Hobart CLPS76ER ML-138258, CLPS86E ML-138177, CLPS86E ML-138176, CLPS86ER ML-138281, CLPS76E ML-138107 User Manual

...

CLe-SERIES

DISHWASHERS

MODEL R-L OPERATION L-R OPERATION

CL44e ML-138101 ML-138102

CLPS66e ML-138103 ML-138104

CLCS66e ML-138109 ML-138110

CL54e ML-138105 ML-138106

CLPS76e ML-138107 ML-138108

CLCS76e ML-138111 ML-138112

CL64e ML-138174 ML-138175

CLPS86e ML-138176 ML-138177

CLCS86e ML-138178 ML-138179

CL44eR ML-138251 ML-138252

CLPS66eR ML-138253 ML-138254

CLCS66eR ML-138259 ML-138260

CL54eR ML-138255 ML-138256

CLPS76eR ML-138257 ML-138258

CLCS76eR ML-138261 ML-138262

CL64eR ML-138278 ML-138279

CLPS86eR ML-138280 ML-138281

CLCS86eR ML-138282 ML-138283

701 S. R IDGE AV ENUE

TRO Y, O HIO 4 5374- 0001

937 3 32-3000

www.h ob art co rp .co m

F44126 Rev. B (February 2011)

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED

TO INSTALL GAS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL

FIELD START-UP AND ADJUSTMENTS OF THE EQUIPMENT COVERED

BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE

FOLLOWED IN THE EVENT THE SMELL OF GAS IS DETECTED. THIS

INFORMATION CAN BE OBTAINED FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN UNITS

AT MAIN SHUTOFF VALVE AND CONTACT THE LOCAL GAS

COMPANY OR GAS SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS OR LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE.

FOR YOUR SAFETY

READ BEFORE OPERATING

DO NOT USE THIS APPLIANCE IF ANY PART HAS BEEN

UNDER WATER. IMMEDIATELY CALL A QUALIFIED SERVICE

TECHNICIAN TO INSPECT THE APPLIANCE AND TO REPLACE

ANY PART OF THE CONTROL SYSTEM AND ANY GAS

CONTROL WHICH HAS BEEN UNDER WATER.

© HOBART 2008

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO

OPERATE THIS DEVICE.

– 2 –

TABLE OF CONTENTS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chemical Sanitizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Adjust Machine Height and Level Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Dish Table Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Water Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Plumbing Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Drain Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Water Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chemical Feeder Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Steam Connection (When Equipped for Steam Heat) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Gas Connection (When Equipped for Gas Heat). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Venting Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Type II Canopy Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pant-Leg Vent Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Exhaust Flow Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Electrical Connections – Dishwasher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Optional Equipment Control Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

CLeR Energy Recovery Set-up Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

CLeR Air Flow Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Curtain Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Keypad and Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Filling the Dishwasher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Starting the Gas Heat Dishwasher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Minimum Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

High-Temperature Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Low-Temperature Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Alternative Temperature Display Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Low FR Temp Alert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Tank Temperature Alert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Dishwashing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Optional Table Limit Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Auto-Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Energy Saver Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Dirty Water Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Deliming Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

DOs and DON'Ts for Your New Hobart Warewasher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Programming Security Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Programming Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Menu Display Prompts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Entering the Parameters Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Navigating the Parameters Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Parameters Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Communications Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

– 3 –

Installation, Operation and Care Of

CLe and CLeR-SERIES DISHWASHERS

SAVE THESE INSTRUCTIONS

GENERAL

CLe and CLeR machines are rack-type warewashers that move the racks from one end

of the machine to the other, exposing the ware to progressive wash and rinse zones.

(Pumps and nal rinse are activated by the inserted rack to energize the specic wash or

rinse action needed.) The CLe and CLeR-series machines are offered in optional lengths,

sections, features, and provide different speeds to meet productivity and performance

requirements. (All CLe and CLeR-Series Dishwashers have electronic controls with digital

temperature displays.)

The CLeR models have an energy recovery system and include all of the standard features

of the CLe. They use an internal condensing system to capture the water vapor and preheat

incoming cold water for the nal rinse. The CLeR units are only available in hot water

sanitizing mode, three phase, and come standard with a built-in 30kW booster heater,

which is designed to maintain nal rinse temperature of 180°F with a minimum incoming

cold water temperature of 55 °F.

Tanks, chambers, frames, legs and adjustable feet are made of welded stainless steel

construction. Hinged inspection doors provide access to the interior wash and rinse zones.

CLPS models provide a 22-inch power scrapper section and hinged access door. The power

scrapper removes the heavy soil before the rack enters the wash zone.

Machines can be ordered as left-to-right or right-to-left operation. Either electric, gas, or

steam tank heat is specied at time of order. Machines come standard ready to operate

with high-temperature sanitizing mode.

Hobart offers three right-angle possibilities to put your machine in a corner installation:

• The Side Loader moves the rack at a right angle into the machine from the scrapping

area.

• The Direct Drive Unloader moves the rack at a right angle coming out of the machine to

tabling where the clean ware can be unracked.

• The Corner Scrapper (CLCS models) puts a Power Scrapper in the corner location at

the load end of your machine, combining right angle entry with a scrapper section.

– 4 –

CHEMICAL SANITIZING

CLe machines can be converted to operate with low-temperature sanitizing mode

(with the use of chemical sanitizers). Refer to Sanitizing Mode programming

instructions on page 34.

Hot water sanitizing mode is designated by "High Temp." on the display when the

machine is turned on. Low-temperature or chemical sanitizing mode is designated

by "Low Temp." on the display when the machine is turned on.

CLe models that operate with chemical sanitization, use incoming water and nal

rinse water at 120°F minimum. Tank heaters raise that temperature to 130°F for

wash (and power rinse, if equipped).

UNPACKING

Immediately after unpacking the dishwasher, check for possible shipping damage.

If the machine is found to be damaged, save the packaging material and contact

the carrier within 15 days of delivery.

Prior to installation, verify that the electrical service agrees with the specications

on the machine data plate, which is located on the left-hand side of the control box.

INSTALLATION

After unpacking the dishwasher, remove the items shipped loose (overow tube

or standpipe, splash shields, curtains and literature envelope with instructions and

chamber hole plug kit) from inside the dishwasher.

INSTALLATION CODES

Installation must be in accordance with state and local codes, or in the absence

of local codes, with the National Fuel Gas Code, ANSI Z223.1 (latest edition), if

applicable, and the National Electrical Code ANSI / NFPA 70 (latest edition). In

Canada, the installation standards are: CAN/CSA B149.1 and CSA C22.1 (latest

editions).

CLeR MODELS

If the unit will not t thru verticle opening, the overall height of the unit can be

decreased 7" by removing the vent stack.

ADJUST MACHINE HEIGHT AND LEVEL MACHINE

Set the dishwasher in its proper location. Adjust the height and level the machine

by turning the adjustable feet in or out as necessary.

DISH TABLE ASSEMBLY

Dish tables should be tted into the dishwasher (Figs. 1, 2 & 3). Use silicone sealant

between table and lip of tank to prevent leakage. Rack track height should be

1

/4 to 5/16" (Fig. 2) above the tank lip. Dish tables should be sloped so that any

from

water carried from the dishwasher will drain back into the machine, but not from

the scrapping area.

NOTE: The dishwasher must be in its nal position, adjusted for proper height and

properly leveled before table assembly and plumbing connections are made.

– 5 –

Fig. 1

Fig. 2

WATER REQUIREMENTS

Proper water quality can improve ware washing performance by reducing spotting,

enhancing effectiveness of labor and extending equipment life. Water conditions

vary from one location to another. The recommended proper water treatment for

effective and efcient use of this equipment will also vary depending on the local

water conditions. Ask your municipal water supplier for details about local water

specics prior to installation.

Recommended water hardness is 3 grains of hardness per gallon or less. Chlorides

must not exceed 30 parts per million. Water hardness above 3 grains per gallon

should be treated by a water conditioner (water softener or in-line treatment). Water

treatment has been shown to reduce costs associated with machine cleaning,

reduce deliming of the dishwasher and reduce detergent usage in the dishwasher.

Sediment, silica, chlorides or other dissolved solids may require particulate ltration

or other water treatment.

If an inspection of the dishwasher or booster heater reveals lime buildup after

the equipment has been in service, in-line water treatment is recommended.

Contact your local Hobart Service ofce for specic recommendations.

Fig. 3

– 6 –

PLUMBING CONNECTIONS

DRAIN CONNECTION

AT EITHER END

STRAINER

safety and plumbing codes.

The plumber who connects this machine is responsible for making certain that both

water and steam lines are THOROUGHLY FLUSHED OUT BEFORE connecting to

any manual valve or solenoid valve.

This ‘‘ush-out’’ is necessary to remove all foreign matter, such as chips (resulting

from cutting or threading of pipes), pipe joint compound from the lines or, if soldered

ttings are used, bits of solder or cuttings from the tubing. Debris, if not removed,

may lodge in the valves and render them inoperative. Manual valves or solenoid

valves found defective by foreign matter and any expenses resulting from this debris

are NOT the responsibility of the manufacturer.

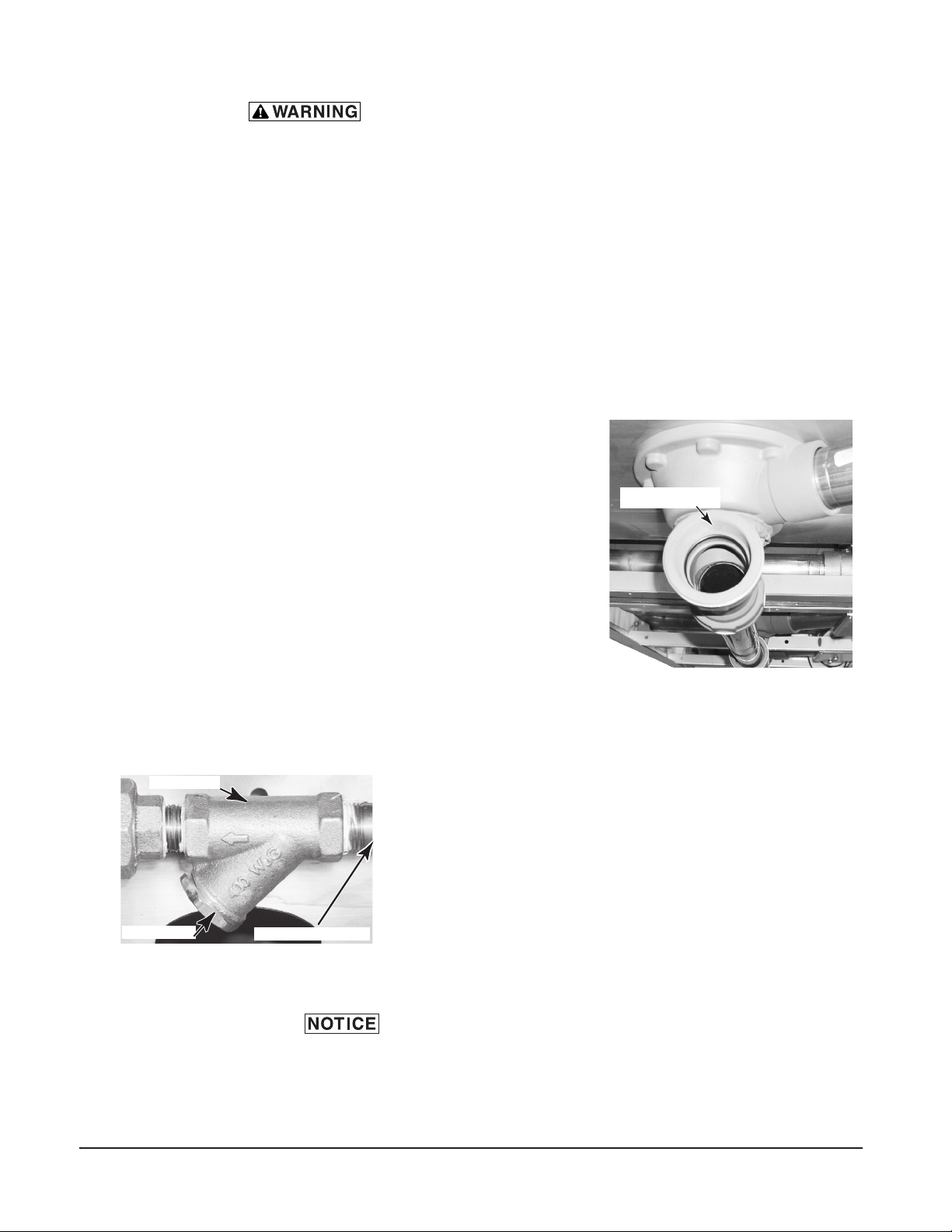

DRAIN CONNECTION

The common drain for the tank(s) requires only

one connection to the oor drain. The drain

can be connected at either end. A pipe plug

is provided for the opposite end. Connect the

drain (Fig. 4) through a trap to the sewer using

2" NPT pipe. If a grease trap is required by

code, it should have a minimum ow capacity

of 31 gallons per minute.

