COMPOUND SAW

MODEL

C 10FCD

POWER TOOLS

C

TECHNICAL DATA

AND

C 10FCD

SERVICE MANUAL

LIST No. E928 May 1999

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

REMARK:

Throughout this TECHNICAL DATA AND SERVICE MANUAL, a symbol(s)

is(are) used in the place of company name(s) and model name(s) of our

competitor(s). The symbol(s) utilized here is(are) as follows:

Competitors

Symbols Utilized

Company Name

Model Name

S

C MAKITA

DELTA

36-220

LS1040

CONTENTS

[ Business Section ]

1. PRODUCT NAME

2. MARKETING OBJECTIVE

3. APPLICA TIONS

4. SELLING POINTS

4-1. Selling Point Descriptions

4-2. Electronic Control and Its Functions

5. SPECIFICATIONS

6. COMPARISONS WITH SIMILAR PRODUCTS

7. PRECAUTIONS IN SALES PROMOTION

7-1. Instruction Manual

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

8. ADJUSTMENT AND OPERATIONAL PRECAUTIONS

8-1. Confirmation of Saw Blade Lower Limit Positioning

8-2. How to Use the Vise Ass'y

8-3. Cutting Operation

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

8-4. Precautions Concerning Electronic Control

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

Page

1

1

1

1

2

6

8

9

11

11

12

12

12

13

15

9. ADJUSTMENT OF COMPONENTS

9-1. Bevel Angle Adjustment

10. PACKING

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

[ Service Section ]

11. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY

11-1. Disassembly

11-2. Reassembly

11-3. Wiring Diagram

11-4. Lead Wire Precautions

11-5. No-load Current

11-6. Reassembly Requiring Adjustment

11-7. Lubrication

11-8. Product Precision

12. REPAIR GUIDE

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

16

16

17

18

18

24

25

25

26

26

27

27

28

13. STANDARD REPAIR TIME (UNIT) SCHEDULES

[ Appendix ]

Assembly Diagram for C 10FCD

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

32

33

1. PRODUCT NAME

Hitachi Compound Saw, Model C 10FCD

2. MARKETING OBJECTIVE

The Model C 10FCD features two outstanding innovations: (1) The saw blade section (head) can be tilted both to

the right and left, permitting easy bevel cutting of a clamped workpiece. (2) Electronic control which minimizes

blade rotation speed change during the cutting operation, thereby providing smoother, cleaner-cuts. These

features are an industry first in the 10" compound saw field. Because of these leading innovations in operability

(right-left bevel cutting and high-quality finish on surfaces), the Model C 10FCD is expected to be the new leader

in 10" compound saw market.

3. APPLICA TIONS

Cutting various types of wood workpieces

Cutting workpieces of plywood, decoration panels, soft fiberboard and hardboard

Cutting aluminum sashes

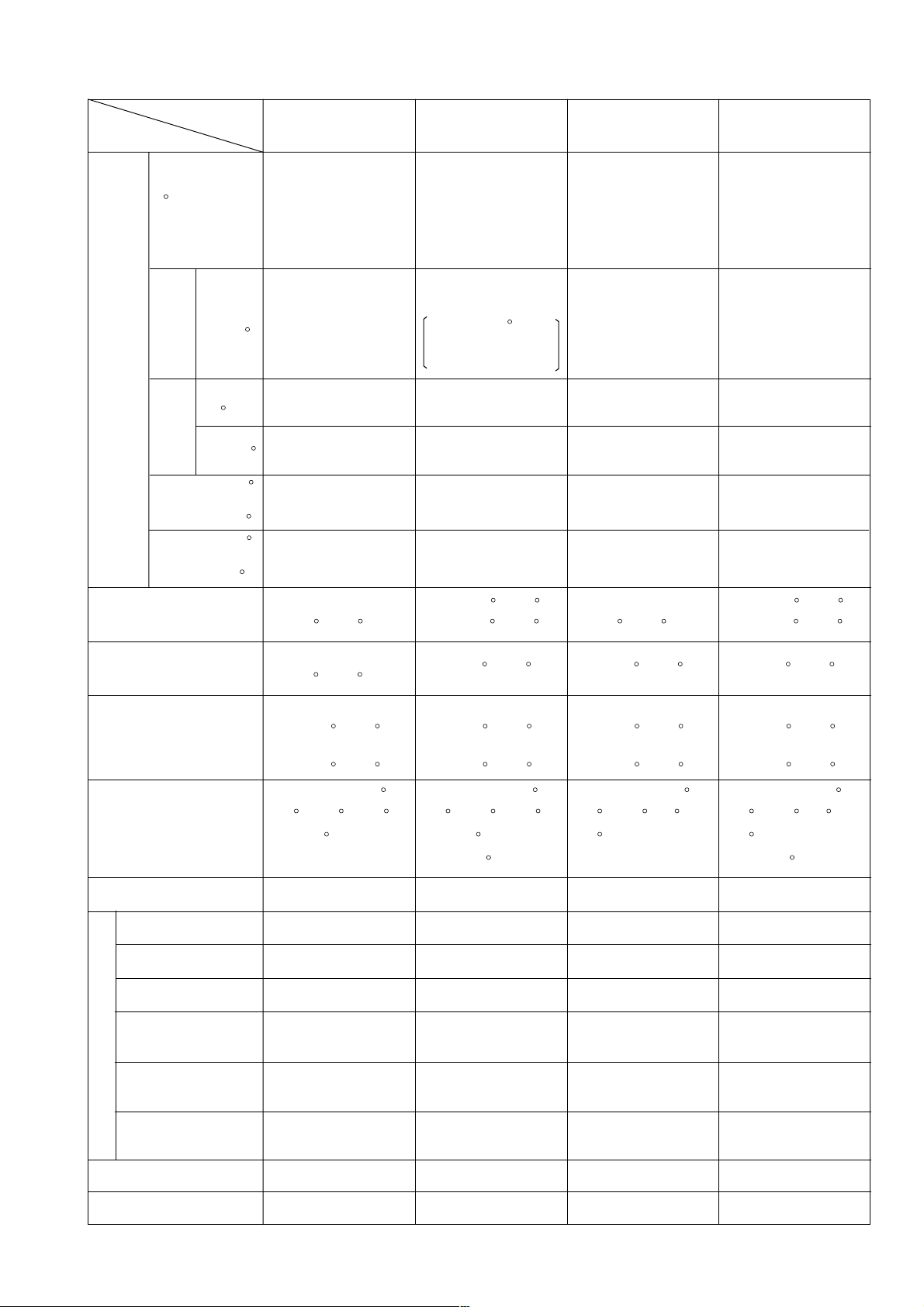

4. SELLING POINTS

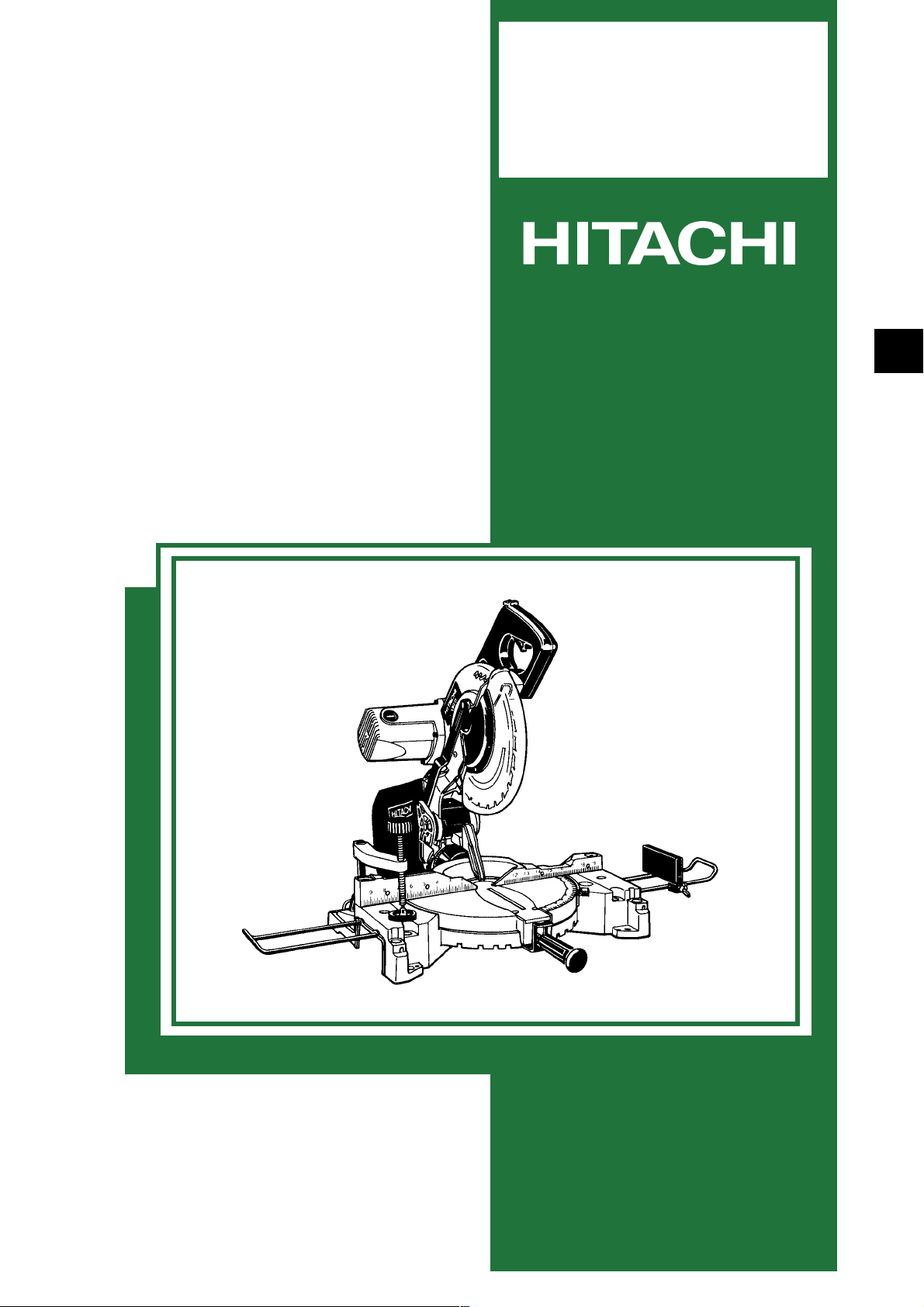

(6)

Minimized reaction during motor start up

(7)

Poly V belt overload protection

Electronically controlled soft

start and motor torque

(5)

Fine surface finish on cuts

Electronically controlled

constant-speed

(3)

Right and left bevel cutting

(4)

Compound miter

and right/left bevel

cutting

(1)

Press cutting

(8)

Equipped with debris guard

to restrict dispersion of chips

for enhanced safety in

operation

(9)

Lightweight design: 13 kg

(Note) Numerals in ( ) are identical with item numbers in "4-1. Selling Point Descriptions"

--- 1 ---

Left

Right

(2)

