Page 1

Warewasher

FTX Series

"Catering Systems"

(with Standard-Control el. heated)

INSTALLATION OPERATION

VERSION 02/02/05

Page 2

Installation and Operating Instructions

for Warewashers FTX Series

Content Page

1Assembly .............................................................................................. 3

2 Electrical connection ............................................................................. 6

3Water connections ................................................................................ 6

4 Exhaust connection............................................................................... 7

5 Detergent and rinse agent dispensing .................................................. 7

6 First run................................................................................................. 8

7Controls............................................................................................... 10

8 Preparation ......................................................................................... 14

9Operation ............................................................................................ 14

10 After dishwashing................................................................................ 16

11 Position of curtains.............................................................................. 17

12 Frost prevention .................................................................................. 17

13 Trouble shooting.................................................................................. 18

Machine noise level is 73 dB (A)

Important Notes

● Use in Accordance with Regulations

This machine is exclusively to be used to wash ware such as plates,

cups, glasses, cutlery, trays etc.

Do not use for electrically heated cooking and heat conservation

appliances.

● Safety

Never hose down the machine.

The "Attention" symbol is shown beside instructions that are essential

for the safe operation of the machine. Please read these passages

very thoroughly.

● Liability

Installations and repairs which are not carried out by authorized

technicians or the use of other than original spare parts, and any

technical alterations to the machine, may affect the warranty set

out in the standard conditions of sale.