Plumbing connections must comply with applicable sanitary,

WATER CONNECTIONS

CLEANOUT

INCOMING WATER

Fig. 5

Fig. 4

1

/2" minimum I.D. pipe size for the incoming water supply

Use

line to the machine (Fig. 5). A owing pressure of 15 to 25

psig must be maintained at the machine. For long runs, use

larger pipe and insulation to ensure adequate pressure and

temperature. On CLe models without built-in booster heater,

if ow pressure exceeds 25 psig, a pressure-reducing valve

(by others) must be installed in the water supply line. On CLe

models with built-in booster heater and all CLeR models, pressure

reducing valves are factory installed in the water supply lines.

For temperature requirements, refer to the Required Incoming

Water Temperature table on page 8.

The water pressure regulator must have a relief bypass. Failure

to use the proper type of pressure regulator may result in damage to the

machine.

A pressure gauge is provided for verication of proper water pressure.

– 7 –

RINSE AID

AND / OR

CHEMICAL

SANITIZER

FEED PORTS

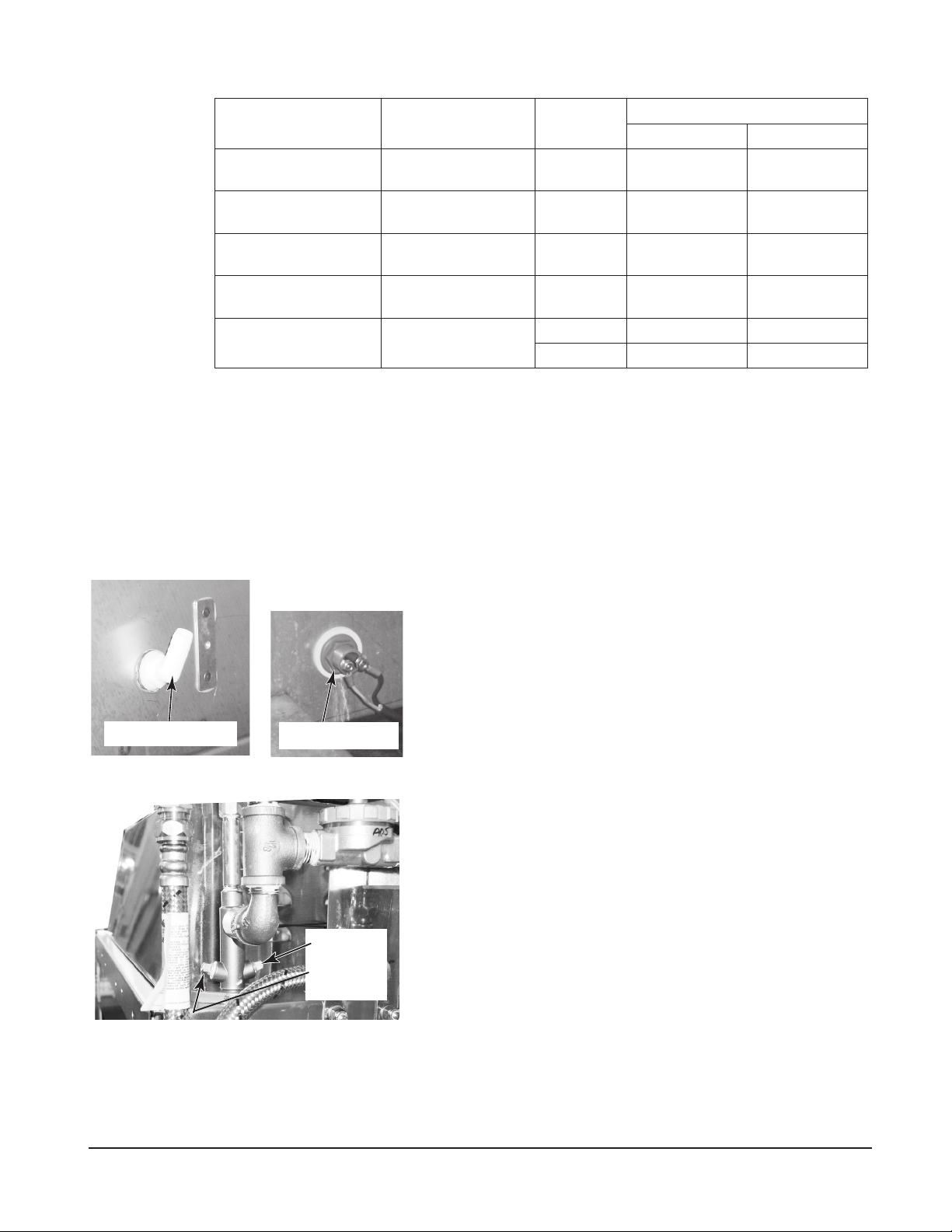

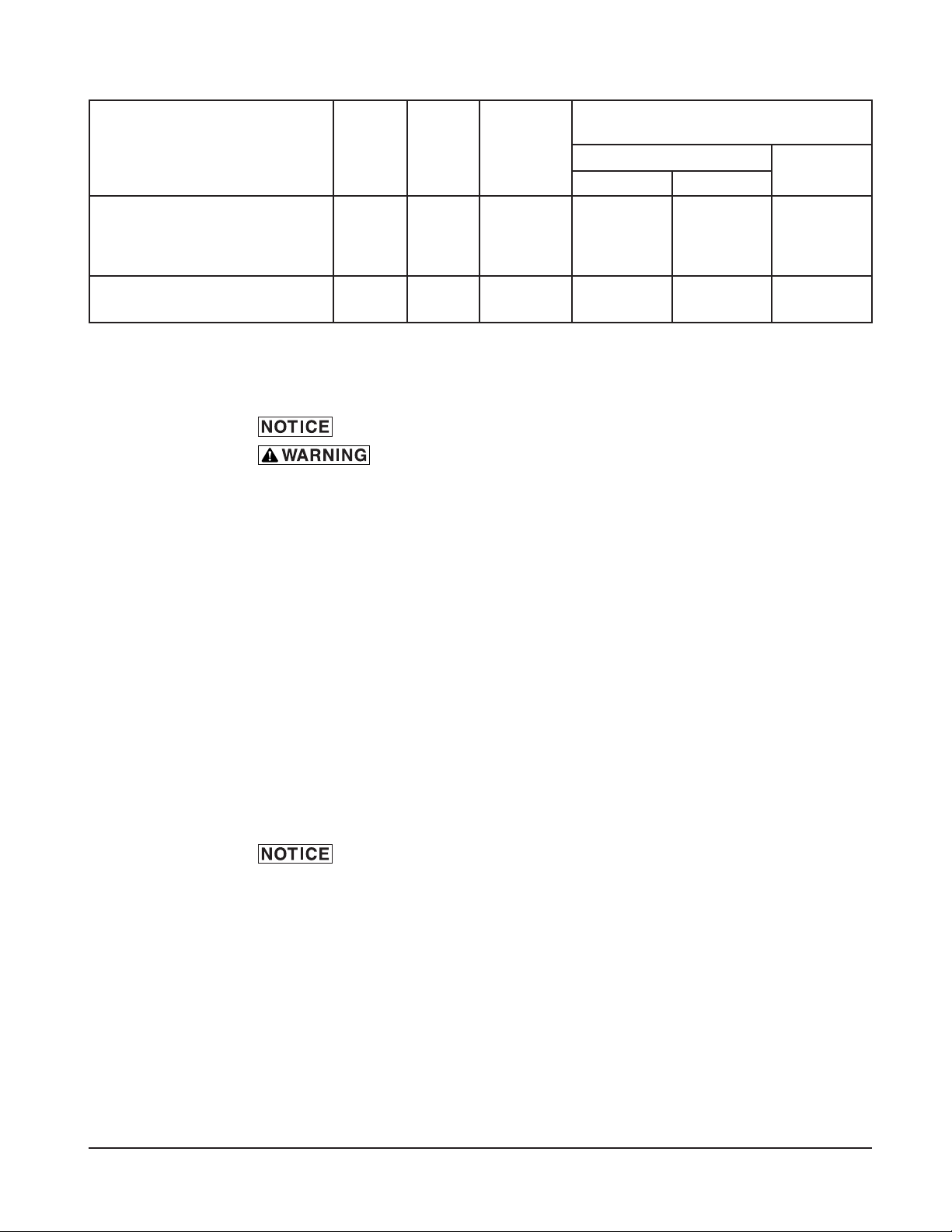

REQUIRED INCOMING WATER TEMPERATURE

Model Sanitizing Mode Connection Water Supply

CLe without Built-in

Booster

CLe without Built-in

Booster

CLe with 15kW Built-

in Booster

CLe with 30kW Built-

in Booster

CLeR with 30kW

Built-in Booster

CHEMICAL FEEDER INSTALLATIONS

This machine must be operated with an automatic detergent feeder and, if

applicable, an automatic chemical sanitizer feeder, including a visual means

to verify that detergents and sanitizers are delivered or a visual or audible

alarm to signal if detergents and sanitizers are not available for delivery

to the respective washing and sanitizing systems. Chemical feeders are

supplied by others. For electrical connection, refer to Optional Equipment

Control Connections, page 16.

Hot Water Sanitizing Hot Water

Chemical Sanitizing Hot Water

Hot Water Sanitizing Hot Water

Hot Water Sanitizing Hot Water

Hot Water Sanitizing Cold Water

Hot Water

Minimum Maximum

180

°F (82°C) 194°F (82°C)

120

°F (49°C)

140

°F (60°C)

110

°F (43°C)

55

°F (13°C)

°F (43°C)

110

N/A

N/A

N/A

N/A

N/A

DETERGENT FEED PORT

(TYPICAL) (BY OTHERS)

Fig. 6 Fig. 7

Fig. 8

DETERGENT SENSOR

(TYPICAL) (BY OTHERS)

Detergent Feeder

Your chemical supplier will install a detergent feeder port

similar to the one shown in Fig. 6, that provides for discharge

of detergent into the wash tank.

