Hobart HFEI102D, HFEI101D, HFEI061D, HFEI201D, HFEI202D Installation, Use And Maintenance Instructions

Page 1

INSTALLATION, USE AND MAINTENANCE INSTRUCTIONS

MANUEL DE MODE D’EMPLOI ET D’ENTRETIEN

ISTRUZIONI DI INSTALLAZIONE, USO E MANUTENZIONE

CONVECTION STEAM OVENS

FOURS MIXTES A CONVECTION ET VAPEUR

FORNI MISTI A CONVEZIONE E VAPORE

HFEI - D

INSTALLATION

INSTALLATION

INSTALLAZIONE

L & R

OPERATION

FONCTIONNEMENT

FUNZIONAMENTO

05/05/2009 Rev.5 164507

GB

F

I

Page 2

ENGLISH ............................................................................................ .......................... page 2 - 17

FRANÇAIS ..................................................................................................................... page 18 - 33

ITALIANO ...................................................................................................................... pagina 34 - 49

CONTENTS

SECTION DESCRIPTION PAGES

General notices .................................................................................................................................... 3

1. Installation ........................................................................................................................................... 4

1.1 Water connection .................................................................................................................................. 4

1.2 Drain connection ................................................................................................................................. 4

1.3 Electrical connection ........................................................................................................................... 4

1.4 Oven capacity....................................................................................................................................... 4

2. Operation ............................................................................................................................................. 6

2.1 General ................................................................................................................................................ 6

2.2 Control panel ....................................................................................................................................... 7

2.2.1 Machine connected to electrical supply ............................................................................................... 8

2.2.1.1 Time adjustment ................................................................................................................................... 8

2.2.1.2 24h or 12h am/pm ................................................................................................................................ 8

2.2.1.3 Service counter..................................................................................................................................... 8

2.2.2 Start up ................................................................................................................................................. 8

2.2.3 Cooking mode selection ....................................................................................................................... 8

2.2.4 Adjustment of temperature, time or humidity ....................................................................................... 10

2.2.5 Fan speed adjustment ........................................................................................................................... 10

2.2.6 Vent position (convection mode only) .................................................................................................. 10

2.2.7 Humidifyer (convection mode only) ..................................................................................................... 10

2.2.8 Fast cool down ..................................................................................................................................... 10

2.2.9 Core probe function ............................................................................................................................. 11

2.2.10 Delta t function .................................................................................................................................... 11

2.2.11 Cooking phases ph 1/10 ....................................................................................................................... 11

2.2.12 Programme function ............................................................................................................................. 12

2.2.12.1 To write a cooking programme ............................................................................................................ 12

2.2.12.2 To execute a programme ...................................................................................................................... 12

2.2.12.3 To visualise a cooking programme ....................................................................................................... 12

2.2.12.4 To erase a programme .......................................................................................................................... 12

2.2.12.5 To modify a programme ....................................................................................................................... 13

2.2.12.6 To name a programme .......................................................................................................................... 13

2.2.13 Particular functions.............................................................................................................................. 14

2.2.13.1 Vp (pasteurisation value) mode (option) ............................................................................................. 14

2.2.13.2 Oven preheating ................................................................................................................................... 14

2.2.13.3 To program preheat start...................................................................................................................... 14

2.2.14 To switch off the oven ........................................................................................................................... 15

2.3 Daily cleaning and maintenance ......................................................................................................... 16

2.4 Autodiagnostic ..................................................................................................................................... 16

Installation diagram ............................................................................................................................. 50

GB

- 2 -

Page 3

GENERAL NOTICES

Machine noise level is less than 70 dB (A)

Important Instructions for Use

- Use in Accordance with Regulations

Hobart Convection Steam Ovens are only intended for baking, roasting, gratinating, steaming and stewing food

products intended for consumption.

- Safety

Do not wash down with a hose or a high pressure cleaner from outside. The “danger” symbol is shown beside

instructions that are essential for the safe operation of the machine. Please read these passages with particular

care.

- Liability

Incorrect installation and repairs not carried out by Hobart Service or their Authorised Service Agent and any

technical modication to the machine not authorised by the manufacturer may cancel the manufacturer

guarantee.

All examples given in these instructions with reference to cooking methods, times and temperatures are dependant

on the quality of the foodstuffs being cooked and may therefore vary.

In the event of the user or the installation technician failing to observe the instructions given in this manual, the

Firm disclaims all responsibility thereof and cannot be held liable for any accident or trouble caused by such nonobservance.

THE MANUFACTURER DISCLAIMS ALL RESPONSIBILITY FOR ANY INACCURACIES IN THIS BOOKLET THAT MAY BE DUE

TO TYPING OR PRINTING MISTAKES. THE MANUFACTURER, MOREOVER, RESERVES RIGHTS TO MAKE MODIFICATIONS

TO THE PRODUCT CONSIDERED USEFUL OR NECESSARY, WITHOUT AFFECTING ITS BASIC FEATURES.

- 3 -

GB

Page 4

1. INSTALLATION

Before removing packaging, verify good state of the box, in case of damage, give necessary claims to the transport company.

DOOR OPENING SIDE As standard, the oven is delivered with door hinged on the left. If you want door hinged on the

right, please specify it when you order the oven.

The oven must be installed and connected in accordance with local codes and regulations.

The oven must be installed on a proper-levelled support/floor. Insure levelling of the oven using a spirit level and the top of

the machine as reference.

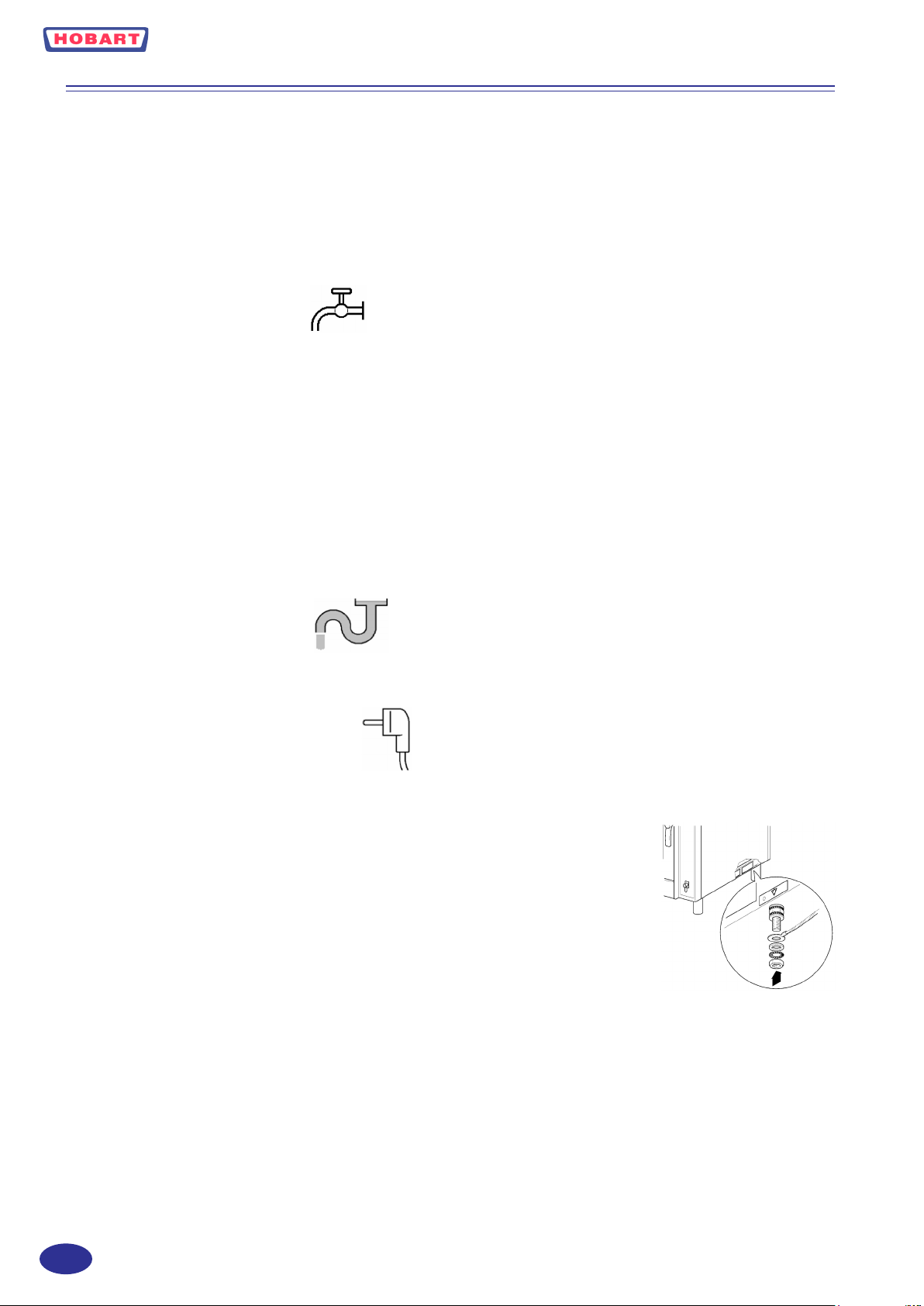

1.1 WATER CONNECTION

Must be cold, potable and softened water (hardness must be below 7 deg. Clark). Inlet water pressure must be within 2 (minimum) and 6 (maximum) bar, or equivalently within 200 and 600 kPascal. Inlet water tubing should allow a minimum flow

of 13 l/mn.

Maximum theoretical water consumption is:

- 6 level GN 1/1: 25 litres / h for steam production and 60 litres per longest cleaning cycle.

- 10 level GN 1/1: 40 litres / h for steam production and 60 litres per longest cleaning cycle.

- 10 level GN 2/1: 55 litres / h for steam production and 80 litres per longest cleaning cycle.

- 20 level GN 1/1: 70 litres / h for steam production and 80 litres per longest cleaning cycle.

- 20 level GN 2/1: 90 litres / h for steam production and 100 litres per longest cleaning cycle

Provide a suitable pressure hose ½”, B.S.P. union nut 3/4”

1.2 DRAIN CONNECTION

Must be open type and drain material must be suitable for water at a temperature up to 100° C.

Drain connection is B.S.P. 1” external thread.

1.3 ELECTRICAL CONNECTION

Should only be made by Hobart service or other authorised service agents and must be in accordance with the installation

requirements and all relevant regulations.

Connected loads are as follow:

- 6 level GN 1/1: 9 kW 3 phases + neutral + Earth

- 10 level GN 1/1: 18 kW 3 phases + neutral + Earth

- 10 level GN 2/1: 24 kW 3 phases + neutral + Earth

- 20 level GN 1/1: 36 kW 3 phases + neutral + Earth

- 20 level GN 2/1: 48 kW 400V/3 PH/N/E or 42kW 230V/3 PH/E

The oven is supplied without a power cable. The specifications of the power supply connection flexible cable must match or

be superior to those of the cable with rubber insulation H07RN-F.

The oven must be included in an equipotential system whose efficiency must be checked according to the standards in force.

The screw marked by ”Equipotential” label is near the terminal block on the base.

If installation is 400V without neutral the oven will have to be modified by a Hobart service.

Remove the right side panel to access entry bush joint and terminal blocks.

1.4 OVEN CAPACITY

Depending on the model, the oven may accommodate a maximum of 6, 10, 20 or 40 levels. Accordingly it may contain a

maximum of 24, 40, 80 or 160 kg of food.

GB

- 4 -

Page 5

ENTRY BUSH

- 5 -

GB

Page 6

2. OPERATION

2.1 GENERAL

To open the door, rotate the handle to horizontal position: door switch will be deactivated.

To close the door, ensure that the handle is horizontal, shut the door, lock the handle in vertical position: door switch is activated.

PROTECTION GRID

GASKET

SHELVES

CONTROL PANEL

DRAIN FILTER

DRIP TRAYS

The drain filter must always be in place. Lateral shelves are removable for cleaning. The protection grid covering fan and

heating elements must always be in place for safety and air flow distribution. It is removable for cleaning. The drip trays

will receive and evacuate water drops during door openings.

