Hobart 9OC24S Operation Manual

Revised 062574

Rev ised 022278

OPERATION, MAINTENANCE, AND OVERHAUL MANUAL

FOR

SELF-PROPELLED GENERATOR SET

MODE L N 0. 9OC24S

TM-240A

103073

SPECIFICATION NO. 5381A AND VARIATIONS

90KVA, 115/200-V AC, 400 tjZ, 3-PHASE

Manufactured by ,

MOTOR GENERATOR DIVISION

HOBART BROTHERS COMPANY

TROY, OH IO 45373

U.S.A.

SAFETY INSTRUCTIONS AND WARNINGS FOR ELECTRICAL POWER EQUIPMENT

ELECTRIC SHOCK can kill. Do not touch live electrical parts.

FUMES AND GASES can be fire and health hazards. Ventilate all fumes and exhaust gases to the outside.

ELECTRIC ARC FLASH can injure eyes, burn skin, cause equipment damage, and ignite combustible material. Do not

use power cables to break load and be sure tools don’t cause short circuits.

IMPROPER PHASE CONNECTION, PARALLELING, OR USE can damage this and attached equipment.

MOVING PARTS can cause serious injury. Keep clear of moving parts.

iMPORTANT - Protect yourself and others. Read and understand all the instructions in this Operating/Instruction

Manual before installing, operating, or servicing this equipment. Keep this manual available for future

use by all operators.

A. GENERAL

Equipment that supplies electrical power can cause serious injury or death, or damage to other equipment or

property, if the operator does not strictly observe all safety rules and take precautionary actions. Safe practices

have developed from past experience in the use of power source equipment. Certain of the practices below apply to

engine driven equipment.

6. SHOCK PREVENTION

Bare conductors, or terminals in the output circuit, or ungrounded, electrically-live equipment can fatally shock a

person. Have a competent electrician verify that the equipment is adequately grounded and learn what terminals

and parts are electrically HOT. Use proper safety clothing, procedures, and test equipment.

The electrical resistance of the body is decreased when wet, thus more easily permitting dangerous currents to flow

through it. When inspecting or servicing equipment, do not work in damp areas without being extremely careful.

Stand on dry rubber mat or dry wood, use insulating gloves that are effective when dampness or sweat cannot be

avoided. Keep your clothing dry and never work alone.

1. Installation and Grounding of Electrically Powered Equipment - Electrical equipment must be installed

and maintained in accordance with the National Electrical Code, ANSI/NFPA 70, and other applicable codes.

A power disconnect switch or circuit breaker must be located at the equipment. Check the nameplate for voltage,

frequency, and phase requirements. If only 3-phase power is available, connect any single-phase rated equipment to

only two wires of the 3-phase line. DO NOT CONNECT the equipment grounding conductor (lead) to the third live

wire of the 3-phase line, g this makes the eauipment frame electricallv

---

HOT, which can cause a fatal shock

--- ----

Be sure to connect the grounding lead, if supplied in a power line cable, to the grounded switch box or building

ground. If not provided, use a separate grounding lead. Be certain that the current (amperage) capacity of the

grounding lead will be adequate for the worst fault current situation. Refer to the National Electrical Code ANSI/

NFPA 70 for details. Do not remove plug ground prongs. Use correct mating receptacles.

2. Output Cables and Terminals - Inspect cables often for damage to the insulation and the connectors. Replace

or repair cracked or worn cables immediately. Do not overload cables. Do not touch output terminal while equip-

ment is energized.

Instruction 910082

Nov 16182 Revised

Page 1

,--

3. Service and Maintenance - This equipment must be maintained in good electrical and mechanical condition

to avoid hazards stemming from disrepair. Report any equipment defect or safety hazard to your supervisor and

discontinue use of the equipment until its safety has been assured. Repairs should be made by qualified personnel

only. Shut OFF all power at the disconnecting switch or line breaker before inspecting or servicing the equipment.

Lock switch OPEN (or remove line fuses) so that power cannot be turned ON accidentally. Disconnect power to

equipment if it is out of service. If troubleshooting must be done with the unit energized, have present another person trained in turning off the equipment and providing or calling for first aid.

C. FIRE AND EXPLOSION PREVENTION

Fire and explosion are caused by electrical short circuits, combustible material near engine exhaust piping, misuse

of batteries and fuel, or unsafe operating or fueling conditions.

1.

Electrical Short Circuits and Overloads - Overloaded or shorted equipment can become hot enough to cause

fires either by self destruction or causing nearby combustibles to ignite. Provide primary input protection to remove short circuited or heavily overloaded equipment from the line.

2. Battery - Batteries may explode and/or give off flammable hydrogen gas. The acid and arcing from a ruptured

battery can cause fires and additional failures. When servicing, do not smoke, causing sparking, or use open flame

near the battery.

3. Enqine Fuel

- Use only approved fuel container or fueling system. Fires and explosions can occur if the fuel

tank is not grounded prior to and during fuel transfer. Shut unit DOWN before removing fuel tank cap. Do not

completely fill tank. Heat from the equipment may cause fuel expansion overflow. Remove all spilled fuel immediately including any that penetrates the unit. After cleanup, open equipment doors and blow fumes away with

compressed air.

D. TOXIC FUME PREVENTION

Carbon Monoxide - Engine exhaust fumes can kill and cause health problems. Pipe or vent the exhaust fumes to a

suitable exhaust duct or outdoors. Never locate engine exhausts near intake ducts or air conditioners.

E. BODILY INJURY PREVENTION

Serious injury can result from contact with fans, belts, and pulleys inside the equipment. Shut DOWN equipment

for inspection and routine maintenance. When equipment is in operation use extreme care in doing necessary

troubleshooting and adjustment.

F. MEDICAL AND FIRST AID TREATMENT

First aid facilities and a qualified first aid person should be available for each shift for immediate treatment of all

injury victims. Electric shock victims should be checked by a physician and taken to a hospital immediately if any

abnormal signs are observed.

EMERGENCY FIRST AID

Call physician immediately. Seek additional assistance and use First Aid techniques recommended

by American Red Cross until medical help arrives.

IF BREATHING IS DIFFICULT, give oxygen, if available, and have victim lie down. FOR ELECTRICAL SHOCK, turn off power. Remove victim; if not breathing, begin artificial respiration,

preferably mouth-to-mouth. If no detectable pulse, begin external heart massage. Call Emergency

Rescue Squad immediately.

G. EQUIPMENT PRECAUTIONARY LABELS

Inspect all precautionary labels on the equipment monthly. Order and replace all labels that cannot be easily read.

Page 2

Instruction 910082

Revised Nov 16/82

WARNING!

SAFETY DEVICE BOX

HOBART PART NO. 6FW-4013A

DANGER! FAILURE TO PROPERLY MAINTAIN THE MICRO SWITCH GEARSHIFT

INTERLOCK CAN RESULT IN INJURY OR DEATH DUE TO UNEXPECTED MOVEMENT OF

THE GPU. PERFORM THE FOLLOWING PROCEDURE EVERY 200 OPERATING HOURS OR

3 MONTHS.

1. Remove the GPU to an area free of personnel and equipment. Set the

emergency brake and chock wheels.

2. With the gearshift in any gear (except neutral) and the clutch pedal engaged,

attempt to start the GPU. If the GPU starts, have qualified maintenance

personnel replace the micro switch, Hobart part no. 403982, and repeat this test

procedure prior to returning the GPU to service.

3. With the gearshift in any gear (except neutral) and the clutch pedal engaged,

switch the GPU to “GENERATE” mode. If the GPU engine does not shut down,

have qualified maintenance personnel replace the micro switch, Hobart part no.

403982, and repeat this test procedure prior to returning the GPU to service.

rOi?IAR~

e

a

‘0

b . @ ,,R

EMOTOR GENERATOR DIVISION

QD

:

