Page 1

MODEL HCK & HDK SERIES

ELECTRIC FRYERS

ELECTRIC FRYERS

MODELS

HCK40 ML-52525

HCK42 ML-52526

HCK91 ML-52527

HCK92 ML-52528

HCKO ML-52529

HDK40 ML-52536

HDK42 ML-52537

HDK91 ML-52540

HDK92 ML-52541

HDKO ML-52531

EXECUTIVE OFFICES

701 RIDGE AVENUE

TROY, OHIO 45374-0001

FORM 19225 (1-95)

Page 2

Installation, Operation and Care of

MODELS HCK40, HCK42, HCK91, HCK92,

HDK40, HDK42, HDK91 & HDK92

HOBART ELECTRIC FRYERS

SAVE THESE INSTRUCTIONS FOR FUTURE USE

GENERAL

Standard features include stainless steel fry tank and front, a high limit device, twin baskets, and on

Models HCK40, HCK42, HDK40 and HDK42, a lift-out fry tank which is easily removed for cleaning.

HCK40, HCK91, HDK40 and HDK91 floor model fryers are equipped with 6" adjustable legs. They may

be ordered without legs for installation on a masonry base. The fryers also can be supplied with a 4"

toe base in place of legs as an optional extra.

Optional features include extra fry tanks, a large single basket supplied in place of twin baskets, syphon

and strainer bags, casters (floor models only), stainless steel fry tank cover, and extra sets of twin

baskets or single baskets. Stainless steel side(s) and back are also available optionally.

