Page 1

CONFIDENTIAL

Dec. 2017

PRODUCT NAME

Hitachi 184 mm (7-1/4”) Circular Saw

Models C 7UR, C 7BUR *For the USA and Canada only

Hitachi 185 mm (7-1/4”) Circular Saw

Model C 7UR *Except for the USA and Canada

CONTENTS

REPAIR GUIDE ---------------------------------------------------------------------------------------------------------------- 1

1. Precautions on disassembly and reassembly ----------------------------------------------------------- 1

• Disassembly ------------------------------------------------------------------------------------------------------ 1

• Reassembly ------------------------------------------------------------------------------------------------------ 6

• Lubrication points and type of lubricant -------------------------------------------------------------------- 8

• Screw tightening torque --------------------------------------------------------------------------------------- 8

• Checking after reassembly ------------------------------------------------------------------------------------- 9

• Wiring diagram ---------------------------------------------------------------------------------------------------10

STANDARD REPAIR TIME (UNIT) SCHEDULES -------------------------------------------------------------------12

Page

C

C 7UR

Overseas Sales Division

Page 2

REPAIR GUIDE

CAUTION: During disassembly and reassembly, and at all other times as well, always exercise

sufficient care in handling to ensure that there is no deviation in the bottom surface

flatness of the base or in its perpendicularity relative to the saw blade.

1. Precautions on disassembly and reassembly

[Bold] numbers in the description below correspond to the item numbers in the parts list and exploded

assembly diagram for the Model C 7UR, and {Bold} numbers correspond to those for the Model C 7BUR.

CAUTION: Prior to disassembly of the circular saw, remove the TCT Saw Blade [12]{12} to protect

the saw blade teeth and yourself.

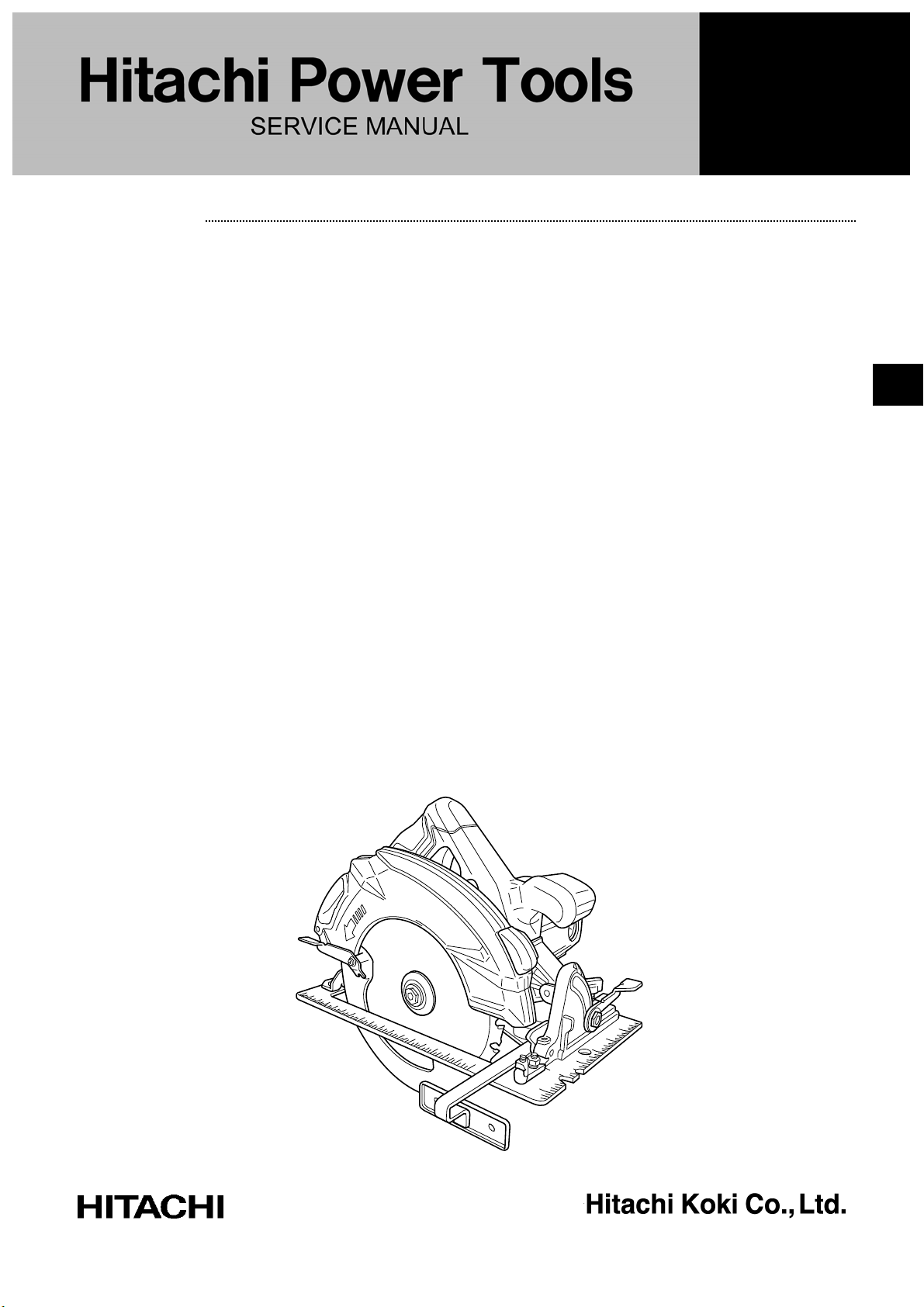

1. Removal of the TCT saw blade

(1) Gently turn the Hex. Socket Hd. Bolt M8 x 15.5 [14]{14} using the accompanying Hex. Bar Wrench 6

mm [503]{502} to lock the Spindle and Gear Set [1]{1} while pushing the Lock Lever [23]{23}.

(2) After locking the Spindle and Gear Set [1]{1}, turn the Hex. Bar Wrench 6 mm [503]{502}

counterclockwise to loosen and remove the Hex. Socket Hd. Bolt M8 x 15.5 [14]{14} and

[13]{13}. Draw the Lever [16] and insert the Lower Guard [8]{8} into the Gear Cover [26]{26} and then

remove the TCT Saw Blade [12]{12}.

NOTE: Be careful not to cut your fingers by the saw blade teeth.

• Removal of the TCT saw blade

[23]{23}

1

(3) Remove Washer (A) [11]{11} from the Spindle and Gear Set [1]{1}. If the Base Plate [65]{62} interferes

with removing Washer (A) [11]{11}, loosen the Lever [66]{63} and adjust to shallower cutting depth.