GB

- 6 -

Page 7

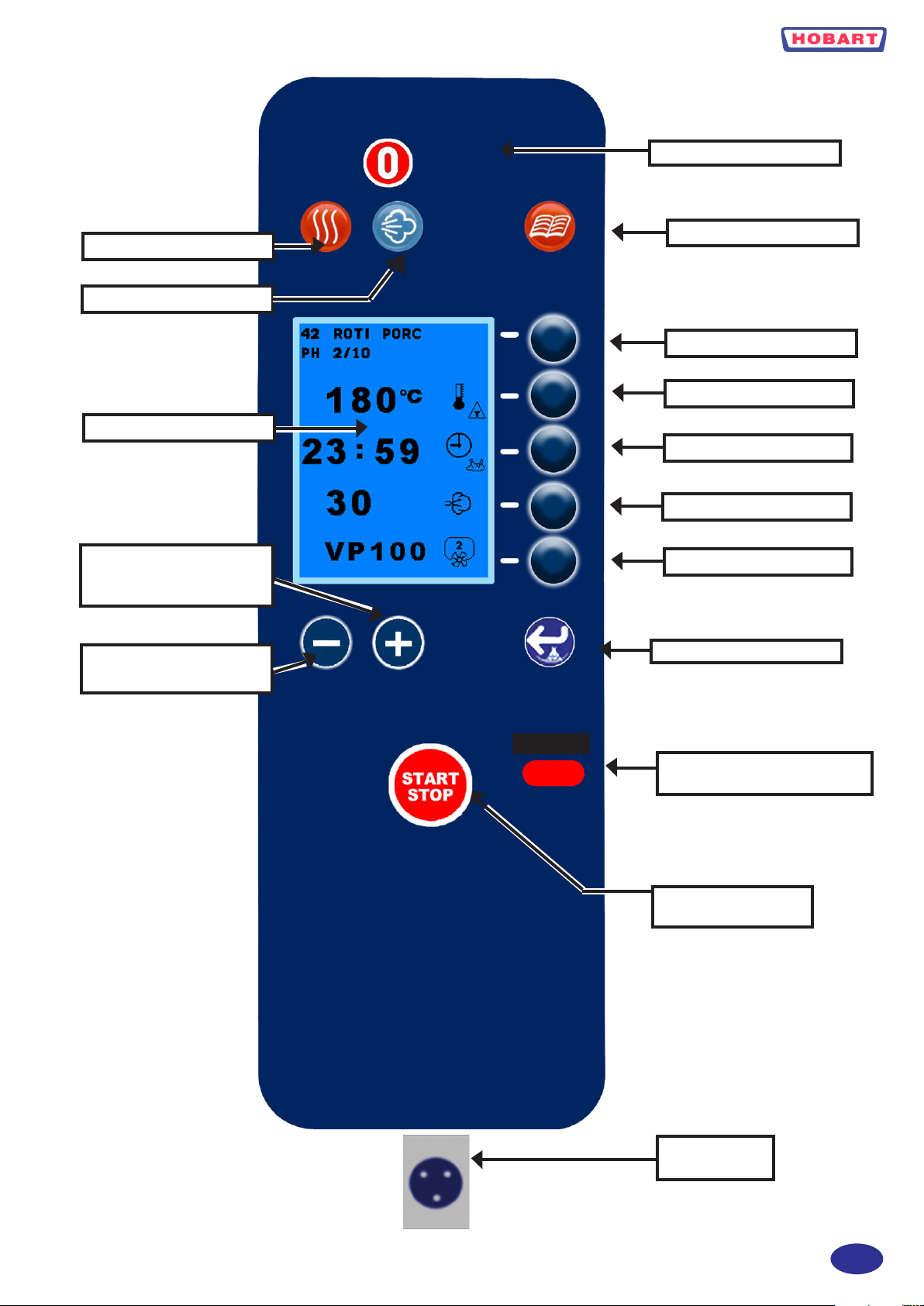

2.2 CONTROL PANEL

ON/OFF SWITCH

CONVECTION : ON/OFF

STEAM : ON/OFF

DISPLAY

PLUS KEY +

SCROLL DOWN

MINUS KEY +

SCROLL UP

PROGRAM

SELECTION LINE 1

SELECTION LINE 2

SELECTION LINE 3

SELECTION LINE 4

SELECTION LINE 5

HUMIDIFYER + ENTER

INFRARED COMMUNICATION

WINDOW

START / STOP

COOKING CYCLES

CORE PROBE

CONNECTOR

- 7 -

GB

Page 8

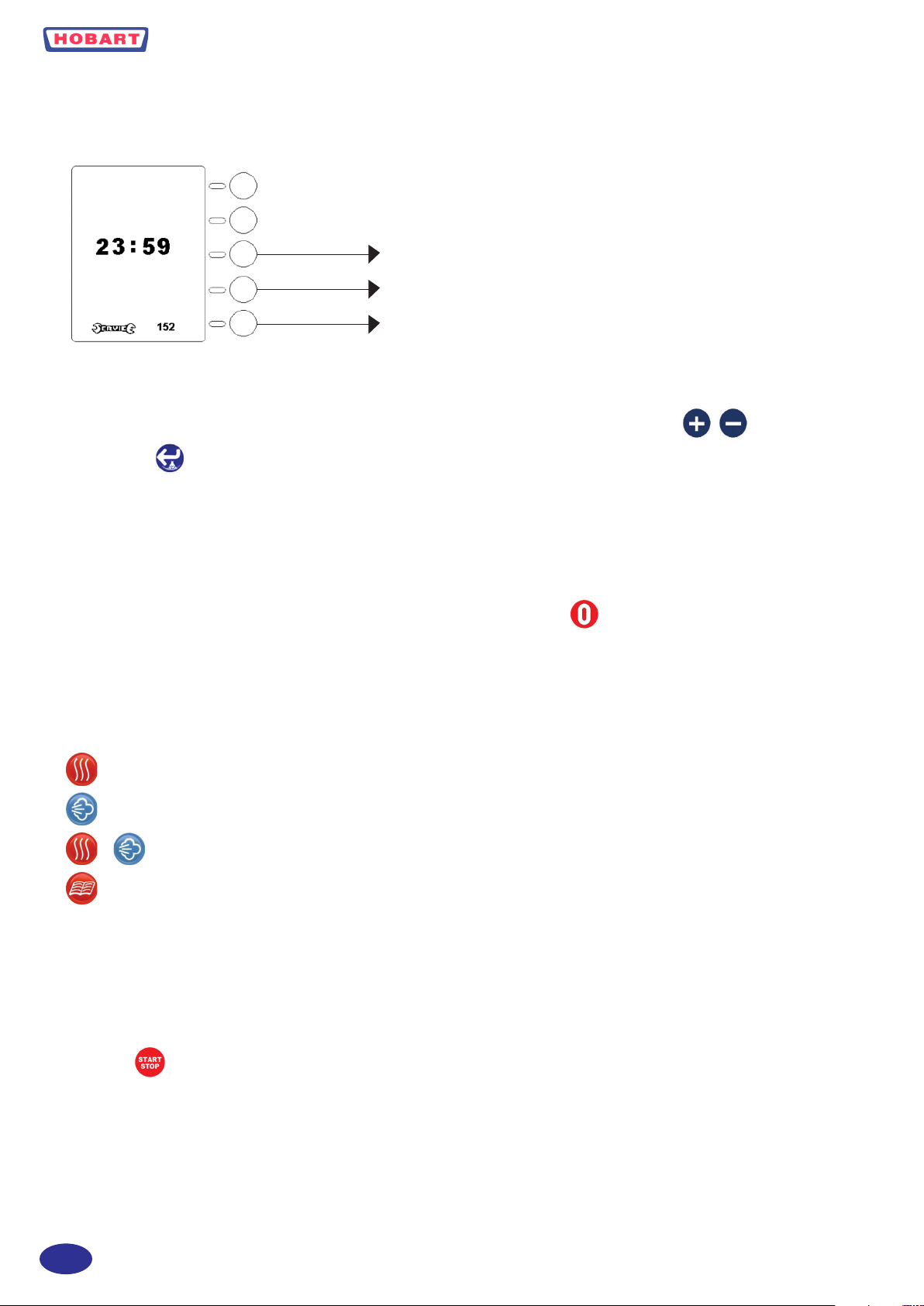

2.2.1 MACHINE CONNECTED TO ELECTRICAL SUPPLY:

When machine is electrically powered, the screen will illuminate and indicate actual time and time left before next descaling

or next service review:

TIME ADJUSTMENT

CHOICE 24h or 12h AM/PM

RESET SERVICE or DELIMING COUNTER

2.2.1.1 TIME AND DATE ADJUSTMENT

To adjust time, press corresponding key (line 3) for 5 seconds, adjust time and date using keys then validate

with enter key .

2.2.1.2 24H OR 12H AM/PM

To switch from 24 h display to 12 h AM/PM display press corresponding key (line 4) until correct time mode is displayed.

2.2.1.3 SERVICE COUNTER

To reset service or descaling counter, press corresponding key (line 5) during 5 seconds. After 15 minutes without any action

on the control panel, the screen will switch off. It can be reactivated by pressing or by opening/closing the door.

2.2.2 START UP

Selecting a cooking mode starts up the oven. To deactivate a cooking mode press again the illuminated key.

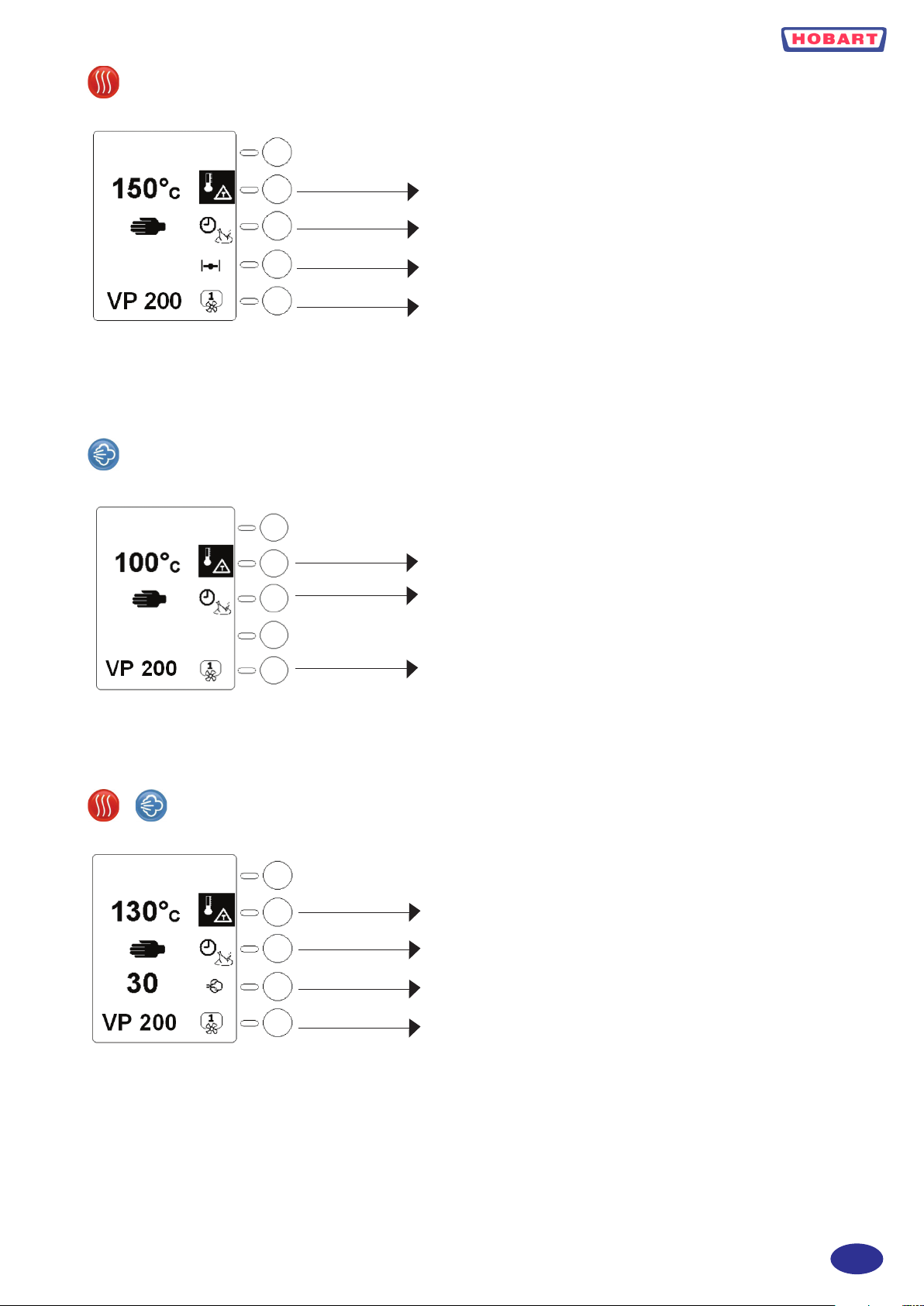

2.2.3 COOKING MODE SELECTION

CONVECTION MODE

STEAM MODE

+ COMBINATION MODE

PROGRAM MODE

After selecting one of the 3 cooking modes:

- The default temperature corresponding to the selected cooking mode is displayed during 5 seconds (inverted contrast

symbol) and is then replaced by real measured cavity temperature.

- Cavity lights are on (only if door is closed and locked).

- Selected cooking mode keys are illuminated.

- By default timer is in manual mode.

- The key starts (illuminated) or stops (off) cooking process.

- Selecting program mode will deactivate other selected cooking modes. If door is opened during a cooking process, the

cooking process will stop and restart where it was when door is closed again.

When selecting a cooking mode, the display will show the following screen:

GB

- 8 -

Page 9

CONVECTION MODE

STEAM MODE

DEFAULT TEMPERATURE DURING 5 Secs.

THEN REAL CAVITY TEMPERATURE

TIMER MANUAL MODE

VENT POSITION

FAN SPEED AND VP (option)

+ COMBINATION MODE

DEFAULT TEMPERATURE DURING 5 Secs.

THEN REAL CAVITY TEMPERATURE

TIMER MANUAL MODE

FAN SPEED AND VP (option)

DEFAULT TEMPERATURE DURING 5 Secs.

