Page 1

YK

No.0520E

CP-X430W

SERVICE MANUAL

Caution

Be sure to read this manual before servicing. To assure safety from re, electric shock, injury, harmful

radiation and materials, various measures are provided in this HITACHI Multimedia LCD Projector. Be sure to

read cautionary items described in the manual to maintain safety before servicing.

Service Warning

(C7X)

1. When replace the lamp, to avoid burns to your ngers. The lamp becomes too hot.

2. Never touch the lamp bulb with a nger or anything else. Never drop it or give it a shock. They may cause

bursting of the bulb.

3. This projector is provided with a high voltage circuit for the lamp. Do not touch the electric parts of power

unit (main), when turn on the projector.

4. Do not touch the exhaust fan, during operation.

5. The LCD module assembly is likely to be damaged. If replacing to the LCD module assembly, do not hold

the FPC of the LCD module assembly.

6. Use the cables which are included with the projector or specied.

Contents

1. Features --------------------------------------------------- 2

2. Specications--------------------------------------------- 2

3. Names of each part ------------------------------------- 3

4. Adjustment ------------------------------------------------ 5

5. Troubleshooting ---------------------------------------- 11

6. Service points ------------------------------------------ 16

7. Block diagram ------------------------------------------ 23

8. Connector connection diagram -------------------- 24

9. Wiring diagram ----------------------------------------- 25

10.Basic circuit diagram---------------------------------- 30

11.Disassembly diagram--------------------------------- 63

12.Replacement parts list ------------------------------- 65

13.RS-232C communication ---------------------------- 66

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT.

Multimedia LCD Projector

February 2002 Digital Media Systems Division

Page 2

CP-X430W

Liquid crystal

panel

Lamp

RGB

signal

input

Video

signal

input

Signal

output

Drive system

Panel size

Number of pixels

RGB IN

Digital input

Signal

System

System

AUDIO IN

AUDIO IN

VIDEO IN

RGB OUT

AUDIO OUT

S-VIDEO IN

COMPONENT

VIDEO

Audio input

Speaker output

Power supply

Power consumption

Dimensions

Weight

Temperature range

Accessories

TFT active matrix

0.9 inches

1024 (H) × 768 (V)

250W UHB

Video: Analog 0.7Vp-p, 75 terminator

H/V. sync.: TTL level (positive/negative)

Composite sync.: TTL level

D-sub 15-pin shrink jack

Type: T.M.D.S

Amplitude differential signal: DC: 150~1200mV AC: 1.56Vp-p

Amplitude signal: TTL level ("L" : less than 0.8V, "H" : more than 2.0V)

Video: Analog 0.7Vp-p, 75 output impedance (positive)

H/V. sync.: TTL level (positive/negative)

Composite sync.: TTL level

D-sub 15-pin shrink jack

Brightness signal: 1.0Vp-p, 75 terminator

Color signal: 0.286Vp-p (NTSC, burst signal), 75 terminator

0.3Vp-p (PAL/SECAM, burst signal), 75 terminator

Mini DIN 4-pin jack

200mVrms, 47k (max. 3.0Vp-p)

Stereo mini jack

NTSC, NTSC4.43, PAL (BGDHI), SECAM, PAL-M, PAL-N, PAL60

200mVrms, 50k (max. 3.0Vp-p)

RCA jack

1.0Vp-p, 75 terminator

RCA jack

1.0Vp-p, 75 terminator (positive)

0.7Vp-p, 75 terminator (positive)

0.7Vp-p, 75 terminator (positive)

200mVrms, 47k

1W +1W (stereo)

AC100~120V/4.5A, AC220~240V/1.9A

410W

360 (W) × 112.5 (H) × 266 (D) mm

4.5kg (9.92lbs)

Operation : 0~35°C

Storage : -20~60°C

Remote control transmitter × 1

RGB cable × 1

Component cable × 1

Mouse cable (PS/2) × 1

POWER cord × 3

200mVrms, output impedance 1k (max. 3.0Vp-p)

Stereo mini jack

Battery × 2

Carrying bag × 1

Lens cap (set wearing) × 1

User's manual (with Safety Instructions)× 1

1

2

1

2

Y

L

R

CB/CR

PB/PR

480i, 480p, 575i, 720p, 1080i

1. Features

High brightness, High resolution

Compact size, light weight for portability

RS-232C Communication

Auto-adjustment function

2. Specifications

2

Vertical / Horizontal keystone function

P. in P. function

My screen function (User start up screen)

Page 3

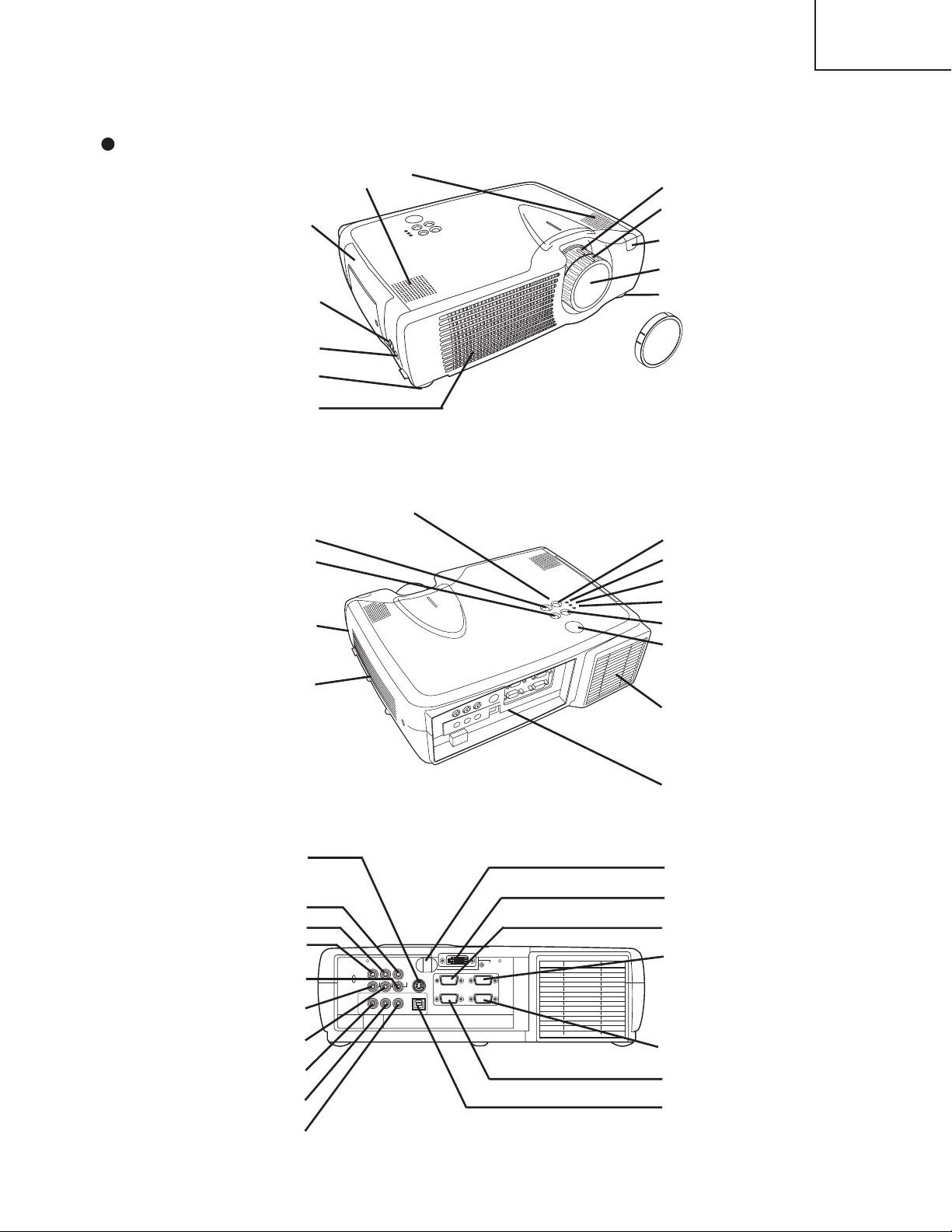

3. Names of each part

Control Panel

AC Inlet

(to the Power Cord)

Power Switch

Foot Adjuster

Ventilation Openings

(Intake)

Zoom Knob

Focus Ring

Remote Control Sensor

Lens

Foot Adjuster

FRONT/LEFT VIEW OF

THE PROJECTOR

Speaker

Carrying Handle

STANDBY/ON Button

KEYSTONE Button

Foot Adjuster Button

Filter Cover

Air Filter and Intake

for the Cooling Fan

INPUT Button

LAMP Indicator

TEMP Indicator

POWER Indicator

RESET Button

MENU Button

Ventilation Openings

(exhaust)

REAR/RIGHT VIEW OF

THE PROJECTOR

Terminal Panel

(Refer below)

TERMINAL PANEL

S-VIDEO Terminal

COMPONENT VIDEO

Y Terminal

C

B/PB Terminal

C

R/PR Terminal

VIDEO IN Terminal

AUDIO IN R

Terminal

AUDIO IN L

Terminal

AUDIO IN 1

Terminal

AUDIO IN 2

Terminal

AUDIO OUT

Terminal

Remote Control Sensor

DVI Terminal

RGB IN 1 Terminal

RGB IN 2 Terminal

CONTROL Terminal

RGB OUT Terminal

USB Terminal

AUDIO

IN

AUDIO

IN

CR/P

R

COMPONENTVIDEO

RGBIN

RGBOUT CONTROL

12

DVI

CB/P

B

Y

R

AUDIOOUT USB1 2

L

VIDEOIN

S-VIDEOIN

( )

Lens Cap

Parts names

CP-X430W

3

Page 4

CP-X430W

S

T

A

N

D

B

Y

/O

N

LASER

BLANK

RGB

VIDEO

AUTO

MENU

MENU SELECT

KEYSTONE

R

ESET

FREE

ZE

PinP

MAGNIFY

POSITION

OFF

VOLUME

MUTE

REMOTE CONTROL

TRANSMITTER

• Keep the remote control transmitter away from children and pets.

• Do not give the remote control transmitter any physical impact. Take care not to drop.

• Do not place the heavy objects on the remote control transmitter.

• Do not wet the remote control transmitter or place it on any wet object.

• Do not place the remote control transmitter close to the cooling fan of the projector.

• Do not disassemble the remote control transmitter.

NOTE

STANDBY/ON Button

LASER Button

VIDEO Button

Disk Pad

Used to operate the

mouse shift function and

left click function.

AUTO Button

MENU Button

MENU SELECT Button

Used to click the left

mouse button.

, , , Button

Used to operate the

mouse shift function.

MAGNIFY Button

BLANK Button

RGB Button

MOUSE / RIGHT Button

Used to click the right

mouse button.

RESET Button

Used to click the right

mouse button.

FREEZE Button

MUTE Button

PinP Button

KEYSTONE Button

VOLUME Button

These functions works when the mouse control function is activated. Remember, the POSITION,

BLANK ON and MENU ON functions disable the mouse control function.

WARNING • The laser pointer of the remote control transmitter is used in

place of a finger or rod. Never look directly into the laser beam outlet or point

the laser beam at other people. The laser beam can cause vision problems.

CAUTION

• Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

POSITION Button

Complies with 21 CFR 1040. 10 and 1040. 11 except for deviations

pursuant to Laser Notice No.50, dated 2001.7.26

SMK CORPORATION

6-5-5 Togoshi Shinagawa-ku, Tokyo, JAPAN 142-8511

MANUFACTURED

Novemver 2001

PLACE OF MANUFACTURER: A

CAUTION

LASER RADIATIONDO NOT STARE INTO BEAM

MAX. OUTPUT: 1mW

WAVE LENGTH

: 650nm

CLASS2 LASER PRODUCT

LASER RADIATION

IEC60825-1 :1993+A1:1997

MAX. OUTPUT: 1mW

WAVE LENGTH: 650nm

DO NOT STARE INTO BEAM

CLASS2 LASER PRODUCT

AVOID EXPOSURE-

LASER RADIATIONS IS

EMITTED FROM THIS

APERTURE

Remote control transmitter

4

Page 5

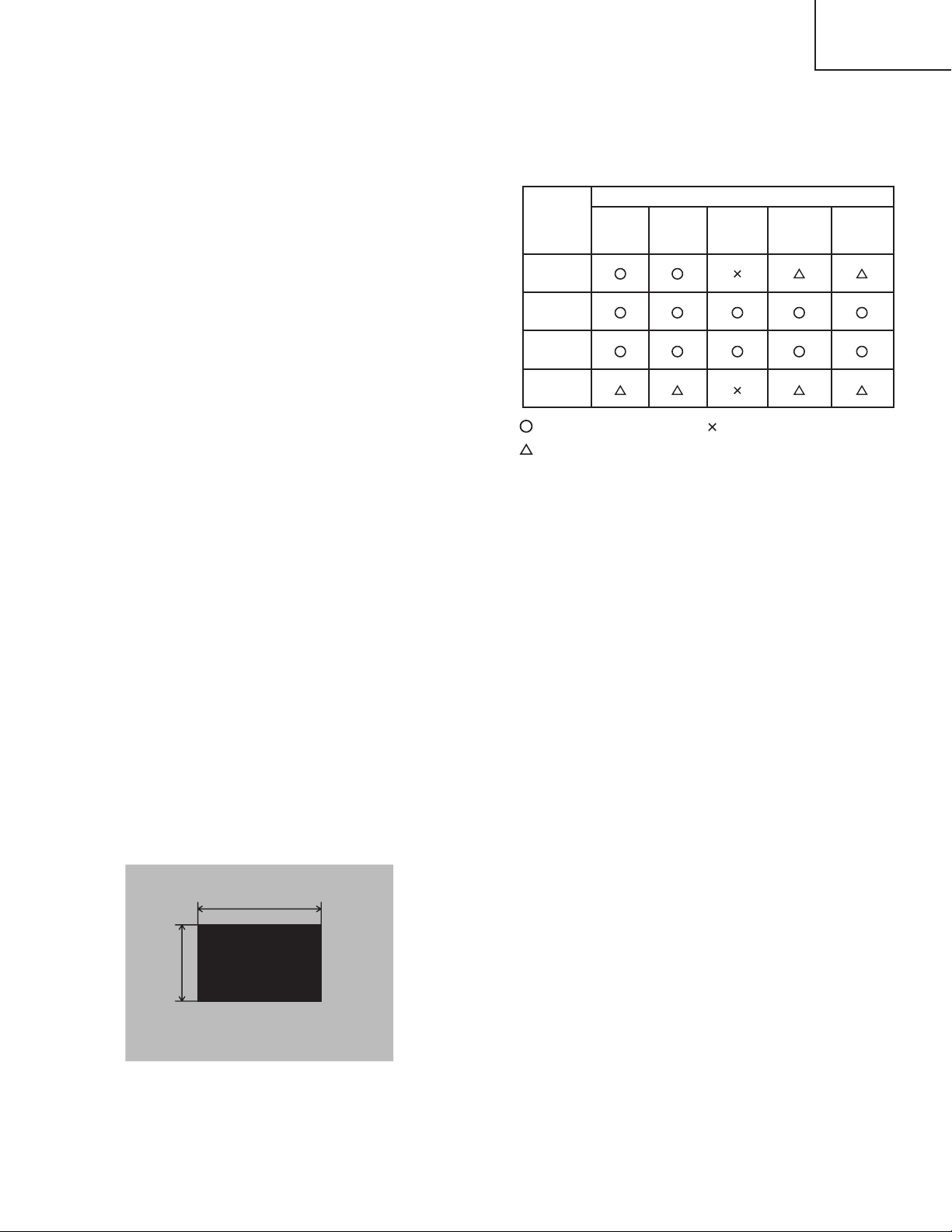

4. Adjustment

Replaced

part

Ghost

(Chap.4-2)