2

Page 3

1 Assembly

Should be carried out by HOBART technician

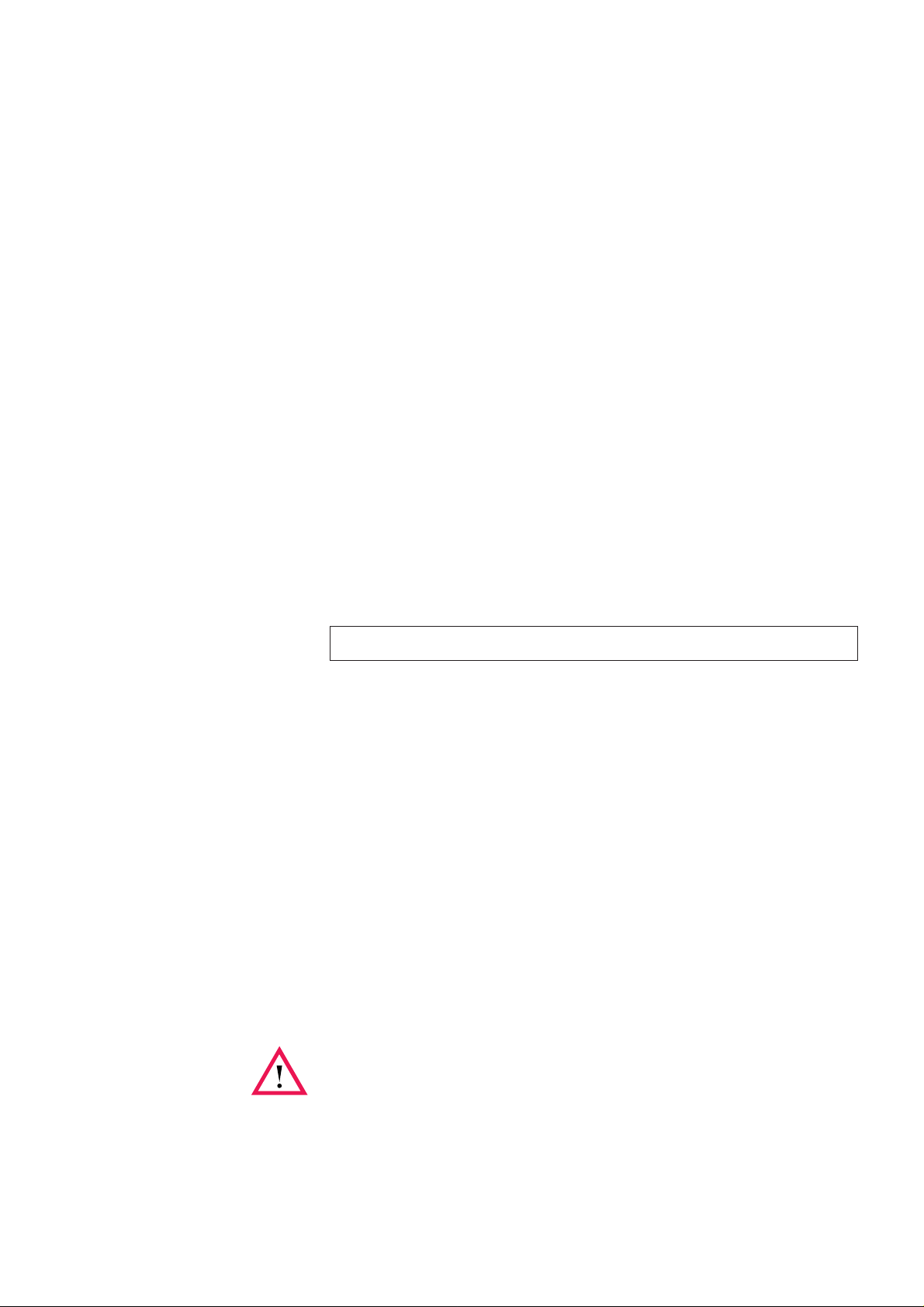

1.1 Transport to installation location

– If possible in its packing and on skid.

– Push on rollers.

– Avoid damage to floor and doors.

1.2 Remove packing

– Cut steel bands.

– Remove carton.

– Remove wooden skid.

– Remove inside packing material and accessories.

1.3 Locating

– According to installation plan.

– Consider wall clearance according to installation plan.

– Consider length of tabling, conveyors, etc.

1.4 Adjusting of machine height

– to loading platform level of 860 mm above floor by turning

the feet.

– Level floor unevenness.

– Distribute machine weight equally onto all feet.

1.5 Assembly of modules

If machine is delivered in separate modules:

Put largest module in place and level.

3

Page 4

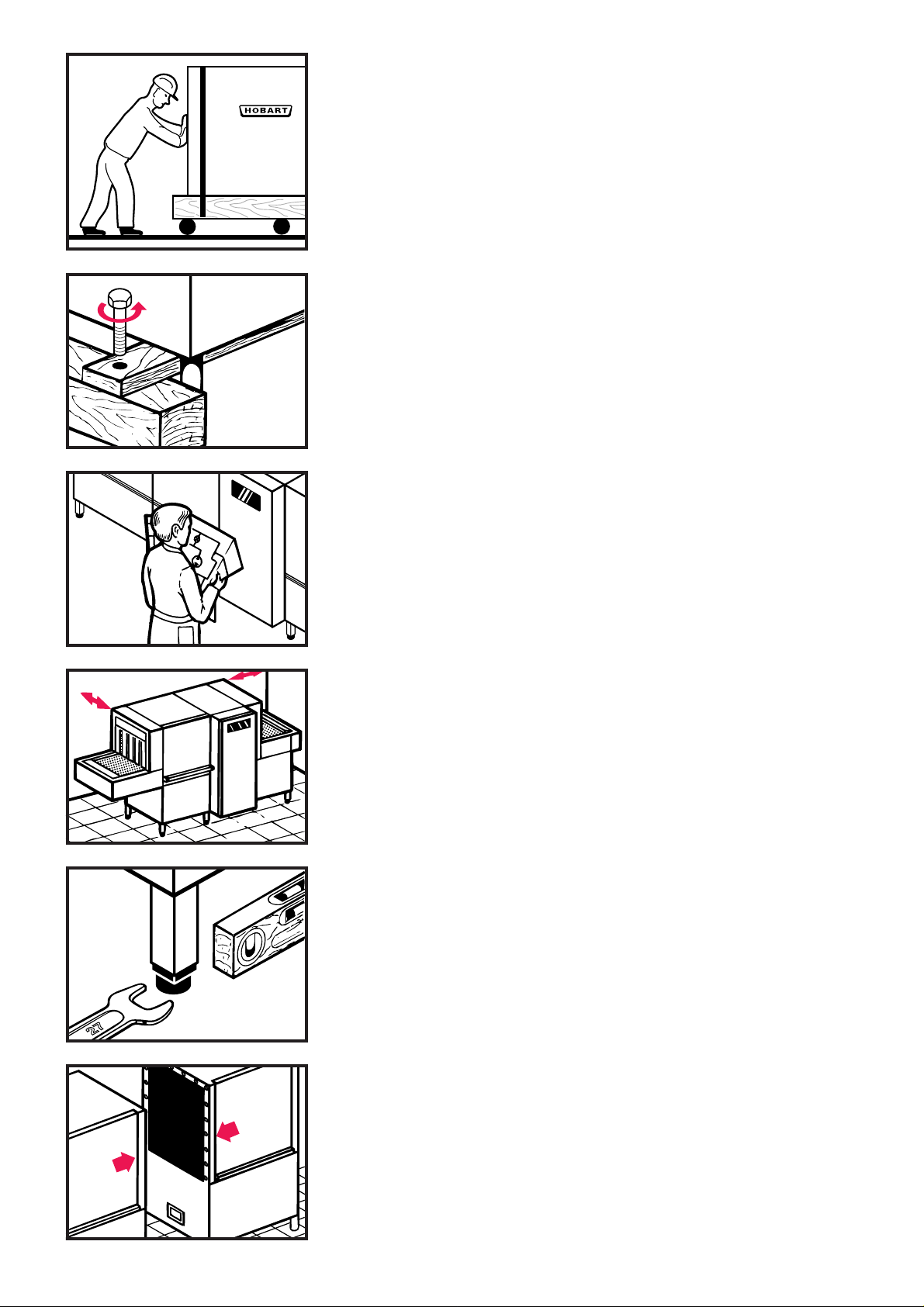

1.5.1 Sealing tape No. 168 834-1

must be stuck on one of the connecting surfaces.