THEN REAL CAVITY TEMPERATURE

TIMER MANUAL MODE

HUMIDITY LEVEL

FAN SPEED AND VP (option)

- 9 -

GB

Page 10

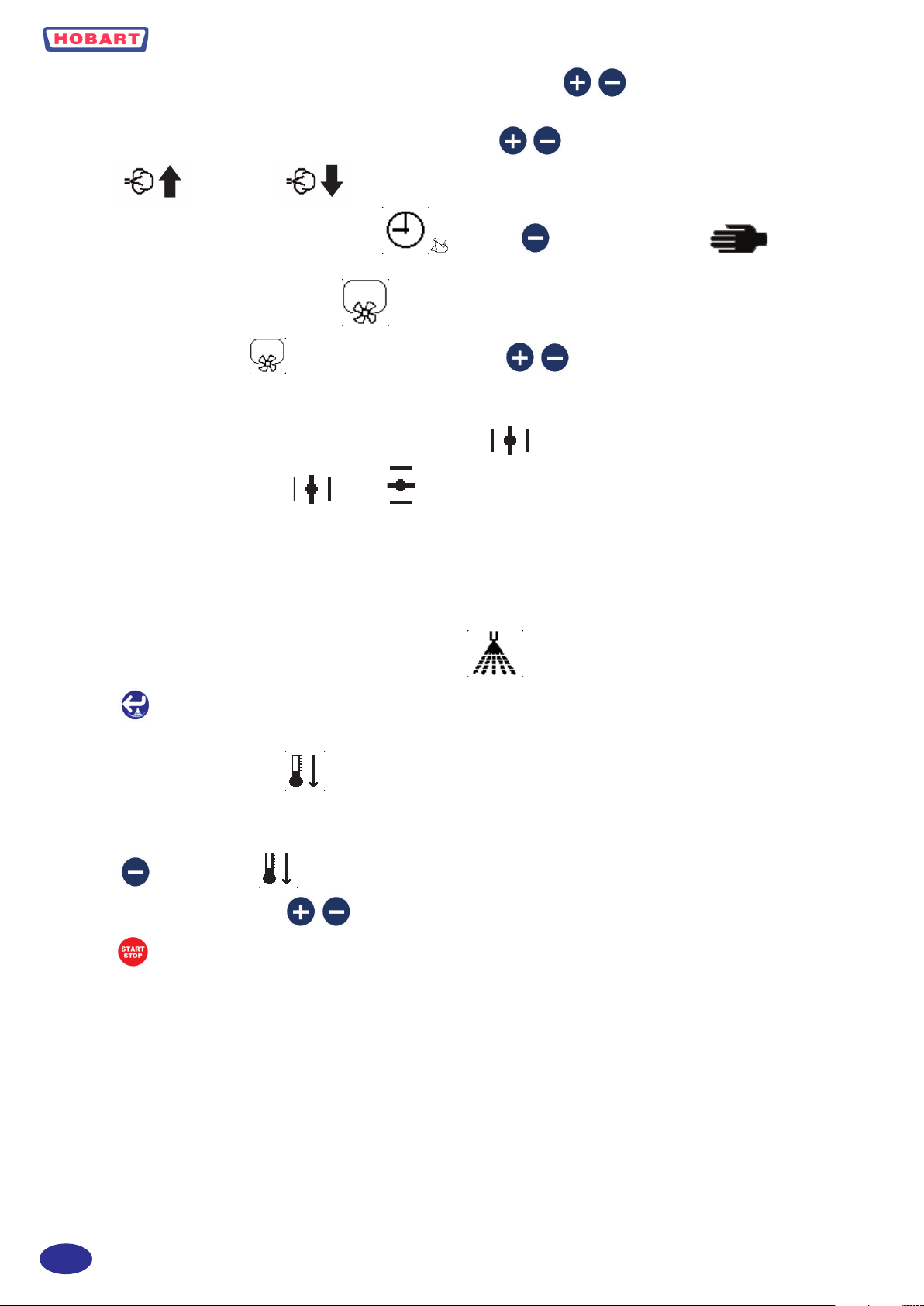

2.2.4 ADJUSTMENT OF TEMPERATURE, TIME OR HUMIDITY .

To adjust one of the above settings, select the line by pressing the corresponding key located on the right side of the screen

(inverted contrast symbol) then adjust desired value with the two keys . In combination mode the display will show

addition or evacuation of humidity. If a cooking time has been set and it is desired to come back to

manual mode (continuous cooking), select the line then press until the manual symbol appears.

2.2.5 FAN SPEED ADJUSTMENT

Select the corresponding line and adjust speed 1 to 4 using keys .

2.2.6 VENT POSITION (CONVECTION MODE ONLY)

Press the corresponding key to open or close .

IT IS NOT NECESSARY TO VALIDATE WITH THE ENTER KEY:

Values are automatically taken into account.

2.2.7 HUMIDIFYER (CONVECTION MODE ONLY)

The key allows injecting water in the cavity during cooking process.

2.2.8 FAST COOL DOWN

Whatever cooking mode has been selected, it is possible to automatically cool down the cavity by water injection in the fan:

1) Press line 3 key (timer)

2) Press until the symbol appears.

3) Adjust desired final temperature .

4) Start

Note: Choosing another mode will stop above process

GB

- 10 -

Page 11

2.2.9 CORE PROBE FUNCTION

Connect core temperature probe into connector located at bottom of control panel. Press during 5 seconds line 3 key

display indicates set core probe temperature and shows following symbol on the right side of the screen. After 5

seconds displayed temperature is real temperature measured by the probe. Adjust desired set temperature as described before.

Place probe into the centre of the food to be controlled, close and lock the door, start cooking process with key. To come

back to timer function, depress for 5 seconds line 3 key .

2.2.10 DELTA T FUNCTION

Cooking with DELTA T automatically controls the cavity cooking temperature, following the product core temperature with

a constant difference. DELTA T can be used with all three cooking modes. Press the corresponding key to line 2 for 5 seconds

the display indicates the default set temperature difference between cavity and core probe for 5 seconds. The symbol

is contrasted on the right of the screen. Core probe function is automatically activated. Adjust set points for DELTA

T and core probe temperatures as described above. Insert core probe into the centre of the food to control, close and lock the

door, press to start cooking process. To cancel DELTA T function, maintain line 2 key pressed for 5 seconds .

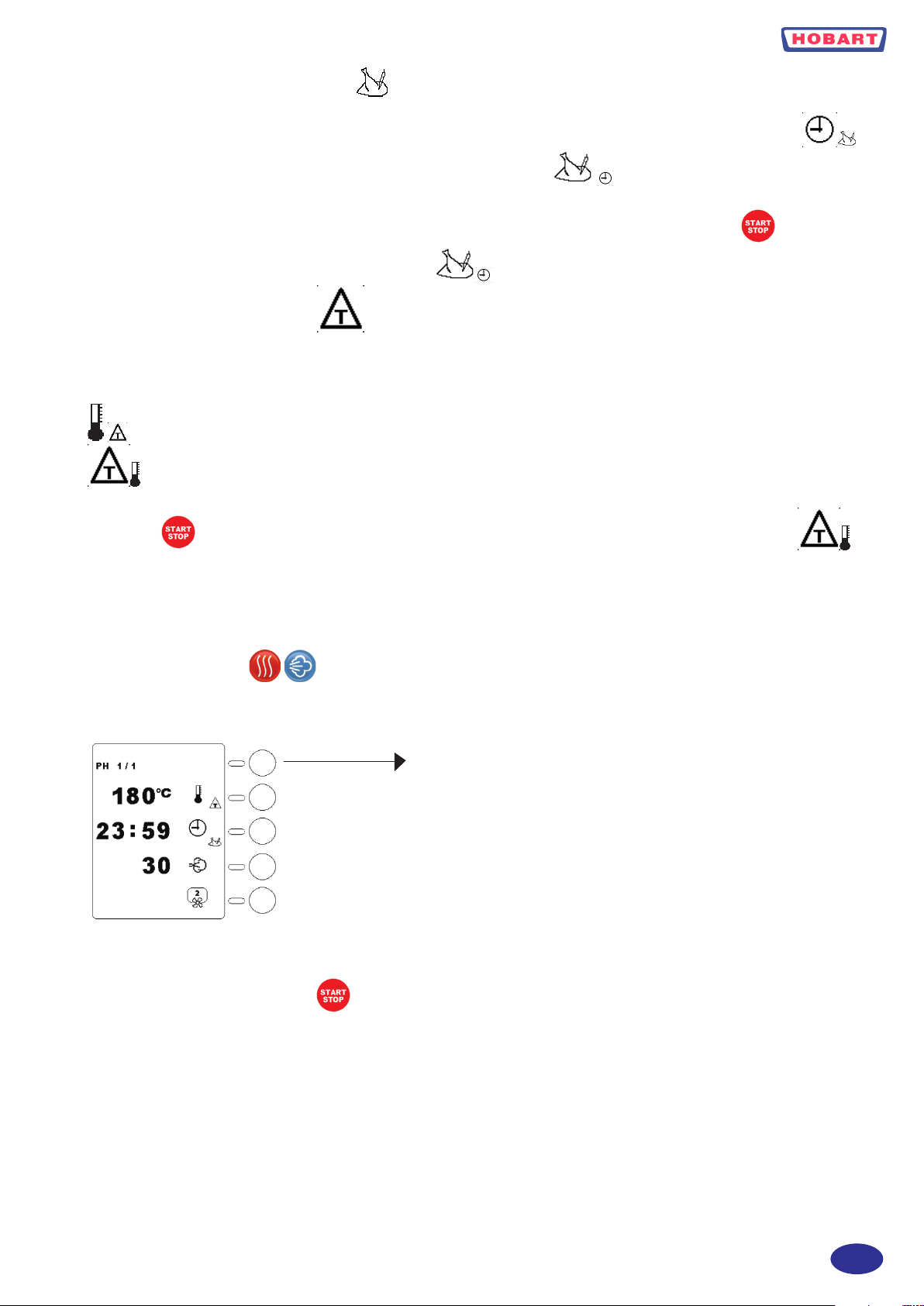

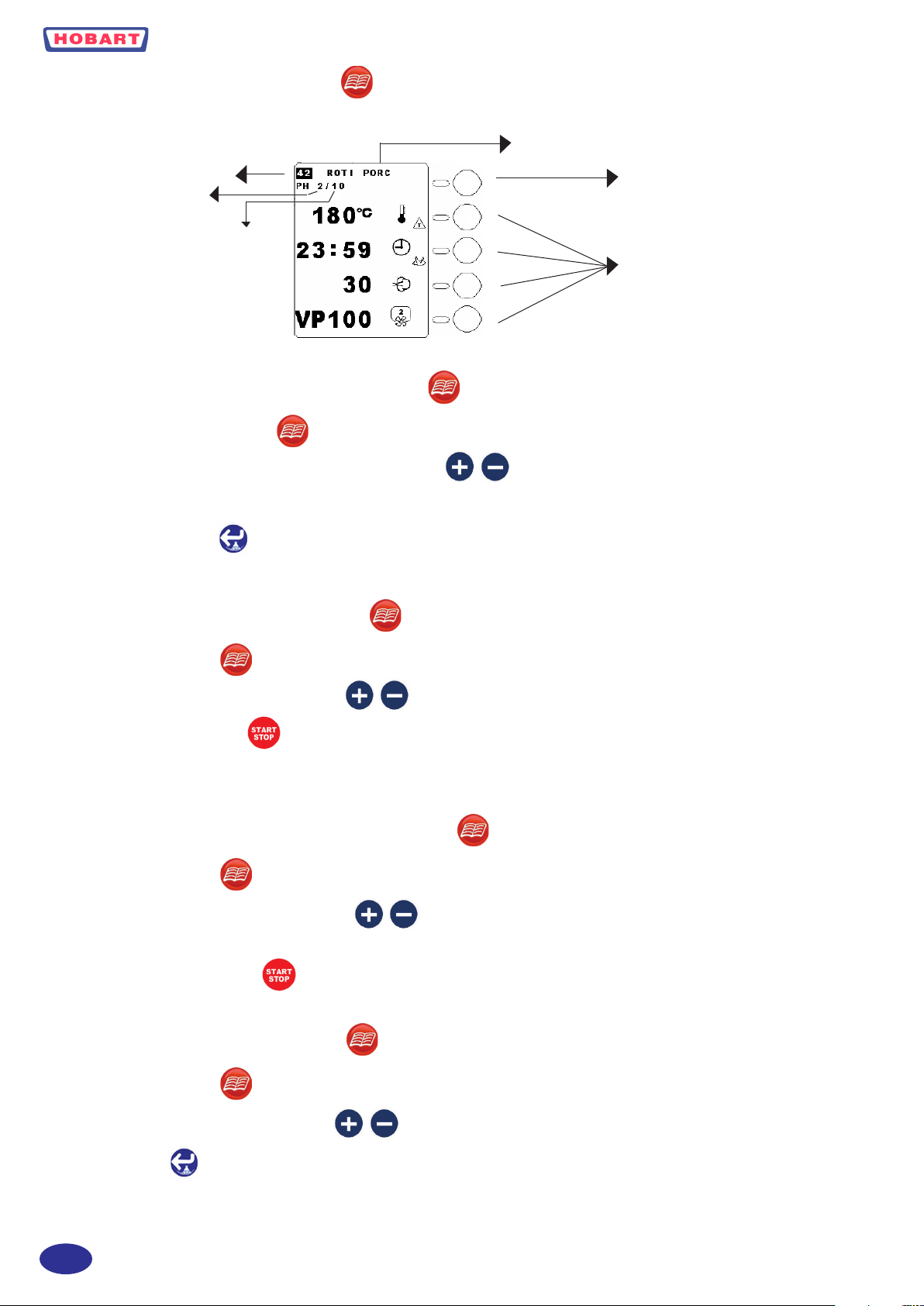

2.2.11 COOKING PHASES PH 1/10

It is possible to link up to 10 cooking phases without using the program function.

1) Select a cooking mode .

2) Adjust cooking temperature or DELTA T temperature.

3) Adjust cooking time or core probe temperature.