Loosen

2

Push in

Disassembly

3

[503]{502}

4

[14]{14}

[13]{13}

[12]{12}

[16]{16}

Washer (B)

5

6

Draw

• Removal of washer (A)

[26]{26}

[11]{11}

[12]{12}

[14]{14}

[13]{13}

Loosen

Tighten

[65]{62}

[66]{63}

-1-

Page 3

}

}

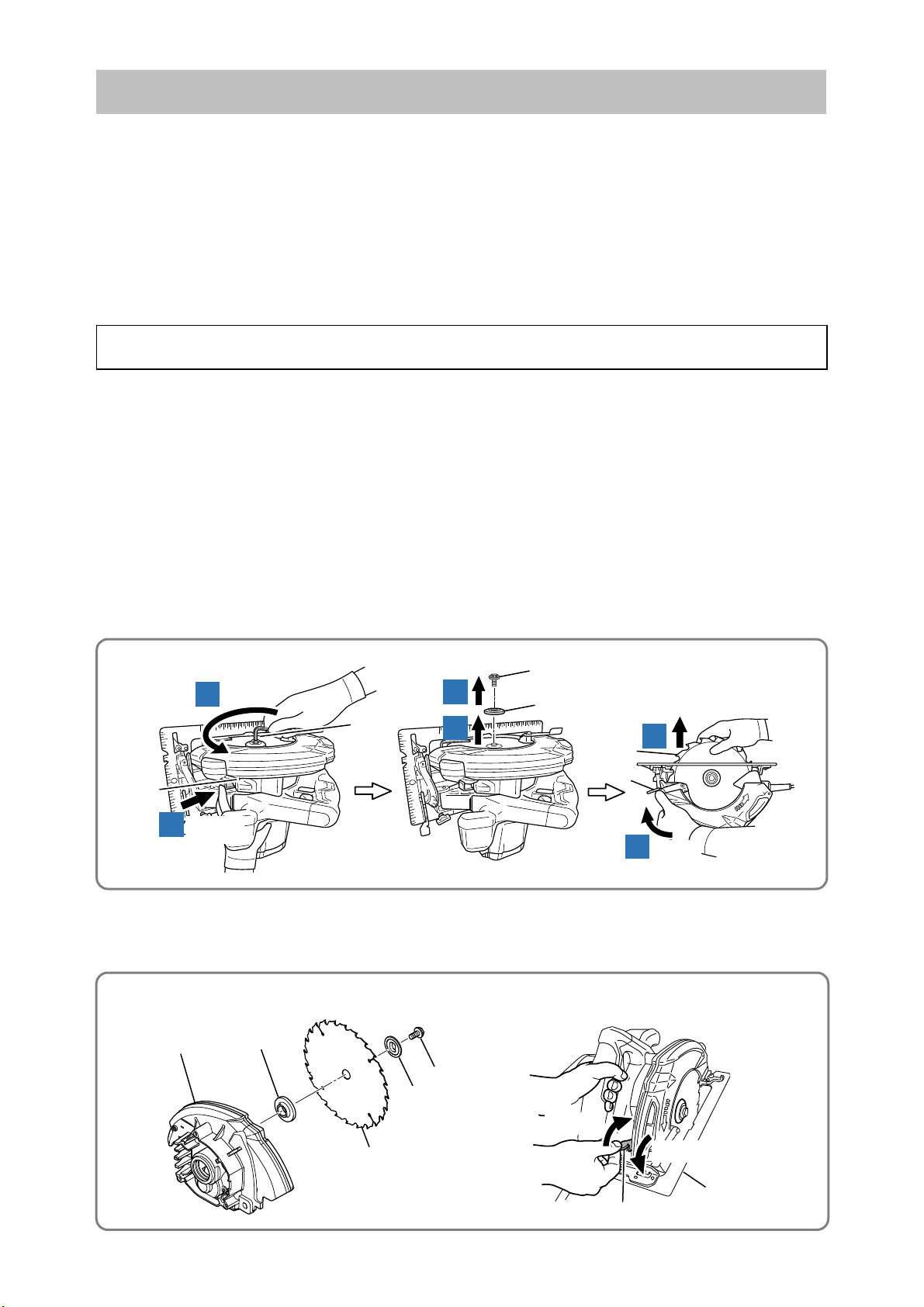

2. Removal of the lower guard

(1) Remove the two Seal Lock Flat Hd. Screws M4 x 10 [10]{10}, then remove the Bearing Cover [9]{9}.

(2) Remove the hook of the Return Spring [7]{7} from the Gear Cover [26]{26} and the Lower Guard [8]{8},

then remove the Lower Guard [8]{8}, Liner [5]{5} and Washer [6]{6}.

• Removal of the lower guard

[26]{26}

[6]{6}

[5]{5}

[7]{7}

[8]{8}

[9]{9}

[10]{10}

3. Removal of the lever

(1) Loosen the Lever [66]{63} and remove the Retaining Ring (E-type) [58]{55}.

(2) Remove the Lever [66]{63}, Lock Nut [59]{56}, Bolt Washer M8 [60]{57}, and Bolt (Square) M8

[29]{29}.

• Removal of Lever

[66]{63

[59]{56

[58]{55}

[29]{29}

[60]{57}

-2-

Page 4

(

)