Flicker

(Chap.4-3)

PSIG

(Chap.4-4)

White

balance

(Chap.4-5)

Color

uniformity

(Chap.4-6)

Dichroic

optics unit

LCD/LENS

prism

assembly

PWB

assembly

drive

Lamp

unit

assembly

Adjustment

30%

30%

112/255

0/255

4-1 Before adjusting

4-4-1 Selection of adjustment

When any parts in the table 4-1 are changed, choose

the proffer adjusting items with the chart.

4-4-2 Setting of condition before adjustment

1. Before starting adjustment, warm up the projector

for about 10 minutes.(Blank white)

2. Set Zoom Wide to Max. And project an image a

distance of more than 40 inches.

3. Normalizing the video adjustment.

(Press the [MENU] button of the Remote control

transmitter to display the Setup menu, and then press

the [RESET] button. And select the [DEFAULT].)

*note : The setup menu is not displayed on with no

signal.

CP-X430W

Table 4-1: Relation between the replaced part and adjustment

:

means need for adjustment.

:

means recommended.

4. Perform all adjustments from the Adjustment menu.

Perform the following operations to display the

Adjustment menu.

a. Press the [MENU] button of the Remote control

transmitter (the Setup menu will appear).

b. Next, press the [RESET] button one time. And

press the [RESET] button again for 5 seconds

or more (the Adjustment menu will appear).

5. Set the normal at OPT-WHISPER in the menu.

6. Set the normal at IMAGE-GAMMA in the menu.

:

means not need for adjustment.

4-2 Ghost adjustment

Signals for internal adjustment

Adjustment procedure

1. Use DAC-P - GHOST - R: in the Adjustment menu

to adjust so that R color ghost is at a minimum.

(Set the adjustment value to default, and then raise

the value. When a light ghost appears to the left of

a vertical line, reduce the value by 2 steps. When a

dark ghost appears to the left of a vertical line,

reduce the value by 3 steps.)

2. In the same way, use DAC-P - GHOST-G: in the

Adjustment menu to adjust so that G color ghost is

at a minimum.

3. In the same way, use DAC-P - GHOST-B: in the

Adjustment menu to adjust so that B color ghost is

at a minimum.

5

Page 6

CP-X430W

30%

30%

112/255

0/255

4-3 Flicker adjustment

Signals for internal adjustment

4-4 P

SIG adjustment (vertical stripe adjustment)

Signals for internal adjustment

(V.COM adjustment)

Adjustment procedure

1. Ma ke th i s a d ju st m en t a f te r c o mp l et in g t h e

adjustment in 4-2 Ghost adjustment.

2. Use DAC-P - V.COM - R: in the Adjustment menu

to adjust so that the flicker at the center of the

screen is less than the flicker at the periphery.

(When the flicker is about the same across the

whole screen, adjust so that the flicker at the

ce n t er o f t h e s c r een i s s o mewhat less than

elsewhere.)

3. In the same way, use DAC-P - V.COM-G: in the

Adjustment menu to adjust the G color flicker.

4. In the same way, use DAC-P - V.COM-B: in the

Adjustment menu to adjust the B color flicker.

Adjustment procedure

1. Ma ke th i s a d ju st m en t a f te r c o mp l et in g t h e

adjustment in 4-3 Flicker adjustment.

2. Use DAC-P - PSIG - G: in the Adjustment menu to

adjust so that the vertical lines spaced every 12

dots are as inconspicuous as possible.

3. Next, use DAC-P - PSIG - B: in the Adjustment

menu to adjust so that the vertical streaks on the

upper of window pattern.

6

Page 7

4-5

White balance adjustment (visual inspection)

Preparations

1. Pe rfor m th es e a dj u st me nt s a ft e r t he P S IG

adjustment described in Section 4-4.

Adjustment procedure

1. First, adjust the G color.

2. Select GAMMA, SUB-CONTRAST, and G: in the

Adjust menu. If the background is white solid,

press the [MENU SELECT] key on the Remote

control transmitter to change to [G] monochrome in

the 28-tone grayscale.

3. Adjust GAMMA, SUB-CONTRAST, and G: in the

Adjust menu so that brightness of 28 steps is best.

4. Don’t adjust GAMMA, SUB-BRIGHT, and G: in the

Adjust menu. Because we want to keep the best

contrast ratio.

5. Then adjust colors R and B.

CP-X430W

2. Reset gamma correction before adjustment.

Place the cursor on [GAMMA] in the Adjustment

menu, pre s s t h e [ RE S ET ] key and se l ec t

[DEFAULT].

6. Select GAMMA, SUB-CONTRAST, and G: in the

Adjust menu. If the background is white solid,

press the [MENU SELECT] key on the Remote

control trasmitter to change to [W] monochrome in

the 28-tone grayscale.

7. Adjust GAMMA, SUB-BRIGHT, R: and B: in the

Adjust menu so that low-brigtness white balance is

best.

8. Adjust GAMMA, SUB-CONTRAST, R: and B: in the

Adjust menu so th at middle-b r ightne ss white

balance is best.

9. Repeat steps 7 to 8 above, and adjust so that

brightness white balance of 28 steps is best.

7

Page 8

CP-X430W

VID-AD

ON

DAC-P GAMMAC. UNIF.

No. 1

R 0

LEVEL

BLACK

MIN MID-L MID-H MAX

STRIPE

OFF

G 0

B 0

Major adjustment lattice point No.

14

12

13

16

15 17

6

4

8

2

1

3

7

5

9

10

11

V/6

H/6 H/3 H/3 H/6

V/3

V/3

V/6

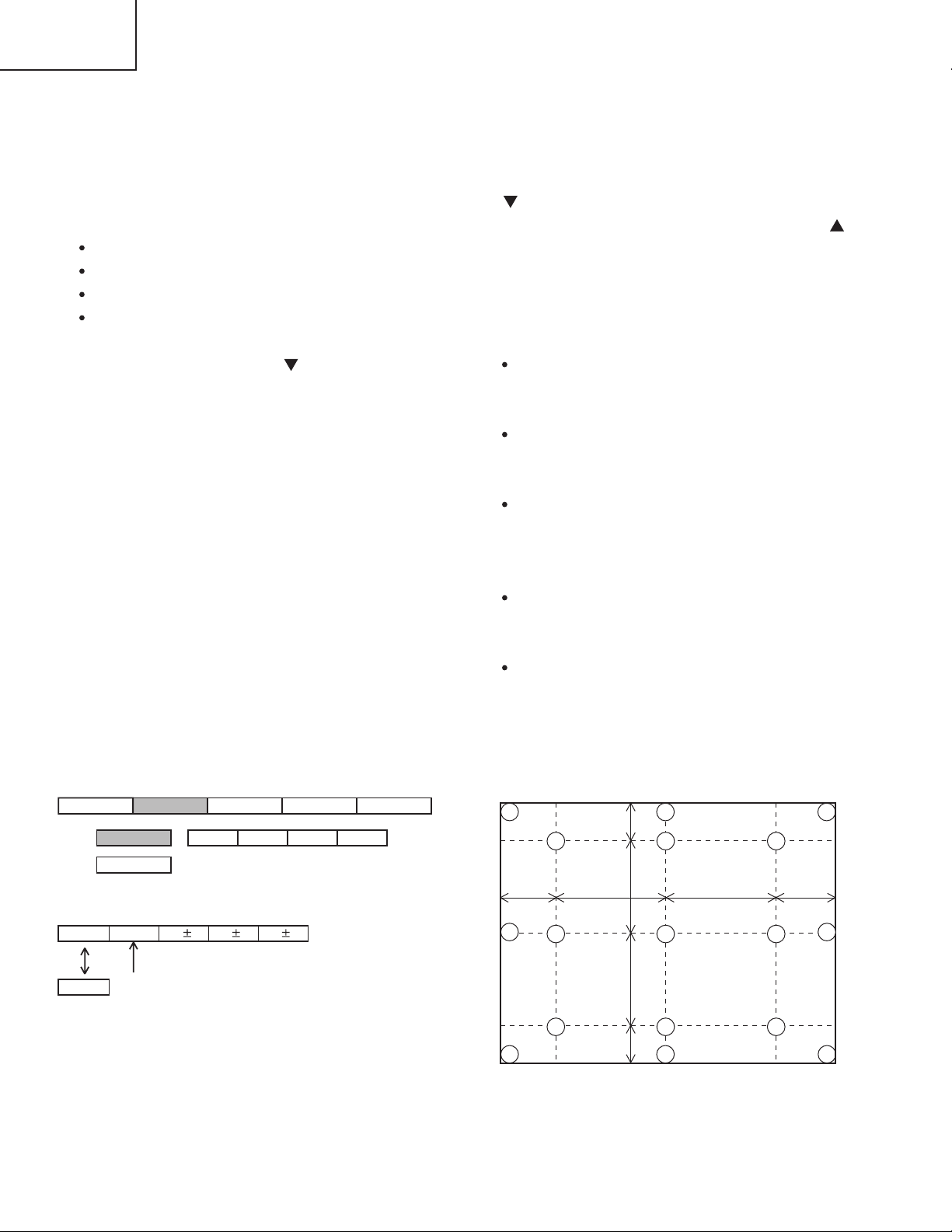

4-6 Color uniformity adjustment

Preparations

1. Perform these adjustments after the white balance

adjustment described in Section 4-5.

2. Make a col o r uniformi t y adjustm e n t fo r the

following four tones.

MIN tone (approx. 10% input signal)

MID-L tone (approx. 21% input signal)

MID-H tone (approx. 50% input signal)

MAX tone (approx. 75% input signal)

3. Place the cursor on the tone to be adjusted in the

Adjust menu and press the [ ] key. This displays

the Adjust Tone menu at the bottom of the screen.

Select the major adjustment lattice point No. and

color, and then adjust them.

4. The major adjustment lattice point numbers (a total

of 17 points) corresponds to the major adjustment

lattice point positions in the diagram on the right.

The color uniformity of the entire screen can be

adjusted by adjusting the white balance for each of

the points starting in order from the low numbers.

5. Adjustment point No.1 should not be adjusted,

because it controls the brightness of the entire

screen.

6. To temporarily turn correction off, place the cursor

on “ON” in the Adjust Tone menu and press the

[ ] key. To turn it on again, place the cursor on

OFF in the Adjust Tone menu and press the [ ]

key.

7. Although this adjustment can also be made using

interna l signals, we will here use the [MENU

SELECT] key on the Remote control transmitter to

select the following two signals.

Solid monochrome adjustment color (use G color

adjustment when a color differential meter is

used).

Soli d white (use for adj ustment oth er than

above).

8. Reset color-shading correction before adjustment.

When 4 tones and all colors are to be reset,

place the cursor on [C.UNIF.] in the Adjustment

menu, pr e s s the [RESET] key and se l ect

[DEFAULT].

When only 1 tone is to be reset, place the cursor

on the tone to be reset, press the [RESET] key

and select [DEFAULT].

Single tone and monochrome resets cannot be

performed.

Adjust menu

Adjust Tone menu

8

Major adjustment lattice point position

Page 9

Adjustment procedure 1

(when a color differential meter is used)

1. First adjust [MID-L] tone [G:].

2. Select adjustment point [No.2][G:].

When the background is not [G] monochrome,

press the [MENU SELECT] key on the Remote

con t rol t ra ns mitt e r to c hang e to s ol id [ G ]

monochrome.

3. Measure the illumination at adjustment points No.

2, No.3, No.10 and No.11.

The values should be:

No.2 = Y2 [lx] No.10 = Y10 [lx]

No.3 = Y3 [lx] No.11 = Y11 [lx]

4. No.2 and No.3 adjustment point have the average

of Y2 and Y3.

Y2 = ( Y2 + Y3 ) / 2 ± 2 [%]

Y3 = ( Y2 + Y3 ) / 2 ± 2 [%]

5. No.10 and No.1 1 adjustment point have the

average of Y10 and Y11.

