.

DON'T rush to finish a job, or take unverified short cuts.

DON'T allow children or animals in or around an unattended

vehicle.

DON'T inflate a tyre to a pressure above the recommended

maximum. Apart from overstressing the carcase and wheel rim,

in extreme cases the tyre may blow off forcibly.

DO ensure that the machine is supported securely at all times.

This is especially important when the machine is blocked up to

aid wheel or fork removal.

DO take care when attempting to slacken a stubborn nut or

bolt. It is generally better to pull on a spanner, rather than push,

so that if slippage occurs you fall away from the machine rather

than on to it.

DO wear eye protection when using power tools such as drill,

sander,

bench grinder etc.

DO use a barrier cream on your hands prior to undertaking dirty

jobs — it will protect your skin from infection as well as making

the dirt easier to remove afterwards; but make sure your hands

aren't left slippery. Note that long-term contact with used

engine oil can be a health hazard.

DO keep loose clothing (cuffs, tie etc) and long hair well out of

the way of moving mechanical parts.

DO remove rings, wristwatch etc, before working on the vehicle

- especially the electrical system.

DO keep your work area tidy - it is only too easy to fall over

articles left lying around.

DO exercise caution when compressing springs for removal or

installation. Ensure that the tension is applied and released in a

controlled manner, using suitable tools which preclude the

possibility of the spring escaping violently.

DO ensure that any lifting tackle used has a safe working load

rating adequate for the job.

DO get someone to check periodically that all is well, when

working alone on the vehicle.

DO carry out work in a logical sequence and check that

everything is correctly assembled and tightened afterwards.

DO remember that your vehicle's safety affects that of yourself

and others. If in doubt on any point, get specialist advice.

IF, in spite of following these precautions, you are unfortunate

enough to injure yourself, seek medical attention as soon as

possible.

DON'Ts

Asbestos

Certain friction, insulating, sealing, and other products such as brake linings, clutch linings, gaskets, etc - contain

asbestos. Extreme care must be taken to avoid inhalation of

dust from such products since it is hazardous to health. If in

doubt, assume that they do contain asbestos.

Fire

Remember at all times that petrol (gasoline) is highly

flammable. Never smoke, or have any kind of naked flame

around, when working on the vehicle. But the risk does not end

there - a spark caused by an electrical short-circuit, by two

metal surfaces contacting each other, by careless use of tools,

or even by static electricity built up in your body under certain

conditions, can ignite petrol vapour, which in a confined space

is highly explosive.

Always disconnect the battery earth (ground) terminal

before working on any part of the fuel or electrical system, and

never risk spilling fuel on to a hot engine or exhaust.

It is recommended that a fire extinguisher of a type suitable

for fuel and electrical fires is kept handy in the garage or

workplace at all times. Never try to extinguish a fuel or electrical

fire with water.

Note: Any reference to a 'torch' appearing in this manual

should always be taken to mean a hand-held battery-operated

electric lamp or flashlight. It does not mean a welding/gas torch

or blowlamp.

Fumes

Certain fumes are highly toxic and can quickly cause

unconsciousness and even death if inhaled to any extent. Petrol

(gasoline) vapour comes into this category, as do the vapours

from certain solvents such as trichloroethylene. Any draining or

pouring of such volatile fluids should be done in a well

ventilated area.

When using cleaning fluids and solvents, read the instructions carefully. Never use materials from unmarked containers they may give off poisonous vapours.

Never run the engine of a motor vehicle in an enclosed

space such as a garage. Exhaust fumes contain carbon monoxide which is extremely poisonous; if you need to run the

engine, always do so in the open air or at least have the rear of

the vehicle outside the workplace.

The battery

Never cause a spark, or allow a naked light, near the

vehicle's battery. It will normally be giving off a certain amount

of hydrogen gas, which is highly explosive.

Always disconnect the battery earth (ground) terminal

before working on the fuel or electrical systems.

If possible, loosen the filler plugs or cover when charging

the battery from an external source. Do not charge at an

excessive rate or the battery may burst.

Take care when topping up and when carrying the battery.

The acid electrolyte, even when diluted, is very corrosive and

should not be allowed to contact the eyes or skin.

If you ever need to prepare electrolyte yourself, always add

the acid slowly to the water, and never the other way round.

Protect against splashes by wearing rubber gloves and goggles.

Mains electricity and electrical equipment

When using an electric power tool, inspection light etc,

always ensure that the appliance is correctly connected to its

plug and that, where necessary, it is properly earthed

(grounded). Do not use such appliances in damp conditions

and, again, beware of creating a spark or applying excessive

heat in the vicinity of fuel or fuel vapour. Also ensure that the

appliances meet the relevant national safety standards.

Ignition HT voltage

A severe electric shock can result from touching certain

parts of the ignition system, such as

engine is running or being cranked, particularly if components

are damp or the insulation is defective. Where an electronic

ignition system is fitted, the HT voltage is much higher and

could prove fatal.

Ihe

HT leads, when the

Routine maintenance

Refer to Chapter 7 for information relating to the

Introduction

Periodic routine maintenance is a continuous process that

commences immediately the machine is used. It must be

carried out at specified mileage recordings, or on a calendar

basis if the machine is not used frequently, whichever is the

sooner. Maintenance should be regarded as an insurance policy,

to help keep the machine in the peak of condition and to ensure

long, trouble-free service. It has the additional benefit of giving

early warning of any faults that may develop and will act as a

regular safety check, to the obvious advantage of both rider and

machine alike.

The various maintenance tasks are described under their

respective mileage and calendar headings. Accompanying

diagrams are provided, where necessary. It should be remembered that the interval between the various maintenance tasks

serves only as a guide. As the machine gets older or is used

under particularly adverse conditions, it would be advisable to

reduce the period between each check.

For ease of reference each service operation is described in

detail under the relevant heading. However, if further general

information is required, it can be found within the manual under

the pertinent section heading in the relevant Chapter.

In order that the routine maintenance tasks are carried out

with as much ease as possible, it is essential that a good selection of general workshop tools is available.

Included in the kit must be a range of metric ring or combination spanners, a selection of crosshead screwdrivers and at

least one pair of circlip pliers.

Additionally, owing to the extreme tightness of most casing

screws on Japanese machines, an impact screwdriver, together

with a choice of large and small crosshead screw bits, is

absolutely indispensable. This is particularly so if the engine has

not been dismantled since leaving the factory.

1985

on Brazilian models

prevent the risk of unexpected failure of any component while

riding the machine and, with experience, can be reduced to a

simple checklist which will only take a few moments to

complete. For those owners who are not inclined to check all

items with such frequency, it is suggested that the best course

is to carry out the checks in the form of a service which can be

undertaken each week or before any long journey. It is essential

that all items are checked and serviced with reasonable

frequency.

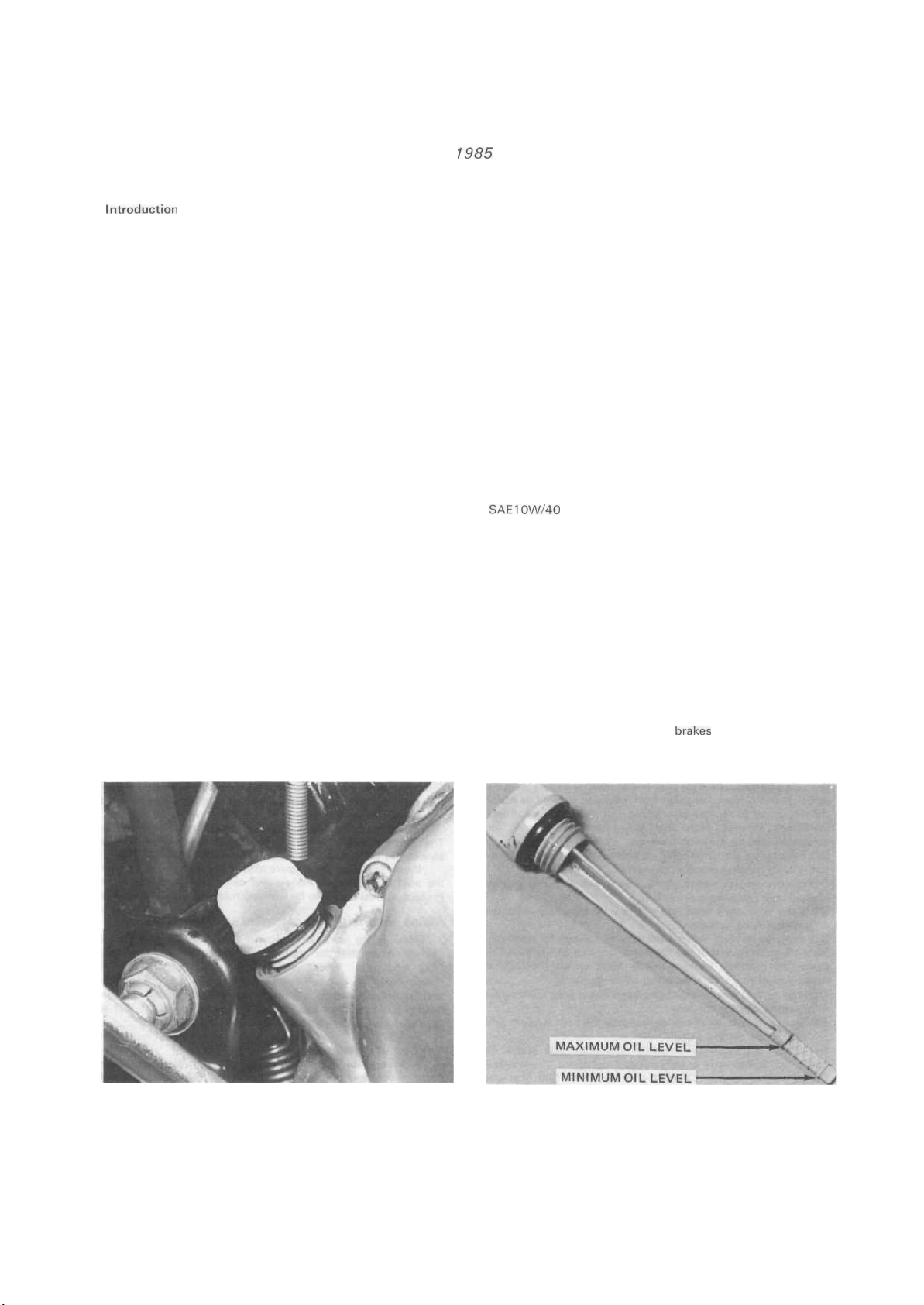

/ Check the engine oil level

With the machine standing upright on its centre stand on

level ground, start the engine and allow it to idle for a few

seconds so that the oil can circulate, then stop the engine. Wait

one or two minutes for the level to settle and unscrew the

dipstick/filler plug from the rear of the crankcase right-hand

cover. Wipe it clean and insert it into the filler orifice; do not

screw it in, but allow it to rest. Withdraw the dipstick; the oil

level should be between the maximum and minimum level lines,

ie in the cross-hatched area.

If topping up is necessary use only good quality

SAE10W/40

level to rise above the top of the cross-hatched area on the

dipstick, and never use the machine if the level is found to be in

the plain area below the cross-hatching; top up immediately.

Tighten the dipstick securely and wash off any spilt oil.

engine oil of the specified type. Do not allow the

2 Check the fuel level

Checking the petrol level may seem obvious, but it is all too

easy to forget. Ensure that you have enough petrol to complete

your journey, or at least to get you to the nearest petrol station.

Daily (pre-ride check)

It is recommended that the following items are checked

whenever the machine is about to be used. This is important to

Rest dipstick in position to obtain correct reading Dipstick shows allowable oil level range

3 Check the brakes

Check the front and rear

without binding. Ensure that the cable or rod linkage is

lubricated and properly adjusted.

brakes

work effectively and

Routine maintenance

Check the tyre pressures and tread wear

4

Check the tyre pressures with a gauge that is known to be

accurate. It is worthwhile purchasing a pocket gauge for this

purpose because the gauges on garage forecourt airlines are

notoriously inaccurate. The pressures, which should be checked

with the tyres cold, are specified at the end of Routine

maintenance and in Chapter 5.

At the same time as the tyre pressures are checked,

examine the tyres themselves. Check them for damage,

especially splitting of the sidewalls. Remove any small stones or

other road debris caught between the treads. When checking

the tyres for damage, they should be examined for tread depth

in view of both the legal and safety aspects. It is vital to keep

the tread depth within the UK legal limits of 1 mm of depth over

three-quarters of the tread breadth around the entire circumference with no bald patches. Many riders, however, consider

nearer 2 mm to be the limit for secure roadholding, traction, and

braking, especially in adverse weather conditions, and it should

be noted that Honda recommend minimum tread depths of 1.5

mm (0.06 in) for the front tyre and 2.0 mm (0.08 in) for the rear;

these measurements to be taken at the centre of the tread.

Renew any tyre that is found to be damaged or excessively

worn.

5 Safety check

Check that the front and rear suspension is operating

correctly, that the chain is lubricated and adjusted correctly and

that the battery is in good condition. Check the throttle and

clutch cables and levers, the gear lever and the footrests and

stand to ensure that they are adjusted correctly, functioning

correctly, and that all nuts and bolts are securely fastened.

6 Legal check

Check that all lights, turn signals, horn and speedometer are

working correctly to make sure that the machine complies with

all legal requirements in this respect. Check also that the

headlamp is correctly aimed to comply with local legislation.