Miter cutting

4-1. Selling Point Descriptions

(1) Press cutting

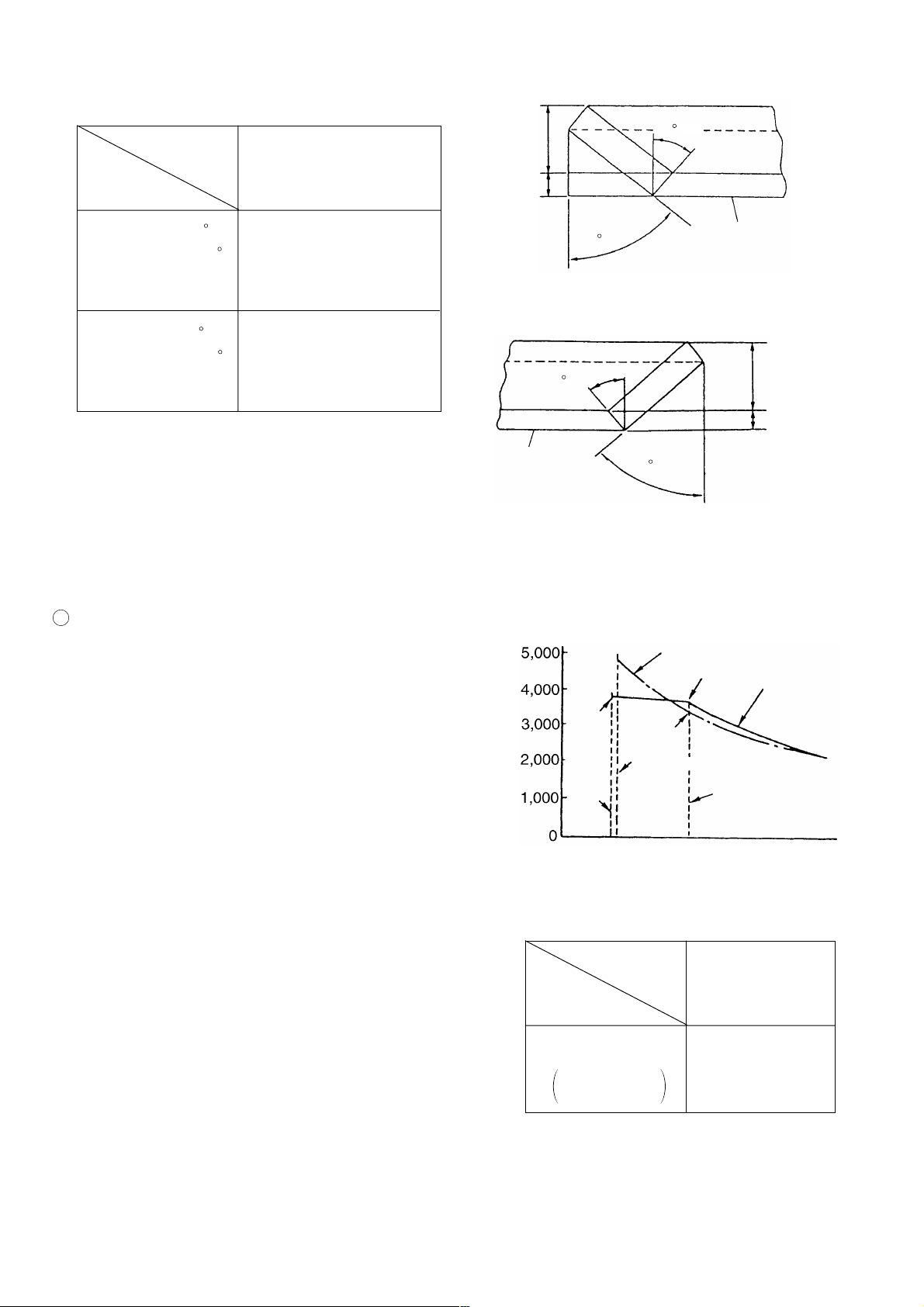

Table 1

(Unit: mm)

Maker

model

Max. cutting

HITACHI

C 10FCD

Workpiece

Width (W)

dimension

69 x 143

(2-23/32" x 5-5/8")

Height x Width

(H x W)

89 x 92

(3-1/2" x 3-5/8")

with aux. board width

17 mm (11/16")

Fig. 1

Press cutting with the head swiveling enables cutting square workpieces as large as shown in Table 1 in a

single sawing operation. (See Fig. 1)

(2) Miter cutting facility

Table 2

(Unit: mm)

Maker

model

Max. cutting

HITACHI

C 10FCD

Width (W)

dimension

Height (H)

Right and left 45

Height x Width

(H x W)

69 x 98

(2-23/32" x 3-7/8")

Workpiece

Right and left

45

Height (H)

Fig. 2

By turning the table to the right or left as desired, the Model C 10FCD is capable of miter cutting of up to 45 to

the right and left.

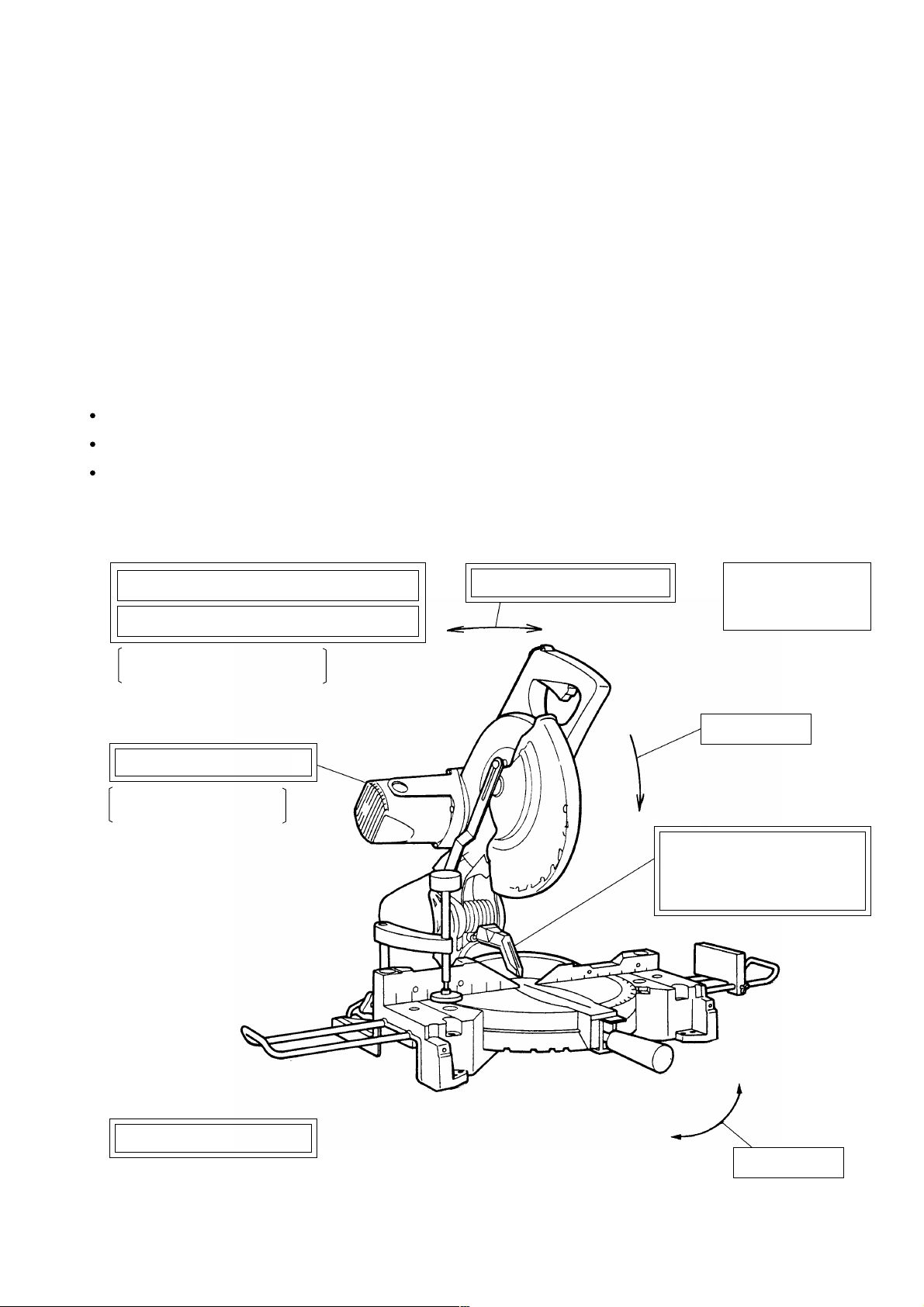

(3) Right and Left bevel cutting facility

1 Advantage of right and left bevel cutting

Window frames

Fig. 4 shows the left bevel cutting by C 10FC2 and Fig. 5 shows the

right and left bevel cutting by C 10FCD.

The purpose of right and left bevel cutting is to achieve accurate 45

bevel cutting for better miter joint work. Generally, window frames

are made by jointing 45 bevel (miter) cut workpieces. (See Fig. 3)

Miter cutting

(45 bevel cutting)

Fig. 3

(a) In the case of C 10FC2, miter cutting is performed by the left bevel cutting function only as shown in Fig. 4.

Therefore, the workpiece must be turned around in the second process and the reference plane, that is, the

surface of the workpiece which contacts to the fence is opposite to that of the first process.

(b) In the case of C 10FCD, more accurate miter cutting is performed because the same reference plane (surface

of the workpiece which contacts to the fence) is used in both the first and the second processes as shown in

Fig. 5. In addition, the working efficiency is improved and long workpieces can be handled in tight places

because there is no need to turn around the workpieces.

--- 2 ---

First process

First process

Saw blade

Second process

Reference plane in

the second process

(surface of the

workpiece which

contacts to the fence)

Fig. 4 Miter cutting by C 10FC2

Reference plane in the first process

(surface of the workpiece which

contacts to the fence)

Turn around

Reference plane

in the first process

Reference plane in the first process

(surface of the workpiece which

contacts to the fence)

Second process

Same reference plane as the first process

Fig. 5 Miter cutting by C 10FCD

2 Maximum cutting dimension

Table 3

Maker

model

Max. cutting

dimension

Right 45

Height x Width

(H x W)

Left 45

Height x Width

(H x W)

Workpieces as wide as shown in Table 3 can be bevel-cut by tilting the saw blade section (head).

HITACHI

C 10FCD

24 x 120

(15/16" x 4-3/4")

45 x 143

(1-25/32" x 5-5/8")

(Unit: mm)

Workpiece

Right 45

Left 45

Fig. 6

Width (W)

Height (H)

--- 3 ---

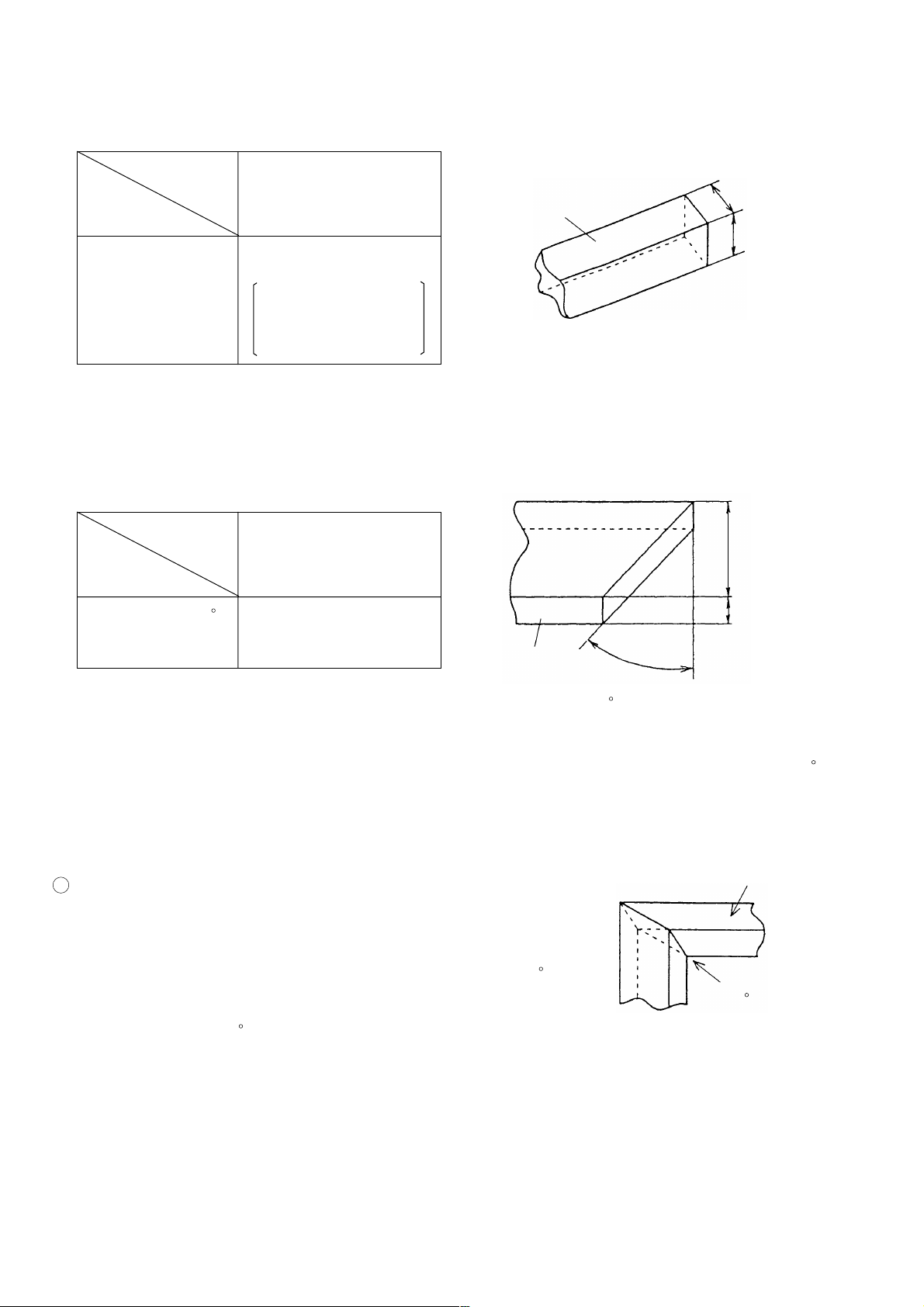

(4) Compound cutting through use of miter and bevel cutting functions

Max. cutting

Maker

model

Table 4

HITACHI

C 10FCD

(Unit: mm)

Width (W)

Height (H)

dimension

45

(Right)

Right bevel 45

Right/Left miter 45

Height x Width

24 x 85

(15/16" x 3-11/32")

(H x W)

Left bevel 45

Right/Left miter 45

Height x Width

45 x 130

(1-25/32" x 5-1/8")

(H x W)

By turning the table to the right or left and inclining the

saw blade section (head) to the right or left, the Model

C 10FCD is capable of compound cutting (bevel and

miter, see Figs. 7 and 8) of workpieces with the maximum

dimensions shown in Table 4.

