Page 1

Model

Modèle

Modelo

CS 33EB

Chain Saw

Tr on ço nn e us e

Motosierra

SAFETY INSTRUCTIONS AND INSTRUCTION MANUAL

WARNING

IMPROPER OR UNSAFE use of this power tool can result in death or serious bodily injury!

This manual contains important information about product safety. Please read and understand this

manual BEFORE operating the power tool. Please keep this manual available for other users and owners

before they use the power tool. This manual should be stored in safe place.

INSTRUCTIONS DE SECURITE ET MODE D’EMPLOI

AVERTISSEMENT

Une utilisation INCORRECTE OU DANGEREUSE de cet outil motorisé peut entraîner la mort ou de

sérieuses blessures corporelles !

Ce mode d’emploi contient d’importantes informations à propos de la sécurité de ce produit. Prière de

lire et de comprendre ce mode d’emploi AVANT d’utiliser l’outil motorisé. Garder ce mode d’emploi à la

disponibilité des autres utilisateurs et propriétaires avant qu’ils utilisent l’outil motorisé. Ce mode d’emploi

doit être conservé dans un endroit sûr.

INSTRUCCIONES DE SEGURIDAD Y MANUAL DE INSTRUCCIONES

ADVERTENCIA

¡La utilización INAPROPIADA O PELIGROSA de esta herramienta eléctrica puede provocar lesiones

graves o la muerte!

Este manual contiene información importante sobre la seguridad del producto. Lea y comprenda este

manual ANTES de utilizar la herramienta eléctrica. Guarde este manual para que puedan leerlo otras

personas antes de utilizar la herramienta eléctrica. Este manual debe ser guardado en un lugar seguro.

Page 2

English

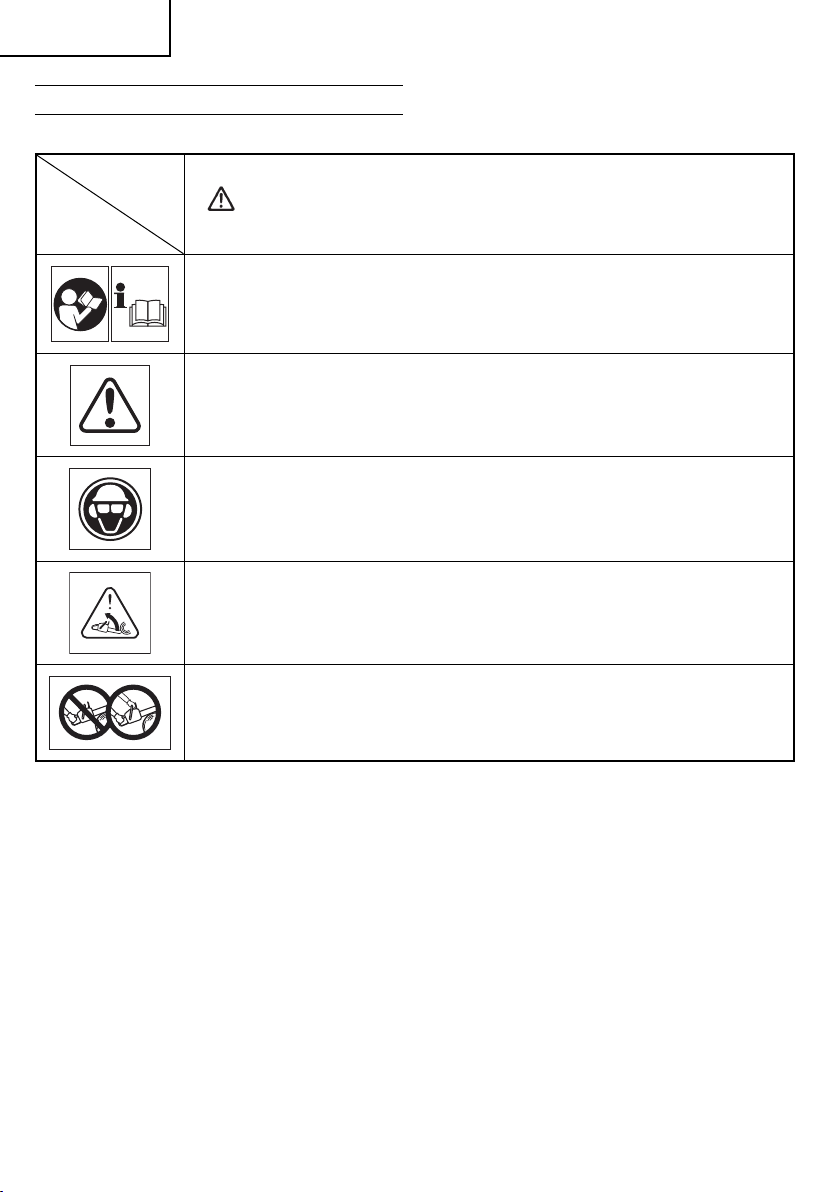

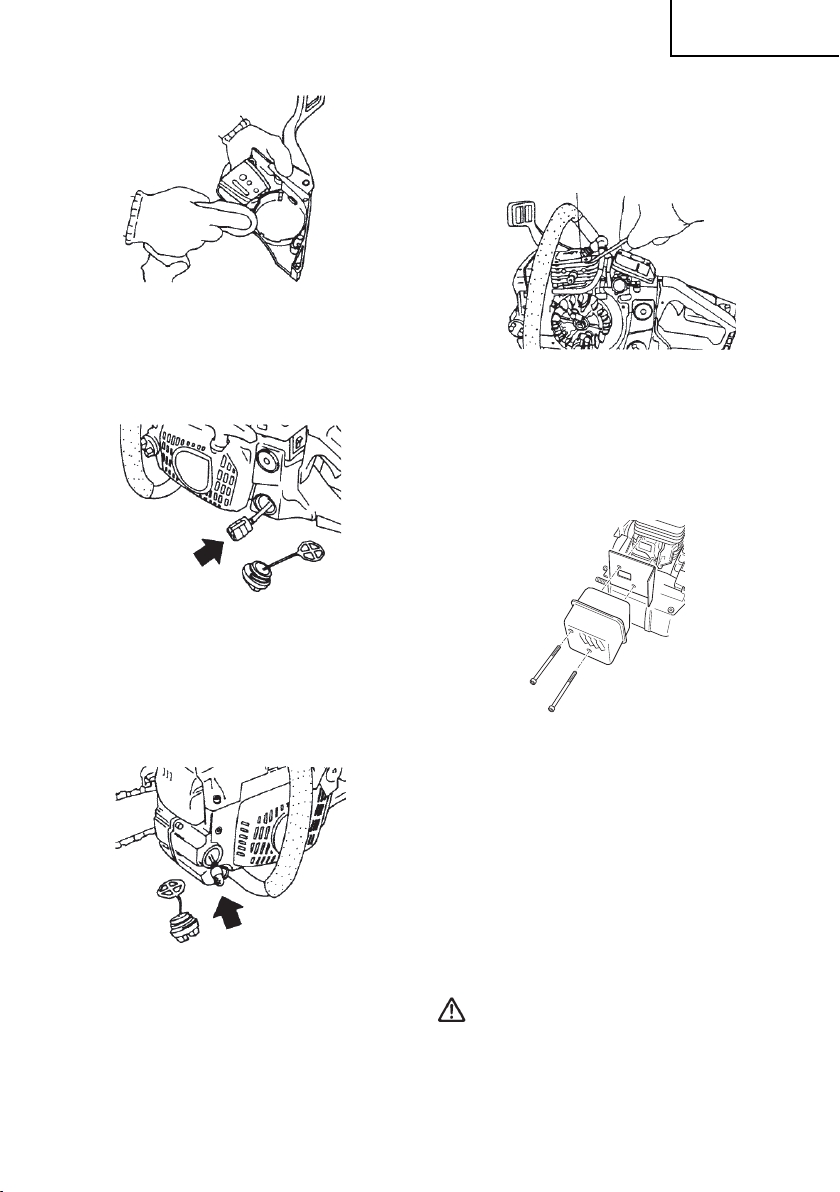

MEANINGS OF SYMBOLS

NOTE: Some units do not carry them.

Symbols

WARNING

The following show symbols used for the machine. Be sure that you understand

their meaning before use.

It is important that you read, fully understand and observe the following safety

precautions and warnings. Careless or improper use of the unit may cause

serious or fatal injury.

Read, understand and follow all warnings and instructions in this manual and on

the unit.

Always wear eye, head and ear protectors when using this unit.

Warning, kickback danger. Be careful of possible sudden and accidental upward

and/or backward motion of the guide bar.

One-handed usage not permitted. While cutting, hold saw fi rmly with both hands

with thumb fi rmly locked around front handle.

Contents

WHAT IS WHAT? ...................................................3

WARNINGS AND SAFETY INSTRUCTIONS .........4

SPECIFICATIONS ..................................................7

ASSEMBLY PROCEDURES ..................................8

OPERATING PROCEDURES .................................9

MAINTENANCE ...................................................15

Parts breakdown

2

Page 3

English

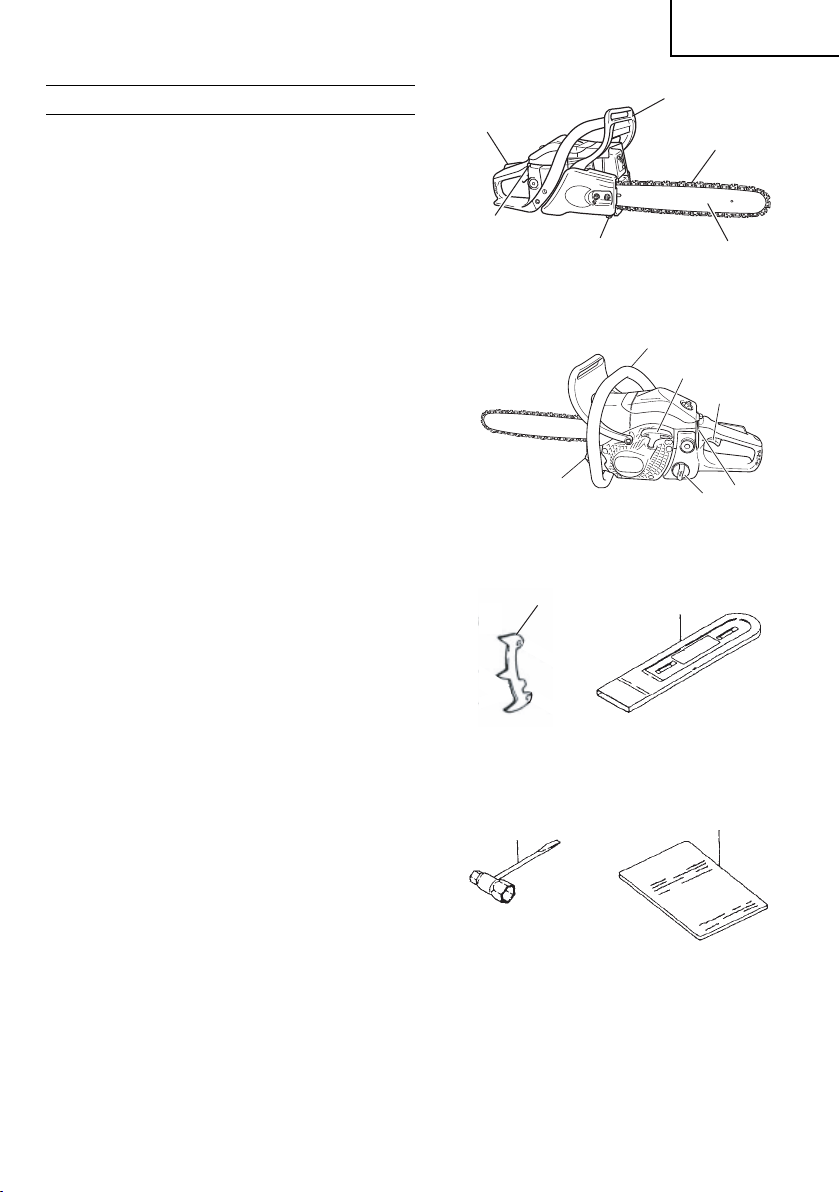

WHAT IS WHAT?

1. Throttle trigger: Device activated by the

operatorʼs fi nger, for controlling the engine

speed.

2. Throttle trigger lockout (Safety trigger): Device

that prevents the accidental operation of the

throttle trigger until manually released.

3. Ignition switch: Device for allowing the engine to

be started or stopped.

4. Oil tank cap: For closing the oil tank.

5. Recoil starter: Pull handle to start the engine.

6. Front handle: Support handle located at or

towards the front of the engine housing.

7. Fuel tank cap: For closing the fuel tank.

8. Choke control knob: Device for enriching the

fuel/air mixture in the carburetor, to aid starting.

9. Guide bar: The part that supports and guides the

saw chain.

10. Saw chain: Chain, serving as a cutting tool.

11. Chain brake (Front hand guard): Device for

stopping or locking the chain.

12. Spiked bumper (optional): Device for acting as a

pivot when in contact with a tree or log.

13. Chain catcher: device for restraining the saw

chain.

14. Guide bar cover: Device for covering the guide

bar and saw chain when the unit is not being

used.

15. Combi box spanner: The tool for removing or

installing a spark plug and tensioning the saw

chain.

16. Handling instructions: Included with unit. Read

before operation and keep for future reference to

learn proper, safe techniques.

11

2

8

13

6

4

12

14

10

9

5

1

3

7

15

16

3

Page 4

English

WARNINGS AND SAFETY

INSTRUCTIONS

Operator safety

○ Always wear a safety face shield or goggles.

○ Always use the gloves to reduce the eff ects of

vibration.

○ Gloves should be used when sharpening chain.

○ Always wear safety protective equipment such as

jacket, trousers, gloves, helmet, boots with steel

toe-caps and non-slip soles whenever you use a

chain saw. For working in trees the safety boots

must be suitable for climbing techniques. Do not

wear loose clothing, jewelry, short pants, sandals

or go barefoot.

Secure hair so it is above shoulder length.

○ Do not operate this tool when you are tired,

ill or under the infl uence of alcohol, drugs or

medication.

○ Never let a child or inexperienced person operate

the machine.

○ Wear hearing protection. Pay attention to your

surroundings.

Be aware of any bystanders who may be

signaling a problem.

Remove safety equipment immediately upon

shutting off engine.

○ Wear head protection.

○ Never start or run the engine inside a closed

room or building.

Breathing exhaust fumes can kill.

○ For respiratory protection, wear a protection

mask while emitting the chain oil mist and dust

from sawdust.

○ Keep handles free of oil and fuel.