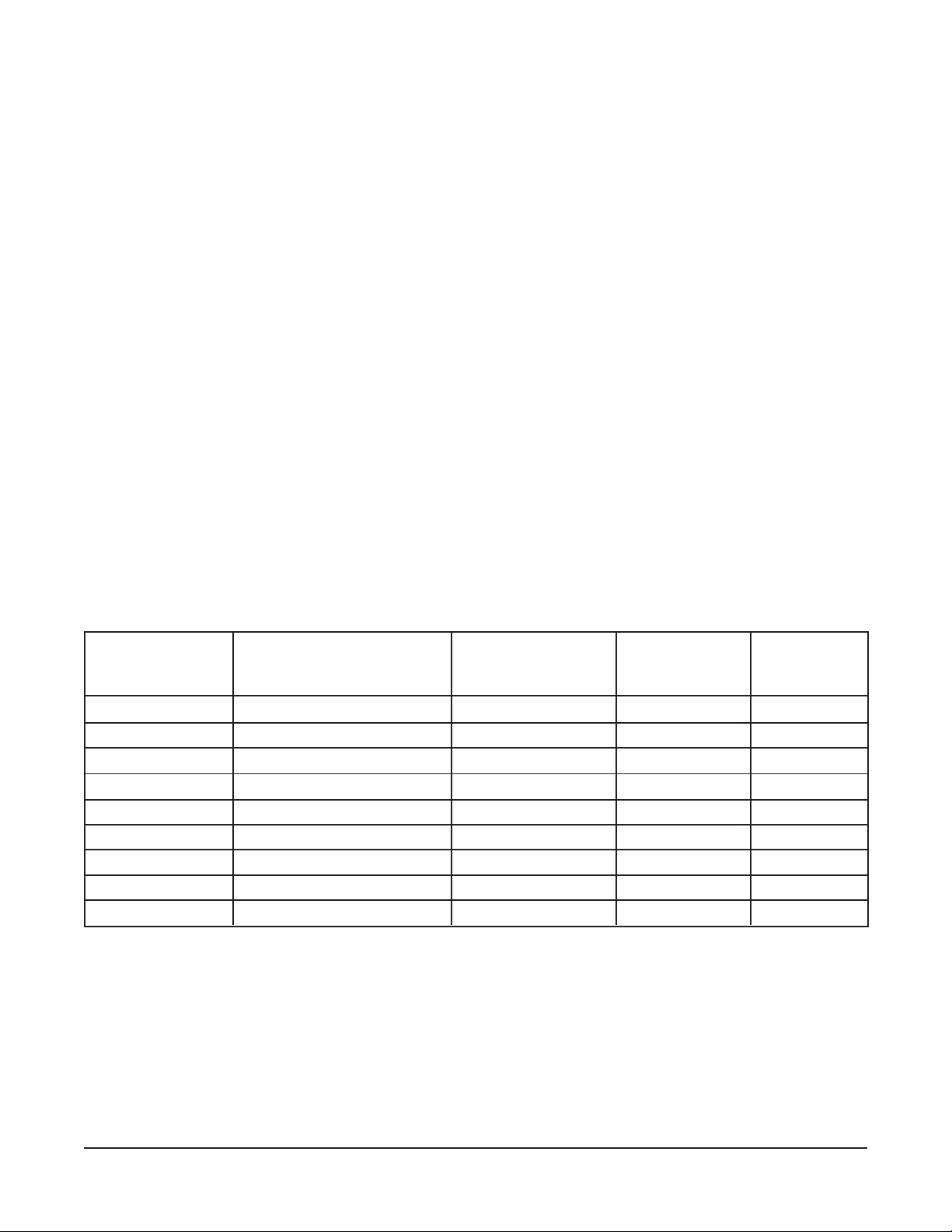

AUTOMATIC

BASKET MELT

MODEL WIDTH / STYLE CONTROLS LIFT CYCLE

HCK40 20" Floor model Mechanical Opt. Opt.

HCK42 20" Countertop Mechanical Opt. Opt.

HCK91 24" Floor model Mechanical Opt. Opt.

HCK92 24" Countertop Mechanical Opt. Opt.

HDK40 20" Floor model Solid State Opt. Std.

HDK42 20" Countertop Solid State Opt. Std.

HDK91 24" Floor model Solid State Opt. Std.

HDK92 24" Countertop Solid State Opt. Std.

HCKO/HDKO 20" Frymate N/A N/A N/A

The HCKO and HDKO Frymate Work Stations may be installed next to any of the HCK or HDK Series

Fryers. The top draining section has a lift-out screen and center drain into a 3-quart, slide-out drain

pan. The interior of the cabinet has storage space for 4 standard #200 pans in drawer-type, non-tilt

pan slides. Pans are not supplied with the Frymate.

The Frymate is equipped with 6" adjustable legs. It may be ordered without legs for installation on a

masonry base, or with a 4" toe base in place of legs as an optional extra.

© HOBART CORPORATION, 1995

– 2 –

Page 3

INSTALLATION

Before installing the fryer, verify that the electrical supply agrees with the specifications on the fryer

data plate which is located on the inside of the door panel on floor model fryers and on the lower front

cover on countertop models.

UNPACKING

Immediately after unpacking the fryer, check it for possible shipping damage. If the fryer is found to

be damaged, save the packaging material and contact the carrier within 15 days of delivery.

Do not use the door or its handle to lift or move the fryer.

LOCATION

The fryer may be installed at 0" clearance from the back or side walls. The fryer must be installed at

least 16" away from any open top flame appliance. Position the fryer for easy accessibility for service.

INSTALLATION CODES AND STANDARDS

Hobart fryers must be installed in accordance with:

In the United States

1. State and local codes.

2. National Electrical Code ANSI/NFPA No. 70 (latest edition). Copies may be obtained from The

National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

3. NFPA Standard #96.

In Canada:

1. Local codes.

2. Canadian Electrical Code, Part 1, C22.1 (latest edition). Copies may be obtained from The

Canadian Standards Association, 178 Rexdale Blvd., Rexdale, Ontario, Canada M9W1R3.

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH TO INDICATE THAT YOU ARE WORKING ON THE CIRCUIT.

– 3 –

Page 4

Position the fryer in its final location. Select the size and type of wire in accordance with National

Electrical Code suitable for carrying the fryer's rated amps and voltage. Use wires suitable for 75°C

on fryers carrying more than 80 amps.

1. Bring conduit containing the proper supply wire to the fryer.

On HCK40/42 and HDK40/42, bring the conduit in through the clearance hole in the back and

terminate on the terminal block housing mounted in the back of the breaker box.

On HCK91 and HDK91, terminate the field supply conduit on the corner of the bottom floor and

bring the supply leads into the breaker box through the removable channel mounted to the right

side.

On HCK92 and HDK92, bring the conduit through the opening in the bottom toward the front of

the fryer.

2. Connect the supply leads to the field terminal block and the green grounding lead to the labeled

ground lug.

Fryers wired for 3-phase service may be changed to 1-phase or vice versa by relocating two wires on

the terminal block as shown on the wiring diagram and the schematic decal which is attached to the

fryer.