(5) Fine surface finish on cuts

1 Constant-speed cutting is achieved by minimizing

revolution variation due to changes in load during sawing

by means of an electronic control, as in the C 10FCD.

As indicated in Fig. 9, revolution variation during sawing is

electronically held to a minimum, while providing a higher

(Left)

45

Workpiece

Rotation speed

(/min)

3800

45

(Right)

Fig. 7

45 (Left)

Fig. 8

3400

Workpiece

Width (W)

Height (H)

Models without electronic

control

3700

HITACHI

C 10FCD

rotation speed during sawing than in the competitiors'.

With this considerably higher speed during sawing (over

No-load

current

No-load current

Rated current

the normal load range), the amount of material cut per

tooth is reduced to ensure a finer quality finish on the cut

surface. Uneven cut surfaces at the start of sawing are

Load current (A)

Fig. 9

caused by numerous runouts of the saw blade due to

revolution changes dependent on load variation.

The electronic control provided in the C 10FCD serves to

maintain relatively constant rotation in a range at which run

out of the saw blade is minimized, even at the no-load

speed. This minimizes surface unevenness during the first

part of the cut. Besides the outstanding feature of cutting

speed which is independent of load variation over a wider

Table 5

Maker

model

Item

No-load sound

presure level

1 m distance

fromthe front

[Unit: dB(A)]

HITACHI

C 10FCD

85

range of operation (for a smooth cut surface with few saw marks), electronic control also offers advantages of

eliminating the sharp metallic noise due to resonance of the saw blade as well as noises during no-load

operation because the no-load speed is maintained at 3,800 /min. (See Table 5)

--- 4 ---

(6) Minimized reaction during motor start

The C 10FCD uses the soft-start system to suppress sound

pressure level when starting and reaction transmitted

through the handle.

Sound pressure level and reaction when starting are as

indicated in Table 6.

A normal speed is reached quickly with minimum sound

pressure level when starting.

Item

Sound pressure level

when starting *

* Sound pressure level when starting: Maximum

value measured at 1 m distance from the front

Table 6

Maker

model

[Unit: dB(A)]

HITACHI

C 10FCD

86

It is readily seen from Table 6 that the electronically

controlled soft start is highly effective.

(7) Poly V belt overload protection

C 10FCD utilizes the poly V belt to transmit the rotation of the motor to the saw blade instead of a conventional

gear transmission system. This is to reduce noise, however, there is a fear of cutting the poly V belt during

overload. To protect the poly V belt, an overload protection circuit is equipped in C 10FCD.

The overload protection circuit stops the motor revolution before the motor locks when an excessive or

abnormal load is applied to the poly V belt, and so protects the poly V belt.

(8) Equipped with debris guard to restrict dispersion of chips for enhanced safety in operation

A debris guard has been adopted to prevent wood chips from adhering to the saw blade at the end of the

cutting operation. The debris guard tilts together with the saw blade during bevel cutting, thereby enhancing

safe operation.

(9) Lightweight design

13 kg in weight, for easy transport in a workshop

--- 5 ---

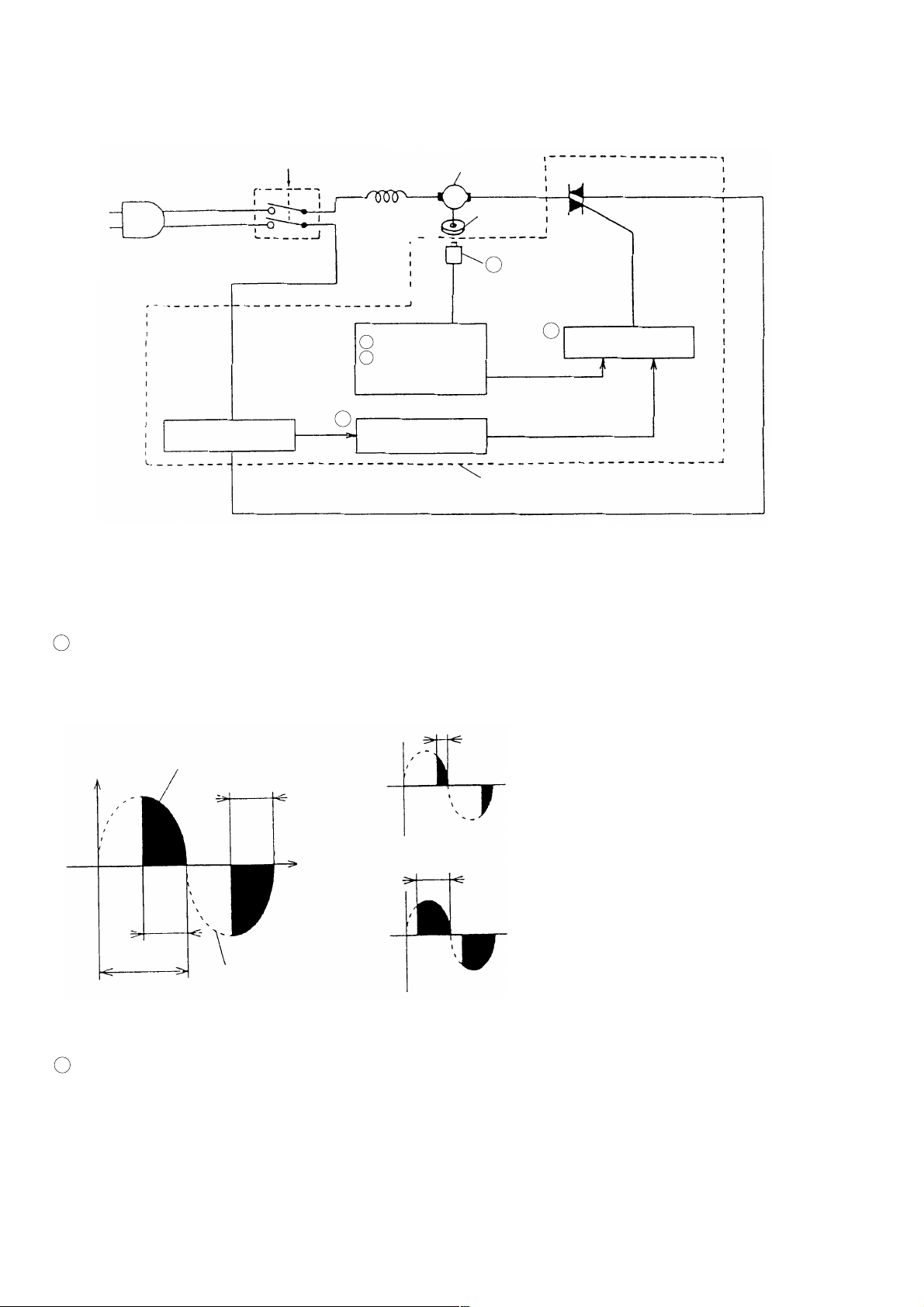

4-2. Electronic Control and Its Functions

(1) Control circuit (block diagram)

Off/On

Load current

detecting circuit

Switch

Stator coil

3 Soft start circuit

4 Constant-speed

control circuit

5

Overload

protection circuit

Motor

Fig. 10

Magnet

2 Rotation speed

detector

1

Phase control circuit

Controller

Phase control

element

(2) Functions

1 Phase control circuit

As illustrated Fig. 11, the phase control element (triac) functions to increase or decrease the time (T) of the line

voltage waveform in order to control the amount of voltage applied to the motor.

t

When ' t ' becomes smaller, motor

Voltage

Waveform of voltage

applied to motor

t

rotation speed and torque decrease.

Time

t

t

When ' t ' becomes larger, motor rotation

speed and torque decrease.

T

Line voltage

waveform (AC)

Fig. 11

When t = T, line voltage (full voltage) is applied.

2 Rotation speed detector

The rotation speed detector detects and monitors the rotation speed of the armature by means of a magnetic

sensor (magnet pick-up), incorporated in the controller, which detects flux changes generated by a magnet

mounted at the armature shaft.

--- 6 ---

3 Soft-start circuit

When the switch is turned on, the soft start-circuit functions to

gradually increase the voltage applied to the motor, thereby

gradually increasing motor rotation speed.

Rotation speed

Switch ON

4 Constant speed control circuit

The constant speed control circuit receives signals from the rotation speed detector, and adjusts the amount of

voltage applied to the motor to keep the rotation speed of the motor as close as possible to a predetermined

value.

5 Overload protection circuit

When an overload sensor detects a motor load current that exceeds the maximum load limit of the

polyethylene V-belt, the overload protection circuit generates a command to cut off the power supplied to the

motor. This circuit is also effective in preventing the motor and the phase control element from being

damaged.

Voltage applied to

motor is gradually

increased.

Time

Fig. 12

(3) Motor characteristics during electronic control

3,800

(When control is not applied)

As load increases,

Saw blade rotation speed (/min)

voltage applied to

motor increases.

Overload protection is activatedNo load

Load current (A)

Voltage applied to motor decreases

suddenly, and motor stops.

Current value determined by load

current limiter circuit

Fig. 13

--- 7 ---

5. SPECIFICATIONS

0 (Right angle)

Maximum

cutting

dimensions

Height x

Width

(H x W)

Miter right/left 45

Right 45

Bevel

Left 45

Miter right/left 45

+

Bevel right 45

Miter right/left 45

+

Bevel left 45

Miter cutting ranges

Bevel cutting range

Compound (miter + bevel) cutting

ranges

Angle stopper positions

Applicable saw blade

Power source type and voltage

69 mm (2-23/32") x 143 mm (5-5/8")

89 mm (3-1/2") x 92 mm (3-5/8") [with aux. board width 17 mm (11/16")]

69 mm (2-23/32") x 98 mm (3-7/8")

24 mm (15/16") x 120 mm (4-3/4")

45 mm (1-25/32") x 143 mm (5-5/8")

24 mm (15/16") x 85 mm (3-11/32")

45 mm (1-25/32") x 98 mm (3-7/8")

Right and left 0 --- 45

Right and left 0 --- 45

Miter: Right and left 0 --- 45 , Bevel: Right and left 0 --- 45

Right and left 0 , 15 , 22.5 , 31.6 and 45

255 mm (10") external dia. x 15.9 mm (5/8") bore

AC single phase 60 Hz, 115 V

Type of motor

Full-load current

No-load rotation speed

Max. output

Main body dimensions

(Width x Depth x Height)

Weight

Coating

Packaging

Cord

Standard accessories

AC single phase commutator motor

115 V --- 13 A

3,800 /min

1,600 W

500 mm x 625 mm x 605 mm

(19-11/16" x 24-5/8" x 23-13/16")

13 kg (28.7 lbs) Gross weight 16 kg (35.3 lbs)

Metallic silver green

Corrugated cardboard box

Type: 2-Conductor cabtire cable Norminal cross-sectional area: 1.25 mm

Length: 2 m (6.6 ft) External dia: 8 mm with mold plug

255 mm (10") TCT saw blade (24 teeth, Code No. 790004)

••••••••••••

for wood and aluminum cutting

Dust bag

Vise ass'y

Extension stay

Machine screw M5

Wrench

2

Optional accessories

Holder ass'y (Code No. 317542)

Vise ass'y (Code No. 317541)

255 mm (10") TCT saw blade (70 teeth, Code No. 976473)