– The sealing tape must overlap at the corners.

1.5.2 Flat gasket No. 229 161

must be stuck on overflow channel flange.

– If old gasket (from factory testing) is still fitted, this must be

removed previously and discarded.

1.5.3 Assembly is possible only with inspection doors removed.

– Loosen screws "X".

– Slide door up.

– Unhook springs from screws "X".

– Slide door up and remove.

1.5.4 Add next module

– Level height (see 1.4).

– Connect by using screws M6 x 12 hex. head, washers,

lockwashers and nuts (supplied).

– Cut protruding sealing tape with knife.

1.5.5 Transport feed

must be removed and returned to Hobart.

4

Page 5

1.6 Condenser and drier

must be mounted according to separate instructions.

1.7 Electrical cables

must be unrolled and drawn through the cable channel.

– Connect wires to the terminals of the electrical components.

– Follow the wiring diagram and the labels on wires and

terminals.

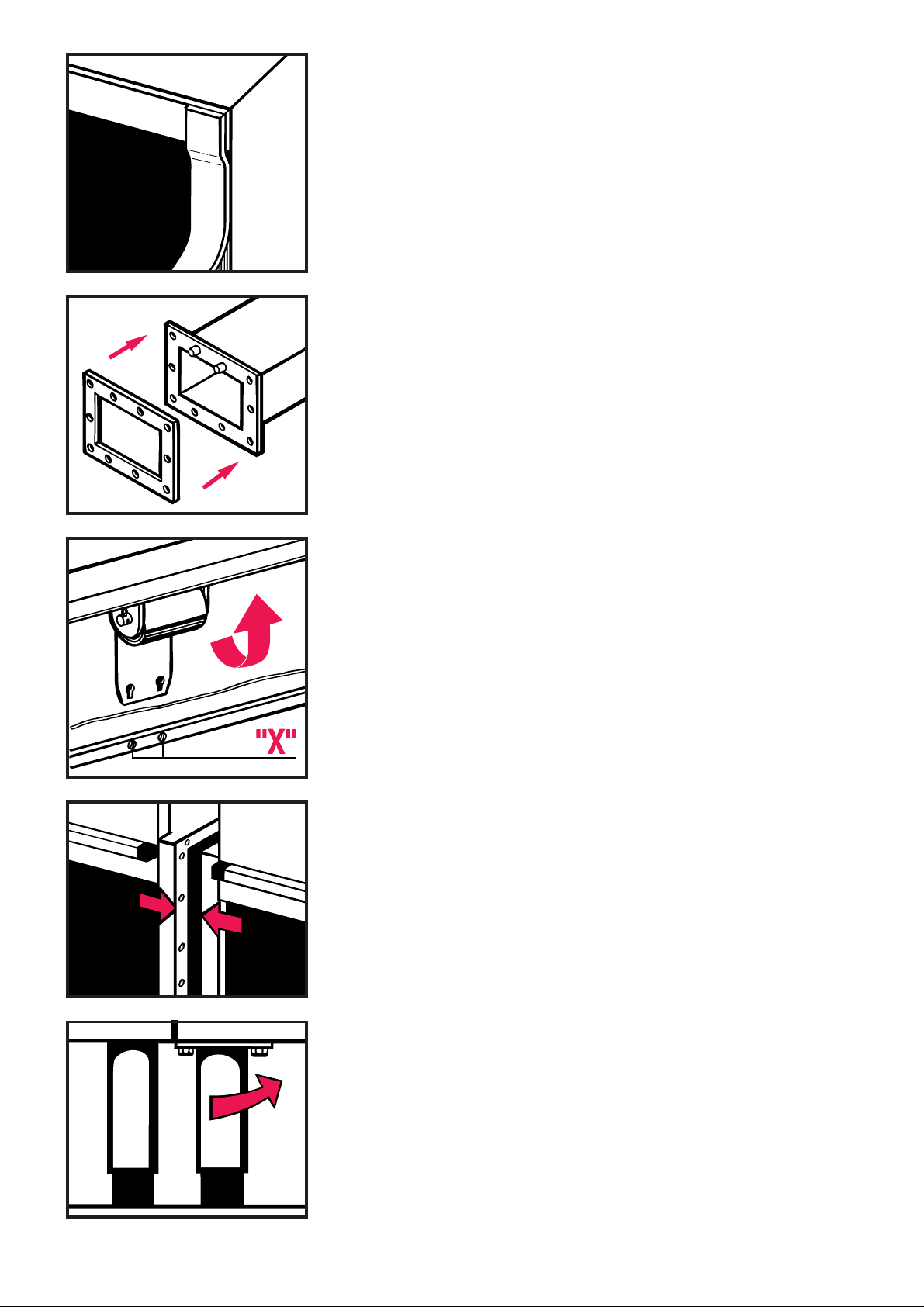

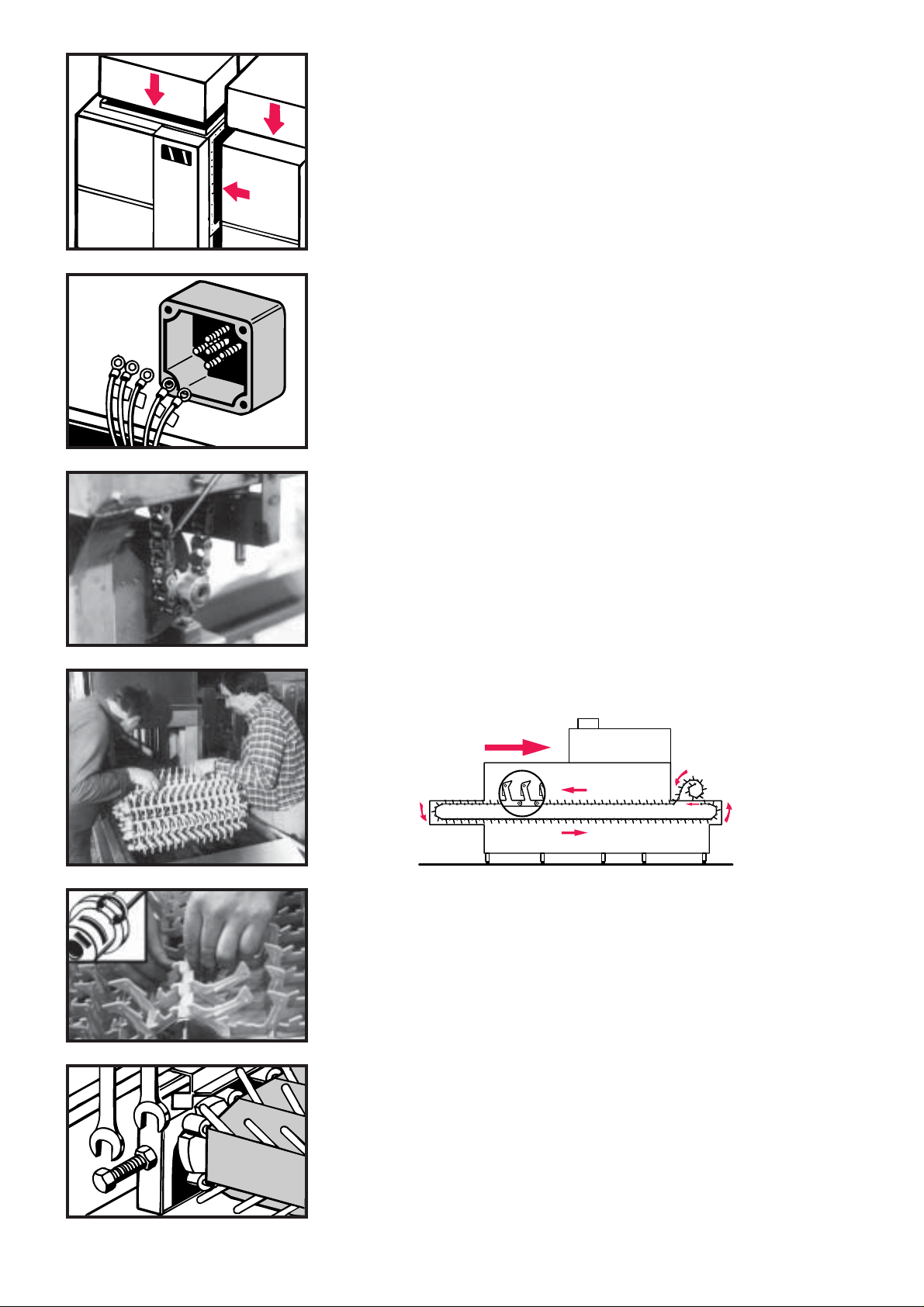

1.8 Mounting the conveyor

– Remove chain between conveyor axle and transport motor

(end of machine).

