Page 1

Item # _____________________________________

Quantity ___________________________________

C.S.I. Section 11400

CLCS76e

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

STANDARD FEATURES

■ 245 racks per hour

■ Opti-RinSe™ system

■ Patent Pending Rapid Return Conveyor Drive

Mechanism

■ Insulated hinged double doors with door

interlock switches

■ Patent Pending Door Seal System

■ 19.5 inch chamber height opening

■ Top mounted micro-processer control module

■ Energy saver mode

■ Dirty water indicator

■ Low temperature alert

■ Conveyor dwell

■ Delime notication

■ Service diagnostics

■ NAFEM Data Protocol compliant

■ Patent Pending Computational Fluid Dynamic

Designed Self-Aligning Wash Manifolds

■ Stainless steel debossed anti-clogging wash

arms

■ Patent Pending Removable Integrated Pump

Intake Screen

■ Stainless steel self-draining pumps and impellers

■ Single, sloping scrap screen and deep basket

■ Stainless panels enclose perimeter and bottom

■ Door actuated drain closure

■ Single point electrical connection (three phase

only), does not include the booster heater

■ Convertible hot water or low temp nal rinse

■ Vent fan and booster heater control

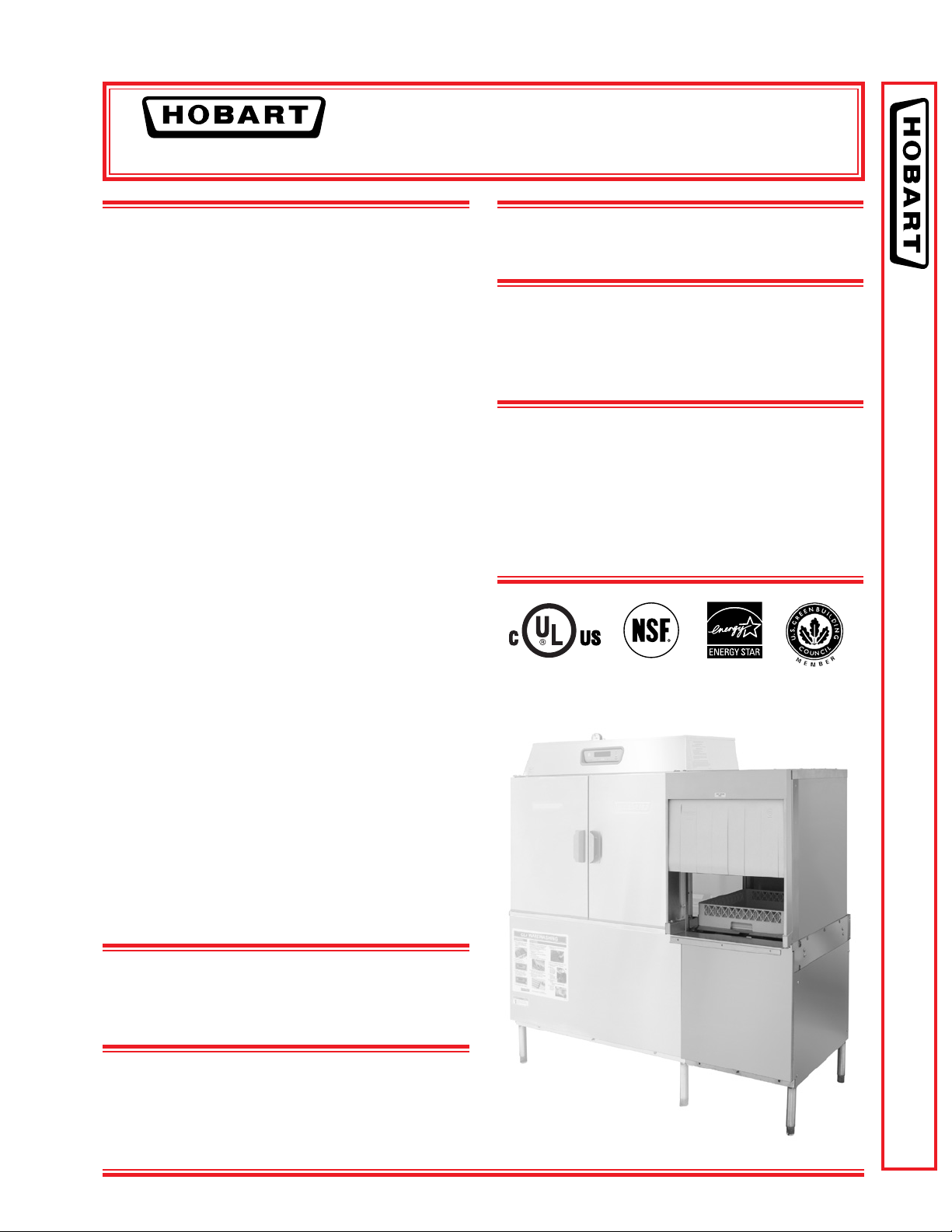

DISHWASHER

MODEL

❑ CLCS76e – Dishwasher

OPTIONS AT EXTRA COST

❑ Stainless steel pressure-less 15 KW or 30 KW

booster heater

❑ Higher than standard chamber

ACCESSORIES

❑ Stainless steel vent hoods

❑ Direct drive unloader

❑ Blower-dryer

❑ Drain water tempering kit

Specications, Details and Dimensions on Inside and Back.

CLCS76e DISHWASHER

DIRECTION OF OPERATION

❑ Right to Left

❑ Left to Right

VOLTAGE

❑ 208/60/1 ❑ 240/60/1 ❑ 380/60/3

❑ 208/60/3 ❑ 240/60/3 ❑ 480/60/3

❑ 600/60/3

F-40243 – CLCS76e Dishwasher Page 1 of 12

CLCS66e shown

Page 2

CLCS76e

DISHWASHER

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

THE CLe WAREWASHER IS NOW STANDARD WITH MORE EFFICIENT FEATURES THAN EVER . . .

