Page 1

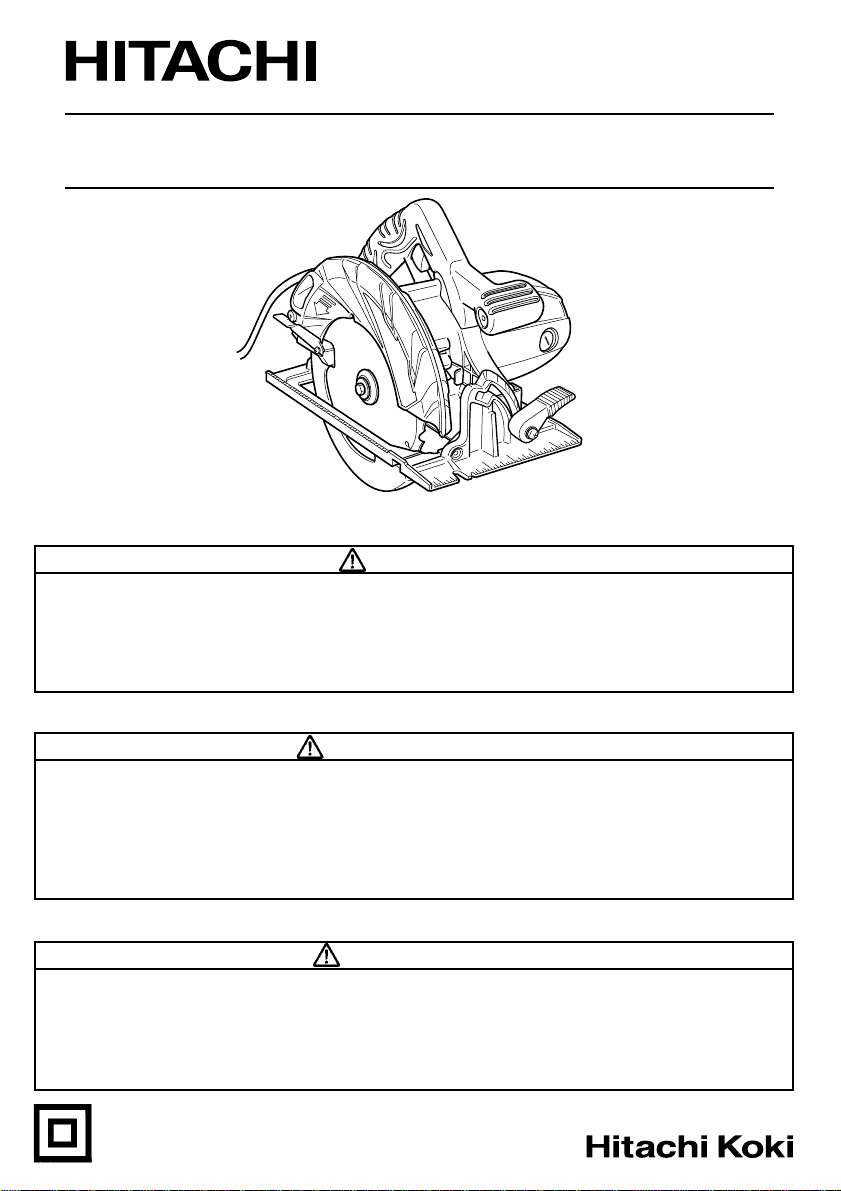

Model Circular saw

Modèle Scie circulaire

Modelo Sierra circular

C 7BMR

SAFETY INSTRUCTIONS AND INSTRUCTION MANUAL

WARNING

IMPROPER OR UNSAFE use of this power tool can result in death or serious bodily

injury!

This manual contains important information about product safety. Please read and

understand this manual BEFORE operating the power tool. Please keep this manual

available for other users and owners before they use the power tool. This manual should

be stored in safe place.

INSTRUCTIONS DE SECURITE ET MODE D’EMPLOI

AVERTISSEMENT

Une utilisation INCORRECTE OU DANGEREUSE de cet outil motorisé peut entraîner la

mort ou de sérieuses blessures corporelles!

Ce mode d’emploi contient d’importantes informations à propos de la sécurité de ce

produit. Prière de lire et de comprendre ce mode d’emploi AVANT d’utiliser l’outil

motorisé. Garder ce mode d’emploi à la disponibilité des autres utilisateurs et propriétaires

avant qu’ils utilisent l’outil motorisé. Ce mode d’emploi doit être conservé dans un

endroit sûr.

INSTRUCCIONES DE SEGURIDAD Y MANUAL DE INSTRUCCIONES

ADVERTENCIA

¡La utilización INAPROPIADA O PELIGROSA de esta herramienta eléctrica puede

resultar en lesiones de gravedad o la muerte!

Este manual contiene información importante sobre la seguridad del producto. Lea y

comprenda este manual ANTES de utilizar la herramienta eléctrica. Guarde este manual

para que puedan leerlo otras personas antes de utilizar la herramienta eléctrica. Este

manual debe ser guardado en un lugar seguro.

DOUBLE INSULATION

DOUBLE ISOLATION

AISLAMIENTO DOBLE

Page 2

English

English

IMPORTANT SAFETY INFORMATION .............. 3

MEANINGS OF SIGNAL WORDS ...................... 3

SAFETY .................................................................... 3

GENERAL SAFETY RULES ................................. 3

SAFETY INSTRUCTIONS FOR ALL SAWS .......... 4

FURTHER SAFETY INSTRUCTIONS FOR ALL

SAWS ............................................................. 5

SAFETY INSTRUCTIONS FOR SAWS WITH

INNER PENDULOM GOARD ......................... 5

DIFINITION FOR SYMBOLS USED ON THIS

TOOL............................................................... 6

DOUBLE INSULATION FOR SAFER

OPERATION ................................................... 6

FUNCTIONAL DESCRIPTION.................................... 7

NAME OF PARTS .................................................. 7

SPECIFICATIONS .................................................. 7

Français

INFORMATIONS IMPORTANTES

DE SÉCURITÉ ............................................... 15

SIGNIFICATION DES MOTS

D’AVERTISSEMENT .................................... 15

SECURITE ................................................................ 15

RÈGLES GENERALE DE SÉCURITÉ ................... 15

CONSIGNES DE SÉCURITÉ RELATIVES À

TOUTES LES SCIES ..................................... 17

CONSIGNES DE SÉCURITÉ COMPLÉMENTAIRES

RELATIVES À TOUTES LES SCIES ............. 17

CONSIGNES DE SÉCURITÉ RELATIVES AUX

SCIES AVEC PROTECTEUR À PENDULE

INTERNE ....................................................... 18

DÉFINITIONS POUR LES SYMBOLES UTILISÉS

SUR CET OUTIL ........................................... 18

DOUBLE ISOLATION POUR UN

FONCTIONNEMENT PLUS SUR ................. 18

TABLE DES MATIERES

CONTENTS

Page

Page

ASSEMBLY AND OPERATION ................................. 8

APPLICATIONS ..................................................... 8

PRIOR TO OPERATION ......................................... 8

ADJUSTING THE SAW PRIOR TO USE............... 9

CUTTING PROCEDURES .................................... 10

MOUNTING AND DISMOUNTING THE

SAW BLADE ................................................. 12

MAINTENANCE AND INSPECTION ....................... 13

ACCESSORIES ......................................................... 14

STANDARD ACCESSORIES ............................... 14

OPTIONAL ACCESSORIES ................................. 14

PARTS LIST.............................................................. 39

DESCRIPTION FONCTIONNELLE ........................... 19

NOM DES PARTIES ............................................ 19

SPECIFICATIONS ................................................ 19

ASSEMBLAGE ET FONCTIONNEMENT ................ 20

APPLICATIONS ................................................... 20

AVANT L’UTILISATION ...................................... 20

RÉGLAGE DE LA SCIE AVANT

L’UTILISATION............................................. 21

PROCEDURES DE COUPE .................................. 22

MONTAGE ET DÉMONTAGE DE LA LAME DE

SCIE .............................................................. 24

ENTRETIEN ET INSPECTION .................................. 25

ACCESOIRES ........................................................... 26

ACCESSOIRES STANDARD ............................... 26

ACCESSOIRES EN OPTION................................ 26

LISTE DES PIECES................................................... 39

Page

Page

Español

INFORMACIÓN IMPORTANTE SOBRE

SEGURIDAD ................................................. 27

SIGNIFICADO DE LAS PALABRAS DE

SEÑALIZACIÓN............................................ 27

SEGURIDAD............................................................. 27

NORMAS GENERALES DE SEGURIDAD........... 27

INSTRUCCIONES DE SEGURIDAD PARA TODAS

LAS SIERRAS ............................................... 29

INSTRUCCIONES DE SEGURIDAD ADICIONALES

PARA TODAS LAS SIERRAS....................... 29

INSTRUCCIONES DE SEGURIDAD PARA

SIERRASCON UN PROTECTOR DE

PÉNDULO INTERNO .................................... 30

DEFINICIONES PARA LOS SÍMBOLOS

UTILIZADOS EN ESTA HERRAMIENTA...... 30

AISLAMIENTO DOBLE PARA OFRECER UNA

OPERACIÓN MÁS SEGURA........................ 30

2

Página

ÍNDICE

DESCRIPCIÓN FUNCIONAL.................................... 31

NOMENCLATURA............................................... 31

ESPECIFICACIONES............................................ 31

MONTAJE Y OPERACIÓN ...................................... 32

APLICACIONES ................................................... 32

ANTES DE LA OPERACIÓN ................................ 32

AJUSTE DE LA SIERRA ANTES DE

UTILIZARLA.................................................. 33

PROCEDIMIENTOS DE CORTE .......................... 34

MONTAJE Y DESMONTAJE DE LA

CUCHILLA DE LA SIERRA ........................... 36

MANTENIMIENTO E INSPECCIÓN ........................ 37

ACCESORIOS........................................................... 38

ACCESORIOS ESTÁNDAR ................................. 38

ACCESORIOS OPCIONALES .............................. 38

LISTA DE PIEZAS .................................................... 39

Página

Page 3

English

IMPORTANT SAFETY INFORMATION

Read and understand all of the safety precautions, warnings and operating instructions in the Instruction Manual

before operating or maintaining this power tool.

Most accidents that result from power tool operation and maintenance are caused by the failure to observe basic

safety rules or precautions. An accident can often be avoided by recognizing a potentially hazardous situation

before it occurs, and by observing appropriate safety procedures.

Basic safety precautions are outlined in the “SAFETY” section of this Instruction Manual and in the sections which

contain the operation and maintenance instructions.

Hazards that must be avoided to prevent bodily injury or machine damage are identified by WARNINGS on the

power tool and in this Instruction Manual.

NEVER use this power tool in a manner that has not been specifically recommended by HITACHI.

MEANINGS OF SIGNAL WORDS

WARNING indicates a potentially hazardous situations which, if ignored, could result in death or serious injury.

CAUTION indicates a potentially hazardous situations which, if not avoided, may result in minor or moderate

injury, or may cause machine damage.

NOTE emphasizes essential information.

SAFETY

GENERAL SAFETY RULES

WARNING:

Read all instructions

Failure to follow all instructions listed below may result in electric shock, fire and/or serious injury.

