Page 1

UK Service Training Centre

© The Hobart Mfg Co Ltd (UK) - for use by Hobart service technicians only

Page 111/2002

WARNING:

This Training document is the property of Hobart Manufacturing. Reproduction of

this document is prohibited without the written consent of Hobart Manufacturing.

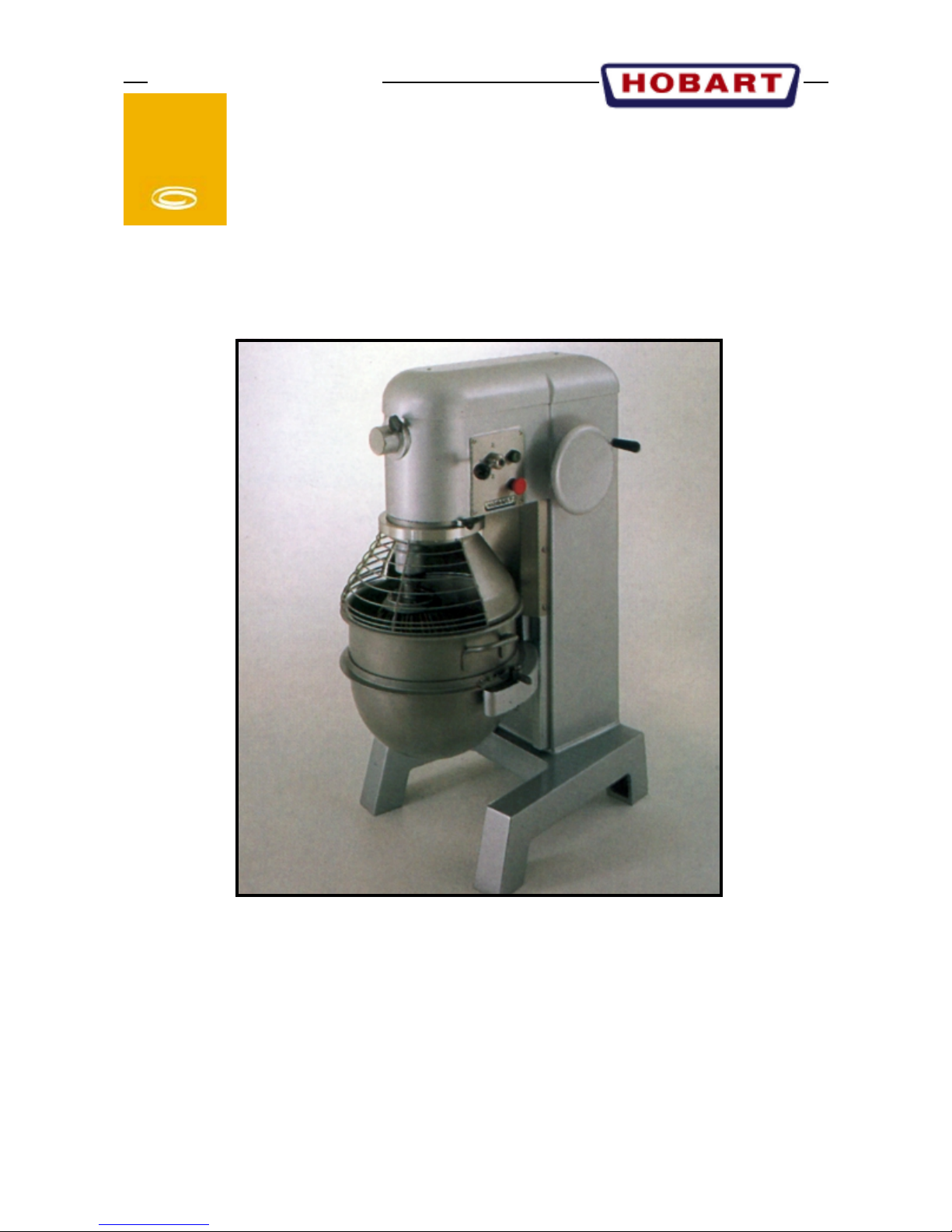

Model:H300

Mix er

Food Preparation

Page 2

UK. SERVICE TRAINING CENTRE

Warning this information is for HOBART STILL trained personnel only.

Reproduction of this information is prohibited without the written consent of HOBART STILL.

2/95

H300 - H400

MIXERS

Contents

GENERAL DATA ........................................................................................................................1

TRANSMISSION - SERVICE .....................................................................................................2

BOWL LIFT MECHANISM........................................................................................................3

WIRING DIAGRAMS .................................................................................................................4

Page 3

UK. SERVICE TRAINING CENTRE

Warning this information is for HOBART STILL trained personnel only.

Reproduction of this information is prohibited without the written consent of HOBART STILL.

Page: 1

2/95

H300 - 400

GENERAL DATA

Underside view of

Transmission

Drill 4.2 mm hole

and use a 5mm tap

to a depth of

10mm.

Pedestal

13.5 mm (x2)

Transmission case

Pedestal (front view)

FIG .1

FIG .2

EPM-E-11-4

EPM-E-11-8

EPM-E-11-17

137044

SCM-E-11-40

(x2)

Bowl support

EPM-E-11-8 EPM-E-11-17

FIG .1

Pedestal

Transmission

case

H300 - H400

240/50/1 - Fuse = 20a. 415/50/3 - Fuse = 6 amp

H300 = 0.75 kW. H400 = 0.75 kW

Bowl sizes

H300 = 29 litre

H400 = 39 litre

Bowl lift = Manual

Speeds = 3

Beater shaft speeds

1st - H300/400 = 68

2nd - H300/400 = 165

3rd - H300/400 = 274

Attachment Hub speeds

1st = 72. 2nd = 174. 3rd = 287

Lubricants

Gearbox = 6.8 kg Marfak multi purpose #2 grease.

