Honda CB400F (1989), CB-1 (1989) Service Manual

_

:

mrn&

i

'>l|

I

I

■

*

Bll

1

r

i*

;

i

m-

m

kg

Wmm

■

mm

m

■

i1

'in

I

mm

■

■

ffl

/1

HP

r

/

I

■

lilt

3

Wm

:

1

I

*

it;

!'

_

~

-

m

_

■

i

%

S

i.

.

ifSittBm»

i»

HIM

M|im

■

t

.ill?

sjUlifli

'

Ml™

Vi

;

.

----

illUBIlIl1*

Jii

$

55$-;-:

.

1

*

18

I

£i:

£

•

'

■

-

m

■-

m

'

M

*

t

1

n

'

m

B

L

J

,i

■

J

;

1

!

j

is!!

i

III

'iiiili]

m

A

1

1

4

f

\

m

i

-

4

I

A

m

f

m

i

r

J

T«

i

I

rX

:

.

a

1

.

I1

a»

li

r

r*

-

I

I

!

;

!

u

m

.

*

Ilk.

‘‘i.

ufSLL

:

I

—

I

♦

♦

»

I

I

I

INTRODUCTION

CONTENTS

This

service

manual

describes

the

service

procedures

for

the

CB400F.

This

Model

Specific

Manual

includes

every

service

pro¬

cedure

that

is

of

a

specific

nature

to

this

particular

model.

Basic

service

procedures

that

are

common

to

other

Honda

Motorcycles/Motor

Scooters

Common

Service

Manual.

This

Model

Specific

Service

Manual

should

be

used

together

With

the

Common

Service

Manual

in

order

to

provide

complete

service

information

on

all

aspects

of

this

motorcycle

1

GENERAL

INFORMATION

I

FRAME/BODY

PANELS/EXHAUST

SYSTEM

MAINTENANCE

>

*

LUBRICATION

<

COOLING

SYSTEM

GC

Follow

the

Maintenance

Schedule

(Section

3)

recom¬

mendations

to

ensure

that

the

vehicle

is

in

peak

operat¬

ing

condition

and

the

emission

levels

are

within

the

standards

set

by

the

U.S.

Environmental

Protection

Agency

and

the

California

Air

Resources

Board.

Performing

the

first

scheduled

maintenance

is

very

im¬

portant.

It

compensates

for

the

initial

wear

that

occurs

during

the

break-in

period.

LU

FUEL

SYSTEM

>

ce

)

Q

ENGINE

REMOVAL/INSTALLATION

o

z

<

8

CYLINDER

HEAD/CYLINDER/PISTON

LU

CLUTCH/GEARSHIFT

LINKAGE

Section

1

and

3

apply

to

the

whole

motorcycle,

section

2

illustrates

procedures

for

removal/installation

of

com¬

ponents

that

may

be

required

to

perform

service

de¬

scribed

in

the

following

sections.

While

section

4

through

1

8

desetibe

parts

of

the

motor¬

cycle,

grouped

according

to

locations.

Z

LU

CRANKSHAFT/TRANSMISSION

FRONT

WHEEL/SUSPENSION/STEERING

2

C/5

C/5

REAR

WHEEL/SUSPENSION

Find

the

section

you

want

on

this

page,

then

turn

to

the

table

of

contents

on

the

first

page

of

the

section.

<

I

O

I

BRAKES

Most

sections

describe

the

service

procedure

through

a

ayatem

illustration.

Refer

to

the

next

page

for

details

on

hew

to

use

this

manual.

IF1

CHARGING

SYSTEM/ALTERNATOR

IGNITION

SYSTEM

If

you

don't

know

the

.source

of

the

trouble,

go

to

sec¬

tion

19,

TROUBLESHOOTING.

<

O

cc

ELECTRIC

STARTER/STARTER

CLUTCH

A

o

LU

ALL

INFORMATION,

ILLUSTRATIONS,

DIREC¬

TIONS

AND

SPECIFICATIONS

INCLUDED

IN

THIS

PUBLICATION

ARE

BASED

ON

THE

LATEST

PRODUCT

INFORMATION

AVAILABLE

AT

THE

TIME

OF

APPROVAL

FOR

PRINTING.

HONDA

MOTOR

CO..

LTD.

RESERVES

THE

RIGHT

TO

MAKE

CHANGES

AT

ANY

TIME

WITHOUT

NOTICE

AND

WITHOUT

INCURRING

ANY

OBLI¬

GATION

WHATEVER.

NO

PART

OF

THIS

PUBLI¬

CATION

MAY

BE

REPRODUCED

WITHOUT

WRITTEN

PERMISSION.

THIS

MANUAL

IS

WRIT¬

TEN

FOR

PERSONS

WHO

HAVE

ACQUIRED

BASIC

KNOWLEDGE

OF

MAINTENANCE

ON

HONDA

MOTORCYCLES

OR

MOTOR

SCOOT¬

ERS.

LIGHTS/METERS/SWITCHES

LU

WIRING

DIAGRAM

TROUBLESHOOTING

!

EH

INDEX

I

Date

of

Issue:

January,

1989

(51

nnMfi

A

n/inxoe

r-n

I

m

HOW

TO

USE

THIS

MANUAL

FINDING

INFORMATION

YOU

NEED

i

))

Dill

•

This

manual

is

divided

into

sections

which

cover

each

of

the

major

components

of

the

motorcycle.

To

quiGkly

find

the

section

you

are

interested

in.

the

first

page

of

each

section

is

marked

with

a

black

tab

that

lines

up

with

one

of

the

thumb

index

tabs

before

this

page.

The

first

page

of

each

section

lists

the

table

of

contents

within

the

section.

Read

the

service

information

and

troubleshooting

related

to

the

section

before

you

begin

working.

•

An

indexofthe

entire

book

is

provided

in

the

last

chapter

to

directly

locate

the

information

you

need.

I

0

JEss

vr

i

[r

-

—

1

-

1

IQ.

I

-

—

>

~

mO

I

))

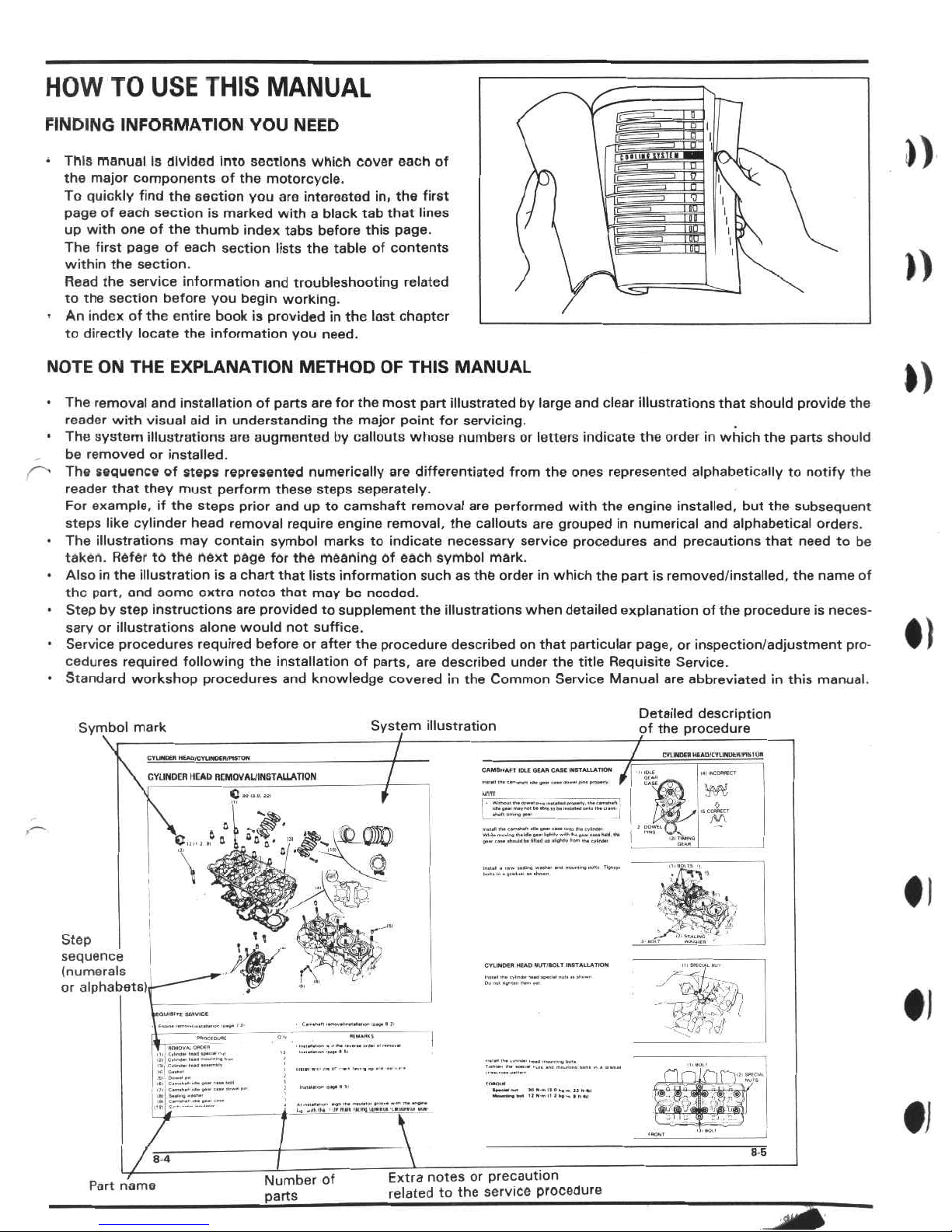

NOTE

ON

THE

EXPLANATION

METHOD

OF

THIS

MANUAL

The

removal

and

installation

of

parts

are

for

the

most

part

illustrated

by

large

and

clear

illustrations

that

should

provide

the

reader

with

visual

aid

in

understanding

the

major

point

for

servicing.

The

system

illustrations

are

augmented

by

callouts

whose

numbersorletters

indicate

the

order

in

which

the

parts

should

be

removed

or

installed.

The

sequence

of

steps

represented

numerically

are

differentiated

from

the

ones

represented

alphabetically

to

notify

the

reader

that

they

must

perform

these

steps

seperately.

For

example,

if

the

steps

prior

and

up

to

camshaft

removal

are

performed

with

the

engine

installed,

but

the

subsequent

steps

like

cylinder

head

removal

require

engine

removal,

the

callouts

are

grouped

in

numerical

and

alphabetical

orders.

The

illustrations

may

contain

symbol

markstoindicate

necessary

service

procedures

and

precautions

that

needtobe

taken.

Refer

to

the

next

page

for

the

meaning

of

each

symbol

mark.

Alsointhe

illustration

is

a

chart

that

lists

information

such

as

the

orderinwhich

the

part

is

removed/installed,

the

name

of

the

part,

and

oomo

oxtra

notes

that

may

be

needed.

Step

by

step

instructions

are

providedtosupplement

the

illustrations

when

detailed

explanation

of

the

procedure

is

neces¬

sary

or

illustrations

alone

would

not

suffice.

Service

procedures

required

before

or

after

the

procedure

describedonthat

particular

page,

or

inspection/adjustment

pro¬

cedures

required

following

the

installation

of

parts,

are

described

under

the

title

Requisite

Service.

Standard

workshop

procedures

and

knowledge

covered

in

the

Common

Service

Manual

are

abbreviated

in

this

manual.

•)

Detailed

description

of

the

procedure

—

CAMSHAF

T

IDLE

GIAN

CASE

INSTALLATION

/

.

,

,

l0l£

W

0t<kn

-M-,

System

illustration

Symbol

mark

CTUNDEH

HEAPlCYCINPCHiPtSTOW

CYLINDER

MEAD

RCMOVAUINGTALLATION

m

■a

•

gau

m«Y

'ÿol

b*

obit

10

«•

innatad

cole

i

""ÿ"“I

N.,

jW

b

.....

.».*t

kirn*

iho

camofidiT

«iu

gnu

CBM

unio

tKo

cvlnoo1

*1.1.

mw.lr*

lb.

iA.

gw

UfMv

~*K

IK.

B*.

fllB

KoM

1M

9.0

rju

diiKidboHllod

u»

0»tF»V

from

iKo

eytAdM

!

\l

.

J

TIVI

#1

V

i

■

str

Step

sequence

(numerals

or

alphabets).

*-M£T

t

5

|

-

CVUNOM

MEAD

NUT'SOIT

INSTALLATION

-ÿmu

nxrrr

—

•I

MtnrtDi.Al

111!

C.loyrtr

twofl

Iptooi

nul

(Zl

C»i«i»

b*od

<•*'

On

XTr-“

:

<||

Sodo-J

1.MTBI

*

At

.AtloNOI-v.

MgK

IKO

..lAol.M

0..W..O

»«0>

IKo

on«no

I

U

■UI’IMW

'IUWIWNW

1WIW

MJf

>1—

xm.noif.

1)1101

MM»|WI

1

1

NIKIIi

Kf

-*

ln«l

•1

8

5

8

4

Extra

notes

or

precaution

related

to

the

service

procedure

Number

of

parts

_

Part

name

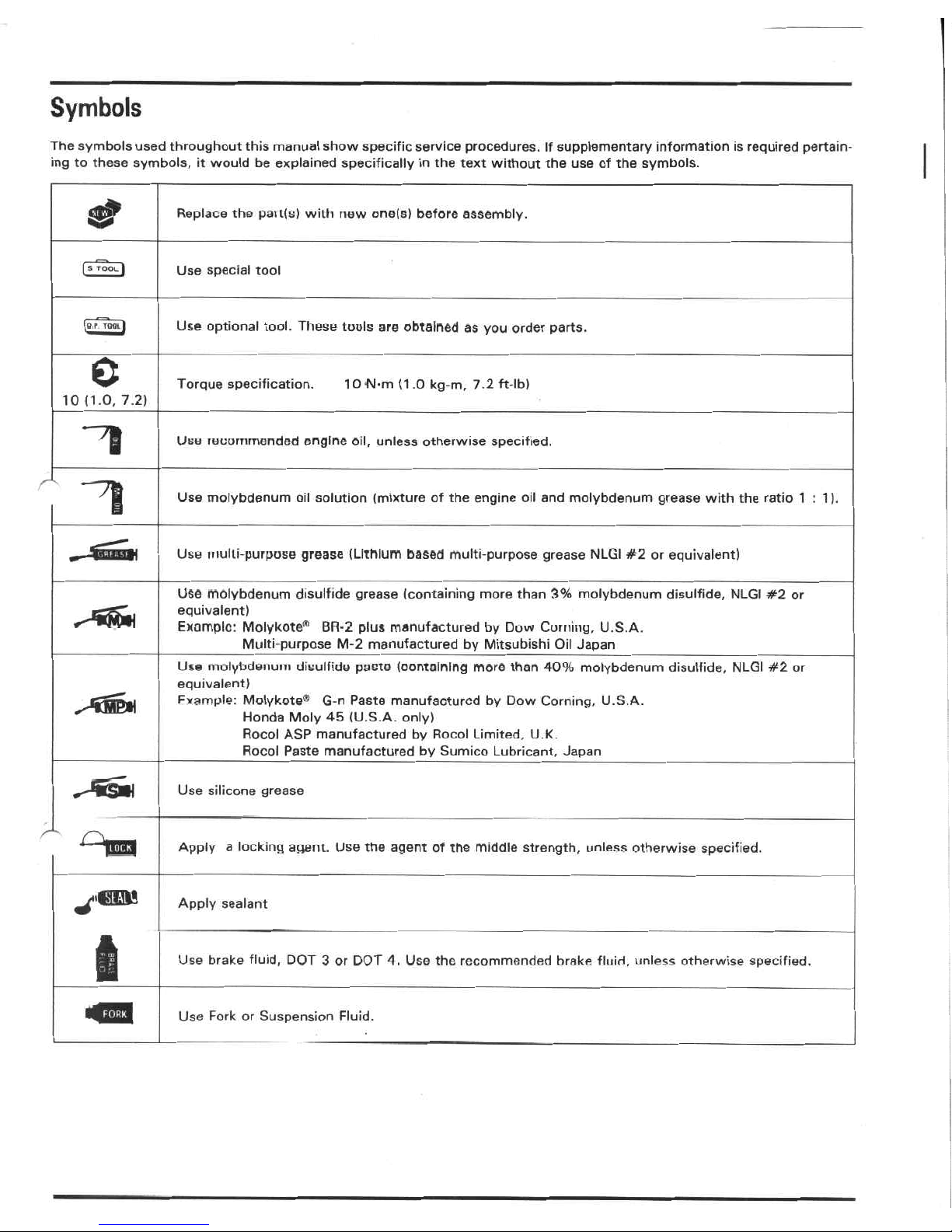

Symbols

The

symbols

used

throughout

this

manual

show

specific

service

procedures.