••••••••••••

for normal cutting

--- 8 ---

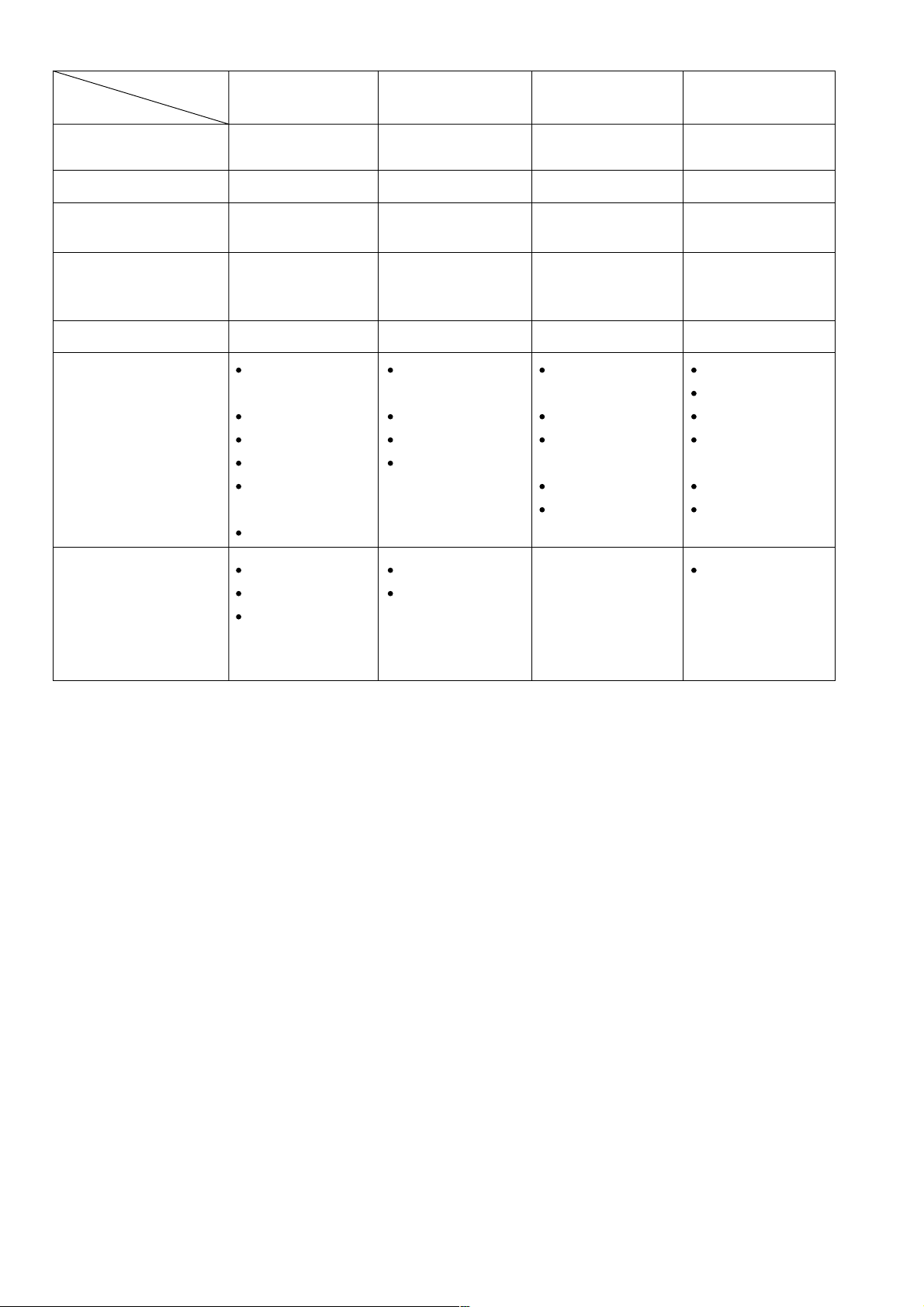

6. COMPARISONS WITH SIMILAR PRODUCTS

Maker/Model

Item

HITACHI

C 10FCD

HITACHI

C 10FC2

S

C

0

(Right angle)

Max.

cutting

Miter

Right/

left 45

dimensions

Height

x Width

(H x W)

Right

45

Bevel

Left 45

Miter right/left 45

+

Bevel right 45

Miter right/left 45

+

Bevel left 45

Miter cutting ranges

69 mm x 143 mm

(2-23/32" x 5-5/8")

89 mm x 92 mm

(3-1/2" x 3-5/8")

[with aux. board width

17 mm (11/16")]

69 mm x 98 mm

(2-23/32" x 3-7/8")

24 mm x 120 mm

(15/16" x 4-3/4")

45 mm x 143 mm

(1-25/32" x 5-5/8")

24 mm x 85 mm

(15/16" x 3-11/32")

45 mm x 98 mm

(1-25/32" x 3-7/8")

Right and left

0 --- 45

67 mm x 146 mm

(2-5/8" x 5-3/4")

89 mm x 92 mm

(3-1/2" x 3-5/8")

[with aux. board width

17 mm (11/16")]

70 mm x 89 mm

(2-3/4" x 3-1/2")

Right 60

70 mm x 73 mm

(2-3/4" x 2-7/8")

---

44 mm x 130 mm

(1-3/4" x 5-1/8")

--- --- ---

44 mm x 89 mm

(1-3/4" x 3-1/2")

Right 0 --- 60

Left 0 --- 45

70 mm x 146 mm

(2-3/4" x 5-3/4")

70 mm x 105 mm

(2-3/4" x 4-1/8")

---

44 mm x 146 mm

(1-3/4" x 5-3/4")

44 mm x 105 mm

(1-3/4" x 4-1/8")

Right and left

0 --- 45

69 mm x 130 mm

(2-3/4" x 5-1/8")

69 mm x 92 mm

(2-3/4" x 3-5/8")

---

35 mm x 130 mm

(1-3/8" x 5-1/8")

35 mm x 92 mm

(1-3/8" x 3-5/8")

Right 0 --- 52

Left 0 --- 45

Bevel cutting ranges

Compound

(miter + bevel)

cutting ranges

Miter: Right and left

Bevel: Right and left

Right and left 0 ,

Angle stopper position

15 , 22.5 , 31.6

and 45

Saw blade outer diameter (mm)

Full-load current (A)

No-load revolution (/min)

Max. output (W)

Soft-start

Motor

Speed control

(electronic control)

(electronic control)

Right and left

0 --- 45

0 --- 45

0 --- 45

255 (10")

115 V --- 13A

3,800

1,600

Provided

Provided

Left 0 --- 45

Miter: Right and left

0 --- 45

Bevel: Left

0 --- 45

Right and left 0 ,

15 , 22.5 , 31.6

and 45

Right 60

255 (10")

115 V --- 15 A

4,900

2,200

No

No

Left 0 --- 45

Miter: Right and left

0 --- 45

Bevel: Left

0 --- 45

Right and left 0 ,

15 , 22.5 , 30 and

45

255 (10")

115 V --- 15 A

4,900

---

No

No

Left 0 --- 45

Miter: Right and left

0 --- 45

Bevel: Left

0 --- 45

Right and left 0 ,

15 , 22.5 , 30 and

45

Right 52

255 (10")

115 V --- 15 A

4,600

---

No

No

Poly V belt

overload protector

Saw blade drive system

Insulation structure

Provided

(electronic control)

Poly V belt and gear

Double insulation

No

Gear

Double insulation

--- 9 ---

No

Gear

Double insulation

No

Gear

Double insulation

Maker/Model

Item

Base size

width x depth (mm)

HITACHI

C 10FCD

500 x 120

(19-11/16" x 4-3/4")

HITACHI

C 10FC2

525 x 150

(20-1 1/16" x 5-29/32")

S

455 x 125

(17-15/16" x 4-15/16")

C

460 x 135

(18-3/32" x 5-5/16")

Debris guard

Dust bag size (mm)

Main unit dimensions

(Width x Depth x

Height) (mm)

Standard accessories

Optional accessories

Provided

300 x 190

(11-13/16" x 7-15/32")

500 x 625 x 605

(19-11/16" x 24-5/8"

x 23-13/16")

13 (28.7 lbs)Product weight (kg)

TCT saw blade

(24 teeth)

Dustbag

Vise ass'y

Extension Stay

5 mm Machine

Screw

Wrench

Holder ass'y

Vise ass'y

255 mm TCT saw

blade (70 teeth)

for normal cutting

Provided

300 x 190

(11-13/16" x 7-15/32")

535 x 600 x 489

(21-1/16" x 23-1/2"

x 19-1/4")

14.5 (32 lbs)

TCT saw blade

(24 teeth)

Dustbag

Vise ass'y

Wrench

Holder ass'y

255 mm TCT saw

blade (70 teeth)

for normal cutting

No

320 x 190

(12-19/32" x 7-15/32")

455 x 595 x 535

(17-29/32" x

23-13/32" x 21")

22 (49 lbs)

Combination saw

blade (104 teeth)

Dustbag

Vise ass'y

(Horizontal)

Holder ass'y

Wrench

No

300 x 150

(11-13/16" x 5-15/16")

476 x 530 x 532

(18-3/4" x 20-7/8" x

20-15/16")

11 (24.2 lbs)

TCT saw blade

Dustbag

Auxiliary plate

13 mm Socket

wrench

Wrench

Triangular rule

Safety goggles

--- 10 ---

7. PRECAUTIONS IN SALES PROMOTION

In the interest of promoting the safest and most efficient use of the Model C 10FCD Compound Saw by all of our

customers, it is very important that at the time of sale the salesperson carefully ensures that the buyer seriously

recognizes the importance of the contents of the Instruction Manual, and fully understands the meaning of the

precautions listed on the various Caution Plates attached to each machine.

7-1. Instruction Manual

Although every effort is made in each step of design, manufacture and inspection to provide protection against

safety hazards, the dangers inherent in the use of any power saw cannot be completely eliminated. Accordingly,

general precautions and suggestions for the use of electric power tools, and specific precautions and suggestions

for the use of the compound saw are listed in the Instruction Manual to enhance the safe, efficient use of the tool

by the customer. Salespersons must be thoroughly familar with the contents of the Instruction Manual to be able

to offer appropriate guidance to the customer during sales promotion.

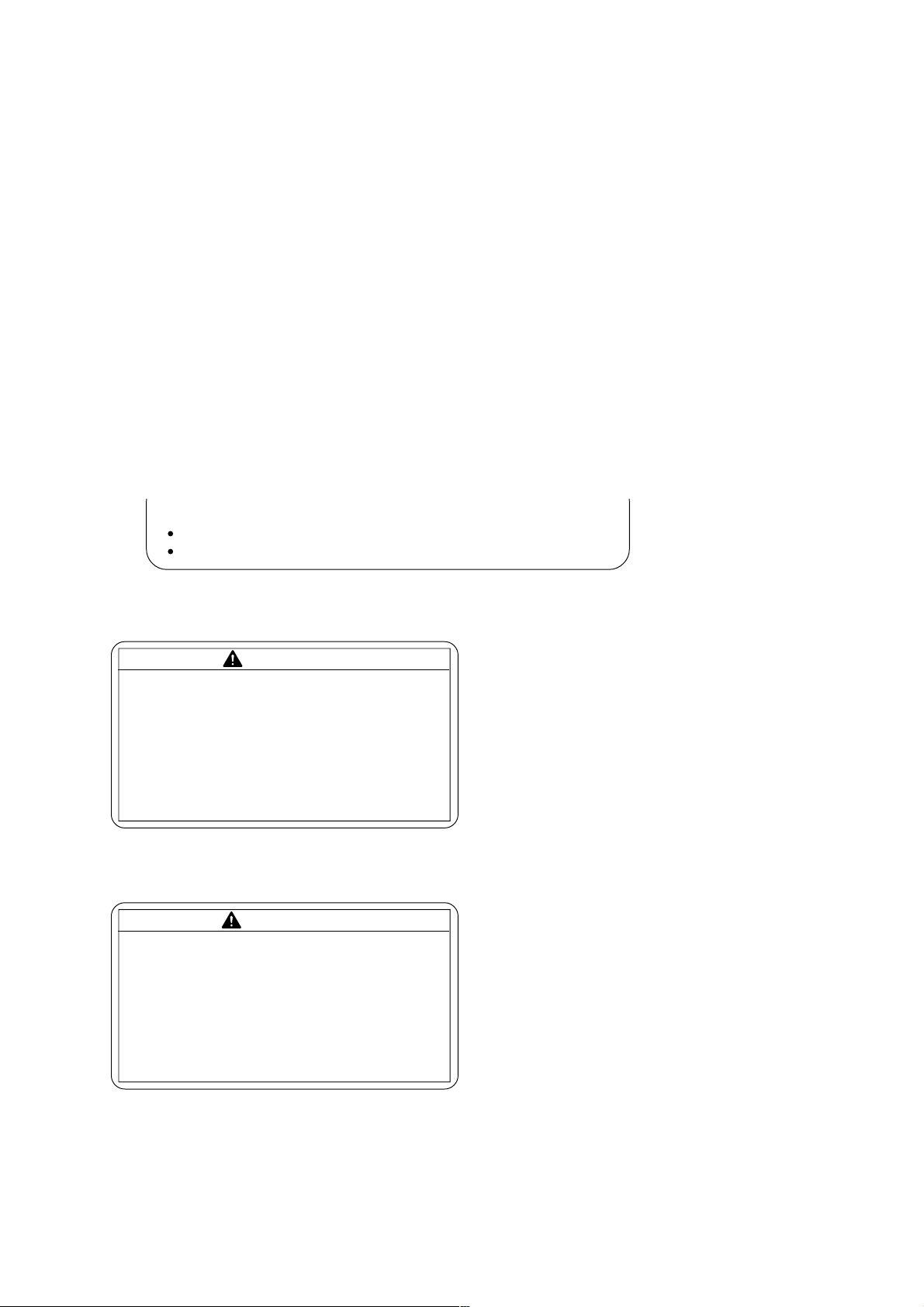

(1) Precautions on the Name Plate

Each Model C 10FCD is furnished with a Name Plate that lists the following precautions.