Inside and out the CLe warewashers by Hobart are packed with standard components and patented design

innovations that make them the biggest value in the dishwasher industry.

Wash Manifolds. Patent pending Computational

The insulated hinged inspection doors provide easy

access in the chamber. Exterior wash pipes and

reduced interior bafes reduce clean-up time.

The patented Rapid Return drive allows for a wide

separation between the wash and the rinse zone.

Fluid Dynamic designed wash manifolds are selfaligning and come with Hobart’s signature debossed

anti-clogging nozzles for superior result.

The Hobart exclusive microprocessor control module

offers a choice of many features, such as an exclusive

Energy Saver Mode, Low Temperature Alerts, and

Dirty Water Indicator. It also displays pertinent

machine status and has a Delime Notication. The

controls have built-in Service Diagnostics and are

NAFEM Data Protocol Compliant.

Soil Management System. Screen design sheds soil

more easily than at screens, reduces frequency of

cleaning — easy to empty large soil particles . . . Just

lift out the scrap basket.

Opti-RinSe™. Hobart’s exclusive patent pending

Opti-RinSe™ signicantly reduces operating cost

by reducing rinse water and the energy required to

heat the water. The unique spray pattern uses large

droplets to more efciently sanitize the ware.

OTHER STANDARD FEATURES . . .

• Patent Pending Thermal Layer Curtains help keep

the heat inside the machine.

• Patented Ball Detent Clutch Conveyor Drive for

maximum protection against conveyor Jams

• Patent Pending Integrated Removable Pump

Intake Screen to offer the ultimate guard of keeping

debris from entering the pump.

• Patent Pending Hinged Door Seals and stainless

steel labyrinth seal for drip-free operation

• Low-Temp Convertibility In Field. All machines

shipped hot. Change software in eld at set up to

low temperature if desired – then, if requirements

change, convert from one mode to the other in the

eld. An exclusive feature – standard from Hobart.