If

supplementary

information

is

required

pertain¬

ing

to

these

symbols,

it

would

be

explained

specifically

in

the

text

without

the

use

of

the

symbols.

Replace

the

pait(s)

with

new

one(s)

before

assembly.

[s

TOOL

I

Use

special

tool

Use

optional

tool.

These

tools

are

obtained

as

you

order

parts.

0

Torque

specification.

1

0

M-m

(1.0

kg-m,

7.2

ft-lb)

10

(1.0,

7.2)

"1

Use

recommended

engine

oil,

unless

otherwise

specified.

‘1

Use

molybdenum

oil

solution

(mixture

of

the

engine

oil

and

molybdenum

grease

with

the

ratio

1:1).

Use

multi-purpose

grease

(Lithium

based

multi-purpose

grease

NLGI

#2

or

equivalent)

Use

molybdenum

disulfide

grease

(containing

more

than

3%

molybdenum

disulfide,

NLGI

#2

or

equivalent)

Example:

Molykote®1

BR-2

plus

manufactured

by

Duw

Corning,

U.S.A.

Multi-purpose

M-2

manufactured

by

Mitsubishi

Oil

Japan

Use

molybdenum

disulfide

paste

(containing

more

than

40%

molybdenum

disulfide,

NLGI

#2

or

equivalent)

Fvample:

Molykote®

G-n

Paste

manufactured

by

Dow

Corning,

U.S.A.

Honda

Moly

45

(U.S.A.

only)

Rocol

ASP

manufactured

by

Rocol

Limited,

U.K.

Rocol

Paste

manufactured

by

Sumico

Lubricant,

Japan

Use

silicone

grease

Apply

a

locking

agent.

Use

the

agent

of

the

middle

strength,

unless

otherwise

specified.

Apply

sealant

Use

brake

fluid,

DOT

3

or

DOT

4.

Use

the

recommended

brake

fluid,

unless

otherwise

specified.

*42

Use

Fork

or

Suspension

Fluid.

1

.

GENERAL

INFORMATION

»

1

GENERAL

SAFETY

MODEL

IDENTIFICATION

SPECIFICATIONS

TORQUE

VALUES

TOOLS

1-1

LUBRICATION

AND

SEAL

POINTS

1

-3

CABLE

AND

HARNESS

ROUTING

1

-4

EMISSION

CONTROL

SYSTEMS

1-18

1-19

1

25

1-14

EMISSION

CONTROL

INFORMATION

LABELS

(U.S.A.

Only)

»

1-28

1-16

GENERAL

SAFETY

»

Carbon

Monoxide

If

the

engine

must

be

running

to

do

some

work,

make

sure

the

area

is

well

ventilated.

Never

run

the

engine

in

an

en¬

closed

area.

Used

Engine/Transmission

Oil

AWARNING

•

Used

engine

oil

(or

transmission

oil

in

two-strokes)

may

cause

skin

cancer

if

repeatedly

left

in

contact

with

the

skin

for

prolonged

periods.

Although

this

is

unlikely

unless

you

handle

used

oil

on

a

daily

basis,

it

is

still

advisable

to

thoroughly

wash

your

hands

with

soap

and

water

as

soon

as

possible

after

handling

used

oil.

KEEP

OUT

OF

REACHOFCHILDREN.

AWARNING

*

The

exhaust

contains

poisonous

carbon

monoxide

gaa

that

can

cause

loss

of

cunsciuusness

and

may

leadtodeath.

Run

the

engine

in

an

open

area

or

with

an

exhaust

evacua¬

tion

system

in

an

enclosed

area.

Brake

Dust

Never

use

an

air

hose

or

dry

brush

to

clean

brake

assemb¬

lies.

Use

an

OSHA-approved

vacuum

cleaner

or

alternate

method

approved

by

OSHA,

designed

to

minimize

the

hazard

caused

by

airborne

asbestos

fibers.

Gasoline

Work

in

a

well

ventilated

area.

Keep

cigarettes,

flames

or

sparks

away

from

the

work

area

or

where

gasoline

is

stored.

>

AWARNING

AWARNING

*

Inhaled

asbestos

fibers

have

been

found

to

cause

respiratory

disease

and

cancer.

•

Gasoline

is

extremely

flammable

and

is

explosive

under

certain

conditions.

KEEP

OUT

OF

REACH

OF

CHILDREN.

Brake

Fluid

CAUTION

Hot

Components

•

Spilling

fluid

on

painted,

plastic

or

rubber

parts

will

damage

them.

Placeaclean

shop

towel

over

these

parts

whenever

the

system

is

serviced.

KEEP

OUT

OF

REACH

OF

CHILDREN.

AWARNING

•

Engine

and

exhaust

system

parts

become

very

hot

and

remain

hot

for

some

time

after

the

engine

is

run.

Wear

Insulated

gloves

or

wait

until

the

engine

and

exhaust

system

have

cooled

before

handling

these

parts.

I

I

>

GENERAL

INFORMATION

Coolant

Under

some

conditions,

the

ethylene

glycolinengine

cool¬

ant

is

combustible

and

Its

flame

is

not

visible.

If

the

ethyl¬

ene

glycol

does

ignite,

you

will

not

see

any

flame,

but

you

can

be

burned.

Nitrogen

Pressure

For

shock

absorbers

with

a

gas-filled

reservoir:

4

A

WARNING

I

*

Use

only

nitrogen

to

pressurize

the

shock

absorber.

The

use

of

an

unstable

gas

can

cause

a

fire

or

explo¬

sion

resulting

in

serious

injury.

•

The

shock

absorber

contains

nitrogen

under

high

pressure.

Allowing

fire

or

heat

near

the

shock

ab¬

sorber

could

lead

to

an

explosion

that

could

result

in

serious

injury.

•

Failuretorelease

the

pressure

from

a

shock

absorber

before

disposing

of

it

may

lead

to

a

possible

explo¬

sion

and

serious

injury

if

it

is

heated

or

pierced.

AWARNING

*

Avoid

spilling

engine

coolantonthe

exhaust

system

or

engine

parts

They

may

be

hot

enough

to

cause

the

coolant

to

ignite

and

burn

without

a

visible

flame.

•

Coolant

(ethylene

glycol)

can

cause

some

skin

irrita¬

tion

and

is

poisonous

if

swallowed.

KEEP

OUT

OF

REACH

OF

CHILDREN.

•

Do

not

remove

the

radiator

cap

when

the

engine

is

hot.

The

coolant

is

undei

pressure

and

could

scald

you.

.

•

Keep

hands

and

clothing

away

from

the

cooling

fan,

as

it

starts

automatically.

(

To

prevent

the

possibility

of

an

explosion,

release

the

ni¬

trogen

by

pressing

the

valve

core.

Then

remove

the

valve

stem

from

the

shock

absorber

reservoir.

Dispose

of

the

oil

in

a

manner

acceptable

to

the

Environmental

Protection

Agency

(fcPA).

I

If

it

contacts

your

skin,

wash

the

affected

areas

immedi¬

ately

with

soap

and

water.

If

it

contacts

your

eye6,

flush

them

thoroughly

with

fresh

water

and

get

immediate

medi¬

cal

attention.

If

it

is

swallowed,

the

victim

must

be

forced

to

vomit

then

rinse

mouth

and

throat

with

fresh

water

before

obtaining

medical

attention.

Becauseofthese

dan¬

gers,

always

Store

coolant

in

a

safe

place,

away

from

the

reach

of

children.

Before

disposal

of

the

shock

absorber,

release

the

nitrogen

by

pressing

the

valve

core.

Then

remove

the

valve

stem

from

the

shock

absorber.

Battery

Hydrogen

Gas

&

Electrolyte

AWARNING

•

The

battery

gives

off

explosive

gases;

keep

sparks,

flames

and

cigarettes

away.

Provide

adequate

venti¬

lation

when

charging.

•

The

battery

contains

sulfuric

acid

(electrolyte).

Con¬

tact

with

skin

or

eyes

may

cause

severe

bums.

Wear

protective

clothing

and

a

face

shield.

If

electrolyte

gets

on

your

skin,

flush

with

water.

—

If

electrolyte

gets

in

your

eyes,

flush

with

water

for

at

least

15

minutes

and

call

a

physician.

•

Electrolyte

is

poisonous.

—

If

swallowed,

drink

large

quantities

of

water

or

milk

and

follow

with

milk

of

magnesia

or

vegeta¬

ble

oil

and

call

a

physician.

KEEP

OUTOFREACH

OF

CHILDREN.

♦

I

♦

i

♦i

1-2

GENERAL

INFORMATION

MODEL

IDENTIFICATION

I

O

0

D

0,

c

o.

'CbJ

f0

Vÿ\

(1)

FRAME

SERIAL

NUMBER

\

0

L

I

The

frame

serial

number

is

stamped

on

the

right

side

of

the

steering

head.

(2)

ENGINE'SERIAL

NUMBER

c

V

m

\

\

o

V/

4$

I

ft

s.

\r\

(3)

VEHICLE

IDENTIFICATION

NUMBER

'

rs,

o.

The

engine

serial

number

is

stamped

on

the

right

side

of

the

crankcase.

The

Vehicle

Identification

Number

(VIN)

is

located

on

the

safety

certification

label

on

the

right

side

of

the

frame

tube.

I

(4)

CARBURETOR

IDENTIFICATION

NUMBER

V

l\

y

(CM

4L

>

\

&

37

N

Sm

__

_

(5)

COLOR

CODE

LABEL

>

The

carburetor

identification

number

is

on

the

rear

side

of

oach

carburetor.

The

color

code

label

is

attached

on

the

left

frame

tube

under

the

seat.

When

ordering

a

color

coded

part,

always

specify

its

designated

color

code.

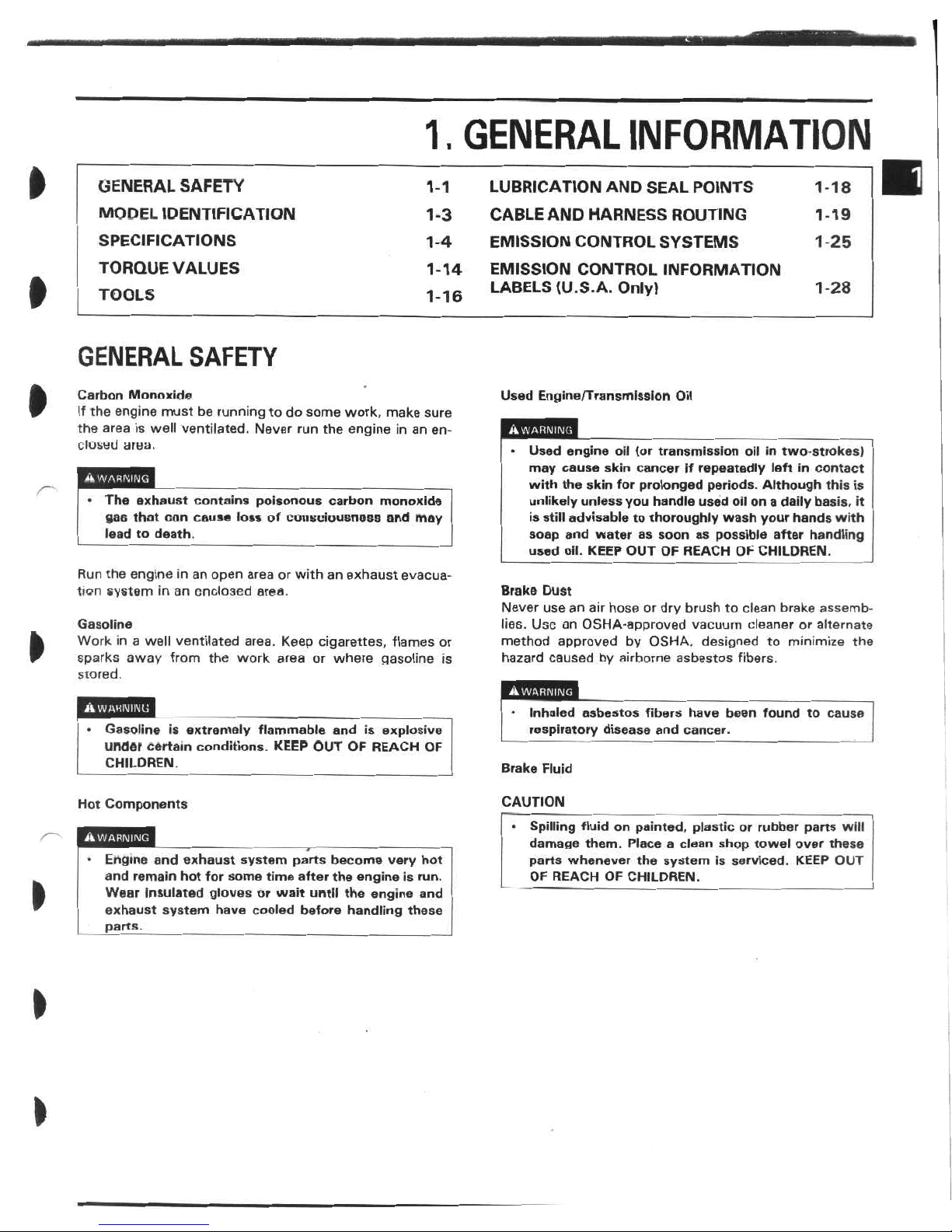

GENERAL

INFORMATION

SPECIFICATIONS

Gi

4

ITEM

SPECIFICATIONS

2,035

mm

(80.