– Put rolled conveyor on exit end of the machine and draw it

through the machine.

– Connect both conveyor ends by the conveyor rod and lock with

safety ring.

– Tension the conveyor at the loading section, equally on both

sides and lock tension screws.

– Replace chain between conveyor axle and transport motor.

5

Page 6

2 Electrical connection

must be carried out by an authorized technician

according to the national and local codes.

2.1 Check

– Open control box (with key) and take out wiring diagram from

the inside of the door.

– Check machine specifications to make sure they correspond to

those of the site supply and to wiring diagram.

– Check site fuse protection.

– Provide main circuit breaker close to the machine (if not built in).

2.2 Connection

– Draw cable through cable gland at the bottom of the control box

rear panel.

– Connect wires to main terminals or to main circuit breaker

(option).

– Tighten all terminal srews in the control box (may be loosened

during transport).

– Tighten all cable glands.

According to EN 60 335 the appliance must be connected to a

equipotential conductor. The connecting screw is located beside

the cable control box.

3Water connection

must be carried out by an authorized technician

according to the national and local codes.

The machine must be operated with water of drinking quality.

3.1 Check

– Make sure that site water supply and drain pipes correspond to

installation plan of machine.

– Identify which pipes are to be connected to corresponding

connections of machine.

– Check correct size of pipe inside diameters.

– Line strainer, pressure reducer, vacuum breaker and safety

valve are fitted to machine as standard.

For U.K.: rinse booster pump optional.

3.2 Fresh water supply for rinse 1/2" (For U .K.: 3/4" BSP)

– should be soft (0 to 4 °Clark, resp. 0,5 mmol/l).

–must be cold if condenser is fitted.

– Provide shut-off valve.

3.3 Fresh water supply for fill (if second connection fitted) 3/4"

– should be soft (0 to 4 °Clark) and warm (40 – 50°C).

– Provide shut-off valve.

6

Page 7

3.4 Drain connections

to be connected to site drain(s):

– Tank drains (50 mm Ø)

–DUAL rinse drain (hose 3/4")

–Drip water drains from drier and exit end of machine require

trapped drain connections.

For U.K.:

Use straight sleeve type TERRINE 213-15, 1 1/2" BSPT male.

Use tundish type drain raised above tank water level.