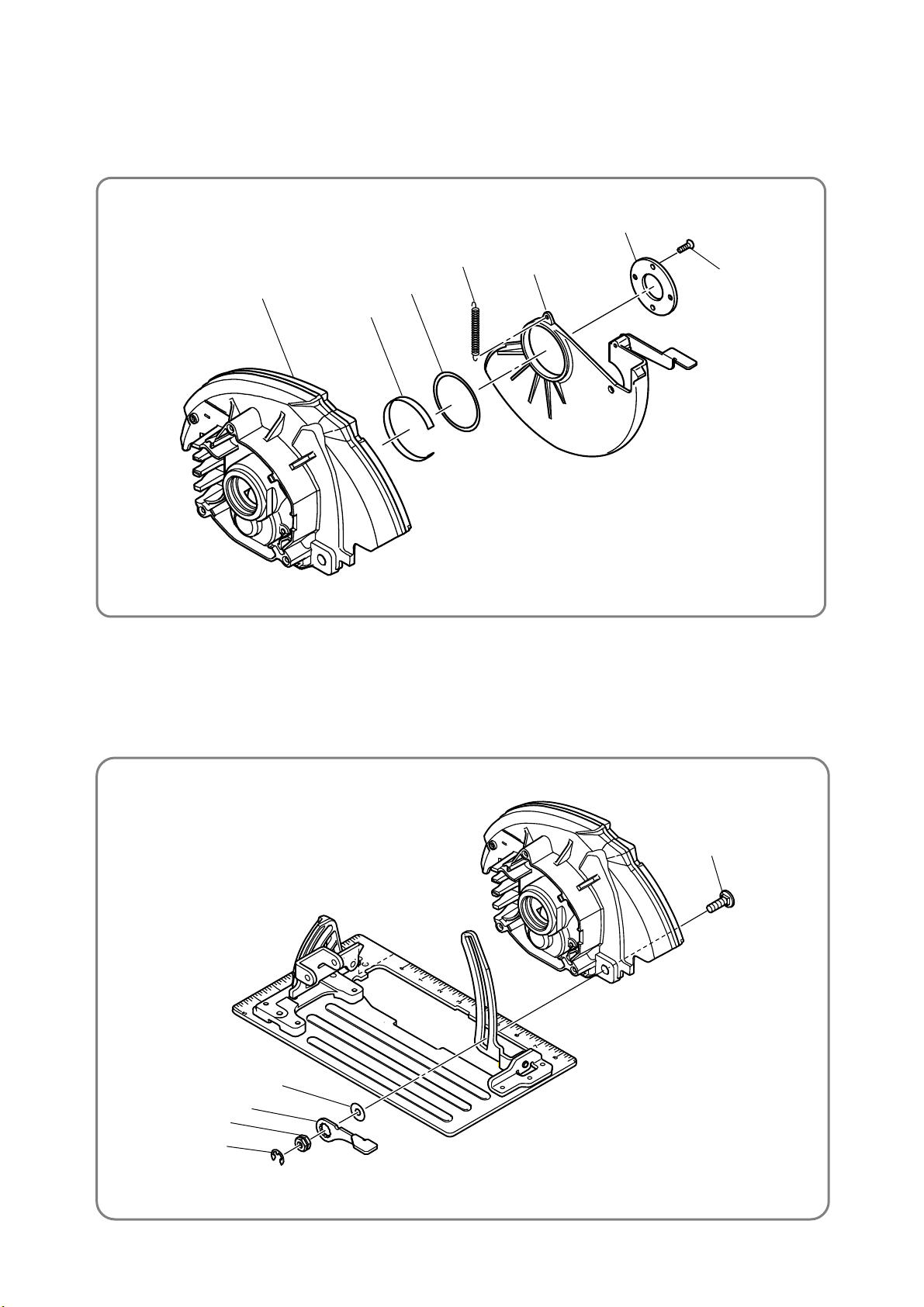

4. Removal of the bearing holder and spindle and gear set

(1) After removing the Lower Guard [8]{8} as described above, loosen the two Seal Lock Flat Hd. Screws

M5 x 14 [3]{3}.

(2) Remove the Bearing Holder [2]{2} together with the Spindle and Gear Set [1]{1} from the Gear Cover

[26]{26}.

• Removal of the bearing holder and spindle and gear set

[26]{26}

[3]{3}

[1]{1}

[2]{2}

5. Separation of the spindle and gear set from the bearing holder

(1) Support the Bearing Holder [2]{2} with an appropriate tubular jig.

(2) Push down on the end of the spindle to separate the Spindle and Gear Set [1]{1} from the Bearing

Holder [2]{2}.

• Separation of the spindle and gear set from the bearing holder

Push

Jig

60 mm

2-23/64"

50 mm

(1-31/32")