1

in)

705

mm

(27.8

in)

1,025

mm

(40.4

in)

1

,370

mm

(53.9

in)

775

mm

(30.5

in)

335

mm

(13.2

in)

130

mm

(5.1

in)

170

kg

(375

lbs)

183

kg

(403

lbs)

1

57

kg

(347

lbs)

Overall

length

Overall

width

Overall

height

Wheel

base

Seat

height

Foot

peg

height

Ground

clearance

Dry

weight

Curb

weight

Maximum

weight

capacity

DIMENTIONS

4

FRAME

Diamond

Telescopic

fork

1

30

mm

(5.1

in)

Swingarm

110

mm

(4.3

in)

Gas-filled

damper

1

10/70-17

54H

140/70-17

66H

G547/G548

K505F/K505

Frame

type

Front

suspension

Front

wheel

travel

Rear

suspension

Rear

wheel

travel

Rear

damper

Front

tire

size

Rear

tire

size

Tire

brand

(Bridgestone)

Front/Rear

Tire

brand

(Dunlop)

Front/Rear

Tire

brand

(Yokohama)

Front/Rear

Tire

brand

(IRC)

Front/Rear

Front

brake

Rear

brake

Caster

angle

Trail

length

Fuel

tank

capacity

Fuel

tank

reserve

capacity

«

Hydraulic

disc

brake

Hydraulic

disc

brake

25u30’

99

mm

(3.9

in)

11

.5

lit

(3.04

US

yal,

2.53

Imp

gal)

3.5

lit

(0.92

US

gal,

0.77

Imp

gal)

(

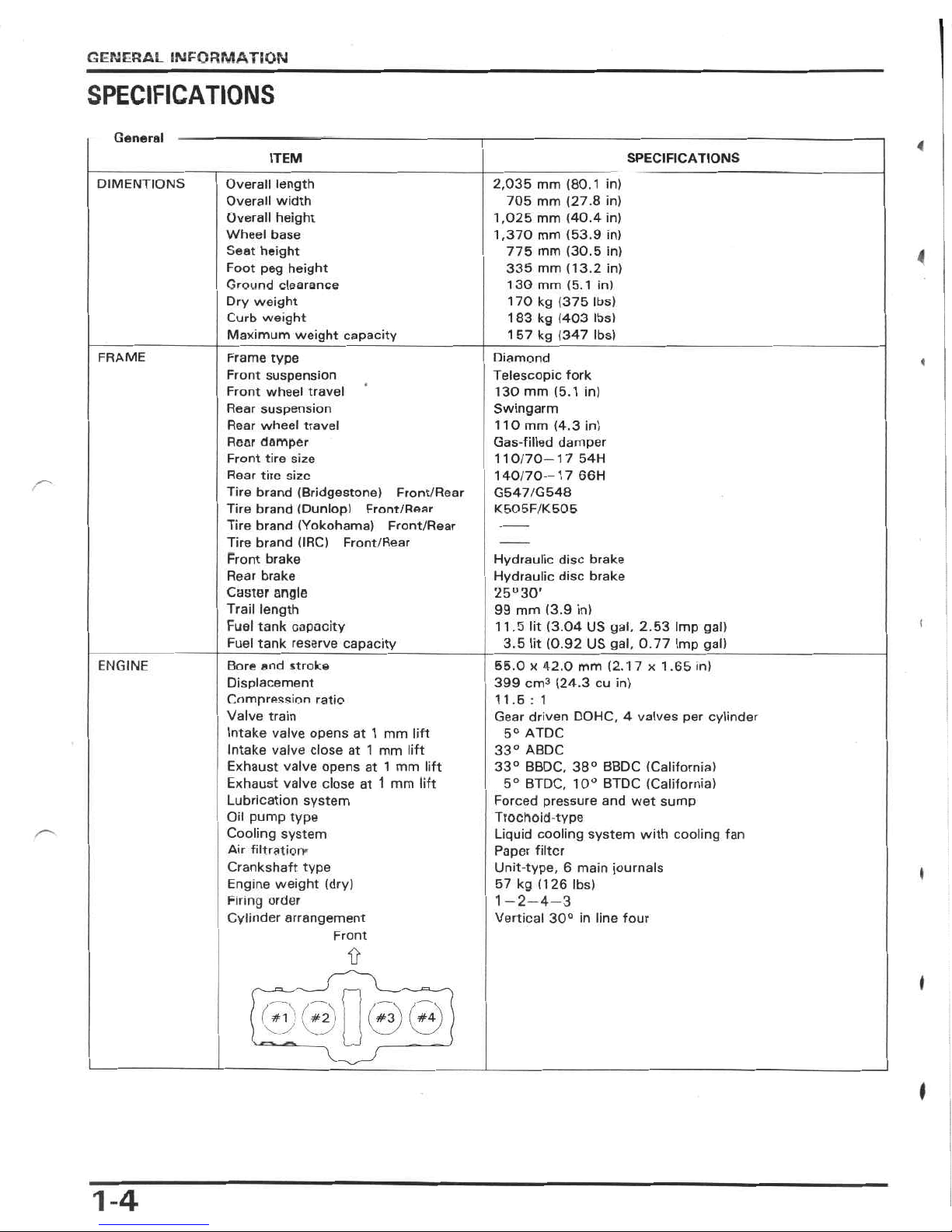

ENGINE

Bore

and

stroke

Displacement

Compression

ratio

Valve

train

Intake

valve

opens

at

1

mm

lift

Intake

valve

close

at

1

mm

lift

Exhaust

valve

opens

at

1

mm

lift

Exhaust

valve

close

at

1

mm

lift

Lubrication

system

Oil

pump

type

Cooling

system

Air

filtration*

Crankshaft

type

Engine

weight

(dry)

Firing

order

Cylinder

arrangement

Front

55.0

x

42.0

mm

(2.17

x

1.65

in)

399

cm3

(24.3

cu

in)

11.6

:

1

Gear

driven

DOHC,

4

valves

per

cylinder

5°

ATDC

33°

ABDC

33°

BBDC,

38°

BBDC

(California)

5°

BTDC,

10°

BTDC

(California)

Forced

pressure

and

wet

sump

Trochoid

type

Liquid

cooling

system

with

cooling

fan

Paper

filter

Unit-type,

6

main

journals

57

kg

(126

lbs)

1

—2—4—3

Vertical

30°

in

line

four

»

I

I

1-4

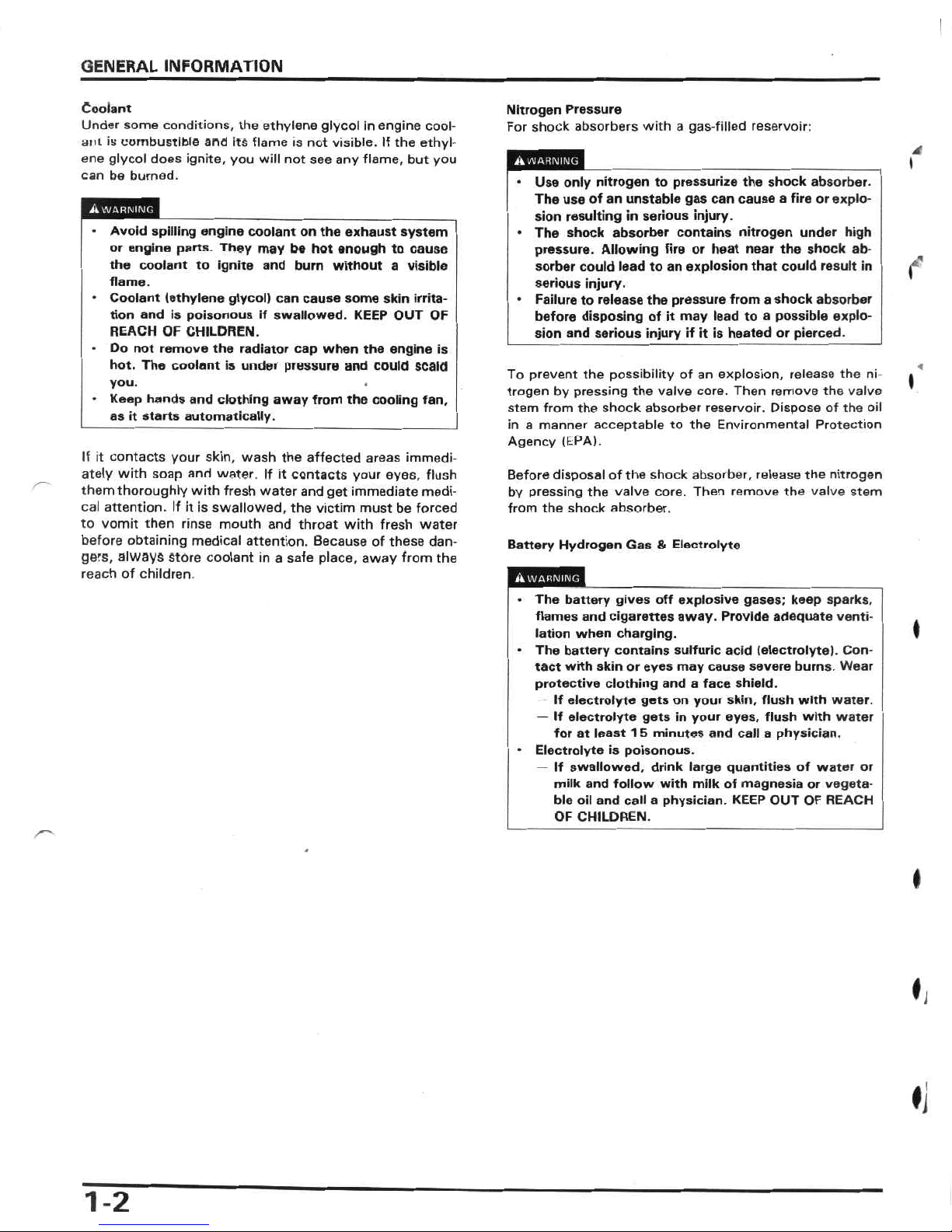

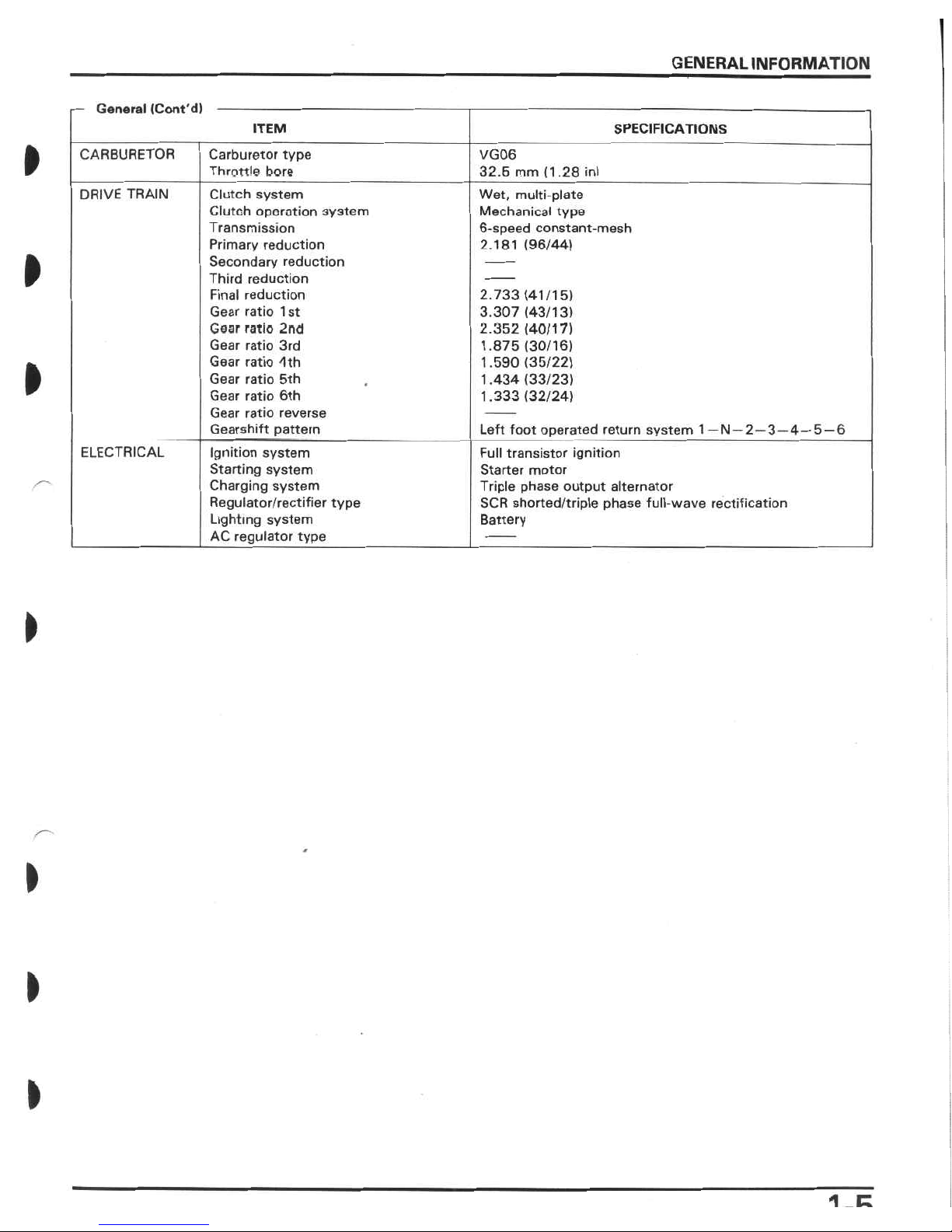

GENERAL

INFORMATION

General

(Cont'd)

ITEM

SPECIFICATIONS

I

CARBURETOR

Carburetor

type

Throttle

bore

VG06

32.

6

mm

(1

.28

in)

DRIVE

TRAIN

Clutch

system

Clutch

oporation

3y3tem

Transmission

Primary

reduction

Secondary

reduction

Third

reduction

Final

reduction

Gear

ratio

1st

Gear

ratio

2nd

Gear

ratio

3rd

Gear

ratio

4th

Gear

ratio

5th

Gear

ratio

6th

Gear

ratio

reverse

Gearshift

pattern

Wet,

multi-plate

Mechanical

type

6-speed

constant-mesh

2.181

(96/44)

»

2.733

(41/15)

3.307

(43/13)

2.352

(40/17)

1.875

(30/16)

1.590

(35/22)

1.434

(33/23)

1.333

(32/24)

»

Left

foot

operated

return

system

1—

N

—

2

—

3—

4—

5

—

6

Full

transistor

ignition

Starter

motor

Triple

phase

output

alternator

SCR

shorted/triple

phase

full-wave

rectification

Battery

ELECTRICAL

Ignition

system

Starting

system

Charging

system

Regulator/rectifier

type

Lighting

system

AC

regulator

type

*

>

)

>

1

E

GENERAL

INFORMATION

Unit:

mm

(in)

Lubrication

Standard

Service

limit

Item

I

2.9

e

(3.06

US

qt,

2.55

Imp

qt)

3.5

t

(3.70

US

qt,

3.08

Imp

qt)

3.1

t

(3.28

US

qt,

2.73

Imp

qt)

HONDA

4-stroke

oil

or

equivalent.

API

service

classification

SEorSF.

Engine

oil

capacity

at

draining

at

disassembly

at

oil

filter

change

Recommended

engine

oil

Q||_

VISCOSITIES

I

The

viscosities

shown

in

the

chart

may

be

used

when

the

average

temperature

in

your

riding

area

is

within

the

indicated

range.