○ Keep hands away from cutting equipment.

○ Do not grab or hold the unit by the cutting

equipment.

○ When the unit turned off , make sure the cutting

attachment has stopped before the unit is set

down.

○ When operation is prolonged, take a break from

time to time so that you may avoid possible

Hand-Arm Vibration Syndrome (HAVS) which is

caused by vibration.

○ The operator must obey the local regulations of

cutting area.

WARNING

● Antivibration systems do not guarantee that

you will not sustain Hand-Arm Vibration

Syndrome or carpal tunnel syndrome.

Therefore, continual end regular users

should monitor closely the condition of

4

their hands and fi ngers. If any of the above

symptoms appear, seek medical advice

immediately.

● Long or continuous exposure to high

noise levels may cause permanent hearing

impairment. Always wear approved hearing

protection when operating a unit/machine.

● If you are using any medical electric/

electronic devices such as a pacemaker,

consult your physician as well as the device

manufacturer prior to operating any power

equipment.

Unit/machine safety

○ Inspect the entire unit/machine before each use.

Replace damaged parts. Check for fuel leaks and

make sure all fasteners are in place and securely

tightened.

○ Replace parts that are cracked, chipped or

damaged in any way before using the unit/

machine.

○ Make sure the side case is properly attached.

○ Keep others away when making carburetor

adjustments.

○ Use only accessories as recommended for this

unit/machine by the manufacturer.

○ Never let the chain strike any obstacle. If the

chain makes contact, the machine should be

stopped and checked carefully.

○ Make sure the automatic oiler is working. Keep

the oil tank fi lled with clean oil. Never let chain

run dry on the bar.

○ All chain saw service, other than the items listed

in the operatorʼs/ ownerʼs manual, should be

performed by competent chain-saw service

personnel. (For example, if improper tools are

used to remove the fl ywheel or if an improper tool

is used to hold the fl ywheel in order to remove the

clutch, structural damage to the fl ywheel could

occur and could subsequently cause the fl ywheel

to burst.)

WARNING

● Never modify the unit/machine in any way.

Do not use your unit/machine for any job

except that for which it is intended.

● Never use chain saw without any safety

equipment or that has faulty safety

equipment. It could result in serious personal

injury.

● Using guide bar/chain other than

recommended by the manufacturer which

are not approved, could result in a high risk

of personal accidents or injury.

Page 5

English

Fuel safety

○ Mix and pour fuel outdoors and where there are

no sparks or fl ames.

○ Use a container approved for fuel.

○ Do not smoke or allow smoking near fuel or the

unit/machine or while using the unit/machine.

○ Wipe up all fuel spills before starting engine.

○ Move at least 3 m away from fueling site before

starting engine.

○ Stop engine before removing fuel cap.

○ Empty the fuel tank before storing the unit/

machine. It is recommended that the fuel be

emptied after each use. If fuel is left in the tank,

store so fuel will not leak.

○ Store unit/machine and fuel in area where fuel

vapors cannot reach sparks or open fl ames

from water heaters, electric motors or switches,

furnaces, etc.

WARNING

Fuel is easy to ignite or get explosion or

inhale fumes, so that pay special attention

when handling or fi lling fuel.

Cutting safety

○ Do not cut any material other than wood or

wooden objects.

○ For respiratory protection, wear an aerosol

protection mask when cutting the wood after

insecticide has been applied.

○ Keep others including children, animals,

bystanders and helpers outside the hazard

zone. Stop the engine immediately if you are

approached.

○ Hold the unit/machine fi rmly with the right hand

on the rear handle and the left hand on the front

handle.

○ Keep fi rm footing and balance. Do not over-

reach.

○ Keep all parts of your body away from the muffl er

and cutting attachment when the engine is

running.

○ Keep Bar/Chain below waist level.

○ Before felling a tree, the operator must be

accustomed to the sawing techniques of the

chain saw.

○ Be sure to pre-plan a safe exit from a failing tree.

○ While cutting, hold saw fi rmly with both hands

with thumb fi rmly locked around front handle,

and stand with feet well balanced and your body

balanced.

○ Stand to the side of the saw when cutting - never

directly behind it.

○ Always keep the spiked bumper face to a tree,

because the chain may suddenly be drawn into a

tree, if so equipped.

○ When completing a cut, be ready to hold up the

units as it breaks into clear, so it will not follow

through and cut your legs, feet or body, or contact

an obstruction.

○ Be alert against kickback (when saw kicks up and

back at operator). Never cut with the nose of the

bar.

○ When relocating to a new work area, be sure to

○ Never place the machine on the ground when

○ Always ensure that the engine is shut off and any

○ Always carry a fi rst-aid kit when operating any

○ Never start or run the engine inside a closed

Maintenance safety

○ Maintain the unit/machine according to

○ Disconnect the spark plug before performing

○ Keep others away when making carburetor

○ Use only genuine HITACHI replacement parts as

Do not disassemble the recoil starter. You

the machine and ensure that all cutting

shut off

attachments are stopped.

running.

cutting attachments have completely stopped

before clearing debris or removing grass from the

cutting attachment.

power equipment.

room or building and/or near the infl ammable

liquid. Breathing exhaust fumes can kill.

recommended procedures.

maintenance except for carburetor adjustments.

adjustments.

recommended by the manufacturer.

CAUTION

may get a possibility of personal injury with

recoil spring.

WARNING

Improper maintenance could result in serious

engine damage or in serious personal injury.

Transport and storage

○ Carry the unit/machine by hand with the engine

stopped and the muffl er away from your body.

○ Allow the engine to cool, empty the fuel tank,

and secure the unit/machine before storing or

transporting in a vehicle.

○ Empty the fuel tank before storing the unit/

machine. It is recommended that the fuel be

emptied after each use. If fuel is left in the tank,

store so fuel will not leak.

5

Page 6

English

○ Store unit/machine out of the reach of children.

○ Clean and maintain the unit carefully and store it

in a dry place.

○ Make sure engine switch is off when transporting

or storing.

○ When transporting in a vehicle or storage, cover

chain with chain cover.

If situations occur which are not covered in this

manual, take care and use common sense. Contact

HITACHI dealer if you need assistance. Pay special

attention to statements preceded by the following

words:

WARNING

Indicates a strong possibility of severe

personal injury or loss of life, if instructions

are not followed.

CAUTION

Indicates a possibility of personal injury or

equipment damage, if instructions are not

followed.

NOTE

Helpful information for correct function and use.

6

Page 7

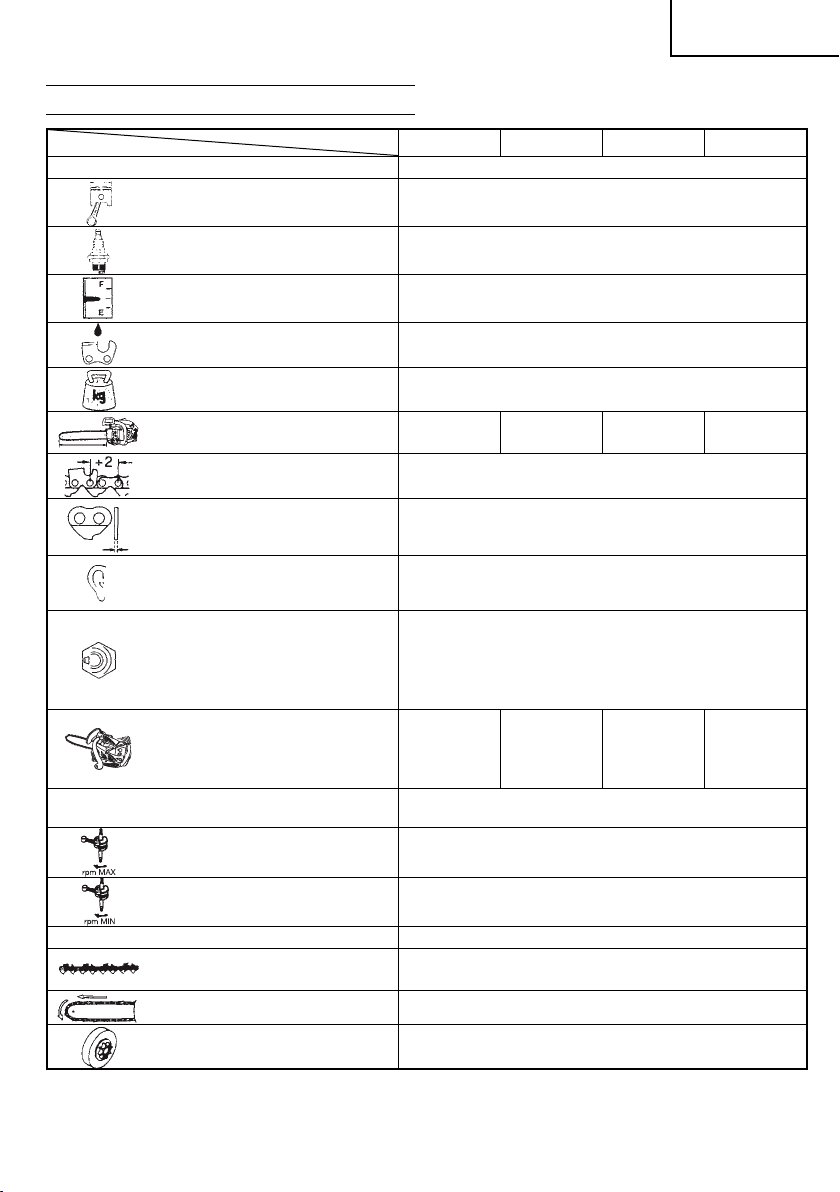

SPECIFICATIONS

Type of equipment Chain saw, portable

Engine Size (cu. in.) 1.96 (32.2 ml)

Spark Plug NGK BPM-6A or equivalent

Fuel Tank Capacity (US pint) 0.74 (350 ml)

Chain Oil Tank Capacity (US pint) 0.53 (250 ml)

Model

CS33EB (30P) CS33EB (35P) CS33EB (40P)

English

CS33EB

Dry Weight (lbs)

(Without guide bar and chain)

Guide bar length (in.) 12 (300 mm) 14 (350 mm)

Chain pitch (in.) 3/8 (9.52 mm)

Chain gauge (in.) 0.05 (1.27 mm)

Sound pressure level

LpA (dB (A))

by ISO 22868

Sound power level

Lw measured (dB (A))

by ISO 22868

Sound power level LwA (dB (A))

by 2000/14/EC

Vibration level (m/s2)

by ISO 22867

Front handle

Rear handle

Max. engine power

by ISO 7293 (kW)

Max. engine speed (min-1) 12,500

Idle engine speed (min-1) 3,100

Specifi c fuel consumption (g/kWh) 500

Type of chain

Max. chain speed (m/sec) 23.8

8.5

8.0

8.4 (3.8 kg)

(400 mm)

92

110

113

9.2

6.7

1.2/9,500

91VG

(Oregon)

16

9.7

6.7

—

—

—

Sprocket (number of teeth) 6

NOTE: Equivalent noise level/vibration levels are calculated as the time-weighted energy total for noise/

vibration levels under various working conditions with the following time distribution: 1/3 idle, 1/3 full,

1/3 racing speed.

* All data subject to change without notice.

7

Page 8

English

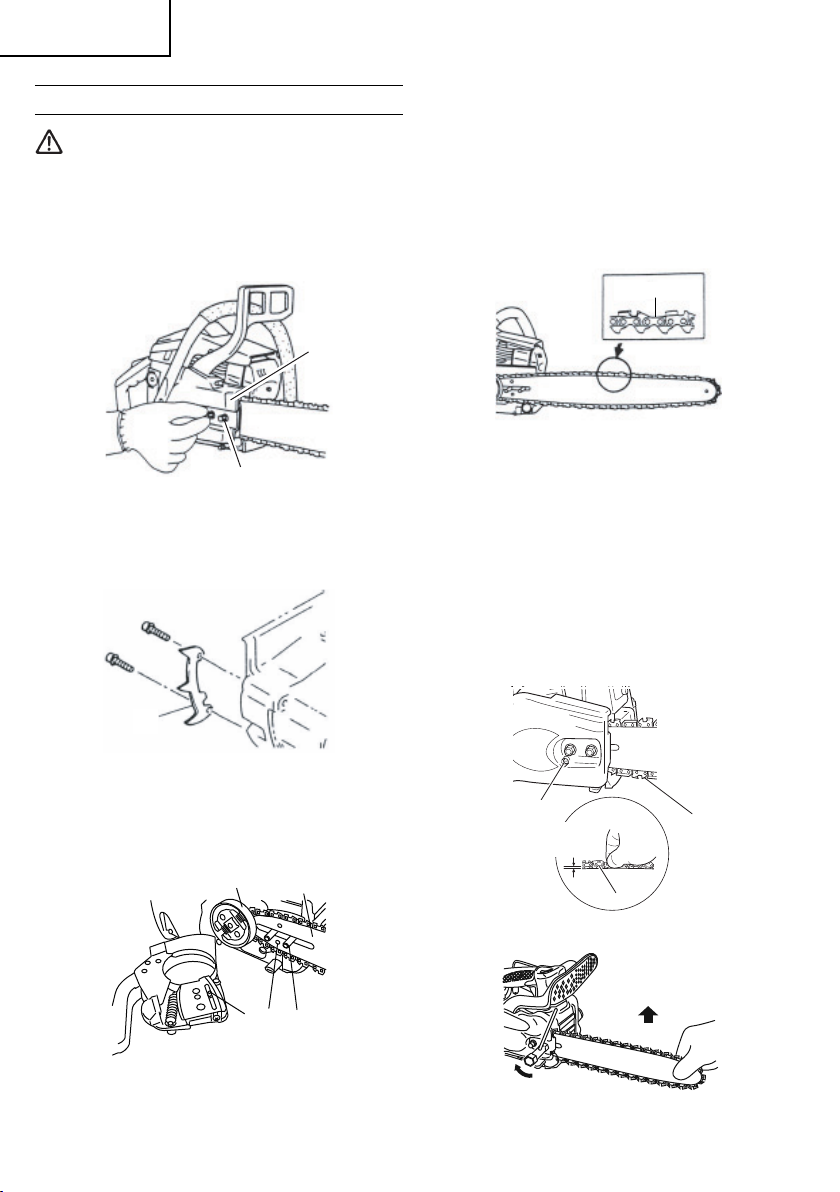

ASSEMBLY PROCEDURES

WARNING

Never try to start engine without side case

securely fastened.