CAUTION

For safe operation, see instruction manual.

Do not expose to rain or use in damp locations.

(2) Warning Label (A)

WARNING

For Your Own Safety Read Instruction

Manual Before Operating Miter Saw.

1. Wear eye protection.

2. Keep hands out of path of saw blade.

3. Do not operate saw without guards in place.

4. Do not perform any operation freehand.

5. Never reach around saw blade.

6. Turn off tool and wait for saw blade to stop

before moving workpiece or changing settings.

7. Disconnect power before changing blade or servicing.

8. Saw blade diameter is 10" (255 mm).

9. No load speed is 3800 /min.

(3) Caution Label (E)

CAUTION

When the Poly-V-belt becomes overloaded, the

overload protective device cuts off the current to stop

the motor. In this case turn the switch off immediately

and raise the handle to its initial position. Then turn the

switch on and run the tool for 20 seconds without load

for cooling of the motor. Then start the cutting

operation. The Poly-V-Belt or the motor will be

damaged if the overload protective device turns off

frequently.

The Warning Label (A) specified by the UL is affixed

on the upper righthand portion of the base. Please

instruct users to strictly observe the contents in 1 to 9

in the Warning Label (A) shown at left.

H390727

The Caution Label (E) is affixed on the side of the rear

cover. Please instruct users to strictly observe the

Caution Label (E).

H390973

--- 11 ---

8. ADJUSTMENT AND OPERATIONAL PRECAUTIONS

8-1. Confirmation of Saw Blade Lower Limit Positioning

6 mm Depth

adjustment

screw

The lower limit of the saw blade cutting depth is factory adjusted

so that when the saw blade is fully lowered, its cutting edge is

24 mm to 28 mm (1-1/32" to 1-3/32") below the upper surface of

the table insert. Lower the saw blade and confirm that it stops at

the correct position.

If it is necessary to adjust the saw blade lower limit, loosen the

6 mm lock nut on the 6 mm depth adjustment screw, and turn the

6 mm depth adjustment screw if necessary. (See Fig.14)

[Caution] Perform the adjustment carefully to ensure that the saw blade does not cut into the table.

Also, on completion of adjustment, ensure without fail that the 6 mm lock nut is securely

tightened.

8-2. How to Use the Vise Ass'y

(1) The vise ass'y can be mounted on either the left side

base or the right side base, and can be raised or

lowered according to the height of the workpiece.

Fig. 14

6 mm

Lock nut

Knob

Vise ass'y

1 Insert the support of the vise ass'y into the hole

located on eigher the left side base or the right side

base.

2 Then tighten the 5 mm clamp bolt as shown in Fig. 15.

3 Turn the knob to thoroughly clamp the workpiece.

(NOTE) The support has two locking grooves into which

the tip of the 5 mm clamp bolt is designed to fit, to

lock the vise ass'y in the desired position.

(2) The vise ass'y can be mounted on either the left side

fence or the right side fence, and can be raised or

lowered according to the height of the workpiece.

1 Insert the support of the vise ass'y into the hole

located on either the left side fence or the right side

fence.

2 Then tighten the 5 mm clamp bolt as shown in Fig. 16.

3 Turn the knob to thoroughly clamp the worikpiece.

Knob

Vise ass'y

Support

Fence

5 mm

Clamp bolt

Base

5 mm

Clamp bolt

Fig. 15

Fig. 16

[Caution] Always confirm that the motor head does not contact the vise ass'y when it is lowered for

cutting. If there is any danger that it may do so, loosen the 5 mm wing bolt slightly and move

the vise ass'y to a position where it will not contact the saw blade.

--- 12 ---

8-3. Cutting Operation

(1) Cutting efficiency will be reduced if a dull saw blade is used, if an excessively long extension cord is used, or if

the wire gauge of the extension cord is too small. (For details on extension cords, please refer to the

Instruction Manual.) This is particularly important when cutting materials with dimensions which are at or near

the maximum capacity for the machine.

(2) The customer should be advised to thoroughly inspect the workpiece to ensure that there are no metallic

objects (nails in particular), sand or other foreign matter in or on the workpiece. Saw blade contact with such

foreign matter will not only shorten the service life of the saw blade, but could cause serious accident. Should

the saw blade tips be broken off, the tips may fly toward the operator.

(3) Press cutting

Like Model C 10FC2 can be used for press cutting of workpieces up to 69 mm x 143 mm (2-23/32" x 5-5/8") in

a single operation by simply pushing the saw blade section (head) downward. The customer should be

cautioned that excessive pressure on the handle will not increase the cutting speed. On the contrary,

excessive pressure may result in reduced cutting efficiency (irregular or rough cutting of the workpiece), and

could also cause overload and subsequent burnout of the motor.

On completion of the cutting operation, turn the switch OFF and wait for the saw blade to come to a complete

stop before raising the saw blade section (head) to its original position. Raising the saw blade section (head)

while the saw blade is rotating may cause unwanted cutting marks on the workpiece.

Techniques to avoid unwanted cutting marks

Uneven and unwanted cutting marks can be avoided throughout the cutting operation by gently and smoothly

pressing down on the handle, so that the entire cutting operation is accomplished in a single uninterrupted

motion.

(4) Miter cutting

Miter cutting is accomplished by turning the table. (For details, please refer to the Instruction Manual.)

(5) Bevel cutting

Bevel cutting of 0 --- 45 to the right or left is accomplished by inclining the saw blade section (head).

(For details, please refer to the Instruction Manual.)

[Caution] When the workpiece is secured on the right or left

side, the cut off portion comes to rest on the side of

the saw blade as illustrated in Fig. 17. If the handle is

raised before the saw blade rotation comes to a

complete stop, there is a chance that the cut off

Fixed-side workpiece

Cut-off-side

workpiece

portion of the workpiece could become jammed

against the saw blade, causing a hazardous

condition. Instruct the customer to ensure without

fail that the saw blade comes to a complete stop

before attempting to raise the handle.

--- 13 ---

Saw blade

Fig. 17

(6) Compound (miter + bevel) cutting

Compound cutting can be accomplished by combining the miter cutting and bevel cutting operations described

in paragraphs (4) and (5) above. (For details, please refer to the Instruction Manual.)

When the saw blade section (head) is inclined 45 to the right or left, the table can be turned up to 45 to the

right and left.

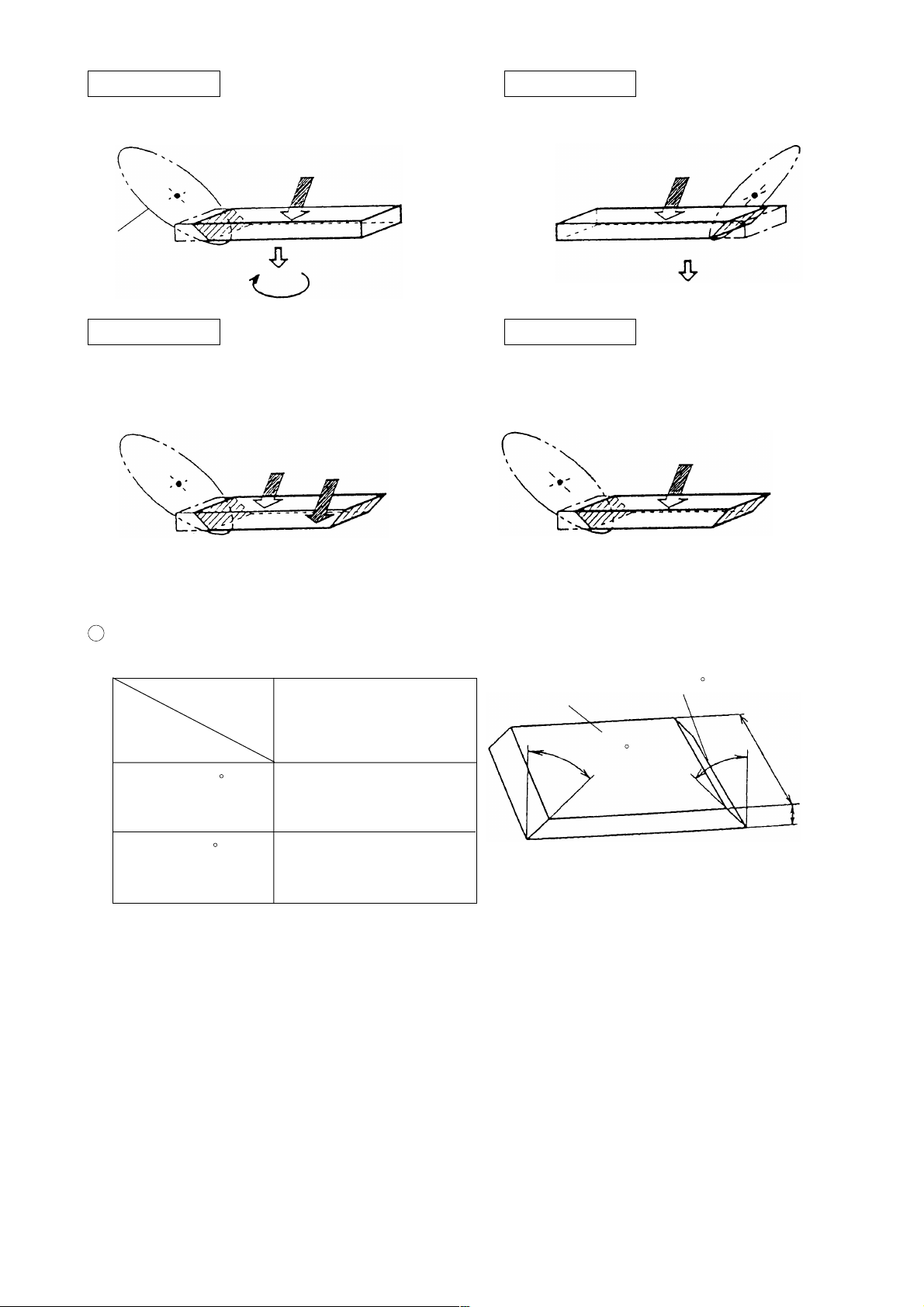

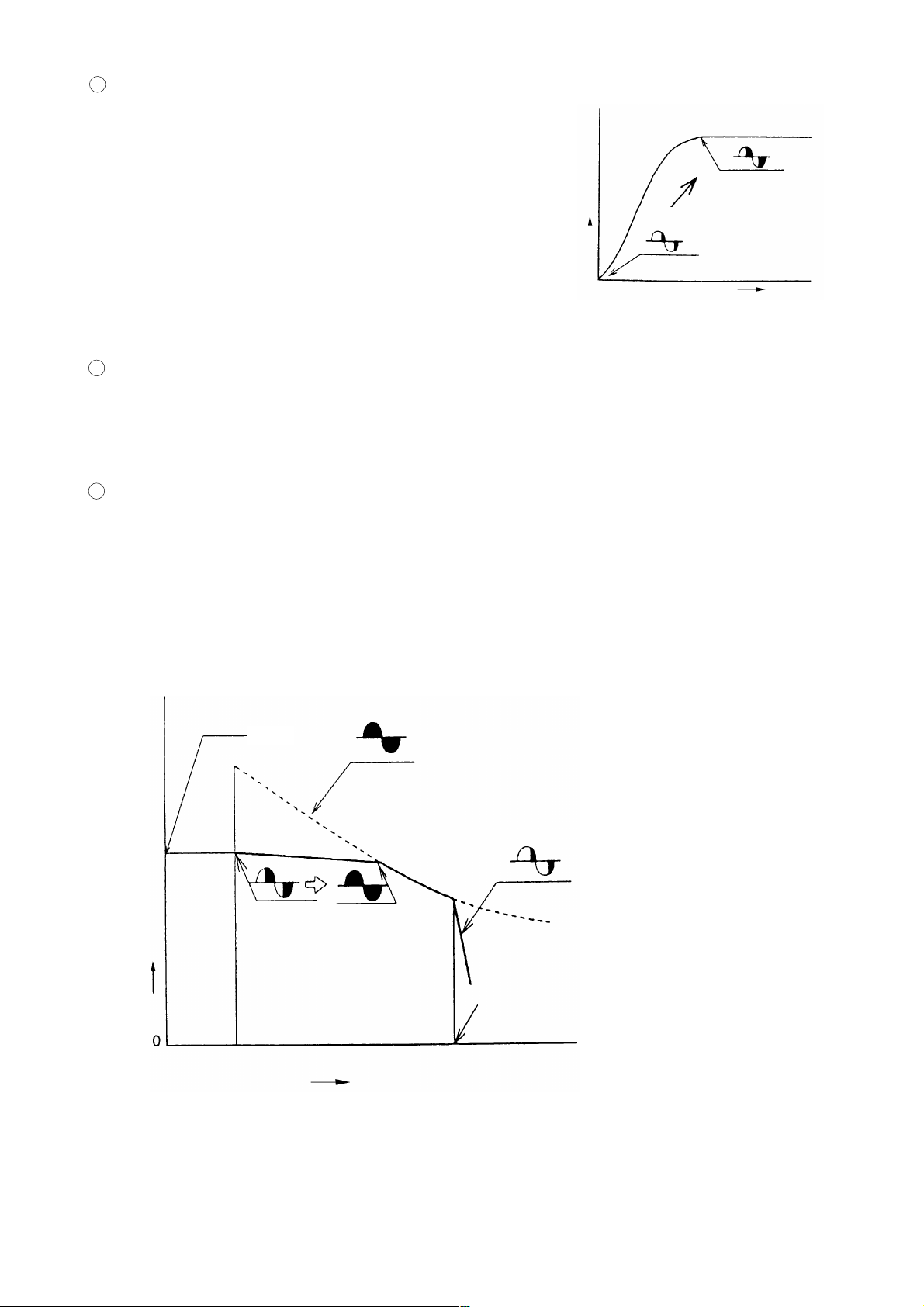

(7) Cut surface quality during miter/bevel cutting

The quality of the cut surface depends on the type of

cutting operation (miter or bevel), the type and

sharpness of the saw blade, whether the workpiece

is cut to the right or left, and various other factors. In

miter and bevel cutting in particular, cutting is

performed across the wood grain, so the condition of

the cut surface depends on whether the wood is cut

with or against the grain. This is the sames as when

using electric portable planers. Customers should

be advised of these phenomena so that they

understand that in cases when the cut surface may

not be as smooth as expected or hoped for, it is not

caused by the performance of the saw blade or the

Model C 10FCD.

