Page 1

Item # ________________________________

Quantity_______________________________

C.S.I. Section 11400

C-LINE

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

STANDARD FEATURES

■ Stainless steel construction

■ Condenser hood

■ 1,000 CFM blower capacity

■1⁄2 H.P. motor

■ 7-foot ceiling height requirement

DIRECTION OF OPERATION

❑ Right to Left

❑ Left to Right

VOLTAGE

❑ 208-240/60/1

CONDENSER

MODEL

❑ C-Line Condenser

Specifications, Details and Dimensions on Inside and Back.

❑ 208-240/60/3

❑ 480/60/3

R

CONDENSER AVAILABILITY

CONDENSERS CRS- CCS- CPW- CRS- CCS- CPW- CRS- CCS- CPW- CRS- CCS- CPW-

REQUIRED

1 CONDENSER NOT NOT NOT NOT

CLEAN AVAIL- X X X AVAIL- X X X AVAIL- X X X AVAIL- X X X

END ABLE ABLE ABLE ABLE

2 CONDENSERS AVAIL- X AVAIL- X AVAIL- X AVAIL- X X X AVAIL- X X X AVAIL- X

C-44A

66A 66A 80A

NOT NOT NOT NOT NOT NOT

ABLE ABLE ABLE ABLE ABLE ABLE

C-54A

76A 76A 90A

C-64A

86A 86A 100A

C-88A

110A 110A 124A

C-LINE CONDENSER

F-8102 – C-Line Condenser Page 1 of 4

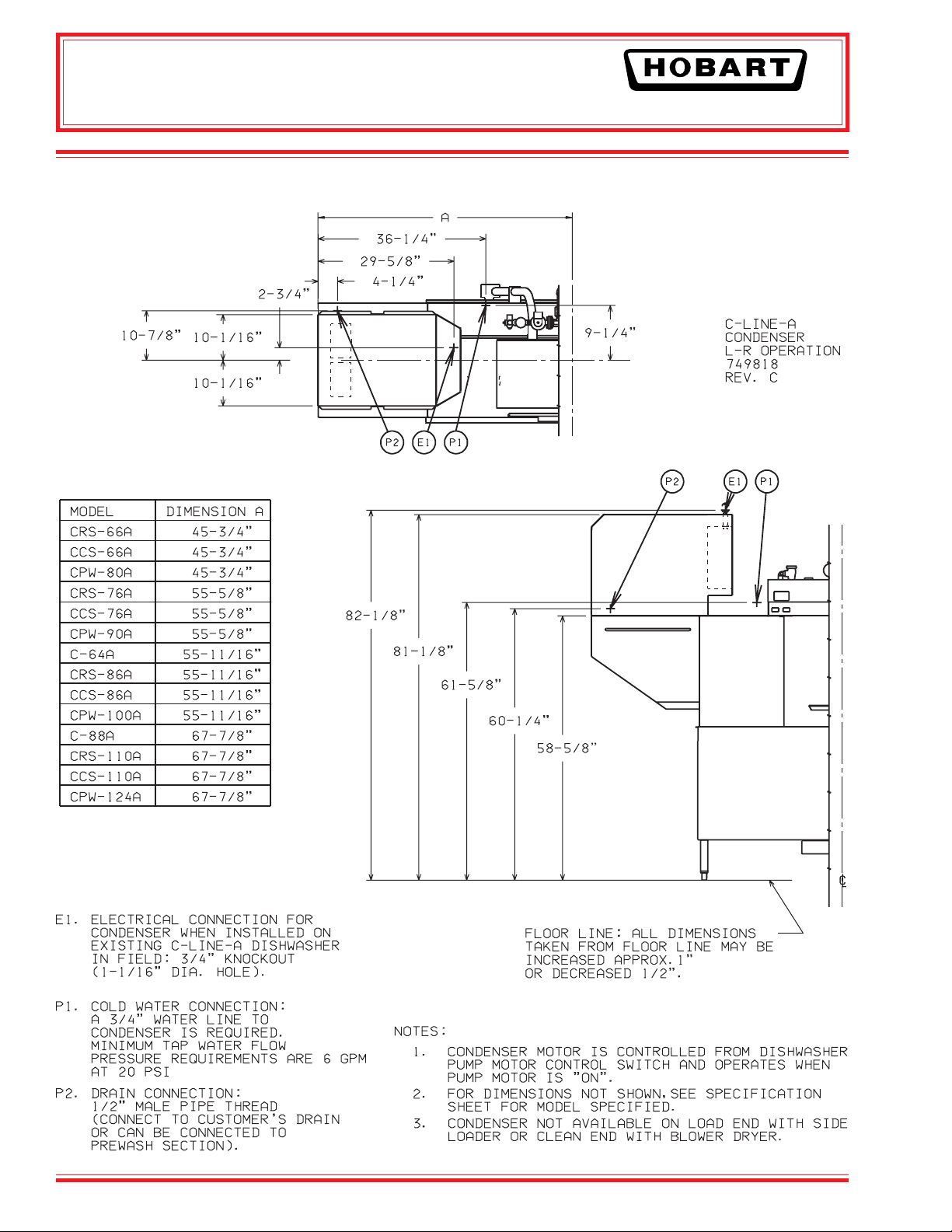

Page 2

C-LINE

CONDENSER

RIGHT TO LEFT OPERATION

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

Page 2 of 4 F-8102 – C-Line Condenser

Page 3

C-LINE

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

LEFT TO RIGHT OPERATION

CONDENSER

F-8102 – C-Line Condenser Page 3 of 4

Page 4

C-LINE

CONDENSER

SPECIFICATIONS

DESIGN: The condenser eliminates need for overhead

watertight ducting. It is mounted over the vent of the

dishwasher and performs the necessary exhaust function

from the dish machine. The unit removes excessive

moisture from the exhaust air and conditions the air for its

return to the dish room. The unit incorporates a centrifugal

blower having 1000 cfm capacity. The blower provides for

the venting and also for air circulation as the conditioned

air is returned to the room. The louvers at the air

discharge can be positioned to alter direction of air flow.

The excess moisture and latent heat is removed from the

vented air by passing the air over water-cooled coils.

Available cold tap water is required for the condenser

coolant. The condensing process results in heating the

cold tap water passing through the coils, and such heated

water can subsequently be used in the prewash tank of

the dishwasher or discharged to drain.

The condenser includes a tap water economizer which

controls the flow rate of coolant water passing through the