4) Validate first phase line1 (PH 1/1) the screen goes to next phase (PH 2/2).

PHASE VALIDATION KEY

5) Reiterate for each phase.

6) After the last phase press the phase validation key twice.

7) Start cooking process by pushing

TO ERASE ONE COOKING PHASE

When the phase to be erased is displayed press the phase validation key for 5 seconds then release.

- 11 -

GB

Page 12

2.2.12 PROGRAMME FUNCTION

It is possible to write and store up to 100 cooking programmes of 10 phases each.

PROGRAMME NAME

PROGRAMME N°

PHASE N°

NUMBER

OF PHASES

2.2.12.1 TO WRITE A COOKING PROGRAMME

1- Press programme key. The key will illuminate.

2- Select programme number under which you want to save: .

3- Write and validate all the phases of the new cooking programme. The programme number will blink to indicate that it has

not been stored yet.

4- Validate programme : Buzzer is activated and programme number will be inverted contrast in order to indicate

saving.

PHASE KEY AND FIRST LINE

SELECTION KEY

KEYS FOR LINE SELECTION OR

SPECIAL FUNCTIONS

2.2.12.2 TO EXECUTE A PROGRAMME

1- Press programme key The key will illuminate.

2- Select programme number that you want: .

3- Start cooking programme The buzzer will be activated at each phase change.

4- The display will show total remaining time until the end of cooking, unless some phases are using core probe temperature.

Pressing one of the line keys will display the corresponding set parameter for the operating phase.

2.2.12.3 TO VISUALISE A COOKING PROGRAMME

1- Press programme key The key will illuminate.

2- Select programme number to be visualised: . The screen will display the first phase of the programme. Press the

phase key (line 1) to visualise and scroll through other phases.

3- To check total time, activate (Except if one of the phases is using core probe).

2.2.12.4 TO ERASE A PROGRAMME

1- Press programme key The key will illuminate.

2- Select programme number to be erased: .

3- Maintain key pressed for 5 seconds.

GB

- 12 -

Page 13

2.2.12.5 TO MODIFY A PROGRAMME

1- Press programme key The key will illuminate.

2- Select programme number to be modified: .

3- Modify desired phases and parameters: The programme number will blink.

4- Validate new programme : The buzzer is activated and the programme number is inverted contrast to indicate sa-

ving.

Notes: You can run a modified programme before validation. In that case, validation can be done after the end of cooking. It

is not possible to insert a phase into a programme.

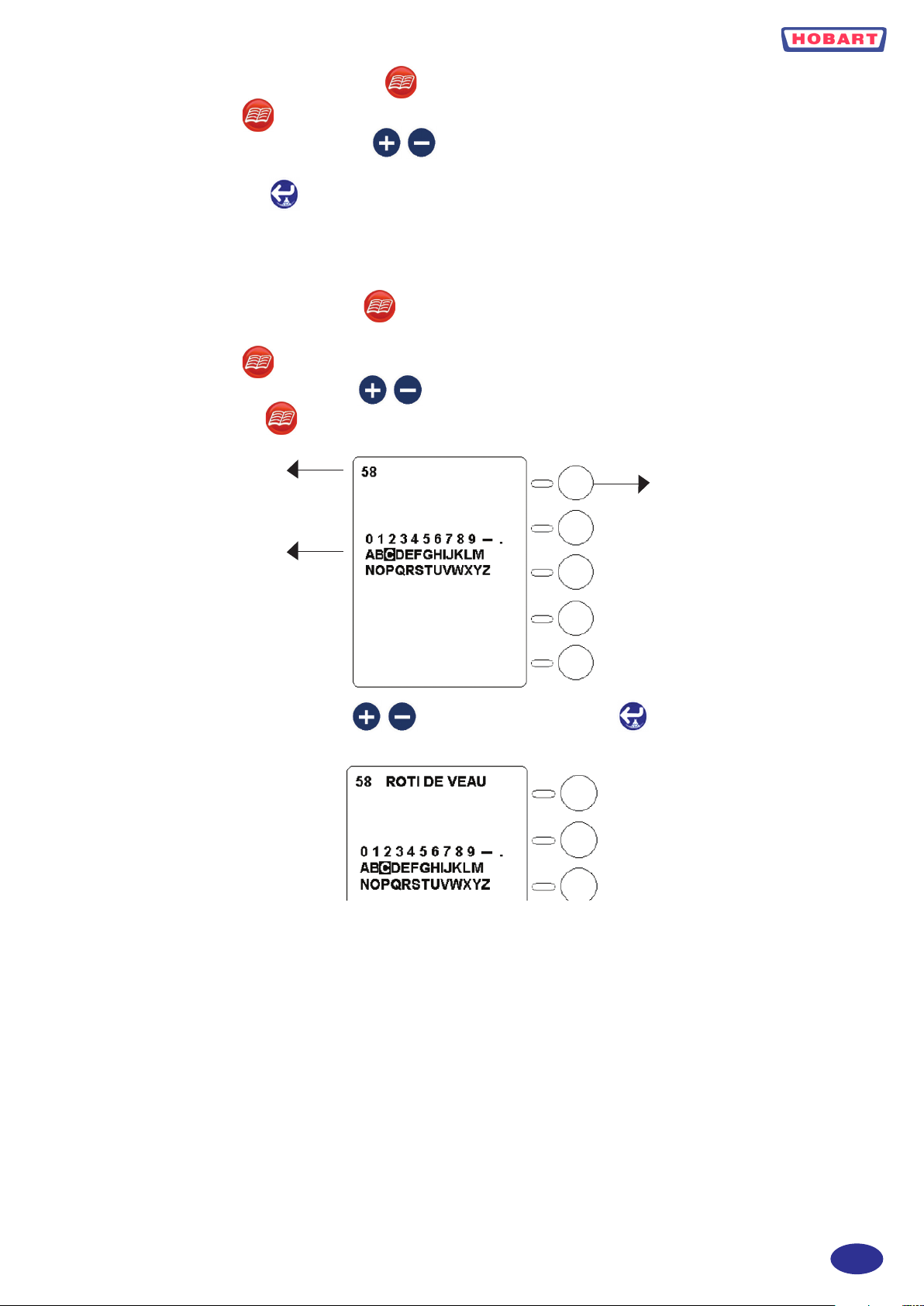

2.2.12.6 TO NAME A PROGRAMME

It is possible to associate a name with a programme number:

1- Press programme key the key will illuminate.

2- Select programme number to be named: .

3- Maintain programme key pressed during 4 seconds. The screen will display the following:

PROGRAMME NUMBER

AVAILABLE CHARACTERS

4- Select letters or numbers with the keys and validate with the enter key Selected characters will locate at

the right of the programme number:

ERASE CHARACTER KEY

- 13 -

GB

Page 14

5- At the end validate the name by pressing for 5 seconds. Programme number stops blinking and buzzer sounds. If you

wish to exit programme press programme key .

2.2.13 PARTICULAR FUNCTIONS

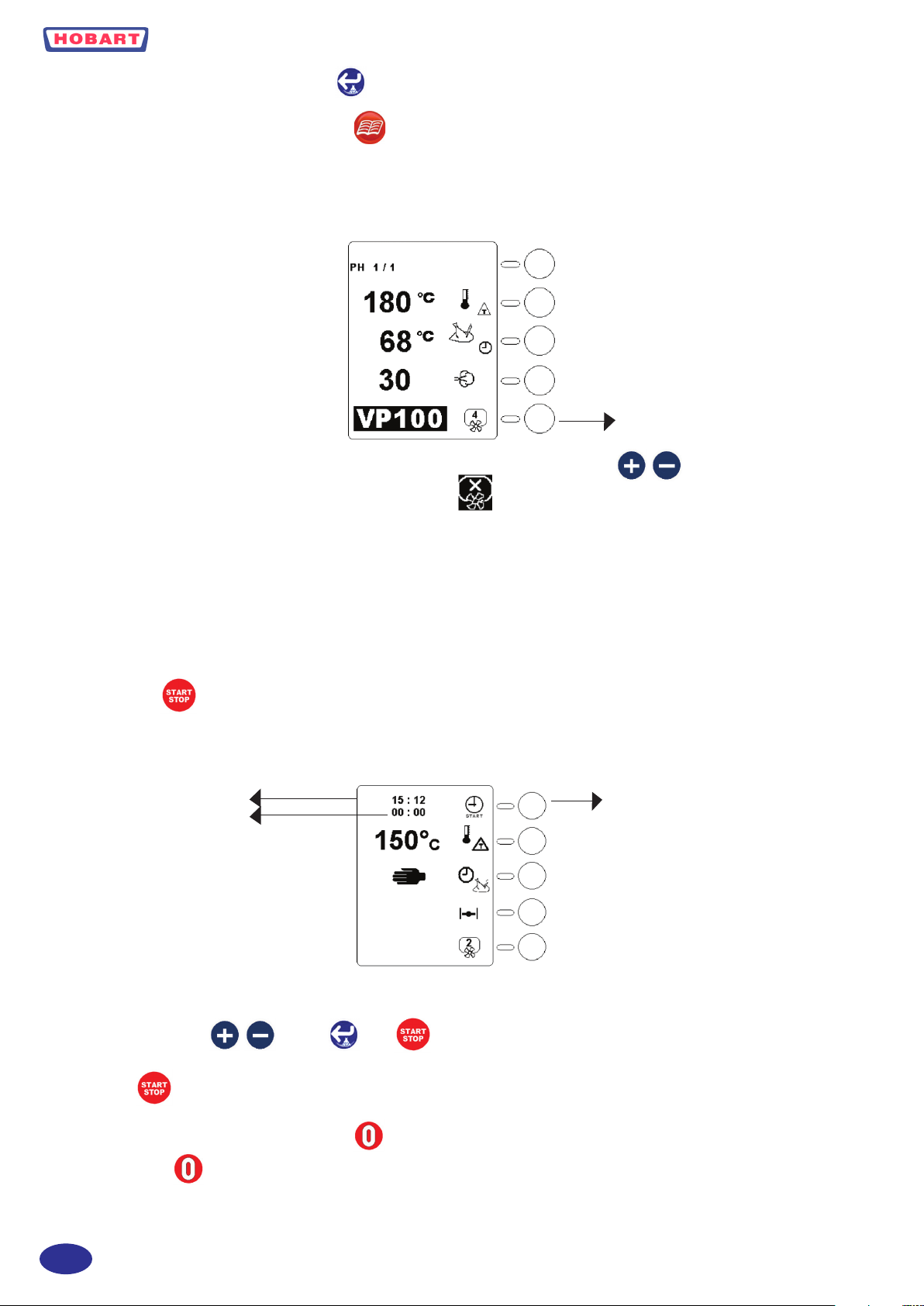

2.2.13.1 VP (PASTEURISATION VALUE) MODE (OPTION)

This function must be selected during initial configuration of the oven. It can only work when core probe is used.

VP KEY FAN SPEED KEY

Press 5 seconds the line 5 key, display of VP will contrast. Adjust desired VP using keys .

One push on line 5 key will change from VP adjustment to fan speed adjustment.

Cooking cycle will only end when set VP and set core probe temperature are reached. To deactivate VP, set VP value at 0.

2.2.13.2 OVEN PREHEATING

When you have selected a cooking mode, adjusted temperature and time or if you are using a programme, it is possible to

automatically preheat the oven at the correct cooking temperature.

In order to do so:

- Write your cooking programme or call an existing programme from the memory

- Press the key during 5 seconds.

2.2.13.3 TO PROGRAM PREHEAT START

It is possible to program the oven in order to start preheating at a given time.

ACTUAL TIME

STARTING TIME

SELECTION KEY

1- Select a cooking mode, adjust desired preheat temperature.

2- Press the selection key.

3- Adjust starting time validate start . It is possible to stop process either by selecting a cooking mode

or pushing .