An electric monitoring device, similar to the one shown in

Fig. 7, will be installed on the side of the wash tank to signal

the feeder to maintain the proper concentration of detergent.

Rinse Agent Feeder

Rinse agent is typically fed into the nal rinse water at one

of the ports on the incoming water line below the pressure

gauge (Fig. 8).

Chemical Sanitizer Feeder

Chemical sanitizer (on

CLe machines using low-temperature

sanitizing) is fed into the nal rinse water line at the other port

on the incoming water line below the pressure gauge (Fig. 8).

– 8 –

STEAM CONNECTION (When Machine is Equipped with Steam Tank Heat)

Steam supply pressure must agree with the steam trap (supplied) which

is rated for 10 to 50 psig differential pressure. If owing pressure exceeds 50 psig,

a pressure regulator (by others) must be installed in the supply line. Steam ow is

controlled by solenoid valves.

For single-tank steam coil installations, two connections are required, one for

supply and one for return. For two-tank steam coil installations, one common supply

connection and two return connections are required.

GAS CONNECTION (When Machine is Equipped with Gas Tank Heat)

Check the gas data plate attached to the dishwasher on the side of the control

box or refer to the tag attached to the gas burner tubing for the type of gas to be

used. All machines are shipped congured for natural gas. If conversion to LP gas

(propane) is required, a conversion kit with instructions is supplied and must be

installed before the machine is operated.

The burner is not adjustable. If owing gas pressure is above 7" W.C. (natural gas)

or 11" W.C. (propane gas), an additional regulator valve (by others) must be installed

in the supply line. Static incoming line pressure should not exceed 14.0" W.C. for

either propane or natural gas.

The gas supply line to the dishwasher must be provided with a

shut-off valve per code. The appliance and its gas connections must be leak

tested before placing the appliance in operation. Use soapy water for leak

tests. DO NOT use an open ame.

The installation must conform with local codes, or in the absence of local codes,

with the National Fuel Gas Code, ANSI Z223.1 (latest edition), available from the

American Gas Association, Inc., 1515 Wilson Blvd., Arlington, VA 22209. In Canada,

comply with CAN/CSA B149.1 and CSA C22.1 (latest editions).

NOTE: For gas line pipe connections, use Loctite 565, Hobart part number 546292,

or a exible sealant suitable for use with Natural and Propane Gases.

• The appliance and its individual shutoff valve must be disconnected from the gas

supply piping system during any pressure testing of that system at test pressures

1

in excess of

/2 psig (3.45 kPa).

• The appliance must be isolated from the gas supply piping system by closing

its individual manual shutoff valve during any pressure testing of the gas supply

1

piping system at test pressures equal to or less than

/2 psig (3.45 kPa).

– 9 –

Models

CL44e, CLPS66e, CLCS66e

CL54e, CLPS76e, CLCS76e

CL44eR, CLPS66eR, CLCS66eR

CL54eR, CLPS76eR, CLCS76eR

CL64e, CLPS86e, CLCS86e

CL64eR, CLPS86eR, CLCS86eR

Dissipate test pressure from the gas supply line before reconnecting the appliance

and its manual shutoff valve to the gas supply line.

the ue gases to the exterior of the building.

Refer to Venting Requirements on pages 10 – 14.

The dishwasher must be installed so that the ow of combustion and ventilation

air will not be obstructed. Ensure that no electrical cables or plumbing are routed

over the gas ue area. Adequate clearances for air openings into the combustion

chamber must be provided. Make sure there is an adequate supply of make-up air

in the room to allow for combustion of the gas at the burner(s).

GAS SPECIFICATIONS

Flowing Gas Pressure - Not Static

Type of

Gas

Natural

Propane

Natural

Propane

BTU/Hr

78,000

78,000

156,000

156,000

Connection

Line Size

1/2" NPT

1/2" NPT

3/4" NPT

3/4" NPT

Inches W.C. (Water Column)

Incoming Line Pressure

Minimum Maximum

3.5" W.C.

9.0" W.C.

3.5" W.C.

9.0" W.C.

7.0" W.C.

11.0" W.C.

7.0" W.C.

11.0" W.C.

Pressure

3.2" W.C.

8.2" W.C.

3.2" W.C.

8.2" W.C.

Failure to follow this procedure may damage the gas valve.

Gas heat machines must be provided with a means to exhaust

Manifold

Keep the appliance area free and clear from all combustible substances. Do not

obstruct the ow of combustion and ventilation air. The dishwasher must have a

minimum clearance from combustible construction of 3" at the rear and 0" at the

sides. A clearance of 23" must be provided at the front and 20" at each end of the

dishwasher for servicing and proper operation.

The burner is ignited automatically by solid-state electronic circuitry. There is no

pilot light. Gas ow is regulated by the temperature control circuit.

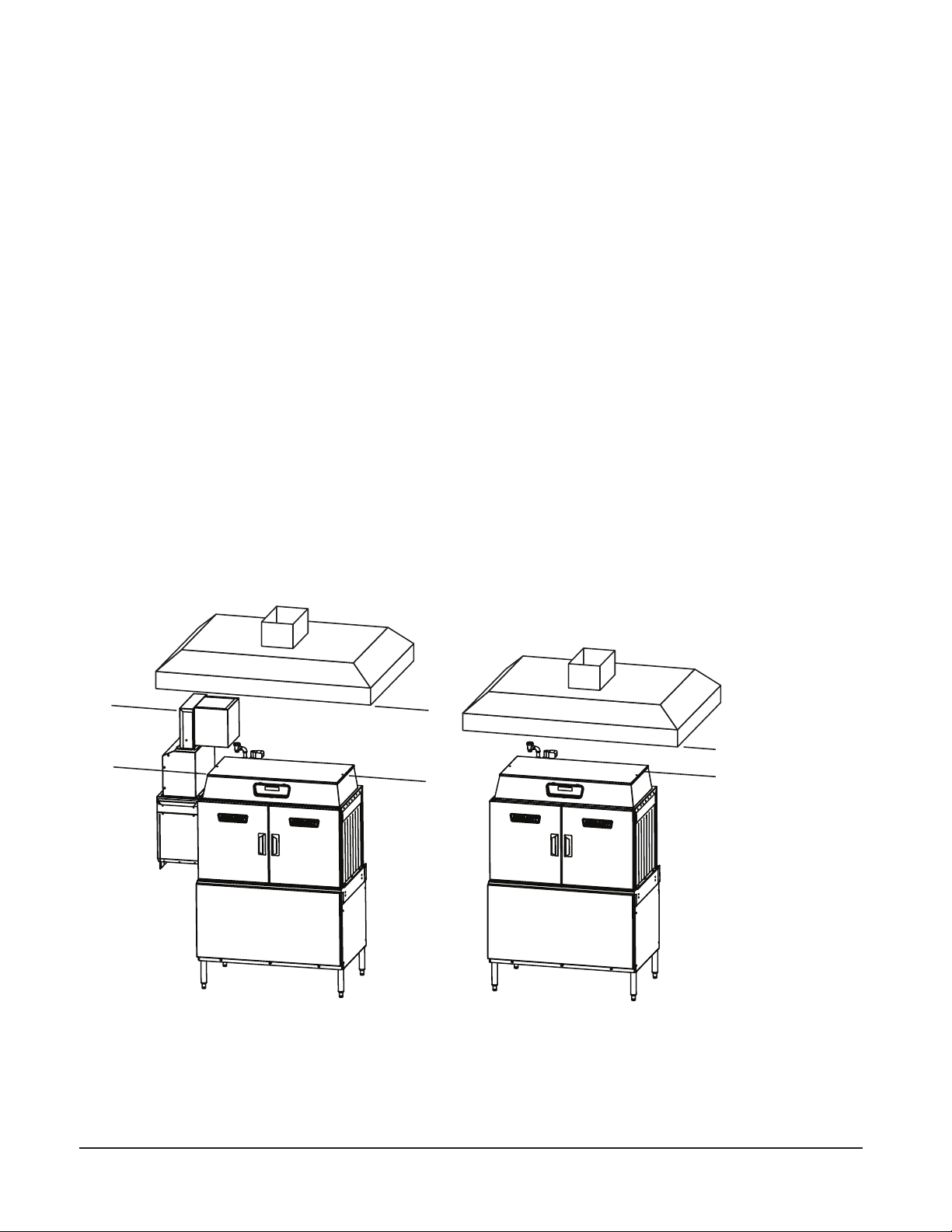

VENTING REQUIREMENTS

(To be supplied and installed by others).

Type II Canopy Hood

Most commercial dishwashers must be provided with external venting per local

codes. The exception is electric or steam heat machines operating in the chemical or

low temperature sanitizing mode where the existing room ventilation will compensate

for the vapors produced. The local authority has nal jurisdiction over this matter.

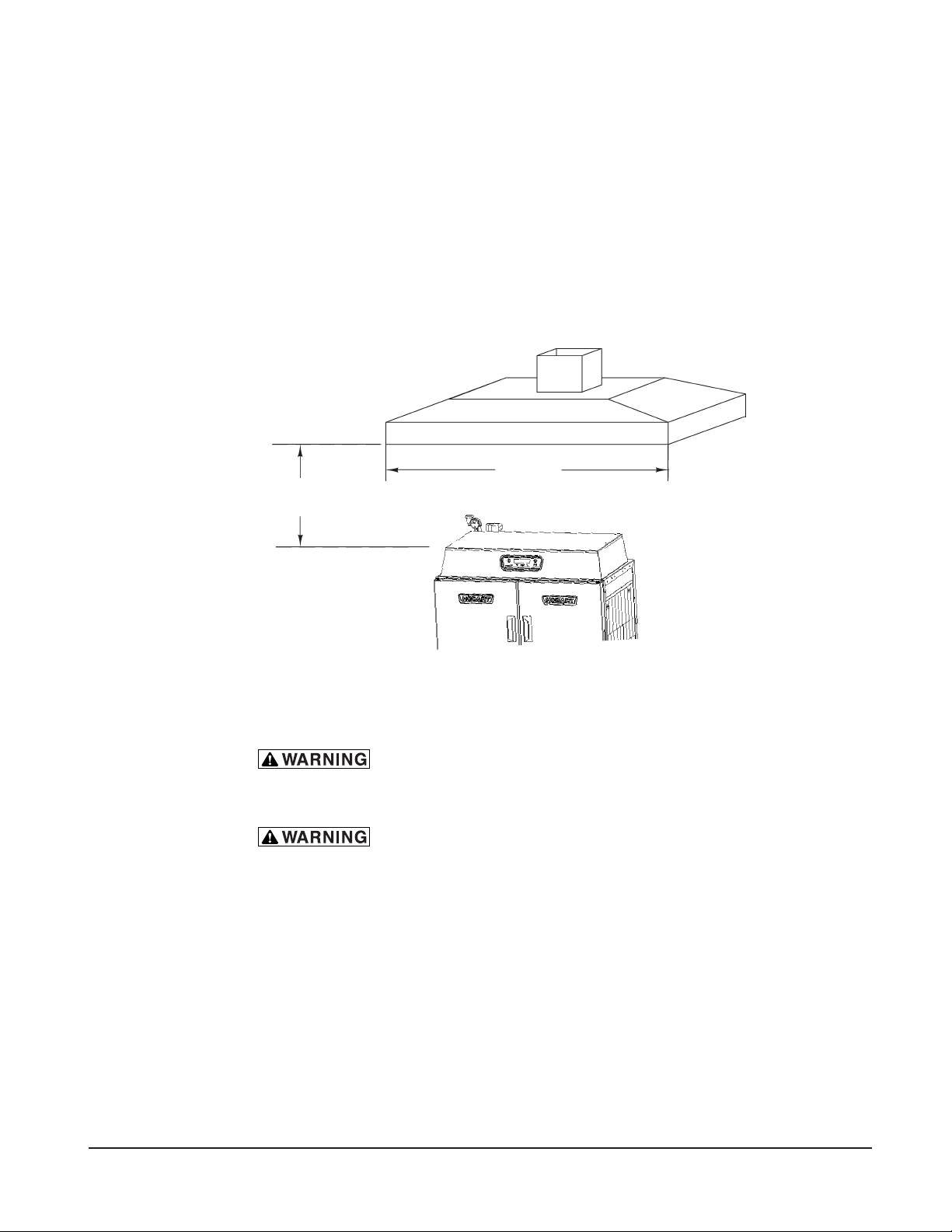

Venting can be provided by either a canopy hood over the whole machine (Fig. 9)

or by the pant-leg duct connection (Fig. 10).