Planetary = 113g Molytex #2 grease (+ bowl

screw)

Use light mineral oil on slideways.

Drill 3.3mm

and tap to

4mm (x2)

H300/400 BOWL GUARD RETROFIT INSTRUCTIONS. PARTS REQUIRED AS LISTED H300 =

ML36437. H400 = ML36438

1. ISOLATE AND DISCONNECT MACHINE FROM

MAINS ELECTRICAL SUPPLY.

2. REMOVE ALL EQUIPMENT

3. REMOVE DRIP CUP - DISCARD.

4. REMOVE PLANETARY INTERNAL GEAR - DISCARD

5. REMOVE BOWL SUPT/PEDESTAL COVER - DISCARD.

6. DRILL & TAP PEDESTAL (FIG 2.)

7. DRILL & TAP TRANSCASE (FIG 1.)

8. FIT BOWL SUPT SWITCH TO PEDESTAL AS DETAILED ( FIG .3)

9. FIT GUARD SENSOR SWITCH & HOUSING TO

TRANSCASE (USING 2 X M5 X 45 SCREWS).

10. FIT NEW BOWL SUPT/PEDESTAL COVER FIT

NEW INTERNAL GEAR.

11. ROTATE FRONT CAGE OF GUARD ASSEMBLY

OVER REAR SHIELD

12. LOCATE AND FIT GUARD ASSEMBLY BY HOLDING IN LOCKING PLUNGER AND LIFT GUARD ASSEMBLY, BY DRIP CUP SECTION, ONTO INTERNAL

GEAR THEN ROTATE CLOCKWISE, RELEASING

LOCKING PLUNGER, UNTIL LOCKED INTO POSITION.

13. CONNECT BOWL SUPT & GUARD SWITCHES (&

FUSE) INTO CONTROL CIRCUIT IN ACCORDANCE

WITH WIRING DIAGRAM

14. CONNECT RC SUPPRESSOR ACROSS TERMINALS Al/A2 OF CONTACTOR.

15. RECONNECT MACHINE TO MAINS ELECTRICAL SUPPLY AND TEST.

Page 4

UK. SERVICE TRAINING CENTRE

Warning this information is for HOBART STILL trained personnel only.

Reproduction of this information is prohibited without the written consent of HOBART STILL.

Page: 2

2/95

H300 - 400

TRANSMISSION - SERVICE

1. Remove Planetary.

2. Fit purpose made sleeve (1 1/4" ID plastic pipe) to

centre shaft and secure this with the Planetary bolt/

washer. The pipe will prevent Slow speed gear coming

apart.

3. Remove transmission cover complete.

4. Locate the Worm gear shaft and pull this out complete.

7. The Transmission shaft can now be lifted out, it may

be necessary to lift the Centre shaft slightly.

8. Remove shifter rod, slide shifter yoke to one side and

lift out the complete Centre shaft.

5. With the Worm gear shaft removed, go to the Bevel

gear and lift this off.

6. With the Bevel gear removed proceed to step 7.

TRANSMISSION SHAFT WORM GEAR SHAFT MOTOR PINIONCENTRE SHAFT

Slow speed gear

(built-in "sprag clutch")

Overhead view of Sprag clutch

as fitted inside Slow speed gear.

Page 5

UK. SERVICE TRAINING CENTRE

Warning this information is for HOBART STILL trained personnel only.

Reproduction of this information is prohibited without the written consent of HOBART STILL.

Page: 3

2/95

H300 - 400

BOWL LIFT MECHANISM

Upper stop screw:- adjust this up or down with the Beater fitted

to the machine to give adequate clearance betwen Bowl and

Beater.

Brass nut:- to remove this go to under side of Bowl yoke and

remove the lower stop bolt. Then ensure the Bowl yoke is wound

down as low as possible (protect paint work). The remove upper

stop screw and the retaining bolt. You will now be able to remove

the brass nut by turning the hand wheel thereby rotating the Bowl

lift screw.

Retaining bolt

Bowl lift screw

Helpfull tips

Q. Product left at base of bowl during mix.

A. Gap between Beater and Bowl is too great, adjust the upper stop screw.

Q. Bowl lift creeps down on it's own with product loaded bowl.

A. Too much product in bowl or the Brass nut is worn (see above to

replace).

Beater shaft kit = 142921 (H300/400)

comprises of the following;

52173 Beater Shaft

BB-E-3-41 Ball Bearing

RR-E-2-3 Retaining Ring

9608E Pin Beater Shaft

OS-E-2-14 Oil Seal

52174 Beater Pinion 18T

BB-E-3-31 Ball Bearing

SC-E-10-13 Grub Screw 3/8" UNC

SC-E-10-11 Grub Screw 3/8" UNC

WK-E-2-4 WoodruffKey

Page 6

UK. SERVICE TRAINING CENTRE

Warning this information is for HOBART STILL trained personnel only.

Reproduction of this information is prohibited without the written consent of HOBART STILL.

Page: 4

2/95

H300 - 400

WIRING DIAGRAMS

138724 start

138725 run

Stephan motor

232185-21

Brook motor 1.1 kw

Brook motor

1.1 kw

Example of Bowl lift and guard safety switches fitted

Loading...

Loading...