• Door Actuated Drain Closure. Closing the door

automatically actuates drain closure, eliminates

extra manual steps, ensures that closure is in the

correct position.

Page 2 of 12 F-40243 – CLCS76e Dishwasher

Page 3

CLCS76e

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

AVAILABLE OPTIONS AND ACCESSORIES . . .

Flexibility is synonymous with Hobart CLe dishwash ers. If your operation demands a dishwasher with a

vent hood, an extended hood . . . a power scrapper,

just specify the combination of options that suit your

needs.

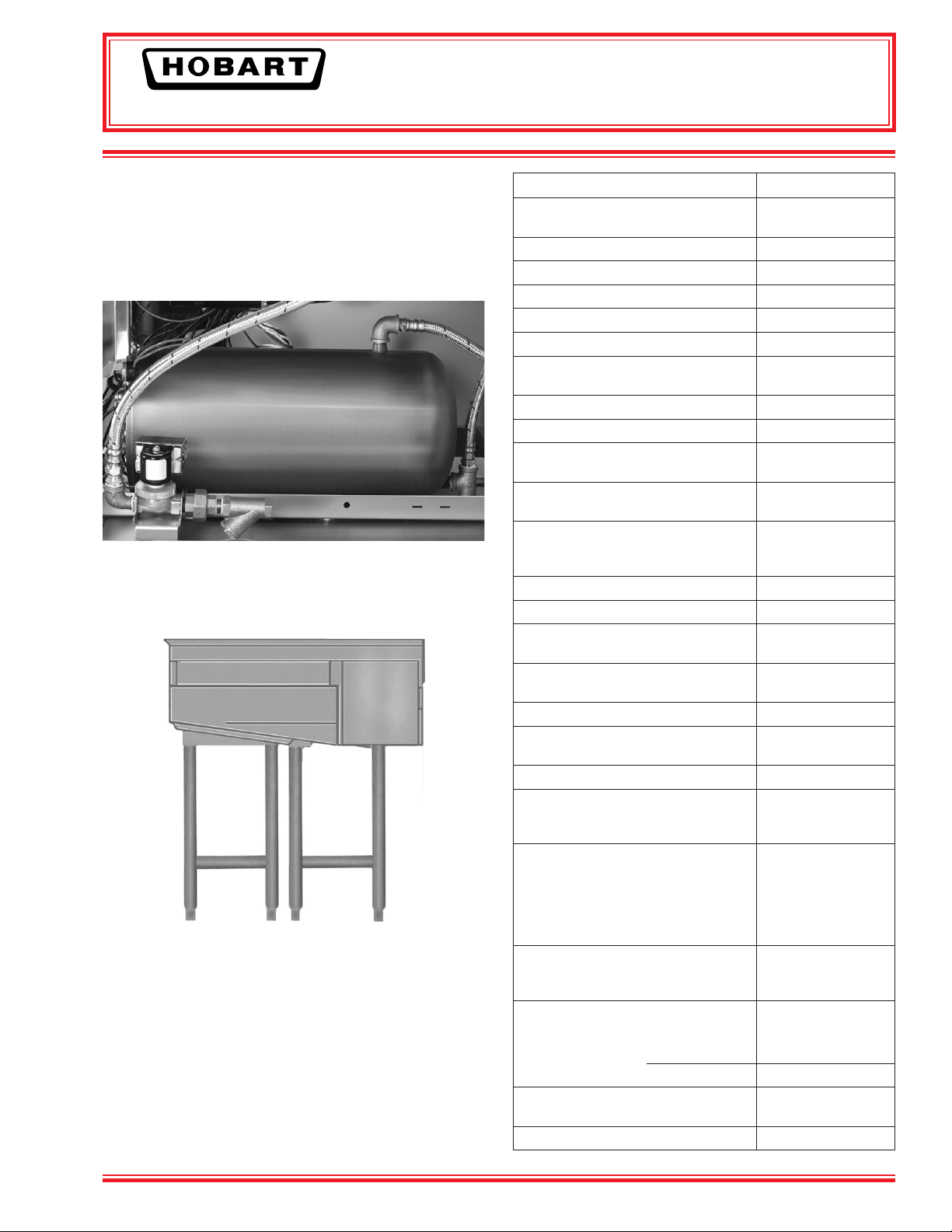

Built-in Pressureless Stainless Steel Booster Heater.