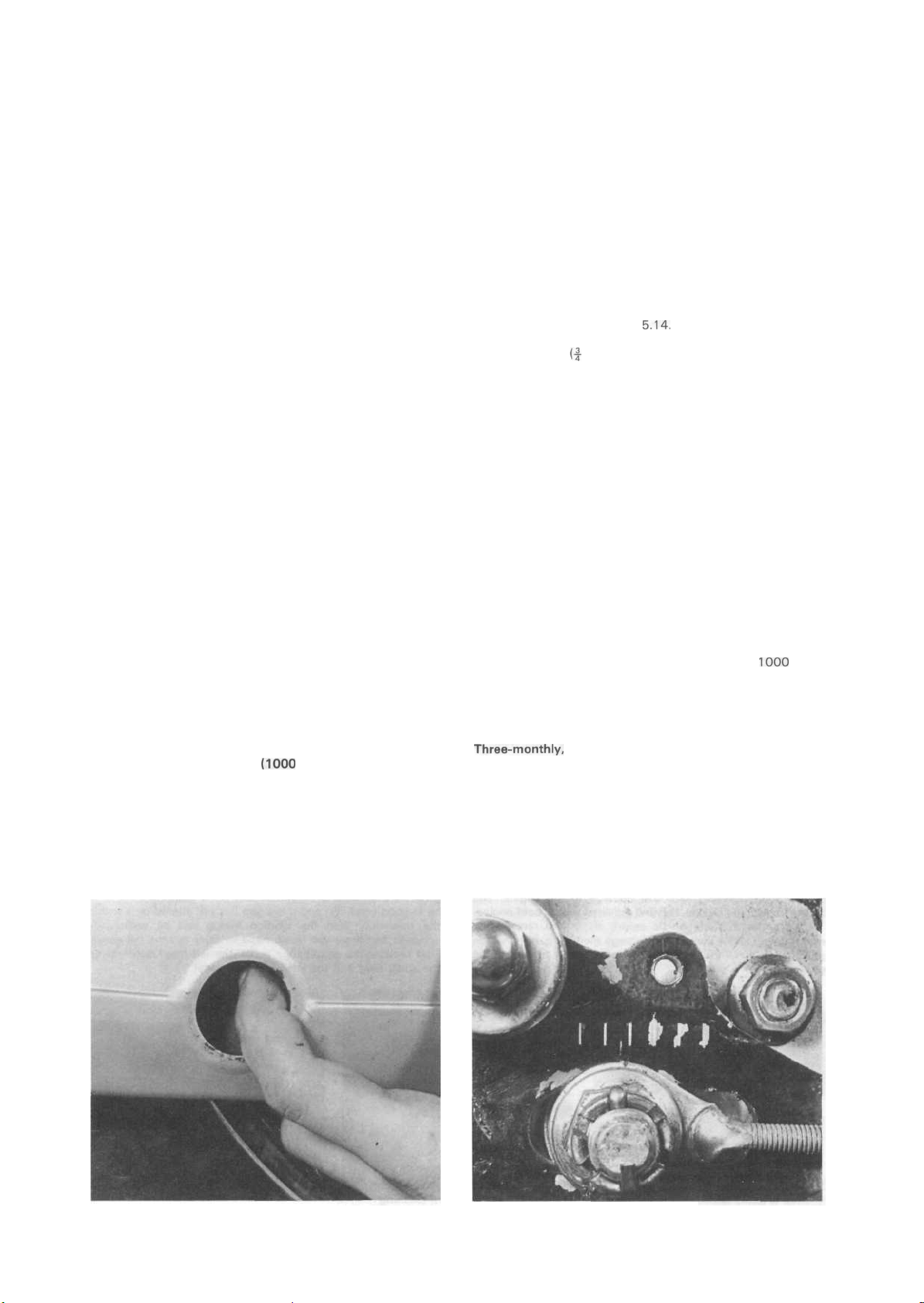

2 Check the final drive chain

Despite its full enclosure, the final drive chain requires

regular attention to ensure maximum chain life. Remove the

rubber plug from the chaincase inspection aperture to check the

tension and carry out temporary lubrication. The best lubricant

is commercial chain lubricant, contained in an aerosol can;

engine oil or gear oil are better than nothing but are flung off too

quickly to be of any real use. Best of all are the special chain

greases described in Chapter

Adjust the chain after lubrication, so that there is approximately 20 mm

Always check with the chain at the tightest point as a chain

rarely wears evenly during service.

Adjustment is accomplished after placing the machine on

the centre stand and slackening the spindle nut, so that the

wheel can be drawn backwards by means of the drawbolt

adjusters in the swinging arm fork ends.

The torque arm nut and the rear brake adjuster must also be

slackened during this operation. Adjust the drawbolts an equal

amount to preserve wheel alignment. The fork ends are clearly

marked with a series of parallel lines above the adjusters, to

provide a simple visual check.

(|-

in) slack in the middle of the lower run.

5.14.

3 Additional engine oil change

Since the engine relies so heavily on the quantity and

quality of its oil, and since the oil in any motorcycle engine is

worked far harder than in other vehicles, it is recommended that

the engine oil is changed at more frequent intervals than those

specified by the manufacturer. This is particularly important if

the machine is used at very high speeds for long periods of time,

and even more important if the machine is used only at very

slow speed or for very short journeys. The oil should be changed

at approximate intervals of every month or every

depending on usage. Honda specify that the oil should be

changed at least once annually or every 1 800 miles (3000 km),

whichever comes first.

1000

miles,

Monthly or every 600 miles

(1000

km)

/ Check the battery

The battery should be checked regularly to ensure that the

electrolyte level is maintained between the level lines on the

casing, that the terminals are clean and securely fastened and

that the vent tube is correctly routed and free from blockages.

Refer to Chapter 6.5 for details.

Three-monthly,

or every 1800 miles (3000 km)

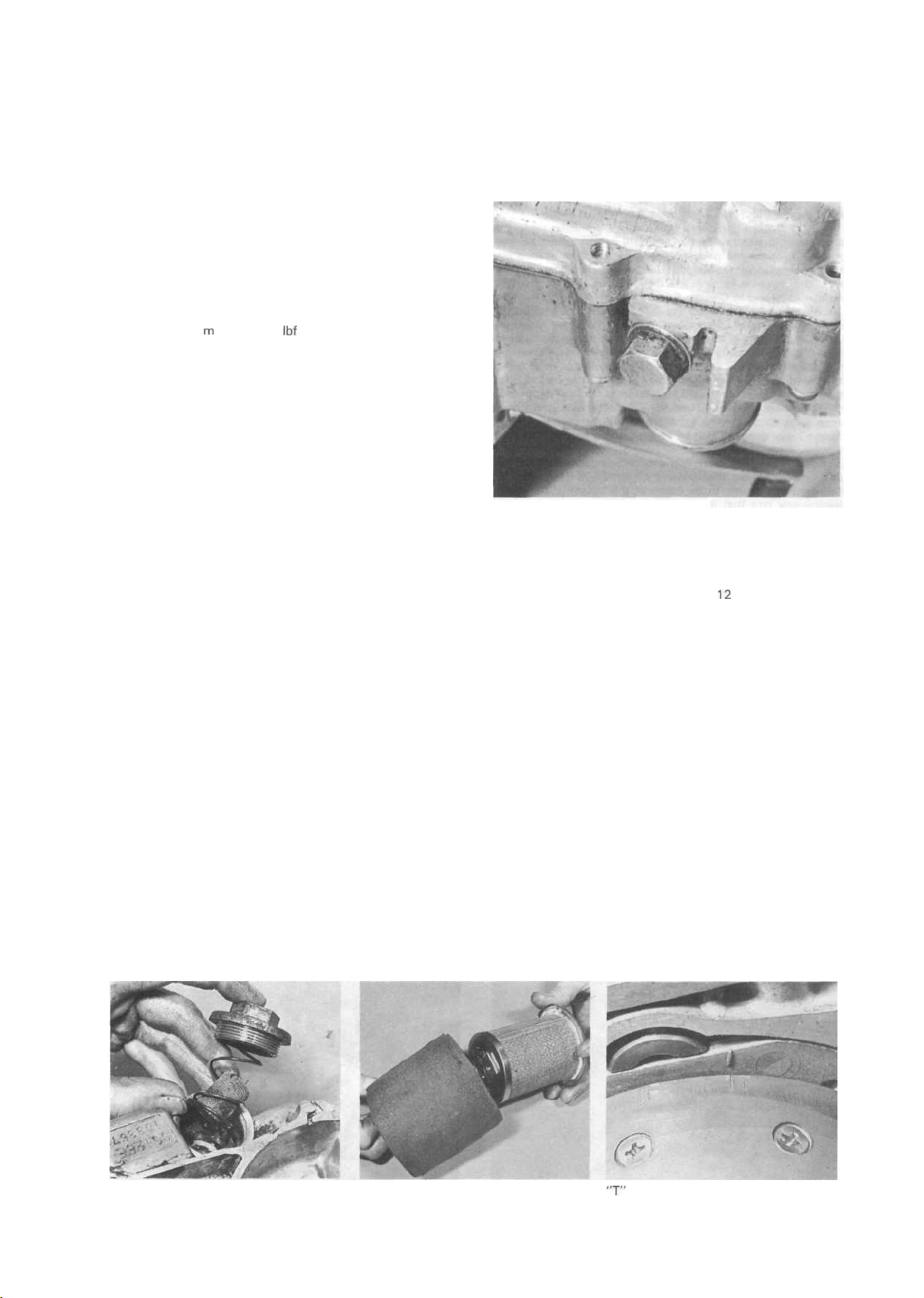

1 Change the engine oil and clean the filter gauze

This is the specified interval at which the engine/gearbox oil

should be changed; in normal use it should be regarded as the

maximum permissible.

It is recommended that the oil be changed after a run to

ensure that the engine is warm. This helps the oil to drain

thoroughly. Obtain a container of at least 1 litre (1.76 pints)

Free play can be felt via the inspection hole Move each adjuster by an equal amount

'

10

capacity and place it beneath the engine unit to catch the old

oil. Unscrew the drain plug on the underside of the crankcase

and allow the oil to drain.

Remove the large hexagon-headed plug which is located

just below the left-hand engine casing. Remove the plug,

followed by the spring and gauze element, and then wash all

these components carefully in a suitable solvent. Wipe out any

residual oil from the housing with a clean lint-free rag prior to

reassembly. Refit the drain plug, tightening it to a torque setting

of 2.0 - 3.5 kgf m (14.5 - 25

the correct quantity and grade of oil.

Six-monthly, or every 3600 miles (6000 km)

Repeat all service operations listed under previous

headings, then carry out the following:

Ibf

ft), and refill the engine with

Routine maintenance

/ Clean the air filter

Pull off the right-hand side panel and remove the two nuts

which secure the air filter cover. Withdraw the cover, checking

that the sealing gasket is in good condition, pull out the

retaining spring and withdraw the element assembly. Peel off

the inner and outer foam sleeves. Wash all components in white

spirit (Stoddard solvent) or in warm water and detergent and

dry them thoroughly. Soak the foam sleeves in the specified oil,

then squeeze them gently (do not wring them out or they will be

damaged) to expel all surplus oil. Refit the sleeves to the

element frame. On reassembly ensure that all components are

correctly fitted so that unfiltered air cannot bypass the element.

2 Check the spark plug

Remove the spark plug cap, unscrew the plug and check its

condition, comparing it with the photographs on page

65. If it is badly worn or fouled it must be renewed. If it is fit for

further service check the gap and reset it if necessary, as

described in Chapter 3.8.

3 Check the valve clearances

It is important that the correct valve clearance is

maintained. A small amount of free play is designed into the

valve train to allow for expansion of the various components. If

the setting deviates greatly from that specified, a marked drop

in performance will be evident. In the case of the clearance

becoming too great, it will be found that valve operation will be

noisy, and performance will drop off as a result of the valves not

opening fully. If on the other hand, the clearance is too small

the valves may not close completely. This will not only cause

loss of compression, but will also cause the valves to burn out

very quickly. In extreme cases, a valve head may strike the

piston crown, causing extensive damage to the engine. The

clearances should be checked and adjusted with a cold engine.

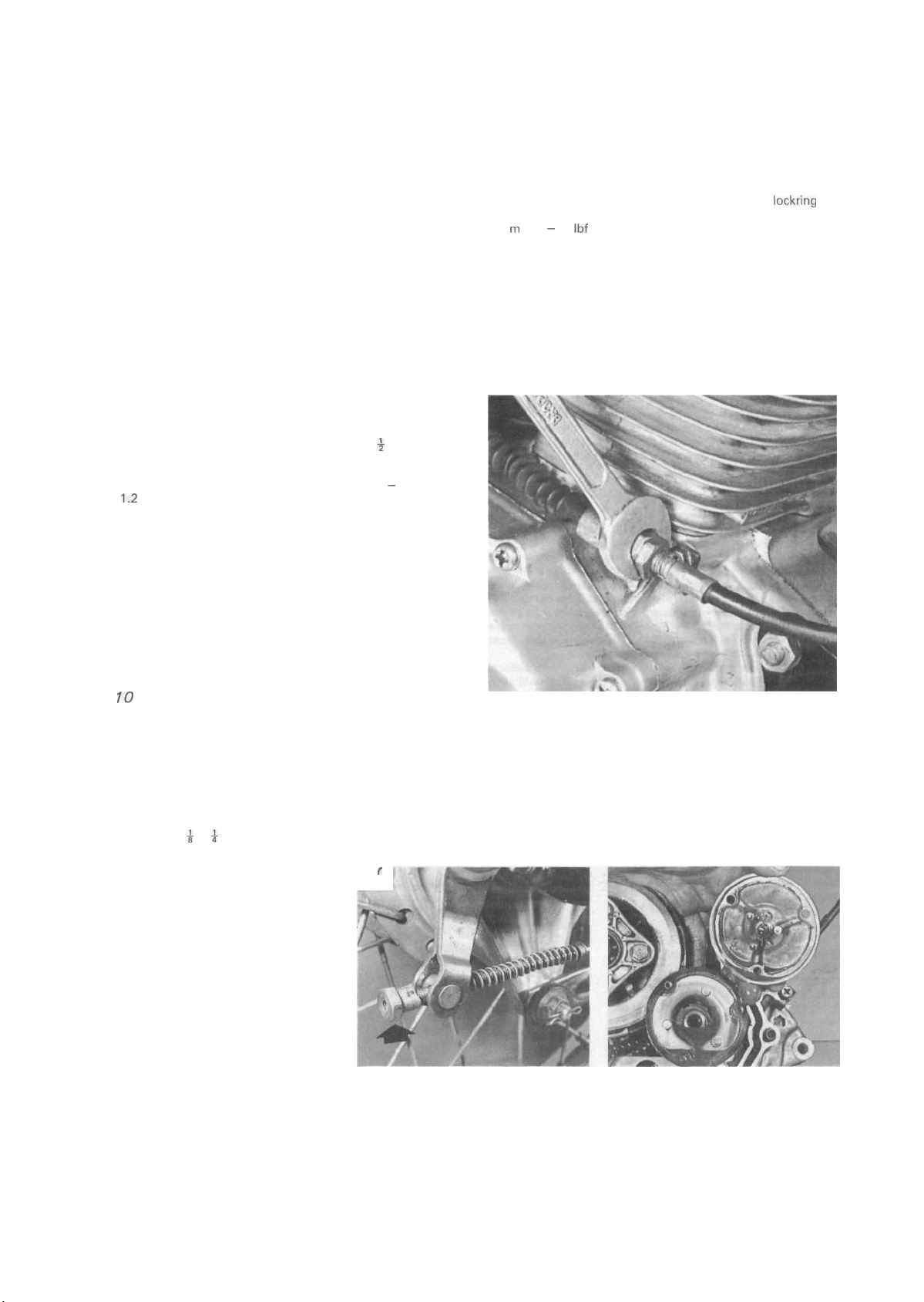

Place the machine on its centre stand and remove the

rocker cover, taking care not to damage the 0 ring. Remove the

gearchange pedal and the left-hand outer cover to expose the

generator rotor.