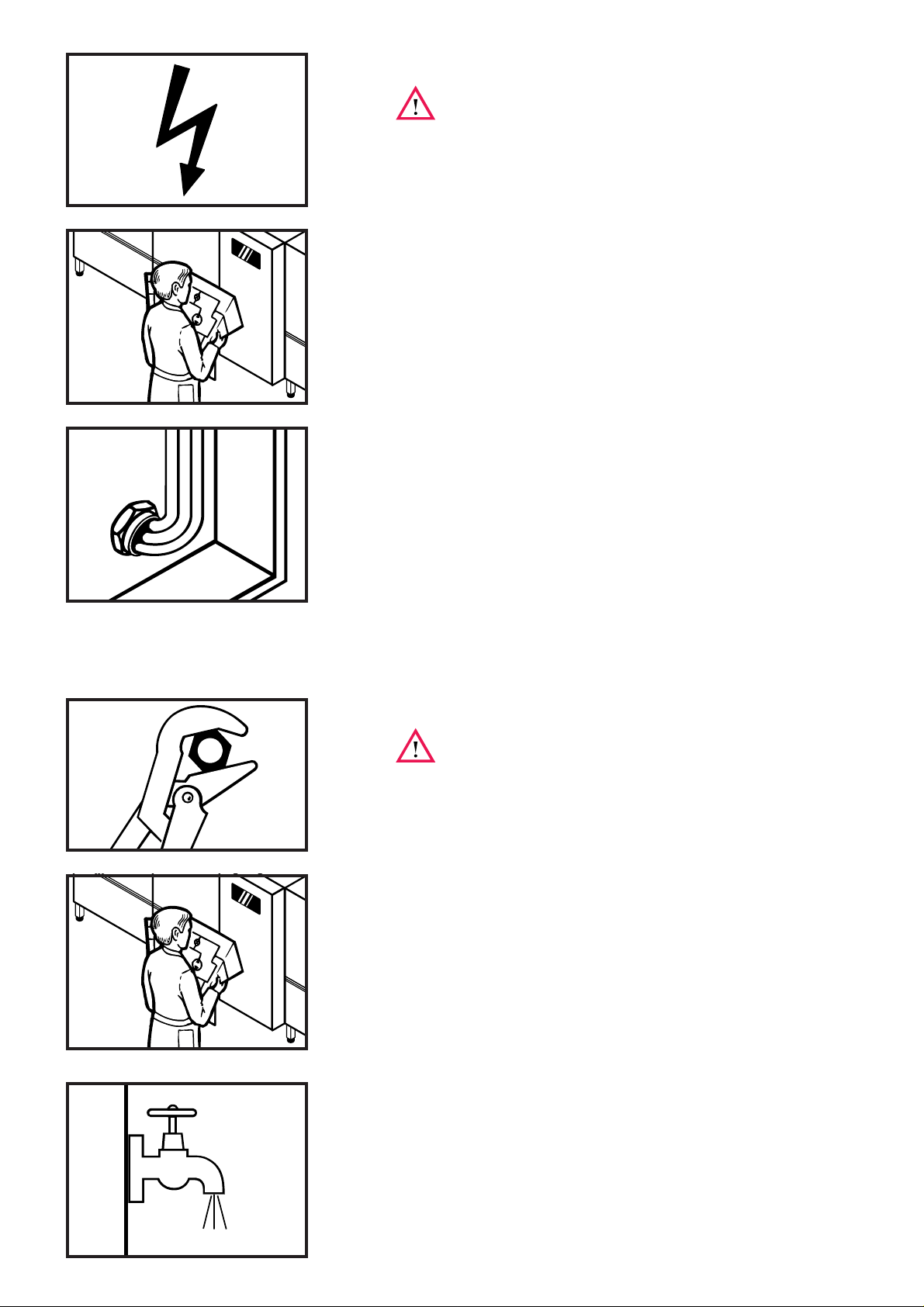

4 Exhaust connection

– Connection must be carried out in coordination with competent

ventilation engineer.

– Compare installation plan to site conditions.

Exhaust pipework

– Connect exhaust stack of 300 mm OD (not supplied) from

machine to site exhaust channel.

For U.K.: machine without ventilator:

connect exhaust stack of 147 x 477 mm.

– To prevent leakage, connect stack in such a way that

condensate water drops back into the machine.

– Air fan shown is to draw vapour through heat exchange

condenser, not to pressurise vapour through exhaust ductwork.

– In case of extremely low temperatures:

Provide insulation and anti-freeze shutter.

5 Dispensers

of detergent and rinse agent

– Normally, dispensers and controls are delivered and installed by

the detergent and rinse agent suppliers.

B

A

– Install dispensers, controls and containers such that they are

easy to handle and do not disturb machine operation.

– Rinse agent connections are provided for choice before (A) and

after rinse booster heater (B).

– Terminals are provided in the control box (see wiring diagr amme).

– Check for sufficient pre-dosage.

Use only commercial detergent and rinse agent.

Please pay attention to the manufacturers safety rules

and instructions.

7

Page 8

6 First run

A

Must be carried out to adjust and check machine functions.

See also chapter 7 (control elements).

Only to be done by an authorized

HOBART technician.

6.1 Preparation

– Switch off main switch.

– Check if detergent and rinse agent containers are filled.

– Open water supply.

– Open control box and switch on all circuit breakers and

motor protection switches.

Exception: if electrical rinse booster heater is installed:

make sure that its protection switch is switched off (see

wiring diagramme).

– Put strainers and curtains in place (see chapter 9).

– Close inspection doors.

– Switch on main switch.

– Switch on site exhaust extraction (if exists).

°C

B

III

0

III

B

– Set ON / OFF-switch to "fill" position.

When water sprays out of the rinse jets:

– Check if all rinse jets sprays correctly.

If not: remove rinse arms and clean jets.

– Push machine OFF button.

– Switch off main switch.

Electrically heated machine:

– Open control box and remove the film from the protection switch

of rinse booster heater (A). Switch on protection switch (B).

– Switch on main switch and push machine ON Button.

– After correct water level has reached, fill switches off

automatically and the tank heating(s) switch(es) on.

– When correct temperatures obtained (the green OK pilot light

illuminates), the machine is ready for operation. Push conveyor

ON button.

6.2 Fill rinse booster heater and tank(s)

8

Page 9

bar

l/h 100 200 300 400 500

bar

0,1

0,2

0,3

0,4

0,5

0,6

0,7

6.3 Check

– Direction of rotation of motors (see arrows on motors):

- pumps

- drier blower

- exhaust ventilator

– Check and eliminate possible leakages on:

- drain pipework

- water supply pipework, heating pipework

- machine housing, bottom of tanks, exhaust system.

6.4 Adjustment of flow pressure

at the pressure gauge of the rinse booster heater.

6.5 Adjustment of temperatures

Temperatures are adjusted at factory.

6.6 Detergent and rinse agent dispensing

should be adjusted by product specialist.

6.7 Adjustment of exhaust system

Must be carried out by HOBART technicians only during first run

with washware.