»

»

o

20

40

60

80

IOO

*F

I

-20

-10

Oil

pressure

at

oil

pressure

switch

Oil

pump

roter

tip

clearance

©

body

clearance

@

end

clearance

(3)

m

fO

50

10

*C

O

490

kPa

(5

kg/cm2,71psi)

0.10

(0.004)

0.15-0.22

(0.006-0.009)

0.02-0.07

(0.001-0.003)

0.15

(0.006)

0.35

(0.014)

0.10

(0.004)

<3>

©y

®

/

-

Fuel

system

-

Carburetor

identification

number

VG06B

VG06C

#105

I

(California)

Main

jet

(High

altitude)

(2,

3)

(1,

4)

(Front)

(Rear)

Slow

jet

Jet

needle

crip

position

rilot

screw

initial

opening

#35

2-1/4

turns

out

2-1/2

turns

out

1

turn

out

1/2

turn

in

from

initial

opening

(California)

Pilnt

screw

adjustment

final

opening

Pilot

screw

high

altitude

adjustment

Air

screw

initial

opening

I

(California)

Air

screw

high

altitude

adjustment

Float

level

Carburetor

vacuum

difference

Base

caibureior

(For

carburetor

synchronization)

Idle

speed

8.0

(0.31)

Within

30

mmHg

(1.2

inHg)

No.2carburetor

1

,300

±100

rpm

1

,400

±100

rpm

2-6

(0.08-0.24)

(California)

1

Throttle

grip

free

play

Accelerator

pump

clearance

Secondary

air

supply

system

Air

injection

control

valve

vacuum

pressure

Reed

valves

are

built

into

the

ASV

360

mmHg

(14.2

inHg)

1-6

GENERAL

INFORMATION

Unit:

mm

(in)

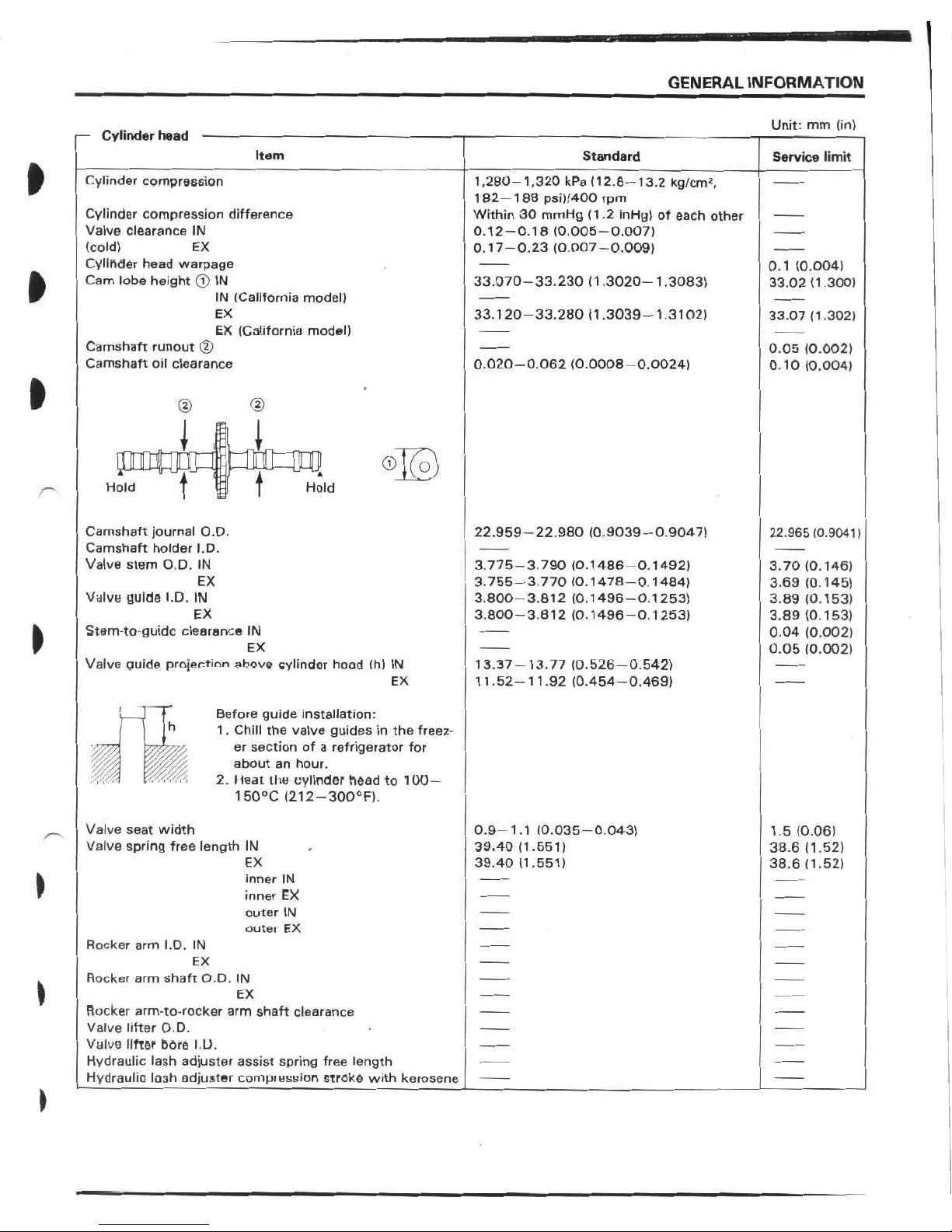

Cylinder

head

Item

Standard

Service

limit

ft

Cylinder

compression

1,280-1,320

kPa

(12.8-13.2

kg/cm2,

182-188

psi)/400

rpm

Within

30

mmHg

(1.2

inHg)

of

each

other

0.12-0.18

(0.005-0.007)

0.17-0.23

(0.007-0.009)

Cylinder

compression

difference

Valve

clearance

IN

(cold)

Cylinder

head

warpage

Cam

lobe

height

©

IN

EX

0.1

(0.004)

33.02

(1.300)

ft

33.070-33.230

(1.3020-1.3083)

IN

(California

model)

EX

33.120-33.280

<

1

.3039—

1

.3102)

33.07

(1.302)

EX

(California

model)

Camshaft

runout

©

Camshaft

oil

clearance

0.05

(0.002)

0.10

(0.004)

0.020-0.062

(0.0008-0.0024)

ft

©

J

i

JBCBHP

®E°)

t

t

Hold

Hold

Camshaft

journal

O.D.

Camshaft

holder

I.D.

Valve

stem

O.D.

IN

22.959-22.980

(0.9039-0.9047)

22.965

(0.9041)

3.775-3.790

(0.1486-0.1492)

3.755-3.770

(0.1478-0.1484)

3.800-3.812

(0.1496-0.1253)

3.800-3.812

(0.1496-0.1253)

3.70

(0.146)

3.69

(0.145)

3.89

(0.153)

3.89

(0.153)

0.04

(0.002)

0.05

(0.002)

EX

Valve

guide

I.D.

IN

EX

>

Stem-to-guidc

clearance

IN

EX

Valve

guide

projection

above

cylinder

head

(h)

IN

13.37-13.77

(0.526-0.542)

1

1.52-

1

1

.92

(0.454-0.469)

EX

Before

guide

installation:

1

.

Chill

the

valve

guides

in

the

freez¬

er

section

of

a

refrigerator

for

about

an

hour.

2.

Heat

the

cylinder

head

to

100—

1

50°C

(21

2

—

300°F).

h

i

Valve

seat

width

Valve

spring

free

length

IN

0.9-1.

1

(0.035-0.043)

39.40

(1.551)

39.40

(1.551)

1.5

(0.06)

38.6

(1.52)

38.6

(1.52)

EX

)

inner

IN

inner

EX

outer

IN

outei

EX

Rocker

arm

I.D.

IN

EX

Rocker

arm

shaft

O.D.

IN

EX

Rocker

arm-to-rocker

arm

shaft

clearance

Valve

lifter

O.D.

Valve

lifter

bcre

I.D.

Hydraulic

lash

adjuster

assist

spring

free

length

Hydraulic

lash

adjuster

compiession

stroke

with

kerosene

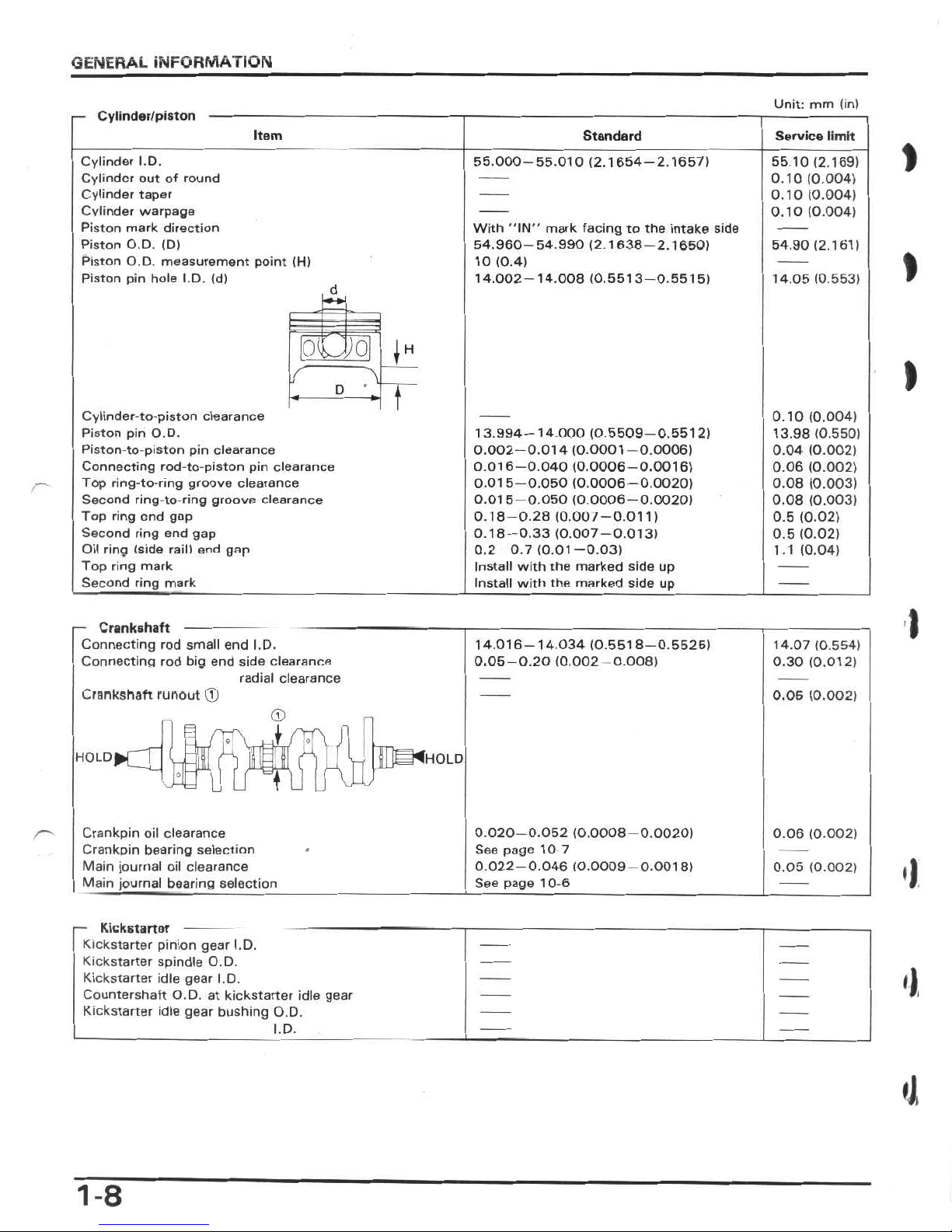

GENERAL

INFORMATION

Unit:

mm

(in)

Cylinder/piston

Item

Standard

Service

limit

Cylinder

I.D.

Cylinder

out

of

round

Cylinder

taper

Cylinder

warpage

Piston

mark

direction

Piston

O.D.

(D)

Piston

O.D.

measurement

point

(H)

Piston

pin

hole

I.D.

(d)

55.000-55.010

(2.1654-2.1657)

55.10

(2.169)

0.10

(0.004)

0.10

(0.004)

0.10

(0.004)

With

"IN"

mark

facing

to

the

intake

side

54.960-54.990

(2.1638-2.1650)

10

(0.4)

14.002-14.008

(0.5513-0.5515)

54.90

(2.161)

I

14.05

(0.553)

d

0O5II

I

D

Cylinder-to-piston

clearance

Piston

pin

O.D.

Piston-to-piston

pin

clearance

Connecting

rod-to-piston

pin

clearance

Top

ring-to-ring

groove

clearance

Second

ring-to-ring

groove

clearance

Top

ring

end

gap

Second

ring

end

gap

Oil

ring

(side

rail)

end

gap

Top

ring

mark

Second

ring

mark

0.10

(0.004)

13.98

(0.550)

0.04

(0.002)

0.06

(0.002)

0.08

(0.003)

0.08

(0.003)

0.5

(0.02)

0.5

(0.02)

1.1

(0.04)

13.994-14

000

(0.5509-0.5512)

0.002-0.014

(0.0001-0.0006)

0.016-0.040

(0.0006-0.0016)

0.015-0.050

(0.0006-0.0020)

0.015

0.050

(0.0006-0.0020)

0.18-0.28

(0.00/-0.011)

0.18-0.33

(0.007-0.013)

0.2

0.7(0.01-0.03)

Install

with

the

marked

side

up

Install

with

the

marked

side

up

I

i

-

Crankshaft

-

-

Connecting

rod

small

end

I.D.

Connecting

rod

big

end

side

clearance

radial

clearance

14.016-14.034

(0.5518-0.5525)

0.05-0.20(0.002

0.008)

14.07

(0.554)

0.30

(0.012)

Crankshaft

runout

(jj

0.05

(0.002)

©

I

/1

O

H0LDÿ[_

UNHOLD

t

Crankpin

oil

clearance

Crankpin

bearing

selection

Main

journal

oil

clearance

Main

journal

bearing

selection

0.020-0.052

(0.0008-0.0020)

See

page

10

7

0.022-0.046

(0.0009-0.0018)

See

page

10-6

0.06

(0.002)

')

0.05

(0.002)

-

Kickstartor

--

--

Kickstarter

pinion

gear

I.D.

Kickstarter

spindle

O.D.

Kickstarter

idle

gear

I.D.

Countershaft

O.D.

at

kickstarter

idle

gear

Kickstarter

idle

gear

bushing

O.D.

'1

I.D.