Remove plug and allow old oil to drain

Remove the spark plug, then slowly rotate the engine anticlockwise by way of the generator rotor, watching the inlet

valve. When it has opened and closed again (sunk down and

risen up to its original position), rotate the engine further until

the T mark on the rotor periphery aligns exactly with the raised

index mark which is positioned between

the crankshaft) on the generator stator. The engine will then be

in the correct position for checking the valve clearances, namely

at Top Dead Centre (TDC) on the compression stroke; check

that there is free play at both rockers.

Using a 0.08 mm (0.003 in) feeler gauge, check the

clearance between the top of each valve stem and its corresponding rocker. The feeler gauge must be a light sliding fit,

with the rocker and valve stem just nipping it. If necessary,

slacken the locknut, and turn the small square-headed adjuster

to obtain the correct setting. Tighten the locknut, holding the

adjuster at the same time to prevent it from moving. Finally,

recheck the setting and then repeat the procedure on the other

rocker.

12

and 1 o'clock (from

4 Check the contact breaker points and ignition

timing

Note: since the generator stator plate is located by its

countersunk retaining screws, the ignition timing can only be

altered by opening or closing the contact breaker gap; therefore

both operations are described as one. The full procedure is

given here for ease of reference, but if the points are found to

be in good condition and if the gap has not altered or is within

the tolerance, then the ignition timing will be sufficiently

accurate and there will be no need to carry out the full check.

First remove the gearchange pedal, the left-hand outer cover,

the spark plug and the left-hand side panel.

Strainer is easily removed for cleaning Dismantle the element for cleaning

and lubrication

-j-

mark should align as shown

Routine maintenance

11

Checking the condition of the contact breaker points

The contact breaker assembly can be viewed through one

of the generator rotor slots; turn the rotor until the points open.

Use a small screwdriver to push the moving point open against

its spring. Examine the point contact faces. If they are burnt or

pitted, remove the points for cleaning or renewal, see Chapter

3.4. Light surface deposits can be removed with crocus paper or

a piece of stiff card.

If the contact faces are badly burnt or pitted, or if the

moving contact fibre heel shows signs of wear or damage,

renew the assembly. It is essential that the points are in good

condition if the ignition timing is to be correct; use only genuine

Honda parts when renewing. If the faces are only mildly

marked, clean them using an oilstone or fine emery but be

careful to keep them square. If it is necessary to separate the

moving contact from the fixed one, carefully remove the circlip

fitted to the pivot post and note carefully the arrangement of

washers at both the pivot post and spring blade fixing. On

reassembly, the moving contact must be able to move freely;

apply a smear of grease to the pivot post. Note also that the low

tension lead terminal and the moving contact spring blade must

be connected to each other via the small bolt, but that both

must be completely insulated from the fixed contact. The engine

will not run if a short-circuit occurs at this point.

Refit the points to the stator plate and the rotor to the

crankshaft. Tighten the rotor nut to a torque setting of 4.0 - 5.0

kgf m (29 - 36

lubricating wick.

Checking the ignition timing

Disconnect the generator wiring at the connector block

joining it to the main wiring loom and identify the black or

black/white wire leading to the points. The best way of

establishing exactly when the points open is to use either a

multimeter set to its most sensitive resistance scale, or a

battery and bulb test circuit; refer to Chapter 3 for details. The

meter needle will flicker to indicate increased resistance as the

points open, or the bulb (which will be lit when the points are

closed) will glow dimmer; note that a high-wattage bulb must

be used to make this more obvious to the eye.

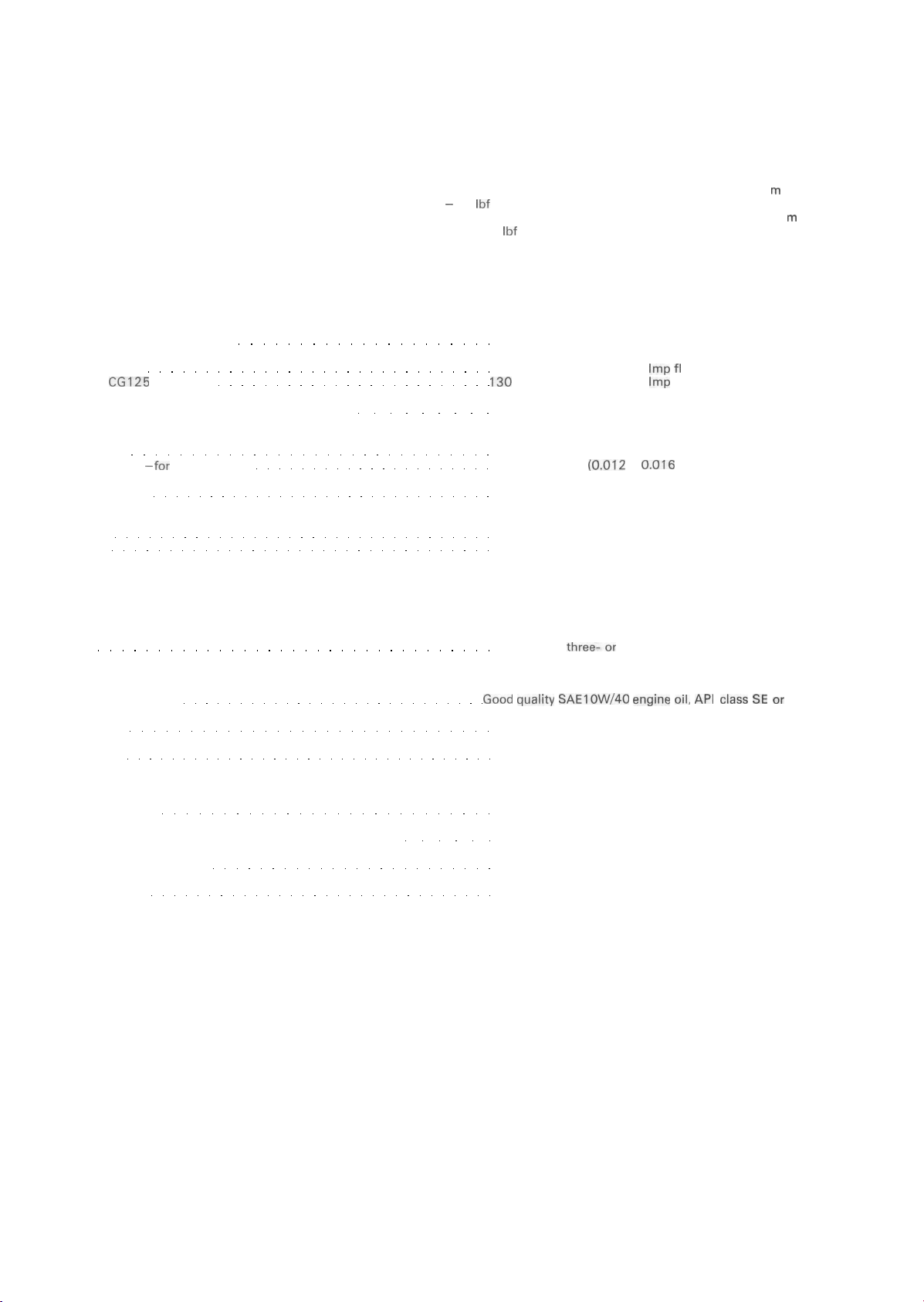

Turn the rotor anticlockwise until the meter needle deflects

(or the bulb dims); at this point the rotor 'F' mark should align

exactly with the raised index mark on the stator plate.

The setting is adjusted by opening or closing the points gap

to advance or retard respectively the ignition timing. Repeat the

procedure to check that the timing is now correct.

When the timing is correct, measure very carefully the

points gap, to ensure that the dwell angle is correct for the

maximum spark intensity. If the gap is found to be outside the

permitted tolerance the contact breaker points are excessively

worn and must be renewed.

Fit a new set of contact breaker points; note that it is

essential that only genuine Honda points are used. Refit the

rotor and set the points gap to exactly 0.35 mm

Ibf

ft), then apply a few drops of oil to the cam

(0.014

in), then

repeat the procedure given above. The ignition timing should be

correct.

Note: The above procedure is described in full as it is the

most accurate means of setting the ignition timing. In practice

there is no need to repeat the full procedure at every service

interval. Instead it is sufficient to check that the points gap is

within tolerances.

If

a strobe timing light is available the

can be checked. Connect the light following its manufacturer's

instructions, then start the engine and allow it to idle. At idle

speed the

just above idle speed the mark should appear to move as the

advance begins until at 3000

full advance mark are aligned with the index mark. If the

movement is stiff and jerky, or if the advance range is restricted,

the rotor must be removed so that the ATU can be dismantled

for cleaning and greasing.

'F

mark should align with the raised index mark; at

rpm

ATU's

performance

the two parallel lines of the

5 General checks and lubrication

At regular intervals the control cables must be thoroughly

lubricated, using light machine oil. This can be done by either

disconnecting the cable upper end and fitting a proprietary

cable oiler to pump oil through, or by removing the cable from

the machine and hanging it up overnight so that oil can drain

through the cable from a small funnel attached to its upper end.

Ensure that the cables are correctly routed and adjusted on

refitting. Grease the speedometer drive cable as described in

Chapter

4.17.

Check all pivots and control levers, cleaning and lubricating

them to prevent wear or corrosion. Where necessary, dismantle

and clean any moving part which may have become stiff in

operation. Similarly clean, check and grease the stand pivots

and ensure that the return spring holds the stand securely.

Check around the machine, looking for. loose nuts, bolts or

screws, retightening them as necessary.

It is advisable to lubricate the handlebar switches and stop

lamp switches with WD40 or a similar water dispersant

lubricant.

6 Check the fuel system

Referring to the relevant Sections of Chapter 2 (or of

Chapter 7 for (T)PFC carburettors) for full details check that the

petrol tank, tap, and feed pipe are in good condition and

securely fastened with no leaks. Check also that the choke

operates correctly. If rough running of the engine has

developed, some adjustment of the carburettor pilot setting and

tickover speed may be required. Do not make these

adjustments unless they are obviously required; there is little to

be gained by unwarranted attention to the carburettor.

Switch on the petrol tap and unscrew the float bowl drain

plug, allowing a small quantity of petrol to flush through. If large

amounts of dirt or water are found in the petrol, the system

components must be drained and cleaned out.

Once the carburettor has been checked and reset if

necessary, the throttle cable free play can be checked. Open

Set clearance so that the feeler gauge

is a sliding fit

"F" mark should align just as points

separate

Contact breaker gap is measured

via aperture

12

Routine maintenance

and close the throttle several times, allowing it to snap shut

under its own pressure. Ensure that it is able to shut off quickly

and fully at all handlebar positions, then check that there is 2 —

6 mm (0.08 - 0.24 in) of cable free play, measured in terms of

twistgrip rotation. If adjustment is necessary, use first the

adjuster which is set below the twistgrip. If there is an

insufficient range of adjustment the surplus free play can be

eliminated by peeling back the rubber cover and by using the

adjuster on the carburettor top.

7 Check the clutch adjustment

Fine adjustment is provided on the handlebar lever by way

of a threaded adjuster and lockring. Should this prove

insufficient, a second adjuster nut and locknut can be found at

the cable lower end. These should be set to give 10-20 mm

(0.4 — 0.8 in) movement at the lever end before the clutch

begins to lift.

8 Check the brakes

The brakes are adjusted by a nut at the end of the brake

cable or rod, as appropriate, with the front brake having an

additional fine adjuster at the cable handlebar end. To adjust the

brakes place the machine on its centre stand with the wheel to

be adjusted clear of the ground. Spin the wheel and tighten the

adjusting nut until a rubbing sound is heard as the shoes begin

to contact the drum, then unscrew the nut by \ - 1 turn until

the sound ceases. Spin the wheel hard and apply the brake

firmly to settle all components, then re-check the setting. This

procedure should give the specified setting of 20 - 30 mm (0.8

-

1.2

in) free play, measured at the lever or pedal tip. Check that

the stop lamp rear switch is set so that the lamp lights just as

pedal free play is taken up and the brake is beginning to engage.

At regular intervals the wheels should be removed so that

each brake assembly can be cleaned and checked for wear.

Renew any worn components and apply a smear of grease to

the camshaft bearing surfaces on reassembly. See Chapter 5.4.

Take great care not to overtighten the lockring. It is possible

to place a pressure of several tons on the head bearings by

over-tightening even though the handlebars may seem to turn

quite freely. Overtight bearings will cause the machine to roll at

low speeds and give imprecise steering. Adjustment is correct if

there is no play in the bearings and the handlebars swing to full

lock either side when the machine is supported with the front

wheel clear of the ground. Only a light tap on each end should

cause the handlebars to swing. Secure the

tightening the steering stem nut to a torque setting of 6.0 - 9.0

kgf m (43 - 65

Examine closely the front and rear suspension. Ensure that

the front forks work smoothly and progressively by pumping

them up and down whilst the front brake is held on. Any faults

revealed by this check should be investigated further. Check

carefully for signs of leaks around the front fork oil seals. If any

damage is found, it must be repaired immediately as described

in the relevant Sections of Chapter 4.

To check the swinging arm place the machine on its centre

stand then pull and push horizontally at the rear end of the

swinging arm; there should be no discernible play at the pivot.

Ibf

ft) then check that the setting has not altered.

lockring

by

9 Check the wheels

Referring to Chapter 5.2 check the wheel rims for runout,

the spokes for straightness, security and even tension, and the

bearings for signs of free play. Any faults found must be

rectified immediately.

10

Check the suspension and steering

Support the machine so that it is secure with the front

wheel clear of the ground, then grasp the front fork legs near

the wheel spindle and push and pull firmly in a fore and aft

direction. If play is evident between the top and bottom fork

yokes and the steering head, the steering head bearings are in

need of adjustment. Imprecise handling or a tendency for the

front forks to judder may be caused by this fault.

Bearing adjustment is correct when the lockring is

tightened until resistance to movement is felt and then

loosened by \ to \ of a turn. The lockring should be rotated by

means of a C-spanner after slackening the steering stem nut.

'

Main clutch cable adjuster is at lower end of cable

Annually, or every 7200 miles (12 000 km)

Repeat all service operations listed under previous

headings, then carry out the following:

7 Renew the spark plug

The spark plug should be renewed at this interval,

regardless of its apparent condition.