The term “power tool” in all of the warnings listed below refers to your mains-operated (corded) power tool

or battery-operated (cordless) power tool.

SAVE THESE INSTRUCTIONS

1) Work area safety

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust.

Power tools create sparks which may ignite

the dust of fumes.

c) Keep children and bystanders away while

operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way.

Do not use any adapter plugs with earthed

(grounded) power tools.

Unmodified plugs and matching outlets will

reduce risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators.

There is an increased risk of electric shock if

your body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions.

Water entering a power tool will increase the

risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool.

Keep cord away from heat, oil, sharp edges

or moving parts.

Damaged or entangled cords increase the risk

of electric shock.

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired

or under the influence of drugs, alcohol or

medication.

A moment of inattention while operating

power tools may result in serious personal

injury.

3

Page 4

English

b) Use safety equipment. Always wear eye

protection.

Safety equipment such as dust mask, nonskid safety shoes, hard hat, or hearing

protection used for appropriate conditions

will reduce personal injuries.

c) Avoid accidental starting. Ensure the switch

is in the off position before plugging in.

Carrying power tools with your finger on the

switch or plugging in power tools that have

the switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on.

A wrench or a key left attached to a rotating

part of the power tool may result in personal

injury.

e) Do not overreach. Keep proper footing and

balance at all times.

This enables better control of the power tool

in unexpected situations.

f) Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and

gloves away from moving parts.

Loose clothes, jewellery or long hair can be

caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities,

ensure these are connected and properly

used.

Use of these devices can reduce dust-related

hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application.

The correct power tool will do the job better

and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off.

Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools.

Such preventive safety measures reduce the

risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition

that may affect the power tools operation.

If damaged, have the power tool repaired

before use.

Many accidents are caused by poorly

maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and tool bits

etc., in accordance with these instructions

and in the manner intended for the particular

type of power tool, taking into account the

working conditions and the work to be

performed.

Use of the power tool for operations different

from intended could result in a hazardous

situation.

5) Service

a) Have your power tool serviced by a qualified

repair person using only identical

replacement parts.

This will ensure that the safety of the power

tool is maintained.

–WARNING–

To reduce the risk of injury, user must read

instruction manual.

SAFETY INSTRUCTIONS FOR ALL SAWS

DANGER!

a) Keep hands away from cutting area and the blade.

Keep your second hand on auxiliary handle, or

motor housing.

If both hands are holding the saw, they cannot be

cut by the blade.

b) Do not reach underneath the workpiece.

The guard cannot protect you from the blade below

the workpiece.

c) Adjust the cutting depth to the thickness of the

workpiece.

Less than a full tooth of the blade teeth should be

visible below the workpiece.

d) Never hold piece being cut in your hands or across

your leg. Secure the workpiece to a stable

platform.

It is important to support the work properly to

minimize body exposure, blade binding, or loss of

control.

e) Hold power tool by insulated gripping surfaces

when performing an operation where the cutting

tool may contact hidden wiring or its own cord.

Contact with a “live” wire will also make exposed

metal parts of the power tool “live” and shock the

operator.

f) When ripping always use a rip fence or straight

edge guide.

This improves the accuracy of cut and reduces the

chance of blade binding.

4

Page 5

English

g) Always use blades with correct size and shape

(diamond versus round) of arbour holes.

Blades that do not match the mounting hardware of

the saw will run eccentrically, causing loss of control.

h) Never use damaged or incorrect blade washers

or bolt.

The blade washers and bolt were specially

designed for your saw, for optimum performance

and safety of operation.

䡬

Never use any abrasive wheels

Burst of abrasive wheel cause serious injury of

operator or persons around the working area.

d) Support large panels to minimize the risk of blade

pinching and kickback.

Large panels tend to sag under their own weight.

Supports must be placed under the panel on both

sides, near the line of cut and near the edge of the

panel.

e) Do not use dull or damaged blades.

Unsharpened or improperly set blades produce

narrow kerf causing excessive friction, blade

binding and kickback.

f) Blade depth and bevel adjusting locking levers

must be tight and secure before making cut.

If blade adjustment shifts while cutting, it may

FURTHER SAFETY INSTRUCTIONS FOR

ALL SAWS

Causes and operator prevention of kickback:

–Kickback is a sudden reaction to a pinched, bound

or misaligned saw blade, causing an uncontrolled

saw to lift up and out of the workpiece toward the

operator.

– When the blade is pinched or bound tightly by the

kerf closing down, the blade stalls and the motor

reaction drives the unit rapidly back toward the

operator.

–If the blade becomes twisted or misaligned in the

cut, the teeth at the back edge of the blade can dig

into the top surface of the wood causing the blade

to climb out of the kerf and jump back toward the

operator.

cause binding and kickback.

g) Use extra caution when making a “plunge cut”

into existing walls or other blind areas.

The protruding blade may cut objects that can

cause kickback.

SAFETY INSTRUCTIONS FOR SAWS WITH

INNER PENDULUM GUARD

a) Check lower guard for proper closing before each

use. Do not operate the saw if lower guard does

not move freely and close instantly. Never clamp

or tie the lower guard into the open position.

If saw is accidentally dropped, lower guard may

be bent.

Raise the lower guard with the retracting handle

and make sure it moves freely and does not touch

the blade or any other part, in all angles and depth

of cut.

Kickback is the result of saw misuse and/or incorrect

operating procedures or conditions and can be avoided

by taking proper precautions as given below.

b) Check the operation of the lower guard spring. If

the guard and the spring are not operating

properly, they must be serviced before use.

Lower guard may operate sluggishly due to

a) Maintain a firm grip with both hands on the saw

and position your arms to resist kickback forces.

Position your body to either side of the blade, but

not in line with the blade.

Kickback could cause the saw to jump backwards,

but kickback forces can be controlled by the

operator, if proper precautions are taken.

b) When blade is binding, or when interrupting a cut

for any reason, release the trigger and hold the

saw motionless in the material until the blade

comes to a complete stop.

Never attempt to remove the saw from the work

or pull the saw backward while the blade is in

motion or kickback may occur.

Investigate and take corrective actions to eliminate

the cause of blade binding.

c) When restarting a saw in the workpiece, centre

the saw blade in the kerf and check that saw teeth

are not engaged into the material.

damaged parts, gummy deposits, or build-up of

debris.

c) Lower guard should be retracted manually only

for special cuts such as “plunge cuts” and

“compound cuts”. Raise lower guard by retracting

handle and as soon as blade enters the material,

the lower guard must be released.

For all other sawing, the lower guard should

operate automatically.

d) Always observe that the lower guard is covering

the blade before placing saw down on bench or

floor.

An unprotected, coasting blade will cause the saw

to walk backwards, cutting whatever is in its path.

Be aware of the time it takes for the blade to stop

after switch is released.

If saw blade is binding, it may walk up or kickback

from the workpiece as the saw is restarted.

5

Page 6

English

DEFINITIONS FOR SYMBOLS USED ON

THIS TOOL

V................. volts

Hz ............... hertz

A ................ amperes

no ........................ no load speed

.............. Class II Construction

---/min ........ revolutions or reciprocation per minute

............... alternating or direct current

DOUBLE INSULATION FOR SAFER

OPERATION

To ensure safer operation of this power tool, HITACHI

has adopted a double insulation design. “Double

insulation” means that two physically separated

insulation systems have been used to insulate the

electrically conductive materials connected to the power

supply from the outer frame handled by the operator.

Therefore, either the symbol “ ” or the words “Double

insulation” appear on the power tool or on the nameplate.

Although this system has no external grounding, you

must still follow the normal electrical safety precautions

given in this Instruction Manual, including not using the

power tool in wet environments.

To keep the double insulation system effective, follow

these precautions:

䡬

Only HITACHI AUTHORIZED SERVICE CENTER

should disassemble or assemble this power tool,

and only genuine HITACHI replacement parts

should be installed.

䡬

Clean the exterior of the power tool only with a

soft cloth moistened with soapy water, and dry

thoroughly.

Never use solvents, gasoline or thinners on plastic

components; otherwise the plastic may dissolve.

SAVE THESE INSTRUCTIONS

AND

MAKE THEM AVAILABLE TO OTHER USERS

AND

OWNERS OF THIS TOOL!

6

Page 7

English

FUNCTIONAL DESCRIPTION

NOTE:

The information contained in this Instruction Manual is designed to assist you in the safe operation and

maintenance of the power tool.

NEVER operate, or attempt any maintenance on the tool unless you have first read and understood all safey

instructions contained in this manual.

Some illustrations in this Instruction Manual may show details or attachments that differ from those on your

own power tool.

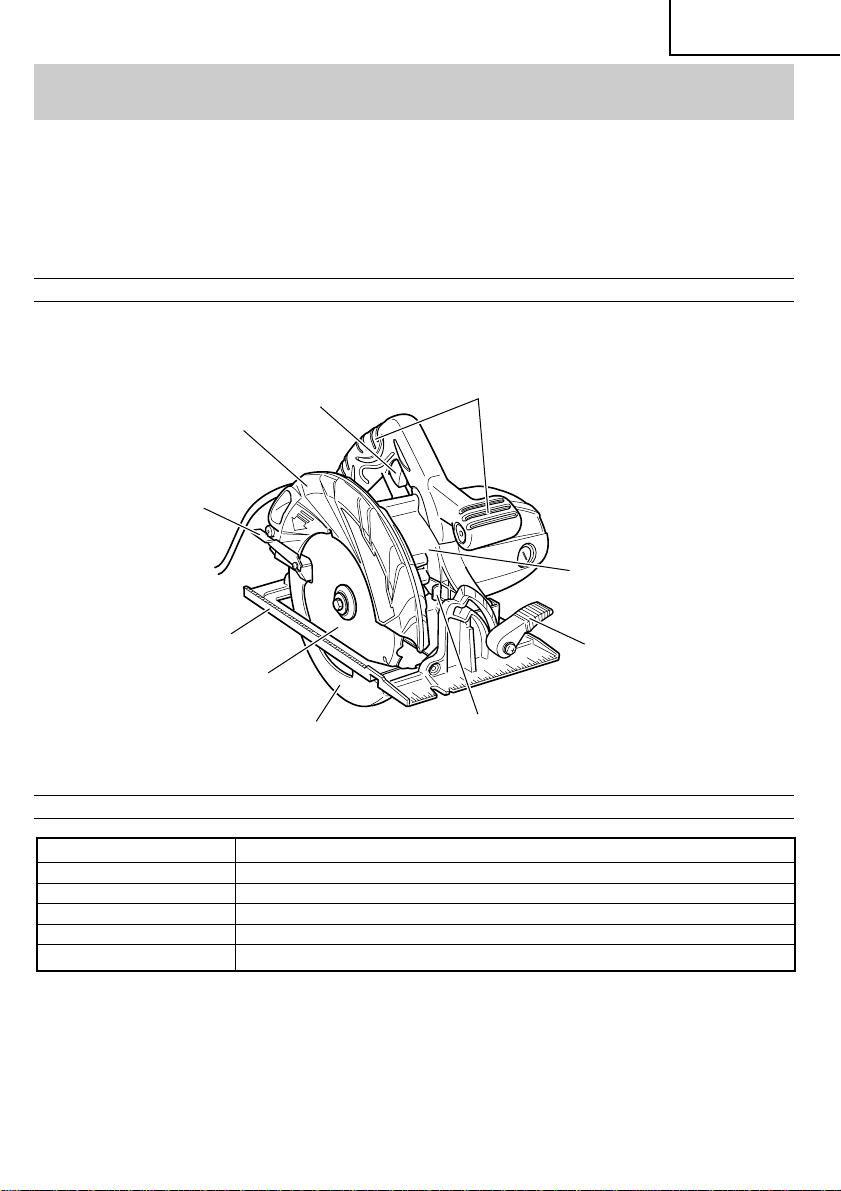

NAME OF PARTS

Handle

Switch

Blade cover

Lever

(Retracting

handle)

(Insulated gripping surface)

Gear cover

Base

Saw blade

Lower guard

SPECIFICATIONS

Motor Single-Phase, Series Commutator Motor

Power Source Single-Phase 120V AC 60Hz, 120V DC

Max. Cutting Depth 2-3/8" (60mm)

Current 15 A

No-Load Speed 5,800/min.