[1]{1}

[2]{2}

-3-

Page 5

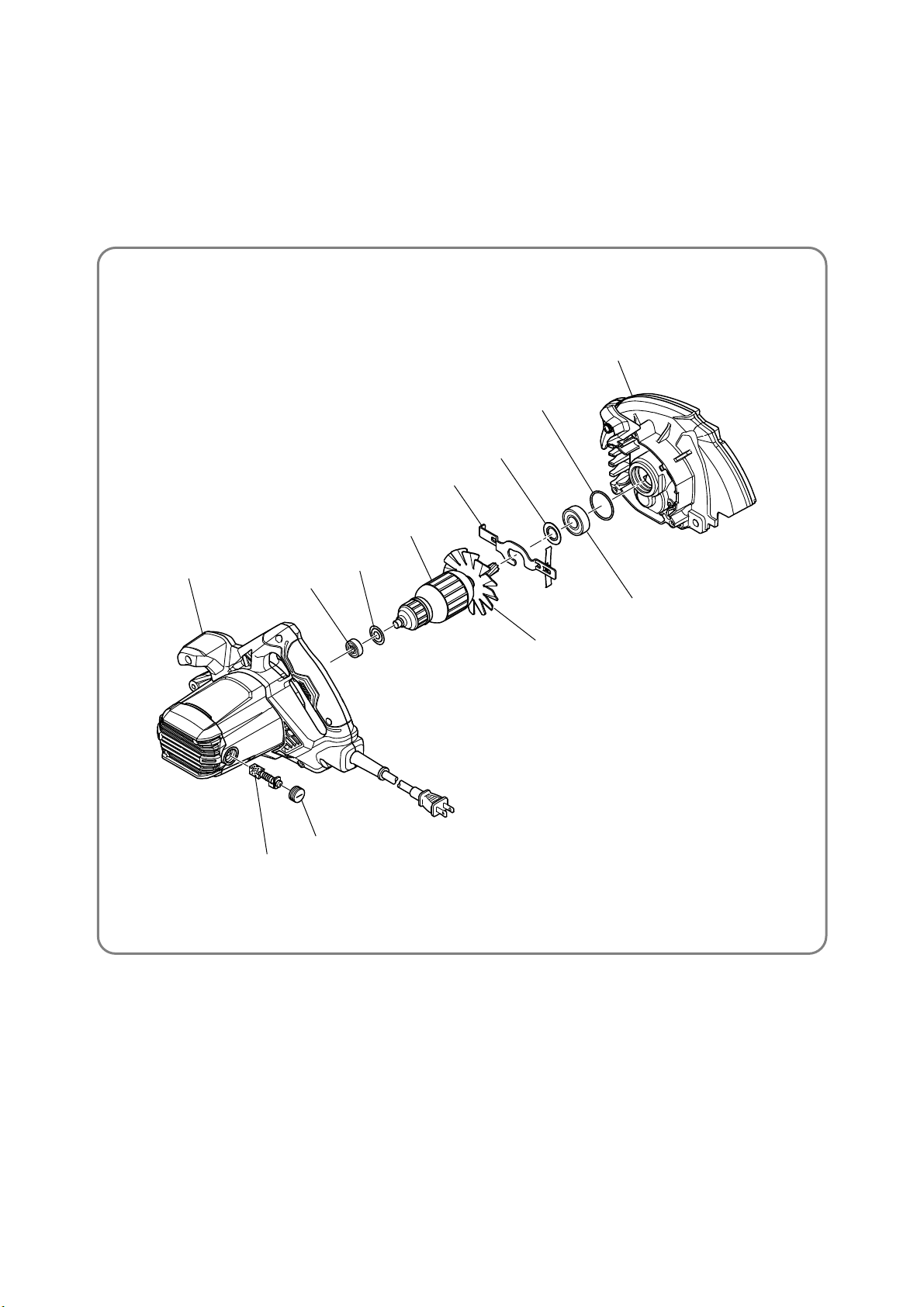

6. Disassembly of the motor unit

(1) Remove the Brush Caps [45]{42} and take out the Carbon Brushes [44]{41}.

(2) Loosen the Machine Screws M5 x 50 [39]{36} and separate the Housing Ass'y [42]{39} from the Gear

Cover [26]{26}. If the Armature [22]{22} is remained in the Housing Ass'y [42]{39}, gently tap the

Housing Ass'y [42]{39} on the edge of the surface where the Gear Cover [26]{26} is mounted with a

wooden or plastic hammer and remove the Armature [22]{22}.

NOTE: Do not hit the fan of the Armature [22]{22}.