Interwired and interplumbed. Saves on installation and

saves oor space. Simplies operation with just one

switch to power dishmachine and booster.

DDU38e Direct Drive Unloader. Center pawl to be

connected to dishwasher conveyor by means of a

stainless steel adjustable rod. As conveyor drives,

center pawl drives racks around 90 degree corner.

The DDU38e is designed to move the racks at the

same speed as the conveyor dishwasher speed.

The DDU38e adds 38" to the length of the machine.

OTHER AVAILABLE ACCESSORIES . . .

Blower-dryer, steam booster heater, and a singlepoint electrical connection to include electric booster

heater.

Machine Ratings (Mechanical)

Racks per hour (193⁄4" x 193⁄4") 245

Conveyor Speed - feet per minute 6.8 max.

Dishes per Hour (Average 25 per rack) 6,100

Glasses per Hour (Average 45 per rack) 10,980

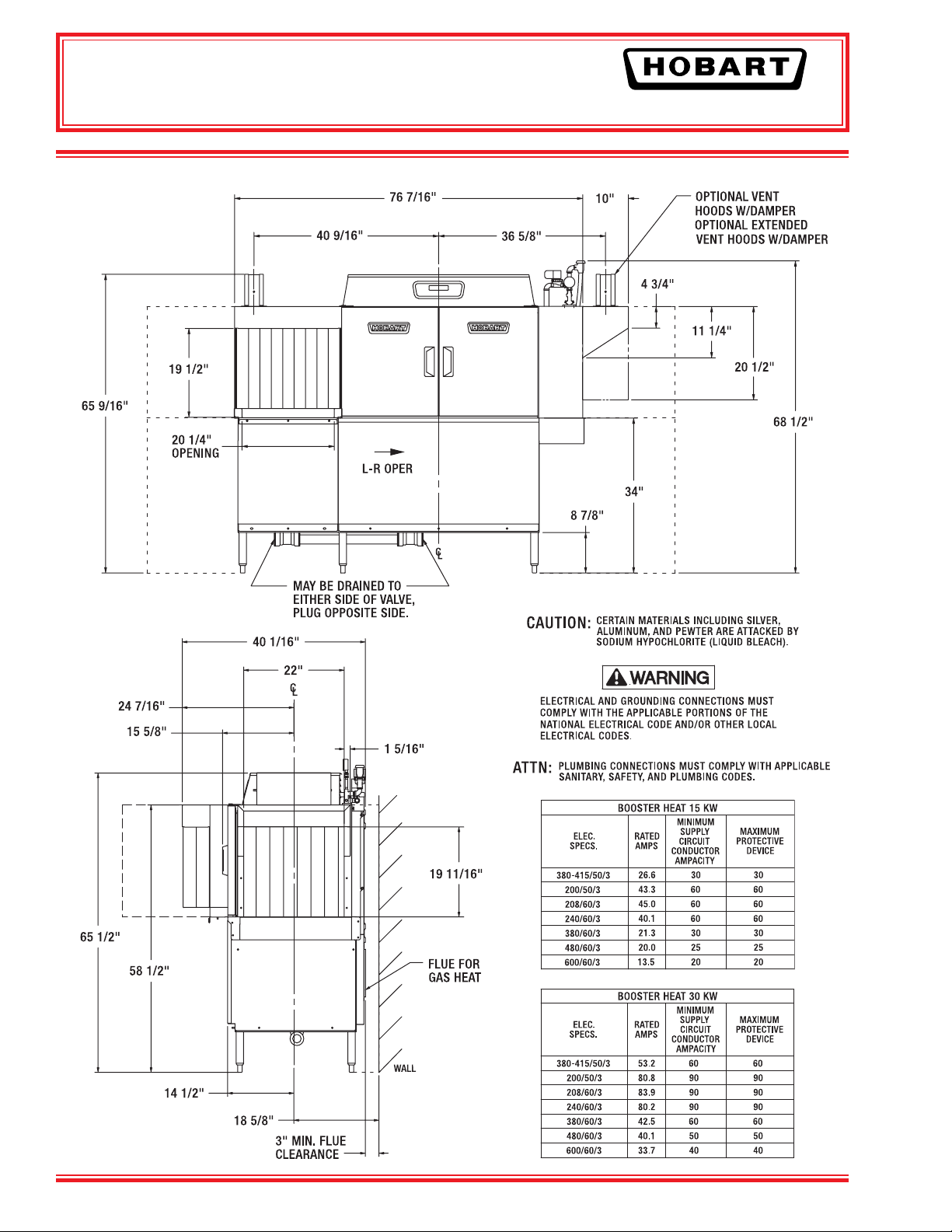

Floor Space – Table to Table (Inches) 76

Overall Dimensions – H x W x D (Inches) 681⁄2 x 761⁄2 x 311⁄4

Motor H.P. Power Scrapper 2

Conveyor Drive H.P.

Number of Tanks 2

Tank Capacity – Gallons Power Scrapper 23

Pump Capacity –

Gallons per Minute - Weir Test 165

Heating Equipment –

(For keeping power wash hot)

Gas Burners (with Natural Gas) 78,000 BTU per hr.

Electric Heating Unit – Size Used 15 KW

Optional Booster Heater / Final Rinse 15 KW / 30 KW

Rinse – Minutes operated during hour of

maximum operation 60

Final Rinse Flow – Gals. per min.

At 15 PSI Flow Pressure 1.98

At 20 PSI Flow Pressure 2.30

Final Rinse Flow – Gals. per hr. – MAXIMUM

At 15 PSI Flow Pressure 119

At 20 PSI Flow Pressure 138

Rinse 20 PSI Flow Pressure

Gal./Rack

Steam Consumption –

Pounds per hr. - MAXIMUM

Approx. 30 lbs. per hr. = 1 boiler H.P. (BHP)