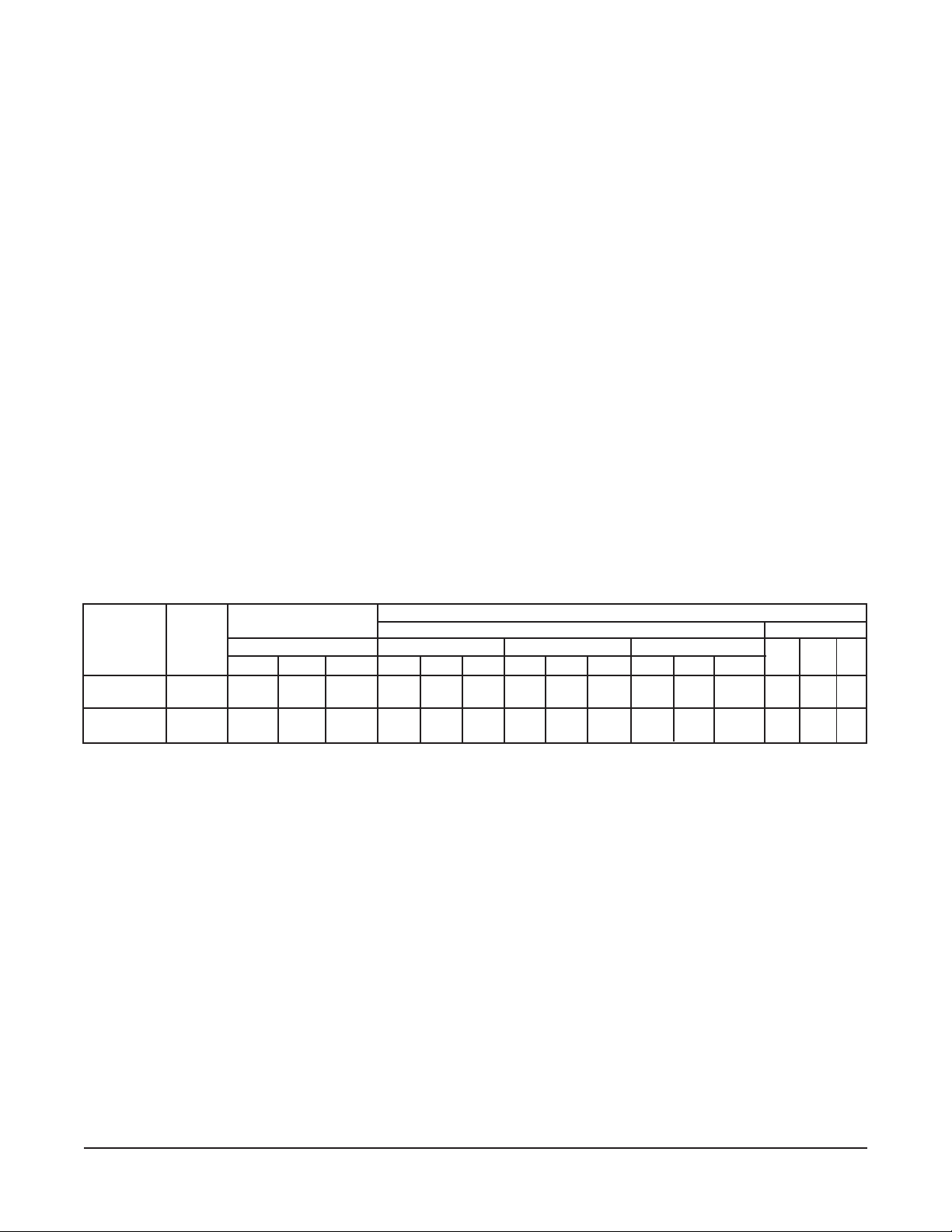

ELECTRICAL DATA CHART

TOTAL 3-PHASE LOADING NOMINAL AMPS PER LINE WIRE

MODEL K.W. KW PER PHASE 3 PHASE 1 PHASE

CONN. 208, 240 & 480 V. 208 V. 240 V. 480 V. 208 240 480

X-Y Y-Z X-Z X Y Z X Y Z X Y Z V. V. V.

HCK40/42,

HDK40/42

HCK91/92,

HDK91/92

12 3.8 3.8 4.2 34 33 34 29 28 29 15 14 15 58 50 25

21.0 5.25 10.5 5.25 44 66 66 38 57 57 20 30 30 101 88 44

LEVELING

Level floor model fryers. Place a carpenter's level on top of the fryer and turn the adjustable legs to

level fryer front-to-back and side-to-side.

Countertop models must be placed on a level surface.

BEFORE FIRST USE

Clean fryer thoroughly, following procedures described in this manual under CLEANING — WEEKLY

OR AS REQUIRED. Clean all fryer accessories. Rinse all parts thoroughly and wipe dry.