9

Page 10

7 Controls

5 6 7 9

°C °C

0

III

BACKWARD

III

?

21 3 4

14

8

13

NOT - AUS

11

10

O

I

12

15

10

Page 11

1 ON / OFF switch

Switches the machine on or off. Starts the fill cycle (exhaust and heating will start automatically).

2 Conveyor ON button

Switches the conveyor of the machine on. The wash cycle will be start automatically.

3 Conveyor OFF button

Switches the conveyor and wash off.

4 Conveyor speed selection switch

I = slow (e. g. for containers) II = middle (according DIN 10 510) III = fast (nominal speed)

5 OK pilot light (green)

Indicates, that the machine is ready for use.

6Temperature display – rinse 2

Indicates the current temperature of the pre rinse water (membrane filtration).

7Temperature display – final rinse

Indicates the current temperature of the final rinse water.

8Temperature display button

By pushing this button the display indicates individual temper atures of rinse or drier temperatures.

(see chapter 7.1)

9Warning light (red)

Indicates that one of the temperature probes is defective. The temperature display (6) indicates the Nº of the

defect probe, the temperature display (7) indicates the failure.

(e.g.: S = short circuit, L = open circuit)

10 Conveyor ON button at the loading section

Switches the conveyor of the machine on. The wash cycle starts automatically.

11 Conveyor OFF button at the loading section

Switches the conveyor and wash off.

12 Main switch

Must be in position I during operation and in position 0 during repair and maintenance.

13 Emergency Stop button

Switches the machine off. Must be unlocked for operation.

14 Backward key switch

By turning the switch clockwise, the conveyor belt will set a preadjusted distance backward.

(e. g. parts of washware are blocking the conveyor belt)

Danger of injury!

Must be carried out by an authorized technician !

15 Traffic light

Indicates the stage of the machines.

(e.g. green = the installation is ready; red / yellow = the installation has a fault)

The exact cause of fault, will be indicated at the screen of the central operation unit.

11

Page 12

BACKWARD

III

III

?

°C °C

°C °C

7.1 Temperature display

By pushing this button (8), individual temperatures (such as

pre-wash, wash, rinse or drier) can be displayed.

Press the temperature display button.

The rinse temperature displays (6) and (7) change into the

display mode. The temperature display (6) indicates the selected

measuring point, the temperature display (7) indicates the current

temperature.

Measuring point 1

Indicates the current wash temperature of the A-tank.

Measuring point 2

Indicates the current temperature of the B-tank.

°C °C

°C °C

°C °C

°C °C

Measuring point 3

Indicates the current temperature of the dual rinse.

Measuring point 4

Indicates the current temperature of the pre rinse (membrane rinse).

Measuring point 5

Indicates the current temperature of the final rinse.

Measuring point 6

Indicates the current temperature of the last drier.

12

°C °C

By pushing the temperature display button again, the display

changes back into the basic mode.

(Current rinse temperature display.)

Page 13

7.2 Faults

°C

°C °C

°C °C

If a failure arises during operation, it will be indicated by the

flashing of the red warning light.

– The flashing of warning light without other information at the

temperature displays (6) and (7), indicates a motor fault.

– The flashing of warning light and a further indication appears at

the temperature displays, it indicates a temperature probe

fault (short circuit or open circuit).

Example:

Pilot light failure illuminates and the left temperature display (6)

shows F 1, and the right display (7) shows an S or L.

This means:

The temperature probe F 1 failed by a short circuit (S) or a open

circuit (L).

III

°C

BACKWARD

III

III

?

BACKWARD

III

7.3 Conveyor reset

If parts of washware are blocking the conveyor belt, the machine

switches off (to avoid damages).

– The Warning light (red) of the tr affic light illuminates.

Danger of injury !

Must be carried out by an authorized technician !

– By turning the switch glockwise, the conveyor belt will set a

preadjusted distance backwards and the jammed piece can be

removed.

– The Warning light (red) switches off and by pressing the

Conveyor ON button the normal operation starts.

7.4 End-switch

Switches off transport if washware is not un-loaded from conve yor.

After washware is taken off from conveyor transport moves on

automatically.

The picture beside shows a machine without an additional

conveyor system. On machines with a roller conveyor on the exit,

the conveyor end switch wil be a roller.

13

Page 14

8 Preparation

Put curtains in place Check correct strainer position. Check wash arms.

(see chapter 12).

°C

BA

III

0

Close inspection doors (drains Check content of wash and rinse Start the conveyor by pushing the

close automatically). chemical containers. conveyor ON button. Wash and

Open water supply valve. Switch on main switch and set the rinse start directly.

Steam or hot water heated ON / OFF-switch to "fill" position.

machines: open heating valves. The machine starts fill and heating

automatically. Wait until the green

OK pilot light illuminates.