In the cutting examples illustrated in Fig. 18, the cut

surfaces on the sides marked A are better than

A

Better

[Left bevel cutting]

B

[Miter cutting]

B

A

Better

B

[Right bevel cutting]

A

Better

Fig. 18

A

Better

B

those on the sides marked B .

--- 14 ---

8-4. Precautions Concerning Electronic Control

(1) Polyethylene V-belt overload protection

The rotation of the motor is transferred to the saw blade by a polyethylene V-belt. When an extremely heavy

or abnormal load is applied to the polyethylene V-belt, the overload protection circuit functions to stop the

motor, protecting the V-belt from wear or damage due to slipping.

In such a case, instruct the customer to immediately turn the switch OFF, lift up the handle, and return the saw

blade section (head) to its original position. Then, turn the switch ON, and allow the machine to idle about 20

seconds so that the motor can be cooled by the motor fan. When the sow blade rotation speed returns to

normal, cutting can be resumed.

In addition, the customer should be advised to give particular attention to the following points:

1 Avoid cutting operations that cause the overload protection circuit to function repeatedly.

[Reason] There is a danger that the polyethylene V-belt and/or motor may be damaged.

2 Do not restart cutting until the saw blade rotation speed has returned to normal.

[Reason] If cutting is restarted before the rotation speed returns to normal, the overload protection circuit

will function again, even with a light load.

Even if the switch is not turned OFF after the saw blade section (head) has been raised to its original position,

the rotation speed will return to normal. However, it takes longer (4 to 10 seconds) than if the switch is turned

OFF and then turned ON again so that the soft-start circuit functions.

Accordingly, turning the switch OFF and then ON again allows the operator to restart the cutting operation

more quickly and more safely.

(2) Operating the Model C 10FCD near an electric welding machine may cause fluctuations in the rotation speed.

The control circuit in the Model C 10FCD contains a magnetic sensor (a flux change detecting element) and a

triac (which may malfunction because of excessive electrical noise). Accordingly, customers should be

advised not to operate the Model C 10FCD in the immediate vicinity of other machines that generate

extremely strong magnetic fields or excessive electrical noise.

(3) Operate the machine with correct voltage supply

Large voltage drops caused by an unstable power supply may cause the overload protection circuit to

function, or lower the output of the motor and affect efficient cutting. Advise the customer to check the power

supply before operating the machine.

In addition, the customer should be advised to pay particular attention to the following points:

1 If an extension cord is used, it should be kept as short as possible and within the requirements listed in the

Instruction Manual.

[Reason] An excessively long extension cord causes voltage drop.

2 Direct current (DC) cannot be used.

[Reason] The built-in controllers will only function with alternating current (AC).

--- 15 ---

9. ADJUSTMENT OF COMPONENTS

9-1. Bevel Angle Adjustment

When shipped from the factory, the heights of 6 mm

bolt (A), 6 mm bolt (B) and 5 mm hex. socket. hd. bolt

(C) are adjusted so that the saw blade section (head)

will stop at 0 (right-angle), 45 to the left and 45 to the

right. To change the head stop positions, instruct the

customer to adjust the height of 6 mm bolt (A), 6 mm

bolt (B) and 5 mm hex. socket. hd. bolt (C) as

described below. For example, to change the 45 to the

right stopper, pull up the locating bar in the direction

indicated by the arrow in Fig. 21 and tilt the head to the

right.

When setting the head to the 0 position, be sure to

replace the locating bar (press down it in the opposite

direction from that indicated by the arrow in Fig. 20.

As illustrated in Fig. 19, adjustment of the 0 (right

angle) can be accomplished by loosening the 5 mm nut

(lock nut) and turning the 5 mm hex. socket hed. bolt

(C) to raise or lower it by an appropriate dimension to

change the position at which it comes in contact with

locating bar.

On completion of adjustment, ensure that the 5 mm nut

(lock nut) is securely tightened.

Clamp handle

Locating bar

Bevel angle

scale

Indicator

6 mm Nut

(Lock nut)

5 mm Hex. socket

hd. bolt (C)

(Stopper for 0 )

Fig. 19

Clamp handle

Locating bar

6 mm Bolt (A)

(Stopper for right 45

bevel angle)

Fig. 20

As illustrated in Figs. 20 and 21, adjustment of the

bevel angle can be accomplished by loosening the 6

mm nut (lock nut) and turning the 6 mm bolt (A) and 6

mm bolt (B) to raise or lower it by an appropriate

dimension to change the position at which it comes in

contact with angle regulator.

On completion of adjustment, ensure that the 6 mm nut

(lock nut) is securely tightened.

Adjustment of the squareness of the saw blade with

relation to the table can also be accomplished by

adjusting the stopper bolts as described above.

Clamp handle

Locating

5 mm Hex. socket

hd. bolt (C)

(Stopper for 0 )

Pull

up

bar

6 mm bolt (B)

(Stopper for left 45

bevel angle)

6 mm Nut

(Lock nut)

Fig. 21

--- 16 ---

10. PACKING

The main body of the Model C 10FCD is sandwiched between packing (A) and packing (B) made of styrofoam.

This system makes the packaging work easier.

(1) Preparation

Remove the vise ass'y, extension stay and dust bag from the main unit.

Then swivel the table through 45 toward the right.

Fix the angle regulator securely with the clamp lever.

Position the clamp lever vertically to keep the clamp lever from contact with packing (A) when putting the main

unit on packing (A).

Push down the head section and insert the plunger handle to secure the head section at the lower position.

(2) How to install packing (A)

Put packing (A) in the carton box.

Put the main unit in packing (A).

(3) How to install packing (B)

Put packing (B) on the main unit. Put the vise ass'y, the extension stay and the dust bag in the groove of

packing (B).

Close the lids of the carton box and bind them together.

--- 17 ---

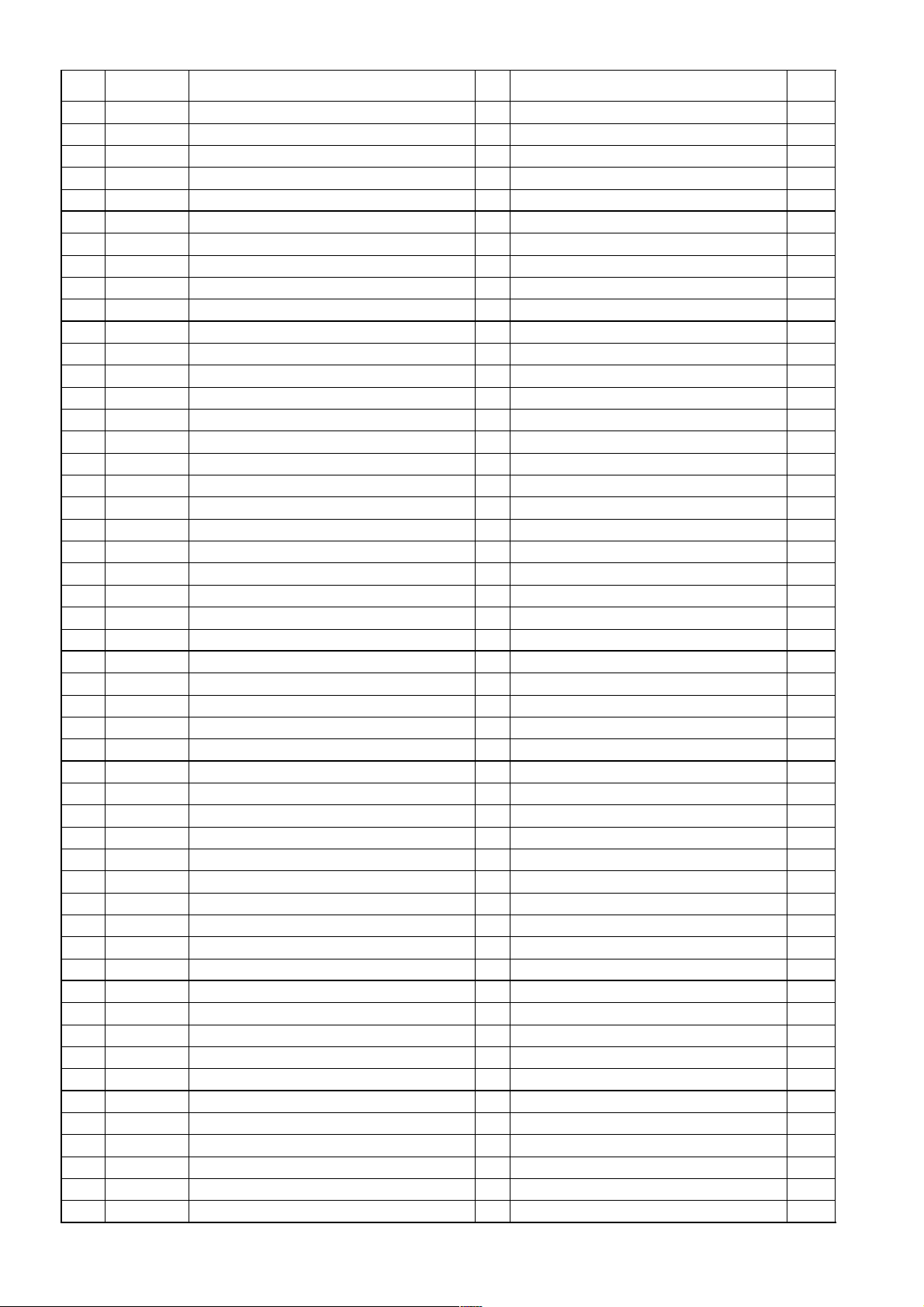

11. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY

11-1. Disassembly

Special attention in disassembly should be given to the following items.

The circled numbers in the following figures and the [Bold] numbers in the descriptions below correspond to the

item numbers in the Parts List and the exploded assembly diagrams.

* Be sure to first disconnect the power plug when performing disassembly and replacement of the saw blade.

Item

No.

1

Disassembly

points

Switch

Controller (R)

Cutter shaft

703

15

16

17

131

59

58

57

Disassembly procedure Necessary tools

24

60

61

62

130

19

20

25

21

22

26

65

23

27

28

66

34

141

29

33

32

38

37

36

35

45

67

68

69

44

46

30

31

132

47

39

48

49

133

40

41

42

43

64

63

18

93

3

2

1

5

4

8

10

7

6

9

11

12

13

14

94

160

95

159

701

96

Fig. 22

--- 18 ---

Item

No.

Disassembly

points

Disassembly procedure Necessary tools

1 Switch

Controller (R)

Cutter shaft

(Continued)

1. Loosen the Counter Hd. Screw M5 x 12 [60] and turn the Cutter

Shaft Guard [61] upward so that the Bolt (Left Hand) M8 x 25 [93]

can be seen.

2. Put the Wrench [702] on the Bolt (Left Hand) M8 x 25 [93] and

turn the Wrench [702] until the Bracket Stop [67] is aligned with

the groove of the Cutter Shaft [46] while pushing the Bracket Stop

[67]. Then, loosen the Bolt (Left Hand) M8 x 25 [93] and remove

the Bolt (Left Hand) M8 x 25 [93], Blade Washer M30 [94], outside

Arbor Collar [95], TCT Saw Blade [701], inside Arbor Collar [95]

and Collar D25.4 [96].