• Disassembly of the motor unit

[26]{26}

[34]{32}

[32]{30}

[23]{23}

[53]{56}

[22]{22}

[18]{18}

[17]{17}

[33]{31}

Fan

[45]{42}

[44]{41}

-4-

Page 6

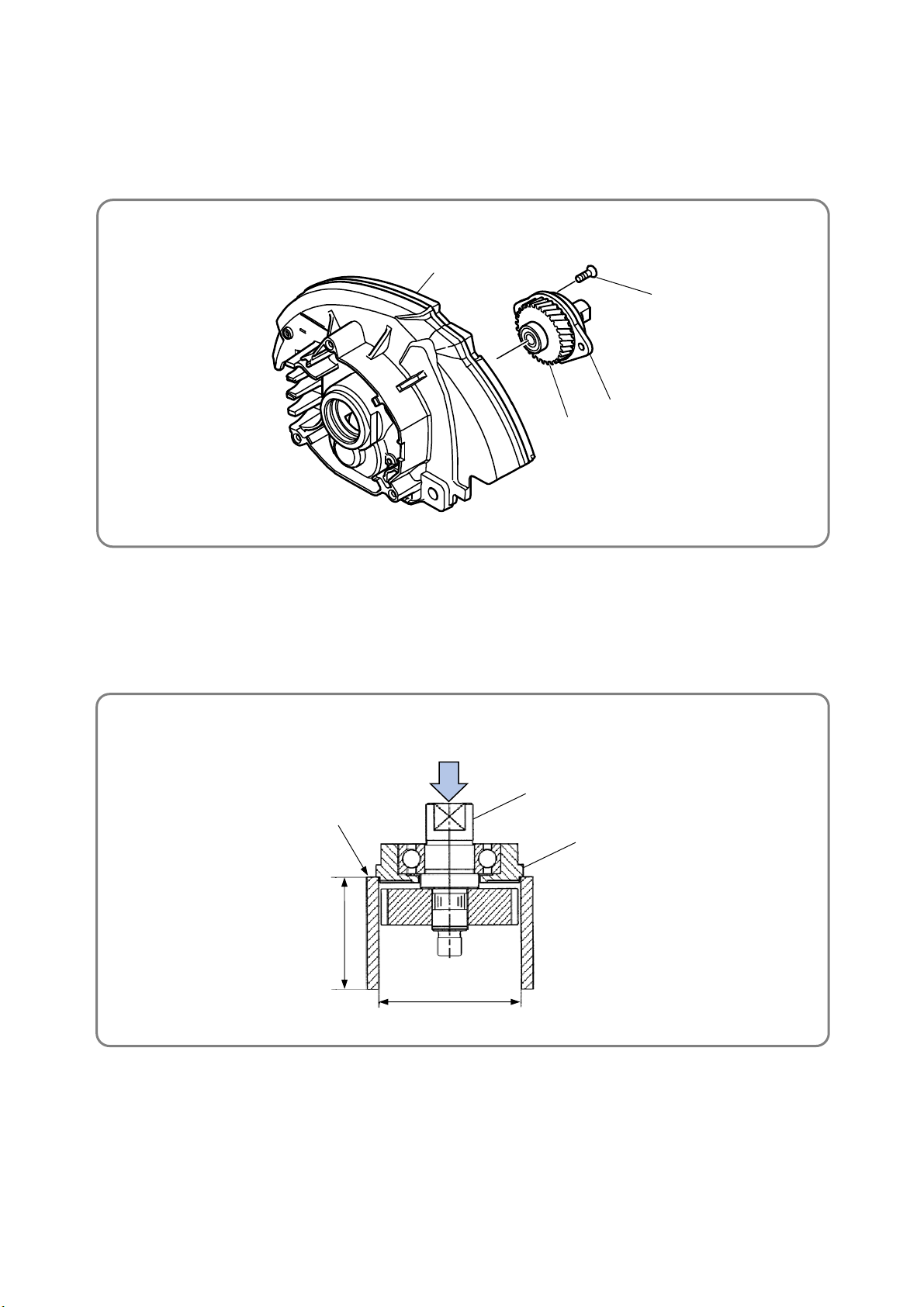

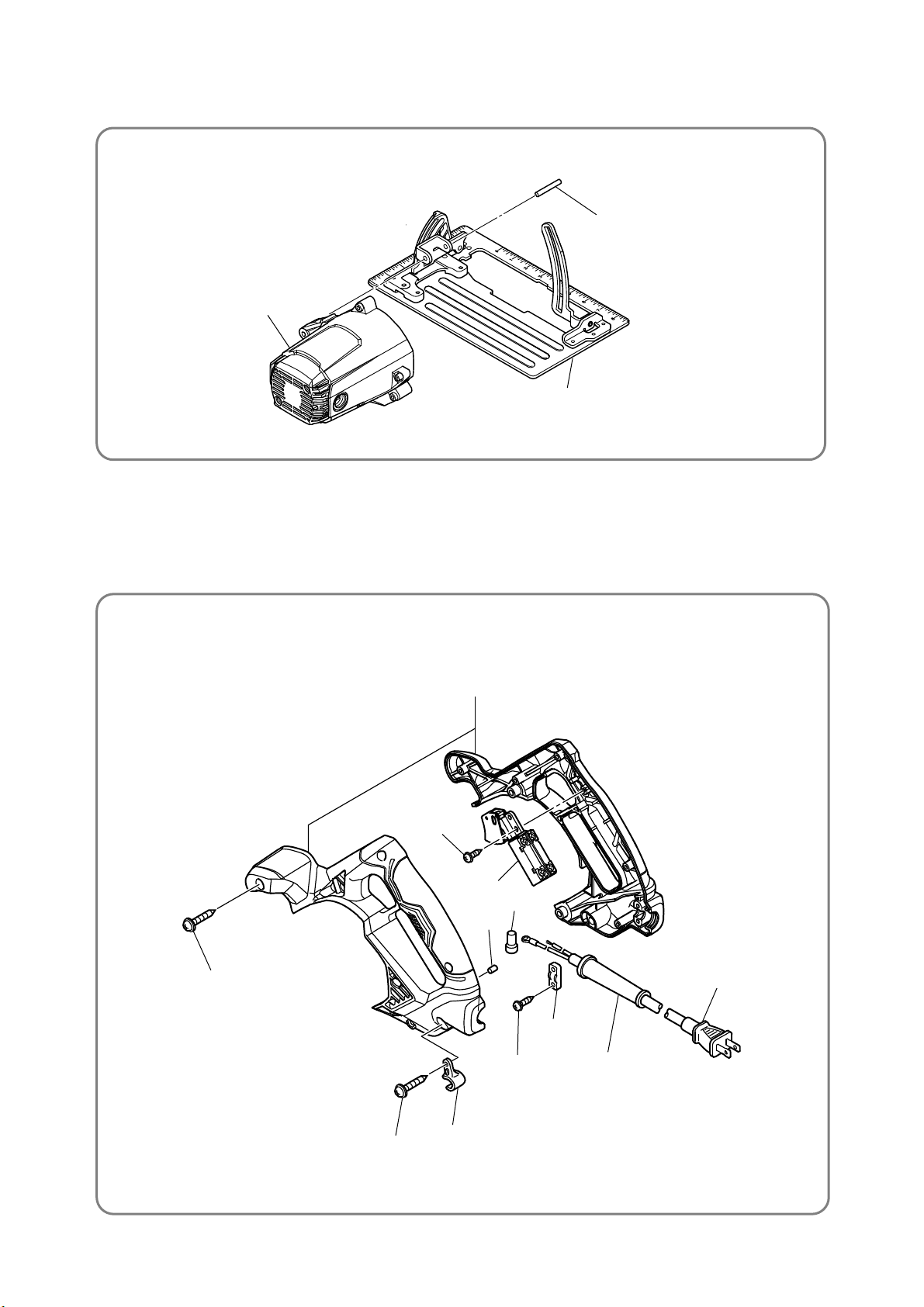

7. Removal of the base ass’y

Extract the Roll Pin D6 x 40 [74]{71} and remove the Base Ass’y [77]{74} from the Housing Ass’y [42]{39}.

• Removal of the base ass'y

[74]{71}

[42]{39}

[77]{74}

8. Disassembly of handle (A).(B) set

(1) Loosen and remove the six Tapping Screws D4 x 20 [38]{35}.

(2) Remove handle (B).

(3) Remove the Switch [48]{45}, Cord [55]{52}, etc. from handle (A).

• Disassembly of handle (A).(B) set

[38]{35}

[47]{44}

[48]{45}

[51]{46}

[56]{53}

{48}

[53]{50}

[52]{49}

[55]{52}

[54]{51}

[38]{35}

[46]{43}

-5-

Page 7

Reassembly

Generally, perform reassembly by reversing the disassembly procedure. However, special attention should

be given to the following items. Refer to “Lubrication points and type of lubricant” on page 8 for the grease

required for reassembly.

1. Reassembly of the power supply unit and its vicinity

Perform wiring according to the wiring diagrams shown on pages 10 and 11 when replacing the Stator Ass'y

[20]{20}, Cord [55]{52}, Noise Suppressor [35] or the Switch [48]{45}. Mount the Cord Clip [53]{50} in the

direction shown in the following figure.

• Mounting the cord clip

For the USA, Canada, and Mexico

[52]{49}

Other than the USA, Canada, and Mexico

[52]

[53]{50}

Protrusion

[53]

Protrusion

2. Mounting the stator ass'y

Press-fit the Stator Ass'y [20]{20} into the Housing Ass'y [42]{39} so that the internal wire of the Stator

Ass'y [20]{20} is positioned to the opposite side of the name plate on the Housing Ass'y [42]{39}. Refer to

the wiring diagrams on pages 10 and 11. After press-fitting, hook the Brush Terminal [19]{19} on the Brush

Holder [43]{40}.

3. Mounting the lock lever

(1) Mount the O-ring [34]{32} into the Gear Cover [26]{26}. Mount the Lock Lever [23]{23} between the fan

of the Armature [22]{22} and Dust Washer (B) [32]{30}. Mount the Ball Bearing [33]{31} to it. Then

carefully mount this assembly into the Gear Cover [26]{26}.

NOTE: Check that both ends of the flat spring on the Lock Lever [23]{23} are properly supported

by the ribs inside the Gear Cover [26]{26}.

(2) After mounting the Lock Lever [23]{23}, push the Lock Lever [23]{23} by hand and check that it returns

to its original position when released.

• Mounting the lock lever

[23]{23}

[22]{22}

[33]{31}

[32]{30}

[26]{26}

[26]{26}

Rib

[34]{32}

[23]{23}

Rib

-6-

Page 8

4. Mounting the bearing holder

(1) Mount the Bearing Holder [2]{2} to the Gear Cover [26]{26} positioning the protrusion on either left or

right side of the Bearing Holder [2]{2} downward.

• Mounting the bearing holder

The Bearing Holder [2]{2} has a protrusion on either left or right side.

[26]{26}

Protrusion

NG

OK

Position of the protrusion

NG

OK

-7-

Page 9

Lubrication points and type of lubricant

Apply specified amount of grease to the following portions.

Grease (Nippeco BC-4)

• Pinion tooth flank of the Armature [22]{22} ····························································· About 1 g

• Gear tooth flank of the Spindle and Gear Set [1]{1} ·················································· About 2 g

• Inside the gear chamber of the Gear Cover [26]{26} ················································· About 6 g

Prepare the following grease as necessary.

Item Registered part name Net weight Code No.