1. Remove chain bar clamp nuts (1).

2. Remove the side case (2) as pinching the rear

part of the side case (2). (Fig. 1)

2

1

Fig. 1

* In case of installing the spiked bumper (3),

install the spiked bumper (3) (if so equipped) to

the unit with two screws. (Fig. 2)

NOTE

Slightly move the bar back and forth and make

sure the chain tension boss (7) fi ts into the hole

(8) in the bar properly. (Fig. 3)

4. Confi rm the direction of saw chain (9) is correct

as in the fi gure, and align the chain on the

sprocket. (Fig. 4)

9

Fig. 4

5. Guide the chain drive links into the bar groove all

around the bar.

6. Install the side case (2) onto the bolts (5).

Then tighten the clamp nuts (1) temporarily.

(

Fig. 1

7. Raise the bar end, and tighten the chain (9)

)

by turning the tension adjustment bolt (10)

clockwise. To check proper tension, lightly lift

up the center of chain and there should be about

0.02 – 0.04 ″ (0.5 – 1.0 mm) clearance between

bar and edge of drive link (11). (Fig. 5, 6)

3

Fig. 2

3. Install the chain bar (4) onto the bolts (5), then

push it toward the sprocket (6) as far as it will go.

Make sure that the boss of chain tension adjust

bolt (7) fi ts into the hole of the bar (8). (Fig. 3)

6

Fig. 3

8

4

8

5

7

10

0.02 – 0.04 ″

(0.5 – 1 mm)

9

11

Fig. 5

Fig. 6

Page 9

English

CAUTION

PROPER TENSION IS EXTREMELY

IMPORTANT

8. Raise the bar end and securely tighten the chain

bar clamp nuts with the combi box spanner.

(Fig. 6)

9. A new chain will stretch so adjust the chain after

a few cuts and watch chain tension carefully for

the fi rst half hour of cutting.

NOTE

Check the chain tension frequently for optimum

performance and durability.

CAUTION

● When the chain is excessively tightened,

the bar and chain will be damaged rapidly.

Conversely, when the chain is excessively

loosened, it may get out of the groove in the

bar.

● Always wear gloves when touching the

chain.

WARNING

During operation, hold chain saw fi rmly with

both hands. A single hand operation may

cause serious injury.

OPERATING PROCEDURES

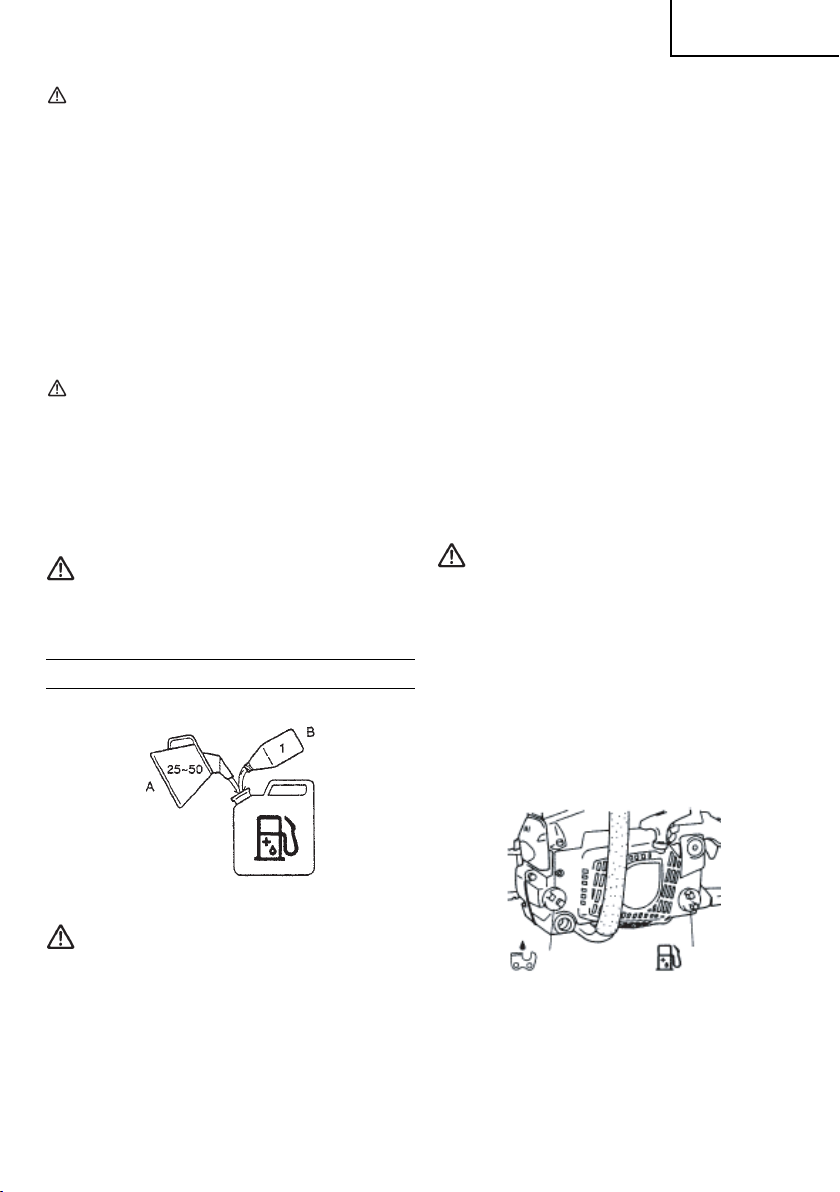

Fuel (Fig. 7)

Fuel

○ Always use branded 89 octane unleaded

gasoline.

○ Use genuine two-cycle oil or use a mix between

25:1 to 50:1, please consult the oil bottle for the

ratio or HITACHI dealer.

○ Only for the state of California at 50:1.

○ If genuine oil is not available, use an anti-oxidant

added quality oil expressly labeled for air-cooled

2-cycle engine use (JASO FC GRADE OIL or ISO

EGC GRADE). Do not use BIA or TCW (2-stroke

water-cooling type) mixed oil.

○ Never use multi-grade oil (10 W/30) or waste oil.

○ Always mix fuel and oil in a separate clean

container.

Always start by fi lling half the amount of gasoline,

which is to be used.

Then add the whole amount of oil. Mix (shake) the

fuel mixture. Add the remaining amount of gasoline.

Mix (shake) the fuel-mix thoroughly before fi lling the

fuel tank.

Fueling

WARNING (Fig. 8)

● Always shut off the engine before refueling.

● Slowly open the fuel tank (12), when fi lling

up with fuel, so that possible overpressure

disappears.

● Tighten the fuel cap carefully, after fueling.

● Always move the unit at least 10 ft. (3 m)

from the fueling area before

● Always wash any spilled fuel from clothing

immediately with soap.

● Be sure to check any fuel leaking after

refueling.

starting.

Fig. 7

WARNING

● The chain saw is equipped with a two-stroke

engine. Always run the engine on fuel, which

is mixed with oil. Provide good ventilation,

when fueling or handling fuel.

● Fuel contains highly fl ammable and it is

possible to get the serious personal injury

when inhaling or spilling on your body.

Always pay attention when handling fuel.

Always have good ventilation when handling

fuel inside building.

13

Fig. 8

Before fueling, clean the tank cap area carefully,

to ensure that no dirt falls into the tank. Make sure

that the fuel is well mixed by shaking the container,

before fueling.

12

9

Page 10

English

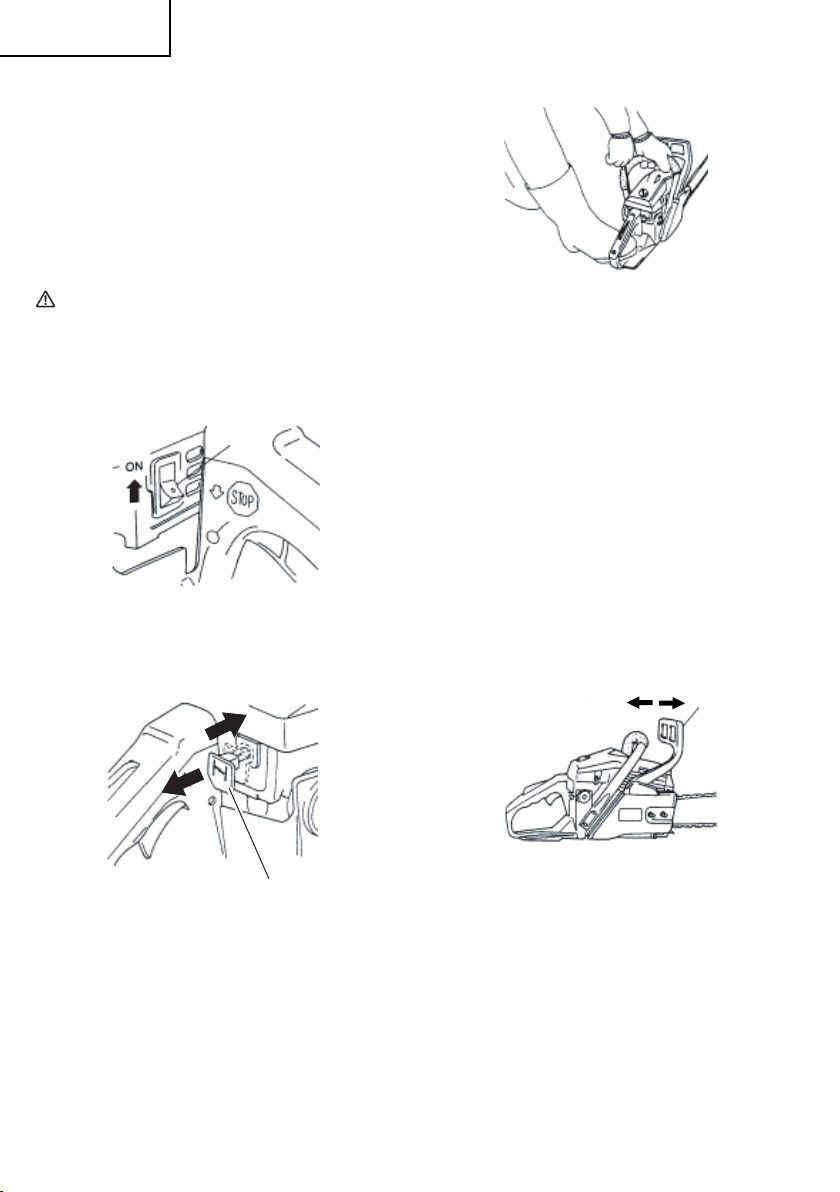

Chain oil (Fig. 8)

Fill up with chain oil (13). Always use good quality

chain oil. When the engine is running, the chain oil is

automatically discharged.

NOTE

When pouring fuel (12) or chain oil (13) into the

tank, place the unit with cap side up. (Fig. 8)

Starting (Fig. 9, 10)

CAUTION

Before starting, make sure chain brake is

disengaged (if so equipped) and that the bar/

chain does not touch anything.

1. Set ignition switch (14) to ON position. (Fig. 9)

14

Fig. 9

2. Pull the choke lever (15) down to choked position

(Fig. 10). This will automatically lock the throttle in

starting position. (Fig. 9)

15

Fig. 10

3. Pull recoil starter briskly, taking care to keep the

handle in your grasp and not allowing it to snap

back. (Fig. 9)

4. When you hear fi rst ignition, return the choke to

run position. (Fig. 10)

5. Pull recoil starter briskly again in the

aforementioned manner. (Fig. 11)

After engine starts, make sure the chain brake is

disengaged.

Fig. 11

NOTE

If engine does not start, repeat procedures from

2 to 5.

6. After starting engine, allow the engine about 2–3

minutes to warm up before subjecting it to any

load.

Chain brake operation (Fig. 12)

Chain brake (16), if so equipped, is designed to

activate in an emergency such as kick-back action.

Please check to verify that it works properly before

use.

Application of brake is made by moving the front

guard towards the bar. During the chain brake

operation, even if the throttle lever is pulled, the

engine speed does not increase and the chain does

not turn. To release the brake, pull up the chain

brake lever.

16

Fig. 12

How to confi rm:

1) Turn off the engine.

2) Holding the chain saw horizontally, release your

hand from the front handle, hit the tip of the guide

bar to a stump or a piece of wood, and confi rm

brake operation. Operating level varies by bar

size.

10

Page 11

In case the brake is not eff ective, ask our dealer for

inspection and repairs. If the engine keeps rotating

at high speed with the brake engaged, the clutch will

overheat causing trouble.

When the brake engages during operation,

immediately release the throttle lever to stop the

engine.

WARNING

Do not carry the machine with the engine

running.

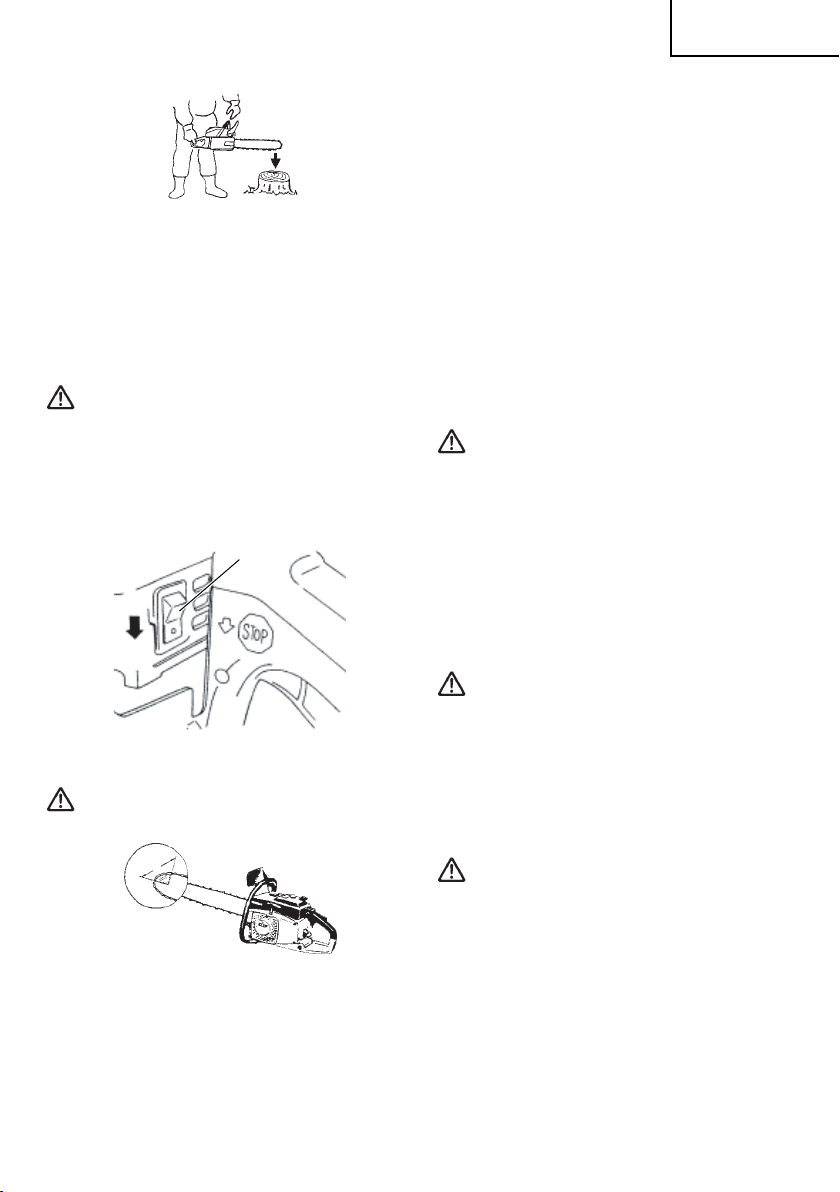

Stopping (Fig. 13)

Decrease engine speed, and push ignition switch

(14) to stop position.