Lightly season backsplash area to avoid possible surface corrosion. With a soft, lint-free cloth, apply

a thin layer of cooking oil over entire backsplash area. This should also be done after every cleaning.

– 4 –

Page 5

OPERATION

WARNING: HOT OIL AND PARTS CAN CAUSE BURNS. USE CARE WHEN OPERATING,

CLEANING AND SERVICING THE FRYER.

CONTROLS — MODELS HCK40/42 and HCK91/92 (Fig's. 1 & 2)

Power Switch — Turns electric power to the fryer on or off.

ON Indicator Light — (Red) Indicates electric power to the fryer is on.

HEAT Indicator Light — (Amber) Indicates heating elements are supplying heat.

Thermostat — Controls temperature of oil in tank. Temperature range is 0-400°F.

Fry/Melt Switch — (Optional - Not shown.) Position on MELT when solid shortening is being

melted; then position on FRY for normal operation.

Automatic Basket — Set to desired frying cycle time. At end of set time, baskets will automatically

Lift Timers (Optional) raise. Timer range is 0 to 15 minutes.

Ball Pull Rod — (Models HCK40/42 only.) Raises elements from tank when pulled straight

out. Lowers elements into tank when pushed in.

Power Switch

Power Switch

On Indicator

Light

Automatic Basket Lift Timers (optional)

On Indicator

Light

Thermostat

HCK40/42

Fig. 1

Thermostat

Heat Indicator

Light

Ball Pull Rod

PL-40539-1

Heat Indicator

Light

Automatic Basket Lift Timers (optional)

HCK91/92

Fig. 2

– 5 –

PL-40540-1

Page 6

CONTROLS — MODELS HDK40/42 and HDK91/92 (Fig's. 3 and 4)

Power Switch — Turns electric power to the fryer on or off.

ON Indicator Light — (Red) Indicates electric power to the fryer is on.

HEAT Indicator Light — (Amber) Indicates heating elements are supplying heat.

High Limit Light — When ON, indicates that the oil temperature is higher than 400°F, or that

the heating elements are not covered with shortening, and the system

has shut down. Call your local Hobart Service Office.

Temperature Controller — Controls temperature of oil in tank. Temperature range is 0-375°F.

Fry/Melt Switch — Position on MELT when solid shortening is being melted; then position

on FRY for normal operation.

Ball Pull Rod — (Models HDK40/42 only.) Raises elements from tank when pulled

straight out. Lowers elements into tank when pushed in.

On Indicator Light

Power Switch

On Indicator Light

Power Switch

Temperature Controller

Heat Indicator

Light

HDK40/42

Fig. 3

Temperature Controller

Heat Indicator

Light

High Limit Light

Fry/Melt

Switch

High Limit Light

Fry/Melt

Switch

Ball Pull Rod

PL-40537-1

PL-40538-1

HDK91/92

Fig. 4

ADDING LIQUID SHORTENING TO THE FRYER

Shortening should be between 1" and 2" above the top of the heating elements' surface.

Liquid shortening may be used in all fryers.

– 6 –

Page 7

1. Push power switch to OFF and allow fryer to cool.

2. Remove the fryer basket(s) and support rack (support rack in HCK91/92 / HDK91/92 only).

3. Leave the heating elements in the tank (HCK40/42 and HDK40/42).

4. HCK40/42 / HDK40/42: Pour 30-35 pounds of shortening into the fryer tank.

HCK91/92 / HDK91/92: Pour 78-82 pounds of shortening into the fryer tank.

5. Replace the rack support (HCK91/92 and HDK91/92 only) and fryer basket(s) inside the tank.

6. Push the power switch to ON and turn temperature controller or thermostat to desired temperature.

ADDING SOLID SHORTENING TO THE FRYER

Only fryers equipped with the MELT cycle may use solid shortening. Melting solid shortening without

using the MELT cycle will damage the fry tank and scorch the shortening. Tank warranty may be voided

by improper operation.

Models HCK40/42 and HDK40/42

1. Push power switch to OFF and allow fryer to cool.

2. Remove fryer baskets.

3. Leave the heating elements in the tank.

4. Place 30-35 pounds of solid block shortening in the fryer tank on top of the heating elements.

5. Follow melt cycle operation.

Models HCK91/92 and HDK91/92

1. Remove fry basket and rack support.

2. Place 78-82 pounds of solid block shortening in the fryer tank and pack around the heating

elements.