Front brake adjuster nut

Rear brake adjuster nut Clean out accumulated sediment from

housing

Routine maintenance

13

2 Clean the centrifugal oil filter

Remove the crankcase right-hand cover, as described in

Chapter 1.10, then remove its three retaining screws and

withdraw the filter cover; note the gasket. Carefully clean out

the deposits which will have accumulated around the inner

edge of the unit, noting that these may have become quite

compacted and may need scraping off. Wash each part out

using a lint-free rag soaked in solvent, then dry them off before

refitting the cover. Refit the crankcase cover and refill the

engine to the correct level with the specified oil.

3 Change the front fork oil

Place the machine on the centre stand then remove the fork

top bolts. Unscrew the drain plug from each fork lower leg and

allow the oil to drain into a suitable container. This is accomplished most easily if the legs are attended to in turn. Take

care not to spill any oil onto the brake or tyre. The forks may be

pumped up and down to expel any remaining oil. Refit and

tighten the drain plugs to a torque setting of 0.3 - 0.6 kgf m (2

— 4 Ibf

ft). Refill each fork leg with the specified oil. Refit and

tighten the fork top bolts to a torque setting of 3.0 - 4.0 kgf

(22 - 29

Ibf

ft).

Quick glance maintenance data

Oil capacity

Engine/gearbox unit approx 1.0 litre (1.76 Imp pint)

Front forks — at oil change

CG125 120 - 130 cc (4.22 - 4.58

CG125

K1, B, C, E

Valve clearances - inlet and exhaust, cold engine 0.08 mm (0.003 in)

Contact breaker gap

Nominal 0.35 mm (0.014 in)

Tolerance

Spark plug gap 0.6 - 0.7 mm (0.024 - 0.028 in)

Tyre pressures - solo, tyres cold

Front 25 psi (1.75 kg/cm2)

Rear 28 psi (2.00 kg/cm2)

- for

ignition timing 0.30 - 0.40 mm

130

- 140 cc (4.58 - 4.93

(0.012 - 0.016

Imp fl

Imp

m

oz)

fl oz)

in)

Recommended lubricants

Petrol Either leaded

of 91) or unleaded premium

Engine/gearbox unit

Front forks Automatic transmission fluid (ATF) or equivalent fork oil

Air cleaner SAE80 or 90 gear oil - SAE30 engine oil if gear oil not

Final drive chain Commercial chain lubricant

Brake camshafts, wheel bearings and speedometer drive High melting-point grease

All other greasing points General purpose grease

Control cables Engine oil or light machine oil

Good quality SAE10W/40 engine

available

three-or

four-star (minimum octane rating

oil,

API class SE or

SF

Working conditions and tools

When a major overhaul is contemplated, it is important that

a clean, well-lit working space is available, equipped with a

workbench and vice, and with space for laying out or storing the

dismantled assemblies in an orderly manner where they are

unlikely to be disturbed. The use of a good workshop will give

the satisfaction of work done in comfort and without haste,

where there is little chance of the machine being dismantled

and reassembled in anything other than clean surroundings.

Unfortunately, these ideal working conditions are not always

practicable and under these latter circumstances when

improvisation is called for, extra care and time will be needed.

The other essential requirement is a comprehensive set of

good quality tools. Quality is of prime importance since cheap

tools will prove expensive in the long run if they slip or break

when in use, causing personal injury or expensive damage to

the component being worked on. A good quality tool will last a

long time, and more than justify the cost.

For practically all tools, a tool factor is the best source since

he will have a very comprehensive range compared with the

average garage or accessory shop. Having said that, accessory

shops often offer excellent quality tools at discount prices, so it

pays to shop around. There are plenty of tools around at

reasonable prices, but always aim to purchase items which meet

the relevant national safety standards. If in doubt, seek the

advice of the shop proprietor or manager before making a

purchase.

The basis of any tool kit is a set of open-ended spanners,

which can be used on almost any part of the machine to which

there is reasonable access. A set of ring spanners makes a useful

addition, since they can be used on nuts that are very tight or

where access is restricted. Where the cost has to be kept within

reasonable bounds, a compromise can be effected with a set of

combination spanners - open-ended at one end and having a

ring of the same size on the other end. Socket spanners may also

be considered a good investment, a basic 3/8

kit comprising a ratchet handle and a small number of socket

heads, if money is limited. Additional sockets can be purchased,

as and when they are required. Provided they are slim in profile,

sockets will reach nuts or bolts that are deeply recessed. When

purchasing spanners of any kind, make sure the correct size

standard is purchased. Almost all machines manufactured

outside the UK and the USA have metric nuts and bolts, whilst

those produced in Britain have BSF or BSW sizes. The standard

used in USA is AF, which is also found on some of the later

British machines. Others tools that should be included in the kit

are a range of crosshead screwdrivers, a pair of pliers and a

hammer.

When considering the purchase of tools, it should be

remembered that by carrying out the work oneself, a large

proportion of the normal repair cost, made up by labour

charges, will be saved. The economy made on even a minor

overhaul will go a long way towards the improvement of a

toolkit.

in or 1/2

in drive

In addition to the basic tool kit, certain additional tools can

prove invaluable when they are close to hand, to help speed up

a multitude of repetitive jobs. For example, an impact

screwdriver will ease the removal of screws that have been

tightened by a similar tool, during assembly, Without a risk of

damaging the screw heads. And, of course, it can be used again

to retighten the screws, to ensure an oil or airtight seal results.

Circlip pliers have their uses too, since gear pinions, shafts and

similar components are frequently retained by circlips that are

not too easily displaced by a screwdriver. There are two types of

circlip pliers, one for internal and one for external circlips. They

may also have straight or right-angled jaws.

One of the most useful of all tools is the torque wrench, a

form of spanner that can be adjusted to slip when a measured

amount of force is applied to any bolt or nut. Torque wrench

settings are given in almost every modern workshop or service

manual, where the extent to which a complex component, such

as a cylinder head, can be tightened without fear of distortion or

leakage. The tightening of bearing caps is yet another example.

Overtightening will stretch or even break bolts, necessitating

extra work to extract the broken portions.

As may be expected, the more sophisticated the machine,

the greater is the number of tools likely to be required if it is to

be kept in first class condition by the home mechanic.

Unfortunately there are certain jobs which cannot be

accomplished successfully without the correct equipment and

although there is invariably a specialist who will undertake the

work for a fee, the home mechanic will have to dig more deeply

in his pocket for the purchase of similar equipment if he does

not wish to employ the services of others. Here a word of

caution is necessary, since some of these jobs are best left to

the expert. Although an electrical multimeter of the AVO type

will prove helpful in tracing electrical faults, in inexperienced

hands it may irrevocably damage some of the electrical com-

ponents if a test current is passed through them in the wrong

direction. This can apply to the synchronisation of twin or multiple carburettors too, where a certain amount of expertise is

needed when setting them up with vacuum gauges. These are,

however, exceptions. Some instruments, such as a strobe lamp,

are virtually essential when checking the timing of a machine

powered by

of these special items unless you have the experience to use

them correctly.

removed and replaced without the use of special service tools

(unless absolutely essential), it is worthwhile giving consideration to the purchase of the more commonly used tools if the

machine is regarded as a long term purchase Whilst the alternative methods suggested will remove and replace parts without

risk of damage, the use of the special tools recommended and

sold by the manufacturer will invariably save time.