14

English

towards you. Either of these reactions may cause

you to lose control of the saw which could result in

serious personal injury. Even though your saw has

safety built into its design, you should not rely on

these safety features exclusively. Know where your

bar tip is at all times. Kickback does occur if you

allow the kickback zone (17) of the bar to touch an

object. Do not use that area. Kickback from pinching

is caused by a cut closing and pinching the upper

side of the guide bar. Study your cut and make sure

it will open as you cut through. Maintain control when

the engine is running by always keeping a fi rm grip

on the saw with your right hand on the rear handle,

your left hand on the front handle and your thumbs

and fi ngers encircling the handles. Always hold the

saw with both hands during operation and cut at high

engine speed.

WARNING

● Do not overreach or cut above shoulder

height.

● Use extra caution when felling, and do not

use the saw in a nose-high position or above

shoulder height.

CHAIN CATCHER

The chain catcher is located on the power head just

below the chain to further prevent the possibility of a

broken chain striking the chain saw user.

Fig. 13

WARNING

KICKBACK DANGER (Fig. 14)

17

Fig. 14

One of the most severe dangers when working with

a chain saw is the possibility of kickback. Kickback

may occur when the upper tip of the guide bar

touches an object, or when the wood closes in

and pinches the saw chain in the cut. Tip contact

in some cases may cause a lightning fast reverse

reaction, kicking the guide bar up and back toward

you. Pinching the saw chain along the top of the

guide bar may also push the guide bar rapidly back

WARNING

Do not stand in-line with chain when cutting.

BASIC TECHNIQUES FOR MAKING FELLING,

LIMBING AND BUCKING CUTS

The intention of the following information is to

provide you with the general introduction to wood

cutting techniques.

WARNING

● This information does not cover all specifi c

situations, which may depend on diff erences

in terrain, vegetation, kind of wood, form

and size of trees, etc. Consult your servicing

dealer, forestry agent or local forestry

schools for advice on specifi c woodcutting

problems in your area. This will make your

work more effi cient and safer.

● Avoid cutting in adverse weather conditions,

such as dense fog, heavy rain, bitter cold,

high winds, etc.

Adverse weather is often tiring to work in

and creates potentially dangerous conditions

such as slippery ground.

11

Page 12

English

High winds may force the tree to fall in an

unexpected direction causing property

damage or personal injury.

CAUTION

Never use a chain saw to pry or for any

purpose for which it is not intended.

WARNING

● Avoid stumbling on obstacles such as

stumps, roots, rocks, branches and fallen

trees. Watch out for holes and ditches. Be

extremely cautious when working on slopes

or uneven ground.

Shut off the saw when moving from one work

place to another.

Always cut at wide open throttle. A slow

moving chain can easily catch and force the

saw to jerk.

● Never use the saw with only one hand.

You cannot control the saw properly and

you may lose control and injure yourself

severely.

Keep the saw body close to your body to

improve control and reduce strain.

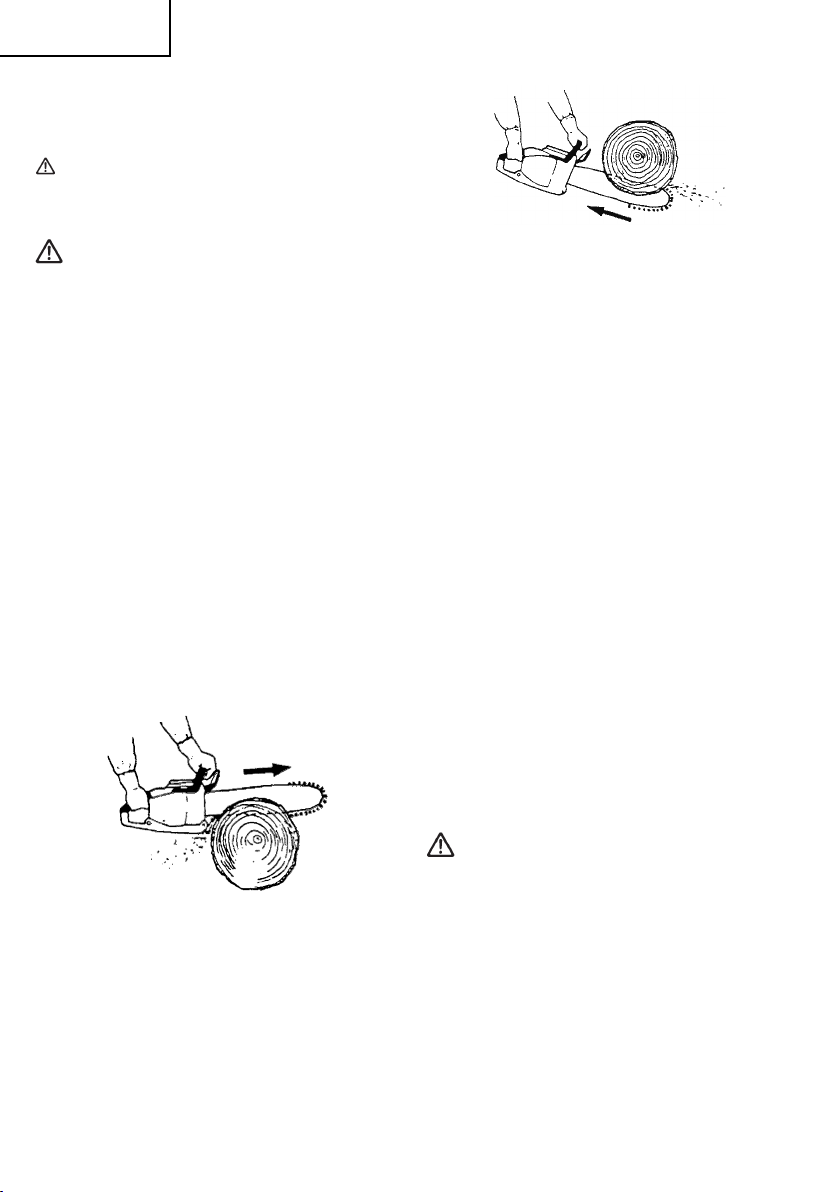

When cutting with the bottom part of the

chain the reactive force will pull the saw

away from you towards the wood you are

cutting.

The saw will control the feeding speed and

sawdust will be directed towards you. (Fig.

15)

Fig. 16

● There is a risk of kickback if the saw is

pushed far enough so that you begin to cut

with the nose of the bar.

The safest cutting method is to cut with the

bottom part of the chain. Sawing with the

upper part makes it much more diffi cult to

control the saw and increases the risk of

kickback.

● In case the chain locked, immediately release

the throttle lever.

If the throttle lever keeps rotating at high

speed with the chain locked, the clutch will

overheat causing trouble.

NOTE

Always keep the spiked bumper face to a tree,

because the chain may suddenly be drawn into a

tree.

FELLING

Felling is more than cutting down a tree. You must

also bring it down as near to an intended place as

possible without damaging the tree or anything else.

Before felling a tree, carefully consider all conditions

which may eff ect the intended direction, such as:

Angle of the tree. Shape of the crown. Snow load on

the crown.

Wind conditions. Obstacles within tree range (e.g.,

other trees, power lines, roads, buildings, etc.).

Fig. 15

● When cutting with the upper part of the chain

the reactive force will push the saw towards

you and away from the wood you are cutting.

(Fig. 16)

12

WARNING

● Always observe the general conditions of

the tree. Look for decay and rot in the trunk

which will make it more likely to snap and

start to fall before you expect it.

● Look for dry branches, which may break and

hit you when you are working.

Always keep animals and people at least

twice the tree length away while felling. Clear

away shrubs and branches from around the

tree.

Prepare a path of retreat away from the

felling direction.

BASIC RULES FOR FELLING TREES

Normally the felling consists of two main cutting

operations, notching and making the felling cut. Start

Page 13

English

making the upper notch cut on the side of the tree

facing the feeling direction. Look through the kerf as

you saw the lower cut so you do not saw too deep

into the trunk. The notch should be deep enough to

create a hinge of suffi cient width and strength. The

notch opening should be wide enough to direct the

fall of the tree as long as possible. Saw the felling

cut from the other side of the tree between one and

two inches (3–5 cm) above the edge of the notch.

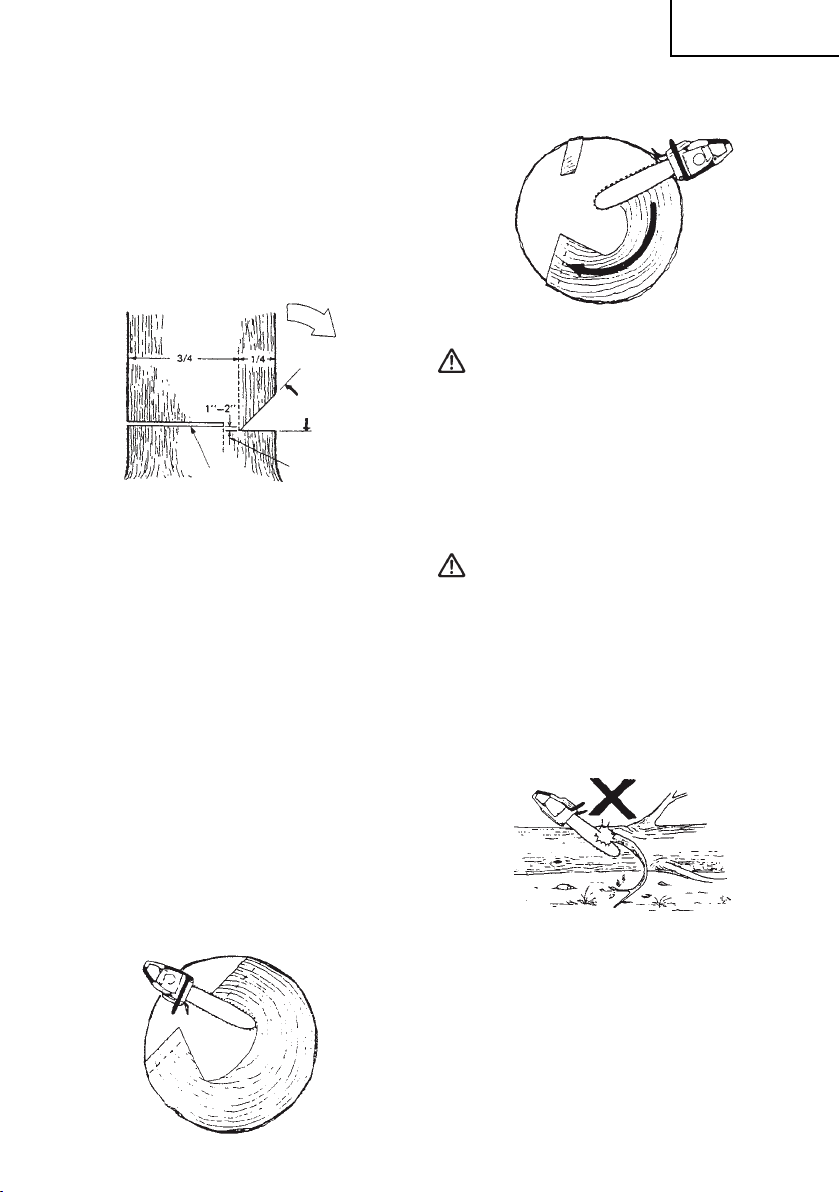

(Fig. 17)

18

19

21

Fig. 17

18. Felling direction

19. 45° minimum notch opening

20. Hinge

21. Felling cut

Never saw completely through the trunk. Always

leave a hinge.

The hinge guides the tree. If the trunk is completely

cut through, you lose control over the felling

direction.

Insert a wedge or a felling lever in the cut well before

the tree becomes unstable and starts to move. This

will prevent the guide bar from binding in the felling

cut if you have misjudged the falling direction. Make

sure no people have come into the range of the

falling tree before you push it over.

20

Complete the felling cut by sawing around the trunk

as in the Fig. 19.

Fig. 19

WARNING

These methods are extremely dangerous

because they involve the use of the nose of

guide bar and can result in kickback.

Only properly trained professionals should

attempt these techniques.