4

1-8

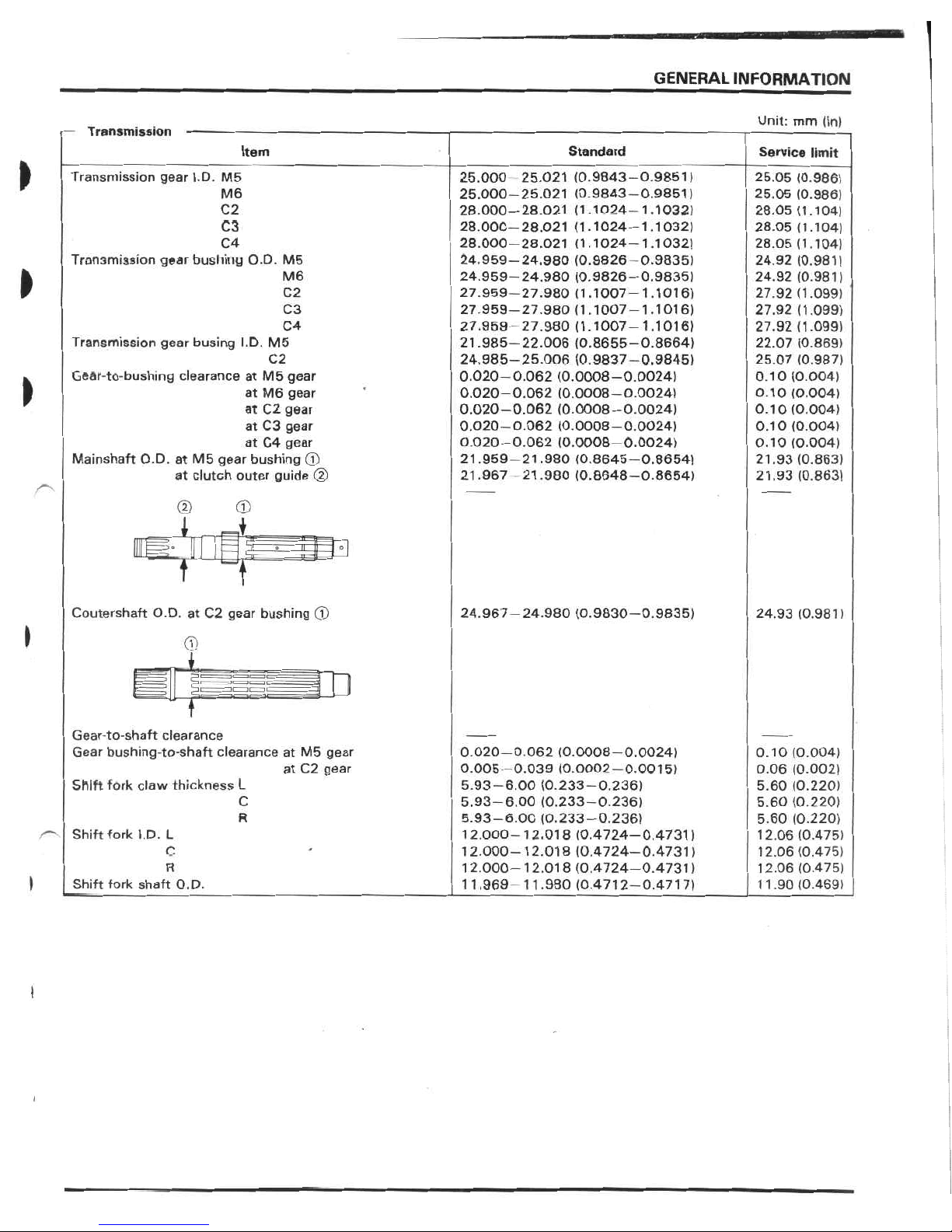

GENERAL

INFORMATION

Unit:

mm

(in)

Transmission

Item

Standard

Service

limit

►

Transmission

gear

I.D.

M5

25.000

25.021

(0.9843-0.9851)

25.000-25.021

(0.9843-0.9851)

28.000-28.021

(1.1024-1.1032)

28.000-28.021

(1.1024-1.1032)

28.000-28.021

(1.1024-1.1032)

24.959-24,980

(0.9826

-0.9835)

24.959-24.980

(0.9826-0.9835)

27.959-27.980

(1.1007-1.1016)

27.959-27.980

(1.1007-1.1016)

27.959

27.980(1.1007-1.1016)

21.985-22.006

(0.8655-0.8664)

24.985-25.006

(0.9837-0.9845)

0.020-0.062

(0.0008-0.0024)

0.020-0.062

(0.0008-0.0024)

0.020-0.062

(0.0008-0.0024)

0.020-0.062

(0.0008-0.0024)

0.020-0.062

(0.0008-0.0024)

21.959-21.980

(0.8645-0.8654)

21.967

-21.980

(0.8648-0.8654)

25.05

(0.986)

25.05

(0.986)

28.05

(1.104)

28.05

(1.104)

28.05

(1.104)

24.92

(0.981)

24.92

(0.981)

27.92

(1.099)

27.92

(1.099)

27.92

(1.099)

22.07

(0.869)

25.07

(0.987)

0.10

(0.004)

0.10

(0.004)

0.10

(0.004)

0.10

(0.004)

0.10

(0.004)

21.93

(0.863)

21.93

(0.863)

M6

C2

C3

C4

Transmission

gear

bushing

O.D.

M5

M6

C2

C3

C4

Transmission

gear

busing

I.D.

M5

C2

Gear-to-bushing

clearance

at

M5

gear

at

M6

gear

at

C2

gear

at

C3

gear

at

C4

gear

Mainshaft

O.D.

at

M5

gear

bushing

©

at

clutch

outer

guide

©

>

©

©

1

A

mrÿm

i

Coutershaft

O.D.

at

C2

gear

bushing

©

24.967-24.980

(0.9830-0.9835)

24.93

(0.981)

©

I

T

Gear-to-shaft

clearance

Gear

bushing-to-shaft

clearanceatM5

gear

at

C2

gear

0.020-0

062

(0.0008-0.0024)

0.005-0.039

(0.0002-0.0015)

5.93-6.00

(0.233-0.236)

5.93-6.00

(0.233-0.236)

5.93-6.00

(0.233-0.236)

12.000-12.018

(0.4724-0.4731)

12.000-12.018

(0.4724-0.4731)

12.000-12.018

(0.4724-0.4731)

11.969

11.980(0.4712-0.4717)

0.10

(0.004)

0.06

(0.002)

5.60

(0.220)

5.60

(0.220)

5.60

(0.220)

12.06

(0.475)

12.06

(0.475)

12.06

(0.475)

11.90

(0.469)

Shift

fork

claw

thickness

L

C

R

Shift

fork

I.D.

L

C

R

I

Shift

fork

shaft

O.D.

I

i

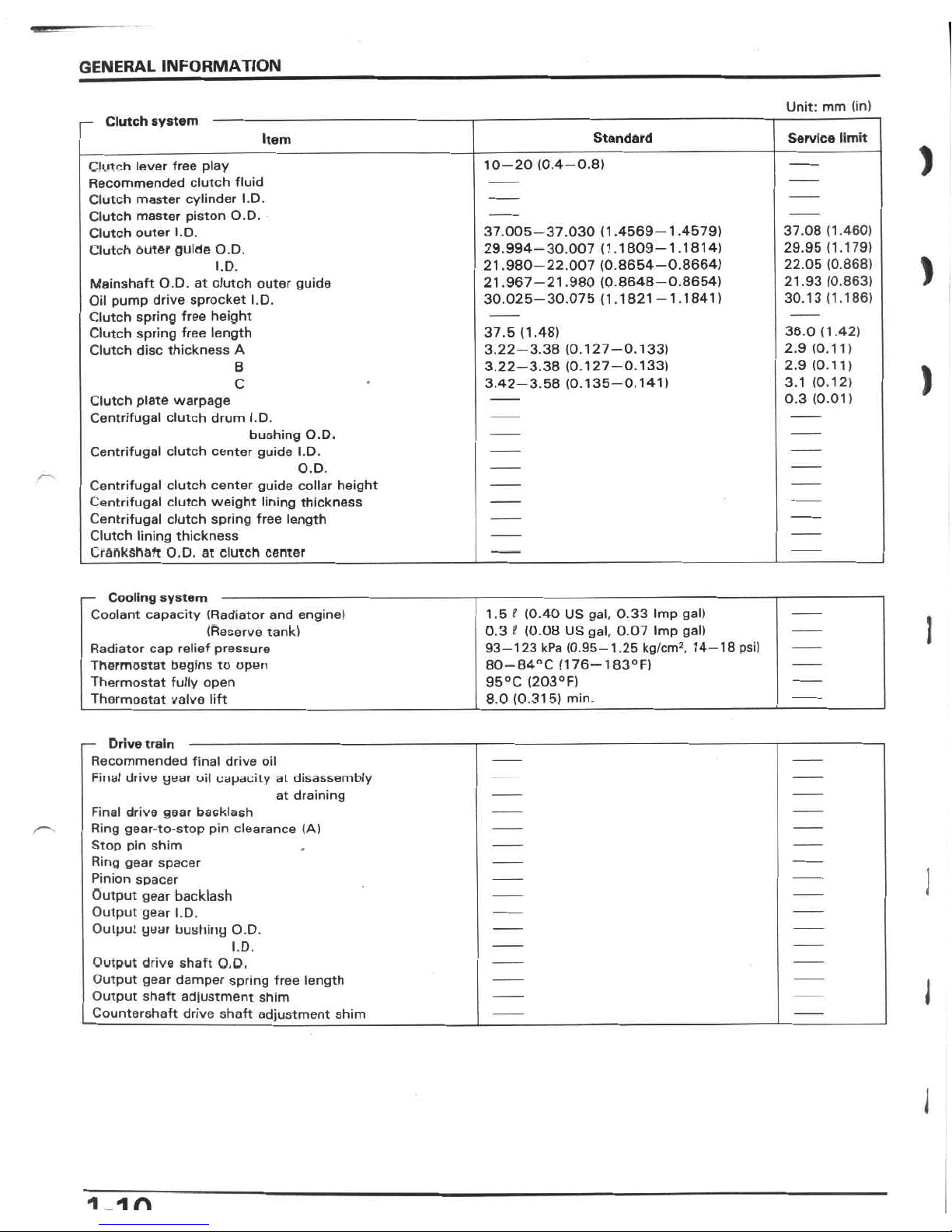

GENERAL

INFORMATION

Unit:

mm

(in)

Clutch

system

Service

limit

Item

Standard

>

10-20

(0.4—

0.8)

Clutch

lever

free

play

Recommended

clutch

fluid

Clutch

master

cylinder

I.D.

Clutch

master

piston

O.D.

Clutch

outer

I.D.

Clutch

outer

guide

O.D.

37.005-37.030

(1.4569-1.4579)

29.994-30.007

(1.1809-1.1814)

21.980-22.007

(0.8654-0.8664)

21.967-21.980

(0.8648-0.8654)

30.025-30.075

(1.1821-1.1841)

37.08

(1.460)

29.95

(1.179)

22.05

(0.868)

21.93

(0.863)

30.13

(1.186)

)

I.D.

Mainshaft

O.D.

at

clutch

outer

guide

Oil

pump

drive

sprocket

I.D.

Clutch

spring

free

height

Clutch

spring

free

length

Clutch

disc

thickness

A

36.0

(1.42)

2.9

(0.11)

2.9

(0.11)

3.1

(0.12)

0.3

(0.01)

37.5

(1.48)

3.22-3.38

(0.127-0.133)

3.22-3.38

(0.127-0.133)

3.42-3.58

(0.135-0.141)

B

)

C

Clutch

plate

warpage

Centrifugal

clutch

drum

I.D.

bushing

O.D.

Centrifugal

clutch

center

guide

I.D.

O.D.

Centrifugal

clutch

center

guide

collar

height

Centrifugal

clutch

weight

lining

thickness

Centrifugal

clutch

spring

free

length

Clutch

lining

thickness

Crankshaft

O.D.

at

clutch

center

-

Cooling

system

-

Coolant

capacity

(Radiator

and

engine)

(Reserve

tank)

Radiator

cap

relief

pressure

Thermostat

begins

to

open

Thermostat

fully

open

Thermostat

valve

lift

1

.5

(

(0.40

US

gal,

0.33

Imp

gal)

0.3

f

(0.08

US

gal,

0.07

Imp

gal)

93-123

kPa

(0.95-1.25

kg/cm2,

14-18

psi)

80—

04"C

(1

76—

1

83°F)

95°C

(203°F)

8.0

(0.315)

min.

I

-

Drive

train

-

Recommended

final

drive

oil

Filial

diive

yeai

uil

capacityatdisassembly

at

draining

Final

drive

gear

backlash

Ring

gear-to-stop

pin

clearance

(A)

Stop

pin

shim

Ring

gear

spacer

Pinion

spacer

Output

gear

backlash

Output

gear

I.D.

Output

gear

bushing

O.D.

I

I.D.

Output

drive

shaft

O.D.

Output

gear

damper

spring

free

length

Output

shaft

adjustment

shim

Countershaft

drive

shaft

adjustment

shim

I

J

1

_1

A

GENERAL

INFORMATION

Unit:

mm

(in)

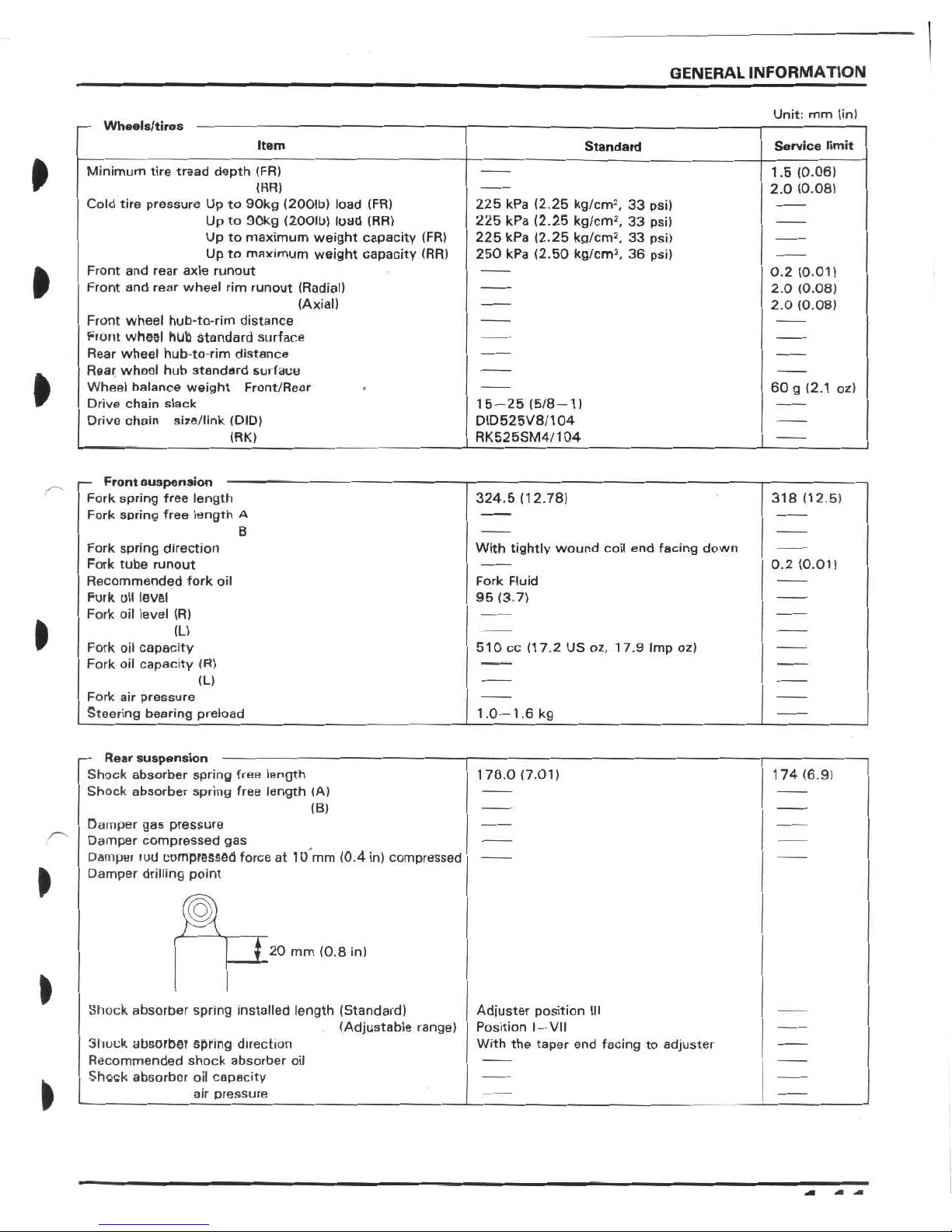

Wheeis/tires

Service

limit

Item

Standard

ft

Minimum

tire

tread

depth

(FR)