Grease (Nippeco BC-4) Grease (Nippeco BC-4) 75 g 372814

Screw tightening torque

Tightening torque

Location Name of screw or bolt

No.

used

N•m kgf•cm

[2]{2} Bearing Holder [3]{3} Seal Lock Flat Hd. Screw M5 x 14 2 2.7 - 4.1 2.0 - 3.0

[9]{9} Bearing Cover [10]{10} Seal Lock Flat Hd. Screw M4 x 10 2 1.4 - 2.2 1.0 - 1.6

[12]{12} TCT Saw Blade [14]{14} Hex. Socket Hd. Bolt M8 x 15.5 1 7.8 - 11.8 5.8 - 8.7

[16]{16} Lever [15]{15} Machine Screw (W/Washers) M4 x 12 (Black) 1 0.8 - 1.2 0.6 - 0.9

[24]{24} Flow Guide (B) [15]{15} Machine Screw (W/Washers) M4 x 12 (Black) 1 1.4 - 2.2 1.0 - 1.6

[27]{27} Cushion [28]{28} Flat Hd. Screw M6 x 20 1 —*1 —

[40]{37} Tail Cover [38]{35} Tapping Screw (W/Flange) D4 x 20 (Black) 2 1.5 - 2.5 1.1 - 1.8

[46]{43} Cord Holder [38]{35} Tapping Screw (W/Flange) D4 x 20 (Black) 1 1.5 - 2.5 1.1 - 1.84

[56]{53} Handle (A).(B) Set [38]{35} Tapping Screw (W/Flange) D4 x 20 (Black) 5 1.5 - 2.5 1.1 - 1.84

Main body

[42]{39} Housing Ass'y [39]{36} Machine Screw (W/Washers) M5 x 50 (Black) 3 2.7 - 4.1 2.0 - 3.0

[43]{40} Brush Holder [41]{38} Hex. Socket Set Screw M5 x 8 2 0.5 - 1.0 0.4 - 0.74

[44]{41} Carbon Brush [45]{42} Brush Cap 2 0.5 - 1.5 0.4 - 0.74

[48]{45} Switch [47]{44} Tapping Screw (W/Flange) D4 x 10 (Black) 2 1.5 - 2.5 1.1 - 1.84

[53]{50} Cord Clip [52]{49} Tapping Screw (W/Flange) D4 x 16 2 1.5 - 2.5 1.1 - 1.84

[57]{54} Lever (A) [59]{56} Lock Nut 1 1.4 - 2.0 1.0 - 1.5

[66]{63} Lever [59]{56} Lock Nut 1 1.4 - 2.0 1.0 - 1.5

[61]{58} Bevel Stand [63]{60} Seal Lock Flat Hd. Screw M5 x 14 4 2.7 - 4.1 2.0 - 3.0

*1

[72]{69} Step Pin [67]{64} Seal Lock Hex. Socket Set Screw M5 x 6 1 2.7 - 4.1 2.0 - 3.0

[75]{72} Link [76]{73} Seal Lock Flat Hd. Screw M4 x 8 3 1.4 - 2.2 1.0 - 1.6

Base ass'y

[69]{66} U-nut M5 [71]{68} Special Bolt 1 2.7 - 4.1 2.0 - 3.0

*1: Tighten the Flat Hd. Screw M6 x 20 [28]{28} until it is flush with the Cushion [27]{27}.

-8-

Page 10

• Check the following after reassembly.

(1) Adjust the base ass’y angle to 90°±0.5° with the Slotted Hd. Set Screw (Seal Lock) M6 x 8 [64]{61}.

(2) Check that the Base Ass’y [77]{74} operates smoothly. (Adjust the cutting depth and tilt angle.)

(3) Check the switch operation.

(4) Check that the Lower Guard [8]{8} moves smoothly and returns within the operating range (maximum

to minimum cutting depth, tilt angle of 0° to 55°) of the Base Ass’y [77]{74}.

(5) Check the insulation resistance and dielectric strength voltage.

Insulation resistance: 7 MΩ or higher with DC 500 V megohm tester

Dielectric strength: AC 4,000 V/1 minute, with no abnormalities

(6) Check that runout of the saw blade is up to 0.7 mm at 160 mm dia. position.

(7) Check that the direction indicated by the arrow mark on the TCT Saw Blade [12]{12} matches that of the

arrow mark on the Gear Cover [26]{26}.

(8) Perform checking according to the handling instructions.

• Cleaning the cover

Clean the exterior of the tool with a soft cloth moistened with soapy water, and dry thoroughly. Do not use

chloric solvent, gasoline, and thinner for cleaning. Otherwise, the plastic components may be melted.

Checking after reassembly

-9-

Page 11

Wiring diagram

Connect the wires as illustrated in the diagrams below.

Be sure to connect the wires correctly. If the wires are incorrectly connected, the motor may not turn or

other problems could occur.

• Connecting and wiring diagrams of the Model C 7UR for the USA, Canada, and Mexico (120 V)

Switch

Stator coil

White

5±1

Power

source

White

Black

White

Armature

Stator coil

• Connecting and wiring diagrams of the Model C 7UR for the UK (110 V)

Ferrite core

Blue

Power

source

Brown

5±1

Noise suppressor

Ferrite

core

Switch

White

White

Stator coil

Armature

Noise

suppressor

Stator coil

-10-

Page 12

r

r

r

• Connecting and wiring diagrams of the Model C 7UR for countries other than the USA, Canada, and Mexico (230 V to 240 V)

Switch

Stator coil

Brown

Blue

Black

Blue

Switch (Brake)

Powe

source

5±1

Noise suppressor

• Connecting and wiring diagrams of the Model C 7BUR for the USA, Canada, and Mexico (120 V)

Blue

Blue

Armature

Noise

suppressor

Stator coil

Stator

Powe

source

5±1

Connector

Armature

Brake coil

Stator coil

White

Yellow

Black

Connecto

-11-

Page 13

MODEL

C 7UR

C 7BUR

STANDARD REPAIR TIME (UNIT) SCHEDULES

Variable

General Assembly

10 20 30 40 50 60 min.