CDI

ignition system. In short, do not purchase any

Although this manual shows how components can be

Chapter

1 Engine, clutch and gearbox

Refer to Chapter 7 for information relating to the

Contents

General description 1

Operations with the engine unit in the frame 2

Operations with engine removed 3

Method of engine/gearbox removal 4

Removing the engine/gearbox unit 5

Dismantling the engine and gearbox unit : general ... 6

Dismantling the engine and gearbox unit : removing

the cylinder head, barrel and piston 7

Dismantling the engine and gearbox unit : removing

the generator assembly 8

Dismantling the engine/gearbox unit : removing the

cam gear and shaft 9

Dismantling the engine/gearbox unit : removing the

centrifugal oil filter 10

Dismantling the engine/gearbox unit : removing the

oil pump

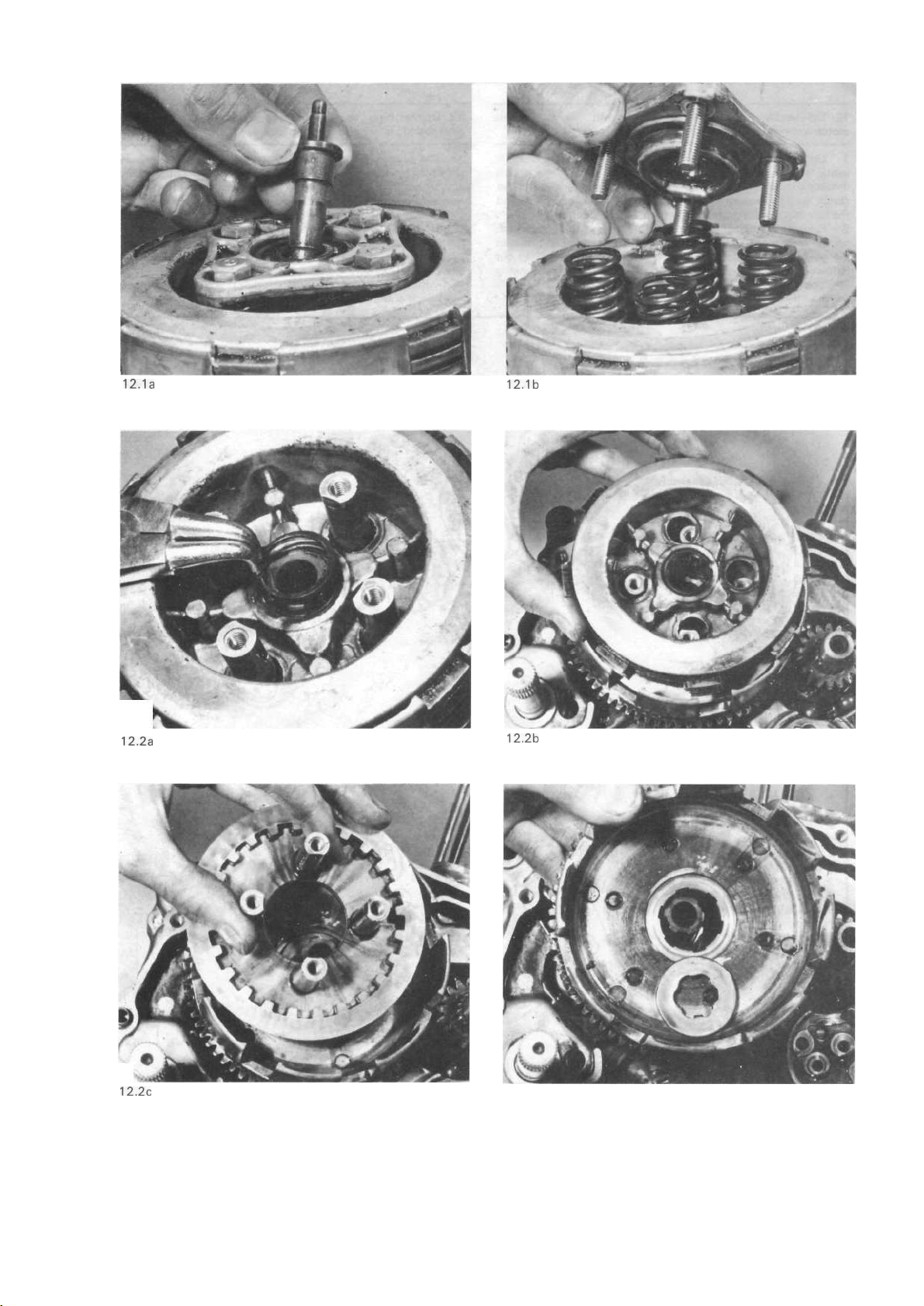

Dismantling the engine/gearbox unit : removing the

clutch assembly and crankshaft pinion 12

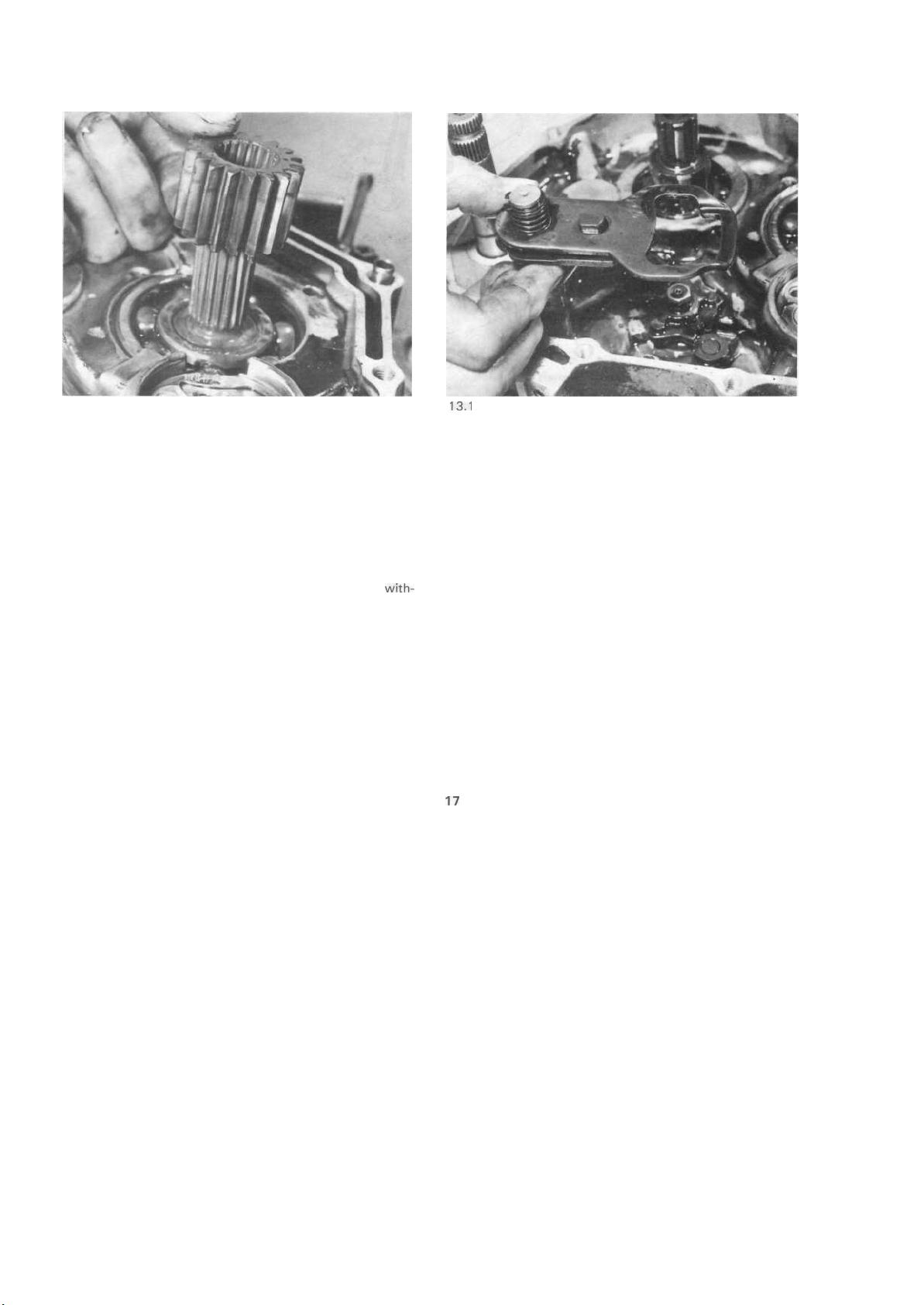

Dismantling the engine/gearbox unit : removing the

gearchange shaft and mechanism 13

Dismantling the engine/gearbox unit : removing the

end float plunger and neutral switch 14

Dismantling the engine/gearbox unit : separating the

crankcase halves

Dismantling the engine/gearbox unit : removing the

kickstart mechanism, crankshaft assembly and gearbox

components 16

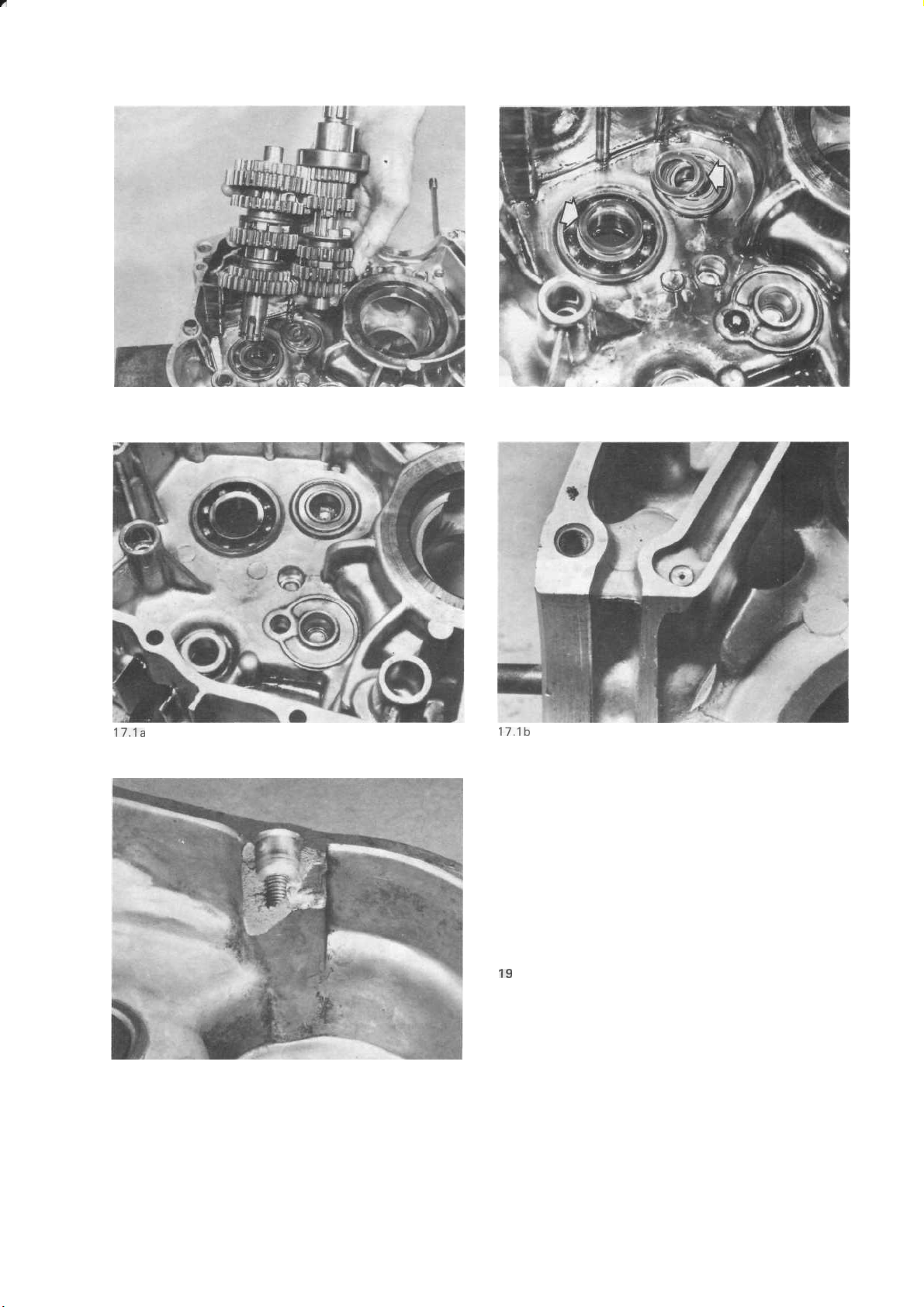

Examination and renovation : general 17

Crankshaft and gearbox main bearings : removal ... 18

Examination and renovation: big-end and main

bearings 19

Examination and renovation: gudgeon pin, small

end and piston bosses 20

11

15

1985

on Brazilian models

Examination and renovation : piston and piston rings 21

Examination and renovation : cylinder barrel 22

Cylinder head : valve removal, examination and

renovation 23

Examination and decarbonisation : cylinder head ... 24

Examination and renovation : rocker arms, adjusters and

pushrods 25

Examination and renovation : cam gear and lobe, and

cam followers 26

Examination and renovation : trochoidal oil pump ... 27

Examination and renovation : clutch and primary drive 28

Examination and renovation: gearbox components 29

Engine casings and covers : examination and repair ... 30

Engine reassembly : general 31

Engine reassembly : gear clusters and selector

mechanism reassembly and replacement 32

Engine reassembly : replacing the crankcase

components 33

Preparation of crankcase jointing surfaces : joining the

crankcase 34

Replacing the crankshaft pinion, oil pump and

gearchange mechanism 35

Replacing the clutch assembly and centrifugal oil filter 36

Replacing the camshaft, generator and left-hand casing

fittings 37

Replacing the gearbox sprocket 38

Refitting the piston, cylinder barrel, cylinder head and

rocker arms 39

Refitting the engine/gearbox unit in the frame 40

Starting and running the rebuilt engine 41

Fault diagnosis: engine 42

Fault diagnosis: clutch 43

Fault diagnosis: gearbox 44

Specifications

Engine (general)

Type

Bore

Stroke

Capacity

Compression ratio

CG125 CG125 K1, B

CG125-C, E

Piston

Type

Skirt

OD

Wear limit

Gudgeon

Wear limit

Gudgeon pin bore

Wear limit

pin

OD

ID

Air cooled, single cylinder, four stroke

56.5

mm (2.224 in)

49.5

mm (1.949 in)

124cc(7.56cuin)

9.0:1

9.2:1

Forged aluminium alloy

56.45 - 56.48 mm (2.2224 - 2.2236 in)

56.35 mm

14.99

14.96

15.00 -

15.04

(2.2185

- 15.00

mm (0.5890 in)

15.01 mm (0.5906 - 0.5909 in)

mm

(0.5921

in)

mm (0.5902 - 0.5906 in)

in)

16 Chapter 1 Engine, clutch and gearbox

Piston rings : 2 compression, 1 oil scraper

Ring to groove clearance

Top

0.03-0.05

2nd

0.02-0.05

Wear limit (both)

End gap (Top and 2nd) - installed 0.1 5-0.35 mm (0.0059-0.0138 in)

Wear limit 0.60 mm (0.0236 in)

Thickness (Top and 2nd)

Wearlimit

Cylinder bore diameter 56.50 - 56.51 mm (2.2244 - 2.2248 in) nominal

Wearlimit 56.60 mm (2.2283 in)

Cylinder compression pressure - throttle open, engine fully warmed up

CG125,

CG125-C, E 1 1.5 - 14.5

Valves

Valve timing

Inlet valve opens at TDC

Inlet valve closes at 30°ABDC

Exhaust

Exhaust valve closes at TDC

Valve clearances - inlet and exhaust, cold engine 0.08 mm (0.003 in)

Valve spring free length

Inner 33.5 mm (1.31 89 in) 30.0 mm (1.1 81 1 in)

Outer 40.9 mm (1.6102 in) 39.8 mm (1.5669 in)

Valve seat width

Valve stem diameter

Inlet 5.45 - 5.46 mm 5.42 mm (0.2134 in)

Exhaust 5.43 - 5.44 mm 5.40 mm (0.2126 in)

Valve guide bore diameter 5.47 - 5.48 mm 5.50 mm (0.2165 in)

Valve stem to guide clearance

Inlet 0.01 - 0.03 mm

Exhaust 0.03 - 0.05 mm 0.14 mm (0.0055 in)

Pushrods

Length 1 41.1

Wearlimit ...• 141.00mm (5.5512in)

Cam and followers

Cam follower bore diameter 12.00 - 12.02 mm (0.4724 - 0.4732 in)

Wearlimit

Cam follower shaft diameter 11.976 - 1 1.994 mm (0.471 5 - 0.4722 in)

Wearlimit

Cam lobe height 32.768 - 32.928 mm (1.2901 - 1.2964 in)

Wearlimit

Cam gear shaft diameter 11.970 - 11.980 mm 13.996 - 13.984 mm

Wearlimit

Cam gear bore diameter 12.000 - 12.020 mm 14.060 - 1 4.078 mm

Wear limit N/Av 14.098 mm (0.5550 in)

Gear to shaft clearance 0.020 - 0.050 mm 0.076 -

Wearlimit

0.10

1.45 mm (0.0571 in)

CG125

valve

12.05 mm (0.4744 in)

11.950 mm (0.4705 in)

32.628 mm

N/Av 13.946 mm (0.5491 in)

0.060 mm (0.0024 in) 0.120 mm (0.0047 in)

1.50-1.52

K1, B 10.0 - 12.0

operTs

at 30° BBDC

Standard Wear limit

1.2-1.5

(0.04"72 - 0.0591 in)

(0.2146 - 0.2150

(0.2138 - 0.2142 in)

(0.2154 -

(0.0004 - 0.0012 in)

(0.0012 - 0.0020 in)

Up to eng. no. 1486212 From eng. no. 1486212

(0.4713 - 0.4717 in) (0.5498 - 0.5506 in)

(0.4724 - 0.4732 in) (0.5535 - 0.5543 in)

(0.0008 - 0.0020 in) (0.0030 - 0.0044 in)

mm (0.0012-0.0020 in)

mm

mm (0.0039 in)

5-141.45

(0.0008-0.0020in)

mm (0.0591-0.0598 in)

kg/cm2 (142 - 1 71 psi)

kg/cm2 (164 - 206 psi)

mm 2.0 mm (0.0787 in)

in)

0.2157

in)

0.12

mm (5.5571 - 5.5689 in)

(1.2846

in)

mm (0.0047 in)

0.112

mm

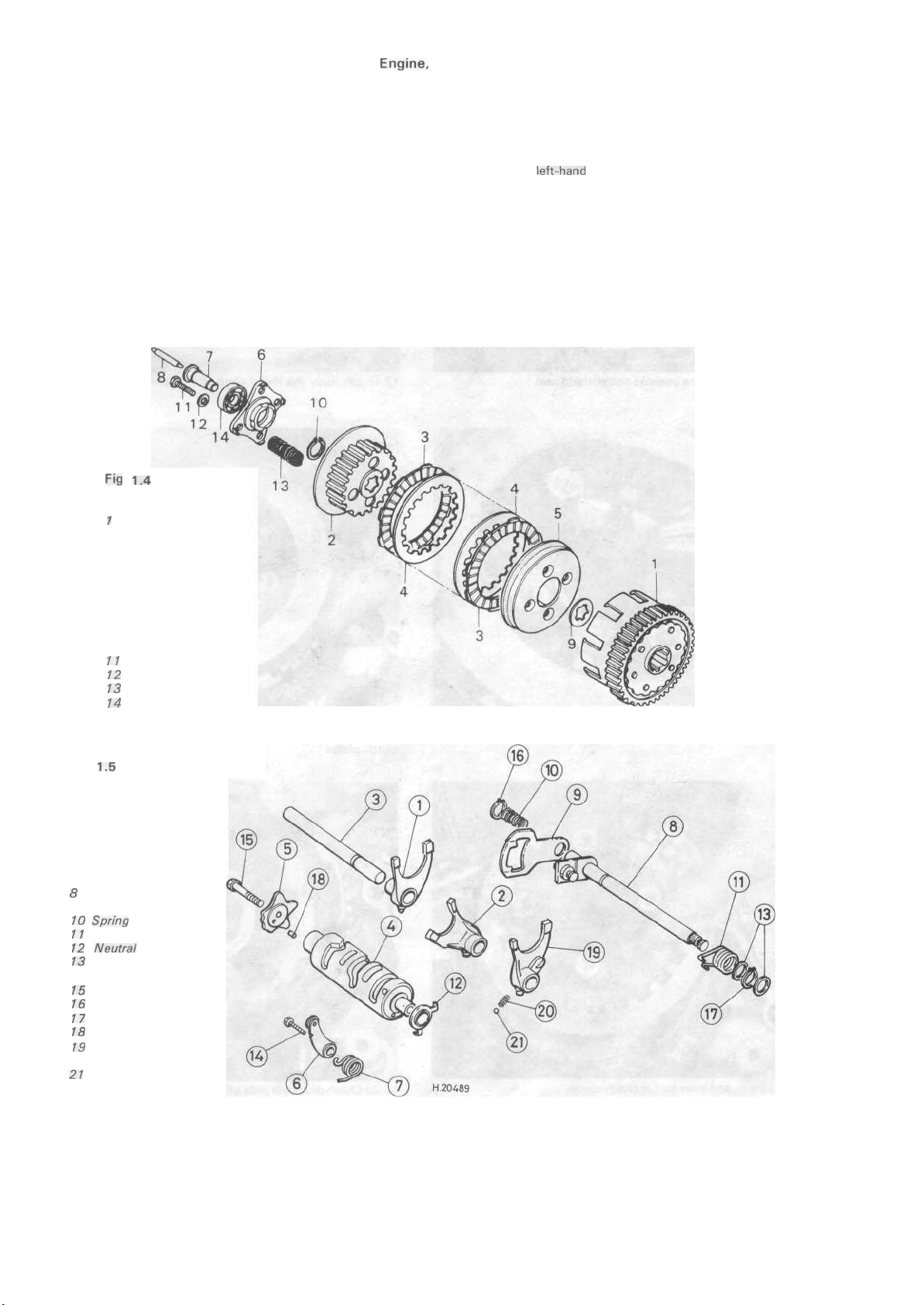

Clutch

Type

Wet,

Number of plates

Plain 4

Friction 5

Plate maximum warpage 0.20 mm (0.0079 in)

Spring free length 35.50 mm

Wearlimit 34.20mm (1.3465 in)

Compressed length 23.00 mm (0.9055 in)

Spring pressure (compressed) 23.8 kg (52.5 lbs)

Wearlimit 21.8 kg (48.1 lbs)

Friction plate thickness 2.90-3.00 mm (0.1 142-0.11 81 in)

Wearlimit 2.60mm (0.1024in)

multiplate

(1.3976

in)

Gearbox

Reduction ratios

Primary drive

1st

2nd

3rd

4th

5th

Final drive

Selector fork claw end thickness ...