z

HOBART BROTHERS COMPANY

OPERATION, MAINTENANCE, AND OVERHAUL MANUAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC. NO. 5381A

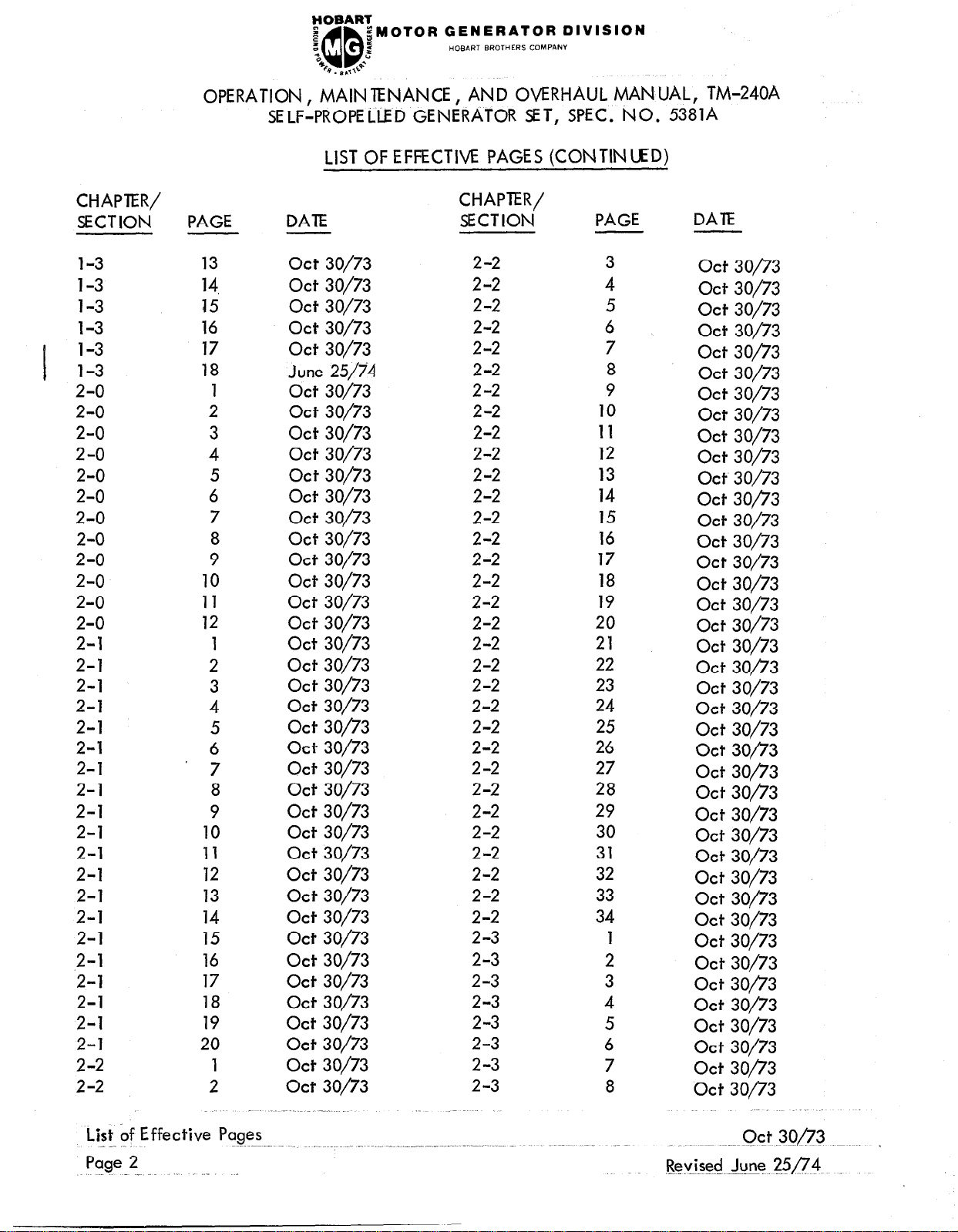

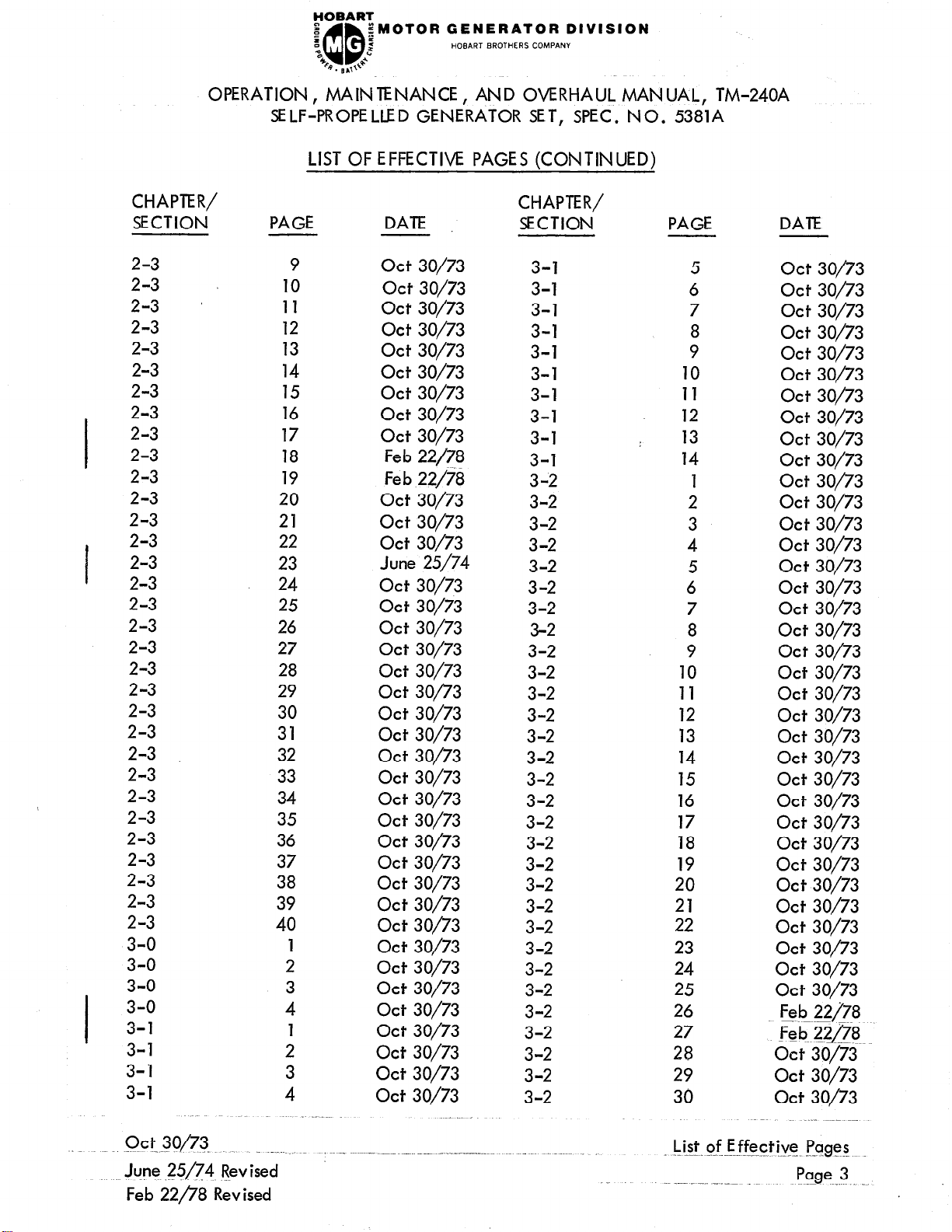

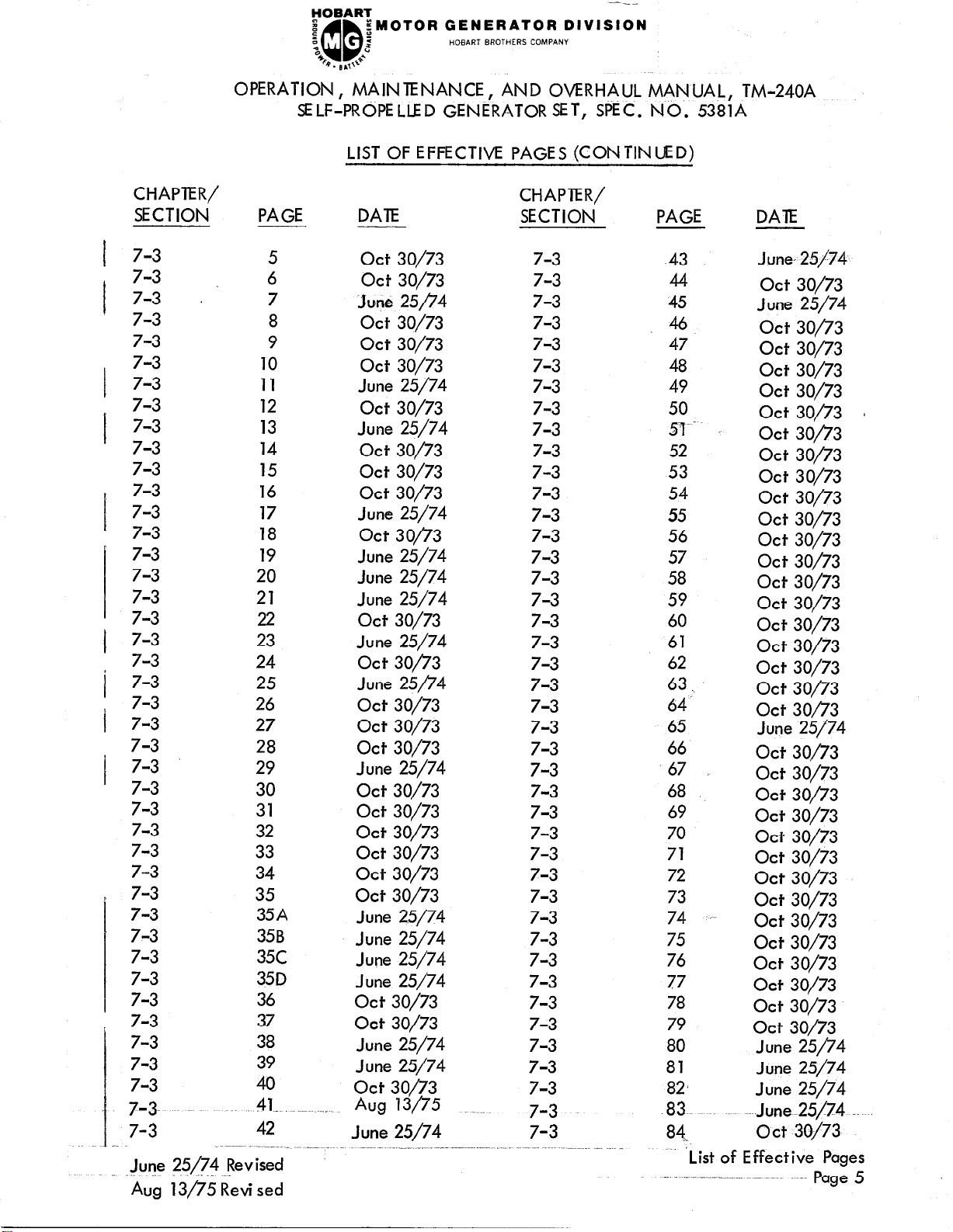

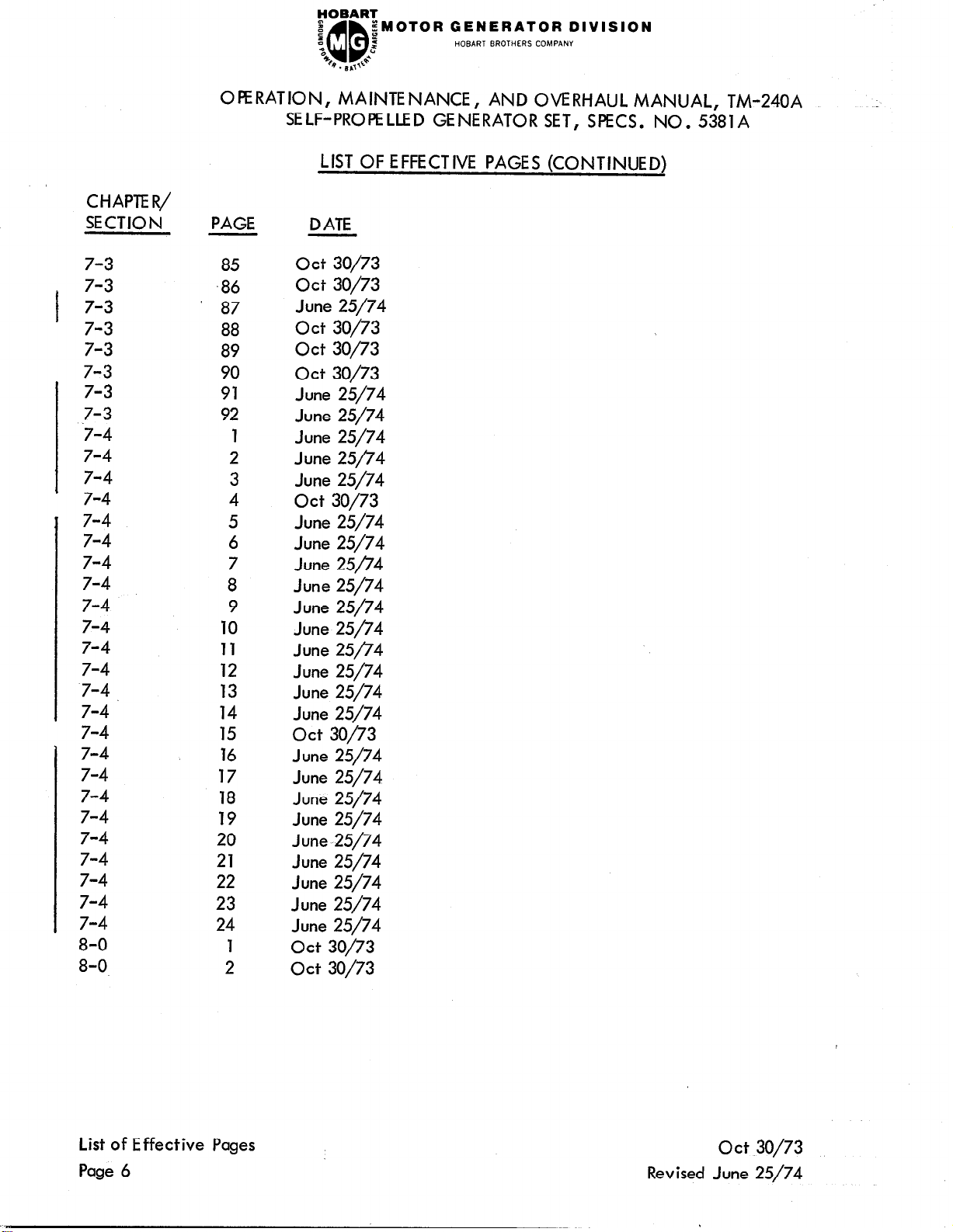

LIST OF EFFECTIVE PAGES

CHAPTER/

SECTION

Introduction

introduction

In troducticn

Introduction

Introduction

Introduction

,

List of

Effective

Pages

Contents

i

Con tents

Con tents

Con tents

Contents

Contents

Contents

Contents

Contents

Contents

1

1-O

1-O

1-o ’

1-O

I

1-o

1-o

1-o

1-o

l-l

1-l

l-l

1-l

l-l

l-l

l-l

l-l

l-l

l-l

PAGE

1

2

3

4

5

6

1 thru 6

DATE

act 30/73

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

Ott 30/73

Feb 22/78

1 June 25/74

2

Ott 30/73

3 act 30/73

4

5

Ott 30/73

Ott 30/73

6 Ott 30/73

7

Ott 30/73

8 Ott 30/73

9

10

June 25/74

Ott 30/73

1 Ott 30/73

2

3

Ott 30/73

Ott 30/73

4 June 25/74

5

6

7

8

Ott 30/73

act 30/73

Ott 30/73

act 30/73

1 act 30/73

2

3

4

5

6

7

8

9

10

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

Ott 30/73

Ott 30/73

act 30/73

Ott 30/73

Ott 30/73

CHAPTER/

SECTION

PAGE

l-l

l-l

l-l

l-l

l-l

l-l

l-l

l-l

l-l

l-l

l-l

l-l 22

l-l

1-l

l-l

l-l 26

l-l

l-l

l-l

1-l

1-l

l-l

l-2

l-2

l-2

l-2

1-2

l-2

l-3

l-3

l-3

l-3

l-3

l-3

l-3

l-3

l-3

l-3

l-3 _

l-3

11

12

13

14

15

16

17

18

19

20

21

23

24

25

27

28

29

30

31

32

2

3

4

5

6

2

3

4

5

6

7

8

9

10

11

12

1

1

DATE

Ott 30/73

act 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

Ott 30/73

act 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

Ott 30/73

June 25/74

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

Ott 30/73

act 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

act 30/73

Ott 30/73

Ott 30/73

act 30/73

June 25/74

..~ Ju_ne 25/74 Revised

Feb 22178 ‘Rev ised

FOBAl?:

e

a

;

b . B ,&

~MOTOR GENERATOR DIVISION

QD

5

t

HOBART BROTHERS COMPANY

OPERATION, MAINTENANCE, AND OVERHAUL MANUAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC. NO. 5381A

LIST OF EFFECTIVE PAGES (CON TIN UED)