Work Flow

Handle

(A).(B) Set

Lower Guard

Return

Spring

Base Ass’y

Bevel Plate

Switch

Cord

Cord Armor

Armature

Ball Bearing

6202VV

Ball Bearing

6000VV

Bearing

Bushing

Spindle and

Gear Set

Bearing

Holder

Ball Bearing

6003VV

Gear Cover

Housing

Ass'y

Stator Ass'y

-12-

Page 14

LIST NO. E544

CIRCULAR SAW

Model C 7UR

501

503

3

2

1

502

12

504

505

9

8

7

6

5

4

22

21

11

10

15

16

15

23

25

24

32

26

34

33

2017 · 10 · 23

14

13

(E1)

28

27

29

30

31

20

58

19

57

18

17

35

36

38

37

39

38

43

42

41

40

44

45

38

56

47

48

50

46

49

51

53

52

59

60

62

63

64

54

68

67

61

65

59

58

55

69

70

29

74

71

75

72

73

60

66

77

29

57

73

67

76

75

76

65

Page 15

PARTS C 7UR

DESCRIPTION REMARKS

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

- 2 - 10 - 17

*ALTERNATIVE PARTS

ITEM

NO.

NO.

USED

CODE NO.CODE NO.

1 372782 SPINDLE AND GEAR SET 1

2 372765 BEARING HOLDER 1

3 992013 SEAL LOCK FLAT HD. SCREW M5 X 14 2

4 6003VV BALL BEARING 6003VVCMPS2L 1

5 998887 LINER 1

6 370591 WASHER 1

7 373026 RETURN SPRING 1

8 372758 LOWER GUARD 1

9 302435 BEARING COVER 1

10 990430 SEAL LOCK FLAT HD. SCREW M4 X 10 2

11 324597 WASHER (A) 1

11 372780 WASHER (A) 1 FOR USA,CAN,MEX

11 321639 WASHER (A) 1 FOR AUS,NZL

12 302412 TCT SAW BLADE 185MM-D30 HOLE-NT18 1

12 302411 TCT SAW BLADE 185MM-D20 HOLE-NT18 1 FOR AUS,NZL

12 TCT SAW BLADE 185MM-D16 HOLE-NT24 1 FOR USA,CAN

12 372102 TCT SAW BLADE 185MM-D16 HOLE-NT24 1 FOR MEX

13 324598 WASHER (B) 1

13 320953 WASHER (B) 1 FOR AUS,NZL

14 324662 HEX. SOCKET HD. BOLT M8 X 15.5 1

15 935196

MACHINE SCREW (W/WASHERS) M4 X 12 (BLACK) 2

16 328045 LEVER 1

17 6000VV BALL BEARING 6000VVCMPS2L 1

18 302428 WASHER (A) 1

19 937623 BRUSH TERMINAL 2

20 340983C STATOR ASS'Y 120V 1 INCLUD.19,36

20 340983B STATOR ASS'Y 110V (W/NOISE SUPPRESSOR) 1 INCLUD.19,35,36

20 340983F STATOR ASS'Y 230-240V(W/NOISE SUPPRESSOR) 1 INCLUD.19,35,36

21 372743 FAN GUIDE 1

22 361074U ARMATURE ASS'Y 110V-120V 1 INCLUD.17,18,32,33

22 361074F ARMATURE 230V-240V 1

23 320959 LOCK LEVER 1

24 372768 FLOW GUIDE (B) 1

25 372767 FLOW GUIDE (A) 1

26 372763 GEAR COVER 1

27 337080 CUSHION 1

28 949794 FLAT HD. SCREW M6 X 20 (10 PCS.) 1

29 372774 BOLT (SQUARE) M8 2

30 935196 MACHINE SCREW (W/WASHERS) M4 X 12 (BLACK) 1 EXCEPT FOR USA,CAN

31 372757 DUST COLLECTOR SET 1 INCLUD.30,505 EXCEPT FOR USA,CAN

32 980700 DUST WASHER (B) 1

33 6202VV BALL BEARING 6202VVCMPS2L 1

34 372783 O-RING (I.D. 34.5) 1

35 930039 NOISE SUPPRESSOR 1 FOR EUROPE,GBR,AUS,NZL

36 311741 TERMINAL 2

36 930804 TERMINAL M4.0 (10 PCS.) 2 FOR USA,CAN,MEX

37 NAME PLATE 1

38 301653

39 997841

TAPPING SCREW (W/FLANGE) D4 X 20 (BLACK) 8

MACHINE SCREW (W/WASHERS) M5 X 50 (BLACK) 3

40 372762 TAIL COVER 1

Page 16

PARTS C 7UR

DESCRIPTION REMARKS

*

*

*

*

*

*

*

*

*

*

10 - 17 - 3 -

*ALTERNATIVE PARTS

NO.

USED

CODE NO.

ITEM

NO.

41 938477 HEX. SOCKET SET SCREW M5 X 8 2

42 372759 HOUSING ASS'Y 1 INCLUD.41,43

43 938241 BRUSH HOLDER 2

44 999038 CARBON BRUSH (1 PAIR) 2

45 945161 BRUSH CAP 2

46 370269 CORD HOLDER 1

47 311945

TAPPING SCREW (W/FLANGE) D4 X 10 (BLACK) 1

48 372781 SWITCH 1

49 334379 FERRITE CORE 1 FOR GBR (110V)

50 980063 TERMINAL 2

50 930804 TERMINAL M4.0 (10 PCS.) 2 FOR USA,CAN,MEX

51 931701 BEARING LOCK 1

52 984750 TAPPING SCREW (W/FLANGE) D4 X 16 2

53 937631 CORD CLIP 1

54 953327 CORD ARMOR D8.8 1

54 938051 CORD ARMOR D10.1 1

55 500453Z CORD 1 (CORD ARMOR D10.1)

55 500439Z CORD 1 (CORD ARMOR D8.8) FOR AUS,NZL

55 500435Z CORD 1 (CORD ARMOR D8.8) FOR GBR (230V)

55 500463Z CORD 1 (CORD ARMOR D8.8) FOR GBR (110V)

55 500247Z CORD 1 (CORD ARMOR D8.8) FOR EUROPE

56 373027 HANDLE (A).(B) SET 1

57 372773 LEVER (A) 1

58 670514 RETAINING RING (E-TYPE) FOR D10 SHAFT 2

59 372772 LOCK NUT 2

60 949433 BOLT WASHER M8 (10 PCS.) 2

61 372764 BEVEL STAND 1

62 372770 BEVEL PLATE 1

63 992013 SEAL LOCK FLAT HD. SCREW M5 X 14 4

64 308109

SLOTTED HD. SET SCREW (SEAL LOCK) M6 X 8 1

65 372769 BASE PLATE 1

66 372745 LEVER 1

67 319541

SEAL LOCK HEX. SOCKET SET SCREW M5 X 6 1

68 372778 SPRING (B) 1

69 308387 U-NUT M5 1

70 372776 STOPPER LEVER 1

71 372777 SPECIAL BOLT 1

72 372775 STEP PIN 1

73 372779

SEAL LOCK HEX. SOCKET SET SCREW M5 X 8 1

74 949686 ROLL PIN D6 X 40 (10 PCS.) 1

75 372771 LINK 1

76 328604 SEAL LOCK FLAT HD. SCREW M4 X 8 3

77 372785 BASE ASS'Y 1 INCLUD.29,57-65,67-73,75,76

Page 17

C 7UR

DESCRIPTION REMARKS

*

*

*

*

- 4 - Printed in Japan 10 - 17

(171023N)

*ALTERNATIVE PARTS

STANDARD ACCESSORIES

NO.