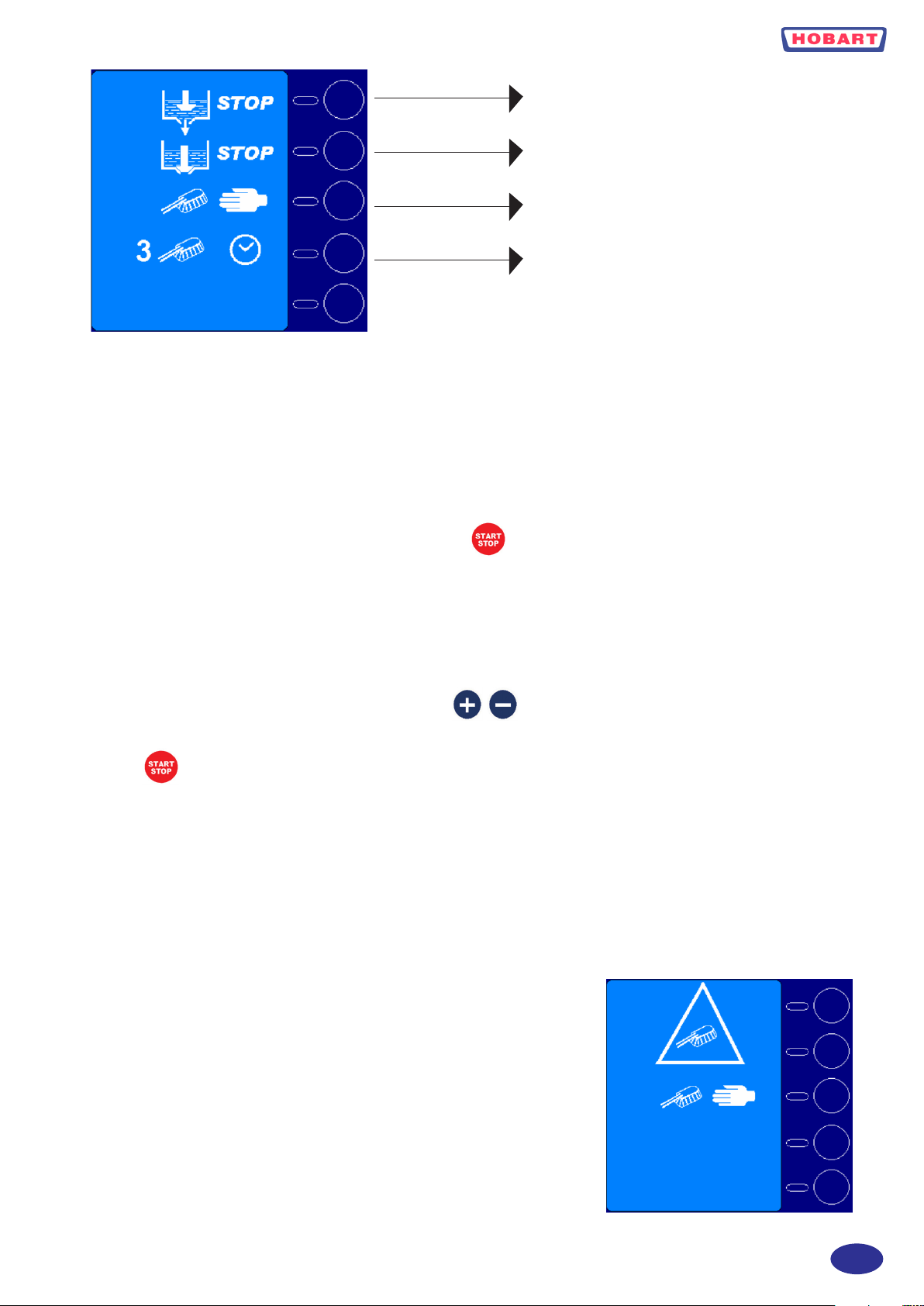

2.2.14 TO SWITCH OFF THE OVEN

Press the off key the display will be as follow:

GB

- 14 -

Page 15

STOP WITH BOILER DRAIN

STOP WITH BOILER FULL

MANUAL CLEAN CYCLE

AUTOMATIC CLEAN CYCLE

STOP WITH BOILER DRAIN

At end of the day if you do not want to carry out a cleaning cycle.

STOP WITH BOILER FULL

For a temporary stop during the day and you plan to use the oven soon there is no need to empty the boiler.

MANUAL CLEAN CYCLE

After pushing the corresponding key, start the cycle with the key. The oven will start in steam mode. A buzzer sound

will advise you to spray the entire cavity with an appropriate detergent, taking all safety measures recommended by the detergent supplier. After closing the door, the cycle will restart and end up with appropriate rinsing of the cavity, followed by a

double boiler drain.

AUTOMATIC CLEAN CYCLE

Before starting an automatic cleaning cycle, verify that you have enough detergent left in the detergent container and that the

pump tube is correctly inserted in the container. Using the keys you can change the amount of detergent (from 0

TO 8) which will be used during the cleaning cycle depending on the degree of dirtiness of your machine. Then start the cycle

with the key. Depending on the status of your machine the cleaning cycle may start with a cool down to bring the ma-

chine at the correct washing temperature.

WARNING:

That screen indicates that the cleaning cycle has not been successfully completed or has been interrupted. There may be

some detergent left in the cavity or in the boiler.

You must thoroughly rinse the cavity of the oven and carry out a double drainage of the boiler (using the STOP WITH

BOILER DRAIN PROGRAM). Or you can select and carry out the MANUAL CLEAN CYCLE.

Do not use the machine without completing one of the above.

IMPORTANT: Always wait complete end of the process before switching of water and electricity.

2.3 DAILY CLEANING AND MAINTENANCE

Remove main pieces of food, which could have fallen in the cavity before starting a cleaning cycle. Perform at least one daily cleaning cycle. Make sure that

the door gasket is clean in order to keep its longevity, wipe it out with a soft wet

cloth after cleaning cycle. Do not use abrasive pads on the glass or stainless steel

surfaces or door gasket, in case of hard to remove stains use an appropriate non

corrosive detergent. Depending on water hardness, you may have to descale the

boiler or the cavity.

To descale the boiler:

- Switch off the oven with boiler drain.

- 15 -

GB

Page 16

- Fill up the boiler with white vinegar or similar descaling product using the steam inlet at the top right hand side of the cavity.

6 level ovens: 5 litres

10 level ovens: 6 litres

20 level ovens: 10 litres

- Select steam mode without starting cycle and wait 30 to 45 minutes depending on the strength of the descaling product.

- Switch off the oven with boiler drain.

- Select steam mode again without starting cycle to rinse the boiler.

- End up with a cleaning cycle.

To descale the cavity:

-Spray on all parts of the cavity a descaling product and let react according to the manufacturer specifications.

-End up with a cleaning cycle.

2.4 AUTODIAGNOSTICS

The microprocessor of your oven constantly checks the proper functioning of the machine, and advises you by a symbol

located on the bottom right of the screen of possible faults on the oven. That symbol appears in place of the fan speed

symbol. Faults are numbered and the corresponding number will be displayed in the screen:

0 Electronic components overheat (CPU)

1 Cavity overheat

2 Boiler overheat

3 Cavity probe fault

4 Vent probe fault

5 Condensates probe fault

6 Boiler probe fault

7 Core probe fault or not connected

8 Fan motor fault

9 Lack of water in the boiler

10 Building energy optimisation system in action

11 Static relays overheat

Notes:

Faults must be corrected otherwise they will be displayed each time a function using the faulty component is selected.

The fault display stays on if the corresponding mode or function cannot be used. Select another mode or function.

The five last faults are memorised and dated.

If a fault occurs during a cooking programme, that programme will stop.

16 If a fault is displayed before starting a programme, it will not be possible to activate that programme.

GB

- 16 -

Page 17

TEMPORARY OPERATION OF THE OVEN IN CASE OF FAULTS

These functions are only here to help you finish your work in case of faulty component. Call your service technician

for repair. Do not use constantly the oven under these functions.

CONVECTION MODE: If the cavity probe is faulty stop the oven and then press the convection key for 10 seconds

. Temperature will be regulated at around 160°C by the core probe, which must be inserted into the cavity and attached

to one of the shelf.

STEAM MODE: If the boiler is faulty, stop the oven . Press steam key for 10 seconds . Steam will be produced by

water injection in the fan at around 100°C. In both of these modes, it is not possible to adjust temperature or select a cooking

time you can only start or stop the cooking cycle by pressing to exit these modes and return to standard modes press

.

- 17 -

GB

Page 18

SOmmAIRE

CHAPITRE DESCRIPTION PAGE

Remarques ...................................................................................................................................... 19

1. Installation .......................................................................................................................................... 20

1.1 Raccordement hydraulique ................................................................................................................. 20

1.2 Raccordement du tuyau de vidange .................................................................................................... 20

1.3 Branchement électrique ...................................................................................................................... 20

1.4 Capacité four ....................................................................................................................................... 20

2. Fonctionnement ................................................................................................................................... 22

2.1 Généralités .......................................................................................................................................... 22

2.2 Panneau de contrôle ............................................................................................................................ 23

2.2.1 Machine branchée a l’alimentation électrique ................................................................................... 24

2.2.1.1 Réglage de l’heure .............................................................................................................................. 24

2.2.1.2 Sélection 24 h ou 12h am/pm .............................................................................................................. 24

2.2.1.3 Compteur d’entretien .......................................................................................................................... 24

2.2.2 Allumage du four ................................................................................................................................. 24

2.2.3 Sélection d’un mode de cuisson .......................................................................................................... 24

2.2.4 Réglage de la température, temps de cuisson ou humidité ................................................................. 26

2.2.5 Réglage de la vitesse de la turbine ...................................................................................................... 26

2.2.6 Position oura (en mode convection seulement) ................................................................................... 26

2.2.7 Humidificateur (en mode convection seulement) ................................................................................ 26

2.2.8 Baisse rapide de la température dans l’enceinte ................................................................................. 26

2.2.9 Fonction sonde à cœur ........................................................................................................................ 27

2.2.10 Fonction Delta T ................................................................................................................................. 27

2.2.11 Phases de cuisson PH 1/10 ................................................................................................................. 27

2.2.12 Fonction programme ........................................................................................................................... 28

2.2.12.1 Enregistrement d’un programme ......................................................................................................... 28

2.2.12.2 Exécution d’un programme ................................................................................................................. 28

2.2.12.3 Affichage d’un programme .................................................................................................................. 28

2.2.12.4 Effacement d’un programme ............................................................................................................... 28

2.2.12.5 Modification d’un programme ............................................................................................................ 29

2.2.12.6 Appellation d’un programme .............................................................................................................. 29

2.2.13 Fonctions particulières ........................................................................................................................ 30

2.2.13.1 Mode VP (valeur de pasteurisation) (option) ..................................................................................... 30

2.2.13.2 Préchauffage du four ........................................................................................................................... 30

2.2.13.3 Programme du préchauffage ............................................................................................................... 30

2.2.14 Arrêt du four ........................................................................................................................................ 31

2.3 Nettoyage quotidien et entretien ......................................................................................................... 32

2.4 Autodiagnostic .................................................................................................................................... 32

Schémas d’installation ........................................................................................................................ 50

F

- 18 -

Page 19

REmARQUES

L’émission sonore de la machine est inférieure à 70 dB (A).

Consignes d’utilisation

- Utiliser le four conformément aux instructions contenues dans ce manuel.

Les fours mixtes à convection et vapeur ne sont adaptés que pour la cuisson, le rôtissage, le gratinage, la cuisson

à la vapeur et à l’étouffée d’aliments destinés à la consommation.

- Sécurité

Il est interdit de nettoyer le four avec un jet d’eau ou un nettoyeur haute pression. Le pictogramme «danger »

veut attirer l’attention du lecteur sur des consignes importantes pour un fonctionnement en toute sûreté du

four. Ces consignes doivent être lues avec beaucoup d’attention.

- Responsabilité

Une erreur d’installation, une réparation non effectuée par le personnel Hobart ou un centre SAV agréé, ainsi

que toute modication non autorisée par le fabricant rend la garantie caduque.

Toutes les méthodes, durées et temps de cuisson reportés dans ce manuel sont donnés à titre d’exemple et

dépendent de la qualité des aliments à cuire.

Le fabricant décline toute responsabilité en cas de dégâts corporels ou matériels provoqués par le non-respect des

instructions reportées dans ce manuel.

LE FABRICANT DECLINE AUSSI TOUTE RESPONSABILITE EN CAS DE DEGATS CORPORELS OU MATERIELS

PROVOQUES PAR UNE ERREUR D’INTERPRETATION OU DES ERREURS D’IMPRESSION DE CE MANUEL. LE

FABRICANT SE RESERVE LE DROIT D’APPORTER TOUTES LES MODIFICATIONS QU’IL JUGERA UTILES, SANS

INFLUER SUR LES CARACTÉRISTIQUES DE BASE DU PRODUIT.

- 19 -

F

Page 20

1. INSTALLATION

Avant de déballer le four, vérifier l’état du colis. En présence de dégâts apparents, veuillez adresser les réclamations d’usage

au transporteur.

OUVERTURE DROITE / GAUCHE DE LA PORTE : Le four est généralement livré avec la porte s’ouvrant par la gauche.

Les clients qui souhaitent une ouverture à droite de la porte doivent le préciser au moment de la commande.

Le four doit être installé et branché conformément à la législation locale en la matière.

Le four doit être installé sur un support ou un plancher de niveau. Vérifier la mise à niveau du four avec un niveau à bulle, en

prenant le sommet du four comme point de repère.

1.1 RACCORDEMENT HYDRAULIQUE

Le four doit être raccordé à un réseau d’eau froide, potable et adoucie (la dureté doit être inférieure à 7° français). Le réseau

d’eau doit avoir une pression entre 2 (minimum) and 6 (maximum) bars, ou également entre 200 et 600 kPascal. Le réseau

d’eau doit ainsi garantir un débit minimum de 13 l/mn.

La consommation d’eau maximale théorique est de :

- GN 1/1 à 6 niveaux : 25 l/h pour la production de vapeur et 60 litres pour le cycle de nettoyage le plus long.

- GN 1/1 à 10 niveaux : 40 l/h pour la production de vapeur et 60 litres pour le cycle de nettoyage le plus long.

- GN 1/1 à 10 niveaux : 55 l/h pour la production de vapeur et 80 litres pour le cycle de nettoyage le plus long.

- GN 1/1 à 20 niveaux : 70 l/h pour la production de vapeur et 80 litres pour le cycle de nettoyage le plus long.

- GN 1/1 à 20 niveaux : 90 l/h pour la production de vapeur et 100 litres pour le cycle de nettoyage le plus long.

Prévoir un flexible rèsistant à la pression, de diamètre intérieur d’1/2”, d’une longueur adéquate et muni de raccords femelles

de jonction B.S.P. 3/4”.

1.2 RACCORDEMENT DU TUYAU DE VIDANGE

Le raccordement doit être de type ouvert et sa composition doit être adaptée à de l’eau pouvant atteindre une température

jusqu’à 100°C. Le raccord du tuyau de vidange est B.S.P. 1” màle.