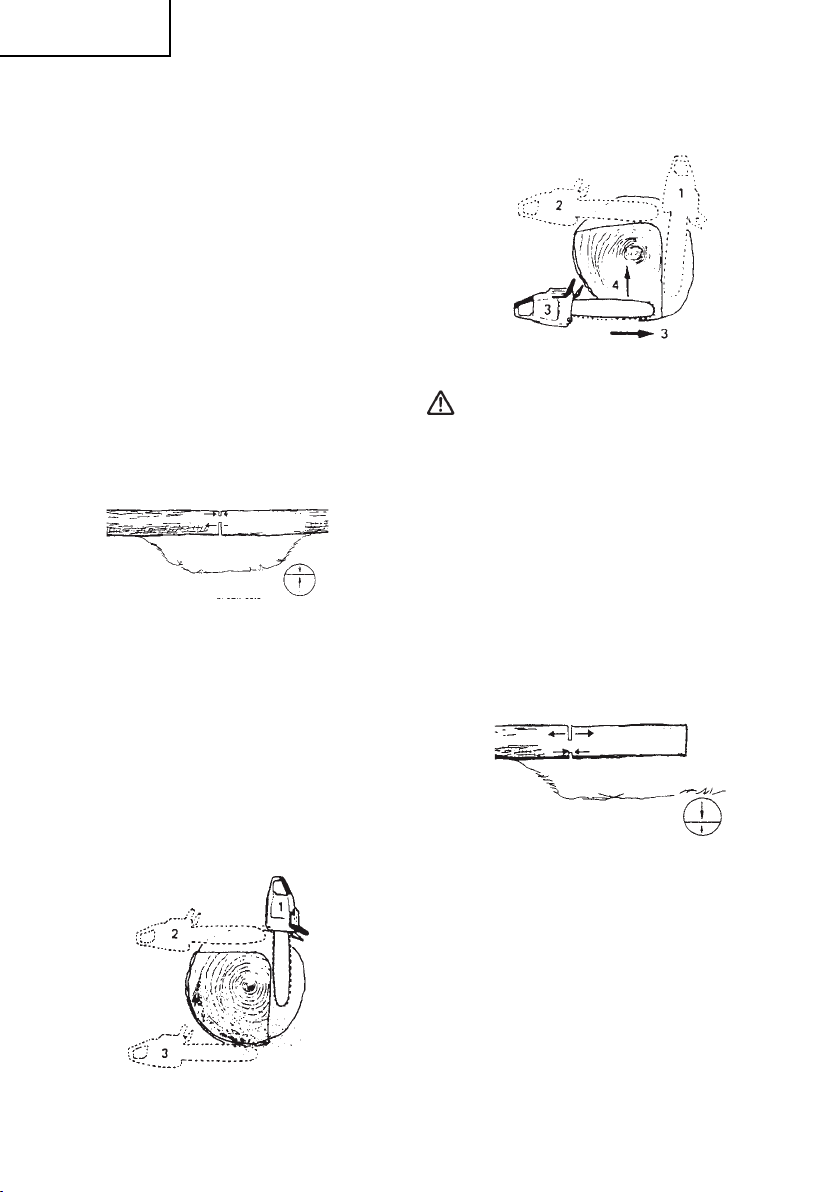

LIMBING

Limbing is removing the branches from a feller tree.

WARNING

A majority of kickback accidents occur

during Iimbing.

Do not use the nose of the guide bar. Be

extremely cautious and avoid contacting the

log, other limbs or objects with the nose of

the guide bar. Be extremely cautious of limbs

under tension. They can spring back towards

you and cause loss of control resulting in

injury. (Fig. 20)

FELLING CUT, TRUNK DIAMETER MORE THAN

TWICE GUIDE BAR LENGTH

Cut a large, wide notch. Then cut a recess into the

center of the notch. Always leave a hinge on both

sides of the center cut. (Fig. 18)

Fig. 18

Fig. 20

Stand on the left side of the trunk. Maintain a secure

footing and rest the saw on the trunk. Hold the saw

close to you so that you are in full control of it. Keep

well away from the chain. Move only when the trunk

is between you and the chain. Watch out for spring

back of limbs under tension.

13

Page 14

English

LIMBING THICK BRANCHES

When limbing thick branches, the guide bar may get

pinched easily. Branches under tension often snap

up, so cut troublesome branches in small steps.

Apply the same principles as for cross cutting. Think

ahead and be aware of the possible consequences

of all your actions.

CROSS CUTTING/BUCKING

Before starting to cut through the log, try to imagine

what is going to happen. Look out for stresses in

the log and cut through it in such a manner that the

guide bar will not get pinched.

CROSS CUTTING LOGS, PRESSURE ON TOP

Take a fi rm stance. Begin with an upper cut. Do

not cut too deeply, about 1/3 of the log diameter is

enough. Finish with a bottom cut.

The saw cuts should meet. (Fig. 21)

24

22

25

26

23

27

Fig. 21

22. Relieving cut

23. Cross cut

24. Pressure on top

25. Pressure side

26. Tension side

27. Relative depth of saw cuts

THICK LOG, LARGER THAN GUIDE BAR

LENGTH

Begin by cutting on the opposite side of the log.

Pull the saw towards you, followed by previous

procedure. (Fig. 22)

If the log is lying on the ground make a boring cut to

avoid cutting into the ground. Finish with a bottom

cut. (Fig. 23)

Fig. 23

WARNING

KICKBACK DANGER

Do not attempt a boring cut if you are not

properly trained. A boring cut involves the

use of the nose of the guide bar and can

result in kickback.

CROSS CUTTING LOGS, PRESSURE ON

BOTTOM

Take a fi rm stance. Begin with a bottom cut. The

depth of the cut should be about 1/3 of the log

diameter.

Finish with an upper cut. The saw cuts should meet.

(Fig. 24)

30

29

31

32

28

33

Fig. 24

28. Relieving cut

29. Cross cut

30. Pressure on bottom

31. Tension side

32. Pressure side

33. Relative depth of saw cuts

THICK LOG, LARGER THAN GUIDE BAR

LENGTH

Begin by cutting on the opposite side of the log.

Pull the saw towards you, followed by previous

Fig. 22

procedure. Make a boring cut if the log is close to

the ground. Finish with a top cut. (Fig. 25)

14

Page 15

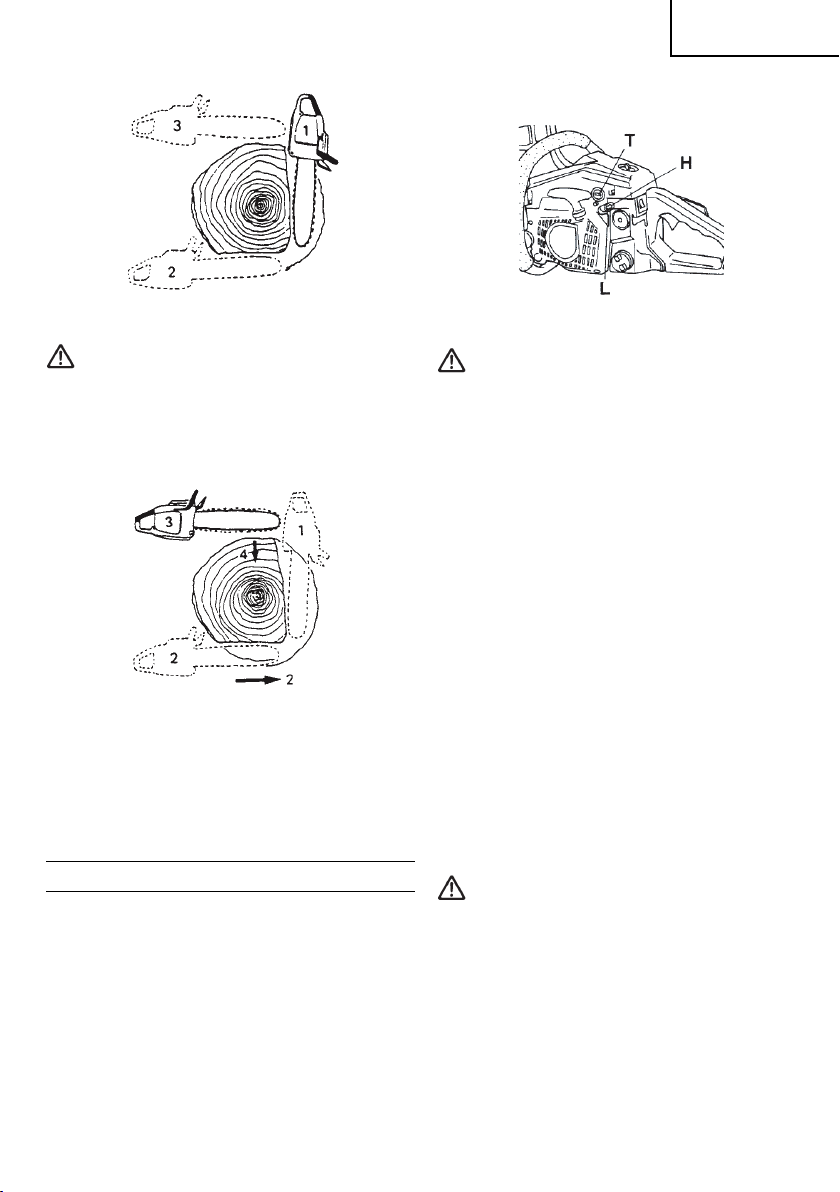

Carburetor adjustment (Fig. 27)

English

Fig. 25

WARNING

KICKBACK DANGER

Do not attempt a boring cut if you are not

properly trained. A boring cut involves the

use of the nose of the guide bar and can

result in kickback. (Fig. 26)

Fig. 26

IF THE SAW GETS STUCK

Stop the engine. Raise the log or change its position,

using a thick branch or pole as a lever. Do not try

to pull the saw free. If you do, you can deform the

handle or be injured by the saw chain if the saw is

suddenly released.

MAINTENANCE

MAINTENANCE, REPLACEMENT OR REPAIR

OF THE EMISSION CONTROL DEVICES AND

SYSTEM MAY BE PERFORMED BY ANY NONROAD ENGINE REPAIR ESTABLISHMENT OR

INDIVIDUAL.

Fig. 27

WARNING

Never start the engine without the complete

clutch cover.

Otherwise the clutch can come loose and

cause personal injuries.

In the carburetor, fuel is mixed with air. When the

engine is test run at the factory, the carburetor is

adjusted. A further adjustment may be required,

according to climate and altitude. The carburetor has

one adjustment possibility:

T = Idle speed adjustment screw.

Idle speed adjustment (T)

Check that the air fi lter is clean. When the idle

speed is correct, the cutting attachment will not

rotate. If adjustment is required, close (clockwise)

the T-screw, with the engine running, until the

cutting attachment starts to rotate. Open (counterclockwise) the screw until the cutting attachment

stops. You have reached the correct idle speed

when the engine runs smoothly in all positions well

below the rpm when the cutting attachment starts to

rotate.

If the cutting attachment still rotates after idle speed

adjustment, contact HITACHI dealer.

WARNING

When the engine is idling the cutting

attachment must under no circumstances

rotate.

NOTE

Some models sold in areas with strict exhaust

emission regulation do not have high and low

speed carburetor adjustments. Such adjustments

may allow the engine to be operated outside

of their emission compliance limits. For these

models, the only carburetor adjustment is idle

speed.

15

Page 16

English

If you are not familiar with this type of adjustment,

please ask for assistance from your HITACHI dealer.

Air fi lter (Fig. 28)

The air fi lter (34) must be cleaned from dust and dirt

in order to avoid:

○ Carburetor malfunctions.

○ Starting problems.

○ Engine power reduction.

○ Unnecessary wear on the engine parts.

○ Abnormal fuel consumption.

Clean the air fi lter daily or more often if working in

exceptionally dusty areas.

Cleaning the air fi lter

Remove the air fi lter cover (35) and the fi lter (34).

35

34

0.024 ″

(0.6 mm)

Fig. 29

NOTE

In some areas, local law requires using a resistor

spark plug to suppress ignition signals. If this

machine was originally equipped with resistor

spark plug, use same type of spark plug for

replacement.

Oiler port (Fig. 30)

Clean the chain oiler port (36) whenever possible.

36

Fig. 28

Rinse them in warm soap suds. Check that the fi lter

is dry before reassembly. An air fi lter that has been

used for some time cannot be cleaned completely.

Therefore, it must regularly be replaced with a new

one. A damaged fi lter must always be replaced.

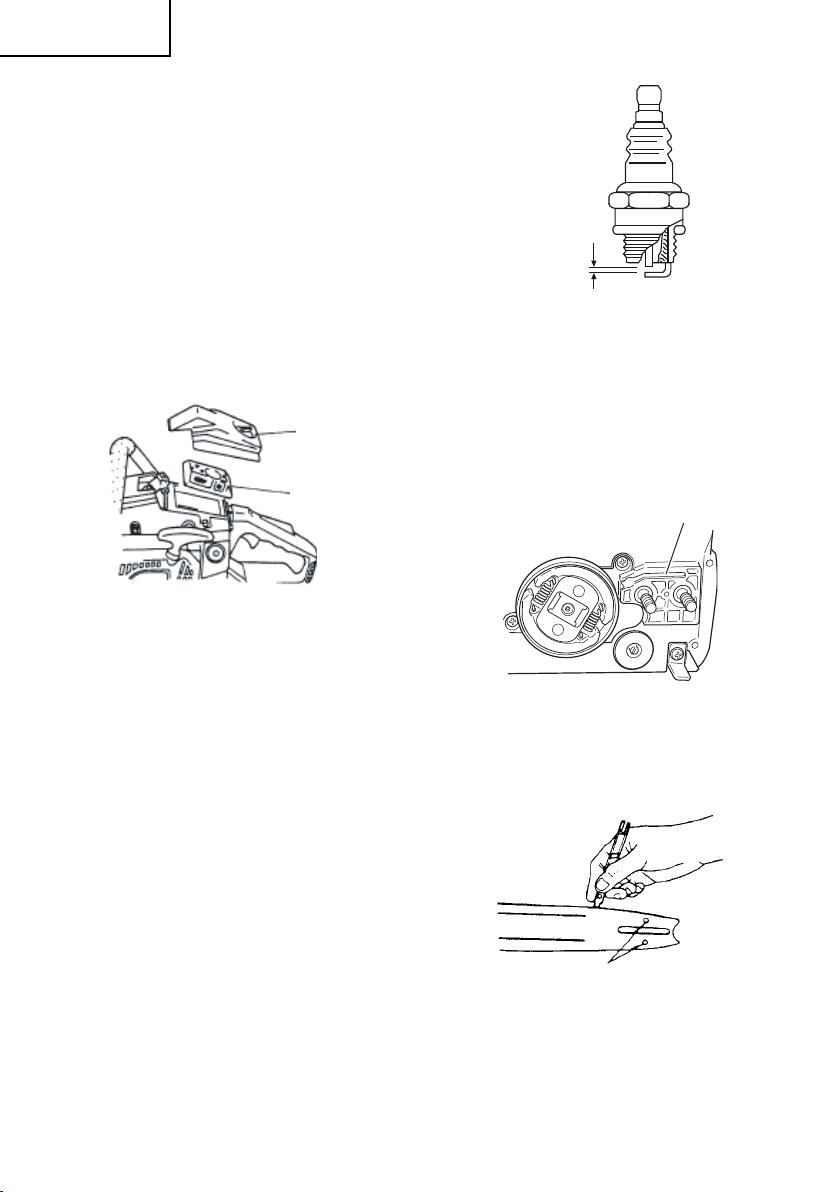

Spark plug (Fig. 29)

The spark plug condition is infl uenced by:

○ An incorrect carburetor setting.

○ Wrong fuel mixture (too much oil in the gasoline)

○ A dirty air fi lter.

○ Hard running conditions (such as cold weather).

These factors cause deposits on the spark plug

electrodes, which may result in malfunction and

starting diffi culties. If the engine is low on power,

diffi cult to start or runs poorly at idling speed, always

check the spark plug fi rst. If the spark plug is dirty,

clean it and check the electrode gap. Readjust if

necessary. The correct gap is 0.024″ (0.6 mm).