CLeR units will require a back draft damper in the ventilation system.

– 10 –

A Hobart CLe or CLeR Series dishwasher equipped for gas tank heat is not provided

with a ue collar and is not intended to have the ue directly connected to a ventilation

system. However, the products of combustion must be vented to the outside air.

Exhaust air must not be vented into a wall, a ceiling, or a concealed space of a

building. A vent hood over the entire dishwasher (Fig. 9) can be employed to vent

both the moist air from the dishwashing chamber and the ue gases from the gas

heater. The volume of ue exhaust required for venting moist air and ue gases

using a single vent hood over the entire dishwasher must be calculated using the

Exhaust Flow Requirements on page 14.

A Type II canopy hood is recommended. A factory-built commercial exhaust hood

may be listed as conforming to Underwriters Laboratory's Standard 710 titled, Exhaust

Hoods for Commercial Cooking Equipment. Hoods must be installed according to

the manufacturer's instructions. Makeup air must be provided so that the exhaust

ow rate results in a positive building pressure in the room where the unit is located

(more outside air than exhaust air). Factory-built hoods not tested to UL Standard

710 and custom built hoods must comply with the following specications: They

must be built from stainless steel, 0.037" [No. 20 Gage] minimum thickness, or

copper sheet weighing at least 24 ounces per square foot; the hood must be secured

in place by noncombustible supports and the hood must meet the Exhaust Flow

Requirements on page 14.

TYPE II

CANOPY HOOD

19 1/8"

,?/(<:;+<*;:/6<3+

),*,5;,9,+05/66+

;6

CLEARANCE

;6

*3,(9(5*,

40504<46=,/(5.

-965;)(*2

40504<46=,9/(5.

(;36(+(5+<536(+

67,505.:

Fig. 9

– 11 –

CLe-SeriesCLeR-Series

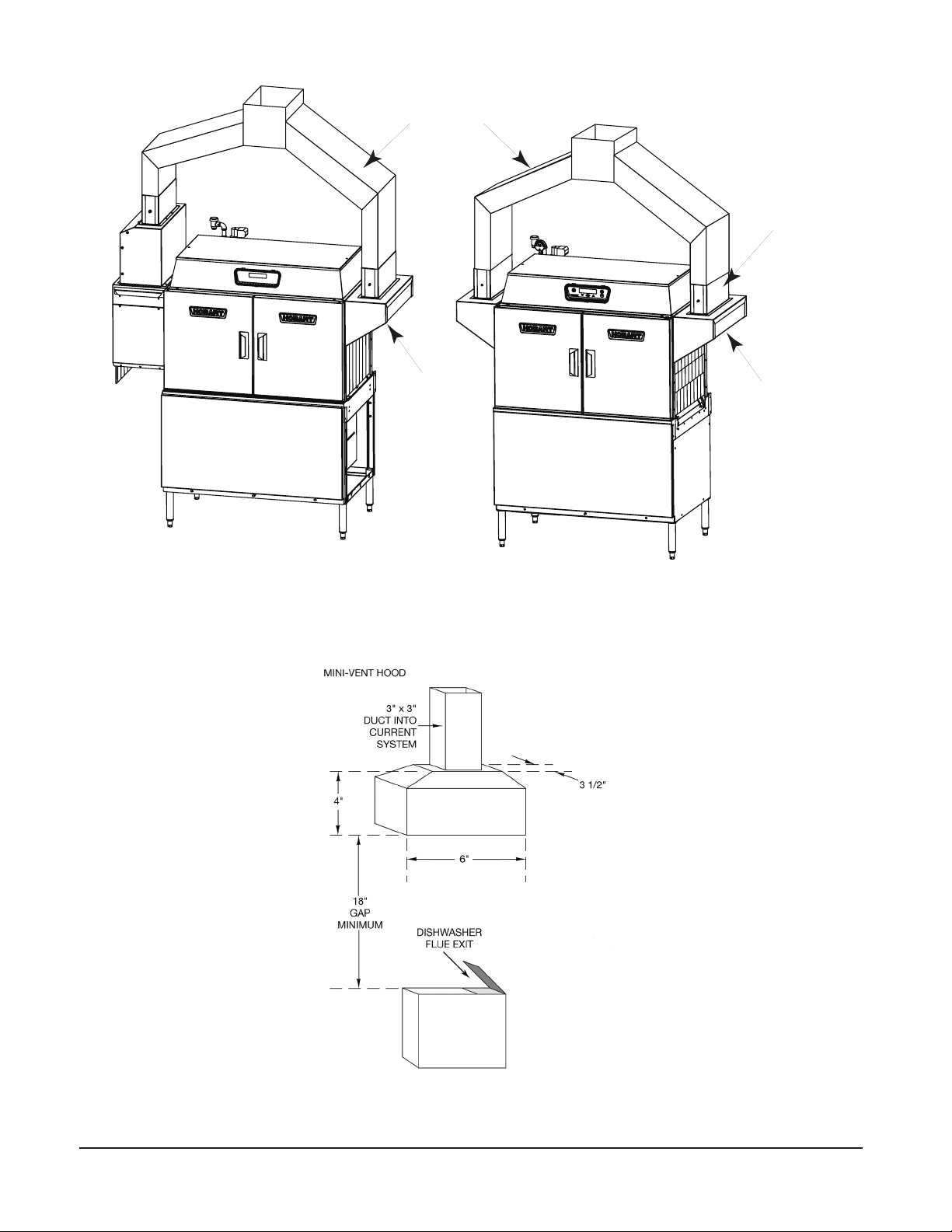

Pant-Leg Vent Connections

Gas heat machines must be provided with a means to exhaust

the ue gases to the exterior of the building.

Pant-Leg duct connectors (Fig. 10) alone DO NOT provide ventilation for the gas

ue at the rear of the machine. A mini-vent hood (Fig. 11) must be used or a canopy

type hood may be used (Fig. 9).

Moist air escapes from each end of the conveyor type dishwasher. The recommended

exhaust requirement is 200 CFM (CLe and CLeR) at the entrance end of the dishwasher

and 400 CFM (CLe)/175 CFM (CLeR) at the discharge end. Optional vent hoods or

extended hoods may be provided at each end of the machine. Sufcient make-up

air must be provided so the exhaust ow results in a positive building pressure in

the room in which the unit is located (more outside air than exhaust air). Hoods are

provided with 4" x 16" vent connectors with vent dampers which allow adjustment

during installation. Typical construction is for 'Pant-Leg' hood connections to the 4"

x 16" vent connectors (Fig. 10). Vent stacks must be watertight and t inside the

vent connector openings.

If using the 'Pant-Leg' duct, a mini-vent hood (Fig. 11) must be used to vent the

ue gases on machines using gas heat. The mini-vent hood must be positioned

a minimum of 18" above the ue exit at the rear of the dishwasher and connected

to existing duct work. The volume of ue exhaust in the mini-vent hood should not

exceed 200 CFM.

In either case, if a powered means of exhaust is used, an electrical interlock

must be provided to allow the ow of gas to the dishwasher burner only when

the exhaust system is in operation.

For more information, refer to the National Fuel Gas Code, ANSI Z223.1, NFPA54.

In all cases, local codes will prevail.

– 12 –

7(5;3,.+<*;

?

=,5;

*655,*;69

,?;,5+,+

/66+

Fig. 10

,?;,5+,+

/66+

CLe-SeriesCLeR-Series

Fig. 11

– 13 –

Exhaust Flow Requirements

CLEARANCE

HEIGHT

LENGTH

The following is based on the 2009 International Mechanical Code (IMC):

The ow of air required for a vent hood is based on the linear length of the face

of the hood, measured along the front side, parallel with the front of the appliance

(refer to LENGTH in Fig. 12). The minimum net air ow for Type II hoods used with

dishwashers is 100 CFM per linear foot of hood length. Simply multiply the hood's

length, in feet, times 100 CFM to obtain the required ow rate.

Subtract make-up air ow supplied directly to a hood cavity, from the total exhaust

ow rate of the hood, if applicable.

For hood designs not covered by these calculations consult the latest edition of the

IMC or other local codes.

Fig. 12

ELECTRICAL CONNECTIONS — DISHWASHER

Electrical and grounding connections must comply with the

applicable portions of the National Electrical Code, ANSI / NFPA 70, latest

edition, and / or other local electrical codes.

Disconnect the electrical power to the machine and follow

lockout / tagout procedures. There may be multiple circuits. Be sure all

circuits are disconnected.

Connect a permanent electrical power supply to the terminal block in the control

box on top of the machine. Refer to the machine data plate for proper connection

information and the electrical diagram located inside the control box cover.

– 14 –

Single-Point Electrical Connection (S.P.E.C.) — Three-Phase Only

All three-phase machines are prewired for single-point electrical connection for the

motors, controls and electric tank heaters; however, electric tank heat machines

(three-phase only) may be eld wired for separate electrical connections. Refer

to the wiring diagram inside the control box lid. NOTE: The booster heater, when

supplied, is always provided with a separate electrical connection.

Motor Rotation — Three-Phase Only

Before placing a three-phase machine into service, check to verify that

the conveyor motor rotates in the correct direction. (The control box is pre-wired

at the factory so that all motors are phased together. If the conveyor motor rotation

is correct, the pump motors will also be correct.) Incorrect rotation will result in

unacceptable performance.

To check the conveyor motor's rotation:

Close the machine doors, press POWER on the keypad and allow the machine to

ll. When the machine is completely lled, press POWER to turn the machine off.

Disconnect the electrical power to the machine and follow

lockout / tagout procedures. There may be multiple circuits. Be sure all

circuits are disconnected.

Remove the front panel below the doors. Reconnect the electrical power to the

machine, being careful not to touch any uninsulated electrical parts exposed by

removing the front panel. Press START / ENTER on the keypad and verify proper

motor rotation, as follows:

The conveyor motor and clutch must rotate counterclockwise for machines with

right-to-left operation, and clockwise for machines with left-to-right operation.

If the rotation of the conveyor motor is correct, press POWER to turn the machine

off. Disconnect electrical power to the machine, and replace the front panel.

If the conveyor motor does not rotate in the proper direction, disconnect the electrical

power to the machine. At the machine control box on top of the machine, reverse

any two of the incoming power supply leads, either the leads to the entire machine,

or the leads to the motor and controls if they are wired independent of the heaters.

Do not simply reverse the leads to the conveyor motor.

Reconnect the electrical power to the machine. Re-check the conveyor motor's

rotation. The conveyor motor and clutch must rotate counterclockwise for machines

with right-to-left operation, and clockwise for machines with left-to-right operation.