1.3 BRANCHEMENT ÉLECTRIQUE

Le branchement électrique doit être effectué par le personnel du fabricant ou par d’autres électriciens agréés, et doit être

conforme à toutes les exigences d’installation et à toutes les normes en vigueur en matière.

Les puissances installèes sont les suivantes :

- GN 1/1 à 6 niveaux : 9 kW 3 phases + neutre + Terre

- GN 1/1 à 10 niveaux : 18 kW 3 phases + neutre + Terre

- GN 2/1 à 10 niveaux : 24 kW 3 phases + neutre + Terre

- GN 1/1 à 20 niveaux : 36 kW 3 phases + neutre + Terre

- GN 2/1 à 20 niveaux : 48 kW 400V/3 PH/N/T ou 42kW 230V/3 PH/T

L’appareil est livré sans câble d’alimentation. Le flexible pour le branchement à la ligne électrique doit être conforme au

flexible modèle H07RN-F.

L’appareil doit être inclus dans un système équipotentiel dont le fonctionnement doit être vérifié conformément à la

réglementation en vigueur. La vis marquée avec l’étiquette “Equipotentiel” se trouve à côté du bornier sur la base.

Si l’installation est en 400V et n’a pas de neutre, le four doit être modifié par le personnel du fabricant Hobart. Démonter le

panneau de droite pour accéder au presse étoupe d’entrée et au bornier.

1.4 CAPACITÉ FOUR

Selon le model, le four peut loger 6, 10, 20 ou 40 niveaux. En conséquence il peut contenir un maximum de 24, 40, 80 ou

160 kg de nourriture.

F

- 20 -

Page 21

PRESSE ÉTOUPE

- 21 -

F

Page 22

2. FONCTIONNEmENT

2.1 GÉNÉRALITÉS

Pour ouvrir la porte, tourner la poignée à l’horizontale, ce qui provoquera le déverrouillage de la porte.

Pour refermer la porte, vérifier si la poignée est à l’horizontale, refermer la porte et bloquer la poignée en position verticale,

ce qui provoquera le verrouillage de la porte.

GRILLE DE PROTECTION

JOINT

GLISSIÉRES

PANNEAU DE CONTRÔLE

FILTRE DE VIDANGE

ÉGOUTTOIR PORTE

Le filtre de vidange doit toujours être installé dans sa position. Les glissières latérales sont amovibles pour faciliter leur nettoyage. La grille de protection, qui couvre la turbine et les résistances, doit toujours être installée dans sa position pour des

raisons de sécurité et pour une distribution homogène du flux d’air. Elle peut être démontée pour son nettoyage. L’égouttoir

de la porte recueille et élimine les gouttes d’eau lorsque la porte est fermée, tandis que l’égouttoir du four recueille et élimine

les gouttes dans toutes les situations.

F

- 22 -

Page 23

2.2 PANNEAU DE CONTRÔLE

TOUCHE ARRET

CONVECTION :M / A

VAPEUR : M / A

AFFICHEUR

TOUCHE +

DÉROULEMENT VERS LE

BAS DE L’ÉCRAN

TOUCHE -

DÉROULEMENT VERS LE

HAUT

PROGRAMME

LIGNE DE SÉLECTION 1

LIGNE DE SÉLECTION 2

LIGNE DE SÉLECTION 3

LIGNE DE SÉLECTION 4

LIGNE DE SÉLECTION 5

HUMIDIFICATEUR OU

VALIDATION

FENÊTRE DE COMMUNICATION

A INFRAROUGES

MARCHE / ARRÊT

CYCLES

DE CUISSON

CONNECTEUR

SONDE À CŒUR

- 23 -

F

Page 24

2.2.1 MACHINE BRANCHÉE A L’ALIMENTATION ÉLECTRIQUE :

Une fois que la machine est alimentée, l’écran s’allume et affiche l’heure et le temps qui doit s’écouler avant le prochain

détartrage ou la prochaine révision :

RÉGLAGE DE L’HEURE

SÉLECTION 24 h OU 12h AM/PM

REINITIALISATION COMPTEUR DE DETARTRAGE OU

D’ENTRETIEN

2.2.1.1 RÉGLAGE DATE ET HEURE

Pour régler l’heure, appuyer sur la touche correspondante (ligne 3) pendant 5 secondes, régler l’heure et la date avec les

touches, puis confirmer avec la touche Enter .

2.2.1.2 24H OU 12H AM/PM

Pour passer de l’affichage à 24 h à celui de 12 h AM/PM, appuyer sur la touche correspondante (ligne 4) jusqu’à ce que la

modalité sélectionnée s’affiche.

2.2.1.3 COMPTEUR D’ENTRETIEN

Pour effacer le compteur d’entretien ou de détartrage, appuyer sur la touche correspondante (ligne 5) pendant 5 secondes. Si

aucune fonction n’est activée pendant 15 minutes, l’écran du panneau de contrôle s’éteint. Pour le rallumer, il suffit d’ouvrir

ou de fermer la porte ou d’appuyer sur .

2.2.2 MISE EN ROUTE DU FOUR

Sélectionner un mode de cuisson, pour desactiver le mode sélectionné appuyer de nouveau sur la touche.

2.2.3 SÉLECTION DU MODE DE CUISSON

MODE CONVECTION

MODE VAPEUR

+ MODE MIXTE

MODE PROGRAMME

Après avoir sélectionné un des 3 modes de cuisson :

- La température préétablie correspondant au mode de cuisson sélectionné s’affiche pendant 5 secondes, remplacée

ensuite par la température réelle de l’enceinte.

- L’enceinte de cuisson est éclairée (mais seulement si la porte est fermée et verrouillée).

- Les touches des modes de cuisson sélectionnés s’allument.

- Implicitement la minuterie est en mode manuel.

- La touche met en marche (allumée) ou arrête (éteinte) le processus de cuisson.

- La sélection du mode programme désactive les autres modes de cuisson sélectionnés. En cas d’ouverture de la porte pendant

la cuisson, le four s’arrête immédiatement pour reprendre du point où il s’était arrêté dès que la porte a été refermée.

F

- 24 -

Page 25

Après avoir sélectionné un mode de cuisson, l’écran affiche les données suivantes :

MODE CONVECTION

TEMPÉRATURE DE CONSIGNE PENDANT 5 sec.

PUIS TEMPÉRATURE RÉELLE DE L’ENCEINTE

MODE MANUEL / MINUTERIE / SONDE A COEUR

POSITION DE L’OURA

VITESSE TURBINE / VALEUR PASTEURISATRICE (option)

MODE VAPEUR

+ MODE MIXTE

TEMPÉRATURE DE CONSIGNE PENDANT 5 sec.

PUIS TEMPÉRATURE RÉELLE DE L’ENCEINTE

MODE MANUEL / MINUTERIE / SONDE A COEUR

VITESSE TURBINE / VALEUR PASTEURISATRICE (option)

TEMPÉRATURE DE CONSIGNE PENDANT 5 sec.

PUIS TEMPÉRATURE RÉELLE DE L’ENCEINTE

MODE MANUEL / MINUTERIE / SONDE A COEUR

NIVEAU HUMIDITÉ

VITESSE TURBINE / VALEUR PASTEURISATRICE (option)

- 25 -

F

Page 26

2.2.4 RÉGLAGE DE LA TEMPÉRATURE, TEMPS DE CUISSON OU HUMIDITÉ .

Pour régler une des fonctions ci-dessus, sélectionner la ligne en appuyant sur la touche correspondante sur le côté droit

de l’écran (symbole en négatif), puis entrer la valeur souhaitée avec les deux touches . En mode mixte, l’écran

affichera adjonction ou élimination d’humidité. Si un temps de cuisson a été programmé et l’on

souhaite revenir au mode manuel (cuisson continue), selectionner la ligne et appuyer sur jusqu’à ce que

le symbole manuel s’affiche.

2.2.5 RÉGLAGE DE LA VITESSE DE LA TURBINE

Sélectionner la ligne correspondante et régler la vitesse de 1 à 4 avec les touches .

2.2.6 POSITION DE L’OURA (EN MODE CONVECTION SEULEMENT)

Appuyer sur la touche correspondante pour ouvrir ou fermer .

IL N’EST PAS NÉCESSAIRE DE CONFIRMER AVEC LA TOUCHE VALIDATION

car les paramètres sont mis au point automatiquement.

2.2.7 HUMIDIFICATEUR (EN MODE CONVECTION SEULEMENT)

La touche permet d’introduire de l’eau dans l’enceinte pendant la cuisson.

2.2.8 REFROIDISSEMENT RAPIDE DE LA TEMPÉRATURE DANS L’ENCEINTE

Quel que soit le mode de cuisson sélectionné, il est possible de refroidir rapidement l’enceinte de cuisson en injectant de l’eau

froide et à une pression préétablie dans la turbine :

1) Appuyer sur la touche de la ligne 3 (minuterie) en manuel.

2) Appuyer sur jusqu’à ce que le symbole s’affiche.

3) Régler la température finale souhaitée .

4) Mettre en route .

Note : la sélection d’un autre mode arrêtera le processus sélectionné au-dessus.

F

- 26 -

Page 27

2.2.9 FONCTION SONDE À CŒUR

Brancher la sonde de température à cœur au connecteur situé au bas du panneau de contrôle. Appuyer pendant 5 secondes sur

la touche de la ligne 3. l’écran affiche la température de la sonde à cœur programmée ainsi que le symbole suivant

à la droite de l’écran. Après 5 secondes, l’écran affiche la température actuelle de la sonde. Régler la température souhaitée

comme décrit plus haut. Enfoncer la sonde au milieu de l’aliment à contrôler, fermer et verrouiller la porte et mettre en

route le processus de cuisson avec la touche . Pour revenir à la fonction minuterie, appuyer pendant 5 secondes sur

la touche de la ligne 3.

2.2.10 FONCTION DELTA T

La fonction DELTA T contrôle automatiquement la température de l’enceinte en suivant la température au cœur de l’aliment

et en l’ajustant constamment. La fonction DELTA T peut être utilisée avec les trois modes. Appuyer pendant 5 secondes sur

la touche de la ligne 2. l’écran affiche la différence de température préétablie programmée entre l’enceinte et la sonde

à cœur pendant 5 secondes. Le symbole s’affiche à la droite de l’écran. La fonction sonde à cœur s’active automatiquement. Entrer les paramètres de la températures DELTA T et sonde à cœur comme décrit ci-dessus. Enfoncer la sonde au

milieu de l’aliment à contrôler, fermer la porte, appuyer sur pour mettre en route la cuisson. Pour annuler la fonction

DELTA T, appuyer sur la touche de la ligne 2 pendant 5 secondes. .

2.2.11 PHASES DE CUISSON PH 1/10

Il est possible de mettre au point jusqu’à 10 phases de cuisson.

1) Sélectionner un mode de cuisson. .

2) Régler la température de cuisson ou la température DELTA T.

3) Régler le temps de cuisson ou sélectionner la fonction sonde à cœur.

4) Confirmer la première phase sur la ligne 1 (PH 1/1) ; l’écran passe à la deuxième phase (PH 2/2).

TOUCHE CONFIRMATION PHASE

5) Répéter les mêmes opérations pour chaque phase.

6) Après la dernière phase, appuyer deux fois sur la touche de confirmation de phase.

7) Mettre en route la cuisson en appuyant sur

POUR EFFACER UNE PHASE DE CUISSON

Lorsque la phase à effacer est affichée, appuyer sur la touche de confirmation de la phase pendant 5 secondes, puis relâcher.

Un signal sonore confirme l’effacement.

- 27 -

F

Page 28

2.2.12 FONCTION PROGRAMME

Il est possible d’entrer et de stocker jusqu’à 100 programmes de cuisson de 10 phases chacun.

NOM DU PROGRAMME

N° PROGRAMME

N° PHASE

TOUCHE PHASE ET TOUCHE DE

SÉLECTION PREMIÈRE LIGNE

NOMBRE DE

PHASES

SÉLECTION LIGNES OU FONCTIONS

2.2.12.1 ENREGISTREMENT D’UN PROGRAMME DE CUISSON

1- Appuyer sur la touche programme. La touche s’illumine.

2- Sélectionner le numéro de programme sous lequel on souhaite enregistrer. .

3- Entrer et confirmer toutes les phases du nouveau programme de cuisson. Le numéro du programme clignotera pour indiquer

qu’il n’a pas encore été enregistré.

4- Confirmer le programme : Le buzzer sonnera et le numéro du programme s’affichera en négatif pour indiquer qu’il

a été enregistré.

2.2.12.2 EXÉCUTION D’UN PROGRAMME

1- Appuyer sur la touche programme. La touche s’illumine.

TOUCHES DE

SPÉCIALES

2- Sélectionner le numéro de programme souhaité: .

3- L’écran affichera le temps qui reste jusqu’à la fin de la cuisson, à moins que certaines phases ne prévoient l’utilisation de

la température de la sonde à cœur. La pression d’une des touches de ligne affichera le paramètre correspondant qui a été

mis en consigne pour la phase en cours.

2.2.12.3 POUR AFFICHER UN PROGRAMME DE CUISSON

1- Appuyer sur la touche programme. La touche s’illumine.

2- Sélectionner le numéro de programme à afficher. . L’écran affichera la première phase du programme. Appuyer

sur la touche de phase (ligne 1) pour afficher et dérouler les autres phases.

3- Pour vérifier le temps total, activer (Sauf si une des phases utilise la sonde à cœur).

2.2.12.4 E FFACEMENT D’UN PROGRAMME

1- Appuyer sur la touche programme. la touche s’illumine.