Wear limit

Selector fork bore diameter

Wear limit

Selector fork shaft diameter

Wear limit

Kickstart shaft diameter - at pinion

Up to engine number 1020010

Engine number

Wear limit

Kickstart pinion bore diameter

Up to engine number 1020010

Wear limit

Engine number

Wear limit

1020011

1020011

on ...

on ...

Chapter 1 Engine, clutch and gearbox

4.055:1 (18/73T)

2.769:1 (13/36T)

1.882:1

(17/32T)

1.450:1 (20/29T)

1.174:1 (23/27T)

1.000:1 (25/25T)

2.267:1 (15/34T)

4.93 - 5.00 mm (0.1941 - 0.1969 in)

4.70 mm (0.1850 in)

12.00 - 12.02

12.05 mm (0.4744 in)

1 1.98 - 1 1.99 mm (0.4717 - 0.4721 in)

1 1.96 mm (0.4709 in)

N/Av

19.959 - 19.980

19.900 mm (0.7835 in)

24.900 - 24.920 mm (0.9803 -

24.940 mm (0.9819 in)

20.000 -

20.050 mm (0.7894 in)

20.021

mm (0.4724 - 0.4732 in)

mm (0.7858 - 0.7866 in)

0.9811

mm (0.7874 - 0.7882 in)

17

in)

1 General description

The engine unit employed in the Honda

the single cylinder air cooled four stroke type. Unlike most other

machines in the Honda range, the CG125 utilises a pushrod

operated valve arrangement.

The unit is of all-alloy construction, employing vertically

split crankcases which house both the crankshaft assembly and

the gear clusters. The cylinder head and cylinder barrel are also

of light alloy, the latter incorporating a steel liner in which the

cylinder bore is machined.

Lubrication is provided by a small trochoidal oil pump

feeding the major engine components. The lubricating oil is contained in the lower portion of the crankcase which forms a com-

bined sump and an oil bath for the gearbox components.

2 Operations with the engine unit in the frame

It

is not necessary to remove the engine unit from the frame

unless the crankshaft assembly and/or the gearbox internals

require attention. Most operations can be accomplished with

the engine in place, such as:

1 Removal and replacement of the cylinder head.

2 Removal and replacement of the cylinder barrel and piston.

3 Removal and replacement of the camshaft.

4 Removal and replacement of the generator.

5 Removal and replacement of the contact breaker assembly.

6 Removal and replacement of the clutch assembly.

7 Removal and replacement of the centrifugal oil filter.

8 Removal and replacement of the oil pump.

When several operations need to be undertaken

simultaneously, it will probably be advantageous to remove the

complete engine unit from the frame, an operation that should

take approximately one hour, working at a leisurely pace. This

will give the advantage of better access and more working

space.

3 Operations with engine removed

1 Removal and replacement of the crankshaft assembly.

2 Removal and replacement of the gear cluster, selectors and

gearbox main bearings.

CG125

models is of

4 Method of engine/gearbox removal

As mentioned previously, the engine and gearbox are of unit

construction, and it is necessary to remove the unit complete, in

order to gain access to the internal components. Separation and

reassembly are only possible with the engine unit removed from

the frame. It is recommended that the procedure detailed below

is adhered to, as in certain instances, components are much

easier to remove whilst the unit is supported by the frame.

5 Removing the engine/gearbox unit

1 Place the machine securely on its centre stand, ensuring

that there is no likelihood of it falling over during engine

removal. Engine removal can be made much easier if the

machine is raised about two feet by means of a stand. A stout

table can be modified for this purpose, or alternatively, a few

substantial planks and some concrete blocks will suffice. This

procedure is by no means essential, but will greatly ease the

discomfort of squatting or kneeling down to work.

2 Place a container of at least one litre beneath the engine

unit, then remove the drain plug and leave the oil to drain while

further dismantling is carried out. Turn the fuel tap to the off

position and prise off the fuel pipe from the stub at the base of

the tap. A small screwdriver can be used to ease the pipe off

without straining it.

3 Release the seat mounting bolts, which are located

immediately above the rear indicator lamps, and lift the seat

away from the frame. Disengage the rear of the petrol tank from

the rubber block which retains it. The tank can then be pulled

upwards and back to release the front mounting blocks.

4 Slacken off the clutch cable adjuster nuts, and release the

cable from the actuating arm on the top of the engine casing.

Disengage the cable and lodge it clear of the engine. The spark

plug lead should also be detached and placed out of the way on

the top frame tube.

5 Unscrew the carburettor top and withdraw the throttle

valve assembly. There is no need to disconnect the cable, but

the assembly should be positioned where it will not get

damaged during engine removal. Disconnect the rubber intake

hose, then remove the two nuts which hold the carburettor

flange to the cylinder head. The carburettor body should be

lifted away, together with the heat shield and spacer or inlet

stub. Pull off the crankcase breather pipe.

6 Remove the two nuts which retain the exhaust pipe to the

cylinder head, sliding the flange clear and removing the two

18

Chapter 1 Engine, clutch and gearbox

packing pieces behind it. The exhaust is secured by two nuts to

its mounting bracket, which is secured to the frame by a bolt

and by the swinging arm pivot bolt retaining nut. These should

be removed and the complete system withdrawn. The footrest

assembly should be removed after unscrewing the four bolts

which hold it to the underside of the crankcase.

7 Remove the gearchange pedal pinch bolt and slide the

pedal off its splines. Remove the left-hand outer cover, and

place it to one side to await reassembly. The gearbox sprocket

is retained by a locking plate which in turn is held in position by

two bolts. Remove the bolts, to allow the plate to be turned

slightly and drawn off the splined shaft.

8 Remove the left-hand side panel which is a push fit in the

frame lugs. It is also worth removing the right-hand panel to

avoid any risk of damage to the paint finish. Remove the screw

from the battery negative (—) terminal and release the two green

leads to isolate the battery from the electrical system. Separate

the white multiple connector block to disconnect the generator;

this will be found adjacent to the battery.

9 The engine is now held only by the five mounting bolts.

Remove the two front bolts and place them to one side. It is

worthwhile removing the entire engine plate to gain the

maximum amount of manoeuvring room. Remove the lower

rear mounting bolt, noting that the nut may be difficult to reach

if the exhaust mounting bracket has not been removed,

followed by the upper bolt which passes through a lug in the

cylinder head. Finally, release the remaining rear mounting bolt,

disengaging the generator harness from its clip. As the bolt is

withdrawn, the unit will drop free, and it is advisable to have an

assistant to hand to help with these final stages. Note that

whilst not strictly necessary, it was found helpful to remove the

left-hand head steady plate to provide better clearance. The unit

is not heavy, and can easily be lifted clear of the frame by one

person.