Weight (without cord) 10.5 lbs (4.8 kg)

Lock lever

Fig. 1

Lever (A)

7

Page 8

English

ASSEMBLY AND OPERATION

APPLICATIONS

䡬

Cutting Various types of wood.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized

conforms to the power source requirements

specified on the product nameplate.

2. Power switch

Ensure that the switch is in the OFF position. If the

plug is connected to a receptacle while the switch

is in the ON position, the power tool will start

operating immediately and can cause serious injury.

3. Extension cord

When the work area is far away from the power

source, use an extension cord of sufficient

thickness and rated capacity. The extension cord

should be kept as short as practicable.

WARNING:

Damaged cord must be replaced or repaired.

4. Check the receptacle

If the receptacle only loosely accepts the plug, the

receptacle must be repaired. Contact a licensed

electrician to make appropriate repairs.

If such a faulty receptacle is used, it may cause

overheating, resulting in a serious hazard.

5. Confirming condition of the environment:

Confirm that the work site is placed under appropriate

conditions conforming to prescribed precautions.

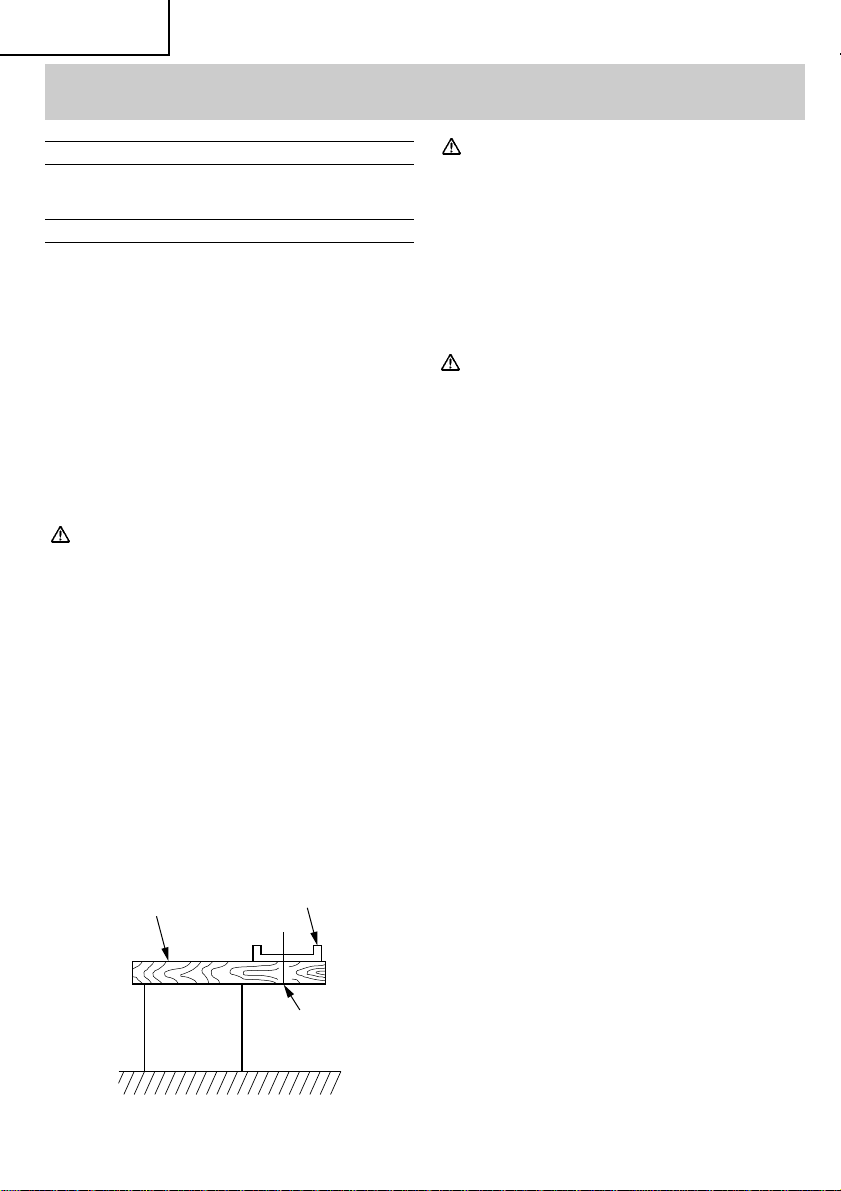

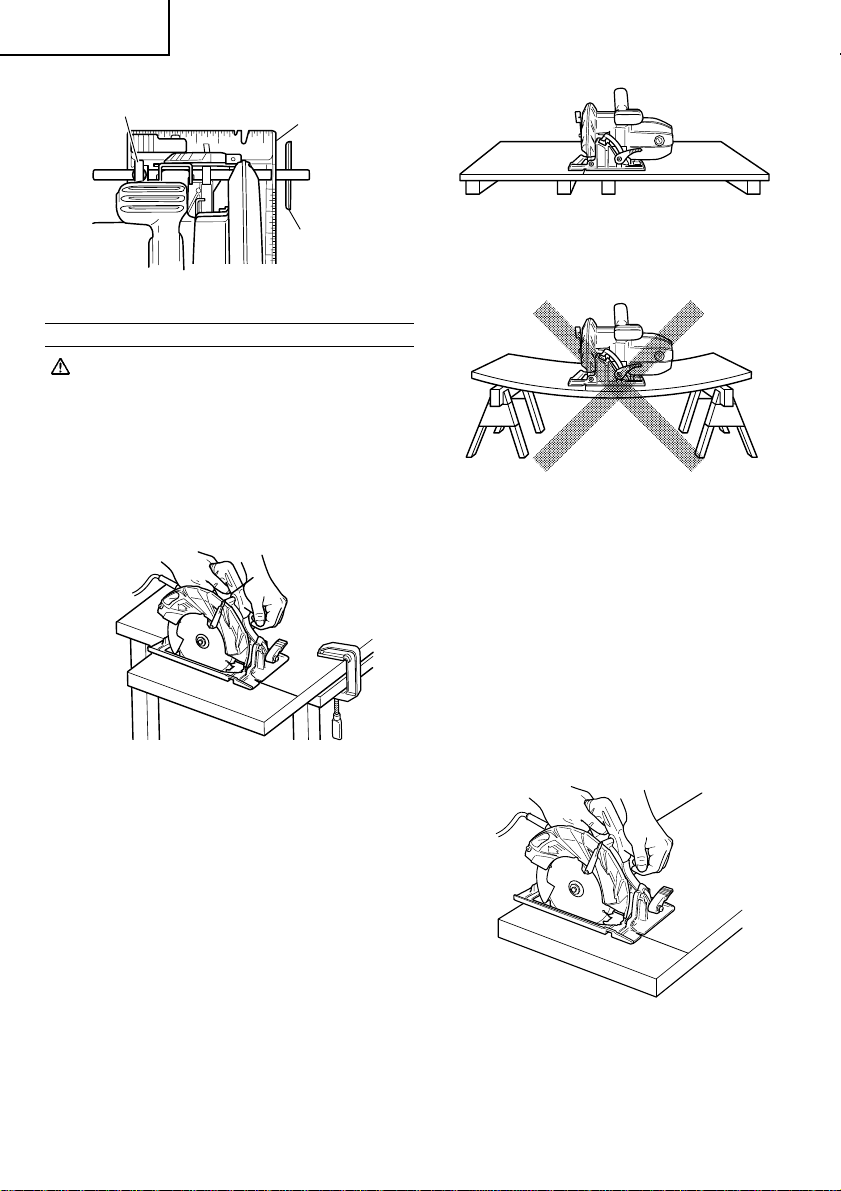

6. Prepare a wooden workbench (Fig. 2)

Since the saw blade will extend beyond the lower

surface of the work piece, place the work piece on

a workbench when cutting. If a square block is

utilized as a workbench, select level ground to

ensure it is properly stabilized. An unstable

workbench will result in hazardous operation.

Work piece

Workbench

Base

Saw blade

CAUTION:

To avoid possible accident, always ensure that the

portion of work piece remaining after cutting is

securely anchored or held in position.

7. Check if lever (A)s are tightened.

If the lever (A) to adjust cutting depth (Fig. 3) and

lever (A) to adjust angle of inclination (Fig. 4) are

loose, injury can result. Make sure that they are

tightened securely.

8. Check performance of safety cover

WARNING:

Make absolutely sure that the safety cover is not

fixed. Also, check and see if it can move smoothly.

If the saw blade is kept exposed injury can result.

The lower guard (refer to Fig. 1) serves to protect

your body from coming into contact with the saw

blade. Make absolutely certain that the cover

smoothly performs to cover the saw blade. If the

safety cover should not move smoothly, never use

it without repairing it.

In such a case, get in touch with the store where

you bought the circular saw or the HITACHI

Authorized Service Center for necessary repair.

9. Eye protection

When you use the tool, make certain that you wear

eye protection.

10. Check if saw blade is tightened

Refer to [mounting and dismounting the saw

blade] in Page 12, and make sure that the flange

bolt is tightened securely.

11. Check for proper operation of the brake.

Your saw has an automatic electric brake which is

designed to stop the blade from coasting in about

3 seconds, after you release the trigger switch. It

is useful when making certain cuts in wood where

a coasting blade would result a wide imprecise cut.

Occasionally, under certain conditions, the brake

will not function properly and won't stop the saw

in the 3 seconds discussed above.

If this condition persists, turn the saw on and off

four or five times. If the brake still does not stop

the blade in about 3 seconds, the problem may be

worn brushes. Replace the brushes and try the saw

again. If the problem still persists, have the tool

serviced at a HITACHI AUTHRIZED SERVICE

CENTER.

Fig. 2

8

Page 9

ADJUSTSING THE SAW PRIOR TO USE

WARNING:

To avoid serious accidents, ensure the switch is

in OFF position, and disconnect the plug from the

receptacle.