Y10 = ( Y10 + Y11 ) / 2 ± 2 [%]

Y11 = ( Y10 + Y11 ) / 2 ± 2 [%]

6. Then adjust [MID-L] tone [R] and [B].

When the background is [G] monochrome, press

the [MENU SELECT] key on the Remote control

transmitter to change to solid white.

7. Measure the color coordinates of adjustment point

[No.1] and make a note of them.

Assume that they are x = x1, y = y1.

Note: When the CL-100 color and color difference

meter is us e d , the [ ](delta ) mo d e is

convenient. When adjustment point [No.1]

color coordinate has been selected, set the

slide switch on the side to [ ](delta) while

holding down the [F] button on the front

panel. The measurement shown after this

displays the deviation from measurement

point 1.

8. Measure the color coordinates of measurement

point [No.2] and adjust [No.2][R:] and [B:] so that

the coordinates are as follows.

x = x1 ± 0.005 , y = y1 ± 0.010

CP-X430W

9. Similarly, measure adjustment points [No.3] to

[No.17] and adjust their color coordinates starting

in order from the small number points.

This completes adjustments required for [MIN].

Note: Since excessive correction may lead to a

correction data overview dur ing internal

calculations, use the following values for

reference.

[No.2] to [No.5] ± 40 or less

[No.6] to [No.9] ± 50 or less

[No.10] to [No.13] ± 70 or less

[No.14] to [No.17] ± 120 or less

10. Then adjust [MIN] tone [G] so that the adjustment

data set three times as much as [MID-L] tone [G].

This completes [G] color adjustments.

11. Then adjust [MIN] tone [R] and [B].

Select [No.2] [B:] and press the [MENU SELECT]

key on the Remote control transmitter to change to

solid white.

12. Measure the color coordinates of adjustment point

[No.1] and make a note of them.

Assume that they are x = x1, y = y1.

13. N o w m ea s u r e th e c ol or co o r di na te s o f

measurement point [No.2] and adjust [No.2][R:]

and [B:] so that the coordinates are as follows.

x = x1 ± 0.005 , y = y1 ± 0.010 (Target)

x = x1 ± 0.020 , y = y1 ± 0.040

14. Similarly, measure adjustment points [No.3] to

[No.17] and adjust their color coordinates starting

in order from the small number points.

This completes [MIN] tone adjustments.

15. Now make similar adjustments for [MID-H] tone.

(Adjust [MID-H] tone [G] so that the adjustment

data set half as many as [MID-L] tone [G].)

16. Now make similar adjustments for [MAX] tone.

(Adjust [MAX] tone [G] so that the adjustment data

set half as many as [MID-L] tone [G].)

9

Page 10

CP-X430W

8

3

16

17

9

11

6

14

2

12

15

13

10

7

4

1

5

8

3

16

17

9

11

14

12

15

13

10

4

1

5

6

2

7

8

3

16

17

9

11

6

2

12

13

14

15

10

7

4

1

5

14

12

15

13

10

4

1

5

6

2

7

8

3

16

17

9

11

17

9

15

13

7

5

3

17

9

11

15

13

10

1

5

6

2

7

8

16

17

9

6

12

13

7

4

5

14

12

10

4

1

6

2

8

3

16

17

9

11

3

11

2101

16

14

12

8

6

4

8

4

16

14

12

3

11

2

14

15

10

1

5

7

15 13

17

9

15

13

7

5

3

17

9

11

6

17

9

6

13

7

5

14

12

10

4

6

2

8

16

3

11

2101

16

14

12

8

6

4

8

4

16

14

12

3

11

2

14

15

10

5

7

15

1012

13

15

5

7

12

418

17

13

1

3

11

16

95

17

9

15

13

7

5

3

17

9

11

6

17

9

6

13

7

5

14

12

10

4

6

2

8

16

3

11

2

1

16

14

12

8

4

8

4

16

14

12

3

2

14

15

10

5

7

15

1012

13

5

7

12

4

1

17

13

1

3511

9

11

8

16

15

10

6

Adjustment procedure 2

(visual inspection)

1. First adjust [MIN] tone [G:].

2. Select [No.2] [G:].

If the background is [G] monochrome, press the

[MENU SEL ECT] key on the Rem ote con trol

transmitter to change to solid white.

3. View measurement point [No.2] and [No.3].

Lower the [G] color intensity only of the color point

whose [G] color is more intense than measurement

point [No.1].

4. View measurement point [No.10] and [No.11].

Lower the [G] color intensity only of the color point

whose [G] color is more intense than measurement

point [No.1], and raise the intensity of the point

whose color intensity is lower than measurement

point [No.1].

5. Now adjust the [MIN] tone for colors [R] and [B].

6. View measurement points [No.2], [No.3], [No.10]

an d [No.1 1 ] . Adjust the [ R ] and [ B ] of e ach

measurement point so that they have the same

color as measurement point [No.1].

Adjustment technique:

First, adjust [B:] of the point whose color is to be

adjusted so that it approximates that of [No.1]. If

[R:] is low at this time, the image will have cyan

cast, in which case [R:] is increased. On the other

hand, if [R:] is excessive, the image will have a

magenta cast, in which case [R:] is decreased.

Overall, a cyan cast makes it easy to see color shading.

7. Next, view measurement points [No.4], [No.5],

[No.12], [No.13] and make similar adjustments.

8.

Then adjust measurement points [No.6], [No.7], [No.8],

[No.9], [No.14], [No.15], [No.16] and [No.17].

This completes the [MIN] tone adjustments.

9. Make similar another three tones as described in

steps 1 to 8 above.

No. 2 deviation range No. 10 deviation range No. 3 deviation range No. 11 deviation range

No. 4 deviation range No. 12 deviation range No. 5 deviation range No. 13 deviation range

No. 6 deviation range No. 7 deviation range No. 8 deviation range No. 9 deviation range

No. 14 deviation range No. 15 deviation range No. 16 deviation range No. 17 deviation range