coils. A higher flow rate of coolant is provided at full

operation. However, when no dishware is passing through

the dishwasher the coolant flow is reduced to effect

economy. Tap water flow pressure requirement is 20 psi

minimum at a flow rate of 6 gpm. If condenser is to be

connected to a chilled water closed loop system, consult

factory for special ordering information.

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

1

CONSTRUCTION: The overall dimensions are 20

1

⁄4" long by 221⁄2" high, which provides for installation

by 30

⁄8" wide

on C-Line machines in rooms having only 7-foot ceiling

height. The outer chassis enclosure, interior bulkheads,

structural reinforcing, and control enclosures are of

stainless steel. Extended vent hood is included as part of

condenser assembly.

Construction provides for easy serviceability. The top and

end panels are removable, as well as the louvers. The

panels allow access to coils, blower, and electrical

controls. The removal of louvers provides sufficient

clearance for motor removal and servicing.

MOTOR: The blower is operated by a totally enclosed built

for Hobart

1

⁄2 H.P. motor having grease-packed ball

bearings. Single-phase is capacitor-start, induction-run

type. Three-phase is polyphase, squirrel-cage inductionrun type. Available electrical specifications are

208-240/60/1, 208-240/60/3, 480/60/3. Also available in

electrical specifications of 200-240/60/1, 200-240/50/3,

380/60/3 and 380-415/50/3 not submitted for U L Listing.

For electrical specifications not listed above, write or call

factory for further details.

DISCHARGE AIR TEMPERATURE VS. TAP WATER FLOW FOR CD SERIES CONDENSER

INSTALLED ON HOBART C-LINE DISHWASHERS

NOTE

The curve chart provides for estimating

the temperature of the air discharged

from the Condenser into the dish room.

Values are average and are subject to

change in air currents and the point of

measurement.

Tap water flow pressure requirement is

20 psi minimum; minimum flow rate at

idle 2 gpm, maximum flow rate with final

rinse actuated 6 gpm.

If condenser is to be connected to a

chilled water closed loop system,

consult factory for special prices and

ordering information.

As continued product improvement is a policy of Hobart, specifications are subject to change without notice.

Page 4 of 4 F-8102 – C-Line Condenser

F-8102 (REV. 1/04) LITHO IN U.S.A. (H-01)

Printed On Recycled Paper

Loading...

Loading...