CHAPTER/

SECTION

l-3

l-3

l-3

l-3

l-3

l-3

I

2-o

2-o

2-o

2-o

2-o

2-o

2-o

2-o

2-o

2-o

2-o

2-o

2-l

2-l

2-l

2-l

2-l

2-l

2-l

2-l

2-l

2-l

2-l

2-l

2-l

2-l

2-l

.2-l

2-l

2-l

2-l

2-l

2-2

2-2

PAGE

DAlE

13 act 30/73

14,

act 30/73

15 Ott 30/73

16 act 30/73

17 Ott 30/73

18

1

2

June 25/i4

act 30/73

Ott 30/73

3 act 30/73

4

Ott 30/73

5 Ott 30/73

6 Ott 30/73 2-2

7

8

Ott 30/73

Ott 30/73

9 act 30/73

10 act 30/73

11

Ott 30/73 2-2

12 act 30/73

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Ott 30/73 2-2

act 30/73 2-2

act 30/73

act 30/73 2-2

act 30/73

act 30/73

act 30/73

act 30/73

act 30/73 2-2

act 30/73 2-2

act 30/73

act 30/73

act 30/73

act 30/73 2-2

act 30/73

act 30/73

17 act 30/73

18 act 30/73

19 act 30/73

20

1

2

act 30/73

Ott 30/73

Ott 30/73

CHAPTER/

SECTION

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-3

2-3

2-3

2-3

2-3

2-3

2-3

2-3

PAGE

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

1

2

3

4

5

6

7

8

DAIE

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

act 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

act 3op3

act 30/73

act 30/73

act 30/73

act 30/73

act 30/73

act 30/73

act 30/73

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

act 30/73

Ott 30/73

act 30/73

‘Ott 30/73

List bf Effective Pages

_ -

Page 2

_ ~~ .-.-GM .xm ..~ ‘

Revised June 25/‘?‘9

.--.-..~...-~.--.-- ..-

FOBART

B

z

“c

QB

48

gMOTOR GENERATOR DIVISION

0. B.0

c

‘Q+

2

HOBART BRCJTHERS COMPANY

OPERATION, MAINTENANCE. AND OVERHAUL MANUAL. TM-240A

SELFlPROPELlED GENiRATOR SET, SPEC. NO. 53&A

LIST OF EFFECTIVE PAGES (CONTINUED)

CHAPTER/

SECTION

PAGE

2-3

2-3

2-3 ’

2-3

2-3

2-3

2-3

2-3

2-3

2-3

2-3

2-3

2-3

10

11

12

13

14

15

16

17

18

19

20

21

2-3 22

2-3

2-3

2-3

2-3

2-3

2-3

2-3

2-3

2-3

2-3

2-3

2-3

2-3

2-3

2-3

2-3

2-3

2-3

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

3-o

3-o

3-o

3-o

3-l

3-l

3-l

3-l

4

2

3

4

2

3

9

1

1

DATE

Ott 30/73

act 30/73

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Feb 22/78

Feb 22/78

Ott 30/73

Ott 30/73

Ott 30/73

June 25/74

Ott 30/73

act 30/73

act 30/73

act 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

act 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

act 30/73

act 30/73

Ott 30/73

act 30/73

~. .~.

CHAPTER/

SECTION

PAGE

3-l

3-l 6

3-l

3-l

3-l

3-l

3-l

3-l

3-l

3-l

3-2

3-2 2

3-2 3

3-2 4

3-2

3-2

3-2 7

3-2

3-2

3-2

3-2

3-2

3-2

3-2

3-2

3-2

3-2

3-2

3-2

3-2

3-2

3-2

3-2

3-2

3-2

3-2

3-2

3-2

3-2

3-2

10

11

12

13

14

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

5

6

8

9

5

7

8

9

1

DATE

Ott 30/73

act 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

Ott 30/73

OctW73.

June .?5n4 Rev ised

Feb 22/?8 Revised

j&t. @Ffective Pages

Page 3

HOBART

E

z

“0

QD

b . I ,,d

~MOTOR GENERATOR DIVISION

z

5

HOBART BROTHERS COMPANY

OF’ERATION, MAINTENANCE, AND OVERHAUL MANUAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC. NO. 5381A

LIST OF EFFECTIVE PAGES (CON TIN UED)

CHAPTER/

SECTION

4-o

4-o

4-l

4-l

4-l

4-l

4-l

4-l

4-l

4-l

4-l

4-l

4-l

4-l

4-l

4-l

4-2

4-2

4-2

4-2

5-o

5-o

5-l

5-l

5-l

5-l

5-l

5-l

5-l

5-l

5-2

5-2

6-O

6-O

6-l

6-l

6-l

6-l

6-l

6-l

PAGE DATE

1

?

’ 1

2

act

act

Ott

Ott

3 Ott

4 Ott

5

6

7

8

9

10

Ott

Ott

Ott

Ott

Ott

Ott

11 Ott

12

Ott

13 act

14

1

2

3

4

1

2

1

2

3

4

5

6

7

8

1

2

1

2

1

2

3

4

5

6

Ott

Ott

act

act

Ott

act

Ott

act

Ott

Ott

Ott

Ott

Ott

Ott

Ott

Ott

Ott

Ott

Ott

act

Ott

Ott

Ott

Ott

Ott

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

30/73

CHAPTER/

SECTION

6-l

6-l

6-l

6-l

6-l

6-l

6-l

6-l

6-l

6-l

6-l

6-l

6-l

6-l

6-l

6-l

6-l

6-l

6-2

6-2

7-o

7-o

7-o

7-o

7-l

7-l

7-l

7-l

7-2

7-2

7-2

7-2

7-2

7-2

7-2

7-2

7-3

7-3

7-3

7-3

PAGE DATE

7

8

9

10

11

12

13

14’

15

16

17

18

19

20

21

22

23

24

1

2

1

2

3

Ott 30/73

act 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

Ott 30/73

act 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Feb 22/Z-

Fe&$!78

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

June 25/74

June 25/74

4 Ott 30/73

1

2

Ott 30/73

Ott 30/73

3 Ott 30/73

4

1

2

3

4

5

6

7

8

1

2

3

4

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

Ott 30/73

Ott 30/73

Ott 30/73

June 25/74

June 25/74

Ott 30/73

Ott 30/73

Ott 30/73

‘Ott 30/73

List of Effective Pages

Page 4

Ott 30/73

Revised J.une_25/?4~.

Revised Feb 22/78

FOBART

e

a

3

4k

OPERATION, MAINTENANCE, AND OVERHAUL MANUAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC. NO. 5381A

:MOTOR GENERATOR DIVISION

:

z

QB

4.B,&

LIST OF EFFECTIVE PAGES (CON TIN UEDI

HOBART BRCJTHERS COMw.NY

CHAPlER/

SECTlOti

7-3

I

7-3

7-3 (

I

7-3

7-3

7-3 7-3

I

7-3

7-3

I

7-3

7-3

7-3

I

7-3

I

7-3

p 7-3

7-3

7-3

7-3

7-3

I

7-3

~

7-3

1

7-3 7-3

i

7-3

7-3 ’

I

7-3

7-3

7-3

7-3

7-3

7-3 7-3

I

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3.

7-3

June ?5/74 Revised

Aug 13/75 Revi sed

PAGE

5

6

7

8

9

10

11

12

13

14

15

16

17 June 25/74

18

19

20

21

22

23

24

25 June 25p4

26

27

28

29 June 25/74

30

31

32

33

34

35

35A

35B

35c

35D

36

37

38

39

40

.41-..~-

42

DAlE

Ott 30/73

Ott 30/73

June 25p4

Ott 30/73

Ott 30/73

Ott 30/73

June 25/74

Ott 30/73

June 25/74

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

June 25/74

June 25/74

June 25/74

Ott 30/73

June 25/74

Ott 30/73

act 30/73

act 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

Ott 30/73

June 25/74

June 25/74

June 25/74

June 25/74

Ott 30/73

Ott 30/73

June 25/74

June 25/74

act 30/73

Aug 13/75

June 25/74

CHAP7ER/

SECTION

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

PAGE

43

44

45

46

47

48

49

50

y--

52

53

54

55

56

57

58

59

60

61

62

63 .,

64‘

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82)

83

84,

List of Effective Pages

DAIE

June- 25174

Ott 30/73

June 25/74

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

act 30/73

June 25/74

Ott 30/73

act 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

Ott 30/73

June 25/74

June 25/74

June 25/74

June 25174

Ott 30/73

~~~ -- Page 5

CHAPTE I?/

SECTION

FOBART

I

z

“a

b. s,,+e

iMOTOR GENERATOR DIVISION

QD

a

2

HOBART BROTHERS CCIMPANY

OARATION, MAINTENANCE, AND OVERHAUL MANUAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPECS. NO. 5381A

LIST OF EFFECTIVE PAGES (CONTINUED)

PAGE

D ATE

7-3

7-3

7-3

I

7-3

7-3

7-3

7-3

,7-3

7-4

7-4

7-4

’ 7-4

, 7-4

7-4

7-4

7-4

7-4

7-4

7-4

7-4

‘7-4

7-4

7-4

7-4

7-4

7-4

7-4

7-4

7-4

7-4

7-4

7-4

8-O

8-O

85

,86

87

88

89

90

91

92

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

2

3

4

1

Ott 30/73

Ott 30/73

June 25/74

Ott 30/73

Ott 30/73

Ott 30/73

June 25/74

June 25/74

June 25/74

June 25p4

June 25/74

Ott 30/73

June 25/74

June 25/74

June 25n4

June 25/74

June 25/74

June 25/74

June 25/74

June 25/74

June 25/74

June 25/74

act 30/73

June 25/74

June 25/74

June 25/74

June 25/74

June 25/74

June 25/74

June 25/74

June 25/74

June 25/74

Ott 30/73

Ott 30/73

List of Effective Pages

Page 6

act 30/73

Revised June 25/74

FOBART

I

::

“c

b. &*

;MOTOR GENERATOR DIVISION

QD

2

2

HOBART BROTHERS COMPANY

OPERATION, MAINTENANCE, AND OVERHAUL MAN UAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC. NO. 5381A

INTRODUCTION

1. Genera I

The Introduction has been relocated to the front of the manual because we wish it to

be noticed and read first.

It has also been expanded in an attempt to give the reader

a better understanding of the manual and to make it more helpful and easier to use.

If you expect the manual to be useful to you, please read the introduction.

2.

scope

The manual contains descriptive,

maintenance, trouble shooting and overhaul information for a basic 400-Hertz, generator set and its different optional Variations.

qualified information throughout the manual will apply to the basic set and all variations.

identified as such. An explanation of “variations”

Any information which applies only to a specific variation will be qualified and

and how to identify all generator

sets is given in the Description, Chapter/Section l-l (Chapter 1, Section 1).

3. P

urpose

The manual’s purpose is to provide information and instructions to experienced operators,

electricians, and mechanics who have never seen or operated this generator set.

the intent of the manual to guide and assist operators and maintenance personnel in the

proper use and maintenance of the equipment.

4. Contents

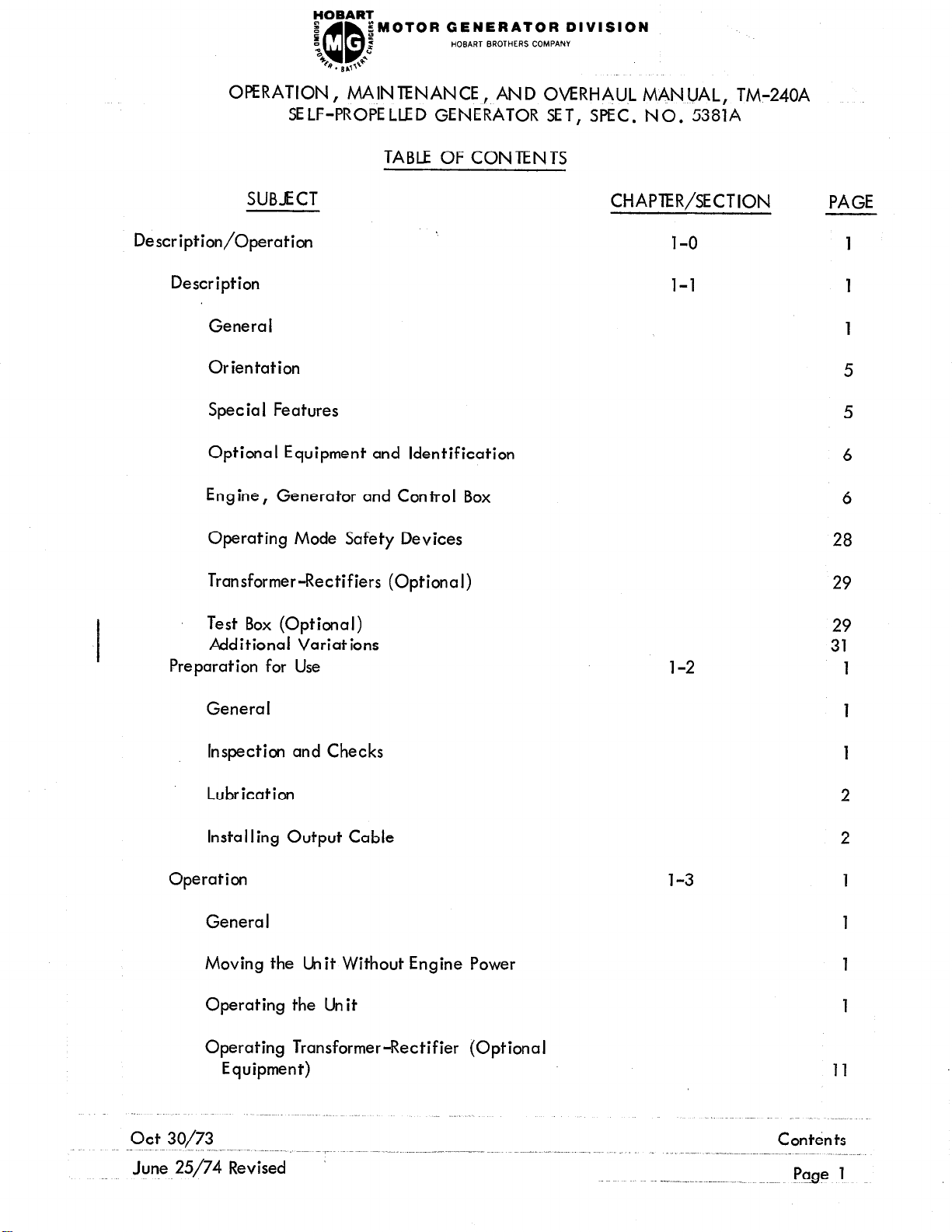

Immediately following the Introduction is a List of Effective Pages which lists each

page in the manual by its Chapter/Section, and page number. Directly opposite

each page number listing is a date which indicates whether the page is original or

revised.

A complete Table of Contents appears next in sequence. It contains a list of all

Chapters, Sections, and the principal paragraph titles within each Section. The location of each listing is identified by Chapter/Section and page number. A complete

list of illustrations with their locations is located at the end of the Table of Contents.

Un-

G

It is

The main text of the manual is divided into eight Chapters as follows:

Chapter 1. Description/Operation

Chapter 2. Servicing

Chapter 3. Trouble Shooting

Chapter 4. RemovaI/lnstaI laticn

Chapter 5.

Repairs

act 30/73 Introduction