If the rotation of the conveyor motor is correct, press POWER to turn the machine

off. Disconnect the electrical power to the machine. Replace the top cover to the

control box, and replace the front panel.

– 15 –

Optional Equipment Control Connections

Electrical and grounding connections must comply with the

applicable portions of the National Electrical Code, NFPA 70 (latest edition)

and / or other local electrical codes.

Disconnect the electrical power to the machine and follow

lockout / tagout procedures. There may be multiple circuits. Be sure all

circuits are disconnected.

Detergent Feeder

The maximum rating for a detergent dispenser connected to DPS1 and DPS2 is

1.5 amps at line voltage. Refer to Chemical Feeder Installations, page 8.

Rinse Aid Feeder and / or Chemical Sanitizer Feeder

The maximum rating for a rinse aid dispenser and / or chemical sanitizer feeder

connected to RPS1 and RPS2 is 1.5 amps at line voltage. Refer to Chemical

Feeder Installations, page 8.

Vent Fan Control

The maximum rating for a vent fan control connected to VFC1 and VFC2 is 1.5

amps, pilot duty.

CLeR ENERGY RECOVERY SETUP

measurements while power is applied to the machine. Exercise extreme caution

at all times. If test points are not easily accessible, disconnect power and follow

lockout/tagout procedures, attach test equipment and reapply power to test.

Set up procedures must be performed after hot and cold water connections

have been completed, tanks are full, and machine is cold.

1. Verify that both manual hot and cold water supply valves are on.

2. Turn m ain pow er to the

machine OFF at customer’s

disconnect.

3. Remove the top cover from the

control box.

4. Remove the end cover at the

unload end of machine.

5. Disconnect thermistor (6QTM)

connection located at the rear

of the coil enclosure assembly

at the back of the machine.

Certain procedures in this section require electrical test or

THERMISTOR (6QTM)

CONNECTION

– 16 –

Fig. 13

6. Open door of dishwasher and insert

a dish rack upside down in nal rinse

zone to activate nal rinse ow.

Leave all curtains in

place.

7. Turn main power to the machine ON

at customer’s disconnect.

Fig. 14

a) Press power button on keypad

to turn machine on. (Located on

front of main control box).

b) Verify yellow LED on solid

state thermostat (1SST) is ON.

(Located in the control box at

right rear corner.)

c) Verify warm water valve (4SOL,

located under unload end of

machine) turns on.

d) Verify cold water valve (3SOL,

located under unload end of

machine) turns on.

VERIFY YELLOW

LED IS ON

SOLID STATE

THERMOSTAT (1SST)

Fig. 15

COLD WATER

VALVE (3SOL)

– 17 –

WARM WATER

VALVE (4SOL)

Fig. 16

8. Adjust pressure regulator

in the cold water plumbing

assembly (loca t ed under

unload end of machine) until

nal rinse pressure gauge

reads 20 ± 5 PSI.

Fig. 17

COLD WATER

PRESSURE

REGULATOR

9. After the cold water pressure is established, reconnect the thermistor (6QTM)

connection.

a) Verify red light on solid state thermostat (1SST) is ON.

b) Verify warm water valve (4SOL) turns off.

c) Verify hot water valve (1SOL, located under unload end of machine) turns

ON.

10. Adjust the pressure regulator

in the hot water plumbing

assembly (loca t ed under

unload end of machine) until

HOT WATER

VALVE (1SOL)

nal rinse pressure gauge

reading matches the value set

for the cold water supply, 20 ±

5 PSI.

HOT WATER

PRESSURE

REGULATOR

Fig. 18

11. Press power button on keypad to turn machine off.

12. Turn main power to machine OFF at customer’s disconnect.

13. Open door of dishwasher and remove dish rack from nal rinse zone.

14. Replace the top cover on the control box.

15. Replace the end cover at the unload end of machine.

16. Turn main power to the machine ON at customer’s disconnect; machine is

now ready for normal operation.

– 18 –

CLeR AIR FLOW ADJUSTMENT

1. Turn main power to machine OFF at customer's disconnect.

2. Open door of dishwasher and insert a dish rack upside down in nal rinse zone

to activate nal rinse ow.

3. Turn main power to machine ON at customer's disconnect.

4. Press power button on keypad to turn machine on. (Located on front of main

control box).

5. Press start button on keypad to turn pumps and nal rinse on.

6. V e r i f y t h a t t h e t a n k

temperature(s) and nal rinse

temperature are above the

ADJUST DAMPER

SHAFT TO

HORIZONTAL

minimum requirements. (If

not, press the stop button on

keypad to turn pumps off and

allow temperatures to heat up.)

7. Completely close vent by

adjusting vent stack damper

shaft to horizontal position.

8. Vent stack damper adjustment:

Fig. 19

Opening the vent stack damper too far may cause low tank temperatures.

a) For pant leg vent systems, adjust the vent stack damper shaft until the

steam escaping from around the bottom of the energy recovery hood and

curtain is eliminated. (Note: Do not over adjust the damper. Adjust in small

increments just until the steam is eliminated. If curtain is being drawn in,

damper is overadjusted.)

b) For canopy hood vent systems,

adjust the vent stack damper shaft to

approximately 15° to 25° open.

– 19 –

Fig. 20

Verify that the steam escaping

from around the bottom of the

energy recovery hood and

curtain is eliminated. (Note:

Do not over adjust the damper.

Adjust in small increments just

until the steam is eliminated.

If curtain is being drawn in,

damper is overadjusted.)

9. Press power button on keypad

to turn machine off.

ADJUST DAMPER SHAFT

UNTIL STEAM IS

ELIMINATED AT THIS AREA

10. Turn main power to machine

OFF at customer's disconnect.

Fig. 20

11. Open door of dishwasher and remove dish rack from nal rinse zone.

12. Turn main power to machine ON at customer's disconnect; machine is now

ready for normal operation.

– 20 –

PREPARATION

CONNECTOR

PIPE

WASH ARM

GUIDE

LATCH

END

CAPS

STRAINER

PAN

STRAINER

BUCKET

WASH ARM

GUIDE

CONNECTOR PIPE

END CAPS

END CAPS

PREWASH ARM

CONNECTOR PIPE

GUIDE

LATCH

STRAINER

PANS

CONNECTOR

PIPE

STRAINER

BUCKET

PREWASH ARM

GUIDE

Make sure the dishwasher is clean

and all parts are in place.

OPERATION

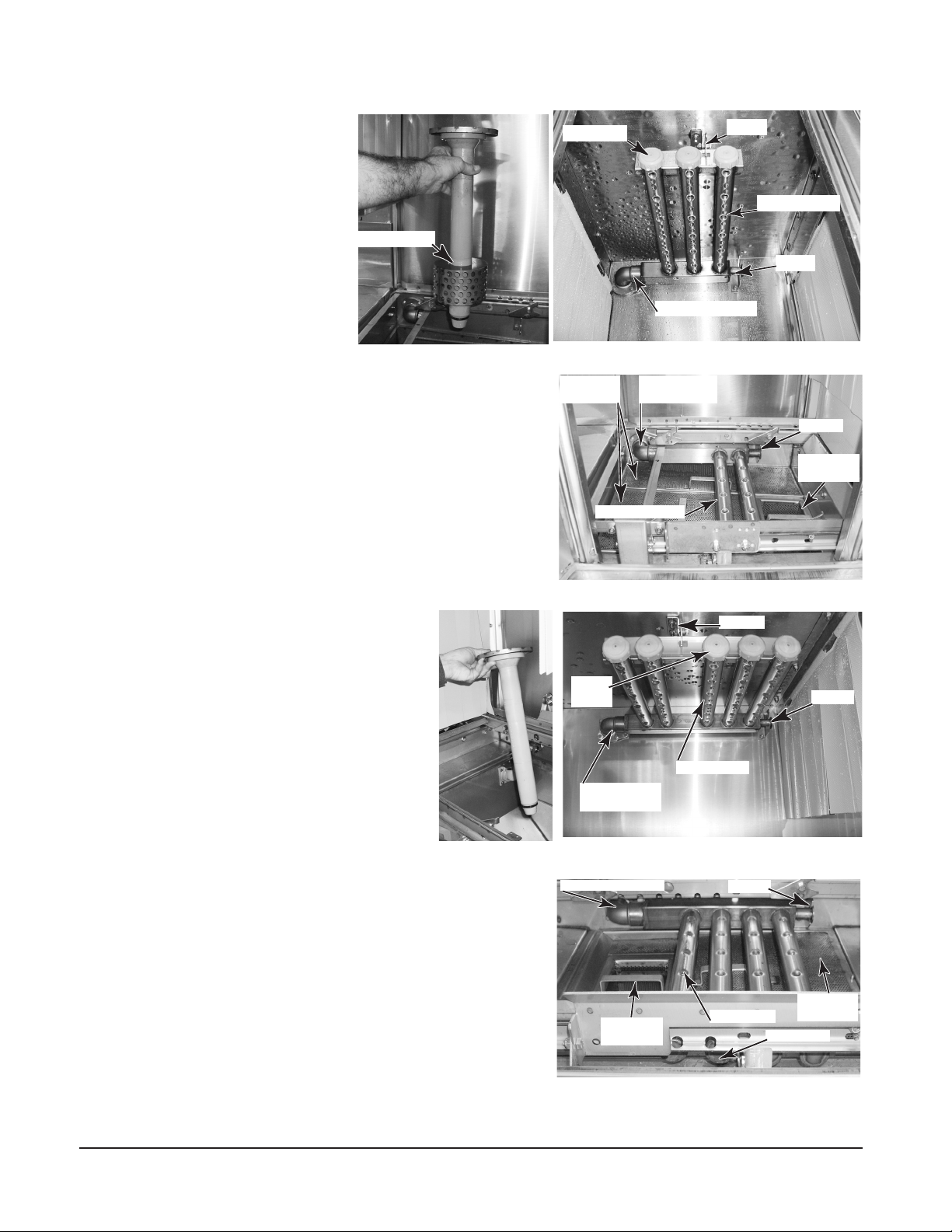

If Equipped with Scrapper (PS/CS)

STANDPIPE

Install the standpipe in the scrapper

tank (Fig. 21). Standpipe with strainer

(Fig. 21) goes in the rst tank where

the rack enters the machine.

Install the rear and side strainer pans

Fig. 21

and lower the strainer bucket (Fig. 23).

Install the upper wash arm (Fig. 22) and the lower wash arm

(Fig. 23) in the scrapper with all end caps. Push arm onto the

connector pipe so the opposite end is held by the guide; then

lift or lower into position.

Wash / Rinse Tanks

Install the standpipe(s) in the tank(s) (Figs. 21

and / or 24). Standpipe without strainer (Fig.

24) goes in second / third tank.

Fig. 22

Fig. 23

Install the strainer pan and the strainer bucket

(Fig. 26).

Install the upper wash arm (Fig. 25) and

the lower wash arm (Fig. 26) with all end

caps. Push arm onto the connector pipe

so the opposite end is held by the guide

(Figs. 25, 26); then lift or lower into position.

Curtains & Doors

Hang all curtains according to the appropriate curtain diagram

(pages 21 – 23).

Close all doors: This lowers and seats the standpipe(s).