Dishwasher, based on 20 PSI steam and

on customer supplying final rinse water

at 180°F maximum 65

Steam Booster, if used on 20 PSI steam 20 PSI water flowing - 130°F entering

water raised to 180°F min. 60

Exhaust Requirements –

Cubic Feet per minute

Peak Rate of Drain Flow – Gallons per minute.

(Initial rate with full tank) 38

Shipping Weight Crated – Approximate lbs. 613

DISHWASHER

CLCS76e

Wash 2

1

⁄6

Wash 23

Hot Water Sanitizing -

Chemical Sanitizing

.56 - 180°F – .56 - 120°F

Entrance End 200

Discharge End 400

F-40243 – CLCS76e Dishwasher Page 3 of 12

Page 4

CLCS76e

DISHWASHER

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

Page 4 of 12 F-40243 – CLCS76e Dishwasher

Page 5

CLCS76e

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

DISHWASHER

LOAD END

UNLOAD END

F-40243 – CLCS76e Dishwasher Page 5 of 12

Page 6

CLCS76e

ELECTRIC L-R

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

Page 6 of 12 F-40243 – CLCS76e Dishwasher

Page 7

CLCS76e

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

ELECTRIC R-L

F-40243 – CLCS76e Dishwasher Page 7 of 12

Page 8

CLCS76e

GAS L-R

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

Page 8 of 12 F-40243 – CLCS76e Dishwasher

Page 9

CLCS76e

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

GAS R-L

F-40243 – CLCS76e Dishwasher Page 9 of 12

Page 10

CLCS76e

STEAM L-R

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

Page 10 of 12 F-40243 – CLCS76e Dishwasher

Page 11

CLCS76e

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

STEAM R-L

F-40243 – CLCS76e Dishwasher Page 11 of 12

Page 12

CLCS76e

DISHWASHER

SPECIFICATIONS: Meets requirements of A.S.S.E. Standard No.