10

Page 11

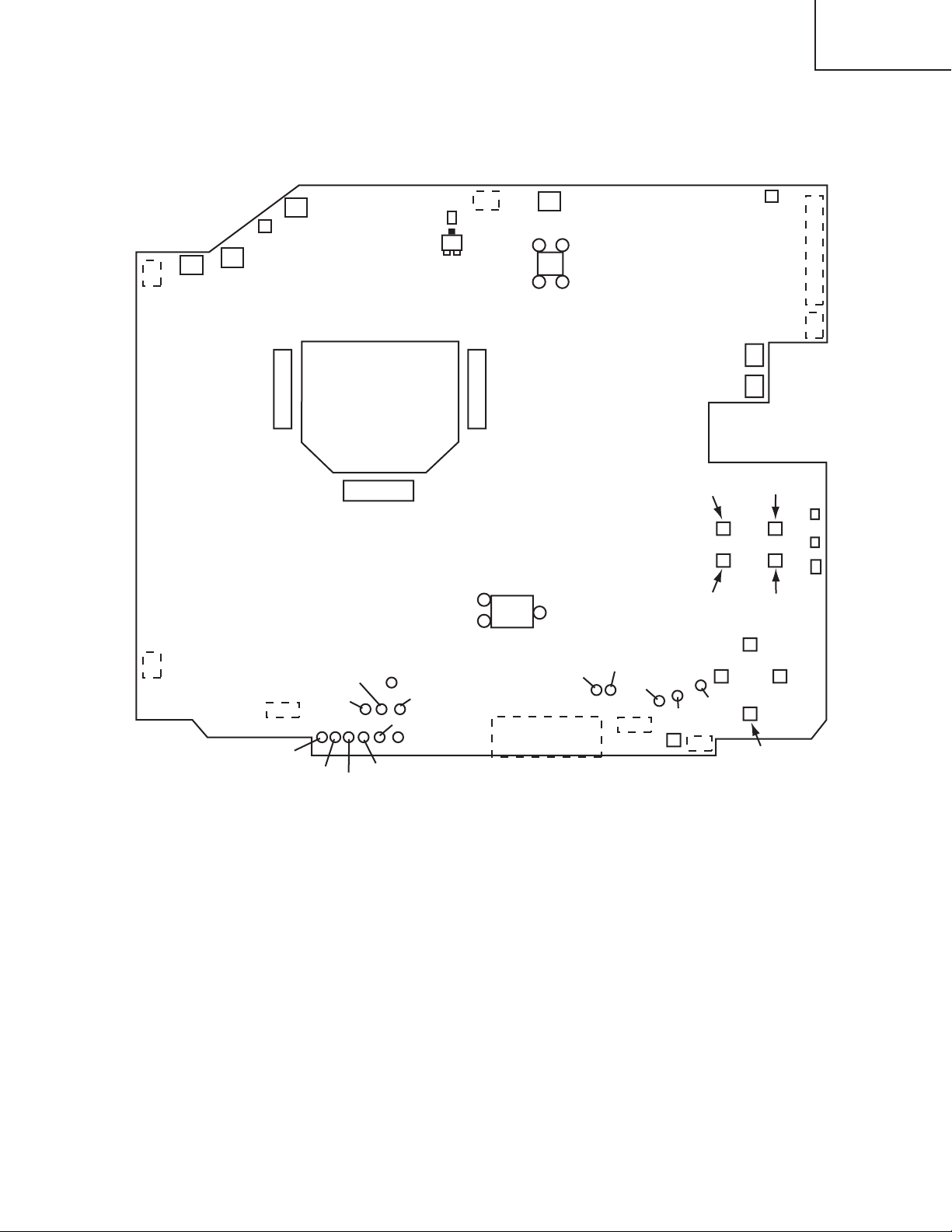

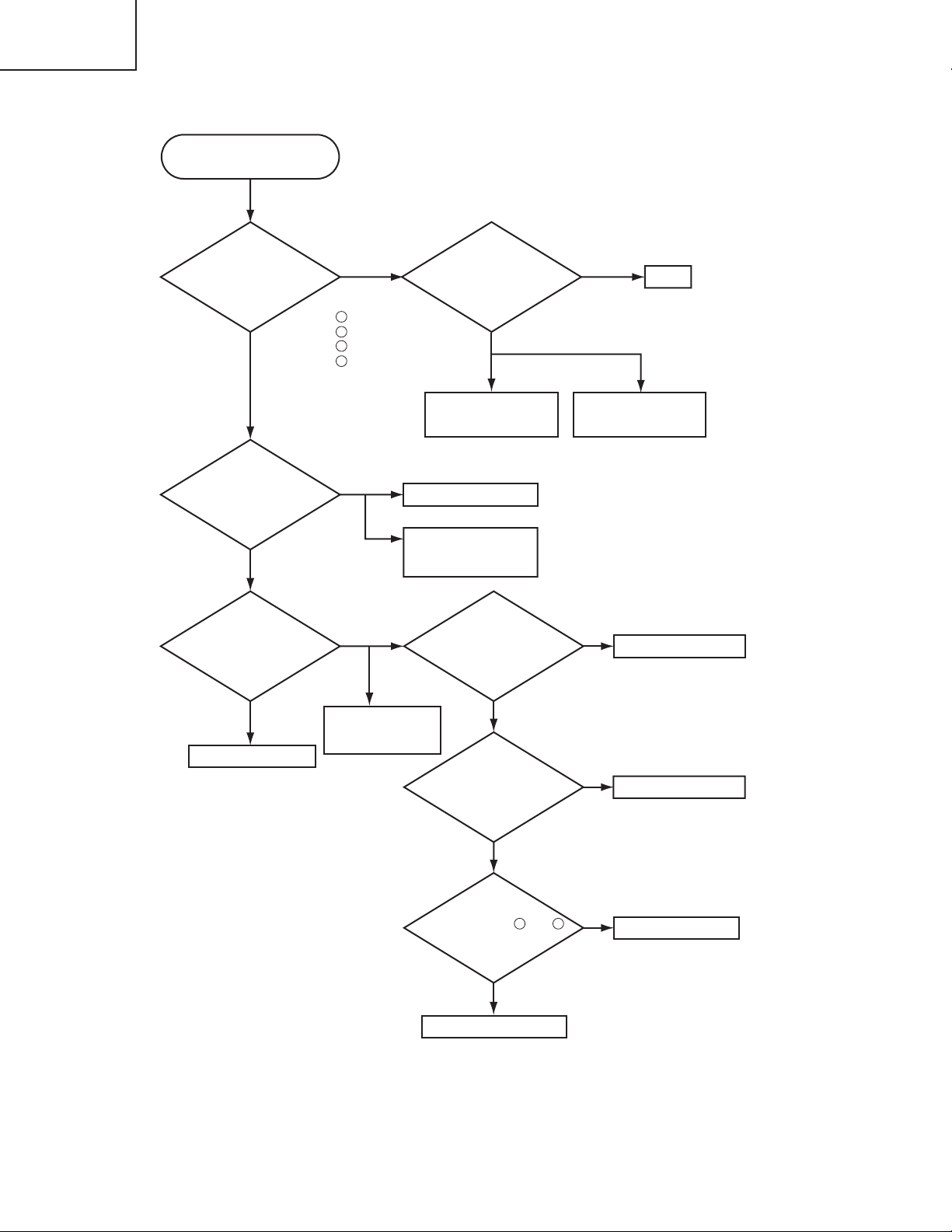

5. Troubleshooting

S201

E803

E802

ESPL

E806

E805

10 1

11

20

1

3

2

L818

Q801

C

E302

I256

ESPR

E800

E811

E808

E809

S302 S303

D302

D301

D303

S307

S308

S304

S305

S306

CH106

CH104

CH102

CH113

EG03

CH112

S309

E807

E101

E804

I102

CHV33

EV01

CHV34

CHV36

CHV35

CHV22

CHV23

CHV26

CHV27

CHV28

CHV29

E801

P502 P702

P602

Check points at trouble shooting

CP-X430W

11

Page 12

CP-X430W

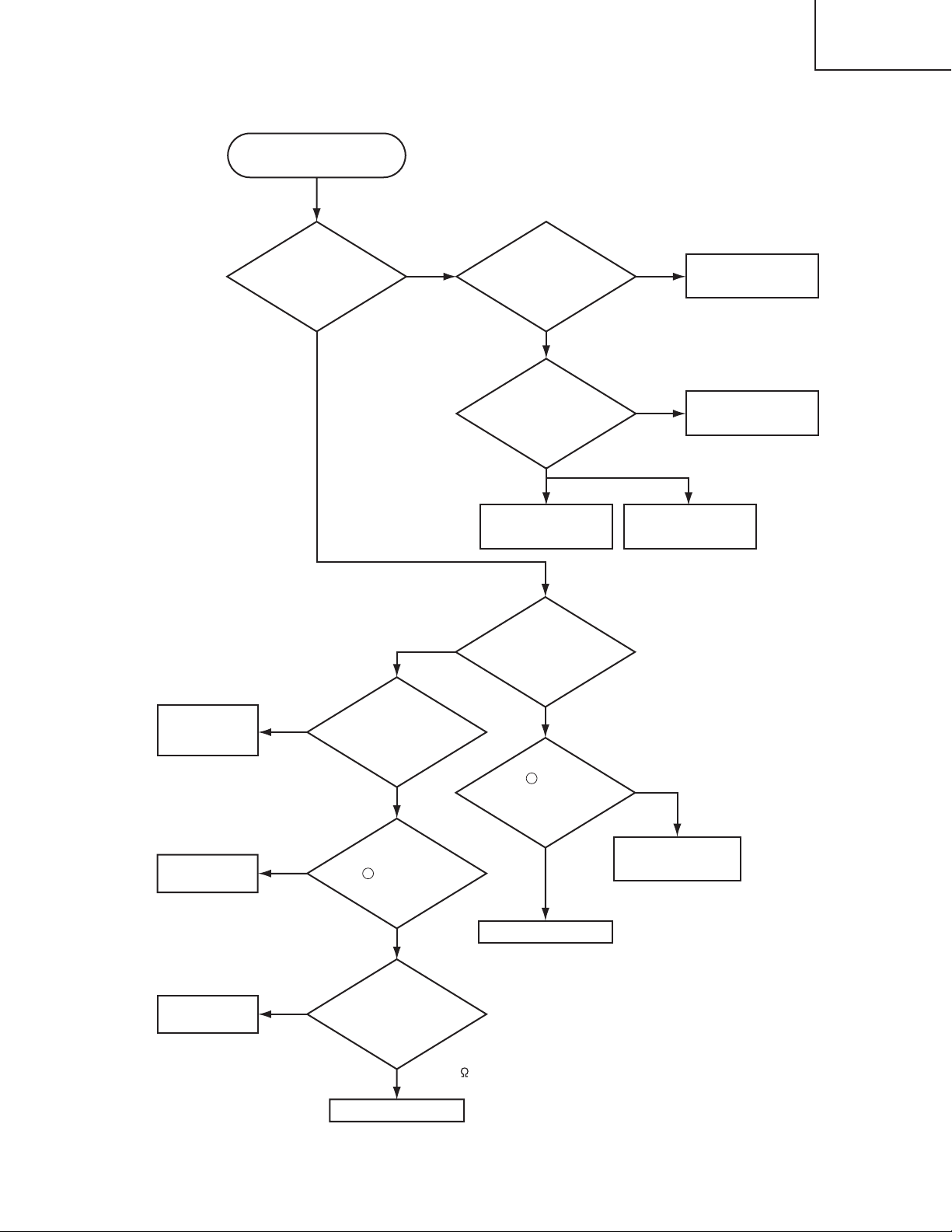

Power can not be turned on

Are voltage

input on the PWB

assembly Drive at

standby mode?

: +16.5V

: +15V

: +4V

: +6V

E800

E800

E800

E800

Power unit (circuit)

Fuse

on Power unit (circuit)

NO

YES

Disconnect

TSW from Power unit

(circuit). And check

TSW short or

open?

PWB assembly Drive

Lamp

or

Power unit (ballast)

Short

TSW

Open

What is the state of

TEMP indicator

D301?

Not light

DC FAN (for LCD panel)

Lights

Lights

Blinks

DC FAN (exhaust)

or

PWB assembly Sensor

What is the state of

LAMP indicator

D302?

Not light

Blinks

1

4

6

12

Is the LAMP

connection?

OK

Set the LAMP again

Is the

voltage at pin and

of E807 same?

NO

YES

PWB assembly Limit SW

PWB assembly Drive

Is the LAMP COVER

set?

OK

Set the LAMP COVER

NG

NG

1 2

12

Page 13

Lamp does not light

What is the state of

LAMP indicator D302

during operation?

Power unit (ballast)

Lamp

PWB assembly Drive

Power unit (ballast)

Light Light

PWB assembly Drive

YES

Not light

NO

YES

Change the lamp.

Does lamp light?

Power unit (circuit)

Not light

NO

What is the state of

TEMP indicator

D301?

Not light

Blinks

PWB assembly Drive

Connect

E302

(for PWB

assembly Sensor)

NO

"L" = 0V

L (0V)

YES

Is the

voltage at collector

of Q801 on the PWB assembly

Drive fixed to "L" during

warming-up?

"L" = 0V

Is E302

(PWB assembly Sensor)

surely connected with

PWB assembly Drive

by the cable?

DC FAN

H (3.3V)

Measure

sure voltage at

the of I256 on the

PWB assembly

Drive.

PWB assembly

Sensor

Infinity

about 10k

Measure

the resistance of

TH950 on the PWB

assembly Sensor at

disconnecting

E302.

Is the voltage

at pin of L818 on

the PWB assembly Drive

set to "L" during

warming-up?

8

2

CP-X430W

13

Page 14

CP-X430W

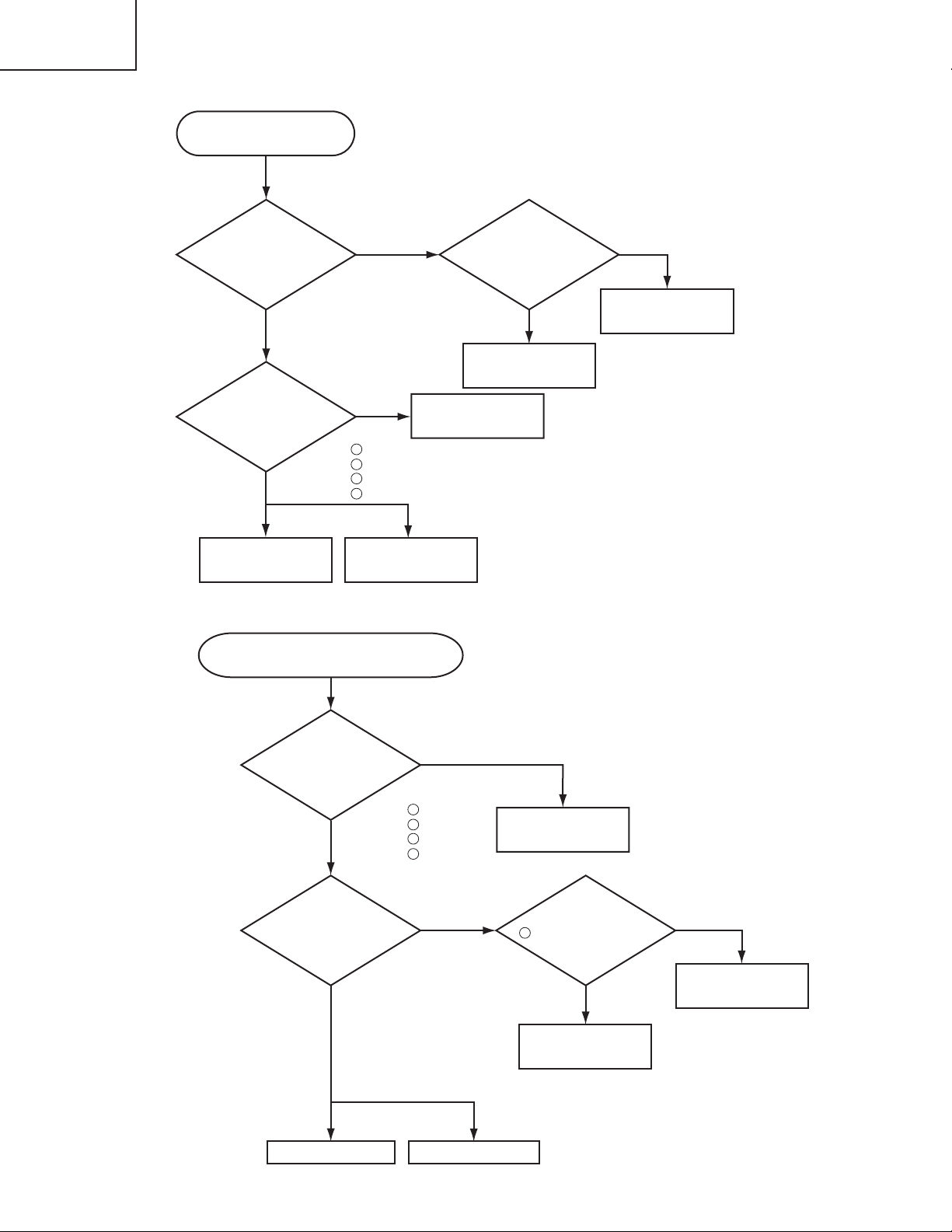

Picture is not displayed when

the RGB signal is input

Are signal

input at each pin on the

PWB assembly

Drive?

PWB assembly Signal

IC (IS01)

EL4332CS

PWB assembly Drive

LCD panel

NO

YES

Check at operating mode

CH106 : R signal

CH102 : G signal

CH104 : B signal

CH112 : H sync

CH113 : V sync

Power unit

(circuit)

Change the

IS01 on the PWB

assembly Signal is it

repaired?

YES

NO

NO

YES

Are voltage input

at each pin on the PWB

assembly Drive?

: +16.5V

: +15V

: +4V

: +6V

E800

E800

E800

E800

1

4

6

12

Power unit (circuit)

NO

YES

Are voltage

input at each pin on

the PWB assembly

Drive?

PWB assembly Drive LCD module assembly

Are signal

input at these

pins of EV01 on the

PWB assembly

Drive?

Measure

the voltage at pin

of I102 on the PWB

assembly

Drive.

NO

YES

0V

5V

PWB assembly Drive

PWB assembly Signal

Check at operating mode

CHV29 : VIDEO (Composite)

CHV28 : S-VIDEO (Y)

CHV27 : S-VIDEO (C)

CHV34 : Component (Y)

CHV35 : Component (Cb)

CHV36 : Component (Cr)

Picture is not displayed when the VIDEO,

S-VIDEO, Component Signal is input

3

: +16.5V

: +15V

: +4V

: +6V

E800

E800

E800

E800

1

4

6

12

14

Page 15

CP-X430W

PWB assembly Drive Speaker

Check at operating mode

No sound

NO

YES

PWB assembly Signal

Are signal input

at each pin on the PWB

assembly Drive?

CHV26 : Audio (L)

CHV33 : Audio (R)

Are the

signals input at each

pin of EV01 on the PWB

assembly

Drive?

PWB assembly Signal

YES

PWB assembly Drive

NO

CHV22: RX

CHV23: TX

Pin No RS-232C

1

2

3

6

7

9

10

12

13

14

SEL0

RTS

GND

RDP

TDP

Check at operating mode

Can not control to RS-232C

15

Page 16

CP-X430W

E803

E801

E802

E806

E805

E302

P702P502

P602

E800

E811

E808

E809

E804

E807

6. Service points

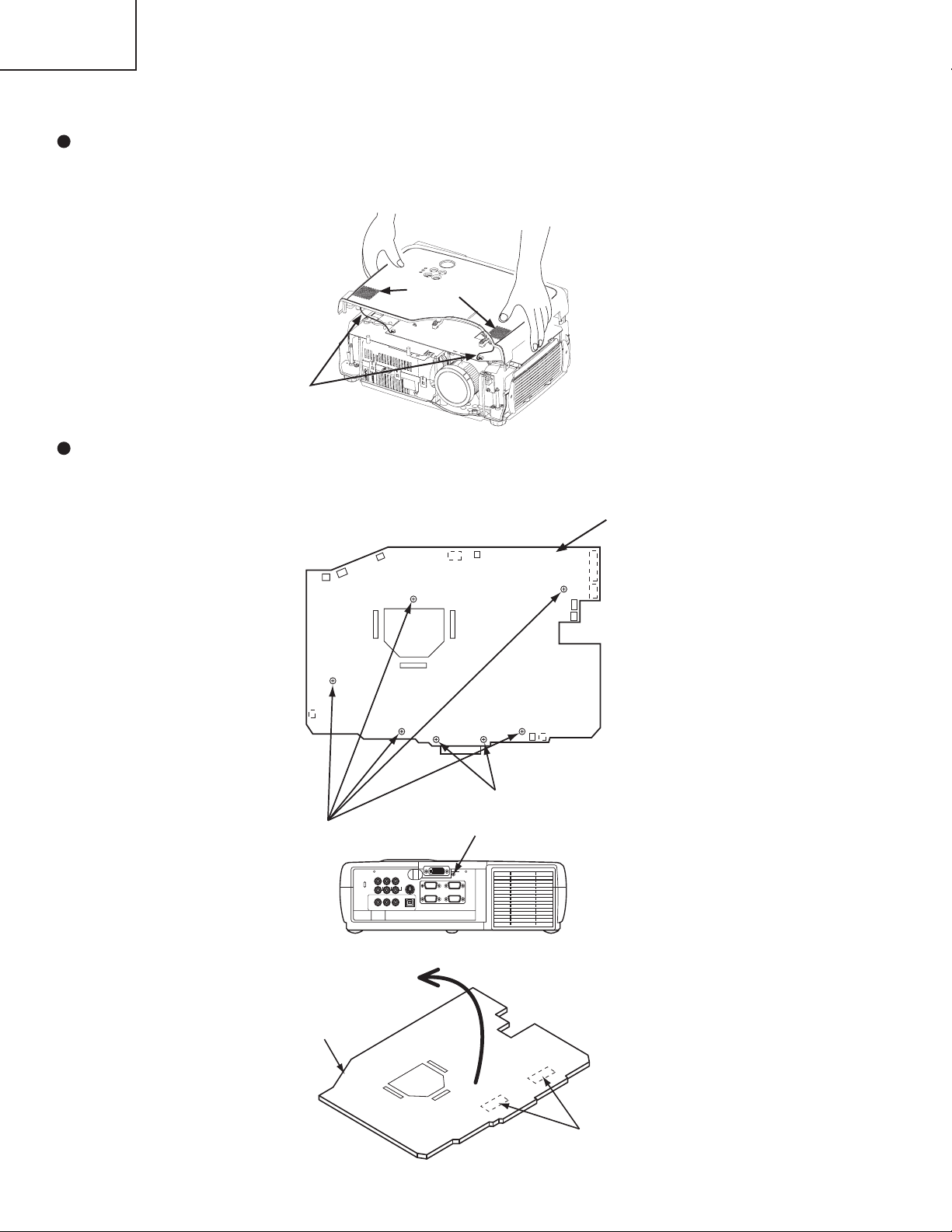

Cautions when removing the Upper case assembly

When you remove the Upper case assembly, avoid to damage wires between speakers on the Upper case

assembly and PWB assembly Drive on the Bottom case assembly.