Fig. 24 Fig. 25

Fig. 26

– 21 –

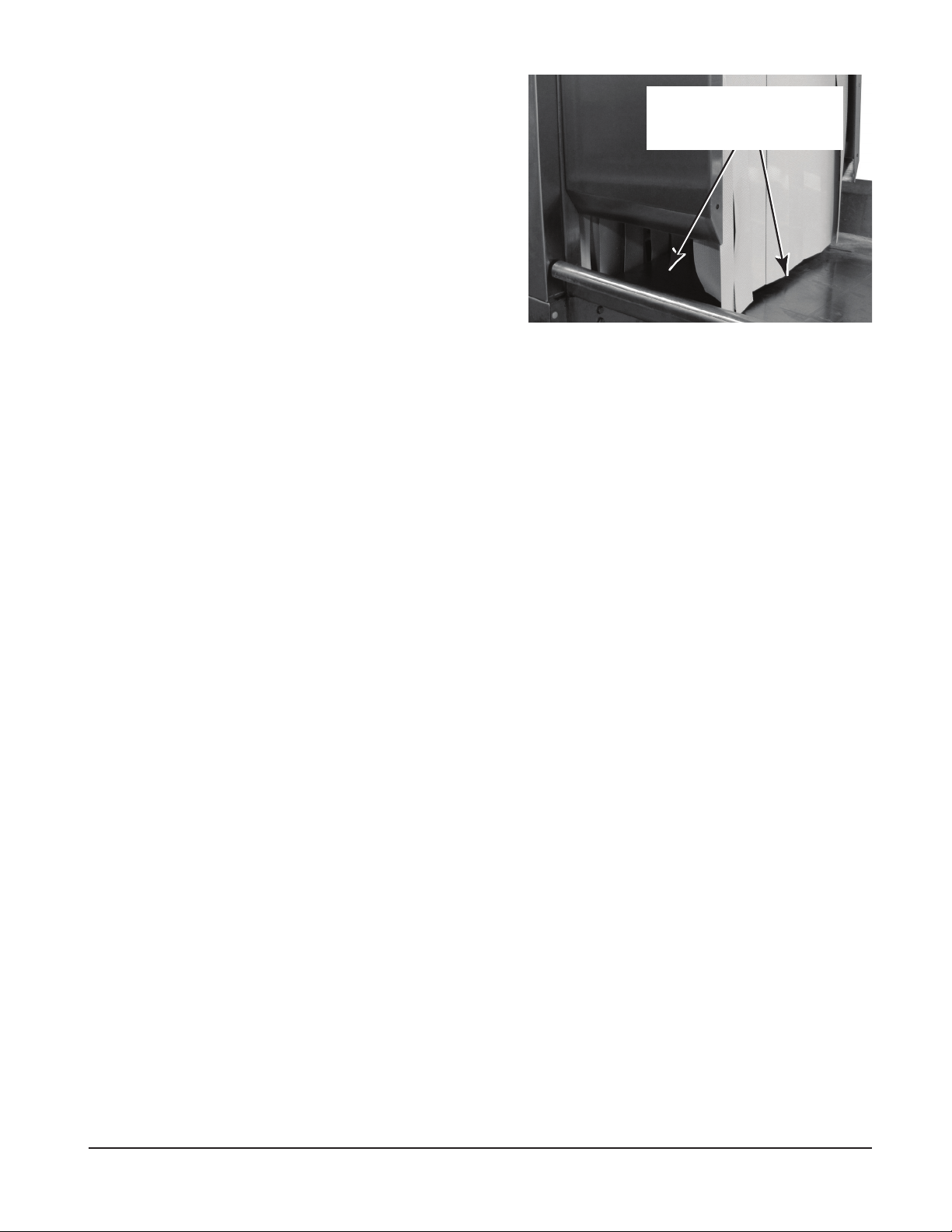

CLeR Models

Ensure drip pan is installed in energy recovery hood

assembly.

CURTAIN INSTALLATION

Curtains are keyed for proper installation.

CLeR models require an additional curtain at discharge of hood assembly.

INSTALL DRIP PAN IN

ENERGY RECOVERY

HOOD ASSEMBLY

Fig. 27

CL44e, CL54e CL64e

CL44eR, CL54eR CL64eR

RIGHT TO LEFT

CLeR

Unit

FINAL

RINSE

WASH

S S CO

CLeR

Unit

FINAL

RINSE

RINSE

⇐

LEFT TO RIGHT

L L L L M L

WASH

FINAL

RINSE

L

CLeR

Unit

WASH

⇒

S CO S

L LL L LL M

RINSE

WASH

CLeR

Unit

FINAL

RINSE

L

919758 Long STD

L

919975 Long HTS

S

919509 Short

CO

936922 Carry Over

M

936428 Middle STD

M

936429 Middle HTS

CS

936520 CS

CSS

936931 CS Side

– 22 –

Single-Tank Machines with Power Scrapper (CLPS) or Corner Scrapper (CLCS)

CLPS66e, CLPS76e CLCS66e, CLCS76e

CLPS66eR, CLPS76eR CLCS66eR, CLCS76eR

RIGHT TO LEFT

⇐

LEFT TO RIGHT

⇒

CLeR

Unit

FINAL

RINSE

L L L LL L

SCRAPPER

S

WASH

S S

WASH

SCRAPPER

CLeR

Unit

FINAL

RINSE

S S

CLeR

Unit

FINAL

RINSE

S

CSS

SCRAPPER

CS

WASH

CSS

WASH

CSS

SCRAPPER

CS

FINAL

RINSE

CSS

CLeR

Unit

LL L L LL

Two-Tank Machines with Power Scrapper (CLPS)

CLPS86e, CLPS86eR

CLeR

Unit

FINAL

RINSE

RIGHT TO LEFT

RINSE

S CO S

WASH

⇐

L L M L

SCRAPPER

LEFT TO RIGHT

RINSEWASH

⇒

S CO S

SCRAPPER

FINAL

RINSE

CLeR

Unit

L

919758 Long STD

L

919975 Long HTS

S

919509 Short

CO

936922 Carry Over

M

936428 Middle STD

M

936429 Middle HTS

CS

936520 CS

CSS

936931 CS Side

– 23 –

L LML

Two-Tank Machines with Corner Scrapper (CLCS)

CLeR

Unit

FINAL

RINSE

RIGHT TO LEFT

⇐

L L

CSS

LEFT TO RIGHT

⇒

CLCS86e, CLCS86eR

RINSE

S CO

SCRAPPER

CS

CSS

M L

WASH

WASH

CSS

SCRAPPER

CS

RINSE

CSS

CLeR

Unit

FINAL

RINSE

SCO

KEYPAD AND DISPLAY

L M L L

L

919758 Long STD

L

919975 Long HTS

S

919509 Short

CO

936922 Carry Over

M

936428 Middle STD

M

936429 Middle HTS

CS

936520 CS

CSS

936931 CS Side

76>,9

+0:73(@

4,5<+V^U(YYV^

*65=,@69+>,33

:;(9;,5;,9

:;67

<W(YYV^

Fig. 28

The controls are mounted on top of the dishwasher. The Keypad and Display are

mounted in front of the control box (Fig. 28).

– 24 –

FILLING THE DISHWASHER

All water supply valves must be opened and the electric supply must be turned on

before the machine will function. Make sure Preparation and Curtain Installation

are done, pages 21 – 23.

Close all doors. To begin lling after the machine is ready, press the POWER key

(Fig. 28).

If the machine is equipped with a Power Scrapper or Corner Scrapper, the scrapper

tank will ll with overow water from the wash tank.

STARTING THE GAS HEAT DISHWASHER (When Equipped with Gas Heat)

1.

dishwasher.

2. Turn main gas supply to the dishwasher ON.

3. Wait for 5 minutes to clear out any gas. If you then smell gas, STOP! Follow all

safety information covered on page 2 in IMPORTANT FOR YOUR SAFETY.

4. If you don't smell gas, turn the manual gas valve On.

5. Press the POWER key on the keypad (Fig. 28). Dishwasher will ll automatically

(refer to Filling the Dishwasher, this page). After the tank has lled, the burner

will ignite if heat is required. The ignition system includes a 15-second pre-purge

period before ignition occurs.

6. If the dishwasher will not operate, press the POWER key on the keypad

(Fig. 28) and turn the manual gas valve Off. Call your local Hobart service ofce

or gas supplier.

MINIMUM TEMPERATURES

The water temperatures in the tanks and rinse arms are regulated by the microprocessor

control. The control is preset at the factory and no adjustment should be required. If

an adjustment is necessary or if the machine is to operate at low temperature using

chemical sanitizer, contact your local Hobart service ofce or refer to instructions for

conversion. The digital display veries proper water temperature during operation.

Read the Safety Information on page 2 before operating this

Minimum Temperatures Using High-Temperature Sanitizing

Single-Tank Models

CL44e, CLPS66e, CLCS66e

CL54e, CLPS76e, CLCS76e

CL44eR, CLPS66eR, CLCS66eR

CL54eR, CLPS76eR, CLCS76eR

Two-Tank Models

CL64e, CLPS86e, CLCS86e

CL64eR, CLPS86eR, CLCS86eR

– 25 –

Wash Tank

160°F

150°F 160°F 180°F

Rinse Tank

––––

Final Rinse

180°F

Minimum Temperatures Using Low-Temperature, Chemical Sanitizing

Single-Tank Models

CL44e, CLPS66e, CLCS66e

CL54e, CLPS76e, CLCS76e

Two-Tank Models

CL64e, CLPS86e, CLCS86e 130°F 130°F 120°F

If the tank is accidentally drained before turning off the power switch, the oat-

controlled, low-water protector switch will automatically stop the tank heat.

When the proper water level is returned, the tank heat will automatically restart.

O NOT use the low-water protection as a power on-off switch. Press the

D

POWER key on the keypad to turn the machine off when not in use.

Alternative Temperature Display Names

This table shows the possible temperature names that may appear on the display.

The Long Name is equivalent to the Short Name. Temperature Display Names

vary for different models.

ALTERNATIVE TEMPERATURE DISPLAY NAMES

Indicated Temperature Long Name Short Name

Power Scrapper Tank Scrapper PS

Wash Tank Wash Wsh

Power Rinse Tank Rinse Rns

Final Rinse FinalRinse FnlRns

Wash Tank

130°F

Rinse Tank

––––

Final Rinse

120°F

Low FR Temp. Alert

Displays a message to indicate that the nal rinse temperature was below the

minimum requirement for a short time. This feature can be enabled from the

Parameters Menu, refer to page 34.

Tank Temperature Alert

Displays a message if any tank goes below the minimum for a certain amount of

time. This feature can be enabled from the Parameters Menu; refer to page 34.

– 26 –

DISHWASHING

After the machine has lled, start the pumps by pushing the START / ENTER key

on the keypad (Fig. 28) or by inserting a rack into the machine.

The machine will operate only if the tanks have lled to the proper level and all

doors are closed. Press the STOP key on the keypad to stop the conveyor motor

and pumps.

Pre-scrap dishes thoroughly to remove large food particles and debris. Never use

steel wool on ware that is to be loaded into the dishwasher.

Stack dishes in the racks. Do not stack dishes one on top of another, as water must

have free access to both sides of every dish. Stand plates and dishes up edgewise

(Fig. 29). Cups, glasses and bowls should be inverted in an open-type rack (Fig.29)

or a compartmented rack. Silverware and other small pieces may be scattered loosely

over the bottom of an open-type, at-bottom rack. To minimize splash, position trays

in the rack in the same direction as the motion of the conveyor (Fig. 29).

DO NOT attempt to wash large items (pots, pans, trays, etc.) without rst checking

to make sure they will t through the machine opening. Such large items must not

be washed in this dishwasher unless they will easily pass through it.

DO NOT allow foreign objects to enter the dishwasher,

especially metallic contaminants.