~~~~ Page 1

fOBART

8

z

“c

48

;MOTOR GENERATOR DIVISION

2

z

QQ

4. BL,I’La

HOEIART BROTHERS COMPANY

OPERATION, MAINTENANCE, AND OVERHAUL MANUAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC. NO. 5381A

Chapter 6. Overhaul

Chapter 7.

Chapter 8.

II lustrated Parts List

Manufacturer’s Literature

Each Chapter is divided into as many Sections as necessary. Sections are always referred

to by a combination Chapter/Section number. Example, 2-3 refers to Chapter 2, Section

3.

5. Format

A. Paragraphing and Out I in ing

The material within each Section is divided into main subjects with applicable

paragraph headings and subheadings as required. This method not only helps keep

information closely knit, but provides a means of identifying material for reference

purposes.

For example, a portion of the Description Section might logically follow

this arrange men t and paragraph ing :

1. Control Box

A. Interior Panel

(1) Protective devices

(a) Over load relay

(2) Con tactors

Page N umber ing

B.

Page numbers do not run consecutively throughout the manual. Each page is

identified by the Chapter/Section number in which it appears, and by a page

number within the Chapter/Section. Therefore the first page in each Section is

page 1.

These identifying numbers appear in the lower, outside corner of each

page. Each page also bears a date located in the corner opposite the page number.

This date is either that of original issue, or of the latest revision. Any revision

to the original text is identified by a heavy black line in the left-hand margin.

Illustrations follow a numbering system similar to page numbering. The first

Figure in each Section is Figure 1.

6. How to Use the Manual

A. General

There has always been, and probably always will be, some disagreement between

writers, users-,-specification writers, and others, regarding all phases of manual

Introduction

Page 2

.-~o~t.~o[~~

FOBART

I

::

“c

B . LI ,,+*

;MOTOR GENERATOR DIVISION

:

z

QQ

HOBART BROTHERS COMPANY

OPERATION, MAINTENANCE, AND OVERHAUL MANUAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC. NO. 5381A

preparation and how the manual-can best serve the needs of the user.

It is of

course impossible to completely satisfy al I concerned.

This manual follows the format, rules and style proposed by, and generally accepted

by members of the Air Transport Association.

grouped to help the user locate it quickly.

In so far as possible, information is

All tables, charts, diagrams, etc., as

well as illustrations, are identified by Figure Number (i.e., Fig. 2) to avoid con-

’ fusion.

How to Locate Information

B.

Even if you have read the manual completely and thoroughly, the easiest and quickest way to locate information is by using the Table of Contents. In addition to the

complete Table of Contents in the front of the manual, each Chapter has its own

Table of Contents and List of Illustrations.

(1) Table of Contents

The complete Table of Contents is only five pages long 9 Even if the user has

no idea where a certain bit of information is located, the general location

can be quickly found by running through the Table of Contents. For example,

some adjustment information is needed.

A quick look at the Table of Contents

indicates that “Adjustment/Test” information is located in Chapter/Section 2-3

(Chapter 2, Section 3).

If the specific adjustment being sought is not listed

in the main Table of Contents, turn to Chapter 2 and look in its Table of Con-

tents under “Adiustment/Test” where each adjustment is listed with the page

number location.

, (2) List of Illustrations

Ott 30/73

A complete List of Illustrations follows the Table of Contents and includes the

title, figure number, and Chapter/Section, with page number location of all

illustrations contained in the manual.

Locate the appropriate title in the

List of Illustrations, then turn to the Chapter/Section and page number indicated.

It should be noted here that ALL electrical connection diagrams are located

in Chapter 5, Repair.

(3) References

To avoid repetition and lengthy explanations, references to other material are

used throughout the manual. Both material in the text and illustrations may be

referred to in order to clarify or expand information and instructions. Portions

of the text are referred to by identifying the paragraph in which referenced

material may be found. A reference to other material would be in order right

here by referring to paragraphing information contained in paragraph 5, A

Introduction

FOBART

s

t

“c

‘I;

OPERATION, MAINTENANCE, AND OVERHAUL MANUAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC. NO. 5381A

;MOTOR GENERATOR DIVISION

z

z

QQ

Q. BL,+e

HOBART BROTHERS COMPANY

above .

the reference, only the paragraph identification is given.

Example:

When referenced material is located in another Chapter/Section, both the

Chapter/Section number and the paragraph identification are given.

Example :

Components shown in illustrations and illustrations themse Ives are referenced

in a similar manner. When this type reference is made, the item number of

the part and the Figure number in which it appears are given.

Example:

When referenced material is located in the same Chapter/Section as

(Ref. Para.

the same Chapter/Section.

(Ref. 1-2, Para.

Chapter/Section l-2, and identified by paragraph 1, A.

1, A) means the material is to be found in paragraph 1, A, of

1, A) means that the referenced material is located in

(Ref. 2, Fig. 3) f re ers to item number 2 which appears in illustration Figure

3 of the same Chapter/Section.

When the referenced Figure appears in another Chapter/Section, the reference

will include the Chapter/Section number.

Example :

(Ref. 2-3; 1, Fig.

see item 1, in Figure 4.

Once a Figure number reference has been established for a series of instructional

steps, the Figure number is not repeated. Only the item numbers of parts involved are referenced.

For example, an instruction might appear like this: “Loosen screw (2, Fig. 6),

slide out connector (4), and remove brush (6)“.

When an item is referenced without a figure number, it will always apply to the

last preceding Figure number mentioned in the text.

NOTE:

The word “See” may appear in some references, as (See Fig. 2). It

means exactly the same thing as “Ref. “, however, its ,usage seems a

little more direct and definite.

4) tel Is the user to refer to Chapter/Section 2-3, and to

Introduction

page 4

Ott 30/73

POBARI

e

s

“0

% . B ,J

zMOTOR GENERATOR DIVISION

P

2

QQ

HOBART BROTHERS COMPANY

OPERATION, MAINTENANCE , AND OVERHAUL MAN UAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC. NO. 5381A

7. Abbreviations

The following is a list of abbreviations used throughout the manual. They are not

to be confused with symbols which appear on schematic diagrams.

A - ampere

AC

- alternating current

AR ’ - as required

C

ccw

cw

DC

de!3

F

Fig

GALS

Hz

in .

KG

KVA

KW

MM

No.

Para.

PF

PSI

Pt

Qt

Ref

RPM

Sect

SPEC

- ten tigrade

- counterclockwise

- clockwise

- direct current

- degree

- Fahrenheit

- figure

- gal Ions

- Hertz (cycles per second)

- inch

- kilogram

- kilovolt-ampere

- kilowatt

- millimeter

-number

- paragraph

- power factor

- pounds per square inch

- pint

- quart

- reference (refer to)

- revolutions per minute

- section

- specification

T-R - transformer-rectifier

V - volt

VAR

- variation

FOBART

.z

a

“0

B . ~ .,,J.

gMOTOR GENERATOR DIVISION

5

2

QQ

HOBART BROTHERS COMPANY

OPERATION, MAINTENANCE, AND OVERHAUL MANUAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC. NO. 5381A

lntroc+ction Ott 30/73

Page -6.

nOBAR?

I

:,

“c

QQ

b. s,,++*

OPERATION, MAINTENANCE, AND OVERHAUL MANUAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC. NO. 5381A

pMDTDR GENERATOR DIVISION

i

TABLE OF CONTENTS

HOBART BROTHERS COMPANY

SUBJECT

Description/Operation

Description

Genera I

Orientation

Spec ia I Features

Optional Equipment and Identification

Engine, Generator and Control Box

Operating Mode Safety Devices

Transformer-Rectifiers (Optional)

Test Box (Optional)

Additional Variations

Preparation for Use

CHAPTER/SECTION

1-o 1

l-l

l-2

PAGE

1

6

6

28

29

32;

1

General

Inspection and Checks

Lubrication

Installing Output Cable

Operation l-3

Genera I 1

Moving the Cklit Without Engine Power

Operating the Unit

Operating Transformer-Rectifier (Optional

Equipment) 11

1

1

2

2

1

June 25/74 Revised

P!zP 1

.

OPERATION, MAINTENANCE, AND OVERHAUL MANUAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC. NO. 5381A

TABLE OF CONTENTS (CONT’D.)