The spark plug should be replaced after about 100

operation hours or earlier if the electrodes are badly

eroded.

16

Fig. 30

Guide bar (Fig. 31)

Before using the machine, clean the groove and oiler

port (37) in the bar with the special gauge off ered as

an optional accessory.

37

Fig. 31

Side case (Fig. 32)

Always keep the side case and drive area clean of

saw dust and debris. Periodically apply oil or grease

to this area to protect from corrosion as some trees

contain high levels of acid.

Page 17

Fig. 32

Fuel fi lter (Fig. 33)

Remove the fuel fi lter from the fuel tank and

thoroughly wash it in solvent. After that, push the

fi lter into the tank completely.

Fig. 33

English

Every 100 operating hours, or once a year (more

often if conditions require), clean fi ns and external

surfaces of engine of dust, dirt and oil deposits

which can contribute to improper cooling.

38

Fig. 35

Cleaning the muffl er (Fig. 36)

Remove the muffl er and spark arrestor, if so

equipped, and clean out any excess carbon from

the exhaust port or muffl er inlet every 100 hours of

operation.

NOTE

If the fi lter is hard due to dust and dirt, replace it.

Chain oil fi lter (Fig. 34)

Remove the oil fi lter and thoroughly wash it in

solvent.

Fig. 34

Cleaning the cylinder fi ns (Fig. 35)

When wood chips are caught between cylinder fi ns

(38), the engine may overheat, resulting in lower

output. To avoid this, always keep cylinder fi ns and

fan case clean.

Fig. 36

For long-term storage

Drain all fuel from the fuel tank. Start and let engine

run until it stops. Repair any damage which has

resulted from use. Clean the unit with a clean rag, or

the use of high pressure air hose. Put a few drops

of two-cycle engine oil into the cylinder through the

spark plug hole, and spin the engine over several

times to distribute oil.

Cover the unit and store it in a dry area.

CHAIN SHARPENING

Parts of a cutter (Fig. 37, 38)

WARNING

● Gloves should be used when sharpening

chain.

● Be sure to round off the front edge to reduce

the chance of kickback or tie-strap breakage.

17

Page 18

English

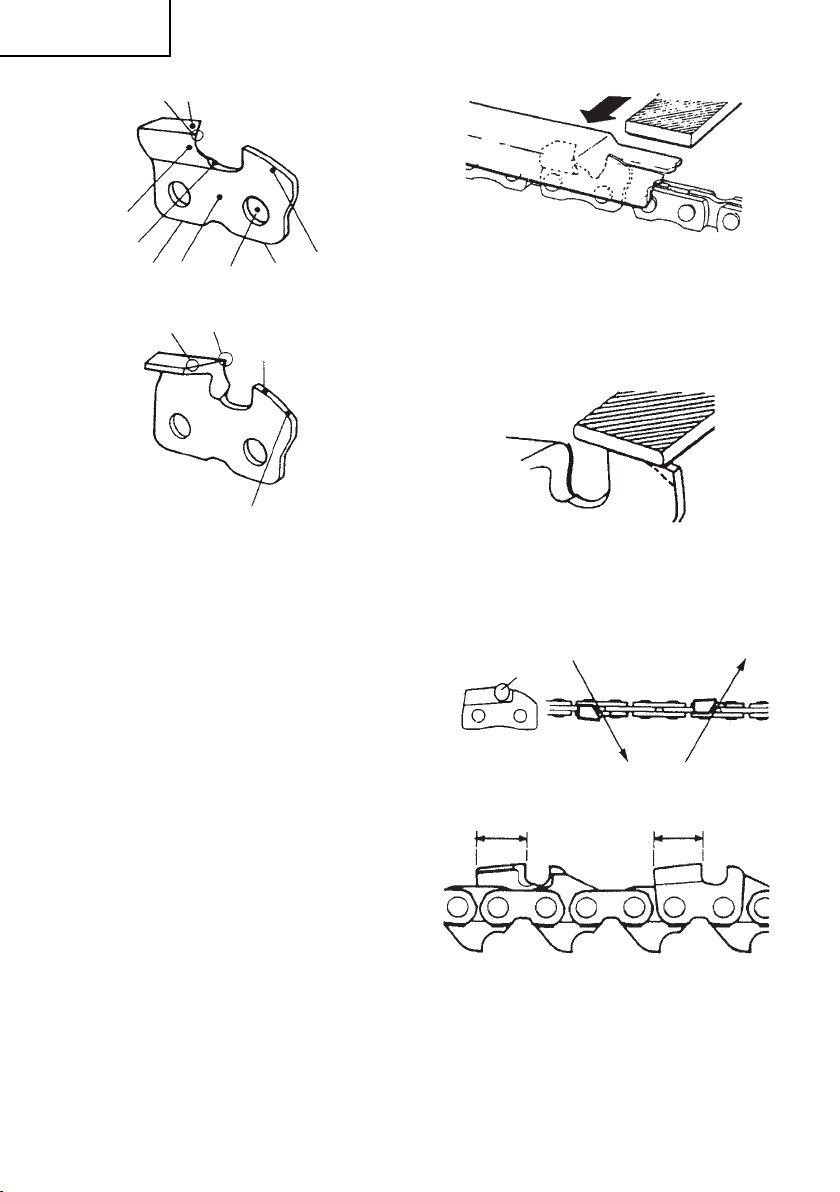

39

40

41

42

43

44

45

Fig. 37

49

48

51

Fig. 38

39. Top plate

40. Working corner

41. Side plate

42. Gullet

43. Heel

44. Chassis

45. Rivet hole

46. Toe

47. Depth gauge

48. Correct angle on top plate (degree of angle

depends on chain type)

49. Slightly protruding “hook” or point (curve on nonchisel chain)

50. Top of depth gauge at correct height below top

plate

51. Front of depth gauge rounded off

47

46

50

Fig. 39

4) Round off front corner to maintain original shape

of depth gauge after using depth gauge tool.

Always follow the recommended depth gauge

setting found in the maintenance or operator

manual for your saw. (Fig. 40)

Fig. 40

GENERAL INSTRUCTIONS FOR FILING

CUTTERS

File (52) cutter on one side of the chain from the

inside out. File on forward stroke only. (Fig. 41)

52

5252

Fig. 41

5) Keep all cutters the same length. (Fig. 42)

LOWERING DEPTH GAUGES WITH A FILE

1) If you sharpen your cutters with a fi le holder,

check and lower the depth.

2) Check depth gauges every third sharpening.

3) Place depth gauge tool on cutter. If depth gauge

projects, fi le it level with the top of the tool.

Always fi le from the inside of the chain toward an

outside cutter. (Fig. 39)

18

Fig. 42

6) File enough to remove any damage to cutting

edges (side plate (53) and top plate (54)) of

cutter. (Fig. 43)

Page 19

53

Fig. 43

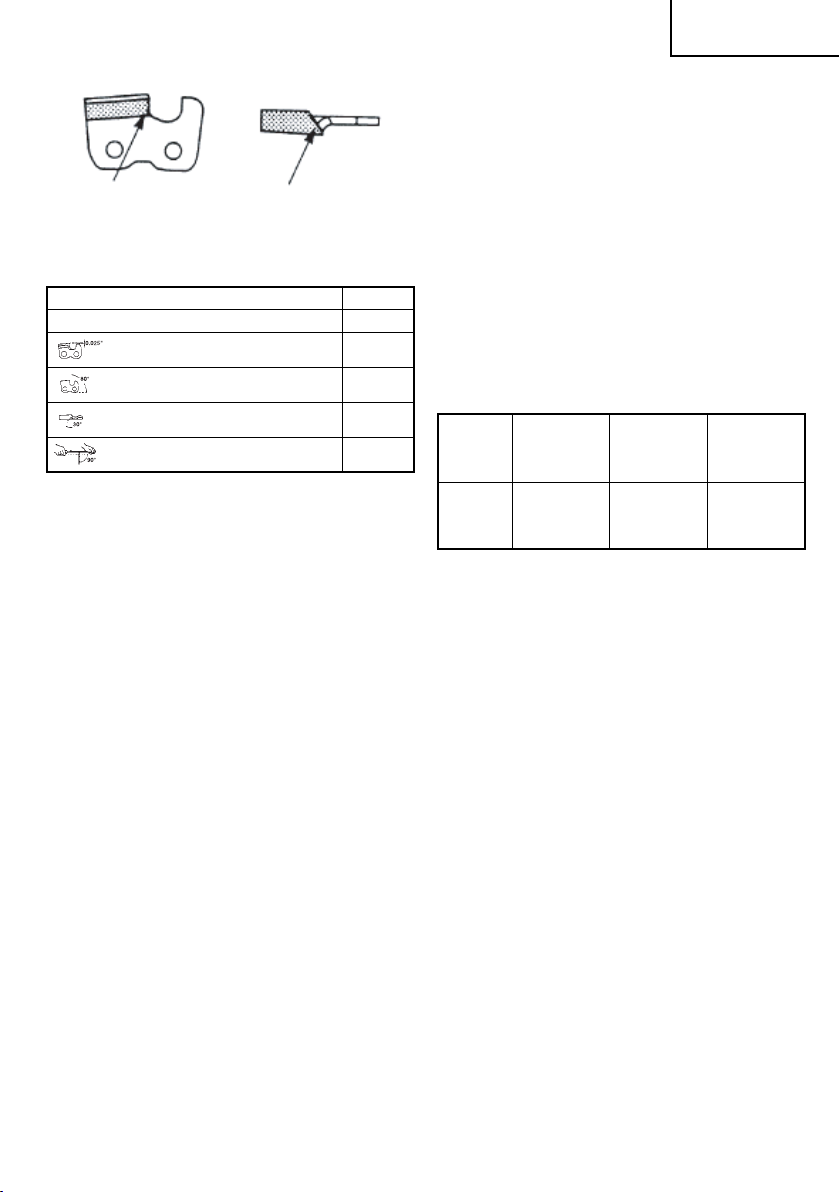

SHARPENING ANGLES FOR SHARPENING SAW

CHAIN

1. Part Number 91VG

2. Pitch 3/8″

3. Depth Gauge Setting 0.025″

4. Side Plate Filing Angle 80°

5. Top Plate Angle 30°

6. File Guide Angle 90°

Maintenance schedule

Below you will fi nd some general maintenance

instructions. For further information please contact

HITACHI dealer.

Daily maintenance

○ Clean the exterior of the unit.

○ Clean the chain oil fi lter port.

○ Clean the groove and oil fi lter port in the guide

bar.

○ Clean the side case of saw dust.

○ Check that the saw chain is sharp.

○ Check that the bar nuts are suffi ciently tightened.

○ Make sure that the chain transport guard is

undamaged and that it can be securely fi tted.

○ Check that nuts and screws are suffi ciently

tightened.

Especially inspect the bolt of muffl er and ensure

that they are properly tightened before starting

engine. Should any of the bolts be loose,

retighten them immediately. Failure to do so

could result in serious hazard.

○ Check the tip of the bar. Please exchange it for

the new one when it is worn out.

○ Check the band of chain brake. Please exchange

it for the new one when it is worn out.

54

English

○ Clean the cooling fi ns on the cylinder and check

that the air intake at the starter is not clogged.

○ Clean the air fi lter.

Monthly maintenance

○ Rinse the fuel tank with gasoline, and clean fuel

fi lter.

○ Clean chain oil fi lter.

○ Clean the exterior of the carburetor and the space

around it.

○ Clean the fan and the space around it.

○ Clean the muffl er of carbon.

NOTE

When ordering the parts to your nearest dealer,

please use the item numbers showing on the

parts breakdown section in this instruction.

MODEL

NO.

OREGON

CS33EB 26779

BAR NO.

26780

160NDEA041

LENGTH-

TYPE

12″ (300 mm)

14″ (350 mm)

16″ (400 mm)

CHAIN NO.

91VG-045X

91VG-052X

91VG-057X

Weekly maintenance

○ Check the starter, especially cord and return

spring.

○ Clean the exterior of the spark plug.

○ Remove the spark plug and check the electrode

gap. Adjust it to 0.024″ (0.6 mm) or change the

spark plug.

19

Page 20

Français

SIGNIFICATION DES SYMBOLES

REMARQUE : Certains appareils n’en sont pas pourvus.

Symboles

ATTENTION

Les symboles suivants sont utilisés pour l’outil. Bien se familiariser avec leur

signifi cation avant d’utiliser l’outil.

Il est essentiel que vous lisiez et compreniez parfaitement les consignes de

sécurité et autres avertissements suivants et que vous les observiez strictement.

L’utilisation inattentive ou inadéquate de cette machine risque de provoquer des

blessures graves ou fatales.

Lisez, comprenez et suivez toutes les instructions et tous les avertissements

donnés dans ce manuel et sur le produit.

Utilisez toujours des lunettes de protection ainsi qu’une protection pour la tête et

les oreilles lorsque vous utilisez ce produit.

Portez une attention particulière aux phénomènes de rebond. Prenez garde

aux mouvements possibles soudains et accidentels du guide-chaîne de votre

tronçonneuse.

L’utilisation d’une tronçonneuse avec une seule main n’est pas autorisée.

Lorsque vous coupez avec votre machine, tenir celle-ci fermement avec les deux

mains, le pouce enserrant la poignée avant.

Sommaire

DESCRIPTION .....................................................21

PRÉCAUTIONS ET CONSIGNES DE

SÉCURITÉ.......................................................22

SPÉCIFICATIONS ................................................25

MONTAGE ...........................................................26

UTILISATION ........................................................27

ENTRETIEN .........................................................34

Liste des pièces détachées

20

Page 21

Français

DESCRIPTION

1. Commande des gaz : Dispositif actionné par

le doigt de l’opérateur pour la commande de

vitesse du moteur.

2. Levier accélérateur bloqué : Dispositif qui

empêche le déclenchement accidentel de

la commande des gaz tant qu’elle n’est pas

relâchée manuellement.

3. Commutateur de marche/arrêt : Dispositif

permettant de lancer ou d’arrêter le moteur.

4. Bouchon du réservoir d’huile : Permet de fermer

le réservoir d’huile.

5. Lanceur à retour automatique : Tirer sur la

poignée pour lancer le moteur.

6. Poignée avant : Poignée de soutien située sur ou

vers l’avant du carter moteur.

7. Bouchon du réservoir de carburant : Permet de

fermer le réservoir de carburant.

8. Bouton de commande du starter : Dispositif

qui enrichit le mélange essence/air dans le

carburateur pour faciliter le démarrage.