2- Sélectionner le numéro du programme à effacer. .

F

- 28 -

Page 29

3- Appuyer sur la touche pendant 5 secondes.

2.2.12.5 MODIFICATION D’UN PROGRAMME

1- Appuyer sur la touche programme. La touche s’illumine.

2- Sélectionner le numéro de programme à modifier. .

3- Modifier les phases et les paramètres souhaités : le numéro du programme se met à clignoter.

4- Confirmer le nouveau programme : Le buzzer sonnera et le numéro du programme s’affichera en négatif pour indiquer

qu’il a été enregistré.

Note : il est possible d’exécuter un programme modifié avant sa confirmation. Dans ce cas, la confirmation peut être effectuée

à la fin de la cuisson. Il n’est pas possible d’insérer une phase dans un programme.

2.2.12.6 APPELLATION D’UN PROGRAMME

Il est possible d’associer un nom à un numéro de programme.

1- Appuyer sur la touche programme. La touche s’illumine.

2- Sélectionner le numéro de programme à baptiser. .

3- Appuyer sur la touche programme pendant 4 secondes. L’écran affichera les données suivantes:

NUMÉRO DE PROGRAMME

CARACTÈRES DISPONIBLES

4- Sélectionner les lettres ou les chiffres avec les touches et confirmer avec la touche Enter Les caractères

sélectionnés se placeront à droite du numéro de programme :

TOUCHE EFFACEMENT

CARACTÈRE

- 29 -

F

Page 30

5- A la fin, confirmer le nom en appuyant sur la touche pendant 5 secondes. Le numéro du programme arrête de clignoter

le buzzer se met à sonner. Pour sortir du programme, appuyer sur la touche programme .

2.2.13 FONCTIONS PARTICULIÈRES

2.2.13.1 MODE VP (VALEUR DE PASTEURISATION) (OPTION)

Cette fonction doit être sélectionnée pendant la configuration initiale du four. Elle ne peut fonctionner que si on utilise la

sonde à cœur.

TOUCHE VP TOUCHE

VITESSE TURBINE

Appuyer pendant 5 secondes sur la touche de la ligne 5, l’écran VP s’affichera. Entrer la valeur VP avec les touches

. En appuyant une fois sur la touche de la ligne 5, le réglage commutera de la VP à la vitesse de la turbine. Le cycle de

cuisson se terminera seulement lorsque la valeur VP et la température de la sonde à cœur programmées auront été atteintes.

Pour désactiver la fonction VP, la programmer à 0.

2.2.13.2 PRÉCHAUFFAGE DU FOUR

Après avoir sélectionné un mode de cuisson, régler la température et le temps. L’utilisation d’un programme permet de préchauffer automatiquement le four à la juste température.

Pour ce faire :

- Créer son propre programme de cuisson ou entrer les coordonnées d’un programme stocké en mémoire.

- Appuyer sur la touche pendant 5 secondes.

2.2.13.3 PROGRAMMATION DU PRÉCHAUFFAGE

Il est possible de programmer le four de façon à faire partir le préchauffage à une heure donnée

HEURE DE MISE EN ROUTE

HEURE ACTUELLE

1- Sélectionner un mode de cuisson et saisir la température de préchauffage souhaitée.

SÉLECTION

HEURE DE DÉPART

2- Appuyer sur la touche de sélection, heure de départ.

3- Entrer l’heure de mise en route, confirmer mettre en route . Le processus peut être stoppé en sélec-

tionnant un mode de cuisson ou en appuyant sur .

F

- 30 -

Page 31

2.2.14 ARRÊT DU FOUR

Appuyer sur la touche OFF l’écran affiche les données suivantes :

ARRÊT AVEC VIDANGE DE LA CHAUDIÈRE

ARRÊT AVEC CHAUDIÈRE PLEINE

CYCLE DE NETTOYAGE MANUEL

CYCLE DE NETTOYAGE AUTOMATIQUE

ARRÊT AVEC VIDANGE DE LA CHAUDIERE

En fin de journée, si on ne souhaite pas effectuer un cycle de nettoyage automatique, il est possible d’arrêter le processus en

appuyant sur cependant, étant donné que la vidange de la chaudière ne peut pas être interrompue, il faudra attendre 5

minutes avant de remettre le four en route.

ARRÊT AVEC CHAUDIERE PLEINE

Pour un arrêt temporaire pendant la journée.

CYCLE DE NETTOYAGE MANUEL

Après avoir appuyé sur la touche correspondante, démarrer le cycle avec la touche . Le four repart en mode vapeur. Un

signal sonore signalera de nettoyer l’enceinte de cuisson en pulvérisant un nettoyant adapté et en adoptant toutes les mesures

de sécurité préconisées par le fabricant. Après avoir fermé la porte, le cycle redémarrera et se terminera par le rinçage de

l’enceinte suivi par une double vidange de la chaudière.

CYCLE DE NETTOYAGE AUTOMATIQUE

Avant d’entamer un cycle de nettoyage automatique, vérifier s’il y a assez de nettoyant dans le réservoir et si le tuyau de la

pompe est introduit correctement dans le réservoir. Les touches permettent de modifier le nombre de cycles de

détergent à choisir en fonction du degré de saleté du four. Mettre ensuite le cycle en route avec la touch . En fonction

de l’état de la machine, le cycle de nettoyage pourrait commencer par un refroidissement afin d’amener la machine à la juste

température de nettoyage (inférieure à 60°C).

ATTENTION !

Cet affichage signale que le cycle de nettoyage n’a pas abouti ou qu’il a été

interrompu. Probablement il y a encore du nettoyant dans l’enceinte de cuisson ou dans la chaudiere. L’enceinte de cuisson doit être rincée à fond et le

chaudiere vidangé deux fois (avec le programme ARRÊT AVEC VIDANGE

DE LA CHAUDIERE). Il est aussi possible de sélectionner et d’effectuer

un CYCLE DE NETTOYAGE MANUEL. Ne pas utiliser le four sans avoir

d’abord complété les opérations précédentes.

IMPORTANT! attendre toujours la fin totale du cycle avant de désactiver

l’eau et l’électricité.

- 31 -

F

Page 32

2.3 NETTOYAGE QUOTIDIEN ET ENTRETIEN

Avant d’entamer un cycle de nettoyage, enlever les morceaux d’aliments qui auraient pu tomber dans l’enceinte. Effectuer

au moins un cycle de nettoyage par jour. Vérifier la propreté du joint de la porte. Afin d’en prolonger la durée, le sécher avec

un chiffon doux après le cycle de nettoyage. Ne pas utiliser de paille en fer, ni d’autres produits abrasifs pour nettoyer les

surfaces en verre et en acier inoxydable ou le joint de la porte. En cas de difficultés à éliminer les taches, utiliser un nettoyant

non corrosif adéquat. En fonction de la dureté de l’eau, il pourrait s’avérer nécessaire de détartrer la chaudère ou l’enceinte

de cuisson.

Pour détartrer la chaudière, procéder de la façon suivante :

- éteindre le four et vidanger la chaudière,

- remplir la chaudière avec du vinaigre blanc ou du détartrant à travers l’orifice d’entrée de la vapeur situé en haut de l’enceinte à droite, en respectant les quantités suivantes :

fours à 6 niveaux : 5 litres

fours à 10 niveaux : 6 litres

fours à 20 niveaux : 10 litres

- sélectionner le mode vapeur sans mettre en route le cycle et laisser agir de 30 à 45 minutes en fonction de l’efficacité du

détartrant,

- éteindre le four et vidanger la chaudière,

- sélectionner à nouveau le mode vapeur sans mettre en route le cycle pour le rinçage de la chaudière,

- terminer par un cycle de nettoyage. Pour détartrer l’enceinte de cuisson, procéder de la façon suivante:

- pulvériser du détartrant sur toutes les cloisons de l’enceinte de cuisson et laisser agir selon le mode d’emploi du fabricant,

- terminer par un cycle de nettoyage.

2.4 AUTODIAGNOSTIC

Le microprocesseur du four vérifie constamment le bon fonctionnement de la machine et signale les pannes par un symbole

situé en bas à droite de l’écran. Ce symbole s’affiche à la place du symbole de la vitesse de la turbine. A chaque panne correspond un numéro qui s’affiche sur l’écran, à savoir :

0 Surchauffe des composants électroniques (CPU)

1 Surchauffe de l’enceinte de cuisson

2 Surchauffe de la chaudière

3 Défaut sonde de l’enceinte de cuisson

4 Défaut sonde d’oura

5 Défaut sonde des condensats

6 Défaut sonde chaudière

7 Sonde à cœur défectueuse ou pas branchée

8 Défaut moteur de la turbine

9 Absence d’eau dans la chaudière

10 Système d’optimisation de l’énergie de l’édifice en action

11 Surchauffe des relais statiques

12 Défaut sonde à la masse

Remarques :

- Les pannes doivent être éliminées, sinon elles continueront à s’afficher chaque fois que l’on sélectionne une fonction qui

utilise le composant défectueux.

- L’afficheur des pannes reste activé si le mode ou la fonction correspondante ne peut pas être utilisée. Sélectionner un autre

mode ou une autre fonction.

- Les cinq dernières pannes sont enregistrées avec la date.

- Si une panne se produit pendant l’exécution d’un programme de cuisson, ledit programme s’arrête.

- Si une panne s’affiche avant la mise en route d’un programme, la mise en route dudit programme sera impossible.

F

- 32 -

Page 33

FONCTIONNEMENT TEMPORAIRE DU FOUR EN CAS DE PANNE

Ces fonctions ont été étudiées seulement pour mener à terme le cycle en cas de panne. Appeler le centre SAV agréé pour

la réparation. Ne pas utiliser le four dans ces conditions.

MODE CONVECTION: En cas de panne de la sonde de l’enceinte de cuisson, arrêter le four . Appuyer sur la touche

convection pendant 10 secondes . La sonde à cœur règle la température autour de 165°C.

MODE VAPEUR: Si la chaudière est en panne, arrêter le four . Appuyer sur la touche vapeur pendant 10 secondes

. Dans ces deux modes, il n’est pas possible de régler la température ou de sélectionner un temps de cuisson. On ne peut que

mettre en route ou arrêter le cycle de cuisson. De la vapeur sera produite par introduction d’eau dans la turbine à 100°C environ. Pour quitter ces modes et revenir au mode standard, appuyer sur .

- 33 -

F

Page 34

INDICE

SEZIONE DESCRIZIONE PAGINA

Note generali ....................................................................................................................................... 35

1. Installazione ........................................................................................................................................ 36

1.1 Collegamento idraulico ....................................................................................................................... 36

1.2 Collegamento dello scarico ................................................................................................................ 36

1.3 Collegamento elettrico ........................................................................................................................ 36

1.4 Capienza forno ..................................................................................................................................... 36

2. Funzionamento .................................................................................................................................... 38

2.1 Generale .............................................................................................................................................. 38

2.2 Pannello di controllo ........................................................................................................................... 39

2.2.1 Macchina collegata all’alimentazione elettrica .................................................................................. 40

2.2.1.1 Regolazione dell’ora ........................................................................................................................... 40

2.2.1.2 24h o 12h am/pm ................................................................................................................................. 40

2.2.1.3 Contatore di assistenza ....................................................................................................................... 40

2.2.2 Avvio .................................................................................................................................................... 40

2.2.3 Selezione della modalità di cottura ..................................................................................................... 40

2.2.4 Regolazione di temperatura, tempo di cottura o umidità .................................................................... 42

2.2.5 Regolazione della velocità della ventola ............................................................................................ 42

2.2.6 Posizione ventilazione (solo modalità termoconvezione) ................................................................... 42

2.2.7 Umidificatore (solo modalità termoconvezione) ................................................................................. 42

2.2.8 Abbattimento rapido temperatura in camera ...................................................................................... 42

2.2.9 Funzione sonda al cuore ..................................................................................................................... 43

2.2.10 Funzione Delta T ................................................................................................................................. 43

2.2.11 Fasi di cottura PH 1/10 ....................................................................................................................... 43

2.2.12 Funzione programma .......................................................................................................................... 44

2.2.12.1 Inserimento di un programma ............................................................................................................. 44

2.2.12.2 Esecuzione di un programma .............................................................................................................. 44

2.2.12.3 Per visualizzare un programma .......................................................................................................... 44

2.2.12.4 Per cancellare un programma ............................................................................................................. 44

2.2.12.5 Per modificare un programma ............................................................................................................ 45

2.2.12.6 Per denominare un programma .......................................................................................................... 45

2.2.13 Funzioni particolari ............................................................................................................................ 46

2.2.13.1 Modalità VP (valore di pastorizzazione) (opzionale) ......................................................................... 46

2.2.13.2 Preriscaldamento del forno ................................................................................................................ 46

2.2.13.3 Programmare l’avvio del preriscaldamento ....................................................................................... 46

2.2.14 Spegnimento del forno ........................................................................................................................ 47

2.3 Pulizia giornaliera e manutenzione .................................................................................................... 48

2.4 Autodiagnosi ....................................................................................................................................... 48

Schemi di installazione ....................................................................................................................... 50

I

- 34 -

Page 35

NOTE GENERALI

Il livello di rumorosità della macchina è inferiore a 70 dB (A)

Importanti istruzioni per l’uso

- Utilizzare in conformità con le disposizioni

I forni misti a termoconvezione e vapore devono essere utilizzati solo per la cottura, arrostitura, gratinatura,

cottura a vapore e cottura in umido di prodotti alimentari destinati al consumo.