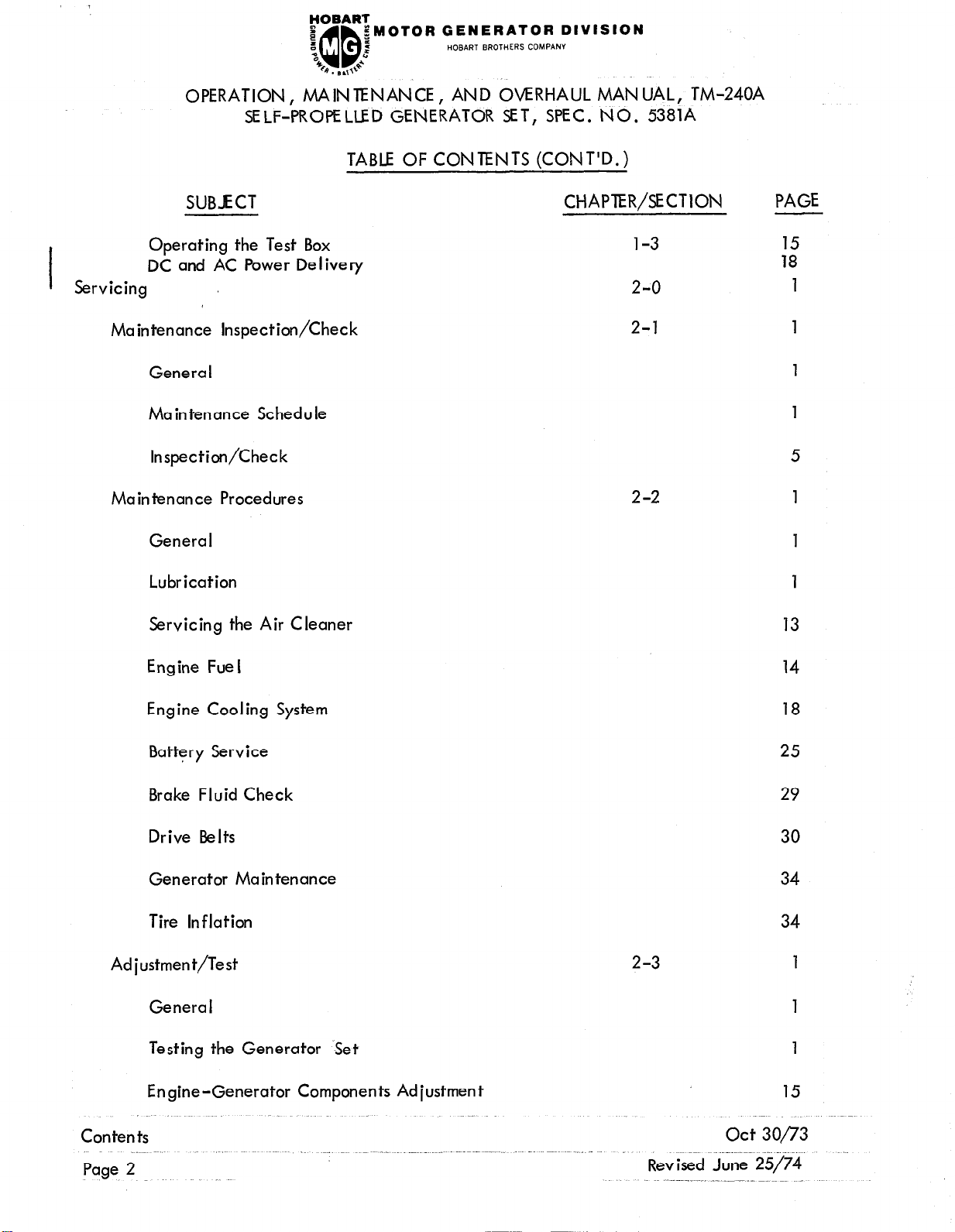

SUBJECT

Operating the Test Box

DC and AC Power Delivery

Servicing

Maintenance Inspection/Check

Genera I

Maintenance Schedule

Inspection/Check

Maintenance Procedures

General

Lubrication 1

Servicing the Air Cleaner

CHAPTER/SECTION

1-3

2-o

2-l

2-2 1

PAGE

:8”

1

1

1

1

5

1

13

Engine Fue I

Engine Cooling System 18

Battery Service 25

Brake Fluid Check

Drive Belts 30

Generator Maintenance 34

Tire Inflation 34

Adjustment/Test

2-3

Genera I

Testing the Generator Set 1

Engine-Generator Components Ad justmen t

14

29

1

1

15

Contents

Page 2

act 30/73

Revised June 25/74

~OFJAI?~

e

a

“c

B

;MOTOR GENERATOR DIVISION

HOBART BROTHERS COMPANY

QD

. 8.0‘

2

c

OPERATION, MAINTENANCE, AND OVERHAUL MANUAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC. NO, 538

1A

TABLE OF CONTENTS (CONT’D .)

SUBICT

Chassis Components Adiustment

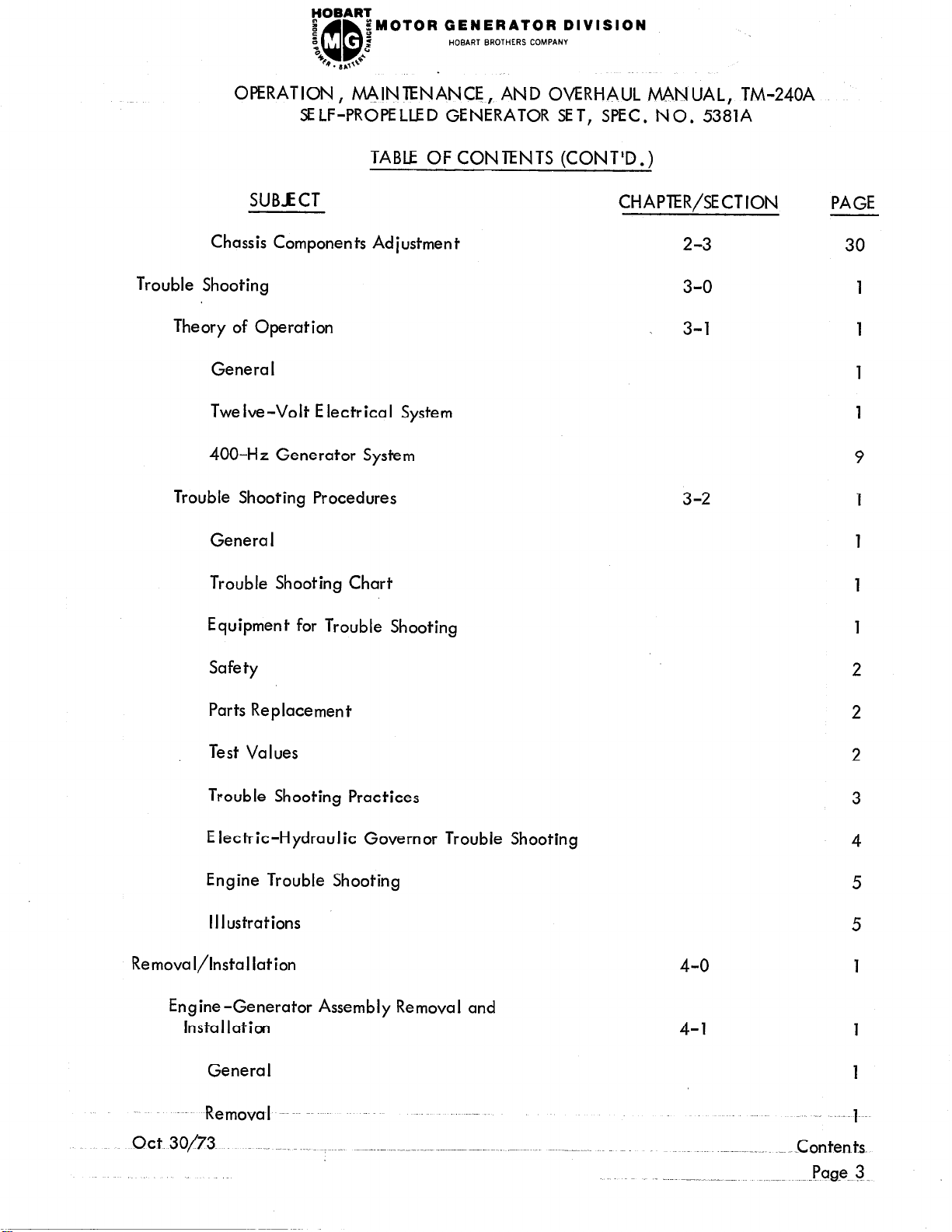

Trouble Shooting

Theory of Operation

General

Twelve-Volt Electrical System

400-Hz Generator System

Trouble Shooting Procedures

Genera I

Trouble Shooting Chart

Equipment for Trouble Shooting

CHAPTER/SECTION PAGE

2-3 30

3-o 1

3-l 1

1

1

9

3-2

1

1

1

1

Safety

Parts Replacement

Test Values

Trouble Shooting Practices

Electric-Hydraulic Governor Trouble Shooting

Engine Trouble Shooting

II lustrations

Removal/Installation

Engine-Generator Assembly Removal and

Installation

Genera I

4-o

4-l

2

2

2

3

4

5

5

1

1

1

Con tents.

HOBART

e

a

‘c

46

;MOTOR GENERATOR DIVISION

QD

Q. B,T+

p:

z

i

HOBART BROTHERS COMPANY

OPERATION, MAINTENANCE, AND OVERHAUL MANUAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC. NO. 538114

TABLE OF CONTENTS (CONT’D.)

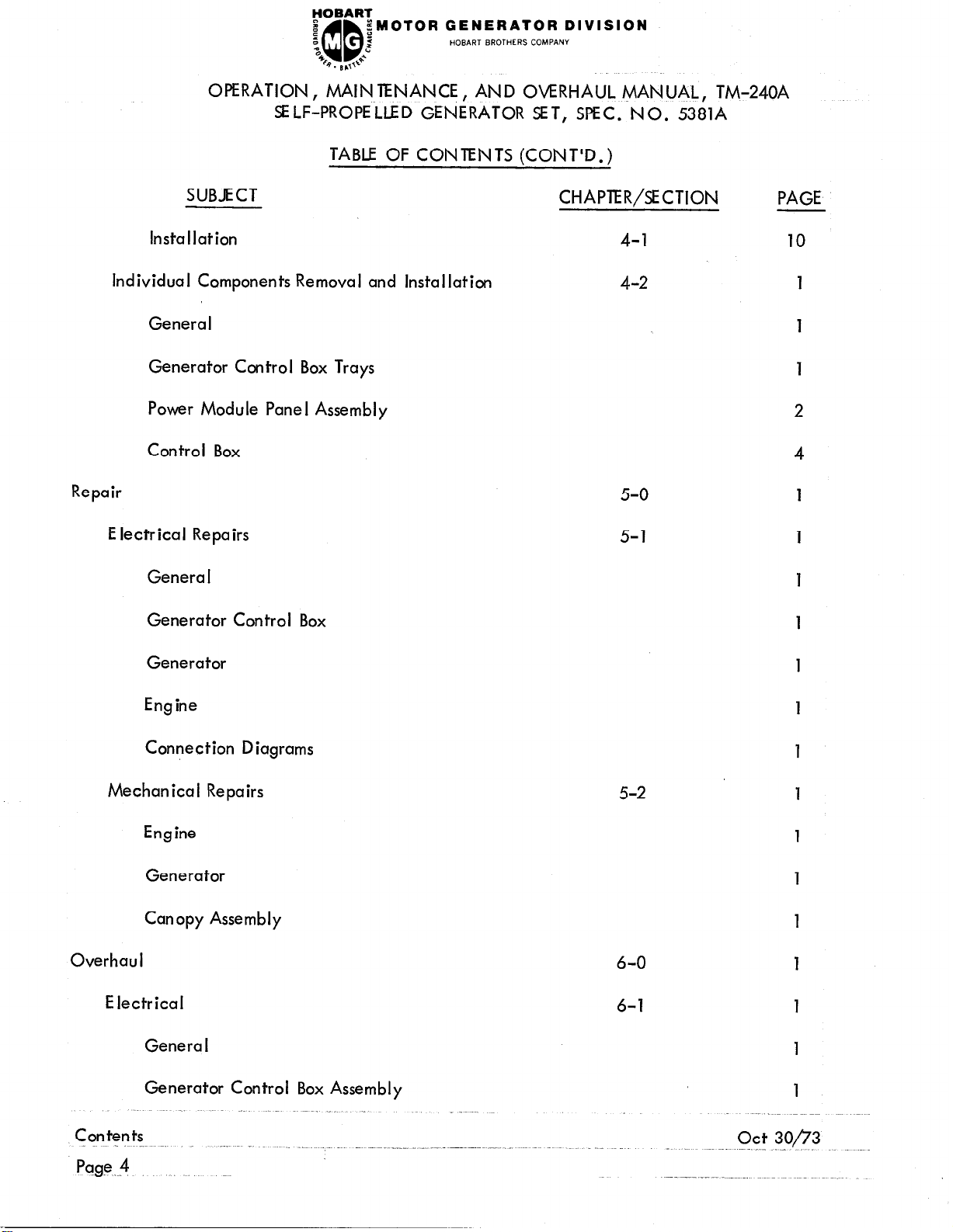

SUBJECT

Installation

Individual Components Removal and Installation

General

Generator Control Box Trays

Power Module Panel Assembly

Control Box

Repair

Electrical Repairs

Genera I

Generator Control Box

CHAPTER/SECTION

4-l

5-o

5-l

PAGE

10

1

1

2

4

1

1

1

1

Generator

Engine

Connection Diagrams

Mechanical Repairs

Engine

Generator

Canopy Assembly

Overhaul

Electrical

Genera I

Generator Control Box Assembly

1

1

5-2

1

1

1

1

6-O

1

6-l 1

1

1

Contents

kg9 .~P

act 30/73

GENERATOR DIVISION

HOBART BROTHERS COMPAW

OPERATION, MAINTENANCE, AND OVERHAUL MANUAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC. NO. 5381A

TABLE OF CONlENTS (CONT’D.)