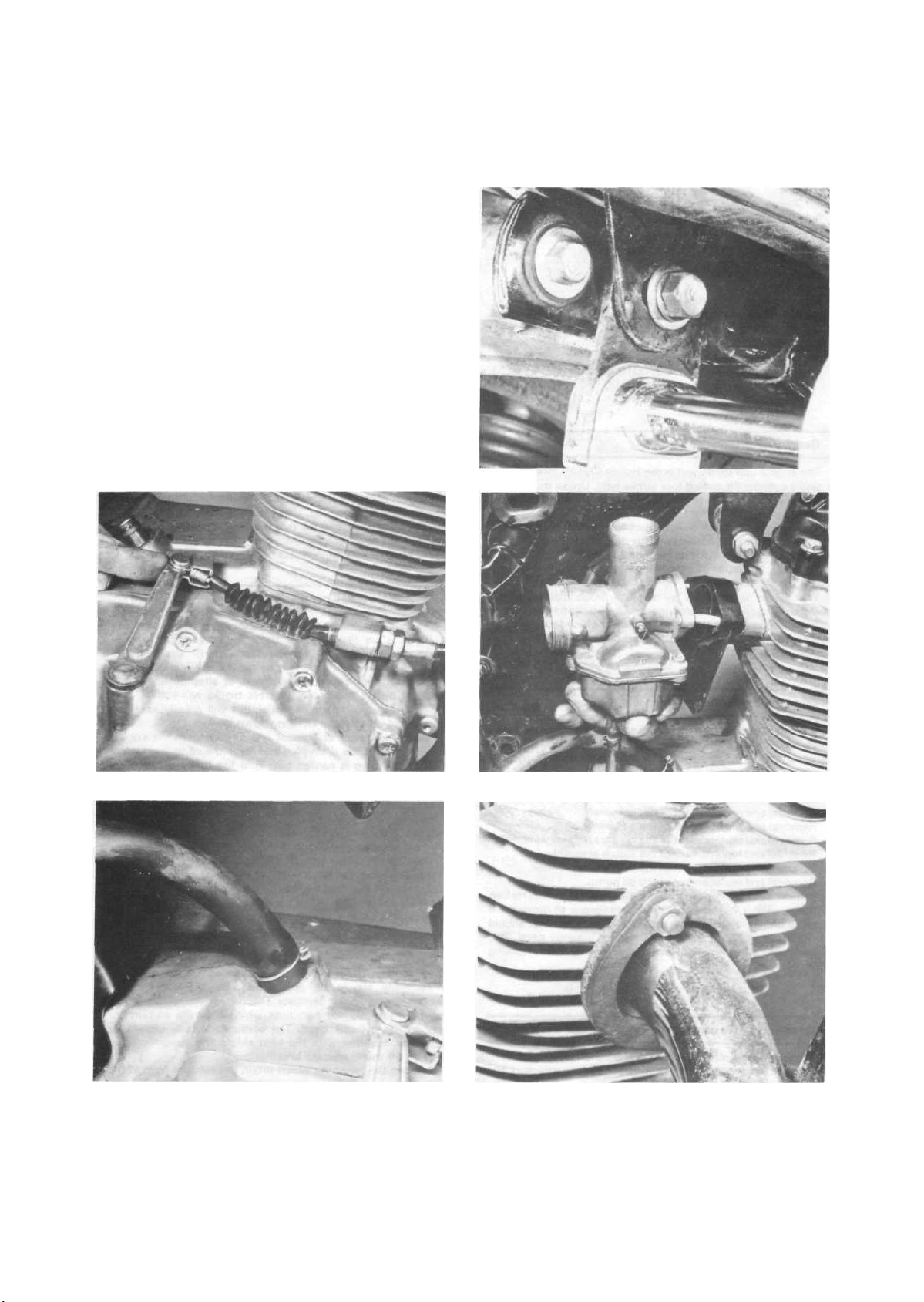

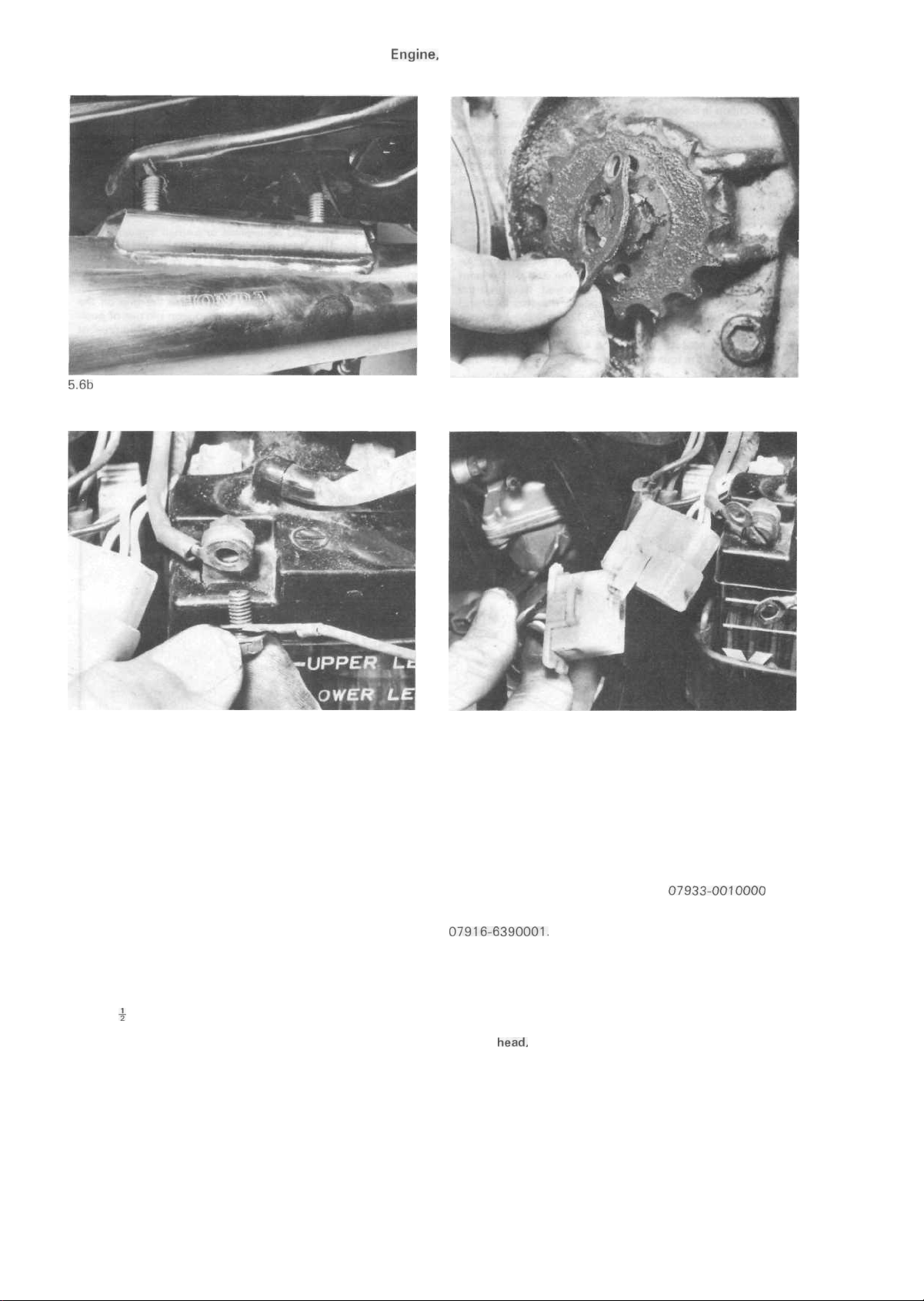

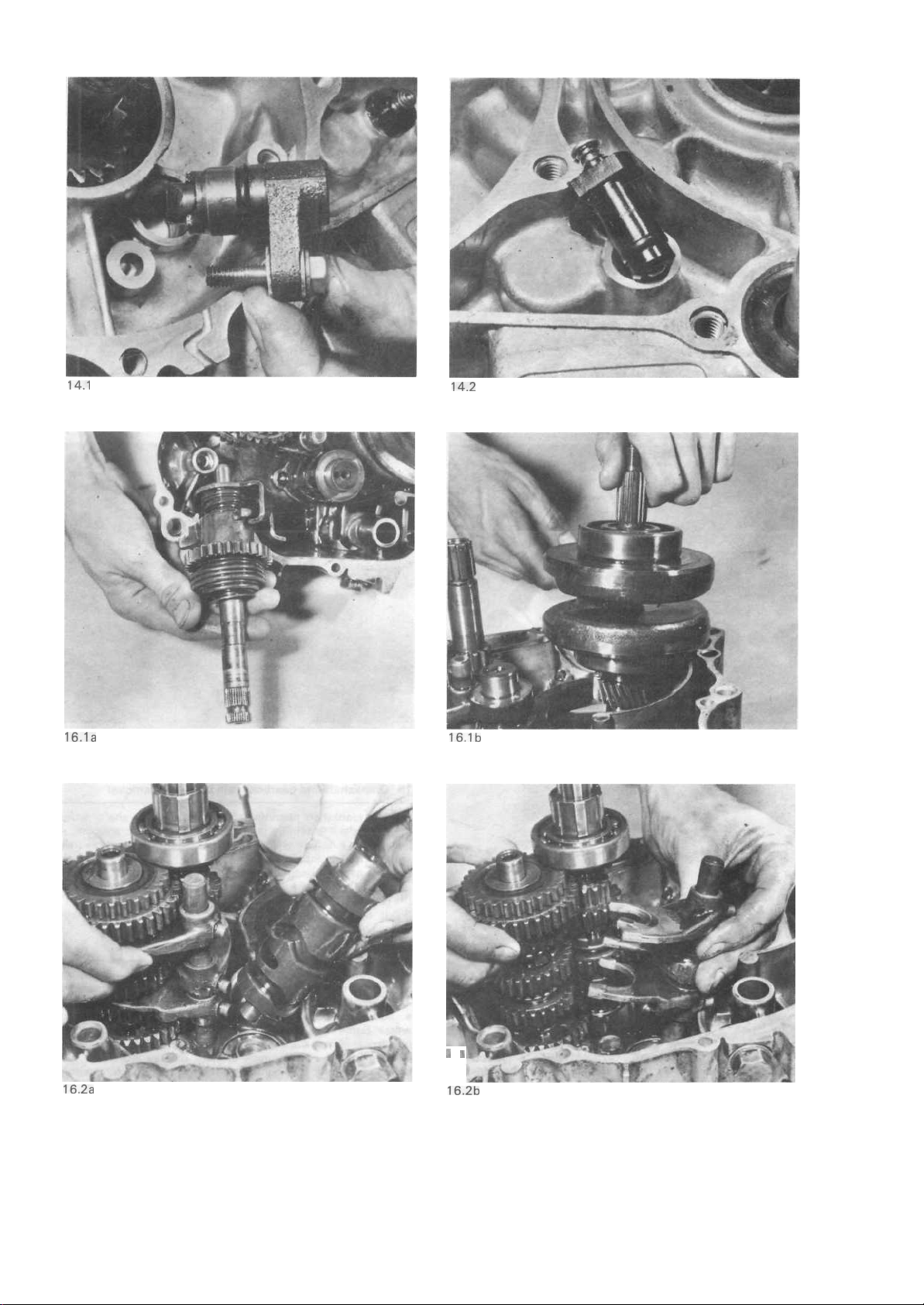

5.3 Seat is retained by two bolts at rear

5.4 Slacken off and remove the clutch cable

5.5b Pull off the crankcase breather pipe

5.5a Remove the carburettor, heatshield and spacer (early

models)

5.6a Remove exhaust pipe flange followed by .

Chapter 1

5.6b

... rear mounting nuts to release complete exhaust system 5.7 Release the locking plate to permit sprocket removal

Engine,

clutch and gearbox

19

5.8a Disconnect the battery to isolate the electrical system

6 Dismantling the engine and gearbox unit: general

1 Before commencing work on the engine unit, the external

surfaces should be cleaned thoroughly. A motor cycle engine

has very little protection from road grit and other foreign matter,

which will find its way into the dismantled engine if this simple

precaution is not taken. One of the proprietary cleaning compounds, such as 'Gunk' or 'Jizer' can be used to good effect,

particularly if the compound is permitted to work into the film of

oil and grease before it is washed away. Special care is

necessary, when washing down to prevent water from entering

the now exposed parts of the engine unit.

2 Never use undue force to remove any stubborn part unless

specific mention is made of this requirement. There is invariably

good reason why a part is difficult to remove, often because the

dismantling operation has been tackled in the wrong sequence.

3 Mention has already been made of the benefits of owning

an impact driver. Most of these tools are equipped with a

standard \ inch drive and an adaptor which can take a variety of

screwdriver bits. It will be found that most engine casing screws

will need jarring free due to both the effects of assembly by

power tools and an inherent tendency for screws to become

pinched in alloy castings.

4 A cursory glance over many machines of only a few years

5.8b ... then separate the generator output lead connector

use, will almost invariably reveal an array of well-chewed screw

heads. Not only is this unsightly, it can also make emergency

repairs impossible. It should also be borne in mind that there are

a number of types of crosshead screwdrivers which differ in the

angle and design of the driving tangs. To this end, it is always

advisable to ensure that the correct tool is available to suit a

particular screw.

5 In addition to the above points, it is worth noting before any

dismantling work is undertaken that it is desirable to have two

service tools available. The first, and most important, is a

flywheel puller, Honda part number

cheaper pattern version, and secondly, a special peg spanner for

releasing the centrifugal oil filter housing, Honda part number

07916-6390001.

tubing, if necessary, but it is much less easy to make do without

the flywheel extractor as the flywheel proved to be a very tight

fit.

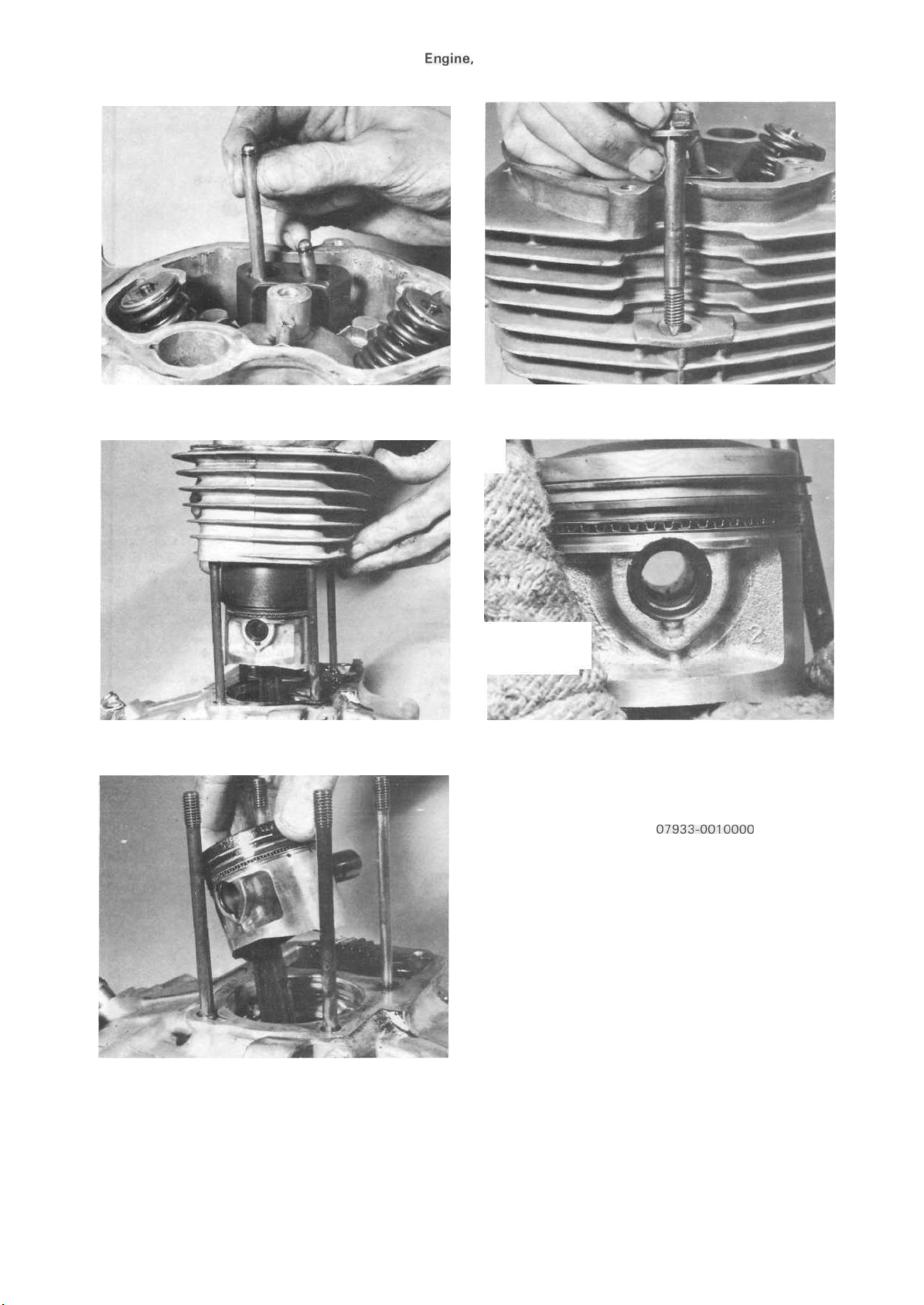

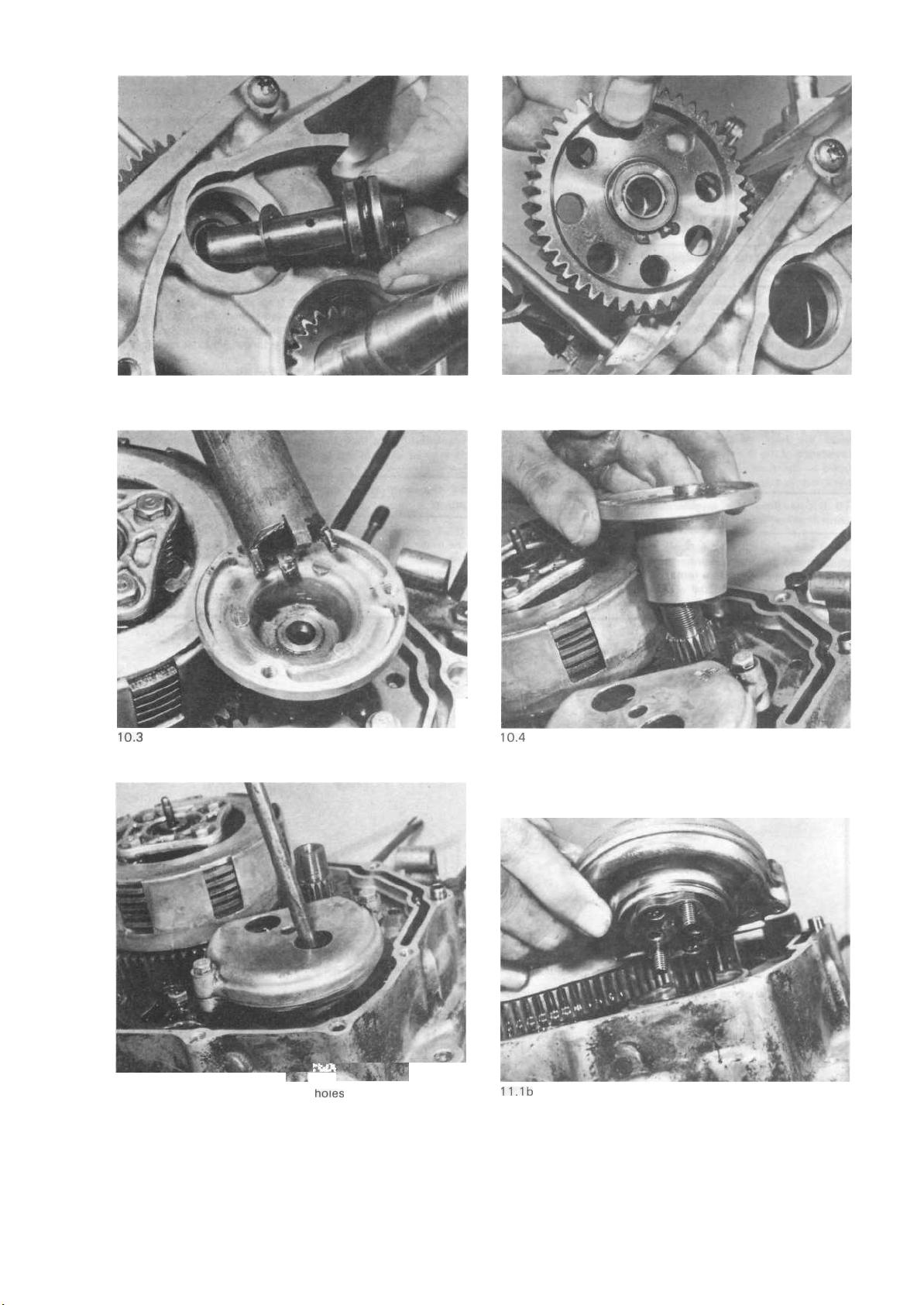

7 Dismantling the engine and gearbox unit: removing the

cylinder

head,

1 If the cylinder head is to be removed with the engine unit in

the frame, start by removing the carburettor and heat shield, the

The latter can be fabricated from a piece of

barrel and piston

07933-0010000

or a

20

Chapter 1 Engine, clutch and gearbox

spark plug lead, the exhaust pipe and the cylinder head steady

bolt, as described in Section 5 of this Chapter.