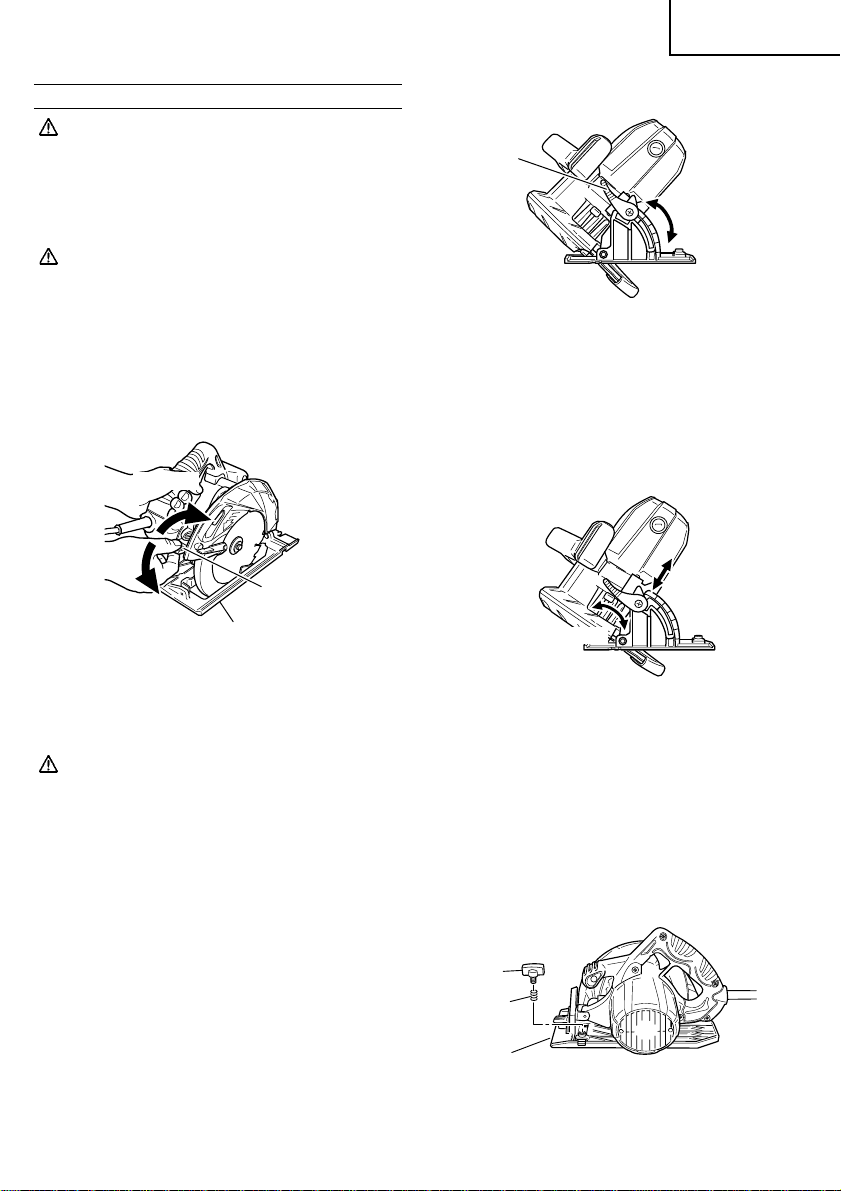

1. Adjusting the cutting depth (Fig. 3)

WARNING:

If the lever (A) is loose, injury can result. Tighten

it securely after adjustment.

To adjust cutting depth, loosen the lever (A) and,

while holding the base with one hand, move the

main body up and down to obtain the prescribed

cutting depth. After adjusting to the prescribed

cutting depth, tighten the lever (A) securely.

Loosen

English

Lever (A)

0˚ – 45˚

Fig. 4

If you use inclination angle of over 45˚, as shown

in Fig. 5 move the lever (A) to inside, the saw blade

may be inclined to a maximum angle of 55˚ in

relation to the base.

Always ensure that the lever (A) is thoroughly

tightened after making the desired adjustment.

Tighten

Lever (A)

Base

Fig. 3

2. Adjusting the angle of inclination

WARNING:

If the lever (A) is loose, injury can result. Tighten

it securely after adjustment.

You can incline saw blade from 0˚ to a maximun

angle of 55˚ in relation to the base.

As shown in Fig. 4 by loosing the lever (A) on the

bevel scale, the saw blade may be inclined to an

angle of 45˚ in relation to the base.

45˚ – 55˚

Fig. 5

3. Regulating the guide (Rip fence) (Fig. 6, 7)

................................................ Optional Accessory

Install the wing bolt (B) and lock spring on the base.

Insert the guide into the base, move it left and right

and adjust the cutting position. Tighten the wing

bolt (B) and fix the guide. The guide can be

installed either from the left or the right side of the

main body.

Wing

bolt (B)

Lock

spring

Base

Fig. 6

9

Page 10

English

Wing bolt (B), Lock spring

Base

Guide

(Rip fence)

Fig. 7

CUTTING PROCEDURES

WARNING:

Do not use any abrasive wheels.

●

●

Never touch the moving parts.

●

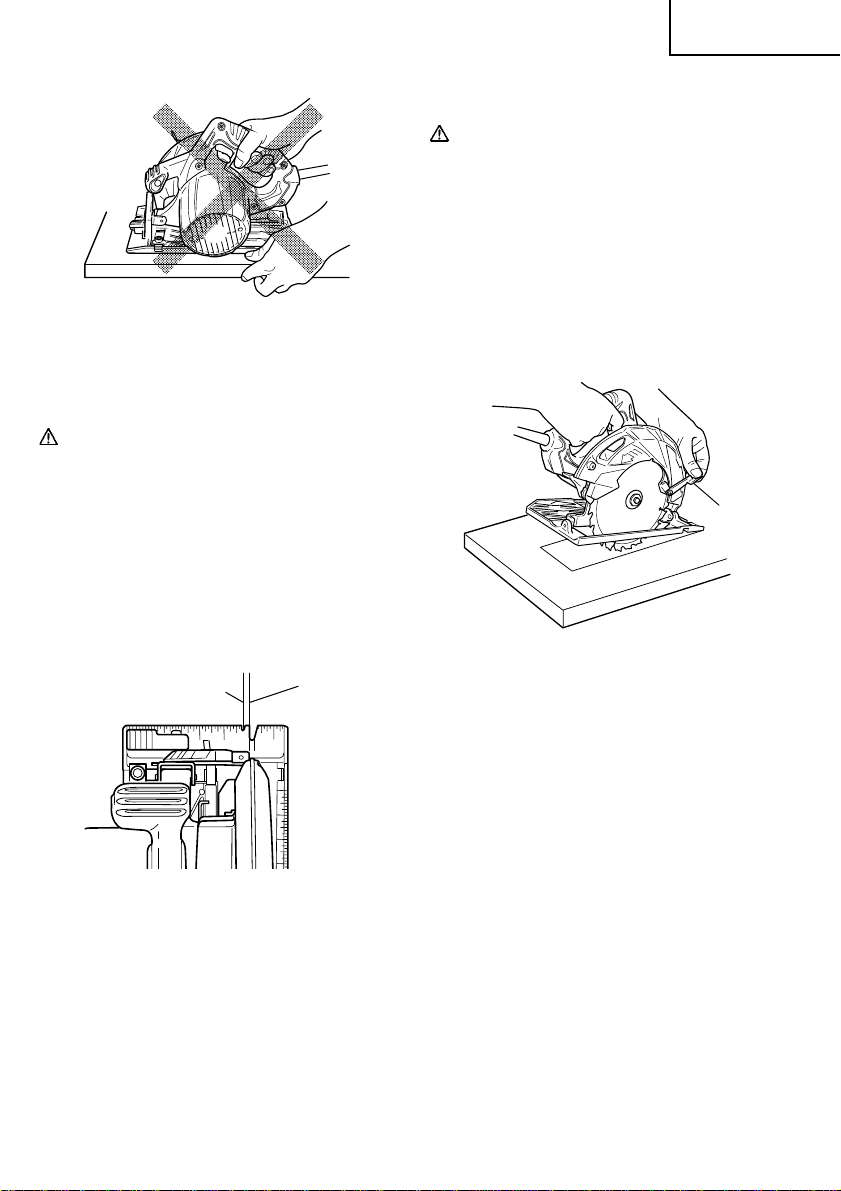

As shown in Fig. 8, be sure to hold the round

handle securely with both hands when cutting.

Contact with "live" wire will make exposed metal

parts of the power tool "live" and shock the

operator. In addition, make sure to secure the

work piece with a clamp when cutting.

Fig. 8

To avoid kickback, do support board

or panel near the cut.

Fig. 9

Don't support board or panel away

from the cut.

Fig. 10

●

Place the wider portion of the saw base on that

part of the work piece which is solidly supported,

not on the section that will fall off when the cut is

made. As examples, Fig. 11 illustrates the RIGHT

way to cut off the end of board, and Fig. 12 the

WRONG way. If the work piece is short or small,

clamp it down.

DON’T TRY TO HOLD SHORT PLACES BY HAND!

●

Should the saw blade be stopped or make an

abnormol noise during operation, turn off the

switch immediately.

●

Don't remove circular saw from work piece during

a cut while the saw blade is moving.

●

Support large panels to minimize the risk of blade

pinching and KICKBACK. Large panels tend to sag

under their own weight. Supports must be placed

under the panel on both sides, near the line of cut

and near the edge of the panel as shown in Fig. 9.

To minimize the risk of blade pinching and

kickback. When cutting operation requires the

resting of the saw on the work piece, the saw shall

be rested on the larger portion and the smaller

piece cut off.

10

Fig. 11

Page 11

[POCKET CUTTING]

WARNING:

To avoid serious accident, ensure the switch is OFF

●

position, and disconnect the plug from the

receptacle before any adjustment.

●

Never tie or wedge the lower guard in a raised

position.

1. Mark the desired cutting area clearly with lines all

side. (See Fig. 14)

Fig. 12

2. Set depth adjustment according to material to be

cut.

3. Push the lever all the way back so the blade is

●

Wear eye protection.

●

Avoid cutting any material like metal, etc., that

exposed as shown in Fig. 14.

give off sparks.

CAUTION:

Always take care in preventing the power cord

●

from coming near the revolving saw blade.

●

Before starting to saw, ensure that the saw blade

has reached full speed revolution.

1. Place the saw body (base) on the work piece, and as

in Fig. 13 align the intended line of cut with the saw

blade, using the notch at the front of the base. This

relationship of base to work pieces should remain

unchanged regardless of the inclination of the base.

When

Inclined 45°

When not

Inclined

4. Tilt saw forward and align the notch (Fig. 13) with

the pre-marked guide line.

5. Release the lever. When the lower guard contacts

the work piece surface, it will be in proper position

to open freely when cutting is commencend.

6. Holding the saw in position, with the blade not

contacting the work piece surface, pull the trigger.

7. After the saw has reached full speed, gradually

lower rear end of the saw until its base rests on

the work surface.

8. Advance saw along the cutting line up to the

Fig. 13

2. The switch should be turned to the ON position

before the saw blade comes into contact with the

work piece. The switch is turned ON when the

trigger is pulled by one’s finger, and is turned OFF

when the trigger is released.

3. Moving the saw straight at a constant speed will

produce optimum cutting.

corner.

9. Release trigger and allow blade to stop completely

before withdrawing the blade from the work piece.

䡩

Never under any circumstances pull the saw

backwards while the blade is in motion, as kickback

may result.

10. Use a jig saw or hand saw to cut the corners out

clean.