3. Put the Cutter Shaft Guard [61] back into position and tighten the

Counter Hd. Screw M5 x 12 [60].

4. Remove the three Hex. Socket Hd. Bolts M8 x 35 [6] with a 6 mm

hex. bar wrench and the three Tapping Screws D4 X 25 [9] with a

Phillips screwdriver. Remove the Handle Cover [3].

5. Remove the Spring [10] and the Switch Lock [11].

6. Remove the two Truss Hd. Tapping Screws D4 x 12 [12] and the

Switch [13].

Phillips

screwdriver

Wrench

(Accessory)

6 mm Hex. bar

wrench

Phillips

screwdriver

7. Disconnect the four internal wires from the Switch [13].

8. Remove the two Tapping Screws D4 X 12 [5] and the Cord Clamp

[4].

9. Remove the Machine Screw M8 x 20 [14] to remove the Handle

[7]. Remove the Wire Protector [25].

10. Remove the three Machine Screws M5 x 16 [31] to remove the

Rear Cover [30].

11. Remove the V-Belt [24].

12. Remove the three Tapping Screws (W/Washers) D4 x 16 [29] to

remove the Connector Box Cover [28].

13. Remove the three Tapping Screws D4 x 16 [33] to remove the

Controller (R) [32] and the Insulating Sleeve [141].

14. Disconnect the three internal wires from the Controller (R) [32].

15. Remove the Connector Box [26].

16. While holding a 13 mm wrench on the dihedral width portion of the

Pulley (A) [21], remove the Bolt M6 x 16 [23]. Remove the Flat

Washer 1/4" x 3/4" [22], Pulley (A) [21], Magnet [20] and Flat

Washer M13 [19].

13 mm Wrench

17. Push in the Bracket Stop [67] to lock the Cutter Shaft [46].

Remove the Chuck Nut M8 [41] with a 13 mm wrench to remove

the Flat Washer [40] and Pulley (B) [39].

18. Remove the three Machine Screws M5 x 16 [42] to remove the

Gear Box [43].

--- 19 ---

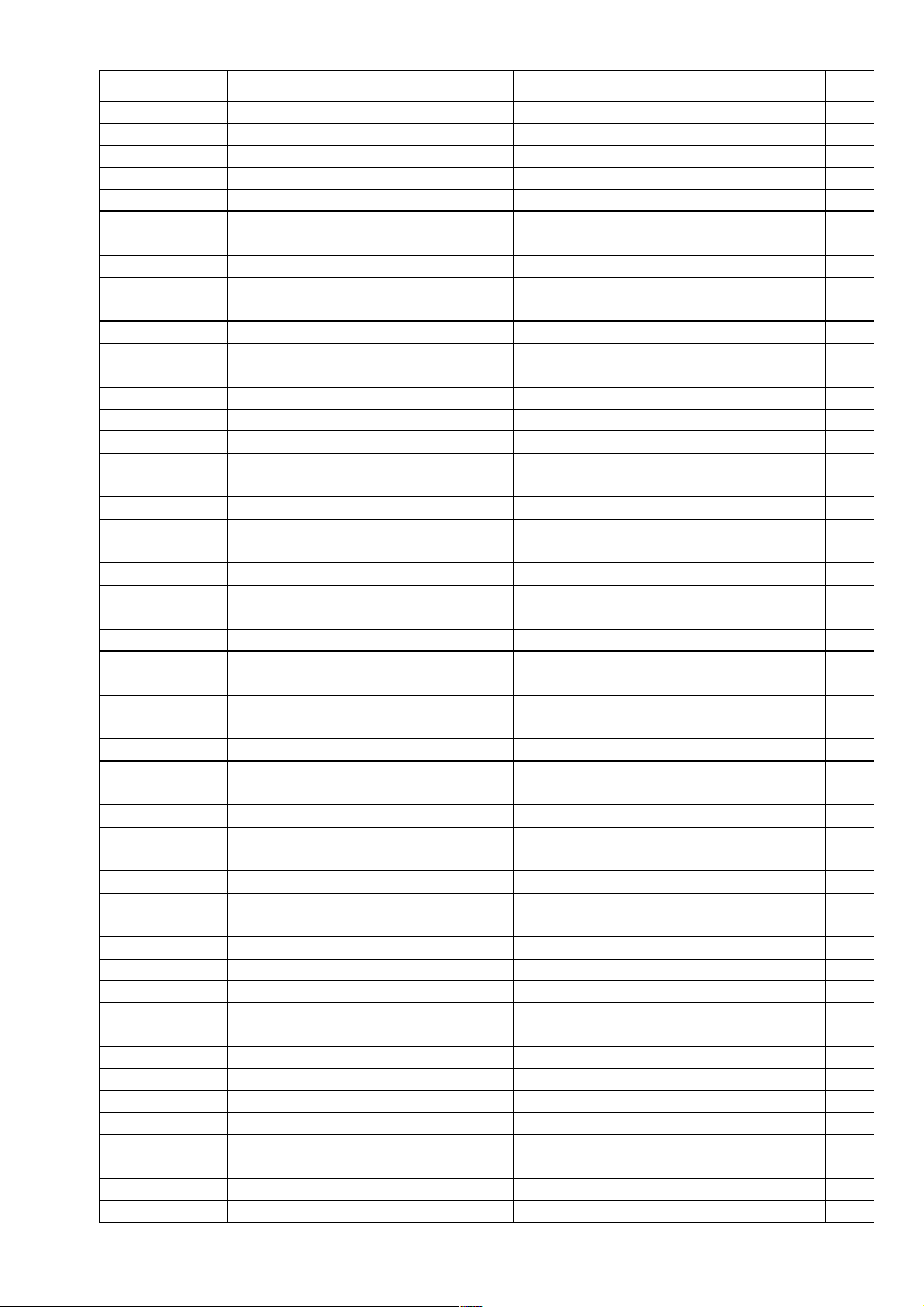

Item

No.

Disassembly

points

Disassembly procedure Necessary tools

1 Switch

Controller (R)

Cutter shaft

(Continued)

Housing ass'y

2

Armature ass'y

Stator

19. Remove the Ball Bearing 6001VVCMPS2L [38] from the Gear

Shaft [36] with a pulley puller. Remove the Ball Bearing

608VVCM2EPS2L [49] from the Cutter Shaft [46] with the pulley

puller.

20. Remove the C-Ring [48] and pull out the Helix Gear [47] from the

Cutter Shaft [46].

21. Remove the two Round Washer Hd. Screws M5 x 8 [34].

By tapping the end surface of the Cutter Shaft [46] (TCT Saw

Blade [701] mounting side) with a plastic hammer, remove the

Cutter Shaft [46]. Remove the Gear Shaft [36].

158

154

156

155

153

157

Pulley puller

Plastic hammer

142

144

143

151

145

152

150

146

147

148

149

Fig. 23

1. Remove the two Brush Caps [149] to remove two Carbon Brushes

[148].

2. Remove the two Machine Screws (W/Washers) M5 x 25 [143] and

the two Machine Screws (W/Washers) M5 x 50 [146]. Remove the

Housing Ass'y [144] with the Armature Ass'y [154] and the Stator

Flatblade

screwdriver

Phillips

screwdriver

[151] mounted.

(1) Disassembly of the armature ass'y

1 By tapping the Arm [158] mounting surface of the Housing Ass'y

[144] with a plastic hammer, remove the Armature Ass'y [154].

2 Remove the Flow Guide [153].

--- 20 ---

Plastic hammer

Item

Disassembly

No.

2

points

Housing ass'y

Armature ass'y

Stator

(Continued)

3 PC-guard arm

Disassembly procedure Necessary tools

(2) Disassembly of the stator

1 Disconnect the Internal Wire [150] from the Brush Holder [147]

and disconnect the internal wires from the Stator [151].

2 Remove the two Machine Screws M5 x 60 [152] that fix the

Stator [151].

3 By tapping the Arm [158] mounting surface of the Housing Ass'y

[144] with a plastic hammer, pull out the Stator [151].

50

51

52

53

54

55

17

131

58

59

56

79

57

60

80

81

82

61

158

62

65

64

63

83

78

77

Fig. 24

1. Remove the Truss Hd. Step Screw M6 x 12 [50] and the Truss Hd.

Round Neck Screw M6 x 10 [51] that fix the Lever [52]. Remove

the Lever [52].

2. Secure the Special Nut Chuck M6 [62] behind the Cutter Shaft

Guard [61] with a 10 mm wrench. Remove the Counter Hd. Screw

M6 x 16 [54], Collar [55], PC-Guard [56] and Spring Guard [57].

3. While inserting the tip of a flatblade screwdriver into the groove at

the rear of the Bracket Stop [81], loosen the Plunger Handle [83]

and remove it together with the Compression Spring [82].

--- 21 ---

Phillips

screwdriver

10 mm Wrench

Flatblade

screwdriver

Item

No.

Disassembly

points

Disassembly procedure Necessary tools

3

PC-guard arm

(Continued)

Fence

4

Angle regulator

Table

70

4. Remove the Set Bolt [80].

(Note) The Set Bolt [80] serves as an upper limit stopper for the Arm

[158], so be prepared for the Arm [158] to rise up when the

Set Bolt [80] is removed.

5. Remove the two Hex. Socket Set Screws M6 x 10 [17] behind the

Arm [158] with a 3 mm hex. bar wrench.

6. Pull out the Pivot Shaft [77] by gently tapping it while holding the

Arm [158].

Removing the Pivot Shaft [77] enables you to remove the Torsion

3 mm Hex. bar

wrench

D 10 metal bar

Plastic hammer

Spring [64] and the Shaft Sleeves [63].

83

71

72

73

74

75

76

78

77

85

84

86

79

87

89

88

97

98

82

81

80

90

99

100

101

91

92

102

103

109

110

107

117

702

120

118

121

122

119

104

123

Fig. 25

105

124

128

129

125

106

126

127

114

111

112

113

108

115

116

--- 22 ---

Item

No.

Disassembly

points

Disassembly procedure Necessary tools

Fence

4

Angle Regulator

Table

(Continued)

1. Remove the three Hex. Socket Hd. Bolts M8 x 45 [117] with a

6 mm hex. bar wrench. Remove the Fence [118].

2. Turn the Clamp Lever [72] counterclockwise and remove it.

3. Remove the Nut Chuck M10 [75] with a 17 mm box wrench to

remove the Angle Regulator [79].

4. Remove the Hex. Socket Set Screw M6 x 10 [106] with a 3 mm

hex. bar wrench to remove the Pivot Shaft [99].

5. Turn the Miter Handle [116] counterclockwise and remove it.

6. Remove the two Hex. Bolts (W/Washers) M6 x 20 [114] with a

10 mm wrench to remove the Spring Plate [115].

7. Remove the Hex. Bolt (W/Washer) M6 x 20 [113] with a 10 mm

wrench. Remove the Flat Washer 1/4" x 5/8" [112] and the

Washer [111].

8. Remove the four Machine Screws M4 x 10 [109] and the Table

Insert [110].

9. With a 13 mm Box wrench, remove the Chuck Nut M8 [102] and

the Flat Washer M8 [103] from the insert space of the Table [108].

Extract the Center Shaft [129] which fixes the Table [108] to the

Base [120] by lifting the Table [108] upward.

6 mm Hex. bar

wrench

17 mm Box

wrench

3 mm Hex. bar

wrench

10 mm wrench

Phillips

screwdriver

13 mm Box

wrench

5 Bracket stop

6 Vise ass'y

158

66

Fig. 26

67

68

69

1. Remove the E-Ring [68] from the Bracket Stop [67].

2. Remove the Bracket Stop [67] and the Spring [66] from the Arm

[158].

137

Pliers

138

135

136

139

140

Fig. 27

1. Remove the Hex. Socket Set Screw M6 x 10 [135] and the

Support [136].

--- 23 ---

3 mm Hex. bar

wrench

11-2. Reassembly

Reassembly can be accomplished by following the disassembly procedures in reverse. However, special

attention should be given to following items.

(1) Prior to reassembly, measure the insulation resistance of the armature, stator, switch and other electrical

coponents and confirm that the insulation resistance of each part is more than 7 M .

(2) When reassembling the Angle Regulator [79] and the Arm [158], apply 2 grams of Hitachi Motor Grease to the

oil groove of the Arm [158].

(3) When replacing the Torsion Spring [64], apply approximately 2 grams of Hitachi Motor Grease to the inner

circumference of the new Torsion Spring [64] prior to reassembly.

(4) When replacing the Rotation Slide Plate [128], reassemble it into the unit as illustrated in Fig. 28. During

reassembly, apply 6 grams of Hitachi Motor Grease to the Rotation Slide Plate [128] against the sliding

surface of the Base [120].