]

Fig. 29

When one rack has been loaded, slide it part way into the machine until the

conveyor dogs catch the rack. Start loading another rack when the previous rack

has completely passed the curtains. The operation of the dishwasher is automatic.

When a rack enters the machine, the pumps and conveyor automatically start.

Each rack moves through the power scrapper (if present), the wash and the rinse

zones, then out onto the clean dish table. The rinse lever is actuated by the dish

rack when it is present in the rinse zone and automatically shuts off the nal rinse

water when no rack is present.

Allow dishes to drain and air-dry before removing the ware from the rack.

The conveyor dwell feature, standard, allows the operator to stop the conveyor

in order to wash heavily soiled dishes for a longer time. When the dish rack

reaches the wash chamber, push the CONVEYOR DWELL key on the keypad

(Fig. 28) to momentarily stop the conveyor. To restart the conveyor, press either

the START / ENTER or the CONVEYOR DWELL keys on the keypad (Fig. 28).

If the rack jams or if the load becomes excessive, an overload mechanism shuts off

the conveyor drive motor and 'Clear Conveyor Jam' displays. Open the doors and

remove the jam. After the jam is cleared, close the doors and push the START /

ENTER key on the keypad (Fig. 28) to restart the dishwasher.

All tank temperatures are shown on the Display (Fig. 28) when the machine is

in operation. The Final Rinse temperature displays – – – until a rack is in the

rinse zone; then, the Final Rinse water temperature displays. After the ware exits

the rinse zone, the Final Rinse temperature display returns to – – – .

– 27 –

Optional Table Limit Switch

DRAIN

LEVER

If a rack reaches the end of the unload table and trips the table limit switch, the

conveyor, pumps and nal rinse shut off. The display alternates between the tank

names and 'Unload Dishes'. After the rack is removed and the table limit switch

resets, normal operation of the dishwasher resumes.

Auto-Timer

To conserve energy, if no rack enters the machine for a preset amount of time, the

Auto-Timer counts down and the pumps and conveyor shut off. Tanks continue to

heat, and tank temperatures display. To resume operation, insert a rack or press

the START / ENTER key on the keypad (Fig. 28).

NOTE: The Auto-Timer shut off setting is preset from the factory at 45 seconds.

You can adjust the setting from 30 to 180 seconds (15 second increments). Refer

to the Parameters Menu, page 34.

Energy Saver Mode

After a period of machine inactivity, the control initiates Energy Saver Mode (ESM):

All warewasher components are turned off, and the display on the control dims,

displaying 'Energy Saver Active / Press STOP to Exit'. To exit Energy Saver Mode,

press the STOP key (Fig. 28). You may press the POWER key to completely turn

the machine off. The period of machine inactivity prior to ESM can be set from 1 to

6 hours in the Parameters Menu; 2 hours is the factory setting. Refer to page 34.

Dirty Water Mode

Three settings are provided; refer to Parameters Menu on page 34.

Disabled – No alarm displays. This is the factory setting.

Alert Only – After a period of operation, 'Water Change Req'd' displays until the

water is changed; however, the control allows machine operation.

Alert & Lockout – After a period of operation,'Change Water Soon' displays for 5

minutes, alerting you to change the water; then, 'Water Change Req'd' displays and

further machine operation is prevented until tanks are drained and relled.

CLEANING

The machine must be thoroughly cleaned at the end of each working shift, or at

least twice a day. Use only products formulated to be safe on stainless steel. Use

a damp cloth and mild soapy water.

1. Press the POWER key on the keypad to turn the machine Off (Fig. 28).

Disconnect the electrical power to the machine and follow

lockout / tagout procedures before you begin cleaning. There may be

multiple circuits. Be sure all circuits are disconnected.

2. Open the doors. Standard door interlock switches

prevent machine operation with inspection doors open.

3. Visually inspect the upper and lower nal rinse nozzles

to make sure they are free of debris.

4. Open drain(s) by pulling drain lever(s) up (Fig. 30).

Fig. 30

– 28 –

5. Remove wash arms. Remove wash arm end caps

WASH

ARM

END

CAPS

PUMP

INTAKE

STRAINER

IN BOTTOM

OF TANK

(Fig. 31) and push any nozzle obstructions into the

wash arms. Thoroughly ush the wash arms in a

sink. Replace the wash arm end caps.

6. Before removing strainer basket(s) and pan(s), clean

off any debris from machine walls using a hose with

spray nozzle. Flush all debris toward the strainers.

7. Clean debris from back side of doors, in between the

Fig. 31

doors and chamber, and around door seal of chamber. Avoid direct spray of

controls on top of unit.

8. Clean dish tables by ushing any debris into the dishwasher.

9. Remove all strainer pan(s) and strainer basket(s). Empty contents into garbage

can or disposer and thoroughly clean pan(s) and basket(s) in a sink. DO

NOT strike strainer pan(s) or strainer basket(s) on solid objects to dislodge

debris. Refer to Figs. 23 & 26 on page 20.

10. When tanks are empty, remove the standpipe and clean the pump intake

strainer(s) on the bottom of the standpipe or at the bottom of the tank

(Figs. 21 & 32).

11. Remove curtains. Thoroughly scrub, rinse

and allow curtains to dry at the end of each

day’s operation.

12. Thoroughly wash out the interior of the

machine with a hose tted with a spray

nozzle. Remove remaining soil with a cloth

or soft brush and mild cleanser. Flush out

again with hose spray. Do not allow food soil

to accumulate on the bottom and/or sides

of the tank.

Fig. 32

13. Return all standpipe(s), strainer pan(s) and

strainer basket(s) to their proper locations

(Figs. 21, 24, 23 & 26) on page 20.

14. Insert the upper wash arm(s) straight onto the connector pipe. Rest the

extension on the guide. Rotate the arm upward to latch it.

15. Insert the lower wash arm(s) straight onto the connector pipe. Rest the

extension on the guide. Swing the front of the arm down until level to fully

position it.

16. Leave doors open and curtains removed while machine is not in use to allow

the interior to air out and dry. Install curtains after machine has dried out.

•

DO NOT attempt to clean Opti-Rinse nal rinse nozzle(s). Opti-

Rinse nozzle(s) should be replaced if they become clogged or if the spray

pattern is ineffective.

• Never use steel wool to clean warewasher surfaces. Use only products

formulated to be safe on stainless steel.

– 29 –

• Reassemble standpipe(s), strainer pan(s) and strainer basket(s), per

page 20.

• Rehang curtains after interior has dried out. Refer to pages 21 — 23.

17. C Le R mo d e ls o nl y :

Remove and clean drip

pan located in energy

recovery hood assembly.

Return to proper location.

DELIMING RECOMMENDATIONS

For questions about frequency of deliming, follow your chemical representative's

recommendations based on visible lime build-up or reduced warewashing

performance. The factory default value for the 'Delime Interval' is 0 hours; this

disables the delime recommendation message. The 'Delime Interval' can be enabled

by increasing the 'Delime Interval' to a higher value. Refer to Delime Interval on the

Parameters Menu on page 34. If enabled, the 'Delime Recommended' message

will display after the ll and nal rinse have operated for the delime interval.

DRIP PAN IN

ENERGY RECOVERY

HOOD ASSEMBLY

Fig. 33

Deliming instructions: Follow instructions on the delime-chemical container. During

deliming, machine should be on with pumps running, but the conveyor can be idle.

Press the CONVEYOR DWELL key on the keypad (Fig. 28) to turn off the conveyor

motor and conveyor during deliming.

The 'Delime Recommended' display message will not clear itself automatically after

the machine has been delimed. To clear the message, follow these instructions:

• Delime the machine: Follow all applicable instructions.

• Enter the Manager Mode (steps 2 – 10, below) use Mgr. Code 1001 per page

26 unless reset to a different number on page 34.

• Find the 'Clear Delime Message' screen by proceeding to step 12, below.

• Press the START / ENTER key on the keypad to clear the delime message

(step 12). The Main screen returns, showing the tank temperatures (return to

step 1). Clearing the message also resets the delime timer back to zero.

CLEARING THE 'DELIME RECOMMENDED' MESSAGE

Display Message Key to Press Function

[ Tank Names ]

1.

[ Tank Temperatures ]

Exit to Main ?

2.

Yes

Enter Security Code?

3.

O Yes START / ENTER Answer Yes

MENU / Down Arrow

MENU / Down Arrow

– 30 –

Security Code:

4.

0ÝÝÝ Up Arrow Change 0 to 1

Security Code:

5.

1ÝÝÝ START / ENTER Go to next digit

Security Code:

6.

Ý0ÝÝ START / ENTER Go to next digit

Security Code:

7.

ÝÝ0Ý START / ENTER Go to next digit

Security Code:

8.

ÝÝÝ0 Up Arrow Change 0 to 1

Security Code:

9.

ÝÝÝ1 START / ENTER Accept 1001

Enter Security Code?

10.

M Yes

Edit Parameters? MENU / Down Arrow

11.

MENU / Down Arrow Letter in lower left

should be 'M'.

Clear Delime Message?

12.

Yes START / ENTER

DOs and DON'Ts for Your New Hobart Warewasher

DO assure proper water hardness of 3 grains per gallon or less.

DO pre-scrap dishes thoroughly.

DO use only detergents recommended by your chemical professional.

DO, at the end of the day, thoroughly clean the machine, rinse and dry (leave

doors open).

DO closely follow your chemical professional's prescribed deliming schedule.

DO use only products formulated to be safe on stainless steel.

DO NOT use detergents formulated for residential dishwashers.

Answer Yes

Return to Step 0.

DO NOT allow food soil to accumulate on the tank bottom, tank sides, or door seal.

DO NOT exceed chemical manufacturer's recommended concentrations for

detergent, sanitizer, rinse aid or lime scale remover.

DO NOT use steel wool to clean ware or warewasher surfaces.

DO NOT allow foreign objects to enter the unit, especially metallic contaminants.

NOTE: Failure to follow use, care and maintenance instructions may void your

Hobart warewasher warranty.

– 31 –

PROGRAMMING

PROGRAMMING SECURITY LEVELS

Your warewasher's microprocessor allows customization options for machine

operation for cleaning your ware, maintaining required tank temperatures and other

functions related to your kitchen operation. To activate or change these features,

the programming edit mode must be entered at an appropriate level.

It is recommended that the warewasher stay in the lowest security level to prevent

options from being modied from what is expected and / or acceptable. The security

level will automatically revert back to Operator when any of the following occur:

1) No keys on the keypad are pressed for 10 minutes or more.

2) The machine is placed in Standby by pressing the POWER key.

3) An invalid Security Code is entered on the 'Enter Security Code?' screen.

The names and descriptions of the security levels are listed from lowest to highest

levels.

NOTE: The letter to the right of the name is the same as the letter you will see at

the lower-left corner of the 'Enter Security Code?' screen: O or M. Refer to Entering

the Parameters Menu, page 33, for more details.

NOTE: The security level does not, by itself, affect the operation of the machine or

inhibit the use of the START, STOP or POWER keys. All of these basic functions

are always available in any security level.

Operator – O

The Operator level is the most basic security level. It is the one that is initiated

by default when the unit is powered up. No security code is required to enter the

Operator security level. From this level you may enter a Security Code to elevate

to a higher security level.

Manager – M

The Manager level is the highest level attainable by the user. It requires the Manager

Code to be entered to access the Manager level.

The Manager security level allows access to all of the options listed in either the

Parameters Menu — Table 1 and / or the Communications Setup Menu — Table 2.

It is recommended that power to the machine be cycled off and on after any

Manager level options are modied and saved.