11. When starting each new cut, repeat as above.

English

Lever

Fig. 14

11

Page 12

English

MOUNTING AND DISMOUNTING THE

SAW BLADE

WARNING:

To avoid serious accident ensure the switch is in

the OFF position, and disconnect the plug from

the receptacle.

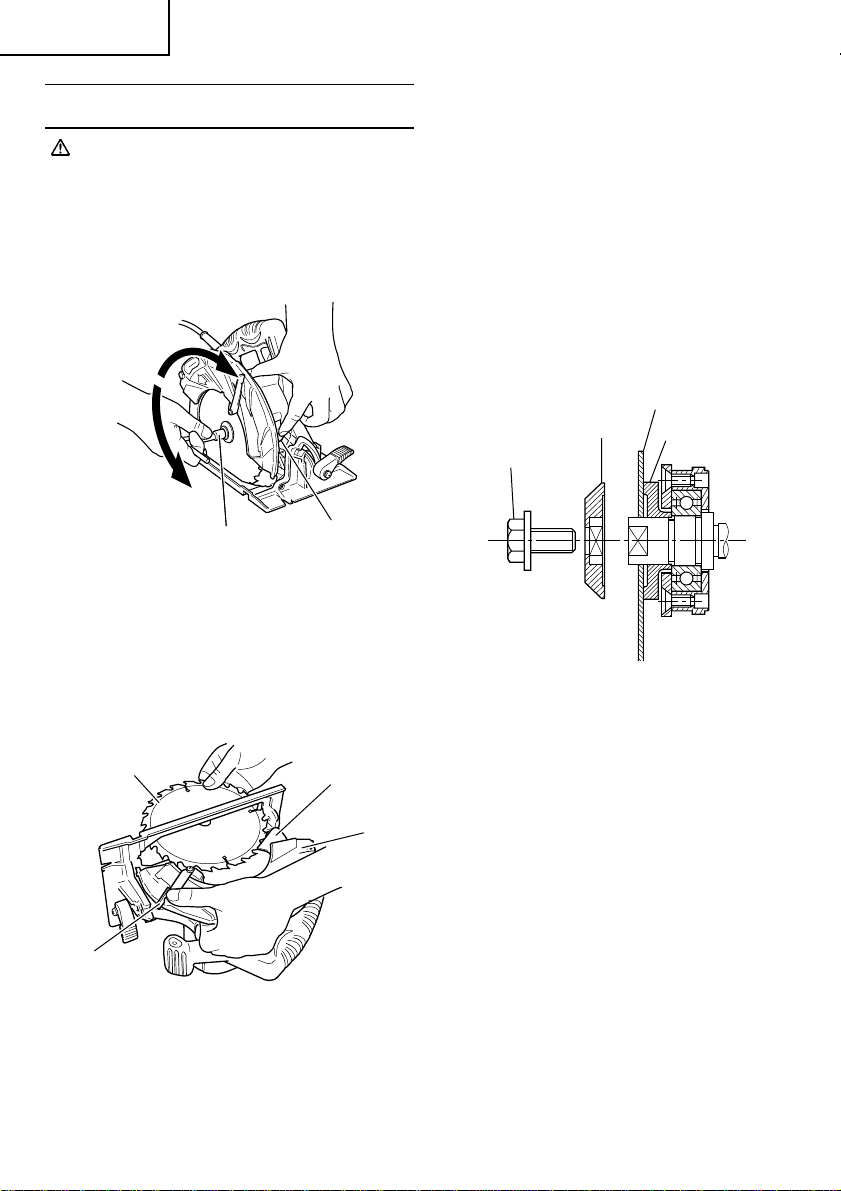

1. Dismounting the saw blade

(1) Set the cutting volume at maximum, and place the

Circular Saw as shown in Fig. 15.

2. Mounting the saw blade

(1) Thoroughly remove any sawdust which has

accumulated on the spindle, bolt and washers.

(2) For mounting saw blade, the concave sides of both

washers (A) and (B) must be fitted to the saw blade

sides. Mount the saw blade on the spindle, and

finally affix washer (B) (See Fig. 17)

(3) To assure proper rotation direction of the saw blade,

the arrow direction on the saw blade must coincide

with the arrow direction on the blade cover.

(4) Using the fingers, tighten the hexagonal bolt

retaining the saw blade as much as possible. Then

depress the lock lever, lock the spindle, and

Tighten

thoroughly tighten the bolt.

(5) Confirm that the lock lever is in the original

position.

Hexagonal

flange bolt

Loosen

Wrench

Lock lever

Fig. 15

(2) Depress the lock lever, lock the spindle, and

remove the hexagonal-flange bolt and washer(B)

with the wrench.

(3) While holding the lever to keep the lower guard

fully retracted into the blade cover, remove the saw

blade. (Fig. 16)

Washer (B)

Saw blade

Washer (A)

Fig. 17

Saw blade

Lever

12

Lower guard

Blade cover

Fig. 16

Page 13

MAINTENANCE AND INSPECTION

English

WARNING:

To avoid serious accident, ensure the switch is in the OFF position and disconnect the plug

from the receptacle during maintenance and inspection.

1. Inspecting the saw blade:

Since use of a dull saw blade will degrade

efficiency and cause possible motor malfunction,

sharpen or replace the saw blade as soon as

abrasion is noted.

CAUTION:

If a dull saw blade is used, reactive force is

increased during cutting operation. Avoid the use

of the dull saw blade without repair.

2. Check the screws

Loose screws are dangerous. Regularly inspect

them and make sure they are tight.

CAUTION:

5. Performance checkup and maintenance of safety

Using this power tool with loosened screws is

extremely dangerous.

3. Inspecting the carbon brushes (Fig. 18)

The motor employs carbon brushes which are

6. Adjusting the base and saw blade to maintain

consumable parts. Replace the carbon brush with

a new one when it becomes worn to its wear limit.

Always keep carbon brushes clean and ensure that

they slide freely within the brush holders.

(1) Turn the base face up (Fig. 20) and loosen the lever

0.67"

(17mm)

Wear limit

38

0.24"(6mm)

No. of carbon

brush

Fig. 18

CAUTION:

Using this circular saw with a carbon brush which

is worn in excess of the wear limit will damge the

motor.

NOTE: Use HITACHI carbon brush No. 38 indicated in

Fig. 18.

(2) Apply a square to the base and the saw blade and,

4. Replacing carbon brushes:

Remove the brush caps with a slotted-head

screwdriver. The carbon brushes can then be easily

removed. (Fig. 19)

Brush cap

Slotted-head

screwdriver

Fig. 19

cover

Keep the safety cover in good shape for smooth

performance at all times. Be sure to make prompt

repair in case of any malfunction.

perpendicularity

The angle between the base and the saw blade

has been adjusted to 90°, however should this

perpendicularity be lost for some reason, adjust

in the following manner.

(A).

Square

Base

Slotted set screw

Fig. 20

turning the slotted set screw with a slotted-head

screwdriver, shift the position of the base to

produce the desired right angle.

13

Page 14

English

7. Service parts list

CAUTION:

Repair, modification and inspection of Hitachi

Power Tools must be carried out by an Hitachi

Authorized Service Center.

This Parts List will be helpful if presented with

the tool to the Hitachi Authorized Service Center

when requesting repair or other maintenance. In

the operation and maintenance of power tools,

the safety regulations and standards prescribed

in each country must be observed.

MODIFICATIONS:

Hitachi Power Tools are constantly being improved

and modified to incorporate the latest technological

advancements.

Accordingly, some parts (i.e. code numbers and/

or design) may be changed without prior notice.

ACCESSORIES

WARNING: Accessories for this power tool are mentioned in this Instruction Manual.

NOTE:

Accessories are subject to change without any obligation on the part of the HITACHI.

STANDARD ACCESSORIES

(1) Saw Blade.............................................................. 1

External Diam Hole Diam. Code No.

7-1/4" (185mm) 5/8" (15.9mm) 327761

(2) Wrench (Code No. 940543) .................................. 1

The use of any other attachment or accessory can be dangerous and could cause injury or

mechanical damage.

OPTIONAL ACCESSORIES.......sold

separately

(1) Guide (Code No. 302691) (Includes (2) and (3).)

(2) Wing Bolt (B) (Code No. 302697)

(3) Lock Spring (Code No. 947859)

NOTE:

Specifications are subject to change without any

obligation on the part of the HITACHI.

14

Page 15

Français

INFORMATIONS IMPORTANTES DE SÉCURITÉ

Lire et comprendre toutes les précautions de sécurité, les avertissements et les instructions de fonctionnement

dans ce mode d’emploi avant d’utiliser ou d’entretenir cet outil motorisé.

La plupart des accidents causés lors de l’utilisation ou de l’entretien de l’outil motorisé proviennent d’un non

respect des règles ou précautions de base de sécurité. Un accident peut la plupart du temps être évité si l’on

reconnaît une situation de danger potentiel avant qu’elle ne se produise, et en observant les procédures de sécurité

appropriées.

Les précautions de base de sécurité sont mises en évidence dans la section “SECURITE” de ce mode d’emploi et

dans les sections qui contiennent les instructions de fonctionnement et d’entretien.

Les dangers qui doivent être évités pour prévenir des blessures corporelles ou un endommagement de la machine

sont identifiés par AVERTISSEMENTS sur l’outil motorisé et dans ce mode d’emploi.

NE JAMAIS utiliser cet outil motorisé d’une manière qui n’est pas spécifiquement recommandée par HITACHI.

SIGNIFICATION DES MOTS D’AVERTISSEMENT

AVERTISSEMENT indique des situations potentiellement dangereuses qui, si elles sont ignorées, pourraient

entraîner la mort ou de sérieuses blessures.

PRECAUTION indique des situations dangereuses potentilles qui, si elles ne sont pas évitées, peuvent entraîner

de mineures et légères blessures ou endommager la machine.

REMARQUE met en relief des informations essentielles.

SECURITE

REGLES GENERALE DE SECURITE

AVERTISSEMENT :

Lire toutes les instructions

Tout manquement à observer ces instructions peut engendrer des chocs électriques, des incendies et/ou des

blessures graves.

Le terme “outil électrique” qui figure dans l'ensemble des avertissements ci-dessous se réfère aux outils

électriques (câblé) ou aux outils à piles (sans fil).

CONSERVER CES INSTRUCTIONS

1) Sécurité de l’aire de travail

a) Maintenir l'aire de travail propre et bien

éclairée.

Les endroits encombrés ou sombres sont

propices aux accidents.

b) Ne pas utiliser d'outils électriques en

présence de liquides, gaz ou poussière

inflammables, au risque de provoquer une

explosion.

Les outils électriques créent des étincelles

susceptibles d'enflammer la poussière.

c) Ne pas laisser les enfants et les visiteurs

s'approcher de vous lorsque vous utiliser un

outil électrique.

Les distractions peuvent faire perdre le

contrôle.

2) Sécurité électrique

a) Les prises de l'outil électrique doivent

correspondre à la prise secteur.

Ne jamais modifier la prise.

Ne pas utiliser d'adaptateurs avec les outils

électriques mis à la masse.

Les prises non modifiées et les prises secteurs

correspondantes réduisent les risques de

choc électrique.

b) Eviter tout contact avec les surfaces mises à

la masse telles que les tuyaux, radiateurs,

bandes et réfrigérateurs.