3. Place basket rack support on top of shortening.

4. Follow melt cycle operation.

Melt Cycle Operation

1. Set the temperature controller to frying temperature.

2. Push power switch to ON.

3. Push Fry/Melt Switch to MELT. The elements will cycle on for 2 seconds and off for 28 seconds

until the shortening melts and reaches a temperature of 135°F. The temperature controller will

bring the shortening to the frying temperature.

4. Place Fry/Melt Switch in the FRY position when ready to fry.

– 7 –

Page 8

FRYING

Place the ON-OFF switch to the ON position. The red ON indicator light will come on.

Turn thermostat or temperature controller to desired temperature. The amber HEAT indicator light will

come on.

When the shortening temperature reaches the set temperature, the amber HEAT light will go off. The

heating elements (and the amber HEAT light) will cycle on and off to maintain the set temperature.

Pieces of product to be fried should be about the same size to ensure uniform doneness.

Drain or wipe dry raw or wet foods to minimize splatter when lowering into the hot oil.

Fill frying baskets half full. Do not overfill baskets.

Carefully lower baskets into oil.

When cooking French fries or onion rings, shake basket several times in a way that does not splatter

the shortening.

Batter-covered foods should be dropped carefully, one by one, into shortening or basket. If you use

the basket, first dip basket into the shortening to reduce batter build-up on basket surfaces.

When frying is completed, remove baskets or product. Hang baskets to drain on rear basket hangers.

Remove food and season it. Do not salt food over the shortening because salt will cause a chemical

change in the oil.

Add fresh shortening as needed. Shortening should be between 1 and 2 inches above the heating

elements.

TURNING THE FRYER OFF

To turn the fryer OFF, place the ON-OFF switch to the OFF position.

Extended Shutdown

Place ON-OFF switch to OFF. Turn thermostat knob to OFF. Apply a thin film of cooking oil to tank

interior and tank back to inhibit rust.

HIGH LIMIT CONTROL

If the shortening becomes overheated, or if the heating elements are not covered with shortening, the

high limit control will shut down the entire control system and the fryer will be inoperable.

If the heating elements are not covered with shortening, add shortening until the level is 1 or 2 inches

above the top of the heating elements. When the temperature of the shortening returns to normal

(300°F), manually reset the circuit breakers (located behind the fryer door on floor model fryers and

behind the lower panel on countertop fryers).

If the high limit control continues to shut the fryer down, contact your local Hobart service office.

– 8 –

Page 9

DAILY FILTERING

Shortening life will be extended by filtering at least once a day, or more often if conditions warrant.

Models HCK91/92 and HDK91/92 are equipped with a

1

/4 turn ball type drain valve. Models HCK40/

42 and HDK40/42 have a removable fry tank that can be lifted out by raising the heating elements out

of the tank, or the shortening can be syphoned out as follows:

Models HCK40/HDK40

Turn the fryer off and allow shortening to cool. Place the syphon assembly (Fig. 5) so that the short

tube rests on the bottom of the tank and the long tube projects down through the hole in the grease

trough. Tie the filter bag to the end of the long tube. Provide a metal container of sufficient capacity

at the end of the long tube inside the storage compartment.

To start the syphoning action, push the stopper in the bowl closed. Fill the bowl with clean liquid

shortening. Pull the stopper to allow shortening to start draining. Push the stopper closed before all

the shortening is drained from the bowl. To stop draining, pull the stopper and empty the bowl

completely.

PL-40541

Fig. 5

Models HCK42/HDK42

Turn the fryer off and allow shortening to cool. Place the syphon assembly (see Fig. 5) so that the short

end rests on the bottom of the tank and the long tube projects down in front of the fryer. Tie the filter

bag to the end of the long tube. Provide a metal container of sufficient capacity at the end of the long

tube.

To start the syphoning action, push the stopper in the bowl closed. Fill bowl with clean liquid

shortening. Pull stopper to allow shortening to start draining. Push stopper closed before all the

shortening is drained from the bowl. To stop draining, pull stopper and empty the bowl completely.

– 9 –

Page 10

Models HCK91/92 and HDK91/92

1. Turn the fryer off and allow shortening to cool.

2. Slowly remove the baskets to prevent splashing.

3. Open the fryer door and place a metal container of sufficient capacity below the drain pipe.

4. If a filter bag is used, tie it securely to the drain pipe. If other filter medium is used, place it in the

metal container.

5. Open the drain valve carefully so the oil stream is directed through the filter.

6. With a small amount of warm shortening, flush out scraps and sediment in the fry tank. Drain the

tank thoroughly and wipe clean.