9. Guide-chaîne : Pièce qui soutient et guide la

chaîne de coupe.

10. Chaîne découpe : Chaîne qui sert d’instrument

découpe.

11. Frein de chaîne (protection de main avant) :

Dispositif d’arrêt ou de verrouillage de la chaîne.

12. Griff e d’abattage (option) : Dispositif qui tient lieu

de pivot quand l’outil entre en contact avec un

arbre ou un billot de bois.

13. Capteur de chaîne : Dispositif qui retient la

chaîne de coupe.

14. Cache de guide-chaîne : Dispositif qui recouvre

le guide-chaîne et la chaîne de coupe quand on

ne se sert pas de l’outil.

15. Clé à douille multiple : Outil qui permet de

déposer et de remonter la bougie et de tendre la

chaîne de coupe.

16. Mode d’emploi : Fourni avec l’outil. Lisez-le

avant d’utiliser l’outil et conservez-le à des fi ns

de référence ultérieure pour apprendre les

techniques d’utilisation correcte et de sécurité.

11

2

8

13

6

4

12

15

14

10

9

5

1

3

7

16

21

Page 22

Français

PRÉCAUTIONS ET CONSIGNES

DE SÉCURITÉ

Sécurité de l’utilisateur

○ Portez toujours une visière et des lunettes de

protection.

○ Portez toujours des gants pour atténuer les

vibrations.

○ Vous devez toujours porter des gants de

protection lorsque vous aff ûtez la chaîne.

○ Portez toujours un équipement de protection tel

qu’un veston, un pantalon, des gants, un casque,

des bottes avec les orteil-casquettes d’acier et

des semelles antidérapantes quand vous utilisez

la tronçonneuse. Pour travailler dans les arbres,

utilisez des bottes les bottes spécialisées pour

l’escalade. Ne portez pas de vêtements amples,

de shorts, de sandales et ne vous promenez pas

pieds nus.

Veillez à attacher vos cheveux s’ils sont longs.

○ N’utilisez cet outil que si vous êtes en pleine

possession de vos moyens physiques (qui vous

n’êtes pas fatigué, malade ou sous l’infl uence

d’un alcool, d’une drogue ou de médicaments).

○ Ne jamais laisser un enfant ou une personne

inexpérimentée se servir de cet outil.

○ Portez un dispositif de protection contre le bruit

pour vos oreilles. Restez vigilant à tout ce qui

vous entoure.

Restez attentif dans l’éventualité où une

personne située à proximité vous signalerait un

problème.

Retirez les équipements de sécurité

immédiatement après avoir coupé le moteur de

l’appareil.

○ Protégez-vous la tête.

○ Ne démarrez jamais le moteur de l’appareil dans

un local clos ou à l’intérieur d’un bâtiment.

L’inhalation des fumées d’échappement peut être

mortelle.

○ Pour la protection respiratoire, porter un masque

quand un nuage d’huile de la chaîne et de la

poussière est émise de la sciure.

○ Nettoyez les poignées de toute trace d’huile ou

de carburant.

○ N’approchez jamais les mains du guide-chaîne et

de la chaîne.

○ N’attrapez jamais, ni ne tenez la machine par

l’extrémité du guide-chaîne.

○ Après l’arrêt de la tronçonneuse, attendez l’arrêt

complet de la chaîne de coupe avant de poser la

machine.

○ Lors d’une utilisation prolongée, veillez à faire

une pause périodiquement, afi n d’éviter le

22

Syndrome des vibrations mains/bras (HAVS)

provoqués par les vibrations.

○ L’utilisateur de la machine doit se conformer

aux réglementations locales de la région dans

laquelle il eff ectue la coupe.

ATTENTION

● Les systèmes anti-vibrations, aussi

bon soient-ils, ne vous protègent pas

complément du syndrome des vibrations

mains/bras (HAVS), ni du syndrome du canal

carpien.

Par conséquent, si vous vous servez de façon

régulière et continue de votre tronçonneuse,

surveillez soigneusement l’état de vos mains

et de vos doigts. Si l’un des symptômes

ci-dessus venait à apparaître, faites vous

examiner immédiatement par votre médecin.

● Une exposition longue ou continue à des

bruits de niveau élevé peut causer les

troubles d’audition permanents. Portez

toujours un équipement de protection

d’oreilles lors de l’utilisation de l’outils.

● Si vous êtes équipé d’un appareillage

médical électrique/ électronique tel qu’un

stimulateur cardiaque, consultez votre

médecin et le fabricant de cet appareillage

avant d’utiliser tout appareil électrique.

Règles de sécurité concernant l’utilisation de la

machine.

○ Contrôlez entièrement votre machine avant

chaque utilisation. Remplacez les pièces

endommagées. Vérifi ez l’absence de fuites de

carburant et assurez-vous que tous les dispositifs

de fi xation sont en place et solidement fi xés.

○ Remplacez les éléments de la machine qui

présentent des fi ssures, des ébréchures ou toute

autre avarie.

○ Assurez-vous que le capot latéral est

correctement installé.

○ Ne laissez personne s’approcher lorsque vous

réglez le carburateur.

○ Utilisez uniquement les accessoires

recommandés par le constructeur pour cette

machine.

○ Ne laissez jamais la chaîne frapper contre un

obstacle quelconque. Si la chaîne rencontre

un obstacle, il est nécessaire d’arrêter le

fonctionnement de la machine et de l’inspecter

soigneusement pour voir si elle n’est pas

endommagée.

○ Assurez-vous que le système de graissage

automatique fonctionne normalement. Le

réservoir d’huile doit toujours être suffi samment

Page 23

Français

rempli d’huile propre. Ne jamais laisser la chaîne

tourner à sec sur le guide-chaîne.

○ Tous les travaux d’entretien de la tronçonneuse,

en dehors de ceux indiqués dans le manuel

d’entretien de l’utilisateur doivent être eff ectués

par un personnel qualifi é pour l’entretien des

tronçonneuses. (Par exemple, des outils

incorrects sont utilisés pour extraire le volant, ou

si un outil incorrect est utilisé pour maintenir le

volant avant la dépose de l’embrayage, cela peut

entraîner des dommages structurels au volant et

peut ensuite provoquer sont éclatement.)

ATTENTION

● Ne modifi ez en aucun cas la machine.

N’utilisez jamais la tronçonneuse pour tout

autre tâche que celles auxquelles elle est

destinée.

● N’utilisez jamais la tronçonneuse sans

aucun équipement de sécurité ou avec

un équipement de sécurité inadapté. Cela

pourrait entraîner des blessures graves.

● Si un guide ou

qui a été recommandée par le fabricant et

qui n’est pas homologuée est utilisé, cela

peut entraîner un risque élevé d’accidents

personnels ou de blessures.

Sécurité au niveau du carburant

○ Faites le mélange et le plein à l’air libre, à

distance de toute étincelle ou fl amme.

○ Utilisez un récipient agréé pour l’essence.

○ Ne fumez pas et ne laissez personne fumer

à proximité du carburant ou de la machine, ni

lorsque vous utilisez la machine.

○ Essuyez soigneusement toutes les traces de

carburant avant de mettre le moteur en marche.

○ Pour démarrer la tronçonneuse, écartez vous

d’au moins 3 mètres de l’endroit où vous avez fait

le plein.

○ Arrêtez le moteur avant de dévisser le bouchon

du réservoir de carburant.

○ Vidangez le réservoir de carburant avant de

remiser la machine. Il est en fait recommandé de

le faire après chaque utilisation. Si le réservoir

n’est pas vide, rangez alors la machine dans une

position telle que le carburant ne risque pas de

couler.

○ Rangez la machine et le carburant dans un

endroit où les vapeurs d’essence ne risquent

pas d’entrer en contact avec des étincelles ou

une fl amme en provenance d’un chauff e-eau,

d’un moteur électrique, d’un commutateur, d’une

chaudière, etc.

une chaîne diff érente de celle

ATTENTION

Le carburant peut s’enfl ammer facilement ou

exploser et l’inhalation de ses vapeurs est

dangereuse. Faites particulièrement attention

lorsque vous manipulez le carburant ou

faites l’appoint du réservoir.

Sécurité au niveau de la coupe

○ N’essayez pas de couper des matériaux autres

que du bois ou des objets en bois.

○ Pour assurer la protection de vos voies

respiratoires, porter un masque de protection

contre les aérosols lorsque vous coupez du bois

qui a été traité avec des insecticides.

○ Éloignez toutes les personnes (enfants, passants,

aides, etc.) et tous les animaux se trouvant dans

la zone dangereuse. Arrêtez immédiatement le

moteur si quelqu’un s’approche de vous.

○ Tenez la machine fermement avec la main droite

sur la poignée postérieure et le gauche sur la

poignée de devant.

○ Tenez vous bien en équilibre sur vos deux

jambes. Ne travaillez jamais en porte-à-faux.

○ Demeurez toujours éloigné du silencieux

d’échappement et de l’ensemble de coupe

lorsque le moteur est en fonctionnement.

○ Maintenir le guide-chaîne en-dessous de la taille.

○ Avant d’abattre un arbre, l’utilisateur devra se

familiariser avec les techniques de coupe et

d’abattage à l’aide d’une tronçonneuse.

○ Avant d’abattre un arbre, assurez-vous de

l’existence d’un abri à proximité.

○ Au cours d’une opération de tronçonnage

maintenez la machine fermement des deux

mains avec le pouce bien bloqué autour de la

poignée avant et les pieds bien stables au sol.

○ Tenez-vous légèrement sur le côté de la

tronçonneuse lorsque vous eff ectuez une coupe

et non pas dans l’axe derrière la machine.

○ Maintenez toujours la griff e d’abattage à la

surface de l’arbre, parce que la chaîne peut

être entraînée soudainement vers l’intérieur de

l’arbre.

○ Lorsque la coupe est terminée, tenez-vous

prêt à tenir fermement l’outil car il se libère

brusquement, pour ne pas en perdre le contrôle

et risquer de vous couper les jambes, les pieds

ou le corps, ni de le toucher.

○ Faites attention aux phénomènes de rebond

(lorsque la scie à chaîne portative avance et

recule par rapport à l’opérateur), et ne coupez

jamais avec l’extrémité du guide-chaîne.

23

Page 24

Français

○ Quand vous déplacez l’appareil d’un lieu à un

autre, vérifi ez que l’appareil est complètement

arrêté et que tous les accessoires de coupe sont

à l’arrêt.

○ Ne placez jamais l’appareil sur le sol en cours de

fonctionnement.

○ Assurez-vous toujours que le moteur est

arrêté et que tous les accessoires de coupe

sont complètement à l’arrêt avant de nettoyer

l’accessoire principal de coupe de tout débris ou

amas d’herbe.

○ Lors de l’utilisation de n’importe quel appareil

électrique/thermique, emportez toujours avec

vous une trousse de premiers soins.

○ Ne démarrez jamais le moteur de l’appareil, ni

n’utilisez jamais l’appareil dans un local clos ou

à l’intérieur d’un bâtiment et/ou à proximité d’un

produit infl ammable. L’inhalation des fumées

d’échappement peut être mortelle.

Sécurité au niveau de l’entretien

○ Entretenez votre machine selon les

recommandations du constructeur.

○ Débranchez la bougie avant toute intervention

d’entretien, à l’exception des opérations de

réglages du carburateur.

○ Ne laissez personne s’approcher lorsque vous

réglez le carburateur.

○ Utilisez uniquement les pièces de rechange

d’origine HITACHI recommandées par le

fabricant.

IMPORTANT

Ne démontez pas le démarreur de recul de

l’appareil. Vous pourriez vous blesser à

cause du ressort de recul.

○ Vidangez le réservoir de carburant avant de

ranger la machine. Il est en fait recommandé de

le faire après chaque utilisation. Si le réservoir

n’est pas vide, rangez alors la machine dans une

position telle que le carburant ne risque pas de

couler.

○ Rangez la machine hors de portée des enfants.

○ Nettoyez et entretenez la machine soigneusement

et rangez-la dans un endroit sec.

○ Assurez vous que le commutateur d’arrêt du

moteur est bien sur la position d’arrêt lors du

transport ou du rangement de la machine.

○ Lors des transports en véhicule ou des

rangements, recouvrez la chaîne de son fourreau

de protection.

Dans l’éventualité de situations qui ne seraient

pas prises en compte par le présent manuel,

redoublez d’attention et de bon sens. Contactez un

concessionnaire HITACHI pour toute assistance.

Faites particulièrement attention aux instructions

introduites par les mots suivants.

ATTENTION

Instructions de première importance pour

éviter des dommages corporels graves ou

mortels.

IMPORTANT

Instructions importantes afi n d’éviter des

dommages corporels ou matériels.

REMARQUE

Informations pratiques pour la compréhension

d’une intervention.

ATTENTION

Un entretien incorrect peut entraîner des

avaries importantes du moteur ou des

blessures graves.

Transport et rangement

○ Portez la machine à la main avec moteur arrêté

et silencieux orienté vers l’extérieur, de l’autre

côté de votre corps.

○ Laissez le moteur refroidir, videz le réservoir

de carburant et veillez à ce que la machine ne

risque pas de tomber lorsque vous la rangez ou

la chargez à bord d’un véhicule.

24

Page 25

SPÉCIFICATIONS

Type d’équipement

Taille du moteur (cu. in.)

Bougie d’allumage

Français

Modèle CS33EB (30P) CS33EB (35P) CS33EB (40P) CS33EB

Tronçonneuse portative

1.96 (32.2 ml)

NGK BPM-6A ou équivalent

Contenance du réservoir de

carburant (Pinte des USA)

Contenance du réservoir

d’huile de chaîne

(Pinte des USA)

Poids à sec (livre)

(Sans le guide-chaîne et la

chaîne)

Longueur du guide-chaîne (in.)

Pas de chaîne (in.)

Calibre de chaîne (in.)

Niveau de pression acoustique

LpA (dB (A))

par ISO 22868

Niveau de puissance sonore

Lw mesuré (dB (A))

par ISO 22868

Niveau de puissance sonore

LwA (dB (A))

par 2000/14/EC

Niveau de vibrations (m/s2)

par ISO 22867

Poignée avant

Poignée arrière

Puissance max. du moteur

selon ISO 7293 (kW)

Régime max. du moteur (min-1)

0.74 (350 ml)

0.53 (250 ml)

8.4 (3.8 kg)

12 (300 mm) 14 (350 mm) 16 (400 mm) —

3/8 (9.52 mm)

0.05 (1.27 mm)

92

110

113

8.5

8.0

9.2

6.7

9.7

6.7

1.2/9,500

12,500

—

—

Régime de ralenti (min-1)

Consommation spécifi que (g/kWh)

Type de chaîne

Vitesse max. de chaîne

(m/sec)

Pignon (nombre de dents)

REMARQUE : Les niveaux de bruit/vibrations équivalents sont calculés comme total d’énergie pondérée

en fonction du temps pour les niveaux de bruit/vibrations dans diverses conditions de travail

avec la répartition temporelle suivante : 1/3 ralenti, 1/3 plein régime, 1/3 vitesse de course.