Le risque de choc électrique est accru en cas

de mise à la masse du corps.

c) Ne pas exposer les outils électriques à la pluie

ou à des conditions humides.

Si l'eau pénètre dans l'outil, cela augmente

les risques de choc électrique.

d) Ne pas utiliser le cordon à tort. Ne jamais

utiliser le cordon pour transporter ou

débrancher l'outil électrique.

Maintenir le cordon loin de la chaleur, de

l'huile, des bords pointus ou des pièces

mobiles.

Les cordons endommagés ou usés

augmentent les risques de choc électrique.

e) En cas d'utilisation d'un outil électrique à

l'extérieur, utiliser un cordon de rallonge

adapté à un usage extérieur.

15

Page 16

Français

L'utilisation d'un cordon adapté à l'usage

extérieur réduit les risques de choc électrique.

3) Sécurité personnelle

a) Restez alerte, regarder ce que vous faites et

usez de votre bon sens en utilisant un outil

électrique.

Ne pas utiliser d'outil électrique si vous êtes

sous l'influence de drogues, d'alcool ou de

médicaments.

Pendant l'utilisation d'outils électrique, un

instant d'inattention peut entraîner des

blessures graves.

b) Utiliser des équipements de sécurité.

Toujours porter des verres de protection.

L'utilisation d'équipements de sécurité tels

que les masques anti-poussière, les

chaussures de sécurité anti-dérapantes, les

casques ou les protections auditives dans des

conditions appropriées réduisent les risques

de blessures.

c) Eviter les démarrages accidentels. Veiller à

ce que l'interrupteur soit en position d'arrêt

avant de brancher l'outil.

Transporter les outils électriques avec le doigt

sur l'interrupteur ou brancher les outils

électriques avec l'interrupteur en position de

marche peut entraîner des accidents.

d) Retirer toute clé de sécurité ou clé avant de

mettre l'outil électrique en marche.

Laisser une clé ou une clé de sécurité sur une

partie mobile de l'outil électrique peut

engendrer des blessures.

e) Ne pas trop se pencher. Toujours garder une

bonne assise et un bon équilibre pendant le

travail.

Cela permet un meilleur contrôle de l'outil

électrique dans des situations imprévisibles.

f) Porter des vêtements adéquats. Ne pas

porter de vêtements amples ni de bijoux.

Maintenir les cheveux, les vêtements et les

gants loin des pièces mobiles.

Les vêtements amples ou les cheveux longs

peuvent se prendre dans les pièces mobiles.

g) En cas de dispositifs destinés au

raccordement d'installations d'extraction et

de recueil de la poussière, veiller à ce qu'ils

soient correctement raccordés et utilisés.

L'utilisation de ces dispositifs peut réduire les

dangers associés à la poussière.

4) Utilisation et entretien d'un outil électrique

a) Ne pas forcer sur l'outil électrique. Utiliser

l'outil électrique adapté à vos travaux.

Le bon outil électrique fera le travail mieux et

en toute sécurité au régime pour lequel il a

été conçu.

b) Ne pas utiliser l'outil électrique si

l'interrupteur ne le met pas en position de

marche et d'arrêt.

Tout outil ne pouvant être contrôlé par

l'interrupteur est dangereux et doit être

réparé.

c) Débrancher la prise ou retirer la batterie avant

de procéder à des réglages, au remplacement

des accessoires ou au stockage des outils

électriques.

Ces mesures préventives de sécurité

réduisent les risques de démarrage accidentel

de l'outil électrique.

d) Stockez les outils électriques inutilisés hors

de la portée des enfants et ne pas laisser des

personnes non familiarisées avec l'outil ou

ces instructions utiliser l'outil électrique.

Les outils électriques sont dangereux entre

les mains d'utilisateurs non habilités.

e) Entretenir les outils électriques. Vérifier

l'absence de mauvais alignement ou d'arrêt,

d'endommagement de pièces ou toute autre

condition susceptible d'affecter l'opération de

l'outil.

Si l'outil est endommagé, le faire réparer

avant utilisation.

De nombreux accidents sont dus à des outils

mal entretenus.

f) Maintenir les outils coupants aiguisés et

propres.

Des outils coupants bien entretenus avec des

bords aiguisés sont moins susceptibles de se

coincer et plus simples à contrôler.

g) Utiliser l'outil électrique, les accessoires et

les mèches de l'outil, etc. conformément à

ces instructions et de la manière destinée

pour le type précis d'outil électrique, en

tenant compte des conditions d'utilisation et

du travail à réaliser.

L'utilisation de l'outil électrique pour des

opérations différentes de celles pour

lesquelles il a été conçu est dangereuse.

5) Service

a) Faire entretenir l'outil électrique par un

technicien habilité à l'aide de pièces de

rechange identiques exclusivement.

Cela garantira le maintien de la sécurité de

l'outil électrique.

–PRECAUTION–

Pour réduire tout risque de blessure, l’utilisateur

doit lire le mode d’emploi.

16

Page 17

Français

CONSIGNES DE SÉCURITÉ RELATIVES À

TOUTES LES SCIES

DANGER!

a) Garder les mains à l’écart de la zone de coupe et

de la lame. Garder la deuxième main sur la poignée

auxiliaire, ou sur le boîtier du moteur.

Si les deux mains tiennent la scie, elles ne peuvent

être coupées par la lame.

b) Ne pas aller sous la pièce.

Le protecteur ne peut pas vous protéger contre la

lame en dessous de la pièce.

c) Régler la profondeur de coupe à l’épaisseur de la

pièce.

Moins d’une dent pleine des dents de la lame doit

être visible en dessous de la pièce.

d) Ne jamais tenir la pièce en découpage dans les

mains ou entre les jambes. Fixer la pièce à une

plateforme stable.

Il est important de correctement supporter la pièce

pour réduire l’exposition du corps, le voilage de la

lame ou la perte de contrôle.

e) Tenir l’outil électrique par les surfaces d’accroche

en effectuant une coupe où l’outil pourrait entrer

en contact avec un câble caché ou son propre

cordon.

Le contact avec un câble conducteur rendra

également les parties métalliques exposées de

l’outil électrique conductrices et provoquera un

choc électrique à l’opérateur.

f) En cas de coupe de fil, utiliser un guide pour coupe

de fil ou un guide à angle droit.

Cela améliore l’exactitude de la coupe et réduit les

risques de voilage de la lame.

g) Toujours utiliser des lames de la taille et de la

forme (diamantée ou ronde) des trous de l’arbre.

Les lames ne correspondant pas au matériel de

montage de la scie fonctionneront de manière

excentrée, ce qui provoquera une perte de

contrôle.

h) Ne jamais utiliser de rondelles ou de boulons

endommagés ou inadéquats.

Les rondelles et les boulons de lame ont été

spécialement conçus pour cette scie, pour une

performance optimale et une fiabilité de

fonctionnement.

䡬

Ne jamais utiliser de roues abrasives

L’explosion de la roue abrasive peut supposer des

blessures graves pour l’opérateur ou les personnes

à proximité de la zone de travail.

CONSIGNES DE SÉCURITÉ

COMPLÉMENTAIRES RELATIVES À TOUTES

LES SCIES

Causes et prévention des retours :

– Le retour est une réaction soudaine d’une lame

pincée, voilée ou mal alignée qui provoque

l’élévation et la sortie d’une scie non contrôlée de

la pièce vers l’opérateur.

– Lorsque la lame est pincée ou voilée fermement

par l’entaille qui se referme, la lame s’arrête et la

réaction du moteur provoque le retour rapide de

l’unité vers l’opérateur.

– Si la lame se tord ou est mal alignée pendant la

coupe, les dents du bord arrière de la lame peut

s’encastrer dans la surface supérieure du bois, ce

qui provoquerait la sortie de la lame de l’entaille et

son retour vers l’opérateur.

Le retour est du à une mauvaise utilisation et/ou à des

procédures d’utilisation incorrectes de la scie et peut

être évité en prenant les précautions adéquates

indiquées ci-dessous.

a) Maintenez la scie fermement avec les deux mains

et positionner les bras de manière à résister aux

forces de retour.

Positionner le corps sur l’un des côtés de la lame

mais pas dans la trajectoire de cette dernière.

Le retour peut faire projeter la scie en arrière mais

les forces de retour peuvent être maîtrisées par

l’opérateur si les précautions nécessaires sont

prises.

b) Lorsque la lame se voile, ou lors de l’interruption

d’une coupe pour une raison ou pour une autre,

lâcher le déclencheur et maintenir la scie immobile

jusqu’à ce que la lame s’arrête complètement.

Ne jamais tenter de retirer une scie de la pièce ou

de tirer la scie en arrière lorsque la lame

fonctionne, au risque de provoquer un retour.

Rechercher la cause et prendre les mesures

correctives pour supprimer la cause du voilage de

la lame.

c) Au redémarrage de la scie dans une pièce, centrer

la lame de scie dans l’entaille et vérifier que les

dents de la scie ne sont pas dans la pièce.

En cas de voilage de la lame de scie, cette dernière

peut se soulever ou se retourner au redémarrage.

d) Soutenir les grands panneaux pour réduire le risque

de pincement de la lame et de retour.

Les grands panneaux ont tendance à s’affaisser

sous leur propre poids. Les supports doivent être

placés sous le panneau des deux côtés, près de la

ligne de coupe et près du bord du panneau.

e) Ne pas utiliser de lames voilées ou endommagées.

Les lames non aiguisées ou mal positionnées

produisent des entailles étroites, ce qui provoque

une friction excessive, le voilage de la lame et un

retour.

17

Page 18

Français

f) Les leviers de verrouillage du réglage de la

profondeur et de l’inclinaison doivent être serrés

et fixés avant de procéder à la coupe.

Si le réglage de la lame change pendant la coupe,

cela peut provoquer le voilage et le retour de la lame.

g) Faire très attention en effectuant une coupe en

enfilade dans des murs existants ou autres zones

de visibilité nulle.

La lame protubérante peut couper des objets

susceptibles de provoquer un retour.

CONSIGNES DE SÉCURITÉ RELATIVES

AUX SCIES AVEC PROTECTEUR À

PENDULE INTERNE

a) Vérifier que le protecteur inférieur est

correctement fermé avant chaque utilisation. Ne

pas utiliser la scie si le protecteur ne se déplace

pas librement et ne se ferme pas instantanément.

Ne jamais clamper ou attacher le protecteur

inférieur en position ouverte.

En cas de chute accidentelle de la scie, le protecteur

inférieur peut se tordre.

Elever le protecteur inférieur avec la poignée de

rétractation et veiller à ce qu’il se déplace librement

et ne touche pas la lame ou toute autre partie, dans

tous les angles et profondeurs de coupe.

b) Vérifier le fonctionnement du ressort du

protecteur inférieur. Si le protecteur et le ressort

ne fonctionnent pas correctement, ils doivent être

réparés avant utilisation.

Le protecteur inférieur peut fonctionner doucement

à cause des parties endommagées, des dépôts

caoutchouteux ou de l’accumulation de débris.

c) Le protecteur inférieur ne doit être rétracté

manuellement que pour les coupes spéciales telles

que les coupes en enfilade et les coupes en

chanfrein composé. Elever le protecteur inférieur

en rétractant la poignée et, dès que la lame pénètre

le matériel, relâcher le protecteur inférieur.