(HR)

Cold

tire

pressure

Up

to

90kg

(2001b)

load

(FR)

Up

to

90kg

(2001b)

load

(RR)

Up

to

maximum

weight

capacity

(FR)

Up

to

maximum

weight

capacity

(RR)

1.B

(0.06)

2.0

(0.08)

225

kPa

(2.25

kg/cm2,

33

psi)

225

kPa

(2.25

kg/cm2,

33

psi)

225

kPa

(2.25

kg/cm2,

33

psi)

250

kPa

(2.50

kg/cm2,

36

psi)

Front

and

rear

axle

runout

ft

0.2

(0.01)

2.0

(0.08)

2.0

(0.08)

Front

and

rear

wheel

rim

runout

(Radial)

(Axial)

Front

wheel

hub-to-rim

distance

Front

wheel

hub

standard

surface

Rear

wheel

hub-to-rim

distance

Rear

wheel

hub

standard

surface

Wheel

balance

weight

Front/Rear

Drive

chain

slack

Drive

chain

size/link

(DID)

(RK>

ft

60

g

(2.1

oz)

15-25

(5/8-1)

DID525V8/1

04

RK525SM4/1

04

-

Front

suspension

-

Fork

spring

free

length

Fork

spring

free

length

A

318

(12.5)

324.5

(12.78)

B

Fork

spring

direction

Fork

tube

runout

Recommended

fork

oil

Furk

oil

level

Fork

oil

level

(R)

With

tightly

wound

coil

end

facing

down

0.2

(0.01)

Fork

Fluid

95

(3.7)

»

(L)

510

cc

(17.2

US

oz,

17.9

Imp

oz)

Fork

oil

capacity

Fork

oil

capacity

(R)

(L)

Fork

air

pressure

Steering

bearing

preload

1.0-

1.6

kg

-

Rear

suspension

-

Shock

absorber

spring

free

length

Shock

absorber

spring

free

length

(A)

174

(6.9)

170.0

(7.01)

(B)

Damper

gas

pressure

Damper

compressed

gas

Dampei

lud

compressed

force

at

10

mm

(0.4

in)

compressed

Damper

drilling

point

»

a

f

20

mm

(0.8

in)

Shock

absorber

spring

installed

length

(Standard)

(Adjustable

range)

Adjuster

position

III

Position

I

—

VII

With

the

taper

end

facing

to

adjuster

Shuck

absorber

spring

direction

Recommended

shock

absorber

oil

Shock

absorber

oil

capacity

air

pressure

GENERAL

INFORMATION

Unit:

mm

(in)

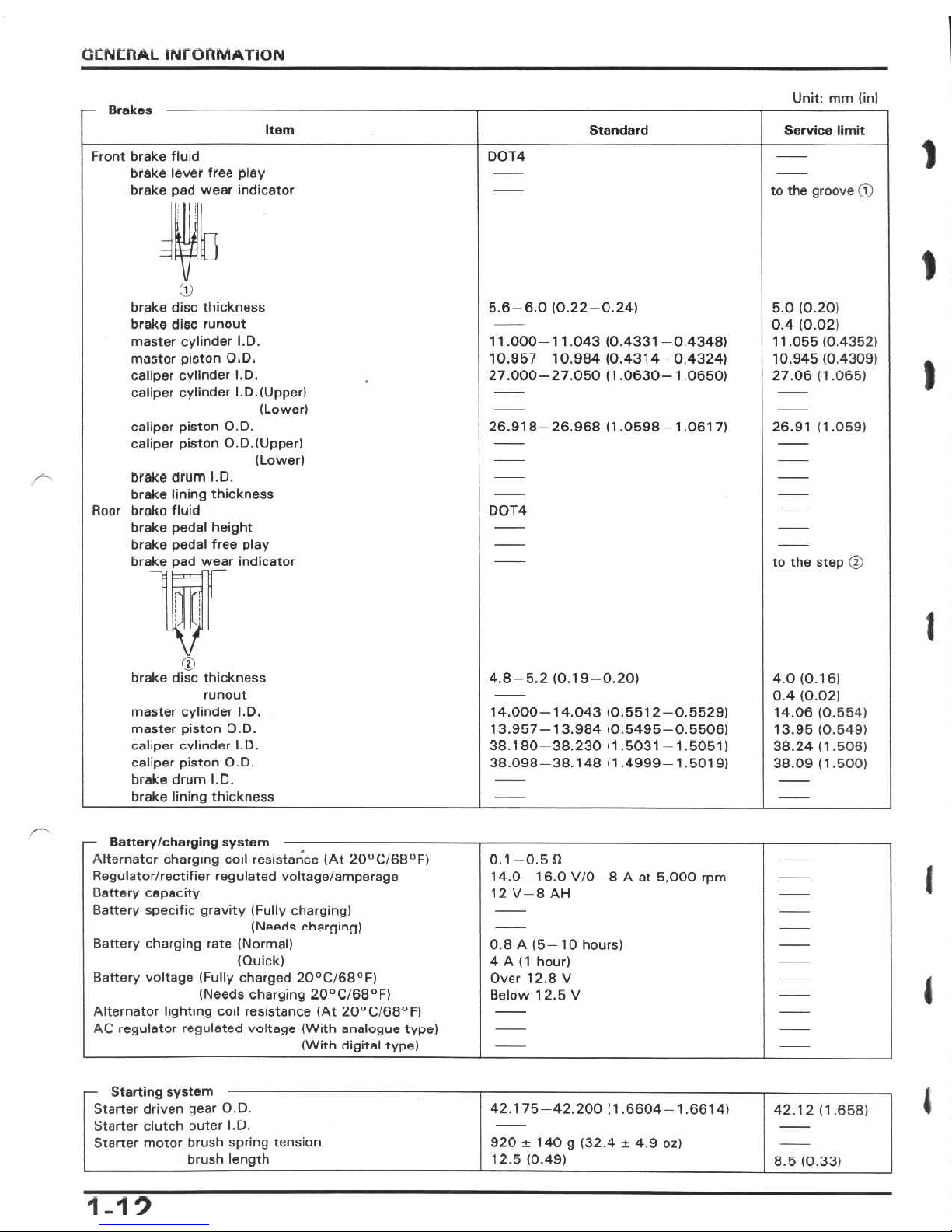

Brakes

Item

Standard

Service

limit

1

Front

brake

fluid

brake

lever

free

play

brake

pad

wear

indicator

D0T4

to

the

groove

©

D

1

©

brake

disc

thickness

brake

disc

runout

master

cylinder

I.D.

moetor

piston

O.D,

caliper

cylinder

I.D.

caliper

cylinder

I.D.

(Upper)

(Lower)

5.

6-6.0

(0.22-0.24)

5.0

(0.20)

0.4

(0.02)

11.055

(0.4352)

10.945

(0.4309)

27.06

(1.065)

11.000-11.043

(0.4331-0.4348)

10.957

10.984(0.4314

0.4324)

27.000-27.050

(1.0630-1.0650)

I

caliper

piston

O.D.

caliper

piston

O.D.

(Upper)

(Lower)

26.918-26.968

(1.0598-1.0617)

26.91

(1.059)

brake

drum

I.D.

brake

lining

thickness

Rear

brake

fluid

brake

pedal

height

brake

pedal

free

play

brake

pad

wear

indicator

lijr

v

D0T4

to

the

step

©

1

©

brake

disc

thickness

runout

master

cylinder

I.D.

master

piston

O.D.

caliper

cylinder

I.D.

caliper

piston

O.D.

brake

drum

I.D.

brake

lining

thickness

4.8-5.

2

(0.19-0.20)

4.0

(0.16)

0.4

(0.02)

14.06

(0.554)

13.95

(0.549)

38.24

(1.506)

38.09

(1.500)

14.000-14.043

(0.5512-0.5529)

13.957-13.984

(0.5495-0.5506)

38.180-38.230

(1

.5031

—

1

.5051

)

38.098-38.148

(1.4999-1.5019)

-

Battery/charging

system

-

Alternator

charging

coil

resistance

(At

20UC/68UF)

Regulator/rectifier

regulated

voltage/amperage

Battery

capacity

Battery

specific

gravity

(Fully

charging)

(Needs

charging)

0.1-0.

5

fi

14.0-16.0

V/0-8

A

at

5,000

rpm

12

V—8AH

I

Battery

charging

rate

(Normal)

(Quick)

0.8

A

(5-10

hours)

4

A

(1

hour)

Over

12.8

V

Below

12.5

V

Battery

voltage

(Fully

charged

20°C/68°F)

(Needs

charging

20°C/68°F)

Alternator

lighting

coil

resistance

(At

20UC/68°F)

AC

regulator

regulated

voltage

(With

analogue

type)

(With

digital

type)

1

-

Starting

system

-

Starter

driven

gear

O.D.

Starter

clutch

outer

I.D.

Starter

motor

brush

spring

tension

brush

length

1

42.175-42.200

(1.6604-1.6614)

42.12

(1.658)

920

±

140

g

(32.4

±

4.9

oz)

12.5

(0.49)

8.5

(0.33)

1-19

'1

-

G

-

-

-

-m

i>

—

-

-

I

IN

11

m

II

J

—

—

I<l

>

—

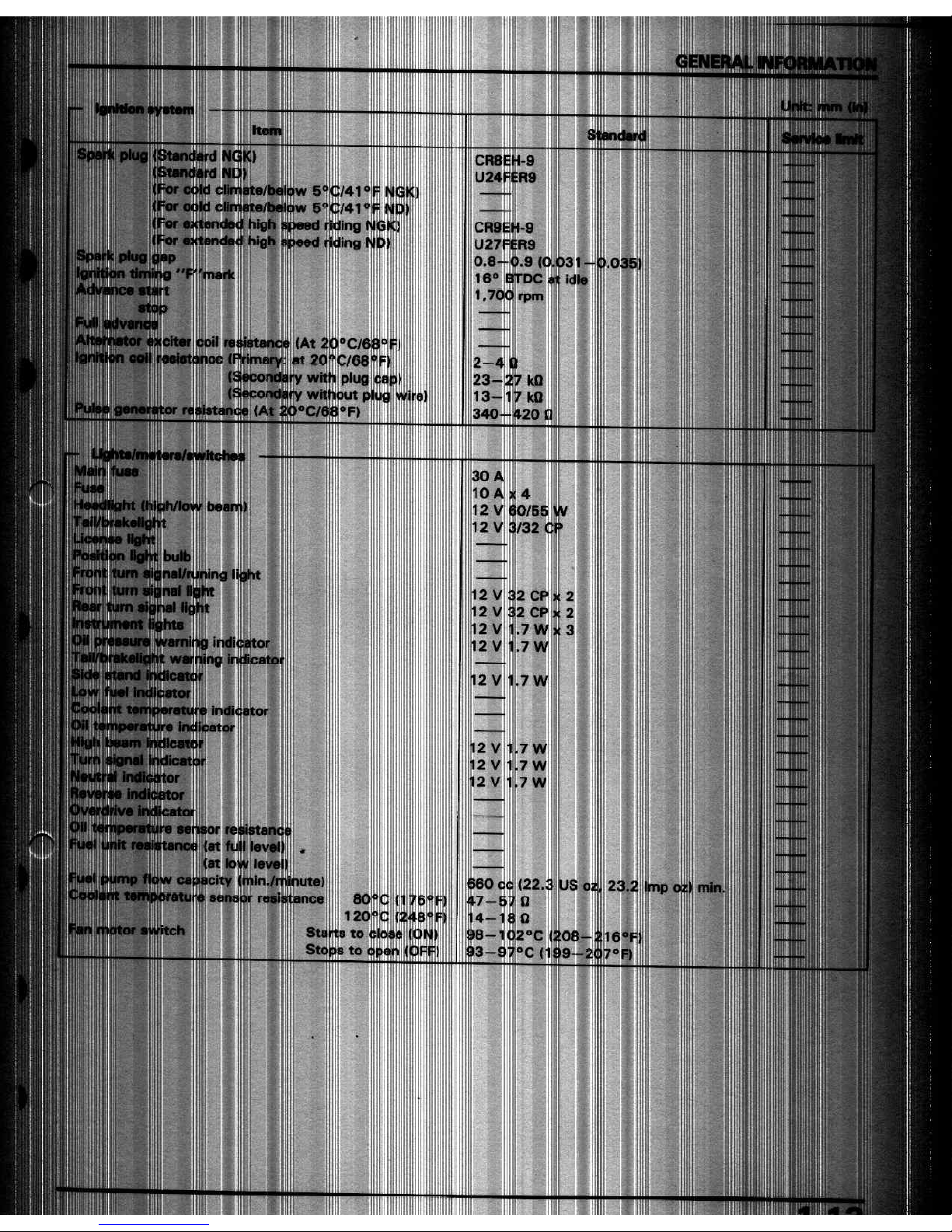

CR8EH-9

U24FER9

5°C/41

0

5ftC/41

°

iding

riding

m

I

i

hi

Cl

9

;

“1

U27

19

i.9

(0.031-

rDC

at

idle

0.8

1.035

"P

16°

€

1.

rpm

I

!

(At

20°C/6

at

?0"C/68

ilre

I

>

(I

2-4

I

plug

23-

kQ

without

C/68°F)

9

wire]

13-

kQ

!

re

it

340-420

Q

!

I

111

ililllll

-

ii

!

ii'ilri!

-

i

:

III®

II

30

A

1

illli!;]

10

A

4

IrHlJlll

“"HI

12

V

’

iMi

ih

iijij

"Hllll'Hjlll

l|!ill|'l|

!

i

1

'ill

ii

j

i'l<

''lilllili

Ii!

.11

ii

l!i

'

"||

ii

mi

i:ll'|.||llh

•

;

:ill:l|

»l

•

iill'lili

III

plitl

!lll|il|l||i!

-

1

!ll|i|i

IP

!

5

12

V

2

I

I'i:

"

111!

M

CP

12

V

2

'lil

li'i|

'

1

ill

1

i|n

III!

iViiifltfliliiJNM

12

V

2

12

V

.7

3

12

V

.7

12

V

as

mui

■7

W

12

V

MiMi

■7

W

7W

12

V

3

I

12

V

'

at

I

Ii

I

at

l<

lin./i

:e)

360

cc

‘23

(22.3

23.2

mp

IS

o;

min.

80°C

Starts

to

co«e

Sto

s

to

(

0

-1

3

■i:

°C

16°F

-9

°C

(

7°F)

1

-

t

;

V

■

i

•

8

S:

m

«1

-

-

ilill!