2 Slacken and remove the three rocker cover mounting bolts,

and lift the cover away, taking care not to damage the rubber

sealing

ring.

with their common support bracket. This is retained by a single

bolt at each end, and a central bolt. Lift out the pushrods and

push them through holes in a piece of card which has been

marked to denote inlet and exhaust. Although the pushrods are

identical, it is preferable to replace them in their original positions.

3 The cylinder head is retained by four large sleeve bolts, one

of which is recessed into the large diameter oil passage. An

additional special bolt passes down into the end of the cam

follower shaft, and this should also be removed. Note that the

pushrod guide bracket will be released as the two left-hand

cylinder head sleeve bolts are removed. The cylinder head can

now be lifted away and placed to one side to await further

attention. Make a note of the position and sizes of the dowels

fitted over three of the four studs. One of these is fitted with an

The rocker arms may be removed as a unit together

0 ring and acts as an oil feed passage.

4 The cylinder barrel is retained by two bolts passing through

a flange on the left-hand side. Once these have been removed,

the barrel can be slid upwards off its mounting studs. As soon

as the bottom of the barrel is clear of the crankcase mouth, the

latter should be packed with clean rag to obviate any risk of

pieces of broken piston ring or other foreign matter falling into

the crankcase. Be careful not to twist the barrel as it is removed,

or the cam follower feet may be scratched on the sharp cam

gear teeth.

5 Use a pair of pointed nose pliers or a small screwdriver to

dislodge the circlips, which should then be discarded. Note that

new circlips should always be fitted in view of the risk of a

displaced circlip causing engine damage. If the gudgeon pin

should prove to be a particularly tight fit, the piston should be

warmed first, to expand the alloy and release the grip on the

steel pin. If it is necessary to tap the gudgeon pin out of position, make sure that the connecting rod is supported to prevent

distortion. On no account use excess force.

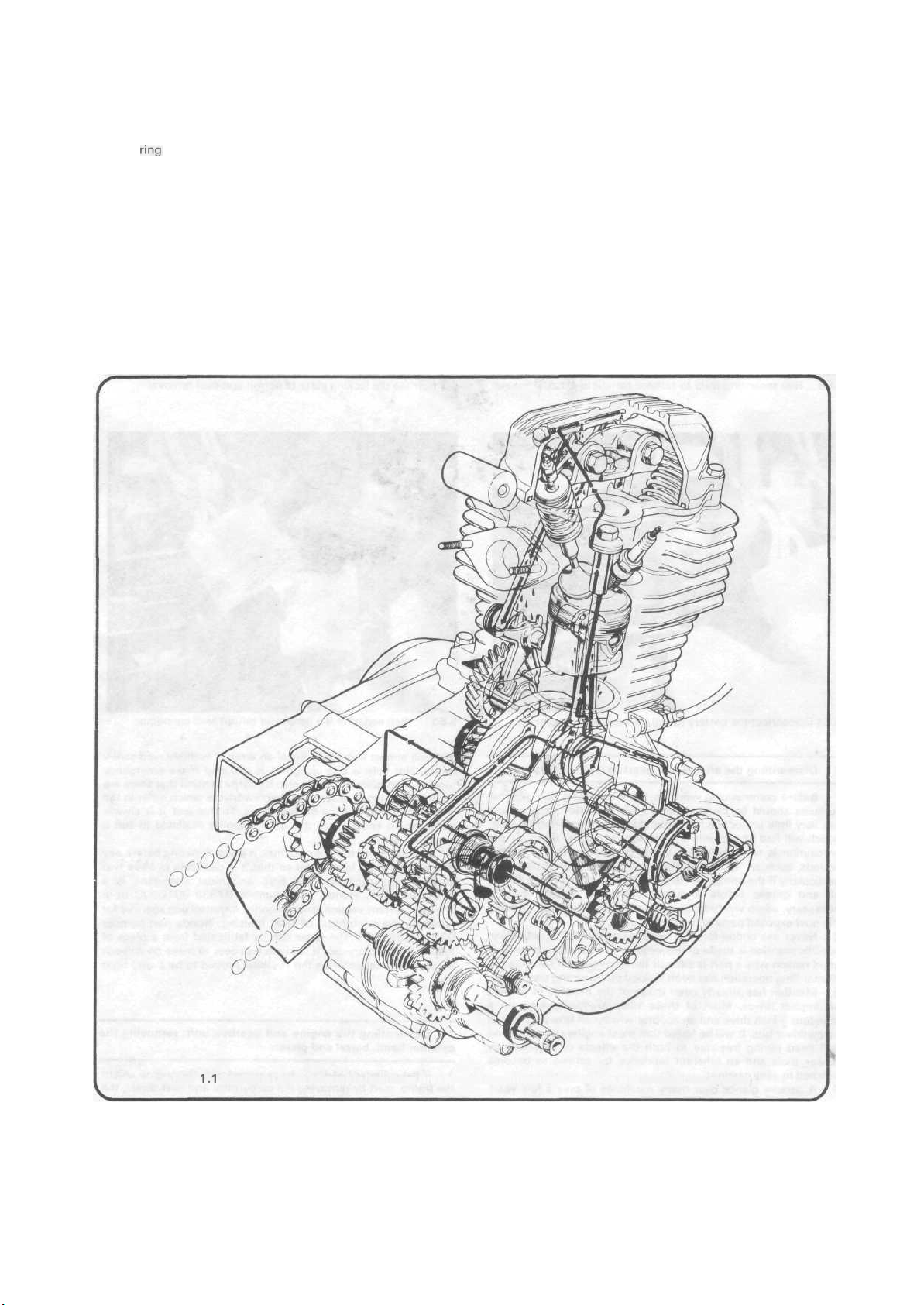

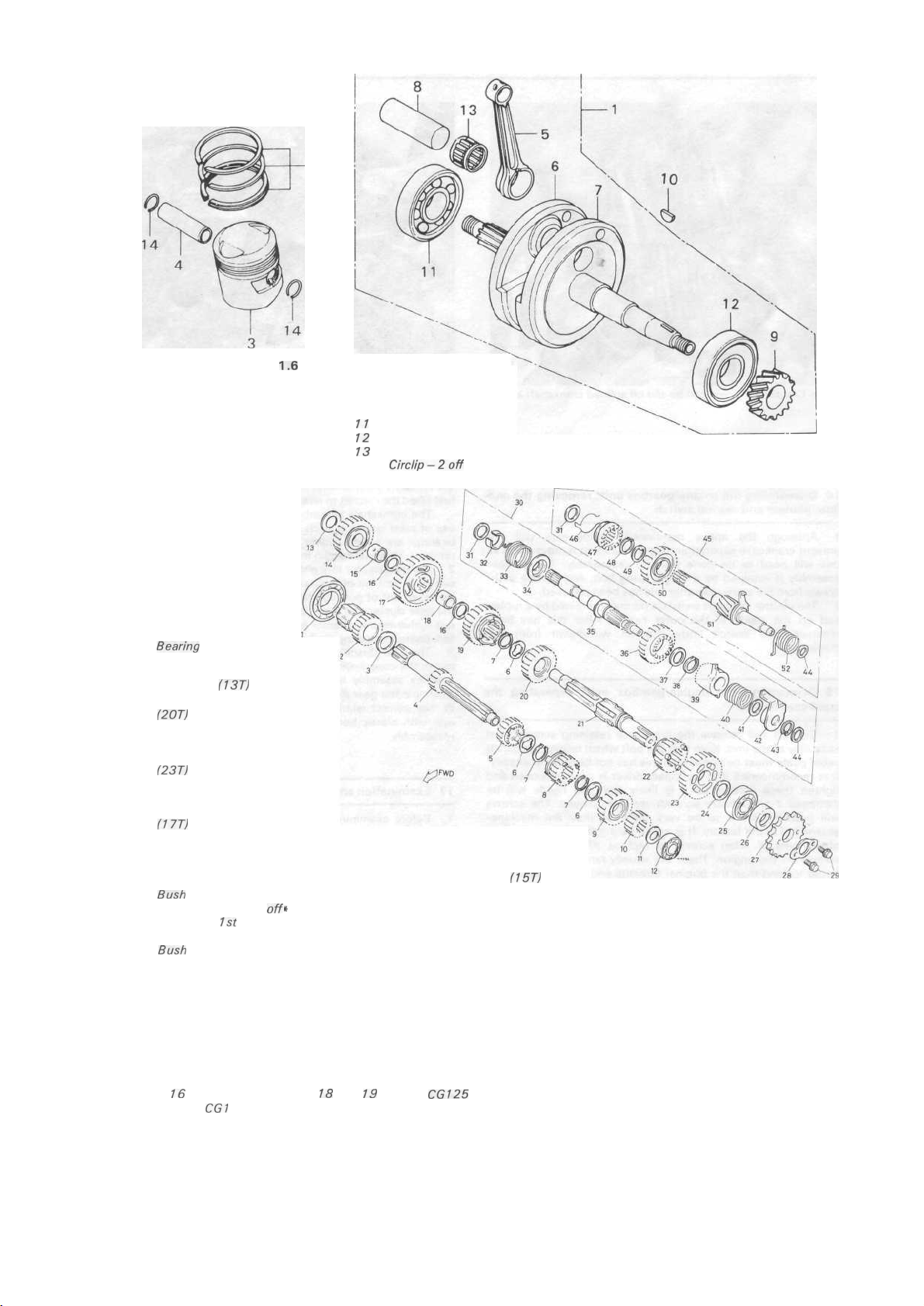

Fig.

1.1

Sectional view of engine/gearbox unit showing component location and lubrication system

24

21

/

Inlet valve guide

2

Exhaust valve guide

3

Cylinder barrel

4

Cylinder base gasket

5

Cylinder head complete

6

Cylinder head gasket

Cylinder head cover

7

8

Rubber seal

Spacer <

9

10

Heat shield <

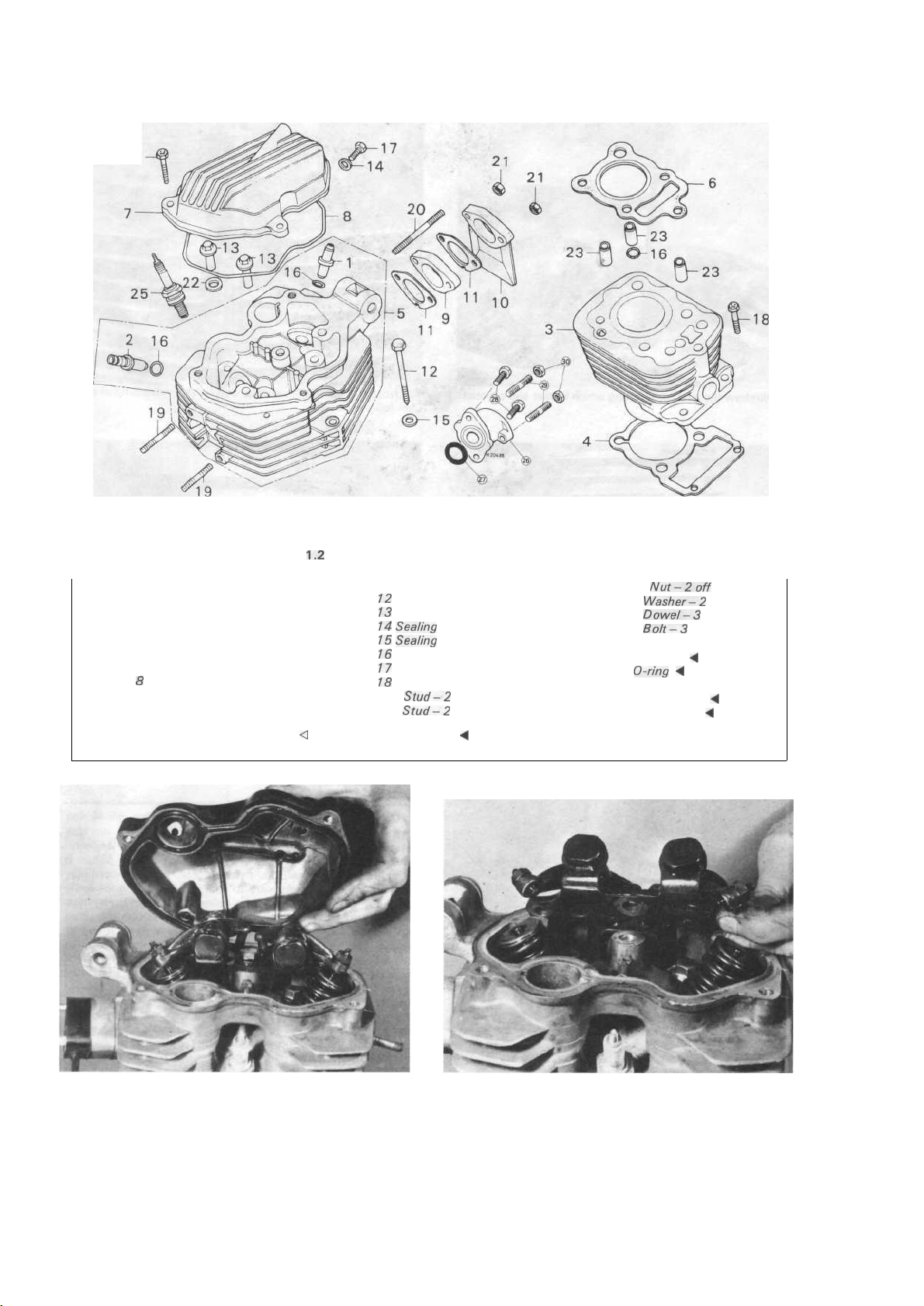

Fig.

1.2

Cylinder head and barrel - component parts

7 7 Gasket - 2 off <

12

Special bolt

13

Sleeve bolt - 4 off

<\

early models

14 Sea/ing

15 Sea/ing

16

0 ring - 3 off

17

Plug

18

Bolt -2 off

19

Stud-2

20

Stud-2

^

washer

washer

off

off

later models

21

Nut-2off

22

Washer-2

23

Dowel-3

24

Bolt-3

25 Sparking plug

26 Inlet stub

27 O-ring

28 Bolt - 2 off <

29 Stud - 2 off

30 Nut - 2 off

off

off

off

-4

<

<

<

7.2a Remove the cylinder head cover to expose the valve gear

7.2b Release the three mounting bolts, and lift rocker assembly

away as a unit

r

22

7.2c Withdraw the pushrods, noting which is inlet and exhaust

Chapter 1