The Security Code for the Manager level can be changed by a kitchen manager

or anyone with the Manager Code. The default code is 1001. As such, it is

recommended that this code be changed from the default and that the new code

be stored in a safe place. If the Manager code is ever lost or forgotten, it can be

reset by Hobart Service.

NOTE: Having Hobart Service reset the Manager Code is not covered under either

the basic or the extended warranties.

– 32 –

PROGRAMMING INSTRUCTIONS

<W(YYV^

+0:73(@

:;(9;,5;,9

:;67

4,5<+V^U(YYV^

76>,9

*65=,@69+>,33

All customization is performed through the on-screen menu using the

MENU / Down arrow and START / ENTER keys located on the keypad on the top of

the machine (Fig. 34).

Menu Display Prompts

Up arrow,

Fig. 34

The following prompts are used inside the menus:

• The Up and MENU / Down arrow keys are used to change parameter values

and to navigate the menu.

• The START / ENTER key is used to accept a value, to perform a specied action

or to enter a submenu. Pressing this key while in the menu will not start the

conveyor and pumps (if not already on). To start the machine while editing a

menu, allow a rack to enter the machine or exit the menu before pressing the

START / ENTER key.

• The STOP key will always cancel what you are doing, discard any changes you

have made since the last save, return to the main screen and stop the machine.

• The text just to the left or right of the circle icon (

) on the display screen shows

what action or command will occur if the START / ENTER key is pressed.

• The up / down arrow icon in the display shows the line or value that will change

if the UP or DOWN arrow key is pressed.

o A pair of solid arrows on the second line ( ), indicates that the displayed

value is the value stored in the control.

o A pair of hollow arrows on the second line ( ), indicates the value has been

changed but has not yet been stored.

– 33 –

Entering the Parameters Menu

The Parameters menu can be entered, and individual options can be modied

anytime the machine is operating or idling.

To enter the Parameters Menu you must rst enter the Security Code:

STEP 1. Press the MENU / Down key from the main screen.

STEP 2. You are prompted on-screen, asking if you wish to exit the menu. Do not

press START / Enter or you will exit back to the main screen showing tank names

and temperatures. Instead, press the MENU / Down Arrow key to continue.

Display Message Key to Press Function

[ Tank Names ]

1.

[ Tank Temperatures ]

Exit to Main ?

2.

Yes

Enter Security Code?

3.

O Yes START / ENTER Answer Yes

Security Code:

4.

0ÝÝÝ Up Arrow Change 0 to 1

Security Code:

5.

1ÝÝÝ START / ENTER Go to next digit

Security Code:

6.

Ý0ÝÝ START / ENTER Go to next digit

Security Code:

7.

ÝÝ0Ý START / ENTER Go to next digit

Security Code:

8.

ÝÝÝ0 Up Arrow Change 0 to 1

Security Code:

9.

ÝÝÝ1 START / ENTER Accept 1001

Enter Security Code?

10.

M Yes MENU / Down Arrow

Edit Parameters?

11.

Yes START / ENTER

Sanitizing Mode

12.

High Temp

MENU / Down Arrow

MENU / Down Arrow

Letter in lower left

should be 'M'.

This is the rst

parameter

STEP 3. You reach the '

Enter Security Code?'

screen. Press the START / Enter key to

indicate that you want to enter the code.

STEPS 4 — 10. The prompt 'Security

Code:' displays on the top line and a

single digit and three asterisks [ 0

ÝÝÝ ]

displays on the bottom line. Use the Up

arrow and MENU / Down arrow keys to

change the Security Code to the appropriate

value. The default Security Code to enter

Manager level is 1001.

The security code can be changed by

anyone with access to the Parameters

Menu, and it is recommended to change

it from the default. If the code is ever lost

for some reason, it can be reset by Hobart

Service, but this is not covered under either

basic or extended warranties.

After pressing START / Enter on the fourth

digit (STEP 9), the prompt 'Enter Security

Code?' returns to the rst line of the display

screen (STEP 10). You have correctly

entered the manager security level if 'M' is

displayed in the lower left corner. If M does

not display, repeat steps 3 – 10.

Navigating the Parameters Menu

If Sanitizing Mode displays (STEP 12), you are in the Parameters Menu. The display

shows the rst editable parameter. You can use the Up or MENU / Down keys to

explore the parameters menu.

Pressing the START / ENTER key allows you to enter that parameter and modify

the setting.

For a list of parameter options, refer to the Parameters Menu – Table 1 on page

34. For a list of communications options, refer to the Communications Menu –

Table 2 on page 35.

STEP 11. Press START / Enter to enter

the Parameters Menu.

– 34 –

Parameter

Name

PARAMETERS MENU — TABLE 1

Description Possible

Values

Default

Value

Sanitizing Mode Sets the operating temperatures that regulate the tank heaters and

the internal booster (if provided): high temperature sanitizing mode,

or low temperature, chemical sanitizing mode.

Auto-Timer Pumps and conveyor shut down after this period of inactivity to save

energy. Refer to page 27.

Low FR Temp.

Alert

Enables or disables a visual alert on the display that indicates that

Final Rinse water temperature is below the required minimum of

180°F (82°C). When enabled, a message will display notifying the

user of this condition. However, machine operation will not change

and ware will continue to run through the machine as expected.

After the temperature increases past the minimum, the message

stops. When disabled, there will be no extra message indicating

a low-temperture event; however, the temperature display will still

show the current Final Rinse water temperature. Refer to page 24.

Tank Temp. Alert Displays a message that the water temperature of a certain tank is

below the minimum required. After the temperature increases past

the minimum, the message stops. Refer to page 24.

Delime Interval Sets the delime interval from 0 to 1000 hours. A setting of 0 disables

this feature. Up arrow increases 10 hours, Down arrow decreases.

Hold Up or Down arrow for faster movement.

Dirty Water Mode

Disabled: Ignores dirty water. Alert Only: Displays 'Water Change

Req'd' after a period of operation but does not require relling. Alert

& Lockout: Displays 'Change Water Soon' for 5 minutes after a period

of operation; then 'Water Change Req'd' displays and machine cannot

run until tank(s) are drained and relled. Refer to page 26.

High Temp.

or

Low Temp.

30 to 180

(in 15 second

increments)

Disabled

or

Enabled

Disabled

or

Enabled

0

to

1000

Disabled,

Alert Only

or

Alert &

Lockout

High

Temp.

45

Disabled

Disabled

0

Disabled

Dirty Water

Interval

Energy Saver

Mode (ESM)

Change Mgr.

Code

Edit

Communications

Setup?

Save Settings

and Exit?

Cancel Settings

and Exit?

Sets the period (in hours) of rinsing before an alert is shown. This

option is only available when Dirty Water Mode is set to 'Alert Only'

or to 'Alert & Lockout'.

ESM begins after a period of machine inactivity. Up arrow increases

by 1 hour. Down arrow decreases by 1 hour. Refer to page 26.

Sets a new Security Code for access to the Manager Level parameters.

It is recommended to change this code from the default value and

store the new code where all kitchen managers, but no operators,

can access it.

Press START / ENTER to access the Communications Setup Menu, to

edit settings for the NAFEM Data Protocol. Refer to Communications

Setup Menu – Table 2, page 35. Press Down arrow or Up arrow to

move down or up the menu.

Press START / ENTER to save the changed settings, exit the

Parameters Menu and return to the main screen. Any settings

th a t were chang e d are saved and most be c ome active

immediately. If one or more settings are not activated immediately,

a message will display indicating that you need to cycle power off

and on to make them active.

Press START / ENTER to exit the Parameters Menu and return to

the main screen. Any settings that were changed are cancelled and

revert back to the previously saved values.

1 – 6 4

1, 2, 3, 4,

5, 6

0000

to

8888

2

1001

– 35 –

Communications Setup Menu

The Communications Setup Menu — Table 2 lists the communication option, a

short description, a list of possible values it can have and the factory default value.

COMMUNICATIONS SETUP MENU — TABLE 2

Parameter

Name

NAFEM DP Baud Adjusts the baud rate of communication between the dishwasher

NAFEM DP ID Adjusts the machine-specic ID for use on a NAFEM Data

Exit to Params? Press START / ENTER to exit the Communications Setup menu

Description Possible

and a NAFEM Data Protocol (NDP) Gateway (sold separately).

This must match the setting in the NDP Gateway. Refer to

documentation that came with the NDP Gateway for instructions

on where to nd this value.

Protocol network. Each device on the network must have a

unique ID. Please refer to any documentation that came with

other NDP-compliant devices to verify that all IDs on the network

are unique.

and return to the Parameters menu. Any settings that were

changed are only saved by choosing the 'Save Settings and

Exit?' option on the Parameters Menu. Changing communication

values typically requires machine power to be cycled off and on.

Values

9600,

19,200

or

38,400

1

to

247

Default

Value

9600

5

lockout / tagout procedures. There may be multiple circuits. Be sure all

circuits are disconnected.

VENT

When cool, check the vent of this dishwasher every six months for obstructions.

LUBRICATION

None required.

SERVICE

Contact your local Hobart Service ofce for any repairs or adjustments needed on

this equipment. If a gas orice tting is to be replaced, have it serviced by qualied

Hobart Service personnel. Long-term service contracts are available on this and

other Hobart products.

MAINTENANCE

Disconnect the electrical power to the machine and follow

– 36 –

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE

No Machine Operation. 1.

Dishes Not Clean. 1.

Leaking Valve. 1. Foreign material preventing proper valve operation. A critical period is soon after

Blown fuse or tripped circuit breaker at power supply.

2.

Inspection door(s) not closed.

3.

Conveyor has jammed.

4.

The Auto-Timer may have timed out. Push START or insert rack.

5.

If table limit switch is used, the switch may be tripped.

6.

The machine is in Energy Saver Mode. Press STOP on the keypad to resume.

Insufcient wash water. Drain obstruction causing an open drain condition.

Worn or torn drain O-ring allowing wash water to drain.

2.

Missing end cap from wash arm.

3.

Wash arm nozzle obstruction.

4.

Worn or torn manifold O-ring allowing wash water to drain.

5.

Loss of water pressure due to pump obstructions.

6.

lockout / tagout procedures. There may be multiple circuits. Be sure all

circuits are disconnected. Drain tank(s) and check for any obstruction at the

pump intake.

7.

Incorrect water temperature. Check circuit breaker to electric heat supply, or main

steam valve, or gas supply valve. Make certain that valve is completely open.

8.

Incorrect detergent dispensing. Contact your detergent sales representative.

9.

Strainer pans or buckets need to be emptied and / or cleaned.

10.

Tanks may need to be drained and lled with clean water.

installation when pipe compound or metal shavings may lodge at the valve seat.

If problem is with a solenoid valve, it is recommended that you contact your local

Hobart Service ofce.

Disconnect the electrical power to the machine and follow

Spotting of Silverware,

Glasses and Dishes.

Low Final Rinse

Temperature

With Built-In Booster

Heater.

1.

Improperly loaded racks.

2.

Incorrect nal rinse water temperature (180°F or 120°F, minimum, page 24).

3.

Loss of water pressure due to pump obstruction.

Disconnect the electrical power to the machine and follow

lockout / tagout procedures. There may be multiple circuits. Be sure all

circuits are disconnected.

Drain tank(s) and check for any obstruction at the pump intake.

4.

Clogged wash arm nozzles.

5.

Improper water hardness (3 grains per gallon or less is recommended).

6.

Incorrect detergent for water type. Contact chemical supplier.

7.

Clogged rinse nozzle(s).

8.