* Toutes les données sont sujettes à modifi cation sans préavis.

3,100

500

91VG

(Oregon)

23.8

6

25

Page 26

Français

MONTAGE

ATTENTION

N’essayez jamais de mettre le moteur en

marche sans le carter latéral solidement fi xé.

1. Retirez l’écrou de blocage (1) du guide-chaîne.

2. Retirez le carter latéral (2) en maintenant la partie

arrière du carter latéral (2). (Fig. 1)

2

1

Fig. 1

* Si vous devez monter la griff e (3), montez la

griff e (3) (le cas échéant) sur l’appareil à l’aide

des deux vis. (Fig. 2)

3

REMARQUE

Déplacez légèrement le guide-chaîne vers l’avant

et vers l’arrière jusqu’à ce que l’ergot (7) pénètre

correctement dans le trou du guide-chaîne (8).

(Fig. 3)

4. Vérifi ez si la direction de la chaîne est correcte

(9) comme indiqué sur la fi gure et alignez la

chaîne sur le pignon. (Fig. 4)

9

Fig. 4

5. Placez les maillons d’entraînement de la chaîne

dans la rainure tout autour du guide-chaîne.

6. Installez le capot latéral (2) sur les boulons (5).

Puis serrez provisoirement les écrous de serrage

(1). (Fig. 1)

7. Soulevez l’extrémité du guide-chaîne et réglez la

tension de la chaîne (9) en tournant le boulon de

réglage de tension (10) dans le sens des aiguilles

d’une montre. Pour vérifi er que la tension de la

chaîne est adéquate, soulevez légèrement le

centre de la chaîne. Il faut qu’il y ait alors un jeu

de 0.02 – 0.04 ″ (0.5 à 1.0 mm) entre le guidechaîne et le bord des maillons d’entraînement de

la chaîne (11). (Fig. 5, 6)

Fig. 2

3. Installez le guide de chaîne (4) sur les boulons

(5), puis poussez-le au maximum vers le pignon

(6). Assurez-vous que le moyeu du boulon

de réglage de tension de chaîne (7) s’adapte

correctement dans le trou dans le trou du guide

de chaîne (8). (Fig. 3)

6

Fig. 3

26

4

8

5

7

10

0.02 – 0.04 ″

(0.5 – 1 mm)

9

11

Fig. 5

Fig. 6

Page 27

Français

IMPORTANT

UNE TENSION CORRECTE DE LA CHAÎNE

EST EXTRÊMEMENT IMPORTANTE!

8. Soulevez l’extrémité du guide-chaîne et, avec la

clé universelle spéciale, resserrez fermement les

écrous de la bride du guide-chaîne. (Fig. 6)

9. Une chaîne neuve peut s’allonger. Pour cette

raison, il convient d’ajuster la tension après

quelques coupes et d’observer attentivement

et régulièrement sa tension durant la première

demi-heure d’utilisation.

REMARQUE

Vérifi ez régulièrement la tension de la chaîne

afi n de conserver à la tronçonneuse des

performances optimales et durables.

IMPORTANT

● Lorsque la chaîne est trop tendue, le guidechaîne ainsi que la chaîne risquent d’être

endommagés rapidement. Inversement,

lorsque la chaîne est trop détendue, elle

risque de sortir de la rainure du guidechaîne.

● Mettez toujours des gants lorsque vous

manipulez la chaîne.

ATTENTION

Durant l’utilisation de la tronçonneuse,

tenez-la fermement à l’aide des deux mains.

L’utilisation de la machine avec une seule

main peut entraîner des blessures graves.

UTILISATION

Carburant (Fig. 7)

● Le carburant contient des substances

hautement infl ammables. Vous risquez des

blessures sévères en cas d’inhalation de

vapeurs ou

du produit sur votre corps. Faites toujours

très attention lorsque vous manipulez le

carburant. Si vous prévoyez de manipuler le

carburant en intérieur, faites-le dans un local

bien ventilé.

Essence

○ Utilisez toujours de l’essence sans plomb avec

un taux d’octane de 89.

○ Utilisez une huile pour moteur à deux temps

ou un mélange variant de 25:1 à 50:1; veuillez

consulter le réservoir d’huile pour la proportion

du mélange ou contacter un concessionnaire

HITACHI.

○ Et une proportion 50:1 pour l’Etat de la Californie

uniquement.

○ Si vous n’utilisez pas une huile d’origine, utilisez

une huile de qualité contenant un antioxydant

recommandé pour être utilisé avec un moteur

à deux temps refroidi à l’air (HUILE JASO

QUALITÉ FC OU ISO QUALITÉ EGC). N’utilisez

jamais des huiles mélangées BIA ou TCW (pour

les moteurs à essence 2 temps à refroidissement

par eau).

○ N’utilisez jamais d’huile Multigrade (10 W/30), ni

d’huile usagée.

○ Eff ectuez toujours le mélange dans un récipient

propre.

Commencez toujours par verser la moitié de

l’essence à mélanger.

Versez ensuite la totalité de l’huile. Mélangez en

agitant le récipient. Ajoutez le reste de l’essence.

Puis agitez le récipient afi n de mélanger

soigneusement le carburant avant de faire le plein.

de renversement accidentel

Fig. 7

ATTENTION

● La tronçonneuse est équipée d’un moteur

à deux temps qui doit impérativement

être alimenté avec un mélange essence/

huile. Veillez à une bonne aération pendant

l’opération de remplissage du réservoir.

Faire le plein

ATTENTION (Fig. 8)

● Ne faites jamais le plein lorsque le moteur

est en fonctionnement.

● Desserrez lentement le bouchon du

réservoir de carburant (12) pour eff ectuer

le remplissage afi n de laisser échapper une

surpression éventuelle.

● Serrez le bouchon soigneusement après

avoir rempli le réservoir de carburant.

● Avant

de redémarrer le moteur, éloignezvous toujours d’au moins 10 pieds (3 m)

de l’endroit ou vous avez fait le plein de

carburant.

27

Page 28

Français

● En cas de renversement accidentel de

carburant sur vos vêtements, lavez-les

immédiatement avec du savon.

● Après chaque appoint de carburant, vérifi ez

toujours qu’il n’y a pas de fuite.

13

Fig. 8

Pendant le remplissage, nettoyez la zone du

bouchon pour être sûr qu’aucune saleté ne tombe

dans le réservoir. Veillez à ce que le mélange soit

bien homogène en agitant à intervalle régulier le

récipient avant et pendant le remplissage.

Huile de chaîne (Fig. 8)

Remplissez le réservoir (13) avec de l’huile de

chaîne. Utilisez toujours de l’huile de chaîne

de bonne qualité. Lorsque le moteur est en

fonctionnement l’huile de chaîne est distribuée

automatiquement.

REMARQUE

Lors du remplissage des réservoirs soit avec du

carburant (12), soit. avec de l’huile de chaîne

(13), placez la machine sur le côté avec le

bouchon orienté vers le haut. (Fig. 8)

Démarrage (Fig. 9, 10)

IMPORTANT

Avant le démarrage, vérifi ez que le frein de la

chaîne est bien désengagé (si la machine en

est équipée) et que le guide/chaîne n’est en

contact avec aucun objet.

12

14

Fig. 9

2. Tirez le levier d’étranglement (15) à fond vers

le bas. Cette opération permettra de verrouiller

automatiquement le papillon du carburateur dans

la position de démarrage. (Fig. 9)

15

Fig. 10

3. Tirez vivement sur la poignée du lanceur à

retour automatique en faisant attention de ne

pas relâcher la poignée brusquement mais

d’accompagner son retour. (Fig. 9)

4. Quand vous entendez le premier allumage,

ramenez le levier d’étrangement en position de

fonctionnement. (Fig. 10)

5. Tirez de nouveau vivement sur la poignée du

lanceur à retour automatique de la manière

indiquée précédemment. (Fig. 11)

Après le démarrage du moteur, vérifi ez que le

frein de la chaîne est désenclenché.

1. Placez le commutateur de marche/arrêt (14) en

position “marche” (ON). (Fig. 9)

28

Fig. 11

Page 29

Français

REMARQUE

Si le moteur ne démarre pas, répétez la

procédure décrite entre les points 2 et 5.

6. Après avoir démarré le monteur, laissez le

moteur chauff er pendant 2 à 3 minutes avant de

le soumettre à une charge quelconque.

Fonctionnement du frein de chaîne (Fig. 12)

Le frein de chaîne (16) (si la machine en est munie)

a été conçu pour entrer en action en cas d’urgence

tel que lors d’un mouvement de rebond. Vérifi ez

s’il fonctionne correctement avant d’utiliser la

tronçonneuse.

Le frein est actionné en déplaçant la protection

de la poignée avant vers le guide-chaîne. Durant

le fonctionnement du frein de chaîne, même si

la commande des gaz est pressée, le régime du

moteur n’augmente pas et la chaîne ne tourne pas.

Pour dégager le frein de chaîne, tirez d’un coup sec

la protection de la poignée avant vers l’arrière.

16

Fig. 12

Lorsque le frein est appliqué accidentellement

pendant le fonctionnement, dégagez le doigt du

papillon immédiatement pour arrêter le moteur.

ATTENTION

Ne transportez pas la machine avec le

moteur en fonctionnement.

Arrêt de la tronçonneuse (Fig. 13)

Réduisez la vitesse et placez le commutateur d’arrêt

(14) sur la position “Stop”.

14

Fig. 13

ATTENTION

DANGER DE REBOND (Fig. 14)

17

Méthode de vérifi cation:

1) Arrêtez le moteur.

2) En maintenant la tronçonneuse horizontalement

avec les deux mains, enlevez la main de la

manette avant et appliquez l’extrémité de la

barre de guidage à une souche pour vérifi er

le bon fonctionnement du frein. Le niveau de

fonctionnement varie en fonction de la taille du

guide de chaîne.

Lorsque le frein fonctionne mal, adressez-vous

à votre concessionnaire pour le faire réparer. Si

vous laissez tourner le moteur à grande vitesse en

appliquant le frein, l’embrayage chauff e et cela peut

entraîner des causes de pannes.

Fig. 14

L’un des plus grands dangers qui guette l’utilisateur

d’une tronçonneuse est le risque d’un rebond

ou d’un brusque mouvement de la machine vers

l’arrière. Les rebonds peuvent survenir lorsque

l’extrémité supérieure du nez du guide-chaîne entre

en contact avec un objet ou lorsque le bois coince

la chaîne durant la coupe. Les contacts avec le nez

du guide-chaîne peuvent provoquer dans certains

cas une rapide réaction inverse, poussant le guidechaîne du haut en bas vers vous. Bloquer la chaîne

de la tronçonneuse du côté supérieur du guidechaîne risque également de pousser soudainement

le guide-chaîne vers vous. Chacune de ces

réactions soudaines peuvent provoquer la perte de

contrôle de la machine par l’utilisateur et provoquer

de graves blessures. Bien que votre tronçonneuse

ait été mise au point en tenant compte de la sécurité

de l’utilisateur vous ne pouvez compter uniquement

sur ces dispositifs de sécurité pour assurer une

utilisation parfaitement sûre. Contrôlez à tout

29

Page 30

Français

moment la position du nez du guide-chaîne. Le

rebond se produira si vous laissez la zone de rebond

(17) du guide-chaîne entrer en contact avec un objet.

En conséquence prenez garde de ne pas utiliser

cette zone. Le rebond provoqué par un pincement

ou un blocage est causé par une coupe se refermant

et coinçant la partie supérieure du guide-chaîne.

Étudiez soigneusement votre coupe et assurez vous

que la fente de coupe s’ouvrira au fur et à mesure de

l’avancement de la coupe. Conserver le contrôle de

la machine lorsque le moteur est en fonctionnement

en la maintenant toujours fermement avec votre

main droite tenant la poignée arrière, votre main

gauche placée sur la poignée avant vos pouces

et vos doigts passés autour des poignées. Tenez

toujours la tronçonneuse des deux mains durant les

opérations de coupe à haut régime du moteur.

ATTENTION

● Ne visez pas trop haut ou ni n’exécutez une

coupe située au-dessus du niveau de votre

épaule.

● Il convient d’être extrêmement prudent

lors de l’abattage et de ne jamais utiliser sa

tronçonneuse avec le nez du guide-chaîne en

l’air ou au-dessus du niveau de son épaule.

CAPTEUR DE CHAÎNE

Le capteur de chaîne est située sur le bloc moteur

au-dessous près de la chaîne pour empêcher

l’éventualité qu’une chaîne rompue puisse venir

frapper l’utilisateur de la tronçonneuse.

ATTENTION

Ne vous mettez pas debout dans l’alignement

de la chaîne lors de la coupe.

TECHNIQUES DE BASE POUR L’ABATTAGE,

L’ÉBRANCHAGE ET LE TRONÇONNAGE

Le but visé par les informations suivantes est de

fournir à l’utilisateur une introduction de caractère

général aux techniques d’abattage des arbres.

ATTENTION

● Les informations données ci-dessous

ne couvrent pas toutes les situations

spécifi ques qui dépendent des conditions de

relief, de végétation, du type de bois, de la

forme et de la taille des arbres, etc. Veuillez

consulter l’agent assurant l’entretien de

votre machine, les agents forestiers ou les

écoles forestières locales pour obtenir des

conseils sur les problèmes spécifi ques

d’abattage pouvant exister dans votre

30

région. Cela permettra de rendre votre travail

plus effi cace et plus sûr.

● Évitez d’utiliser votre tronçonneuse lors de

mauvaises conditions météorologiques, par

exemple dans un brouillard épais, par forte

pluie, par vent violent, etc.

Ces mauvaises conditions météorologiques

rendent le travail beaucoup plus fatiguant

et créent des situations potentiellement

dangereuses comme un sol glissant par

exemple.

Par ailleurs un vent violent risque de forcer

l’arbre à s’abattre dans une direction

imprévue pouvant entraîner des dégâts

matériels ou des blessures corporelles.

IMPORTANT

N’utilisez jamais votre tronçonneuse comme

levier ou comme pied de biche, ou pour tout

autre emploi pour lequel elle n’a pas été

conçue.

ATTENTION