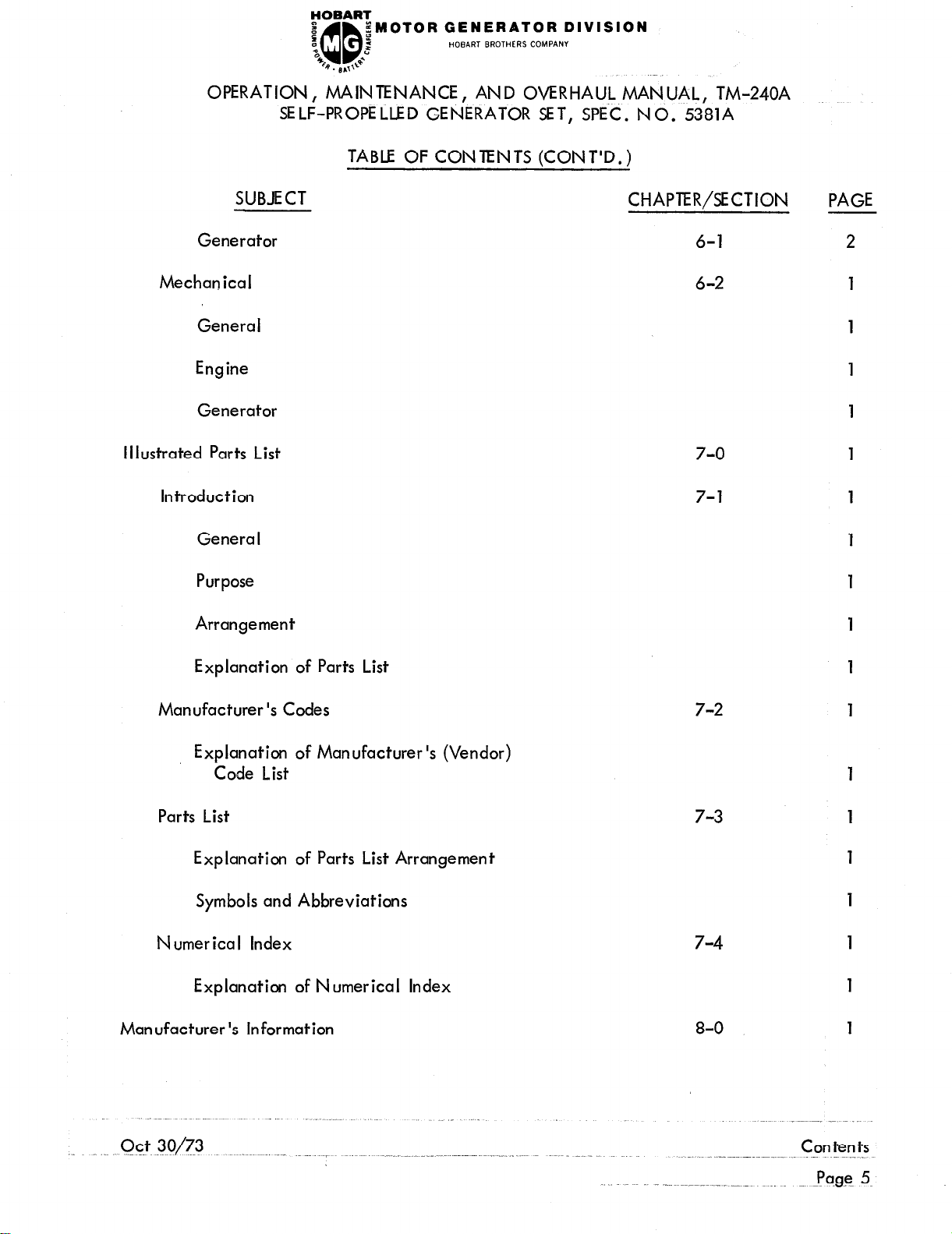

SUBJECT

Generator

Mechanical

General

Engine

Generator

I I lustrated Parts List

Introduction

Genera I

Purpose

Arrangement

CHAPTER/SECTION

6-l

6-2

7-o

7-l

PAGE

2

1

1

1

1

1

1

1

1

1

Explanation of Parts List

Manufacturer’s Codes

, Explanation of Manufacturer’s (Vendor)

Code List

Parts List

Explanation of Parts List Arrangement

Symbols and Abbreviations

N umer ica I Index

Explanation of Numerical Index

Manufacturer’s Information

7-2

1

1

7-3 1

1

1

7-4

1

1

8-O 1

1

FOBART

z

a

“c

B . B ,,&

g”OTOR GENERATOR DIVISION

QB

5

5

HOB/\RT BROTHERS COMPANY

OPERATION, MAINTENANCE, AND OVERHAUL MANUAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC-. NO. 5381A

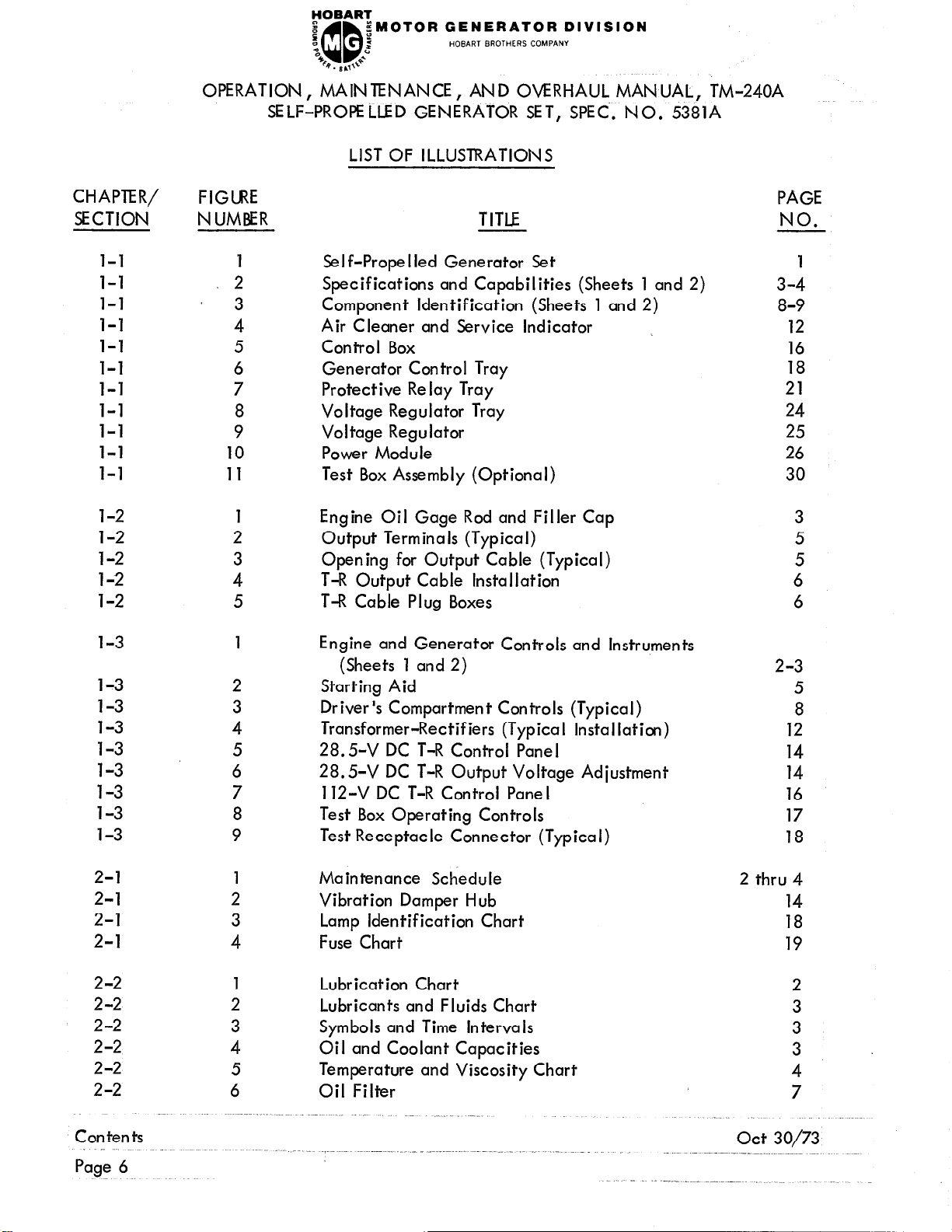

LIST OF ILLUSTRATION S

CHAPTER/

SECTION NUMBER

l-l

l-l

l-l 3

l-l

l-l 5

l-l

l-l

l-l 8

l-l 9

l-l 10

l-l 11

FIGUTE

1

2

4

6

7

TITLE

Self-Propelled Generator Set

Specifications and Capabilities (Sheets 1 and 2)

Component Identification (Sheets 1 and 2)

Air Cleaner and Service Indicator

Control Box

Generator Control Tray

Protective Relay Tray

Voltage Regulator Tray

Voltage Regulator

Power Module

Test Box Assembly (Optional)

l-2 1 Engine Oil Gage Rod and Filler Cap

l-2

l-2 3

l-2

l-2 5

l-3 1

2

4

Output Terminals (Typical)

Opening for Output Cable (Typical)

T-R Output Cable lnsta I lation

T-R Cable Plug Boxes

Engine and Generator Controls and Instruments

(Sheets 1 and 2)

l-3

l-3

l-3

l-3

l-3

l-3

l-3

l-3

Starting Aid

Driver’s Compartment Controls (Typical)

Transformer-Rectifiers (Typical Installation)

28.5-V DC T-R Control Panel

28.5-V DC T-R Output Voltage Adiustment 14

112-V DC T-R Control Panel 16

Test Box Operating Controls

Test Receptacle Connector (Typical) 18

PAGE

NO.

1

3-4

8-9

12

16

18

21

24

25

26

30

2-3

5

8

12

14

17

2-l

2-l

2-l

2-l

2-2

2-2

2-2

2-2

2-2

2-2

Contents

Page 6

1

2

3

4

1

2

3

Maintenance Schedule

Vibration Damper Hub

Lamp Identification Chart 18

Fuse Chart 19

Lubrication Chart

Lubricants and Fluids Chart

Symbols and Time Intervals

4 Oil and Coolant Capacities

5

6

Temperature and Viscosity Chart

Oil Filter

2 thru 4

14

yOBAR7

e

f

‘0

4?

;MOTOR GENERATOR DIVISION

HOBPlRT BROTHERS COMPANY

@

4. B.0

:

‘Q+

OPERATION, MAINTENANCE, AND OVERHAUL MANUAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC. NO. 5381A

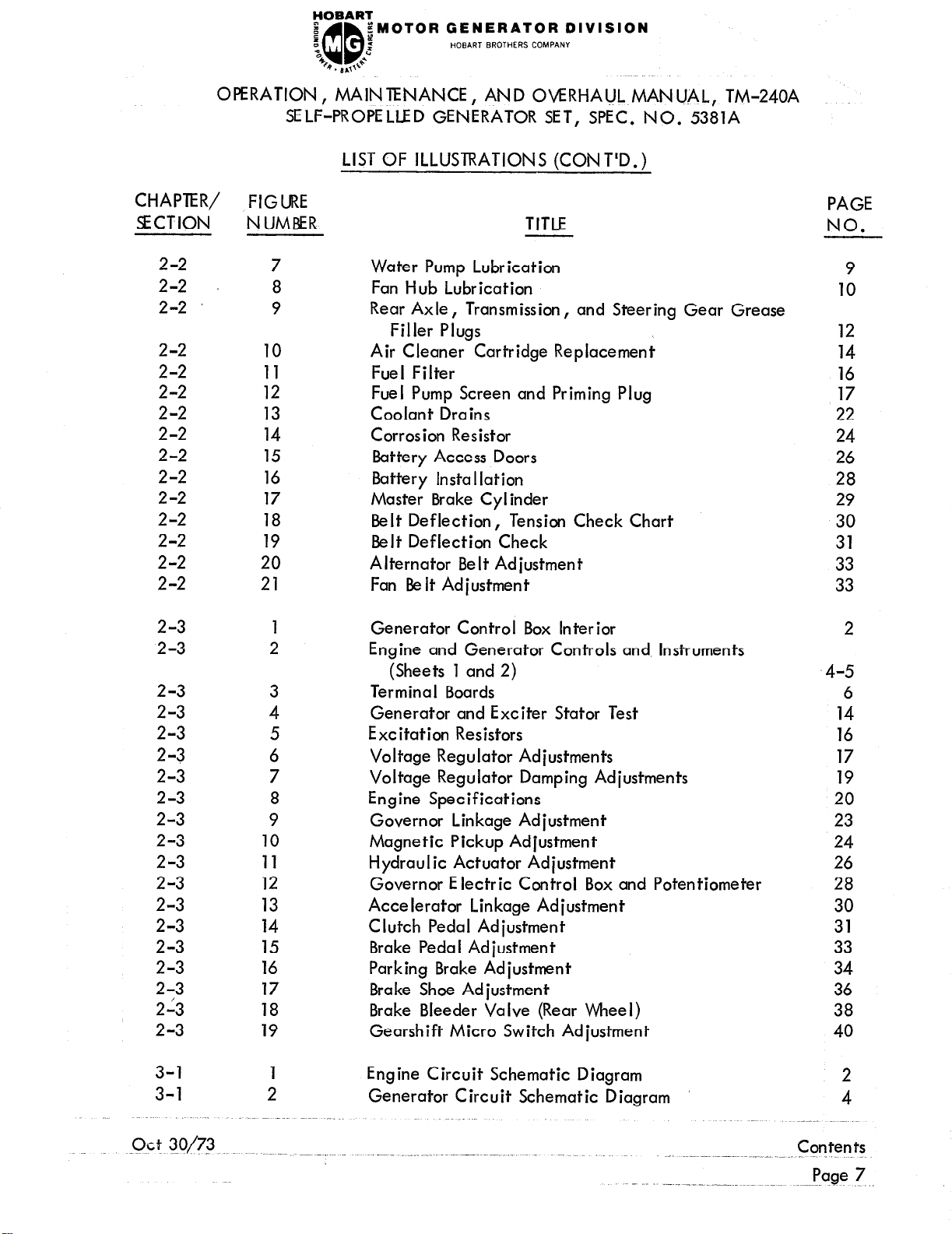

LIST OF ILLUSTRATIONS (CONT’D.)