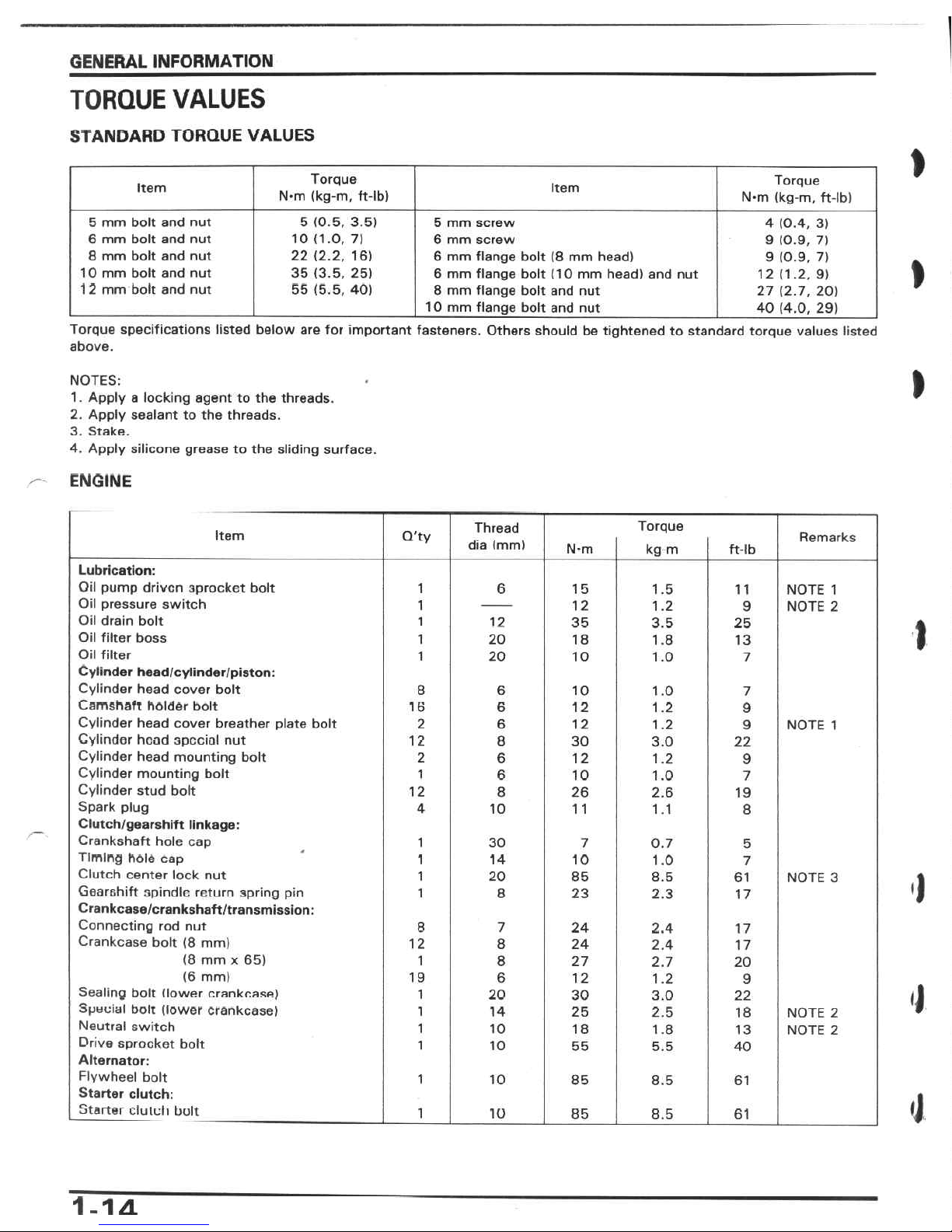

GENERAL

INFORMATION

TORQUE

VALUES

STANDARD

TORQUE

VALUES

I

Torque

N-m

(kg-m,

ft-lb)

Torque

N*m

(kg-m,

ft-lb)

Item

Item

5

(0.5,

3.5)

10

(1.0,

7)

22

(2.2,

16)

35

(3.5,

25)

55

(5.5,

40)

5

mm

bolt

and

nut

6

mm

bolt

and

nut

8

mm

bolt

and

nut

1

0

mm

bolt

and

nut

1

2

mm

bolt

and

nut

5

mm

screw

6

mm

screw

6

mm

flange

bolt

(8

mm

head)

6

mm

flange

bolt

(10

mm

head)

and

nut

8

mm

flange

bolt

and

nut

10

mm

flange

bolt

and

nut

4

(0.4,

3)

9

(0.9,

7)

9

(0.9,

7)

12

(1.2,

9)

27

(2.7,

20)

40

(4.0,

29)

t

Torque

specifications

listed

below

are

for

important

fasteners.

Others

should

be

tightened

to

standard

torque

values

listed

above.

I

NOTES:

1

.

Apply

a

locking

agent

to

the

threads.

2.

Apply

sealant

to

the

threads.

3.

Stake.

4.

Apply

silicone

grease

to

the

sliding

surface.

ENGINE

Torque

kg

m

Thread

dia

(mm)

Item

Q'ty

Remarks

N-m

ft-lb

Lubrication:

Oil

pump

driven

sprocket

bolt

Oil

pressure

switch

Oil

drain

bolt

Oil

filter

boss

Oil

filter

Cylinder

head/cylinder/piston:

Cylinder

head

cover

bolt

Camshaft

holder

bolt

Cylinder

head

cover

breather

plate

bolt

Cylinder

head

special

nut

Cylinder

head

mounting

bolt

Cylinder

mounting

bolt

Cylinder

stud

bolt

Spark

plug

Clutch/gearshift

linkage:

Crankshaft

hole

cap

Timing

hole

cap

Clutch

center

lock

nut

Gearshift

spindle

return

spring

pin

Crankcase/crankshaft/transmission:

Connecting

rod

nut

Crankcase

bolt

(8

mm)

(8

mm

x

65)

(6

mm)

Sealing

bolt

(lower

crankcase)

Spueial

bolt

(lower

crankcase)

Neutral

switch

Drive

sprocket

bolt

Alternator:

Flywheel

bolt

Starter

clutch:

Starter

clutch

bolt

1

6

15

1.5

11

NOTE

1

NOTE

2

1

12

1.2

9

1

12

35

3.5

25

I

1

20

18

1.8

13

1

20

10

1.0

7

8

6

10

1.0

7

IB

6

12

1.2

9

2

6

12

1.2

9

NOTE

1

12

8

30

3.0

22

2

6

12

1.2

9

1

6

10

1.0

7

12

8

26

2.6

19

4

10

1 1

1.1

8

1

30

7

0.7

5

1

14

10

1.0

7

1

20

85

8.5

61

NOTE

3

1

1

8

23

2.3

17

8

7

24

2.4

17

12

8

24

2.4

17

1

8

27

2.7

20

19

6

12

1.2

9

<1

1

20

30

3.0

22

1

14

25

2.5

18

NOTE

2

NOTE

2

1

10

18

1.8

13

1

10

55

5.5

40

1

10

85

8.5

61

•J

1

10

85

8.5

61

1-1

a.

GENERAL

INFORMATION

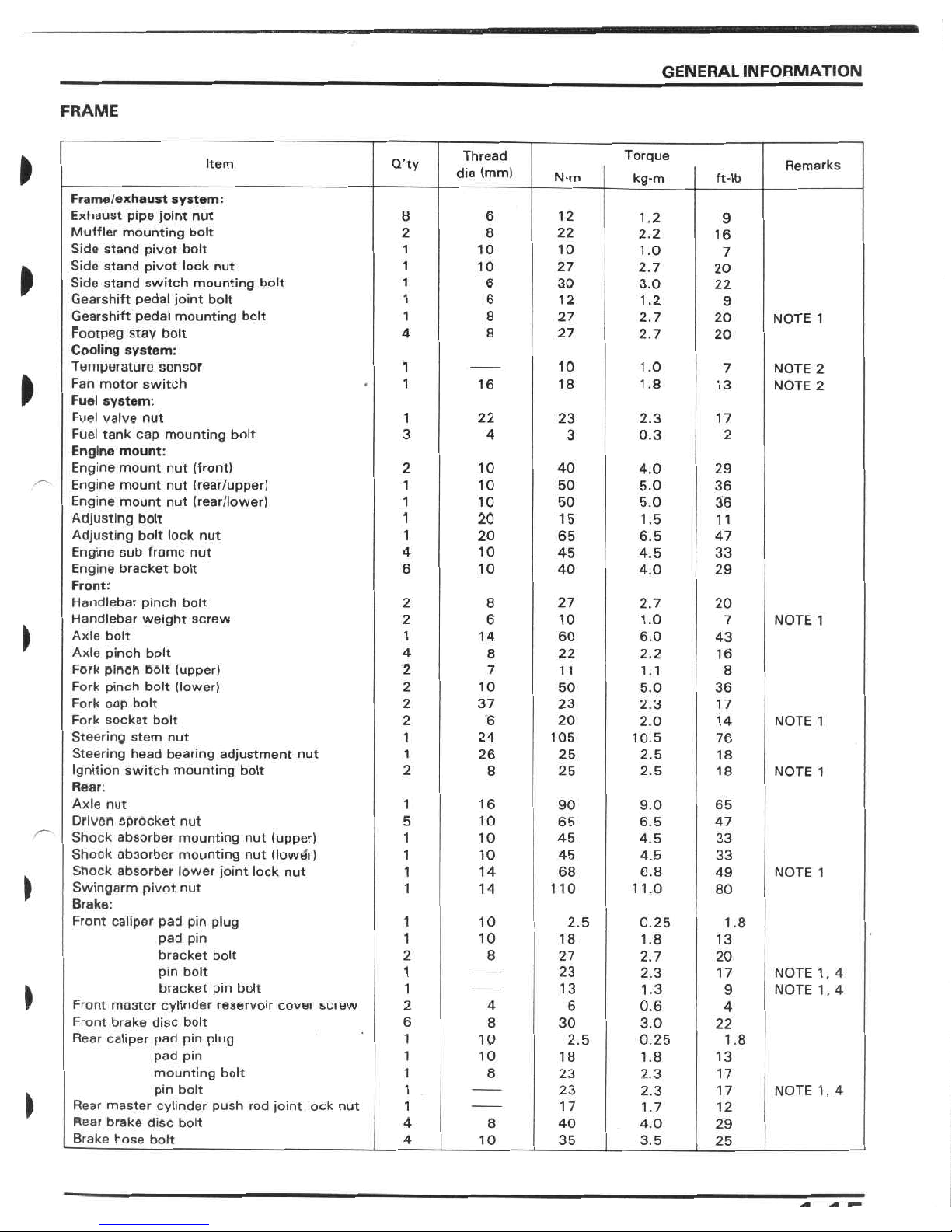

FRAME

Thread

dia

(mm)

Torque

kg-m

>

Item

Q'ty

Remarks

N-m

ft-lb

Frame/exhaust

system:

Exhaust

pipe

joint

nut

Muffler

mounting

bolt

Side

stand

pivot

bolt

Side

stand

pivot

lock

nut

Side

stand

switch

mounting

holt

Gearshift

pedal

joint

bolt

Gearshift

pedal

mounting

bolt

Footpeg

stay

bolt

Cooling

system:

Temperature

sensor

Fan

motor

switch

Fuel

system:

Fuel

valve

nut

Fuel

tank

cap

mounting

bolt

Engine

mount:

Engine

mount

nut

(front)

Engine

mount

nut

(rear/upper)

Engine

mount

nut

(rear/lower)

Adjusting

bolt

Adjusting

bolt

lock

nut

Engino

oub

fromc

nut

Engine

bracket

bolt

Front:

Handlebar

pinch

bolt

Handlebar

weight

screw

Axle

bolt

Axle

pinch

bolt

Fork

pinch

bolt

(upper)

Fork

pinch

bolt

(lower)

Fork

oop

bolt

Fork

socket

bolt

Steering

stem

nut

Steering

head

bearing

adjustment

nut

Ignition

switch

mounting

bolt

Rear:

Axle

nut

Driven

sprocket

nut

Shock

absorber

mounting

nut

(upper)

Shook

absorber

mounting

nut

(lowÿr)

Shock

absorber

lower

joint

lock

nut

Swingarm

pivot

nut

Brake:

Front

caliper

pad

pin

plug

pad

pin

bracket

bolt

pin

bolt

bracket

pin

bolt

Front

mo3tcr

cylinder

reservoir

cover

screw

Front

brake

disc

bolt

Rear

caliper

pad

pin

plug

pad

pin

mounting

bolt

pin

bolt

Rear

master

cylinder

push

rod

joint

lock

nut

Rear

brake

disc

bolt

Brake

hose

bolt

6

8

12

1.2

9

2

8

22

2.2

16

1

10

10

1.0

7

10

1

27

2.7

20

»

6

30

1

3.0

22

1

6

12

1.2

9

8

1

27

2.7

20

NOTE

1

4

8

27

2.7

20

10

1

1.0

7

NOTE

2

NOTE

2

I

18

1

16

1.8

13

22

1

23

2.3

17

3

3

4

0.3

2

2

10

40

4.0

29

10

50

1

5.0

36

36

1

10

50

5.0

20

1

15

1.5

11

20

1

65

6.5

47

10

45

4

4.5

33

6

40

10

4.0

29

2

8

27

2.7

20

6

2

10

1.0

NOTE

1

7

1

60

14

6.0

43

4

8

22

2.2

16

2

7

1

1

1.1

8

2

10

50

5.0

36

2

23

37

2.3

17

2

6

20

2.0

14

NOTE

1

1

24

105

10.5

76

1

26

25

2.5

18

2

8

25

2.5

18

NOTE

1

1

16

90

9.0

65

5

10

65

6.5

47

1

10

45

4.5

33

1

10

45

4.5

33

14

1

68

6.8

NOTE

1

49

)

1

14

110

1

1.0

80

1

10

2.5

0

25

1.8

1

10

18

1.8

13

2

8

27

2.7

20

1

23

2.3

17

NOTE

1,

4

NOTE

1,

4

1

13

1.3

9

»