- Sicurezza

Non lavare dall’esterno con una canna o un pulitore ad alta pressione. Il simbolo di “pericolo” compare accanto

alle istruzioni essenziali per il funzionamento sicuro della macchina. Si prega di leggere questi passaggi con

estrema attenzione.

- Responsabilità

L’errata installazione, le riparazioni non effettuate da tecnici Hobart o da un centro assistenza autorizzato e

qualunque modica tecnica non autorizzata dai produttori potrebbero comportare il decadimento della garanzia

del produttore.

Tutti gli esempi forniti in queste istruzioni con riferimento a metodi, tempi e temperature di cottura dipendono

dalla qualità degli alimenti da cuocere e pertanto possono variare.

Nel caso in cui l’utente o l’installatore non rispettino le istruzioni fornite in questo manuale, la casa declina tutte le

responsabilità da ciò derivanti e non potrà essere ritenuta responsabile per qualsivoglia incidente o problema causato

da tale inosservanza.

IL PRODUTTORE DECLINA QUALUNQUE RESPONSABILITÀ PER QUALSIVOGLIA IMPRECISIONE CONTENUTA IN QUESTO DOCUMENTO CHE POSSA ESSERE DOVUTA A ERRORI DATTILOGRAFICI O TIPOGRAFICI. IL

PRODUTTORE SI RISERVA INOLTRE IL DIRITTO DI APPORTARE AL PRODOTTO LE MODIFICHE CHE RITENGA

UTILI O NECESSARIE, SENZA INFLUIRE SULLE CARATTERISTICHE DI BASE

- 35 -

I

Page 36

1. INSTALLAZIONE

Prima di togliere l’imballaggio, verificare le buone condizioni della scatola; in caso di danni, si prega di presentare le necessarie rimostranze alla società di trasporto.

LATO DI APERTURA SPORTELLO: Normalmente il forno viene consegnato con le cerniere della porta sulla sinistra. Se

si desiderano sul lato destro, si prega di specificare tale preferenza al momento dell’ordine.

Il forno dev’essere installato e collegato in conformità con normative locali.

Il forno dev’essere installato su un supporto o pavimento adeguatamente livellato. Verificare il livellamento del forno utilizzando una livella a bolla d’aria e la parte superiore della macchina come riferimento.

1.1 COLLEGAMENTO IDRAULICO

Deve trattarsi di acqua fredda, potabile e addolcita (con durezza inferiore a 7 gradi Francesi). La rete di alimentazione idrica

deve fornire una pressione compresa fra 2 (minima) e 6 (massima) bar, o equivalentemente fra 200 e 600 kPascal. La rete

deve inoltre garantire una portata minima di 13 l/min.

Il consumo di acqua massimo teorico è:

- 1 GN 1/1 a 6 livelli: 25 litri / h per la produzione di vapore e 60 litri per il ciclo di pulizia più lungo.

- 2 GN 1/1 a 10 livelli: 40 litri / h per la produzione di vapore e 60 litri per il ciclo di pulizia più lungo.

- 3 GN 2/1 a 10 livelli: 55 litri / h per la produzione di vapore e 80 litri per il ciclo di pulizia più lungo.

- 4 GN 1/1 a 20 livelli: 70 litri / h per la produzione di vapore e 80 litri per il ciclo di pulizia più lungo.

- 5 GN 2/1 a 20 livelli: 90 litri / h per la produzione di vapore e 100 litri per il ciclo di pulizia più lungo.

Fornire un flessibile di pressione da ½” adeguato, dado di unione B.S.P. 3/4”

1.2 COLLEGAMENTO DELLO SCARICO

Dev’essere di tipo aperto e il materiale di scarico dev’essere adatto per l’acqua a una temperatura fino a 100° C. il collegamento

dello scarico è b.s.p. 1” a filetto esterno.

1.3 COLLEGAMENTO ELETTRICO

Dev’essere effettuato solo da un tecnico Hobart o a altri tecnici autorizzati e dev’essere conforme con i requisiti di installazione e tutte le normative rilevanti.

I carichi connessi sono i seguenti:

1 GN 1/1 a 6 livelli: 9 kW 3 fasi + neutro + massa

2 GN 1/1 a 10 livelli: 18 kW 3 fasi + neutro + massa

3 GN 2/1 a 10 livelli: 24 kW 3 fasi + neutro + massa

4 GN 1/1 a 20 livelli: 36 kW 3 fasi + neutro + massa

5 GN 2/1 a 20 livelli: 42 kW 400/3 PH/ N/M o 42kW 230V/3 PH/M

L’apparecchiatura viene consegnata senza cavo d’alimentazione. Il cavo flessibile per l’allacciamento alla linea elettrica deve

essere di caratteristiche non inferiori al tipo con isolamento in gomma H07RN-F.

L’apparecchiatura deve essere inclusa in un sistema equipotenziale in accordo alle vigenti norme nazionali e locali. La vite

contrassegnata con la targhetta “Equipotenziale” si trova vicina alla morsettiera sul basamento.

Se l’installazione è a 400V senza neutro, il forno dovrà essere modificato da un tecnico Hobart. Togliere il pannello destro

per accedere alla giunzione della boccola di entrata e alla morsettiera.

1.4 CAPIENZA FORNO

In funzione del modello, il forno può alloggiare 6, 10, 20 o 40 teglie. Di conseguenza può contenere un massimo di 24, 40,

80 o 160 kg di cibo.

I

- 36 -

Page 37

BOCCOLA DI ENTRATA

- 37 -

I

Page 38

2. FUNZIONAmENTO

2.1 GENERALE

Per aprire la porta, ruotare la maniglia in posizione orizzontale: la sicurezza della porta verrà disattivata quando la si apre.

Per chiudere lo sportello, accertarsi che la maniglia sia orizzontale, chiudere lo sportello e bloccare la maniglia in posizione

verticale: la sicurezza della porta verrà attivata.

GRIGLIA DI PROTEZIONE

GUARNIZIONE

RIPIANI

PANNELLO DI

CONTROLLO

RACCOGLI GOCCE

FILTRO DI SCARICO

FORNO

RACCOGLI GOCCE

PORTA

Il filtro di scarico dev’essere sempre in posizione. I ripiani laterali possono essere rimossi per la pulizia. La griglia di protezione che copre la ventola e le resistenze dev’essere sempre in posizione per motivi di sicurezza e per la distribuzione del

flusso dell’aria. Può essere rimossa per la pulizia. Il raccogli gocce porta riceve ed elimina le gocce d’acqua quando la porta

è chiusa. Il raccogli gocce forno riceve ed elimina le gocce d’acqua sempre.

I

- 38 -

Page 39

2.2 PANNELLO DI CONTROLLO

ACCENSIONE / SPEGNIMENTO

TERMOCONVEZIONE : ON/OFF

VAPORE : ON/OFF

DISPLAY

TASTO “PIÙ”

SCORRIMENTO IN BASSO

TASTO “MENO”

SCORRIMENTO IN ALTO

PROGRAMMA

LINEA DI SELEZIONE 1

LINEA DI SELEZIONE 2

LINEA DI SELEZIONE 3

LINEA DI SELEZIONE 4

LINEA DI SELEZIONE 5

UMIDIFICATORE O ENTER

PORTA DI COMUNICAZIONE

A INFRAROSSI

AVVIO / ARRESTO

CICLI DI COTTURA

CONNETTORE SONDA AL

CUORE

- 39 -

I

Page 40

2.2.1 MACCHINA COLLEGATA ALL’ALIMENTAZIONE ELETTRICA:

Quando la macchina è alimentata elettricamente, lo schermo si illuminerà e indicherà l’ora e il tempo che manca alla prossima

disincrostazione o alla prossima revisione di assistenza:

REGOLAZIONE DELL’ORA

SCELTA 24h or 12h AM/PM

AZZERAMENTO CONTATORE

DI SERVIZIO (Reset Service)

2.2.1.1 REGOLAZIONE DATA E ORA

Per regolare l’ora, premere il tasto corrispondente (linea 3) per 5 secondi, regolare ora e data con i tasti quindi con-

validare con il tasto Enter

2.2.1.2 24H O 12H AM/PM

Per passare dalla visualizzazione a 24 h a quella a 12 h AM/PM, premere il tasto corrispondente (linea 4) fino a visualizzare

la modalità corretta.

2.2.1.3 CONTATORE DI ASSISTENZA

Per azzerare il contatore di assistenza o di servizio, premere il tasto corrispondente (linea 5) per 5 secondi. Dopo 15 minuti senza

azione sul pannello di controllo, lo schermo si spegne. Può essere riattivato premendo o aprendo/chiudendo la porta.

2.2.2 AVVIO

La selezione di una modalità di cottura avvia il forno. Per disattivare una modalità di cottura, premere nuovamente il tasto

illuminato.

2.2.3 SELEZIONE DELLA MODALITÀ DI COTTURA

MODALITÀTERMOCONVEZIONE

MODALITÀVAPORE

+ MODALITÀCOMBINATA

MODALITÀ PROGRAMMA

Dopo la selezione di una delle 3 modalità di cottura:

- Viene visualizzata per 5 secondi (con simbolo in negativo) la temperatura predefinita corrispondente alla modalità di cottura

selezionata, sostituita poi dalla temperatura effettiva del vano.

- Le luci del vano cottura si accendono (solo a porta chiusa e bloccata).

- I tasti della modalità di cottura selezionata si illuminano.

- Per default il timer è in modalità manuale.

- Il tasto avvia (illuminato) o arresta (spento) il processo di cottura.

La selezione della modalità programma disattiverà le altre modalità di cottura selezionate. In caso di apertura dello sportello

durante un processo di cottura, questo si arresterà e si riavvierà al punto in cui era nel momento in cui lo sportello è stato

chiuso nuovamente.

I

- 40 -

Page 41

Quando si seleziona una modalità di cottura, il display mostrerà la schermata seguente:

MODALITA’ TERMOCONVEZIONE

TEMPERATURA PREDEFINITA PER 5 sec. POI TEMPERATURA

EFFETTIVA VANO COTTURA

MODALITA’ MANUALE TIMER

POSIZIONE VENTILAZIONE

VELOCITA’ VENTOLA E VP (opzione)

MODALITA’ VAPORE

+ MODALITA’ COMBINATA

TEMPERATURA PREDEFINITA PER 5 sec. POI TEMPERATURA EFFETTIVA VANO COTTURA

MODALITA’ MANUALE TIMER

VELOCITA’ VENTOLA E VP (opzione)

TEMPERATURA PREDEFINITA PER 5 sec. POI TEMPERATURA EFFETTIVA VANO COTTURA

MODALITA’ MANUALE TIMER

LIVELLO UMIDITA’

VELOCITA’ VENTOLA E VP (opzione)

- 41 -

I

Page 42

2.2.4 REGOLAZIONE DI TEMPERATURA, TEMPO DI COTTURA O UMIDITÀ

Per regolare una delle impostazioni sopra descritte, selezionare la linea premendo il tasto corrispondente sul lato destro dello

schermo (simbolo in negativo), quindi regolare il valore desiderato con i due tasti In modalità combinata il display mo-

strerà aggiunta o eliminazione di umidità. Se è stato impostato un tempo di cottura e si desidera tornare

alla modalità manuale (cottura continua), selezionare la linea e premere finché appare il simbolo manuale

.

2.2.5 REGOLAZIONE DELLA VELOCITÀ DELLA VENTOLA

Selezionare la linea corrispondente e regolare la velocità da 1 a 4 con i tasti

2.2.6 POSIZIONE VENTILAZIONE (SOLO MODALITÀ TERMOCONVEZIONE)

Premere il tasto corrispondente per aprire o chiudere .

NON È NECESSARIO CONVALIDARE CON IL TASTO ENTER:

i valori vengono impostati automaticamente.

2.2.7 UMIDIFICATORE (SOLO MODALITÀ TERMOCONVEZIONE)

Il tasto consente di introdurre acqua nel vano durante il processo di cottura.

2.2.8 ABBATTIMENTO RAPIDO TEMPERATURA IN CAMERA

Qualunque sia la modalità di cottura selezionata, è possibile raffreddare automaticamente il vano camera tramite introduzione

di acqua fredda e a pressione preregolata nella ventola:

1) Premete il tasto della linea 3 (timer) in manuale. Premere il tasto fino a quando non scompare il tempo sul visualizzatore

e compare una freccia versi il basso selezionare il comando temperatura e impostare il valore minimo desiderato.

2) Premere finché appare il simbolo .

3) Regolare la temperatura finale desiderata .

4) Avviare .

Nota: la scelta di un’altra modalità arresterà il processo selezionato sopra.

I

- 42 -

Page 43

2.2.9 FUNZIONE SONDA AL CUORE

Collegare la sonda di temperatura al cuore nel connettore situato in fondo al pannello di controllo. Premere per 5 secondi il

tasto della linea 3 il display indica la temperatura della sonda al cuore impostata e mostra il simbolo seguente

sulla destra dello schermo. Dopo 5 secondi il display indica la temperatura della sonda al cuore impostata Regolare la

temperatura impostata desiderata come descritto prima.

Inserire la sonda al centro dell’alimento da controllare,chiudere e bloccare lo sportello, avviare il processo di cottura con

il tasto . Per tornare alla funzione timer, premere per 5 secondi il tasto della linea 3. .

2.2.10 FUNZIONE DELTA T

La cottura con la funzione DELTA T controlla automaticamente la temperatura del vano di cottura, seguendo la temperatura al

cuore del prodotto con una differenza costante. La funzione DELTA T può essere utilizzata con tutte le tre modalità. Premere