Speaker

PWB assembly Drive

Wire from Speaker

Cautions when removing the PWB assembly Drive

When removing the PWB assembly Drive, there is a danger of damaging the connectors, connecting cables and

the PWB assembly Signal.

1) Disconnect 15 cables (including 3 flat cables) and remove 6 screws.

PWB assembly Drive

2) Lift up the PWB assembly Drive.

PWB assembly Drive

16

Remove these 5 screws

FRONT

Don’t remove these 2 screws

Remove this screw.

Rear side

Lift up

Disconnect the 2 board-to-board

REAR

connectors.

Page 17

CP-X430W

Before Replacing the LCD / Lens Prism

You should not replace separately the parts of the liquid crystal LCD / Lens Prism because it works properly only

when used together. Therefore, regarding these parts, you can either replace part, LCD / Lens Prism assembly, or

send the whole unit LCD / Lens Prism assembly back to HITACHI, where we will replace the malfunctioning part,

recondition the device and send it back to you. In that case please contact our distributor.

DISTRIBUTOR HITACHI

Do not disassemble the unit

because replacement of separate

parts is not possible.

For repairs of the product, please

contact our distributor.

Replacement of G Panel Reconditioning

Return

Air Filter

Cleaning the Air filter

The air filter should be cleaned as described below at intervals of approximately 100 hours.

1. Switch the projector power supply OFF, and remove the power cord from the power outlet.

2. Clean the air filter with a vacuum cleaner.

G Panel

Replacing the Air filter

Replace the air filter if contamination cannot be removed, or if it is damaged.

1. Remove the filter cover.

2. Remove the old filter.

3. Set the new filter and filter cover.

CAUTION

Switch power OFF and remove the power cord from the power outlet before beginning mainte-

nance work. Please read the separate “SAFETY INSTRUCTIONS” thoroughly to ensure that

maintenance is performed correctly.

Replace the air lter if contamination cannot be removed, or if it is damaged. Contact your dealer

in such case.(Option Air lter assembly : Parts No. NJ06131)

Do not use the equipment with the air lter removed.

When the air lter is clogged with dust etc. the power supply is switched OFF automatically to

prevent the temperature rising inside the projector.

17

Page 18

CP-X430W

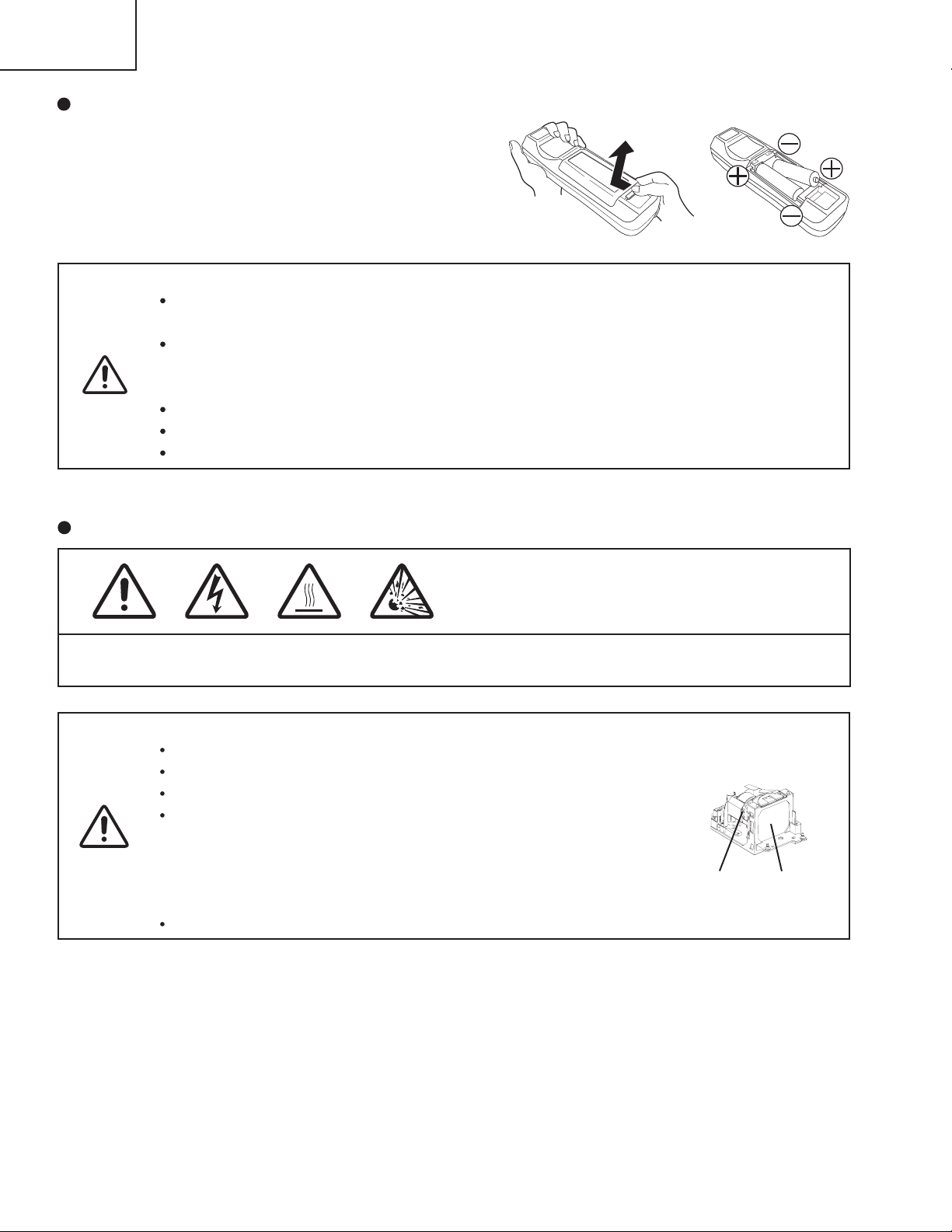

Loading the Batteries

Install the AA batteries into the remote control transmitter.

1. Remove the battery cover.

Push the knob while lifting up the battery cover.

2. Loading the batteries.

Make sure the plus and minus poles are correctly oriented.

3. Close the battery cover.

CAUTION

Use only the specied batteries with this remote control transmitter. Also, do not mix new and old

batteries. This could cause in battery cracking or leakage, which could result in re or personal injury.

When loading the batteries, make sure the plus and minus terminals are correctly oriented as

indicated in the Remote control transmitter. Incorrect orientation could cause battery cracking or

leakage, which could result in personal injury or pollution of the surrounding environment.

When you dispose the battery, you should obey the law in the relative area or country.

Keep the battery away from children and pets.

When not to be used for an extended period, remove the batteries from the Remote control transmitter.

NOTE: Replace the batteries when remote control transmitter operation becomes difficult.

1

2

Lamp (Option Lamp: DT00471)

HIGH VOLTAGE

HIGH TEMPERATURE

HIGH PRESSURE

Before replacing the lamp, switch power OFF, remove the power cord from the power outlet, and wait

approximately 45 minutes until the lamp has cooled. The lamp may explode if handled at high temperatures.

WARNING

For disposal of used lamp, treat according to the instruction of community authorities.

Since the lamp is made of glass, do not apply shock to it and do not scratch it.

Also, do not use old lamp. This could also cause explosion of the lamp.

If it is probable that the lamp has exploded (explosive sound is heard),

disconnect the power plug from the power outlet and ask your dealer to

replace lamp. The lamp is covered by front glass, but in rare cases, the

reector and the inside of the projector may be damaged by scattered broken

pieces of glass, and broken pieces could cause injury when being handled.

Do not use the projector with the lamp cover removed.

Reector

Lamp Life

Projector lamps have a nite life. The image will become darker, and hues will become weaker, after a lamp has

been used for a long period of time.

Replace the lamp if the LAMP indicator is red, or the CHANGE THE LAMP message appears when the projector is

switched ON.

Lamp

Front

glass

NOTE: The LAMP indicator is also red when the lamp unit reaches high temperature. Before replacing the lamp,

switch power OFF, wait approximately 20 minutes, and switch power ON again.

If the LAMP indicator is still red, replace the lamp.

18

Page 19

Replacing the Lamp

1. Switch the projector OFF, remove the power cord from the power outlet,

and wait at least 45 minutes for the unit to cool.

2. Prepare a new lamp.

3. Check that the projector has cooled sufciently, and gently turn it upside

down.

4. Loosen the two screws as shown in the diagram, and remove the lamp

cover.

5. Loosen the three screws, and gently remove the lamp while holding the

grips. Touching the inside of the lamp case may result in uneven coloring.

6. Install the new lamp and tighten the three screws rmly.

Also steadily push the opposite side of the screwed lamp into the unit.

7. Replace the lamp cover in position and tighten the two screws rmly.

8. Gently turn the projector right-side up.

CAUTION

Ensure that screws are tightened properly. Screws not

tightened fully may result in injury or accidents.

Do not use the projector with the lamp cover removed.

CP-X430W

Resetting the Lamp Timer

Reset the lamp timer after replacing the lamp. When the lamp has been replaced after the LAMP indicator is red, or

the CHANGE THE LAMP message is displayed, complete the following operation within ten minutes of switching

power ON. The power will be turned off automatically in over 10 minutes.

1. Switch power ON, and press the RESET button, for approximately three seconds. The ‘LAMP xxxx hr’ message

will appear on the lamp timer on the bottom of the screen.

2. Press the MENU button on the remote control transmitter, or the RESET button on the control panel, while the

lamp timer is displayed. The ‘LAMP xxxx 0 CANCEL’ message will then appear.

3. Press the and select 0, and wait until the timer display is cleared.

NOTE: Do not reset the lamp timer without replacing the lamp. Reset the lamp timer always when replacing the

lamp. The message functions will not operate properly if the lamp timer is not reset correctly.

19

Page 20

CP-X430W

(*1) This message is cleared automatically after approximately three minutes, and

appears every time power is switched ON.

(*2) The unit has a function to turn the power off which will be active when the usage time reaches

2000 hr. However the life of lamp might be much different among lamps, so that it might be

happened that a lamp is cut off before the function is active.

NOTE

Message Contents

CHANGE THE LAMP

AFTER REPLACING LAMP,

RESET THE LAMP TIME.

(*1)

The usage time of lamp will be reaching 2000 hr

shortly.

(*2)

It is recommended to replace the lamp soon. Prepare a

new lamp as a replacement.

CHANGE THE LAMP

AFTER REPLACING LAMP,

RESET THE LAMP TIME.

THE POWER WILL TURN OFF

AFTER

** hr.

(*1)

The usage time of lamp will be reaching 2000 hr shortly.

It is recommended to replace the lamp within * *

hours.

(*2)

It might be happened that the lamp is cut off before * * hr

by any chance. Power will be switched OFF

automatically in * * hours. Replace the lamp as shown in

P.19~20 "Lamp". Always reset the lamp timer after

replacing the lamp.

CHANGE THE LAMP

AFTER REPLACING LAMP,

RESET THE LAMP TIME.

THE POWER WILL

TURN OFF

AFTER 0 hr.

The usage time of lamp is about to reach. Power will be

switched OFF in a few minutes.

(*2)

Switch power OFF immediately and replace the lamp as

shown in P.19~20 "Lamp". Always reset the lamp timer

after replacing the lamp.

NO INPUT IS DETECTED

ON ***

No input signal found.

CHECK THE AIR FLOW

Please remove the obstruction before the suction port.

Check signal input connections and signal sources.

SYNC IS OUT OF RANGE

ON ***

The horizontal or vertical frequency of the input signal is

not within the specified range.

Check the specifications of the equipment and the signal

source.

OSD Message

The messages as described below may appear on the screen at power ON. Take the appropriate measures when

such messages appears.

20

Page 21

CP-X430W

POWER

indicator

LAMP

indicator

TEMP

indicator

Contents

Lights

orange

Turns off Turns off

The Standby mode has been set.

Blinks

green

Turns off Turns off

Warming up. Please wait.

Lights

green

Turns off Turns off

ON. Normal operation possible.

Blinks

orange

Turns off Turns off

Cooling. Please wait.

Blinks red - -

Cooling. Please wait.