2

4

6

0.6

4

6

8

30

3.0

22

1

10

2.5

0.25

1.8

1

10

18

1.8

13

1

8

23

2.3

17

1

23

2.3

NOTE

1,

4

17

\

1

17

1.7

12

4

8

40

4.0

29

4

10

35

3.5

25

GENERAL

INFORMATION

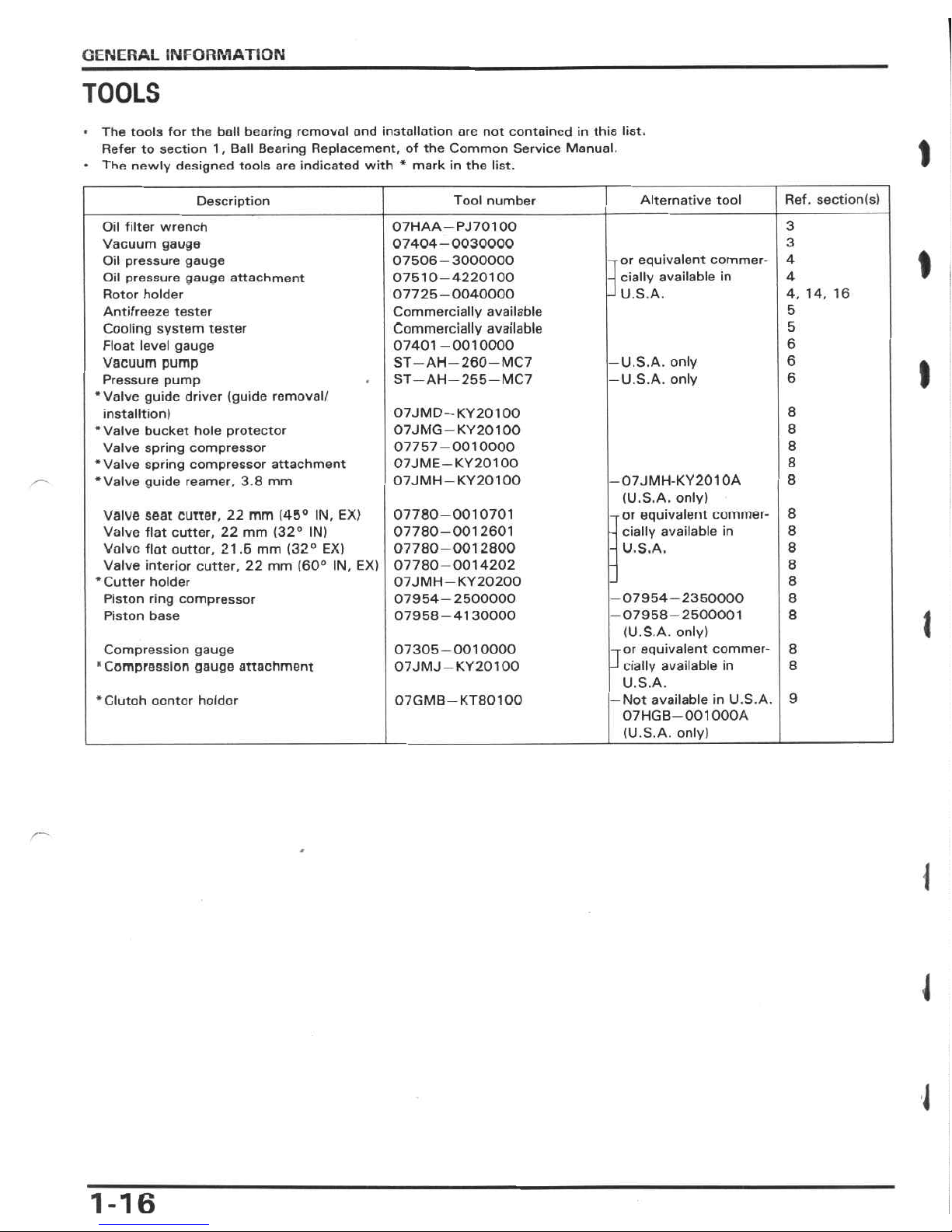

TOOLS

•

The

tools

for

the

boll

bearing

removal

and

installation

arc

not

contained

in

this

list.

Refer

to

section

1

,

Ball

Bearing

Replacement,

of

the

Common

Service

Manual.

•

The

newly

designed

tools

are

indicated

with

*

mark

in

the

list.

1

Ref.

section(s)

Alternative

tool

Tool

number

Description

3

07HAA—PJ701

00

07404-0030000

07506-3000000

07510-4220100

07725-0040000

Commercially

available

Commercially

available

07401-0010000

ST

—AH—

260

—

MC7

ST

—

AH

—

255

—

MC7

Oil

filter

wrench

Vacuum

gauge

Oil

pressure

gauge

Oil

pressure

gauge

attachment

Rotor

holder

Antifreeze

tester

Cooling

system

tester

Float

level

gauge

Vacuum

pump

Pressure

pump

‘Valve

guide

driver

(guide

removal/

installtion)

•Valve

bucket

hole

protector

Valve

spring

compressor

•Valve

spring

compressor

attachment

•Valve

guide

reamer,

3.8

mm

3

I

4

-ror

equivalent

commer-

-

daily

available

in

J

U.S.A.

4

4,

14,

16

5

5

6

6

—

U.S.A.

only

—

U.S.A.

only

I

6

8

07JMD

—

KY20100

07JMG

—

KY201

00

07757-0010000

07JME

—

KY201

00

07JMH

—

KY201

00

8

8

8

—

07JMH-KY201

OA

(U.S.A.

only)

-ror

equivalent

cummer-

-

dally

available

in

-

U.S.A.

8

8

07780-0010701

07780-0012601

07780-0012800

07780-0014202

07JMH

—

KY20200

07954-2500000

07958-4130000

valve

seat

cutter,

22

mm

(45°

IN,

EX)

Valve

flat

cutter,

22

mm

(32°

IN)

Volvo

flat

outtor,

21.6

mm

(32°

EX)

Valve

interior

cutter,

22

mm

(60°

IN,

EX)

•Cutter

holder

Piston

ring

compressor

Piston

base

8

8

8

8

-07954-2350000

-07958-2500001

(U.S.A.

only)

or

equivalent

commer¬

cially

available

in

U.S.A.

—

Not

available

in

U.S.A.

07HGB

—

001

000A

(U.S.A.

only)

8

8

1

8

07305-0010000

07JMJ

—

KY20100

Compression

gauge

"Compression

gauge

attachment

J

8

9

07GMB

—

KT801

00

•Clutoh

oontor

holdor

l

J

J

1-16

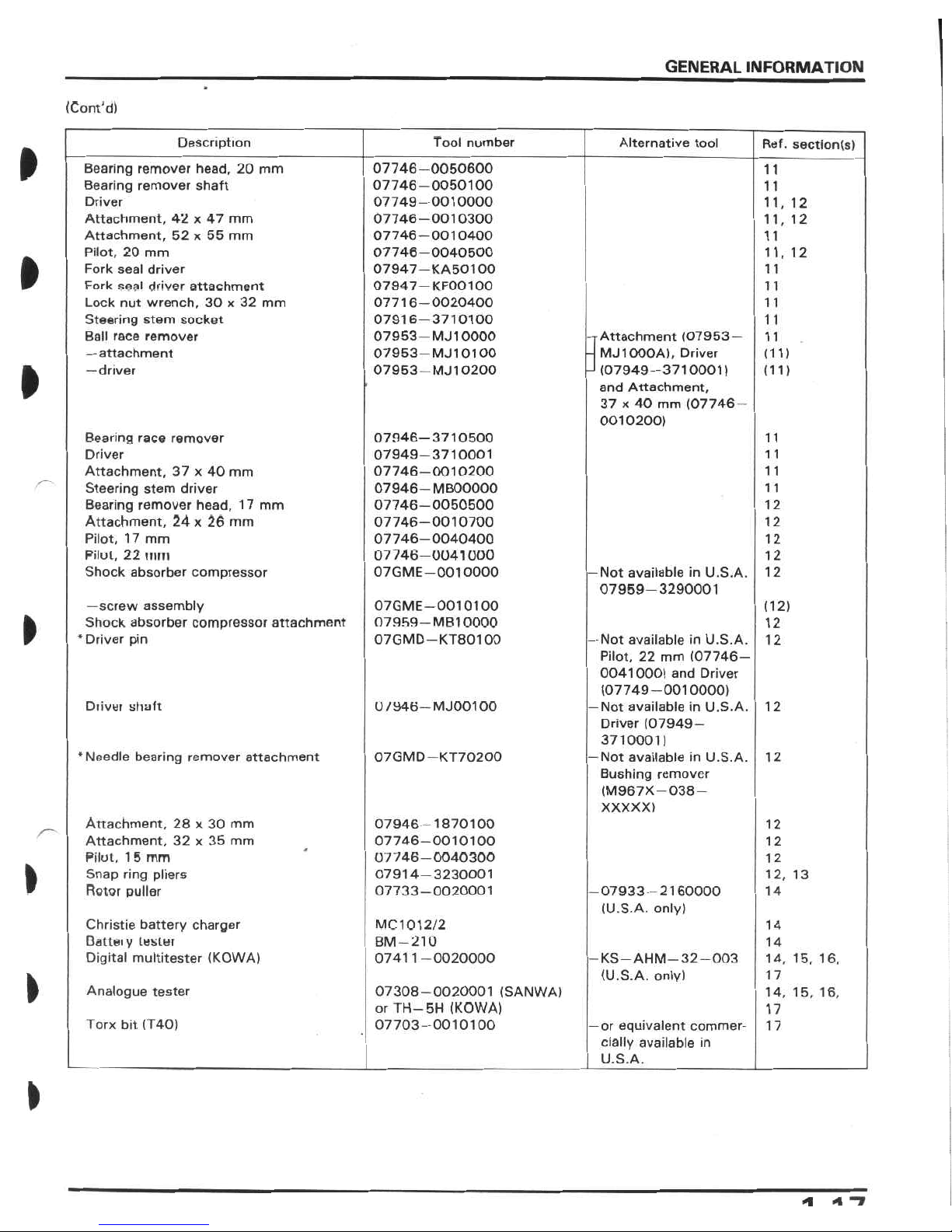

GENERAL

INFORMATION

(Corn'd)

Tool

number

Description

Alternative

tool

Ref.

section(s)

ft

07746-0050600

07746-0050100

07749-0010000

07746-0010300

07746-0010400

07746-0040500

07947-

KA501

00

07947

-KF001

00

07716-0020400

07916-3710100

07953-

MJ

10000

07953

—

MJ1

01

00

07953

—

MJ

10200

Bearing

remover

head,

20

mm

Bearing

remover

shaft

Driver

Attachment,

42

x

47

mm

Attachment,

52

x

55

mm

Pilot,

20

mm

Fork

seal

driver

Fork

seal

driver

attachment

Lock

nut

wrench,

30

x

32

mm

Steering

stem

socket

Ball

race

remover

—

attachment

—driver

1

1

11

11,

12

11,

12

11

11,

12

ft

11

11

11

11

-ÿAttachment

(07953

—

-

MJ1000A),

Driver

-l

(07949-3710001)

and

Attachment,

37

x

40

mm

(07746

—

0010200)

1

1

(11)

ft

(11)

Bearing

race

remover

Driver

Attachment,

37

x

40

mm

Steering

stem

driver

Bearing

remover

head,

17

mm

Attachment,

24

x

26

mm

Pilot,

1

7

mm

Pilot,

22

mm

Shock

absorber

compressor

07946-3710500

07949-3710001

07746-0010200

07946-

MB00000

07746-0050500

07746-0010700

07746-0040400

07746-0041000

07GME

—

001

0000

1 1

11

11

1

1

12

12

12

12

—

Not

available

in

U.S.A.

07959-3290001

12

—screw

assembly

Shock

absorber

compressor

attachment

‘Driver

pin

07GME

—

0010100

07959

—

MB1

0000

07GMD

—

KT801

00

(12)

ft

12

—

Not

available

in

U.S.A.

Pilot,

22

mm

(07746

—

0041000)

and

Driver

(07749-0010000)

—

Not

available

in

U.S.A.

Driver

(07949-

3710001)

—

Not

available

in

U.S.A.

Bushing

remover

(M967X—

038

—

XXXXX)

12

U

/946—

MJ001

00

Diivur

shaft

12

‘Needle

bearing

remover

attachment

07GMD

—

KT70200

12

Attachment,

28

x

30

mm

Attachment,

32x35

mm

Pilot,

1

5

mm

Snap

ring

pliers

Rotor

puller

07946-1870100

07746-0010100

07746-0040300

07914-3230001

07733-0020001

12

12

12

ft

12,

13

-07933-2160000

(U.S.A.

only)

14

Christie

battery

charger

Qatteiy

tester

Digital

multitester

(K0WA)

MC1012/2

BM-210

07411-0020000

14

14

—

KS

—

AHM

—

32

—

003

(U.S.A.

only)

14, 15,

16,

17

ft

Analogue

tester

07308-0020001

(SANWA)

or

TH-5H

(K0WA)

07703-0010100

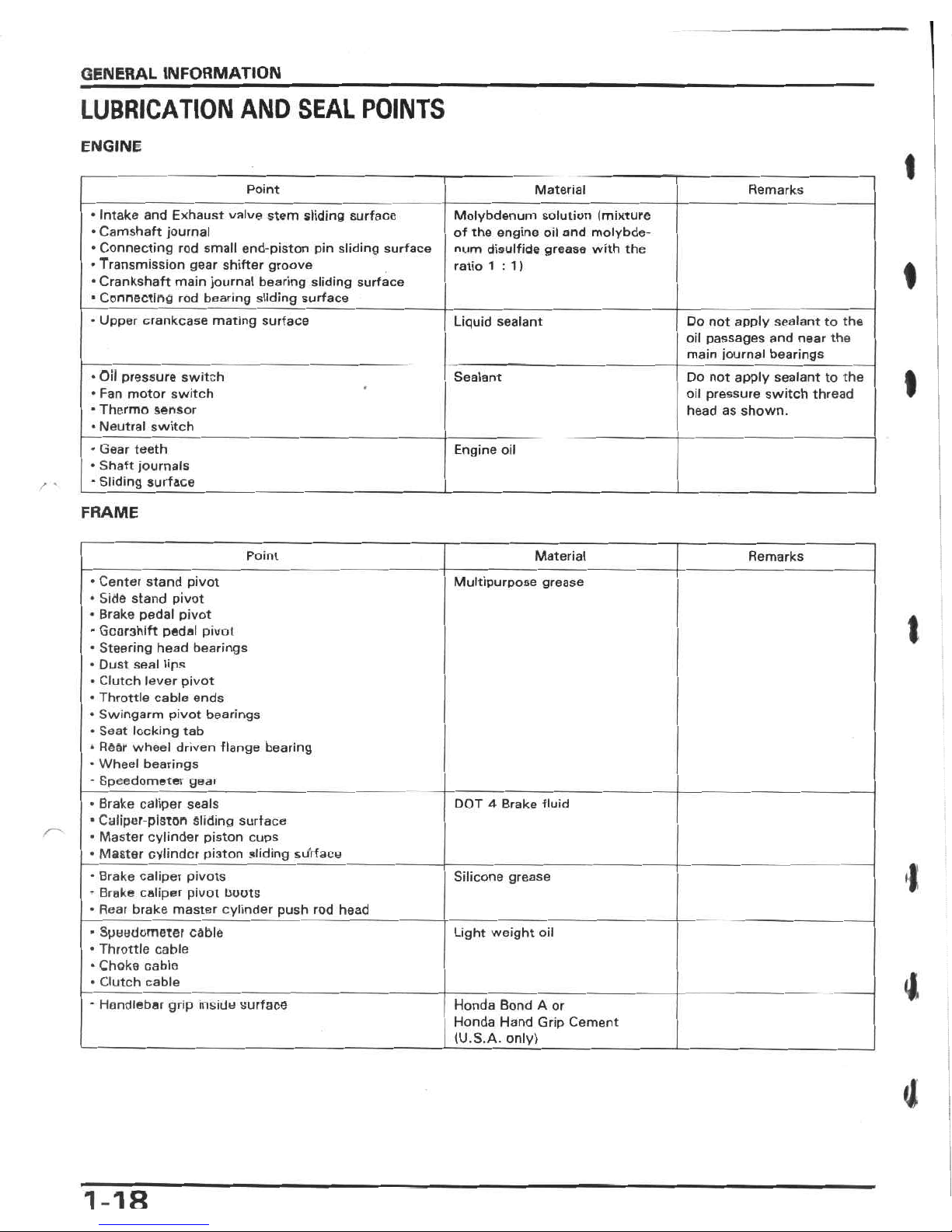

14,