1004.

DESIGN: Semi automatic, high or low temperature single-tank,

rack-type dishwasher with exible patent pending thermal layer

curtains at the ends of chamber and between wash and nal

rinse zones. Insulated hinged inspection doors located in front of

machine provide easy access to wash arms, rinse arms, strainer,

strainer basket, and pump intake screen. Length of machine inside

tank (at table connection) 76". Machine designed to clean and

sanitize with hot water 160°F wash and 180°F (minimum) nal

rinse, or low temperature 130°F wash and 120°F nal rinse and a

chemical sanitizer. Water hardness recommended to be 3 gr. for

best results. Automatic interlocks shut off pump and conveyor if

door is opened when machine is in operation.

CONSTRUCTION: Tanks, chambers, frame, legs, control box,

doors, and all panels are constructed of stainless steel.

PUMPS: The two recirculating stainless steel pumps and impellers with ceramic seat seals. Easily accessible pump assembly

permits quick inspection. The pumps are self-draining. All piping

distributing water to the upper and lower wash arms is stainless

steel tubing.

PUMP MOTORS: Built for Hobart 2 hp grease-packed ball

bearings, splash proof, ventilated with manual, resettable inherent

overload protection. Available in electrical specications of

208-240/60/1, 208-240/60/3, 480/60/3 and 600/60/3. Also

available, but not submitted for UL listing are 200-240/50/3 and

380-415/50/3.

CONTROLS: A stainless steel control module with power and

“start/stop” buttons is mounted on top of the machine. Machine

control circuitry will be operated from a 120-volt control circuit

transformer. Electrical components are completely wired with

105°C, 600V thermoplastic insulated wire with stranded conductors

routed through UL listed electrical conduit or covered wire way.

CONVEYOR: Patent Pending Rapid Return drive, designed for

more even throughput of racks and allows for a 16-inch separation

between the wash and the rinse zone. Racks conveyed automatically through wash and rinse zones and onto clean dish table.

Patented Ball Detent Clutch drive prevents damage to machine

or racks, should movement of racks be obstructed. Rack tracks,

conveyor structure, and drive units of stainless steel for 193⁄4" x

193⁄4" racks as standard. Conveyor speed: 6.8 FPM.

DRIVE MOTOR: Built for Hobart, 1⁄6 horsepower gear motor,

ventilated with manual, resettable inherent overload protection.

Available in electrical specications of 208-240/60/1, 208-240/60/3,

480/60/3 and 600/60/3. Also available, but not submitted for UL

Listing are 200-240/50/3 and 380-415/50/3.

CORNER POWER SCRAPPER: CLCS76e power scrapper is

equipped with an upper and lower wash arm with specially shaped

nozzles having large openings and arranged to effectively scrap all

types of tableware. Power scrapper arms and end caps are easily

removable for cleaning without use of tools. Removable perforated

stainless steel strainer pans support a deep perforated stainless

steel basket. Basket and strainer pans (3) can be removed without

lower wash arm removal.

POWER WASH: Wash tank is equipped with upper and lower

stainless steel Patent Pending CFD Wash Arms which effectively

direct water jets to all ware surfaces. Both upper and lower wash

arms are self-aligning and have easily removable end caps for

cleaning without use of tools. A removable perforated stainless

steel strainer pan supports a deep perforated stainless steel

basket.

FINAL RINSE: Final rinse ow rate: 2.3 gpm, .56 gpr, 138-gph.