The error is found. Take the appropriate measures when the

POWER indicator ceases blinking

Blinks

/Lights red

Lights

red

Turns off

Lamp is not lit.

The interior of the equipment may be too hot. Switch power OFF,

wait 20 minutes until the equipment cools, and check whether the

ventilation openings are blocked, whether the air filter is dirty, or

whether the ambient temperature exceeds 35 °C. And switch

power ON again. Replace the lamp if the same problem occurs.

Blinks

/Lights red

Blinks

red

Turns off

Lamp or lamp cover is not found, or hasn’t been fitted in correctly.

Switch power OFF, and wait for 45 minutes until the equipment

cools. Check fitting of the lamp and lamp cover, and switch power

ON again.

Blinks

/Lights red

Turns off

Blinks

red

The cooling fan is not operating.

Switch power OFF, and wait for 20 minutes until the equipment

cools. Check for foreign matters in the fan, and switch power ON

again.

Blinks

/Lights red

Turns off Lights red

The interior of the equipment is too hot.

Switch power OFF, and wait for 20 minutes until the equipment

cools. Check whether the ventilation openings are blocked,

whether the air filter is dirty, or whether the ambient temperature

exceeds 35 °C. Then switch power ON again.

Lights

green

Blinks

red

Blinks

red

The interior of the equipment is too cool.

Check whether the ambient temperature is below 0°C. Contact your

dealer if the same problem occurs when the ambient temperature is

0~35°C.

When the internal temperature becomes excessive power is switched OFF automatically

for safety reasons, and the indicator is extinguished. Set the power switch to [

O

] and wait for 20

minutes until the equipment has cooled sufficiently.

NOTE

Indicators Message

The POWER indicator, LAMP indicator, and TEMP indicator are lit and blank as follows. Take the appropriate

measures.

21

Page 22

CP-X430W

Setup of a Cooling Fan Speed

When using this projector in the place where altitude is high, we recommend you to set a cooling fan’s speed as

“HIGH”. It is because the cooling efciency of a projector falls and the temperature inside a projector rises easily in

such a place, since the density of air becomes low.

Setting Method of Cooling Fan Speed

1. To display the OSD for cooling fan speed setup:

By the control panel By the remote control transmitter

A proper signal is input

No signal is input

2. Select the “HIGH” on the OSD using the button “ ”. To reset this setup, select the “NORMAL” using the button

“ ”.

3. The OSD will be ended by no operation for 10 seconds or change of input signal. To end immediately, use one of

buttons except buttons “ ”, “ ”, “ ”, “ ”, “RESET”, “MENU SELECT”, “MAGNIFY +/-/OFF”, “FREEZE” (when

no signal is input) or “POSITION” (when no signal is input).

1. Display the menu by the “MENU”

button.

2. Select the “OPT.” on the menu.

3. Continue press the button “ ” rst,

then pr es s the bu t to n “RESET”

together with “ ”, and hold for 3

seconds.

1. Display the menu by the “MENU”

button.

2. Select the “VOLUME” on the menu.

3. Continue press the button “ ” rst,

then pr es s the bu t to n “RESET”

together with “ ”, and hold for 3

seconds.

1. Display the menu by the “MENU”

button.

2. Select the “OPT.” on the menu.

3. Continue pressing the button

“MAGNIFY OFF” for 3 seconds.

1. Display the menu by the “MENU”

button.

2. Select the “VOLUME” on the menu.

3. Continue pressing the button

“MAGNIFY OFF” for 3 seconds.

NOTE:

The “HIGH” mode makes the fan noisy than “NORMAL” mode.

The recall of factory setting sets the fan speed to “NORMAL” mode. You must set the fan speed after recall of

factory setting if you need “HIGH” mode.

22

Page 23

7. Block diagram

0.9"LCD

XGA PANEL

DC POWER

SUPPLY PWB

LAMP POWER

SUPPLY PWB

S/H

DRIVE PWB

CONTROL

PANEL

AC

INPUT

Flash ROM

SP

SUB CPU

PIC

Audio

S-Video

OPTICAL

UNIT

PROJECTION

LENS

Lamp

1M SRAM

64K

EEPROM

DDC

Video

DAC

P/S

COLOR

UNIFORMITY

&

TIMING

GENERATOR

L3E07050

LEVEL

SHIFTER

VIDEO

DECODER

VPC3230Q

TEMP

SENSOR

TEMP

SENSOR

SEL./

COMP.

Component

Video

S/H

IR

RECEIVER

AUDIO_AMP

VOLUME

CONTROL

RGB 1

RGB 2

A/D,PLL

CXA3506

1st_PLL

RGB

A/D

CLAMP

RGB out

Audio Out

SP

SW PWB

DC POWER

REGULATOR

Image_PROCESSOR

PW365-10U

MOUSE

CTL

USB

RS-232C

CTL

DAC

P/S

ext. I/O

DVI

TMDS

RECEIVER

SiI161B

SYNC

SEPARATOR

CXA2151Q

FAN

IR

RECEIVER

REMC PWB

SIGNAL PWB

SIGNAL

SELECTOR

Spread

Spectrum

PLL

Spread Spectrum

X'tal

2nd_PLL

IR

RECEIVER

CP-X430W

23

Page 24

CP-X430W

E950

R/C

(FRONT)

R/C

(UPPER)

S-VIDEO ESM2 EV01 E302

16 RXD 1 1 OUT 1

PWB

17 TXD 2 2 GND 2

assembly

C.VIDEO 18 MOUSE 3 SENSOR

19 REMOTE 4

20 GND 5 E806

21 L.IN 6 1 GND 1

PWB

22 GND 7 2

REMOTE1

2

23 S.CIN 8 P502

1 TEST

3

REMOTE2

3

REMC

24 GND 9 P602 2 COM

25 S.YIN 10 P702 3

VVDD

26 GND 11

4 PCG

27 CVBSIN 12 5 CL R

1

FAN1S

28 GND 13 6 N.C.

E8012LCD-B

FAN

29 9V 14

7

DWN

3

GND

(PANEL-B)

30 9V 15 8 VST

1 5V 16 9 V CK

2 5V 17

10 ENB

3 GND 18 11 N.C.

1

FAN2S

4 Cr/PrIN 19 12 VSSGL

E8022LCD-G FAN

AUDIO-IN 5 GND 20 13 VSS

3

GND (PANEL-G)

(VIDEO-L) 6 Cb/PbIN 21

14 HCK1

4

NC

7 GND 22 15 HCK2

8 Y 23 16 HST

AUDIO-IN(VIDEO-R) 9 GND 24

17 PGT

10 R.IN 25 18 HVDD

1

FAN3S

11 GND 26 19 VSIG12

E8032LCD-R

FAN

AUDIO-IN(RGB1) 12 CLK.A 27

20 VSIG11

3

GND

(PANEL-R)

13 DA TA.A 28 21 VSIG10

AUDIO-IN(RGB2) 14 CS.A 29 22 VSIG9

15 NC 30 23 VSIG8

AUDIO-OUT 24 VSIG7

ESPL1LOUT-

ESM116RGB.R 1 E101 25 VSIG6

2

LOUT+

17 GND 2 26 VSIG5

18 GND 3 27 VSIG4

SPEAKER

19 RGB.G 4 28 VSIG3

20 GND 5 29

21 GND 6

30 VSIG1

ESPR

22 RGB.B 7

1 ROUT-

23 GND 8

2 ROUT+

RGB1-IN 24 GND 9

25 RGB.H-INV 10

SPEAKER

26 RGB.V-INV 11

RGB2-IN 27 R1/R 2 12

E941

28 +5VST 13

E807

29 +5VST 14

1 OUT 1

RGB-OUT 30 GND 15

2 COVER 2

1 GND 16

PWB

assembly

2 +5VST 17

SW.

CONTROL 3 +5VST 18

4 R1/R2 19

E804

5 RGB.V-INV 20

1 FAN4S

6 RGB.H-INV 21

2 OUT FAN

7 GND 22

3 GND (EXHAUST)

8 GND 23

E808

9 RGB.B 24

4 3 2 1

USB(MOUSE) 10 GND 25

11 GND 26

12 RGB.G 27

E800 1 +16.5V 1 CN102

E811 CN103

FAN5S

13 GND 28

2 FAN.GND 2 LAMP FAN

14 GND 29

3 FAN.GND 3 GND (LAMP)

15 RGB.R 30

4 +1 5V 4

NC

5 +15V 5

6 +4V 6

7 +4V 7

8 GND 8

9 GND 9

10 GND 10

11 GND 11

R/C(REAR)

12 +6V

AUDIO +6V

AUDIO GND

POWER 0

12

AC INLET

E805 CN2 CN1 CN101

1 P ON/OFF 1 1 DC IN+ 1

2 GND 2 2 NC 2

3 LAMP.MISS 3 3 DC IN- 3

4 SILENT MODE 4

OUT+

OUT-

CN04

TEMP OUT 1

TEMP RETURN

2

1 1

2 2

3

3

4 VCC

4

VSIG2

31

VSSGR

32

PSIG

E809

1 FAN6S

2 L AMP2 FAN

3 GND

(POWER PWB)

DVI-IN

LAMP UNIT

assembly

POWER

UNIT

POWER

UNIT

(BALLAST)

(CIRCUIT)

PWB assembly DRIVE

PWB assembly

SIGNAL

LCD

PANEL

R/G/B

LAMP

TEMPERATURE

SWITCH

assembly

8. Connector connection diagram

24

Page 25

9. Wiring diagram

Mount sensor board after taking following steps:

Sensor board

CNTH

CNTH

FEB4

TSW

CNPW1

FEB3

CNBAR

FEB1

CNPW2

SKB1

Light

lead

E950

TAP3

Connect CNTH to E950 connector

on sensor board.

Check E950 connector and fix it using

TAP3 (so that connector may not come off).

CN101

CN104

CN102

CN103

Sensor board

Ensure that model

indication of TSW is 90AR1U1N.

1.Power board block wiring

(1) Power board wiring

Before fitting circuit power board into its holder, make sure CNPW1, CNPW2 and TSW cables

are properly connected to CN102, CN103 and CN104 connectors, respectively.

(You cannot connect cables after fitting power board.)

Place the 3 cables through a notch in power board holder leaving no slack in cables.

(Cable slack may touch primary power circuit.)

CN2

Before connecting CNBAR

to CN2 connector, ensure

that it is inserted to the end.

Attach so that hole for securing

SK Binder on FEB3 comes to

connector side as in diagram.

CN1

After connecting CNPWR

to CN1 connector, ensure

to securely lock it.

Put light lead through a notch of ballast holder.

Pull light lead toward outside of holder to leave

no slack in ballast holder, and bind it using

SKB1 as illustrated.

Loop TSW once close to exit point of power

holder cable as in diagram and attach FEB4.

Secure with SK Binder provided.

Attach FEB1 to CNPWR by moving

in the direction shown. Fix it near

the connector using SK binder that

is included in an accessory kit.

Attach FEB3 to CNBAR. Make a loop

at cable outlet on ballast holder as illustrated.

Delete provided SK Binder.

(2) Ballast board block wiring

CNPWR

CP-X430W

25

Page 26

CP-X430W

Wiring when putting ballast board on power board.

Ballast board

Power board

CN101

CN104

CN102

CN103

Ensure that light

lead comes out

of a notch of

ballast holder.

After connecting CNPWR to CN101

connector, ensure to securely lock them.

Connect CNPWR to CN101 connector,

and insert cable into power board

holder as illustrated.

Light

lead

CNPWR

Light

lead

CNBAR

TSW

CNPWR

CNTH

Black coating of light lead

Slide black coating

of light lead.

White coating

of light lead

Ensure that black coating of light lead is

completely within connector.

If not, and when white coating appears

even slightly, slide the black coating

into connector as shown.

(Double coatings are needed for safety.)

Wiring when after putting ballast board on power board.

Clamp CNPW1

and CNPW2

cables at 2 points.

Right view of power board block

(3) Power board block wiring

Fit CNTH around

hook as shown.

Clamp CNPW1 and CNPW2

with PAS1 as in diagram.

Radiation shield

Push CNPWR toward radiation

shield of power board as shown.

Beware that no stress is applied

to power board and ballast

board parts.

CNPW2

CNPW1

PAS1

26

Page 27

CP-X430W

#6402

#6401

Fan for red panel

Fan for green panel

CNLC

Connect CNLC cable to

light switch board

(before mounting board).

CNPW2

CNPW1

#3050

#3054

Light fan

Exhaust fan

#6401

SKB2

SKB2

Approximately

25mm

Fan for blue panel

Light

lead

FEB2

TSW

Screw hole

Before mounting optical unit and power block,

ensure that cables are not caught by any components.

Ensure that cables connected

to fans for red, green and blue

panels came out through the

slit shown.

TAP1

Attach TSW cable

on the curved part

of ballast holder to

TAP1 as shown.

Keep exhaust fan

slits free from cables.

#3055

Exhaust fan

Top View

Side View

CNRM

Connect CNRM

cable to RC board.

Clamp TSW, #3050 and #3054

with PAS3 as in diagram

PAS3

CNBAR

CNTH

2.Wiring when mounting power block and optical unit on bottom case

Connect light lead to

lamp house connector.

Attach FEB2 without

SK binder to light lead,

caring not to cover

the screw hole shown.

(Upper case should

not contact lib.)

To prevent CNBAR from nearing input side of ballast,

pass CNBAR through SK Binder securing hole of

FEB3 as in diagram on right and bind to ballast

holder hook with SKB2. Be sure to pass CNBAR

through SKB2 to allow CNTH to pass through or

beneath binding. Do not over-tighten SK Binder so

FEB3 lifts off ballast holder (as this causes upper

case to lift). As a guide, tighten so that SK Binder ring

comes to about 25mm when crushed.