Pour toutes les autres opérations de sciage, le

protecteur inférieur doit fonctionner

automatiquement.

d) Toujours veiller à ce que le protecteur inférieur

recouvre la lame avant de placer la scie sur l’établi

ou sur le sol.

Une lame glissante et non protégée peut provoquer

son fonctionnement en arrière, ce qui coupera tout

ce qui trouve dans sa trajectoire.

Faire attention au temps que cela prend pour que la

lame s’arrête après avoir appuyé sur l’interrupteur.

DÉFINITIONS POUR LES SYMBOLES

UTILISÉS SUR CET OUTIL

V..............volts

Hz ............ hertz

A ............. ampères

no ............vitesse sans charge

...........Construction de classe II

---/min ..... rotation ou mouvements de va-et-vient

............courant continu ou direct

DOUBLE ISOLATION POUR UN

FONCTIONNEMENT PLUS SUR

Pour assurer un fonctionnement plus sûr de cet outil

motorisé, HITACHI a adopté une conception à double

insolation. “Double isolation” signifie que deux systèmes

d’isolation physiquement séparés ont été utilisés pour

isoler les matériaux conducteurs d’électricité connectés

à l’outil motorisé à partir du cadre extérieur manipulé

par l’utilisateur. C’est pourquoi, le symbole “ ” ou les

mots “Double insulation” (double isolation) apparaissent

sur l’outil motorisé ou sur la plaque signalétique.

Bien que ce système n’ait pas de mise à terre extérieure,

il est quand même nécessaire de suivre les précautions

de sécurité électrique données dans ce mode d’emploi,

y-compris de ne pas utiliser l’outil motorisé dans un

environnement humide.

Pour garder le système de double isolation effectif,

suivre ces précautions:

䡬

Seuls les CENTRES DE SERVICE AUTORISES

HITACHI peuvent démonter et remonter cet outil

motorisé et uniquement des pièces de rechange

HITACHI garanties d’origine doivent être utilisées.

䡬

Nettoyer l’extérieur de l’outil motorisé uniquement

avec un chiffon doux légèrement imbibé d’une

solution savonneuse et essuyer minutieusement.

Ne jamais utiliser des solvants, de l’essence ou des

diluants sur les parties en plastique; sinon le

plastique risquerait de se dissoudre.

par minute

CONSERVER CES INSTRUCTIONS

ET

LES METTRE A LA DISPOSITION DES AUTRES UTILISATEURS

ET

PROPRIETAIRES DE CET OUTIL!

18

Page 19

Français

DESCRIPTION FONCTIONNELLE

REMARQUE:

Les informations contenues dans ce mode d’emploi sont conçues pour assister l’utilisateur dans une utilisation

sans danger et un entretien de l’outil motorisé.

NE JAMAIS utiliser ni entreprendre une révision de l’outil sans avoir d’abord lu et compris toutes les

instructions de sécurité contenues dans ce manuel.

Certaines illustrations dans ce mode d’emploi peuvent montrer des détails ou des accessoires différents de

ceux de l’outil motorisé utilisé.

NOM DES PARTIES

Interrupteur

Carter de lame

Levier

(Poignée de retrait)

Socle

Lame de la scie

Protection inférieure

Fig. 1

SPECIFICATIONS

Moteur Moteur série monophasé à collecteur

Source d’alimentation Secteur, 120V 60Hz, monophasé, 120V DC

Profondeur max. de coupe 2-3/8" (60mm)

Curant 15 A

Vitesse sans charge 5,800/min.

Poids 10.5 lbs (4.8 kg)

Poignée (surface d’accroche isolée)

Couvercle

du pignon

Levier (A)

Levier de blocage

19

Page 20

Français

ASSEMBLAGE ET FONCTIONNEMENT

APPLICATIONS

䡬

Coupe de divers types de bois.

AVANT L’UTILISATION

1. Source d’alimentation

S’assurer que la source d’alimentation qui doit être

utilisée est conforme à la source d’alimentation

requise spécifiée sur la plaque signalétique du

produit.

2. Interrupteur d’alimentation

S’assurer que l’interrupteur est sur la position OFF

(arrêt). Si la fiche est connectée sur une prise alors

que l’interrupteur est sur la position ON (marche),

l’outil motorisé démarrera immédiatement

risquant de causer de sérieuses blessures.

3. Cordon prolongateur

Quand la zone de travail est éloignée de la source

d’alimentation, utiliser un cordon prolongateur

d’épaisseur et de capacité nominale suffisante. Le

cordon prolongateur doit être aussi court que

possible.

AVERTISSEMENT:

Tout cordon endommagé devra être remplacé ou

réparé.

4. Vérifier la prise

Si la prise reçoit la fiche avec beaucoup de jeu,

elle doit être réparée. Contacter un électricien

licencié pour réaliser les réparations nécessaires.

Si une telle prise défectueuse est utilisée, elle peut

causer une surchauffe entraînant des dangers

sérieux.

5. Vérification des conditions d’environnement

Vérifier que l’état de l’aire de travail est conforme

aux précautions.

6. Préparer un établi de travail en bois (Fig. 2).

La lame de scie se déplaçant au-delà de la surface

inférieure du matériau, placer le matériau sur un

établi en bois pour effectuer la coupe. Si l’on utilise

un bloc carré comme établi de travail, sélectionner

un sol de niveau pour bien stabiliser le travail. Un

établi de travail instable risque de rendre le travail

dangereux.

7. Vérifier si les leviers (A) sont bien serrés.

8. Vérifier le bon fonctionnement du carter de sécurité

9. Lunettes de protection

10. Vérifier si la lame est serrée

11. Vérifier que le frein fonctionne correctement.

Matériau

Etabli de travail

Fig. 2

PRECAUTION:

Pour éviter tout risque d’accident, toujours

s’assurer que la section du matériau qui reste

après la coupe est solidement ancrée ou

maintenue en place.

Si le levier (A) de réglage de la profondeur de

coupe (Fig. 3) et le levier (A) de réglage de l’angle

de biseau (Fig. 4) sont desserrés, cela risque

d’entraîner des blessures. Bien s’assurer qu’ils sont

serrés à fond.

AVERTISSEMENT:

Il faudra impérativement vérifier que le carter de

sécurité n’est pas fixé. Par ailleurs, vérifier

également qu’il se déplace en douceur. Si la lame

de scie reste exposée, il y a risque de blessure.

La protection inférieure (voir Fig. 1) sert à protéger

le corps de l’opérateur de tout contact avec la lame

de scie. Vérifier impérativement que le carter de

sécurité fonctionne de façon que la lame de scie

soit toujours couverte. Si le carter de sécurité ne

fonctionne pas en douceur, ne jamais utiliser l’outil

sans avoir réparé le carter.

Dans ce cas, contacter le magasin où l’on a acheté

la scie circulaire ou un service après-vente HITACHI

agréé pour le faire réparer.

Lorsqu’on utilise l’outil, bien porter des lunettes

de protection.

Voir [Montage et demontage de la lame de scie] à

la page 24, et vérifier si le boulon à bride est bien

serré à fond.

La scie possède un frein électrique automatique

Socle

Lame de scie

20

Page 21

Français

conçu pour arrêter la rotation libre de la lame au

bout de 3 secondes environ après le relâchement

de la gâchette. Il est pratique pour certaines coupes

de bois où une lame en rotation libre entraînerait

une imprécision de coupe.

Il peut arriver que dans certaines conditions le frein

ne fonctionne pas correctement et n’arrête pas la

lame dans les 3 secondes, comme signalé cidessus.

Si cette situation se prolonge, allumer la scie et

l’éteindre quatre ou cinq fois de suite. Si le frein

n’arrête toujours pas la lame dans les 3 secondes,

les balais sont peut-être usés. Remplacer les balais

et recommencer. Si le problème persiste, faire

réparer l’outil par un SERVICE APRES-VENTE

HITACHI AGREE.

RÉGLAGE DE LA SCIE AVANT

L’UTILISATION

AVERTISSEMENT :

Pour éviter tout risque d’accident grave, s’assurer

que l’interrupteur est à la position OFF et

débrancher la fiche de la prise secteur.

1. Réglage de la profondeur de coupe (Fig. 3)

AVERTISSEMENT:

Si le levier (A) est lâche, il y a risque de blessure.

Le serrer à fond après le réglage.

Pour régler la profondeur de coupe, desserrer le

levier (A) et, tout en tenant le socle d’une main,

déplacer l’outil principal vers le haut ou vers le bas

de façon à obtenir la profondeur de coupe

spécifiée. Après avoir réglé la profondeur de coupe

spécifiée, resserrer le levier (A) à fond.

2. Réglage de l’angle d’inclinaison

AVERTISSEMENT:

Si le levier (A) est lâche, il y a risque de blessure.

Le serrer à fond après le réglage.

Il est possible d’incliner la lame de 0° à un angle

maximum de 55° par rapport au socle.

Comme indiqué sur la Fig. 4, en desserrant le levier

(A) de l’échelle d’angle de biseau, il est possible

d’incliner la lame de scie à un angle de 45° par

rapport au socle.

Levier (A)

0˚ – 45˚

Fig. 4

Si l’on utilise un angle d’inclinaison de plus de 45°,

comme indiqué sur la Fig. 5, déplacer le levier (A)

vers l’intérieur, et la lame de scie pourra être inclinée

à un angle maximum de 55° par rapport au socle.

Toujours veiller à bien resserrer le levier (A) après

avoir réglé l’angle.

Desserrer

Serrer

Socle

Fig. 3

Levier (A)

45˚ – 55˚

Fig. 5

3. Réglage du guide (garde de refente) (Fig. 6, 7)

...............................................Accessoire en option

Installer le boulon à ailettes (B) et verrouiller le ressort

sur le socle. Insérer le guide dans le socle, le déplacer

vers la gauche et vers la droite et régler la position

de coupe. Serrer le boulon à ailettes (B) et fixer le

guide. Il est possible d'installer le guide sur le côté

gauche ou sur le côté droit du corps de l'outil.

21

Page 22

Français

Boulon à

ailettes (B)

Ressort de

verrouillage

Socle

Boulon à ailettes (B), ressort

de verrouillage

PROCEDURES DE COUPE

AVERTISSEMENT

Ne pas utiliser de roues abrasives.

●

●

Ne jamais toucher les pièces mobiles.

●

Comme cela est indiqué dans la Fig. 8, veiller à

bien tenir la poignée ronde avec les deux mains

pendant une coupe. Le contact avec un câble

conducteur rendra également les parties

métalliques exposées de l’outil électrique

conductrices et provoquera un choc électrique à

l’opérateur. De plus, veiller à bien fixer la piece à

usiner avec un étau pendant la coupe.

Fig. 6

Socle

Guide

(garde de

refente)

Fig. 7

côtés du panneau, près de la ligne de coupe et près

du bord du panneau comme indiqué sur la Fig. 9.

Pour réduire tout risque de pincement de la lame

ou de retour de lame. Lorsqu’une opération de

coupe nécessite que la scie repose sur la pièce,

poser la scie sur le morceau le plus grand et couper

le petit morceau.

Pour éviter tout retour de lame,

soutenir la planche ou le panneau

près de la ligne de coupe.

Fig. 9

Ne pas soutenir la planche ou

le panneau loin de la ligne de coupe.