III

0

°C

III

9 Operation (Remove coarse food soil before washing.)

BA

III

Use loading platform to stack Load trays onto conveyor Do not mix trays and plates

plates. crosswise. (shadow zones).

Slide plates on conveyor.

14

Page 15

Put soup cups with inclination to the Do not place soup cups vertically Put glasses and cups with the

machine on 2 pegs of conveyor. on conveyor. opening facing downwards into

the rack. Glasses should not touch

each other (glass fracture). Use

the correct rack.

Put cutlery vertically and unsorted Wash utensils in utensil rack. Put gastronorm pan and other bowls

with handle downwards into cutlery Put the rack on conveyor. Check with openigs facing downwards on

racks. that no grips or handles protrude conveyor, with inclination to the

Set the cutlery racks on a utensil through the rack or conveyor. machine.

rack and put them on conveyor.

Pass through insulated trays with Do not set the insulated trays with Let the washware be conveyored

the opening downward and cross- opening upward on conveyor. almost to the end of the conveyor

wise. Water will pool in the sections. to give enough time to dry.

Washware may not exceed maximum loading height and width.

15

Page 16

10 After dishwashing

B

°C

III

0

Push Conveyor OFF button. Close shut-off valves. Remove and clean wash arms.

Turn the ON / OFF selector to "0" Remove and clean strainer basket

position. Switch off main switch and flat strainers.

and open inspection doors.

III

Take out curtains. Drain tanks by lifting lever at left Hose down interior of machine and

tank wall. conveyor.

Leave doors open for ventilation.

1

2

Put strainer baskets and flat Put curtains in place. Remove and check rinse arms

strainers back into place. once a week.

16

To clean the machine do not use any chloric, acidic or abrasive products

and no metallic brushs.

Never hose down the exterior of the machine.

Leave the doors open for ventilation.

Page 17

11 Position of curtains

2 2 2 2 2 2 12 2

SABRD2TT D2 D2A

?

FTX 4-SB-6, D2TT, D2, D2A

1

2

13 Frost prevention

Set main switch to "0".

The contactors of the heating elements for the booster should

be disconnected!

All tanks, water pipework and armatures must be totally drained:

– Turn out plug at the bottom of the rinse booster heater.

– Loosen unions next to fill valve.

– Drain site water pipework.

– Drain traps of drain system.

– Steam/hot water heated machines:

drain all heating coils and pipes.

– The condenser – if fitted – must be blown out with

compressed air.

– Reset for operation according to chapter 6.

17

Page 18

14 Troubleshooting

Failure Cause Correction

Tank fill too slow. Line strainer of fill clogged. Clean line strainer.

Solenoid valve defective. Replace solenoid valve (coil).

Tank not filled to correct Overflow / drain leaking or missing. Check overflow / drain gasket.

level.

Vapour escapes from Too low exhaust extraction. Adjustment by HOBART service.

loading or exit section.

Temperatures too low. Too much exhaust extraction. Adjustment by HOBART service.

Dishes soiled after washing. Strainers wrongly positioned. Check strainers.

Fill cycle too short. Adjust fill cycle, follow chapter 6

Too much wash water splashes Check wash arms, curtains and deflector panels.

into loading section. Put dishes correctly on conveyor.

Too much foaming. Use non-foaming detergent only.

Drier blows into machine. Lower slide of drier jet.

Put dishes correctly on conveyor.

Heaters defective. Check heaters and thermostats.

Curtains not or wrongly placed. Check curtains (see chapter 11).

Wash jets clogged. Clean the wash arms.

Too low detergent concentration. Increase detergent dispensing.

Temperatures too low. Check heating system.

Washware wrongly positioned See chapter 9.

Food soil dried-on. Soak dishware before washing.

Streaks and spots on Strainers wrongly positioned. Check strainers.

dishes.

Dishes do not dry. Incorrect temperature or humidity of Check heater and blower of drying unit.

Drops on dishes. Inadequate rinse agent concentration. Increase concentration or change product.

Dishes tilt over. Water pressure from below too high. Replace reducer between lower wash arm and

Wash water splashes into rinse section. Check curtains (see chapter 11).

Rinse jets clogged. Clean rinse jets.

Inadequate rinse agent dispensing. Adjust dispenser.

Too high mineral content of water. Use of demineralized rinse water recommended.

of drying air.

Washware still greasy. Increase detergent dispensing.

wash pipe.

Upper wash arms clogged. Clean wash arms.

Items too light. Put dishes into racks and put cover on racks.

As continued product improvement is a policy of HOBART, specifications are subject to change without notice.

Printed in Germany AG-21331-A-01-05-PC

Loading...

Loading...