27

Page 28

CP-X430W

CNPW2

CNPW1

#6401

#6401

#6402

CNRM

rib

CNTH

CNBAR

E302

E805

ESPR

E806

ESPL

E802

E803

E801

E800

E811

E808

E809

#3050

Connect to light

fan, E808.

DRIVE board

Connect to remote control

board cable, E806.

Connect to red

panel fan, E803.

Insert cables #6491

and #6402 into inside

of rib as in diagram,

to prevent making

contact with speaker

fitting during attachment

of upper case.

Connect to green

panel fan, E802.

Connect to blue panel

fan, E801 (back)

Connect to thermistor

cable, E302.

Connect to ballast control

cable, E805 (back).

E807

P502

P602

P702

Connect flexible cable for panel

to flexible connector.

R: to P501, G: to P601, B: to P701

Connect to E800 and E811 at the back

of circuit power cable.

#1358

Clamp 4 cables with

#1358 as shown.

#3054

Connect to exhaust

fan, E809.

CNLC

Connect to light door

switch cable, E807.

E804

#3055

Connect to exhaust fan, E804 (back). Connecting or

inspecting while keeping board lifted is beneficial.

3.Wiring when mounting drive board

Push surplus CNLC and #3055

cableS to the clearance.

28

Page 29

CP-X430W

4.Wiring when attaching upper case

*Attach A83 to upper case according

to assembly drawing.

Hold upper case when you connect or disconnect

cables so that stress may not be applied to cables.

After cable connection, attach upper case while

pushing surplus A84 cable into case.

Beware not to catch cables with front bezel when

attaching it.

Beware not to catch cables with

front bezel when attaching it.

*Attach A84 to upper case according

to assembly drawing.

Upper case

A84

A83

ESPL

ESPR

Beware not to catch cables with

upper case when attaching it.

Hold upper case when you connect

or disconnect cables so that stress

may not be applied to cables.

After cable connection, attach upper

case while pushing surplus A83

cable into case.

Beware not to catch cables with front

bezel when attaching it.

Beware not to cover screw hole with

core, and not to catch cables with

upper case when attaching it.

29

Page 30

CP-X430W

6

5

4

3

2

1

6

5

4

3

2

1

E

DC

B

A

PWB assembly LIMIT SWITCH (C7X)

PWB assembly SENSOR (C7X)

PWB assembly REMOTE CONTROL (C7X)

10. Basic circuit diagram

Parts with hatching are not mounted.

30

Page 31

CP-x430W

6

5

4

6

5

4

3

2

1

3

2

1

POWER UNIT (BALLAST) (C7X)

ABCDEFG

31

32

Page 32

CP-x430W

6

5

4

Out put connector

6

5

4

3

2

1

3

2

1

POWER UNIT (CIRCUIT) (C7X)

ABCDEFG

33

34

Page 33

(female)

CP-X430W

6

5

(female)

4

6

5

4

3

(female)

2

1

3

2

1

PWB assembly SIGNAL 1 (C7X)

ABCDEFG

35

36

Page 34

CP-X430W

6

5

4

6

5

4

3

2

1

3

2

1

PWB assembly SIGNAL 2 (C7X)

ABCDEFG

37

38

Page 35

CP-X430W

6

(male)

5

4

6

5

4

3

mouseserial

RS232C

2

1

3

2

1

PWB assembly SIGNAL 3 (C7X)

ABCDEFG

39

40

Page 36

CP-X430W

6

5

serial

parallel

4

6

5

4

3

2

1

3

2

1

PWB assembly DRIVE 1 (C7X)

ABCDEFG

41

42

Page 37

CP-X430W

6

5

4

6

5

4

3

2

1

3

2

1

PWB assembly DRIVE 2 (C7X)

ABCDEFG

43

44

Page 38

CP-X430W

6

5

4

6

5

4

3

2

1

3

2

1

PWB assembly DRIVE 3 (C7X)

ABCDEFG

45

46

Page 39

CP-X430W

6

5

4

6

5

4

3

2

1

3

2

1

PWB assembly DRIVE 4 (C7X)

ABCDEFG

47

48

Page 40

CP-X430W

6

5

4

6

5

4

3

2

1

3

2

1

PWB assembly DRIVE 5 (C7X)

ABCDEFG

49

50

Page 41

CP-X430W

6

5

4

6

5

4

3

2

1

3

2

1

PWB assembly DRIVE 6 (C7X)

ABCDEFG

51

52

Page 42

CP-X430W

6

5

4

6

5

4

3

2

1

3

2

1

PWB assembly DRIVE 7 (C7X)

ABCDEFG

53

54

Page 43

CP-X430W

6

5

4

6

5

4

3

2

1

3

2

1

PWB assembly DRIVE 8 (C7X)

ABCDEFG

55

56

Page 44

CP-X430W

6

5

4

6

5

4

3

2

1

3

2

1

PWB assembly DRIVE 9 (C7X)

ABCDEFG

57

58

Page 45

CP-X430W

6

5

4

6

5

4

3

2

1

3

2

1

PWB assembly DRIVE 10 (C7X)

ABCDEFG

59

60

Page 46

CP-X430W

6

5

4

6

5

4

3

2

1

3

2

1

PWB assembly DRIVE 11 (C7X)

ABCDEFG

61

62

Page 47

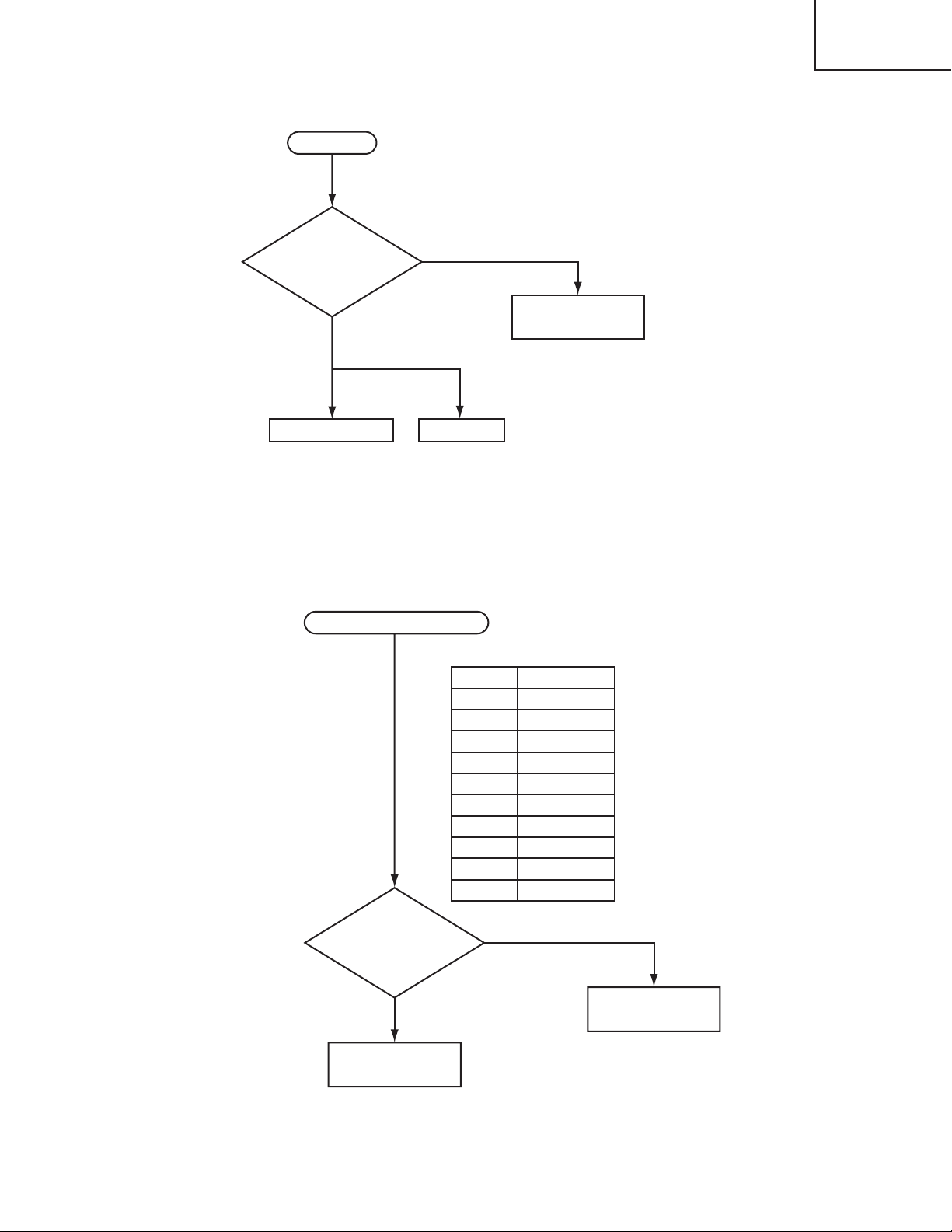

11. Disassembly diagram

2

1

2

3

8

10

11

13

11

12

9

4

6

5

7

CP-X430W

63

Page 48

CP-X430W

14

15

17

19

26

27

28

29

30

18

19

20

21

22

25

24

23

16

64

Page 49

CP-X430W

SYMBOL PARTS SYMBOL PARTS

NO. NO. DESCRIPTION NO. NO. DESCRIPTION

1 QD33871 UPPER CASE ASS'Y 23 JP05395 PWB ASS'Y SENSOR

2 GK00655 SPEAKER 24 2722448 FUSE

3 GS00505 DC FAN(EXHAUST-OUTSIDE) 25 HA01051 POWER UNIT(CIRCUIT)

4 NJ06171 LAMP SWITCH HOUSE 26 JP05388 PWB ASS'Y REMOTE CONTROL

5 GS00771 DC FAN(EXHAUST-INSIDE) 27 JP05392 PWB ASS'Y SIGNAL

6 PV00331 HANDLE 28 CK31602R EL4332CS

7 QD33881 FRONT BEZEL ASS'Y 29 JP05394 PWB ASS'Y LIMIT SWITCH

8 GS00752 DC FAN(LAMP) 30 QD33861 BOTTOM CASE ASS'Y

9 PH31361 FILTER COVER

10 NJ06131 AIR FILTER ASS'Y

11 QJ01061 FRONT FOOT ASS'Y EV00861 POWER SUPPLY CORD (UK TYPE) W/CORE

12 PE00113 RUBBER FOOT EV00881

POWER SUPPLY CORD (UL/CSA TYPE) W/CORE

13 PH31691 LAMP DOOR ASS'Y EV00891

POWER SUPPLY CORD (EUROPE TYPE) W/CORE

14 PC05461 CONTROL BUTTON ASS'Y EW02753 PS/2-2 MOUSE CABLE W/CORE

15 JP05382 PWB ASS'Y DRIVE EW06651 COMPONENT CABLE

16 EA00561R CPC32 CONNECTOR EW06661 RGB-D CABLE(15PIN MALE TO 15 PIN MALE)

17 UE20031 DICHROIC OPTICS UNIT HL01841 REMOTE CONTROL UNIT WITH POINTER

18 GS00755 DC FAN(INTAKE G) NX05741 CLEANING TOOL FOR DUST

19 GS00751 DC FAN(INTAKE R,B) NX05742 COTTON STICK L70

20 UX08051 LCD LENS PRISM ASS'Y QR51551 INSTRUCTION MANUAL S-ASS'Y

21 PH31321 LENS CAP

22 HA01061 POWER UNIT(BALLAST)

12. Replacement Parts list

PRODUCT SAFETY NOTE : Components marked with a have special characteristics important to safety. Before replacing any of there

components, read carefully, the PRODUCT SAFETY NOTICE of this Service Manual. Don't degrade the safety of the projector through

improper servicing.

65

Page 50

CP-X430W

1

23

4

5

6

7

89

10

11

1213

1415

Command data chart

byte_0 byte_1

Action

low high

byte_2 byte_3

Type

low high

byte_4 byte_5

Setting code

low

high

Action Classification Content

Action (byte_0 - 1)

1 SET Change setting to desired value.

2 GET Read projector internal setup value.

4 INCREMENT Increment setup value by 1.

5 DECREMENT Decrement setup value by 1.

6 EXECUTE Run a command.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

RD

TD

GND

SELO

RTS

1

2

3

4

5

6

7

8

9

CD

RD

TD

DTR

GND

DSR

RTS

DTS

RI

1

2 3 4 5

6 7

8

9

13. RS-232C communication

(1) Turn off the projector and computer power supplies and connect with the RS-232C cable.

(2) Turn on the computer power supply and, after the computer has started up, turn on the projector power supply.

Projector Computer

Control jack

D-sub 15-pin shrink jack

Communications setting

19200bps, 8N1

1 Protocol

Consist of header (7 bytes) + command data (6 bytes).

2 Header

BE + EF + 03 + 06 + 00 + CRC_low + CRC_high.

CRC_low : Lower byte of CRC ag for command data.

CRC_high : Upper byte of CRC ag for command data.

RS-232C jack

D-sub 9-pin

3 Command data

66

Page 51

CP-X430W

Requesting projector status (Get command)

(1) Send the request code Header + Command data (‘02H’+‘00H’+ type (2 bytes) +‘00H’+‘00H’) from the computer

to the projector.

(2) The projector returns the response code ‘1DH’+ data (2 bytes) to the computer.

Changing the projector settings (Set command)

(1) Send the setting code Header + Command data (‘01H’+‘00H’+ type (2 bytes) + setting code (2 bytes)) from the

computer to the projector.

(2) The projector changes the setting based on the above setting code.

(3) The projector returns the response code ‘06H’ to the computer.

Using the projector default settings (Reset Command)

(1) The computer sends the default setting code Header + Command data (‘06H’+‘00H’+ type (2 bytes)

+‘00H’+‘00H’) to the projector.

(2) The projector changes the specified setting to the default value.

(3) The projector returns the response code ‘06H’ to the computer.