USED

CODE NO.

ITEM

NO.

501 372784 CASE 1 EXCEPT FOR USA,CAN

502 302691 GUIDE 1 EXCEPT FOR USA,CAN

503 872422 HEX. BAR WRENCH 6MM 1

504 371108 TOOL BAG 1 FOR USA,CAN

505 LEVER 1 EXCEPT FOR USA,CAN

(SUPPLIED WITH ITEM NO.31)

Page 18

LIST NO. E543

CIRCULAR SAW

Model C 7BUR

501

3

2

1

19

18

17

502

12

11

10

9

8

7

6

5

4

22

21

20

15

16

15

23

54

53

25

24

30

55

56

26

32

31

57

58

59

2017 · 10 · 23

14

13

65

64

(E1)

28

27

29

66

67

29

68

69

71

72

70

60

33

44

35

34

36

35

40

39

38

37

41

42

45

47

46

48

50

49

43

35

51

62

61

57

63

56

55

29

54

64

73

72

52

73

74

62

70

Page 19

PARTS C 7BUR

DESCRIPTION REMARKS

- 2 - 10 - 17

*ALTERNATIVE PARTS

ITEM

NO.

NO.

USED

CODE NO.CODE NO.

1 372782 SPINDLE AND GEAR SET 1

2 372765 BEARING HOLDER 1

3 992013 SEAL LOCK FLAT HD. SCREW M5 X 14 2

4 6003VV BALL BEARING 6003VVCMPS2L 1

5 998887 LINER 1

6 370591 WASHER 1

7 373026 RETURN SPRING 1

8 372758 LOWER GUARD 1

9 302435 BEARING COVER 1

10 990430 SEAL LOCK FLAT HD. SCREW M4 X 10 2

11 372780 WASHER (A) 1

12 TCT SAW BLADE 185MM-D16 HOLE-NT24 1

13 324598 WASHER (B) 1

14 324662 HEX. SOCKET HD. BOLT M8 X 15.5 1

15 935196

MACHINE SCREW (W/WASHERS) M4 X 12 (BLACK) 2

16 328045 LEVER 1

17 6000VV BALL BEARING 6000VVCMPS2L 1

18 302428 WASHER (A) 1

19 937623 BRUSH TERMINAL 2

20 340984C STATOR ASS'Y 120V 1 INCLUD.19,33

21 372743 FAN GUIDE 1

22 361074U ARMATURE ASS'Y 110V-120V 1 INCLUD.17,18,30,31

23 320959 LOCK LEVER 1

24 372768 FLOW GUIDE (B) 1

25 372767 FLOW GUIDE (A) 1

26 372763 GEAR COVER 1

27 337080 CUSHION 1

28 949794 FLAT HD. SCREW M6 X 20 (10 PCS.) 1

29 372774 BOLT (SQUARE) M8 2

30 980700 DUST WASHER (B) 1

31 6202VV BALL BEARING 6202VVCMPS2L 1

32 372783 O-RING (I.D. 34.5) 1

33 930804 TERMINAL M4.0 (10 PCS.) 2

34 NAME PLATE 1

35 301653

36 997841

TAPPING SCREW (W/FLANGE) D4 X 20 (BLACK) 8

MACHINE SCREW (W/WASHERS) M5 X 50 (BLACK) 3

37 372762 TAIL COVER 1

38 938477 HEX. SOCKET SET SCREW M5 X 8 2

39 372759 HOUSING ASS'Y 1 INCLUD.38,40

40 938241 BRUSH HOLDER 2

41 999038 CARBON BRUSH (1 PAIR) 2

42 945161 BRUSH CAP 2

43 370269 CORD HOLDER 1

44 311945

TAPPING SCREW (W/FLANGE) D4 X 10 (BLACK) 1

45 373028 SWITCH 1

46 931701 BEARING LOCK 1

47 930804 TERMINAL M4.0 (10 PCS.) 1

48 959141 CONNECTOR 50092 (10 PCS.) 1

49 984750 TAPPING SCREW (W/FLANGE) D4 X 16 2

50 937631 CORD CLIP 1

Page 20

PARTS C 7BUR

DESCRIPTION REMARKS

69

10 - 17 Printed in Japan - 3 -

(171023N)

*ALTERNATIVE PARTS

STANDARD ACCESSORIES

NO.

USED

CODE NO.

ITEM

NO.

NO.

USED

CODE NO.

ITEM

NO.

51 938051 CORD ARMOR D10.1 1

52 500453Z CORD 1 (CORD ARMOR D10.1)

53 373027 HANDLE (A).(B) SET 1

54 372773 LEVER (A) 1

55 670514 RETAINING RING (E-TYPE) FOR D10 SHAFT 2

56 372772 LOCK NUT 2

57 949433 BOLT WASHER M8 (10 PCS.) 2

58 372764 BEVEL STAND 1

59 372770 BEVEL PLATE 1

60 992013 SEAL LOCK FLAT HD. SCREW M5 X 14 4

61 308109

SLOTTED HD. SET SCREW (SEAL LOCK) M6 X 8 1

62 372769 BASE PLATE 1

63 372745 LEVER 1

64 319541

SEAL LOCK HEX. SOCKET SET SCREW M5 X 6 1

65 372778 SPRING (B) 1

66 308387 U-NUT M5 1

67 372776 STOPPER LEVER 1

68 372777 SPECIAL BOLT 1

372775 STEP PIN 1

70 372779

SEAL LOCK HEX. SOCKET SET SCREW M5 X 8 1

71 949686 ROLL PIN D6X40 (10 PCS.) 1

72 372771 LINK 1

73 328604 SEAL LOCK FLAT HD. SCREW M4 X 8 3

74 372785 BASE ASS'Y 1 INCLUD.29,54-62,64-70,72,73

DESCRIPTION REMARKS

501 371108 TOOL BAG 1

502 872422 HEX. BAR WRENCH 6MM 1

Loading...

Loading...