Stainless steel upper and lower Patented Auto Position Rinse

Arms™ have single rows of nozzles. Racks entering the rinse zone

As continued product improvement is a policy of Hobart, specications are subject to change without notice.

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

automatically trigger rinse. Final rinse water line is equipped with

a vacuum breaker downstream of an electrically operated solenoid

valve in common piping system. Removable perforated stainless

steel strainer basket can be removed without removing lower rinse

arm. Rinse agent and Low Temp Final Rinse – Sanitizer agent

(5.25% sodium hypochlorite – bleach) dispenser injection ports

provided in nal rinse piping above chamber. Caution: Certain

materials, including silver, aluminum, and pewter are attacked by

sodium hypochlorite (bleach) in the chemical sanitizing dishwasher

mode of operation.

FILL: Fill water line is equipped with vacuum breaker on downstream side of electrically operated solenoid valve in common

piping system, for automatic maintenance of tank level.

DRAIN AND OVERFLOW: Large bell-type automatic overow

and drain valve inside power scrapper tank controlled from inside

of machine. Power scrapper overows to drain. Wash tank drain

controlled from inside of the machine overows to power scrapper

through large internally mounted stainless steel tubing. Drain seals

are large diameter high temperature o-rings. Drain automatically

seats by closing inspection doors. Common drain utilizes a removable large diameter stainless steel tube sealed by rubber o-rings

at each drain housing. Drain housing can be plumbed from load or

unload end of machine.

STANDARD EQUIPMENT: Digital display of power scrapper, wash

and nal rinse temperature. Positive low water protection for tank

heat. Patent Pending Thermal Layered Curtains throughout

machine are keyed to ensure proper placement. Drains are

automatically closed when inspection doors are closed. Stainless

steel adjustable feet. Bolted stainless steel enclosure panels

around perimeter and underneath machine. Automatic tank ll.

Door interlocks. Auto-timer. Vent fan and booster heater controls.

Single point electrical connection. Low temperature alerts. Service

diagnostics. Dirty water indicator. Delime notication. Conveyor

dwell. Energy Saver Mode. NAFEM Data Protocol compliant.

WASH TANK HEATING SELECTIONS (must choose one):

ELECTRIC: One electric Incoloy® sheathed immersion heater

(15 KW) removable from inside tank. Tank water temperature is

controlled by microprocessor controlled thermostat with positive

low-water protection and magnetic contactor. (Disconnect switches

not furnished.) A high limit device mounted on the surface of the

tank additionally protects heating element.

STEAM: One-inch stainless steel steam coil. Tank water temperature controlled by microprocessor controlled thermostat with

positive low-water protection. Steam supplied to machine through

high temperature steam solenoid valve and line strainer.

GAS: Regulated infrared immersion tube gas burner system.

Microprocessor controlled thermostat and a blower with a pressure

switch control tank water temperature. Positive low water protection is provided. A high limit device mounted on the surface of the

tube additionally protects immersion tube. A solid-state igniter

board controls the gas valve and provides ame ignition. A transformer steps the control circuit voltage down from 120 volts to 24

volts to power the igniter board and gas valve. For natural gas, gas

pressure to burner (customer connection) not to exceed 7" W.C.

For LP gas, gas pressure to burner (customer connection) not to

exceed 11" W.C. If gas pressure is higher than 7" W.C. natural or

11" W.C. LP pressure regulating valve must be supplied (by others)

in the gas line to the dishwasher.

OPTIONAL EQUIPMENT AT EXTRA COST:

Stainless steel pressureless booster heater. Stainless steel vent

hoods with vent stack and locking-type damper. Higher than

standard chamber. Unloaders. Floor mounted steam booster.

193⁄4" x 193⁄4" peg, combination and miscellaneous racks. Table limit

switch. Drain water tempering kit.

Page 12 of 12 F-40243 – CLCS76e Dishwasher

F-40243 (REV. 07/11) LITHO IN U.S.A. (H-01)

Loading...

Loading...