Fig. 10

●

Placer la section large de l’embase de la scie sur

la section de la pièce qui est fermement soutenue,

et non sur la section qui va tomber après la coupe.

A titre d’exemples, la Fig. 11 montre la façon

CORRECTE de couper l’extrémité de la planche, et

la Fig. 12 montre la façon INCORRECTE. Si la pièce

est trop courte ou trop petite, la fixer.

NE PAS ESSAYER DE TENIR LES SECTIONS

COURTES À LA MAIN!

Fig. 8

●

Si la lame s’arrête ou qu’elle fait un bruit anormal

pendant le fonctionnement, couper immédiatement

l’interrupteur.

●

Ne pas enlever la lame de la pièce pendant la coupe

alors que la lame tourne.

●

Soutenir les panneaux volumineux de façon à

réduire les risques de pincement de la lame et de

RETOUR DE LAME. Les panneaux volumineux ont

tendance à plier sous leur propre poids. Il faudra

placer les supports sous le panneau, des deux

22

Fig. 11

Page 23

[COUPE DE POCHES]

AVERTISSEMENT :

Pour éviter tout risque d’accident grave, s’assurer

●

que l’interrupteur est à la position OFF et

débrancher la fiche de la prise secteur avant tout

réglage.

●

Ne jamais attacher ni caler la protection inférieure

en position relevée.

1. Marquer bien lisiblement la section à couper avec

Fig. 12

●

Porter des lunettes de protection.

●

Ne pas scier de matériaux, comme du métal, etc.

susceptibles de projeter des étincelles.

des lignes sur tous les côtés. (Voir Fig. 14)

2. Régler la profondeur de coupe en fonction du

matériau à couper.

3. Pousser le levier à fond vers l’arrière jusqu’à ce

que la lame soit exposée, comme indiqué à la Fig.

14.

PRECAUTION :

Toujours veiller à ce que le cordon d’alimentation

●

n’approche pas de la lame de scie en rotation.

●

Avant de commencer à scier, s’assurer que la lame

de scie a bien atteint sa vitesse de régime.

1. Placer le corps (socle) de la scie sur le matériau,

et, comme indiqué à la Fig. 13, aligner la ligne de

coupe en pointillé sur la lame de scie, en utilisant

l’encoche gravée à l’avant du socle. Ce rapport

entre le socle et le matériau ne devra pas changer

quelle que soit l’inclinaison du socle.

2. Mettre l’interrupteur sur la position ON avant que

la lame de scie n’entre en contact avec le matériau.

L’interrupteur s’allume lorsqu’on tire la gâchette

avec le doigt, et il s’éteint lorsqu’on relâche la

gâchette.

3. Pour obtenir un rendement de coupe maximal,

déplacer la scie en droite ligne et à vitesse

constante.

4. Incliner la scie vers l’avant et aligner l’encoche (Fig.

13) sur la ligne de guidage pré-marquée.

5. Relâcher le levier. Lorsque la protection inférieure

entre en contact avec la surface de la pièce, elle

sera dans la bonne position pour s’ouvrir librement

Inclinaison à 45°

Pas

d’inclinaison

lorsqu’on commencera à couper.

6. Tout en tenant la scie dans cette position, et alors

que la lame n’est pas en contact avec la surface de

la pièce, tirer sur la gâchette.

7. Lorsque la scie a atteint sa vitesse de régime,

abaisser progressivement l’extrémité arrière de la

scie jusqu’à ce que le socle repose sur la surface

de la pièce.

8. Avancer la scie le long de la ligne de coupe

jusqu’au coin.

9. Relâcher la gâchette et attendre que la lame se soit

complètement arrêtée avant de retirer la lame de

la pièce.

䡩

Fig. 13

En aucun cas on ne tirera la lame vers l’arrière

pendant qu’elle tourne, car cela pourrait provoquer

un retour de lame.

10. Utiliser une scie sauteuse ou une scie à main pour

parfaire la coupe des coins.

11. Chaque fois qu’on commence une nouvelle coupe,

recommencer les opérations ci-dessus.

Français

Levier

Fig. 14

23

Page 24

Français

MONTAGE ET DEMONTAGE DE LA LAME

DE SCIE

AVERTISSEMENT:

Pour éviter tout risque d’accident grave, s’assurer

que l’interrupteur est à la position OFF et

débrancher la fiche de la prise secteur avant tout

réglage.

1. Démontage de la lame

(1) Régler le volume de coupe au maximum, et placer

la scie circulaire comme indiqué à la Fig. 15.

2. Montage de la lame

(1) Bien retirer toute la sciure qui s’est accumulée sur

l’axe, le boulon et les rondelles.

(2) Pour monter la lame, les côtés concaves des deux

rondelles (A) et (B) doivent rentrer dans les côtés

de la lame. Monter la lame sur l’axe, puis fixer la

rondelle (B). (Voir Fig. 17)

(3) Pour s’assurer que la lame tourne dans le bon sens,

il faut que la flèche de la lame soit dirigée dans le

même sens que celle du carter de lame.

(4) Avec les doigts, serrer le boulon hexagonal qui fixe

la lame de scie au maximum. Puis, appuyer sur le

levier de verrouillage, verrouiller l’axe et serrer le

boulon à fond.

Serrer

(5) Vérifier que le levier de verrouillage se trouve sur

sa position d’origine.

Boulon à

bride

hexagonal

Desserrer

Clé

Levier de

verrouillage

Fig. 15

(2) Appuyer sur le levier de verrouillage, verrouiller

l’arbre, et retirer le boulon à bride hexagonale et

la rondelle (B) à l’aide de la clé.

(3) Tout en tenant le levier pour maintenir la protection

inférieure complètement rentrée dans le carter de

lame, retirer la lame de scie. (Fig. 16)

Lame de scie

Rondelle

(B)

Fig. 17

Rondelle (A)

Lame de la

scie

Levier

24

Protection

inférieure

Carter du

lame

Fig. 16

Page 25

ENTRETIEN ET INSPECTION

Français

AVERTISSEMENT:

Pour éviter tout risque d’accident grave, s’assurer que l’interrupteur est à la position

OFF et débrancher la fiche de la prise secteur.

1. Inspection de la lame de scie

L’utilisation d’une lame émoussée affectant le

rendement et risquant de provoquer un mauvais

fonctionnement du moteur, affûter ou remplacer

la lame dès que l’on constate une abrasion.

PRECAUTION:

Avec une lame émoussée, la force de réaction

augmente pendant la coupe. Eviter d’utiliser une

lame émoussée sans la réparer.

2. Vérifier les vis.

Des vis mal serrées sont dangereuses. Les

inspecter régulièrement et vérifier qu’elles sont

serrées à fond.

PRECAUTION:

Il serait extrêmement dangereux d’utiliser cet outil

électrique avec des vis mal serrées.

3. Inspection des balais en carbone (Fig. 18)

Le moteur utilise des balais en carbone qui sont

des pièces qui s'usent. Remplacer un balai en

carbone par un nouveau quand il est usé jusqu'à

sa limite d'usure. Toujours garder propres les

balais en carbone et s'assurer qu'ils glissent

librement à l'intérieur des porte-balais.

Limite d'usure

38

0,24"(6mm)

0,67"

(17mm)

No. du balai en

carbone

Fig. 18

Couvercle du

balai

Tournevis à

tête plate

Fig. 19

5. Vérification des performances et entretien du carter

de protection

Maintenir le carter de protection en bon état pour

garantir constamment des performances

régulières. Faire immédiatement réparer l’outil en

cas de mauvais fonctionnement.

6. Réglage du socle et de la lame de scie en vue de la

perpendicularité

L’angle formé par le socle et la lame de scie a été

réglé en usine sur 90°; si cette perpendicularité se

trouve perturbée pour une raison ou pour une

autre, la régler en procédant comme suit.

(1) Retourner le socle (Fig. 20) et desserrer le levier

(A).

Equerre

PRECAUTION:

Utiliser la scie circulaire avec un balai en carbone

qui est usé au-delà de la limite d'usure

endommagera le moteur.

REMARQUE: Utiliser le balai en carbone HITACHI No.

38 indiqué sur la Fig. 18.

4. Remplacement d'un balai en carbone:

(2) Placer une équerre entre le socle et la lame de scie

Retirer le couvercle du balai avec un tournevis à

tête plate. Le balai en carbone peut être alors

facilement retiré. (Fig. 19)

Socle

Vis de fixation fendue

Fig. 20

et déplacer la position du socle en tournant la vis

de fixation fendue avec un tournevis à lame plate

de façon à obtenir un angle droit.

25

Page 26

Français

7. Liste des pièces de rechange

PRECAUCION:

Les réparations, modifications et inspections des

outils électriques Hitachi doivent être confiées à

un service après-vente Hitachi agréé.

Il sera utile de présenter cette liste de pièces au

service après-vente Hitachi agréé lorsqu’on

apporte un outil nécessitant des réparations ou

tout autre entretien.

Lors de l’utilisation et de l’entretien d’un outil

électrique, respecter les règlements et les normes

de sécurité en vigueur dans le pays en question.

ACCESSOIRES

MODIFICATIONS:

Les outils électriques Hitachi sont constamment

améliorés et modifiés afin d’incorporer les tous

derniers progrès technologiques.

En conséquence, il est possible que certaines

pièces (c.-à-d. no. de code et/ou dessin) soient

modifiées sans avis préalable.

AVERTISSEMENT:

REMARQUE:

Les accessoires sont sujets à changement sans obligation de la part de HITACHI.

ACCESSOIRES STANDARD

(1) Lame de la scie ..................................................... 1

Dia. Externe Dia. d'orifice No. de code

7-1/4" (185mm) 5/8" (15,9mm) 327761

(2) Clé (No. de code 940543) ..................................... 1

ACCESSOIRES EN OPTION.....vendus

séparément

(1) Guide (No. de code 302691) (Incluye (2) y (3).)

(2) Boulon-papillon (B) (No. de code 302697)

(3) Ressort de verrouillage (No. de code 947859)

Les accessoires pour cet outil motorisé sont mentionnés dans ce mode d’emploi.

L’utilisation de toute autre fixation ou accessoire peut être dangereux et causer des

blessures ou des dommages mécaniques.

REMARQUE:

Les spécifications sont sujettes à modification sans

aucune obligation de la part de HITACHI.

26

Page 27

Español

INFORMACIÓN IMPORTANTE SOBRE SEGURIDAD

Antes de utilizar o de realizar cualquier trabajo de mantenimiento de esta herramienta eléctrica, lea y comprenda

todas las precauciones de seguridad, advertencias e instrucciones de funcionamiento de este Manual de

instrucciones.

La mayoría de los accidentes producidos en la operación y el mantenimiento de una herramienta eléctrica se

deben a la falta de observación de las normas o precauciones de seguridad. Los accidentes normalmente podrán

evitarse reconociendo una situación potencialmente peligrosa a tiempo y siguiendo los procedimientos de

seguridad apropiados.

Las precauciones básicas de seguridad se describen en la sección “SEGURIDAD” de este Manual de instrucciones

y en las secciones que contienen las instrucciones de operación y mantenimiento.

Para evitar lesiones o el daño de la herramienta eléctrica, los riesgos están identificados con ADVERTENCIAS en