CHAPTER/

FIGURE

SECTION NUMBER

2-2

2-2

2-2 ’

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

2-3 1

2-3

2

2-3 3

2-3 4

2-3 5

2-3

2-3

6

7

2-3 8

2-3 9

2-3

2-3

2-3

10

11

12

2-3 13

2-3 14

2-3 15

2-3

16

2-3 17

213

18

2-3 19

TITLE

Water Pump Lubrication

Fan Hub Lubrication

Rear Axle, Transmission, and Steering Gear Grease

Filler Plugs

Air Cleaner Cartridge Replacement

Fuel Filter

Fuel Pump Screen and Priming Plug

Coolant Drains

C

orrosion Resistor

Battery Access Doors

Battery Installation

Master Brake Cylinder

Belt Deflection, Tension Check Chart

Belt Deflection Check

Alternator Belt Adjustment

Fan Belt Adjustment

Generator Control Box Interior

Engine and Generator Controls and Instruments

(Sheets 1 and 2)

Terminal Boards

Generator and Exciter Stator Test

Excitation Resistors

Voltage Regulator Adjustments

Voltage Regulator Damping Adjustments

Engine Specifications

Governor Linkage Adjustment

Magnetic Pickup Adjustment

Hydraulic Actuator Adjustment

Governor Electric Control Box and Potentiometer

Acce lerator Linkage Adiustmen t

Clutch Pedal Adiustment

Brake Peda I Ad justmen t

Parking Brake Adjustment

Brake Shoe Adjustment

Brake Bleeder Valve (Rear Wheel)

Gearshift Micro Switch Adjustment

PAGE

NO.

9

10

12

14

16

17

22

24

26

28

29

30

31

33

33

2

4-5

6

14

16

17

19

20

23

24

26

28

30

31

33

34

36

38

40

3-l 1

3-l

w W??

2

Engine Circuit Schematic Diagram

Generator Circuit Schematic Diagram

2

4

Contents

Page 7

FOBART

e

a

‘0

b . B ,,+**

;MOTOR GENERATOR DIVISION

2

QD

HOBART BROTHERS COMPANY

OPERATION, MAINTENANCE, AND OVERHAUL MANUAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC. NO. 5381A

LIST OF ILLUSTRATION S (CON T’D. )

CHAPTER/

FIGURE

SECTION NUMBER

3-l 3

3-l

3-l

3-2

3-2

4

t5

1

2

3-2 3

3-2

3-2

3-2

4

5

6

4-l 1

4-l

4-l

2

3

4-l 4

4-l 5

4-l

6

4-l 7

PAGE

TITLE

Governor Speed Setting Potentiometer Schematic

Governor Actuator Cross-Section

Electric Governor Voltage Values

NO.

7

8

9

Engine and Generator Controls and Instruments

(Sheets 1 and 2)

6-7

Starter and Solenoid Switch 8

Termina I Boards 9

Exe itation Resistors 10

End View of Voltage Regulator Amphenol Connector

10

Trouble Shooting Chart 11 thru 30

Self-Propelled Generator Set 3

Accelerator Control Cable Connection 4

Steering Gear 5

Clutch Shaft and Linkage

7

Peda Is and Master Cylinder 8

Pedals Assembly Attachment

Engine-Generator Hoisting Arrangement (Typical)

8

9

4-2

4-2

5-l

5-l

5-l

5-l

5-l

5-l

5-2

6-l

6-l

6-l

6-l

6-l

6-l

6-l

6-l

1

2

1

2

3

Control Tray Removal (Typical)

Power Module Panel Assembly 3

Generator Circuit Connection Diagram 2

Engine Circuit Connection Diagram

Control Box Connection Diagram 4

4 Generator Control Tray Connection Diagram

5

6

Protective Monitor Tray Connection Diagram

Power Module Connection Diagram

No Illustrations

1

2

3

4

5

6

7

8

Generator Lifting Arrangement (Typica I) 2

Generator-to-Engine Connection

Generator Fan and Coupling (Typical)

Wrench Positioned to Prevent Engine Rotation (Typical) 5

Flexible Coupling (Removal or Installation) (Typical)

Coupling Hub and Bushing

Generator Exploded View

Exciter Rotor (Removal or Installation)

2

3

5

6

7

3

4

6

6

8

9

Contents

Page 8

._

Ott 38/73

.-~. .__

GENERATOR DIVISION

HOBART BROTHERS COMPANY

OPERATION, MAINTENANCE, AND OVERHAUL MANUAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC. NO. 538114

LIST OF ILLUSTRATION S (CON T’D , )

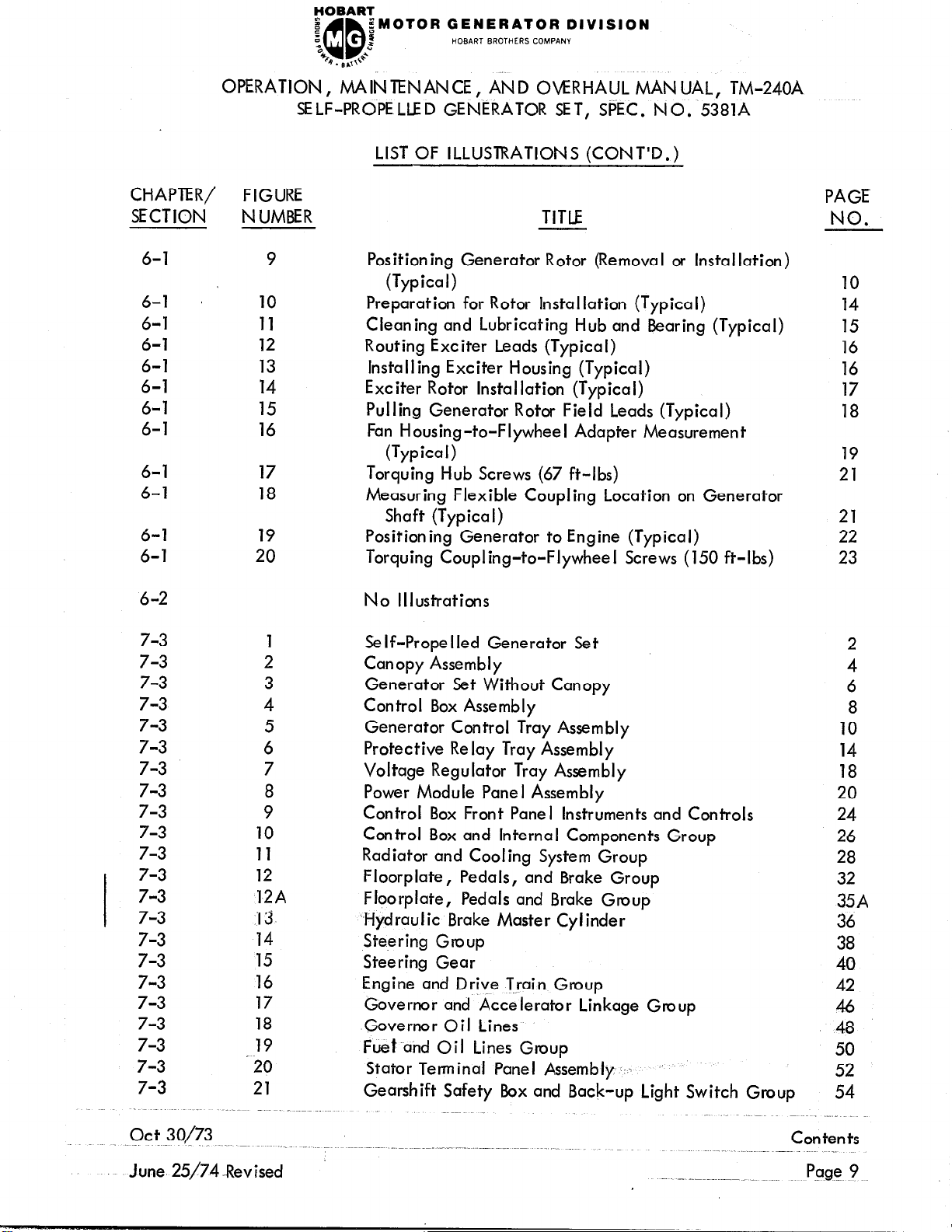

CHAPTER/ FIGURE

SECTION NUMBER

TITLE

6-l 9 Positioning Generator Rotor (Removal or Installation)

(Typical)

6-l 10

6-1

6-l

11

12

6-l 13

6-l

6-1

6-l

14

15

16

Preparation for Rotor lnstal lation (Typica I)

Cleaning and Lubricating Hub and Bearing (Typical)

Routing Exciter Leads (Typical)

Installing Exciter Housing (Typical)

Exciter Rotor Installation (Typical)

Pulling Generator Rotor Field Leads (Typical)

Fan Housing-to-Flywheel Adapter Measurement

(Typical)

6-l 17

6-l

18

Torquing Hub Screws (67 ft-lbs)

Measuring Flexible Coupling Location on Generator

Shaft (Typical)

6-l

19

Positioning Generator to Engine (Typical)

6-l 20 Torquing Coupling-to-Flywheel Screws (150 ft-lbs)

6-2

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-3

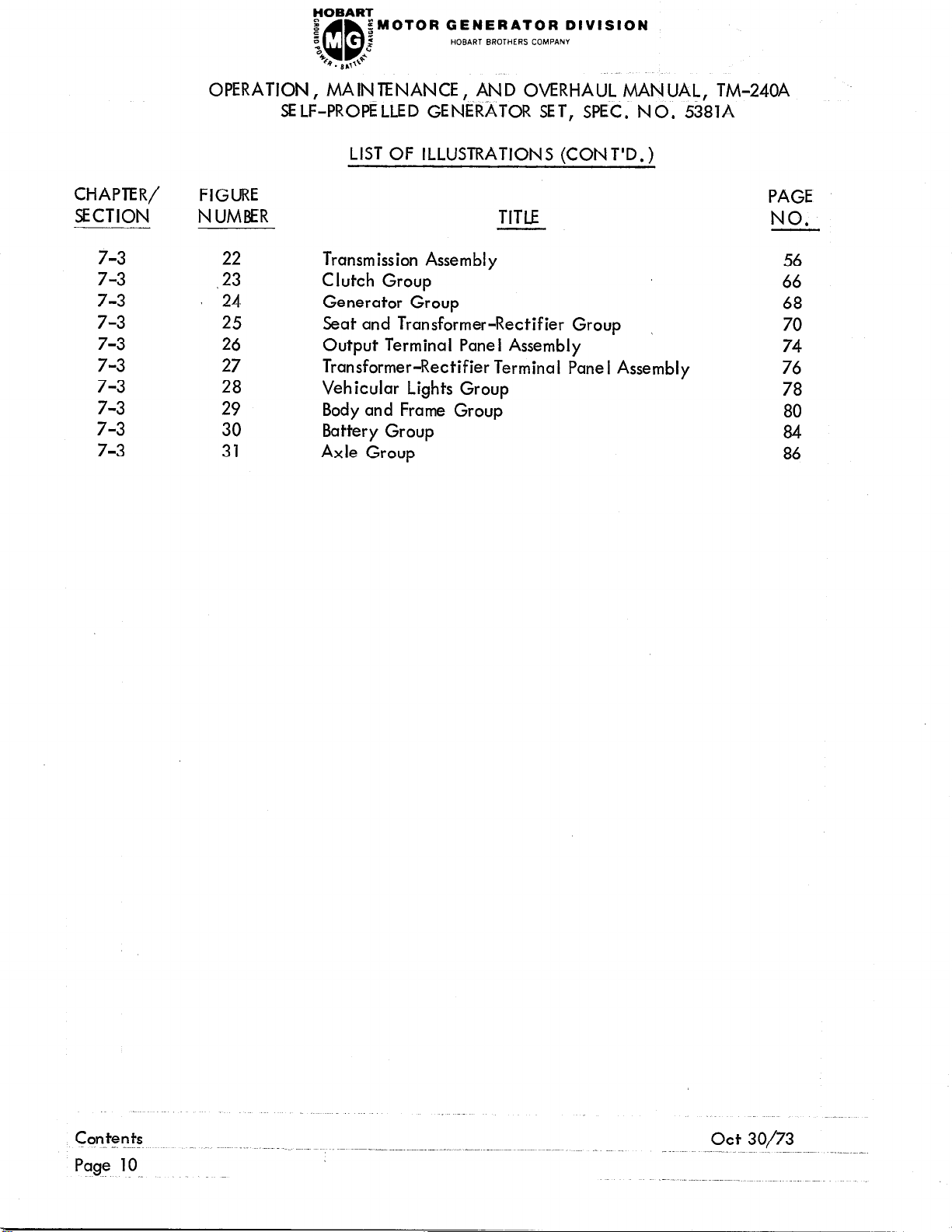

7-3

7-3

1

2

3

4

5

6

7

8

9

10

11

12

12A

-13.