Increasing the projector setting value (Increment command)

(1) The computer sends the increment code Header + Command data (‘04H’+‘00H’+ type (2 bytes) +‘00H’+‘00H’) to

the projector.

(2) The projector increases the setting value on the above setting code.

(3) The projector returns the response code ‘06H’ to the computer.

Decreasing the projector setting value (Decrement command)

(1) The computer sends the decrement code Header + Command data (‘05H’+‘00H’+ type (2 bytes) +‘00H’+‘00H’)

to the projector.

(2) The projector decreases the setting value on the above setting code.

(3) The projector returns the response code ‘06H’ to the computer.

When a command sent by the projector cannot be understood by the computer

When the command sent by the projector cannot be understood, the error command ‘15H’ is returned by the

computer. Some times, the projector ignores RS-232C commands during other works. If the error command ‘15H’ is

returned, please send the same command again.

When data sent by the projector cannot be practice

When the command sent by the projector cannot be practiced, the error code ‘1cH’ +‘xxxxH’ is returned.

When the data length is greater than indicated by the data length code, the projector will ignore the excess data code.

Conversely, when the data length is shorter than indicated by the data length code, an error code will be returned to

the projector.

NOTE:

Operation cannot be guaranteed when the projector receives an undefined command or data.

Provide an interval of at least 40ms between the response code and any other code.

The projector outputs test data when the power supply is switched ON, and when the lamp is lit. Ignore this data.

Commands are not accepted during warm-up.

67

Page 52

CP-X430W

Names Operation type Header

Command data

CRC Action Type Setting code

Blank Color

Set

Red BE EF 03 06 00 3B D3 01 00 00 30 00 00

Orange BE EF 03 06 00 AB D2 01 00 00 30 01 00

Green BE EF 03 06 00 5B D2 01 00 00 30 02 00

Blue BE EF 03 06 00 CB D3 01 00 00 30 03 00

Purple BE EF 03 06 00 FB D1 01 00 00 30 04 00

White BE EF 03 06 00 6B D0 01 00 00 30 05 00

Black BE EF 03 06 00 9B D0 01 00 00 30 06 00

MyScreen BE EF 03 06 00 FB CA 01 00 00 30 20 00

ORIGNAL BE EF 03 06 00 FB E2 01 00 00 30 40 00

Get BE EF 03 06 00 08 D3 02 00 00 30 00 00

Mirror

Set

Normal BE EF 03 06 00 C7 D2 01 00 01 30 00 00

H Inverse BE EF 03 06 00 57 D3 01 00 01 30 01 00

V lnverse BE EF 03 06 00 A7 D3 01 00 01 30 02 00

H&V Inverse BE EF 03 06 00 37 D2 01 00 01 30 03 00

Get BE EF 03 06 00 F4 D2 02 00 01 30 00 00

Freeze

Set

Normal BE EF 03 06 00 83 D2 01 00 02 30 00 00

Freeze BE EF 03 06 00 13 D3 01 00 02 30 01 00

Get BE EF 03 06 00 B0 D2 02 00 02 30 00 00

Menu Color

Set

Red BE EF 03 06 00 7F D3 01 00 03 30 00 00

Orange BE EF 03 06 00 EF D2 01 00 03 30 01 00

Green BE EF 03 06 00 1F D2 01 00 03 30 02 00

Blue BE EF 03 06 00 8F D3 01 00 03 30 03 00

Purple BE EF 03 06 00 BF D1 01 00 03 30 04 00

Transparent BE EF 03 06 00 2F D0 01 00 03 30 05 00

Gray BE EF 03 06 00 DF D0 01 00 03 30 06 00

Get BE EF 03 06 00 4C D3 02 00 03 30 00 00

Startup

Set

ORIGNAL BE EF 03 06 00 0B D2 01 00 04 30 00 00

OFF BE EF 03 06 00 9B D3 01 00 04 30 01 00

MyScreen BE EF 03 06 00 CB CB 01 00 04 30 20 00

Get BE EF 03 06 00 38 D2 02 00 04 30 00 00

Language

Set

English BE EF 03 06 00 F7 D3 01 00 05 30 00 00

Français BE EF 03 06 00 67 D2 01 00 05 30 01 00

Deutsch BE EF 03 06 00 97 D2 01 00 05 30 02 00

Español BE EF 03 06 00 07 D3 01 00 05 30 03 00

Italiano BE EF 03 06 00 37 D1 01 00 05 30 04 00

Norsk BE EF 03 06 00 A7 D0 01 00 05 30 05 00

Nederlands BE EF 03 06 00 57 D0 01 00 05 30 06 00

Português BE EF 03 06 00 C7 D1 01 00 05 30 07 00

Japanese BE EF 03 06 00 37 D4 01 00 05 30 08 00

Get BE EF 03 06 00 C4 D3 02 00 05 30 00 00

Command data chart

68

Page 53

Names Operation type Header

Command data

CRC Action Type Setting code

Magnify

Get BE EF 03 06 00 7C D2 02 00 07 30 00 00

Increment BE EF 03 06 00 1A D2 04 00 07 30 00 00

Decrement BE EF 03 06 00 CB D3 05 00 07 30 00 00

Auto off

Get BE EF 03 06 00 08 86 02 00 10 31 00 00

Increment BE EF 03 06 00 6E 86 04 00 10 31 00 00

Decrement BE EF 03 06 00 BF 87 05 00 10 31 00 00

Brightness Reset Execute BE EF 03 06 00 58 D3 06 00 00 70 00 00

Contrast Reset Execute BE EF 03 06 00 A4 D2 06 00 01 70 00 00

V.Position Reset Execute BE EF 03 06 00 E0 D2 06 00 02 70 00 00

H.Position Reset Execute BE EF 03 06 00 IC D3 06 00 03 70 00 00

H.Size Reset Execute BE EF 03 06 00 68 D2 06 00 04 70 00 00

Color Balance R Reset Execute BE EF 03 06 00 94 D3 06 00 05 70 00 00

Color Balance B Reset Execute BE EF 03 06 00 D0 D3 06 00 06 70 00 00

Sharpness Reset Execute BE EF 03 06 00 C4 D0 06 00 09 70 00 00

Color Reset Execute BE EF 03 06 00 80 D0 06 00 0A 70 00 00

Tint Reset Execute BE EF 03 06 00 7C D1 06 00 0B 70 00 00

Keystone_V Reset Execute BE EF 03 06 00 08 D0 06 00 0C 70 00 00

Keystone_H Reset Execute BE EF 03 06 00 98 D8 06 00 20 70 00 00

Auto Execute BE EF 03 06 00 91 D0 06 00 0A 20 00 00

Blank on/off

Set

off BE EF 03 06 00 FB D8 01 00 20 30 00 00

on BE EF 03 06 00 6B D9 01 00 20 30 01 00

Get BE EF 03 06 00 C8 D8 02 00 20 30 00 00

Error Status Get

BE EF 03 06 00 D9 D8 02 00 20 60 00 00

(Example of Return)

00 00 01 00 02 00 03 00

(Normal) (Cover-error) (Fan-error) (Lamp-error)

04 00 05 00 06 00

(Temp-error) (Air flow-error) (Lamp-Time-over)

Power

Set

OFF

BE EF 03 06 00 2A D3 01 00 00 60 00 00

ON

BE EF 03 06 00 BA D2 01 00 00 60 01 00

Get

BE EF 03 06 00 19 D3 02 00 00 60 00 00

Input Source

Set

RGB1 BE EF 03 06 00 FE D2 01 00 00 20 00 00

RGB2 BE EF 03 06 00 3E D0 01 00 00 20 04 00

DVI BE EF 03 06 00 0E D2 01 00 00 20 03 00

Video BE EF 03 06 00 6E D3 01 00 00 20 01 00

SVideo BE EF 03 06 00 9E D3 01 00 00 20 02 00

Component

BE EF 03 06 00 AE D1 01 00 00 20 05 00

Get BE EF 03 06 00 CD D2 02 00 00 20 00 00

Volume

Get BE EF 03 06 00 31 D3 02 00 01 20 00 00

Increment BE EF 03 06 00 57 D3 04 00 01 20 00 00

Decrement BE EF 03 06 00 86 D2 05 00 01 20 00 00

Command data chart

CP-X430W

69

Page 54

CP-X430W

Names Operation type Header

Command data

CRC Action Type Setting code

Mute

Set

Normal BE EF 03 06 00 46 D3 01 00 02 20 00 00

Mute BE EF 03 06 00 D6 D2 01 00 02 20 01 00

Get BE EF 03 06 00 75 D3 02 00 02 20 00 00

Brightness

Get BE EF 03 06 00 89 D2 02 00 03 20 00 00

Increment BE EF 03 06 00 EF D2 04 00 03 20 00 00

Decrement BE EF 03 06 00 3E D3 05 00 03 20 00 00

Contrast

Get BE EF 03 06 00 FD D3 02 00 04 20 00 00

Increment BE EF 03 06 00 9B D3 04 00 04 20 00 00

Decrement BE EF 03 06 00 4A D2 05 00 04 20 00 00

Color

Balance R

Get BE EF 03 06 00 01 D2 02 00 05 20 00 00

Increment BE EF 03 06 00 67 D2 04 00 05 20 00 00

Decrement BE EF 03 06 00 B6 D3 05 00 05 20 00 00

Color

Balance B

Get BE EF 03 06 00 45 D2 02 00 06 20 00 00

Increment BE EF 03 06 00 23 D2 04 00 06 20 00 00

Decrement BE EF 03 06 00 F2 D3 05 00 06 20 00 00

Keystone_V

Get BE EF 03 06 00 B9 D3 02 00 07 20 00 00

Increment BE EF 03 06 00 DF D3 04 00 07 20 00 00

Decrement BE EF 03 06 00 0E D2 05 00 07 20 00 00

Keystone_H

Get BE EF 03 06 00 E9 D0 02 00 0B 20 00 00

Increment BE EF 03 06 00 8F D0 04 00 0B 20 00 00

Decrement BE EF 03 06 00 5E D1 05 00 0B 20 00 00

Aspect

Set

4:3, Full BE EF 03 06 00 9E D0 01 00 08 20 00 00

16:9 BE EF 03 06 00 0E D1 01 00 08 20 01 00

Small BE EF 03 06 00 FE D1 01 00 08 20 02 00

Get BE EF 03 06 00 AD D0 02 00 08 20 00 00

Display

Position at

16 : 9 or Small

Set

Default BE EF 03 06 00 62 D1 01 00 09 20 00 00

Bottom BE EF 03 06 00 F2 D0 01 00 09 20 01 00

Top BE EF 03 06 00 02 D0 01 00 09 20 02 00

Get BE EF 03 06 00 51 D1 02 00 09 20 00 00

V.Position

Get BE EF 03 06 00 0D 83 02 00 00 21 00 00

Increment BE EF 03 06 00 6B 83 04 00 00 21 00 00

Decrement BE EF 03 06 00 BA 82 05 00 00 21 00 00

H.Position

Get BE EF 03 06 00 F1 82 02 00 01 21 00 00

Increment BE EF 03 06 00 97 82 04 00 01 21 00 00

Decrement BE EF 03 06 00 46 83 05 00 01 21 00 00

H.Size

Get BE EF 03 06 00 B5 82 02 00 02 21 00 00

Increment BE EF 03 06 00 D3 82 04 00 02 21 00 00

Decrement BE EF 03 06 00 02 83 05 00 02 21 00 00

H.Phase

Get BE EF 03 06 00 49 83 02 00 03 21 00 00

Increment BE EF 03 06 00 2F 83 04 00 03 21 00 00

Decrement BE EF 03 06 00 FE 82 05 00 03 21 00 00

Command data chart

70

Page 55

Names Operation type Header

Command data

CRC Action Type Setting code

Sharpness

Get BE EF 03 06 00 F1 72 02 00 01 22 00 00

Increment BE EF 03 06 00 97 72 04 00 01 22 00 00

Decrement BE EF 03 06 00 46 73 05 00 01 22 00 00

Color

Get BE EF 03 06 00 B5 72 02 00 02 22 00 00

Increment BE EF 03 06 00 D3 72 04 00 02 22 00 00

Decrement BE EF 03 06 00 02 73 05 00 02 22 00 00

Tint

Get BE EF 03 06 00 49 73 02 00 03 22 00 00

Increment BE EF 03 06 00 2F 73 04 00 03 22 00 00

Decrement BE EF 03 06 00 FE 72 05 00 03 22 00 00

Video Format

Set

Auto BE EF 03 06 00 9E 75 01 00 00 22 0A 00

NTSC BE EF 03 06 00 FE 71 01 00 00 22 04 00

PAL BE EF 03 06 00 6E 70 01 00 00 22 05 00

SECAM BE EF 03 06 00 6E 75 01 00 00 22 09 00

NTSC 4.43 BE EF 03 06 00 5E 72 01 00 00 22 02 00

M-PAL BE EF 03 06 00 FE 74 01 00 00 22 08 00

N-PAL BE EF 03 06 00 0E 71 01 00 00 22 07 00

Get BE EF 03 06 00 0D 73 02 00 00 22 00 00

HDTV

Set

1080i BE EF 03 06 00 F2 73 01 00 05 22 00 00

1035i BE EF 03 06 00 62 72 01 00 05 22 01 00

Get BE EF 03 06 00 C1 73 02 00 05 22 00 00

PinP Size

Set

off BE EF 03 06 00 FE 22 01 00 00 23 00 00

Large BE EF 03 06 00 6E 23 01 00 00 23 01 00

Small BE EF 03 06 00 9E 23 01 00 00 23 02 00

Get BE EF 03 06 00 CD 22 02 00 00 23 00 00

PinP Position

Set

Upper left BE EF 03 06 00 02 23 01 00 01 23 00 00

Upper right BE EF 03 06 00 92 22 01 00 01 23 01 00

bottom left BE EF 03 06 00 62 22 01 00 01 23 03 00