7. If it is necessary to clean the tank more thoroughly, follow the procedures shown in CLEANING

— WEEKLY OR AS REQUIRED in this manual.

8. Close the drain valve.

9. Return strained shortening to the fry tank.

10. Add shortening until the level is between 1 and 2 inches above the heating elements.

CLEANING

Daily

Clean the exterior of your fryer regularly with a damp cloth and polish with a soft dry cloth. If regular

cleaning is neglected, grease will be burned on and discolorations may form. These may be removed

by washing with any detergent or soap and water. A self-soaping scouring pad may be used for

particularly stubborn discolorations. Always rub with the "GRAIN" in a horizontal direction.

Keeping the fryer exterior clean and free of accumulated grease will prevent stubborn stains from

forming. Wash all exterior surfaces at least once daily. Use a cloth with warm water and a mild soap

or detergent. Follow with a clear rinse, then dry.

Fingerprints are sometimes a problem on highly polished surfaces of stainless steel. They can be

minimized by applying a cleaner that will leave a thin, oily or waxy film. To use these cleaners, simply

wipe on and remove excess with a soft dry cloth. After using, subsequent fingerprints will usually

disappear when wiped lightly with a soft dry cloth or with a cloth containing a little of the cleaner.

If the surface is heavily soiled to start with, wash first with soap or detergent and water.

Weekly or as Required

1. Once the shortening has been drained, flush out scraps and sediment with a small amount of warm

shortening. Allow the tank to drain thoroughly.

– 10 –

Page 11

2. Close the drain valve (Models HCK91/92 and HDK91/92 only).

3. Fill the tank with a non-corrosive, grease-dissolving commercial cleaner, following the

manufacturer's instructions.

4. Turn the fryer on and set the thermostat or temperature controller at a temperature recommended

by the manufacturer of the commercial cleaner. Boil the solution for 15 to 20 minutes. If cleaner

is a water based chemical, temperature may be 190-212°F. Set the temperature as low as

possible; monitor boiling to prevent overflow.

5. Drain (Models HCK91/92 and HDK91/92 ) or syphon (Models HCK40/42 and HDK40/42 ) cleaning

solution from the tank.

6. Close the drain valve (Models HCK91/92 and HDK91/92 only).

7. Refill the fry tank with water. Add 1 cup of vinegar to neutralize alkaline left by the cleaner. Bring

solution to a boil and allow it to stand for a few minutes.

8. Drain (Models HCK91/92 and HDK91/92) or syphon (Models HCK40/42 and HDK40/42) solution

from the tank and rinse thoroughly with clear, hot water. All traces of cleaner must be removed.

Dry the tank thoroughly.

9. Close the drain valve (Models HCK91/92 and HDK91/92 only).

10. Add shortening until the level is between 1and 2 inches above the heating elements.

The fryer is now ready for use.

Heat Tint

In and around equipment where temperatures reach 500°F or more, straw-colored or slightly darkened

areas may appear on stainless steel. This "Heat tint" is caused by a slight oxidation of the stainless

steel and is not harmful. To contol this condition, never use more heat than is absolutely necessary.

Heat tint can be removed by scouring vigorously with stainless steel wool and a paste made of a

scouring powder. Remember to rub in the direction of the polish lines.

Burned-On Foods and Grease

Soaking with hot soapy water will help greatly to remove burned-on foods and grease. Stubborn

deposits can be removed with scouring powder mixed into a paste and applied with stainless steel wool

or sponges. Never use ordinary steel wool; particles of the steel wool can become embedded in, or

lodge on, the surface of the stainless steel and eventually rust, causing unsightly spots and stains.

Likewise, when scraping off heavy deposits of grease or oil from stainless steel equipment, never use

ordinary steel scrapers and knives. Where it is necessary to scrape, use stainless steel, wood, plastic

or rubber tools.

– 11 –

Page 12

MAINTENANCE

WARNING: HOT OIL AND PARTS CAN CAUSE BURNS. USE CARE WHEN OPERATING,

CLEANING AND SERVICING THE FRYER.

WARNING: SPILLING HOT FRYING COMPOUND CAN CAUSE SEVERE BURNS. DO NOT MOVE

FRYER WITHOUT DRAINING ALL FRYING COMPOUND FROM THE TANK.

LUBRICATION

The motors in all HCK/HDK Series Fryers are permanently lubricated and no lubrication is required.

FORM 19225 (1-95) PRINTED IN U.S.A.

– 12 –

Loading...

Loading...