14

15

16

17

18

19

‘20

21

No Illustrations

Self-Propelled Generator Set

Canopy Assembly

Generator Set Without Canopy

Control Box Assembly

Generator Control Tray Assembly

Protective Relay Tray Assembly

Voltage Regulator Tray Assembly

Power Module Panel Assembly

Control Box Front Panel Instruments and Controls

Control Box and Internal Components Group

Radiator and Cooling System Group

Floorplate, Pedals, and Brake Group

Floorplate, Pedals and Brake Group

Hydraulic Brake Master Cylinder

Steering Group

Steering Gear

Engine and Drive Train Group

Governor and Accelerator Linkage Group

Governor Oil Lines

Fuet-and Oil Lines Group

Stator Terminal Panel Assembly ‘.-

Gear-shift Safety Box and Back-up Light Switch Group

PAGE

NO.

10

14

15

16

16

17

18

19

21

21

22

23

2

4

6

8

10

14

18

20

24

26

28

32

35A

36

38

40

42

46

48

50

52

54

Oct30/73

June 25/74Revised

Contents

page 9

FOBAR’I:

e

a

t

B. *,,+*’

;MOTOR GENERATOR DIVISION

QD

:

z

HOBART BROTHERS COMPAN”

OPERATION, MAINTENANCE, AND OVERHAUL MANUAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC. NO, 5381A

LIST OF ILLUSTRATIONS (CON T’D. 1

CHAPTER/

SECTlObi

7-3

7-3

7-3

7-3

7-3

7-3 27

7-3 28

7-3

7-3

7-3

FIGURE

NUMBER

22

,23

TITLE

Transmission Assembly

Clutch Group

PAGE

NO,

56

66

/ 24 Generator Group 68

25 Seat and Transformer-Rectifier Group

26 Output Terminal Panel Assembly

70

74

Transformer-Rectifier Terminal Pane I Assembly 76

29

30

31

Vehicular Lights Group

Body and Frame Group 80

Battery Group

Axle Group 86

78

84

FOBART

8

5

“c

%

;MOTOR GENERATOR DIVISION

QD

*. B,,I~~

oz

2

HOBART BROTHERS COMPANY

OPERATION, MAINTENANCE, AND OVERHAUL MANUAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC. NO, 5381A

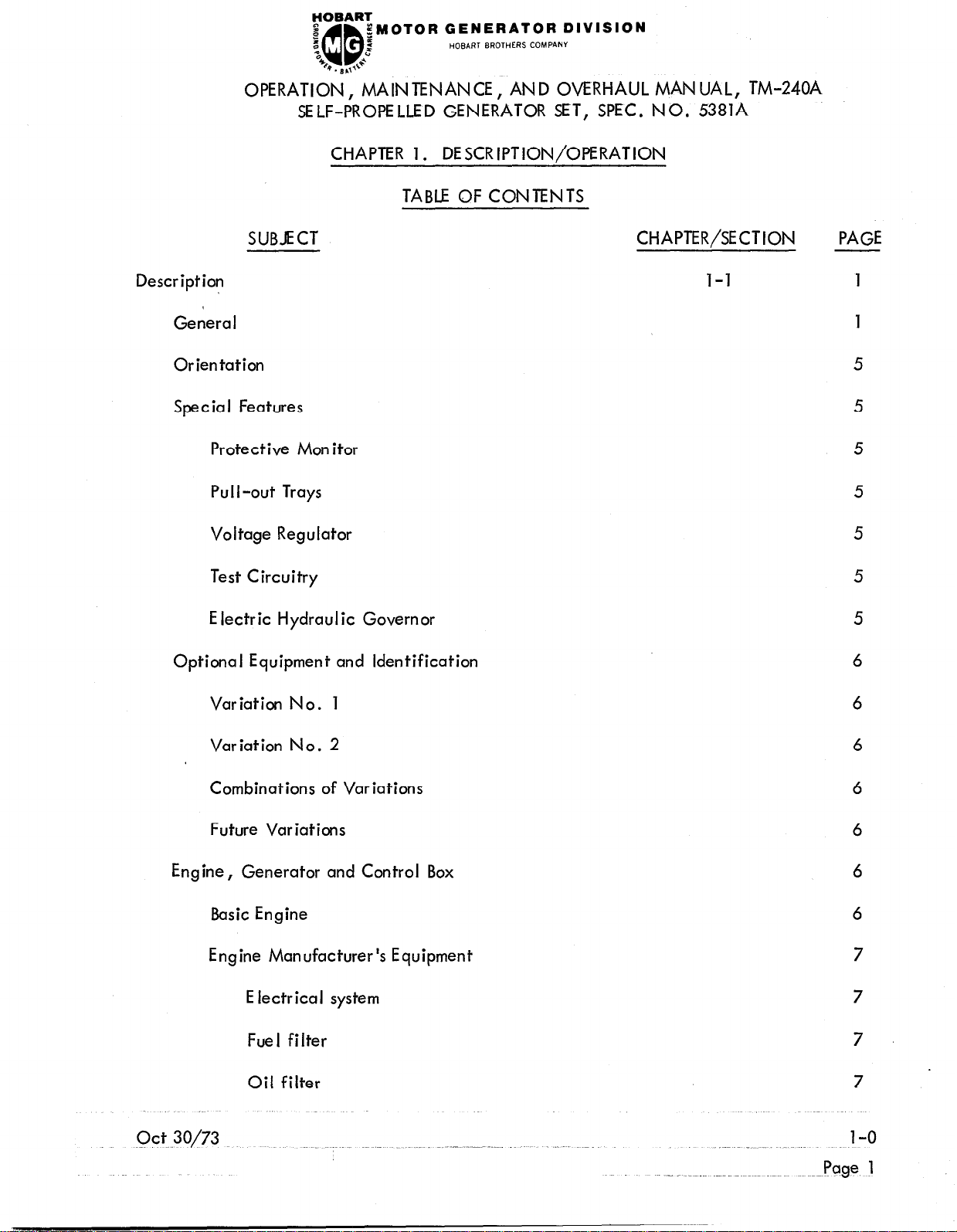

CHAPTER 1. DESCRIPTION/OPERATION

TABLE OF CONTENTS

SUBJECT

Description

General

Orientation

Specia I Features

Protective Monitor

Pull-out Trays

Voltage Regulator

Test Circuitry

Electric Hydraulic Governor

Optional Equipment and Identification

CHAPTER/SECTION PAGE

l-l

1

1

5

5

5

5

5

5

5

6

Variation No. 1

Variation No. 2

Combinations of Variations

Future Variations

Engine, Generator and Control Box

Basic Engine

Engine Manufacturer’s Equipment

Electrical system

filter

I

Fue

Oil filter

6

6

6

6

6

6

7

7

7

GENERATOR DIVISION

HOBART BROTHERS COMPANY

OPERATION, MAINTENANCE ,. AND OVERHAUL MANUAL, TM-240A

SELF-PROPELLED GENERATOR SET, SPEC. NO. 5381A

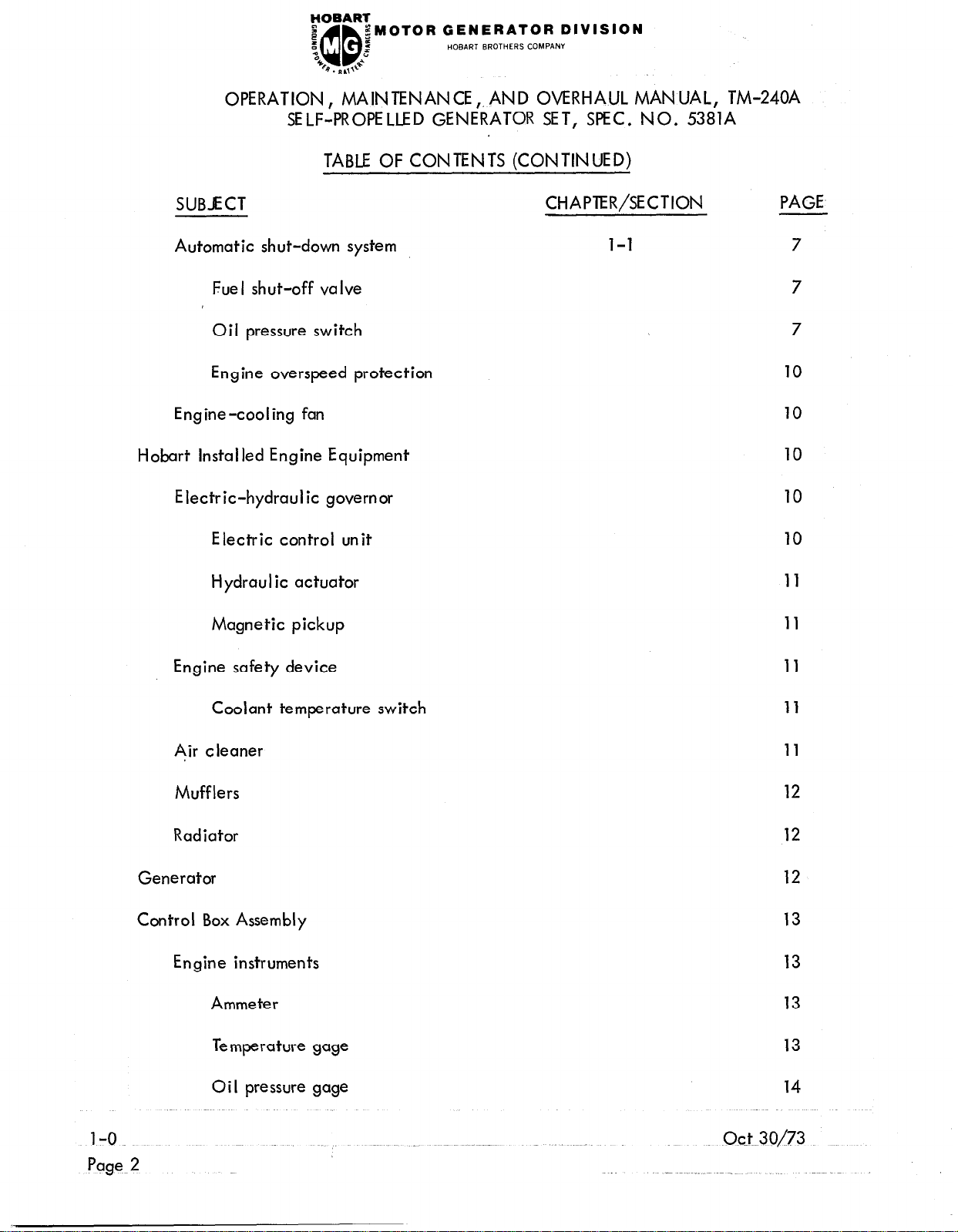

TABLE OF CONTENTS (CONTINUED)

SUBJECT

Automatic shut-down system

Fue I shut-off valve

Oil pressure switch

Engine overspeed protection

Engine-cooling fan

Hobart Installed Engine Equipment

Electric-hydraulic governor

Electric control unit

Hydraulic actuator

Magnetic pickup

CHAPTER/SECTION

l-l

PAGE

7

7

7

10

10

10

10

10

11

11

Engine safety device

Coolant temperature switch

Air cleaner

Mufflers

Radiator

Generator

Control Box Assembly

Engine instruments

Ammeter

Temperature gage

Oi I pressure gage

11

11

11

12

12

12

13

13

13

13

14

l-O_

Page 2

- ..~.~_. _

octt30/73

Loading...

Loading...