102

103

108

120

128

129

Ensure that the Rotation Slide Plate [128] fits

into the groove portion of the Base [120].

Fig. 28

(5) If the Center Shaft [129] at the bottom of the Base [120] is tightened excessively, the movement of the Table

[108] will become sluggish and heavy. If the bolt is loose, it will cause vibration and looseness of the Table

[108] which will reduce cutting accuracy. Adjust the Chuck Nut M8 [102] so that the Table [108] moves

smoothly with minimum play and vibration.

--- 24 ---

11-3. Wiring Diagram

Carefully ensure that wiring is accomplished as illustrated below. As incorrect wiring will result in lack of rotation,

reverse rotation or other malfunctions, close attention is absolutely necessary.

1 Wiring diagram

Armature

ass'y

Brake coil

Stator coil

Stator ass'y

Black

Gray

Blue

1

Black

(Lead wire)

CB

Controller (R)

Fig. 29

A

Switch

1a

1b

White

Black

Power cord

2 Actual wiring diagram

1

Pick up

Gray

Stator

ass'y

Switch

1a1b

1

Black (Lead wire)

Black

Black

Power

cord

Blue

White

B

C

A

Fig. 30

11-4. Lead Wire Precautions

When connecting lead wires, be very careful not to remove the insulation covering of each lead wire more than

needed. Exposed cores of lead wires from connectors, for example, are extremely dangerous. Also, ensure that

the lead wires are not pinched between the mating surfaces of the Handle [7] and the Handle Cover [3].

--- 25 ---

Controller (R)

11-5. No-load Current

After no-load operation for 30 minutes, the no-load current values should be as follows.

Voltage, Frequency

No-load current

11-6. Reassembly Requiring Adjustment

(1) Adjustment of squareness between the saw blade (dummy disc) and the fence

Fence

Square

Saw blade or

dummy disc

Fig. 31

is flush against the side surface of the saw blade (or dummy disc), and move the Fence [118] as necessary so

that it is in an exact right angle with relation to the saw blade (or dummy disc). Finally, tighten the three Hex.

Socket Hd. Bolts M8 x 45 [117] to fix the Fence [118] in position.

115 V, 60 Hz

5.5 A Max.

After disassembly/reassembly or replacement of the Base [120],

Table [108], Fence [118] or Angle Regulator [79], it is necessary to

check the squareness between the saw blade (or dummy disc) and

the Fence [118], and perform adjustment as necessary if they are

not at an exact right angle with relation to each other. Adjustment

procedure is as follows.

First, position the saw blade (or dummy disc) so that it is in the exact

center of the groove on the Table [108] which houses the Table

Insert [110]. Next, as illustrated in Fig. 31, place a square so that it

*Dummy disc: A dummy disc is a toothless disc with the same external diameter as a saw blade, and is used to

perform accurate inspection and adjustments.

(2) Confirmation of saw blade height

The lower limit of the saw blade cutting depth is factory-adjusted so that when the saw blade is fully lowered,

its cutting edge is 26 mm to 28 mm (1-1/32" to 1-3/32") below the upper surface of the Table Insert [110].

Lower the saw blade and confirm that it stops at the correct position.

(3) Adjustment of saw blade lower limit position

When adjusting the lower limit of the saw blade, be sure to use a saw blade with an external diameter of 255

mm. Failure to properly adjust the lower limit position of the saw blade may result in the following problems.

1 Inability to obtain the maximum cutting capacities of the machine

2 There is a danger that the saw blade may come in contact with and cut into the Table [108].

The lower limit of the saw blade cutting depth is adjusted at the factory so that when the saw blade is fully

lowered, its cutting edge is 26 mm to 28 mm (1-1/32" to 1-3/32") below the upper surface of the Table Insert

[110]. If this potion is lower than the specified values, confirm without fail that it does not come in contact with

the Table [108].

If it is necessary to adjust the saw blade lower limit, loosen the Nut M6 [15] on the Hex. Socket Set Screw M6

x 20 [16], and turn the Hex. Socket Set Screw M6 x 20 [16] if necessary.

By turning the Hex. Socket Set Screw M6 x 20 [16] clockwise, the saw blade lower limit is raised.

By turning the Hex. Socket Set Screw M6 x 20 [16] counterclockwise, the saw blade lower limit is lowered.

On completion of adjustment, ensure that the Nut M6 [15] is properly tightened.

[CAUTION] Perform the adjustment carefully to ensure that the saw blade does not cut into the Table

[108].

--- 26 ---

(4) Reassembly of the Table

When reassembling the Table [108] and the Base [120], tighten the Chuck Nut M8 [102] so that the Table

[108] turns smoothly without excessive play or vibration.

During reassembly, liberally apply grease [Hitachi Motor Grease No. 29 (Code No. 930035) is recommended.]

at the points marked A in Fig. 32.

Table [108]

A

A

Base [120]

Center Shaft [129]

Fig. 32

11-7. Lubrication

Advise the customer to lubricate the machine as indicated below at least once a month. Also, prior to applying

lubrication, any sawdust, dirt or other foreign matter should be thoroughly wiped away with a soft cloth.

(1) Swiveling section of the Arm [158] and the Angle Regulator [79]

Coat the swiveling portion of the Arm [158] and the Angle Regulator [79] with machine oil.

(2) Vise ass'y section

Coat the screw threads portion of the Screw Bar [137] of the Vise Ass'y [134] with machine oil.

11-8. Product Precision

On completion of reassembly, confirm precision tolerances.

Unit : mm

Item

Run-out of saw blade (or dummy disc)

Perpendicularity between base and fence

Perpendicularity between saw blade (or dummy disc) and fence

Perpendicularity between saw blade (or dummy disc) and table

Surface alignment of

base and table (Use

the upper surface of

the base as a

reference).

0.38/220 (0.015" / 8-21/32")

0.26/60 (0.01" / 2-3/8")

0.45/100 (0.018" / 4")

0.3/70 (0.012" / 2-3/4")

Tolerance

0.45 ( 0.018")

0

--- 27 ---

12. REPAIR GUIDE

The bracketed numbers correspond to the item numbers in the Parts List.

Item

Phenomenon Cause (s)

Factory

standard

Unit : mm

Inspection • Repair

Adjustment

•

1 Inaccurate cutting

...Inaccurate spuareness of

the cut surface

...Cut surfaces do not fit

together properly.

Fence

Table

Fig. 33

Squareness

0.45/100

Saw blade

Squareness

0.3/70

Fence

a Inaccurate

squareness between

the table and the saw

blade causes the saw

blade to cut into the

workpiece at an

angle.

b Excessive deflection

of the saw blade

(Excessive vibration)

c Inaccurate

squareness between

the fence and the

saw blade

0.3/70

(Dummy disc)

(Fig. 33)

0.38/220

(Dummy disc)

0.45/100

(Fig. 34)

Adjust squareness with the

Hex. Socket Set Screw M6

x 25 [105].

Replace the Arm [158], the

Angle Regulator [79].

(If deformed.)

Replace the Saw Blade

[701].

Check for surface defects

on the Arbor Collar [95] and

the Collar [96], and repair

with a file as necessary.

Replace the Arbor Collar

[95] and the Collar [96] as

necessary.

Loosen the Hex. Socket Hd.

Bolt M8 x 45 [117] and

adjust as necessary.

Replace the Fence [118] as

necessary.

Fig. 34

Fig. 35

Squareness

0.26/60

Fig. 36

Saw blade

0.2 or less

Fence

0.2 or less

Fence

d Inaccurate surface

flatness of the fence

causes workpiece to

move irregularly,

causing poor

squareness of cut

surface.

e Inaccurate surface

flatness of the table

f Inaccurate

squareness between

the fence and the

table and/or the base

causes the

workpiece to tilt at an

angle and prevent

accurate cutting.

0.2 or less

(Fig. 35)

0.2/500

0.26/60

(Fig. 36)

Replace the Fence [118] as

necessary.

Replace the Table [108].

Replace the Fence [118] as

necessary.

--- 28 ---

Item

Phenomenon Cause (s)

Factory

standard

Inspection • Repair

Adjustment

•

(Continued)

1

Base

Fig. 37

Table

g Excessive

misalignment of the

base and the table

causes the saw blade

to cut into the

workpiece at an

angle.

h Loose fitting of

swiveling portion of

the arm and the

angle regulator or

sluggish movement.

As a result,

components may be

deformed because of

unstable arm or

because the operator

must apply excessive

pressure during

operation.

i Excessively fast

cutting speed causes

deflection of the saw

blade and inaccurate

cutting.

0.45

0

(Fig. 37)

---

---

Replace the Base [120]

and/or Table [108] if

deformed.

Check the fitting surfaces of

the Arm [158], Angle

Regulator [79] and Pivot

Shaft [77] for any foreign

substance (such as cutting

dust), and remove it as

necessary.

Reduce cutting speed.

Appropriately 10 seconds

for a square wood

workpiece of 60 mm

(2-3/8").

2 Rough cut surface

Parallelism A = 0.025/54

Parallelism B = 0.02/25.4

A

Arbor collar

A

Arbor collar

Fig. 38

B

Collar

j

Excessive cutting

force (pressure) is

requires because of

dull saw blade.

k The workpiece

moves during cutting

because it is bent or

deformed.

a Large deflection of

the saw blade (It

causes rough cut

surface)

b Each surface

parallism of the arbor

collar and the collar

is inaccurate due to

surface defects

(such as impact

marks and

scratches).

c Inaccurate

squareness between

the table and the

saw blade causes

the saw blade to cut

at an improper angle

and make cutting

marks.

---

---

0.38/220

(Dummy disc)

A : 0.025/54

B : 0.02/25.4

(Fig. 38)

0.3/70

(Fig. 33)

Sharpen the Saw Blade

[701] again.

Correct bend, flex or other

deformation by planing and

try cutting.

Same as the Item 1- b .

Repair impact marks or

scratches at the Arbor

Collar [95] and the Collar

[96] or replace them if

necessary.

Same as the Item 1- a .

--- 29 ---

Item

Phenomenon Cause (s)

Factory

standard

Inspection • Repair

Adjustment

•

2 (Continued)

d Excessively fast

cutting speed

e Improper clamping of

workpiece

f The table is not fixed

with the handle bar.

g

Loose fitting of

swiveling portion of

the arm and the

angle regulator, or

sluggish movement

h Cutting operation

becomes sluggish

because workpiece

is warped or bent.

i Excessive vibration

---

---

Reduce cutting speed.

Properly clamp workpiece

with the Vise Ass'y [134].

---

During cutting, fix the Table

[108] in position with the

Miter Handle [116] without

fail.

---

---

Same as the item 1- h .

Correct warp or bend with

planer.

---

Recheck the items a , b ,

c , d , f and g .

3 Saw blade is locked.

a Excessively fast

cutting speed

b Core diameter of

extension cord is too

small.

c Excessive cutting

force is applied due

to dull saw blade.

d Incorrect saw blade

is used.

---

---

Reduse cutting speed.

Use a thicker and shorter

extension cord.

Extension

cord length

7.5 m

15 m

30 m

---

Resharpen the Saw Blade

Wire gauge

size

2

2.0 mm

2

3.5 mm

Not

recommended

[701].

---

Use a suitable Hitachisupplied saw blade.

An increased number of

teeth on the saw blade

increases the cutting

resistance. When using a

saw blade with a large

number of teeth, reduce the

cutting speed.

e The saw blade binds

in workpiece during

cutting because

workpiece is warped

or bent.

--- 30 ---

---

Correct workpiece

deformation with planer.

Item

Phenomenon Cause (s)

Factory

standard

Inspection • Repair

Adjustment

•

4 Saw blade does not rotate

when switch is triggered.

5 Saw blade runs too slow.

(Not within 3,400 --- 3,800 /min)

a The power cord is

not connected to

power supply.

b The carbon brush

wear exceeds

allowable limit

(6 mm).

c Contact failure of the

switch

d Controller failure

a Power supply

voltage is lower than

rated voltage.

---

Check power supply

voltage.

Connect the power cord to

power supply.

---

Check the Carbon Brushes

[148] for wear.

Replace the Carbon

Brushes [148].

---

Check the Switch [13] for

conductivity.

Replace the Switch [13].

---

Replace the Controller (R)

[32].

---

Check for power supply

voltage.

Check if extension cord is

appropriate. See the

Instruction Manual for

appropriate extension

cords.

6 Saw blade runs too fast.

(Exceeds 4,200/min)

7 Overload protection circuit

continuously functions.

b Controller failure

a Defective magnet

b Controller failure

a Power supply

voltage is lower than

rated voltage.

b Defective controller

failure

---

Replace the Controller (R)

[32].

---

---

Replace the Magnet [20].

Replace the Controller (R)

[32].

---

---

Same as the Item 5 - a .

Replace the Controller (R)

[32].

--- 31 ---

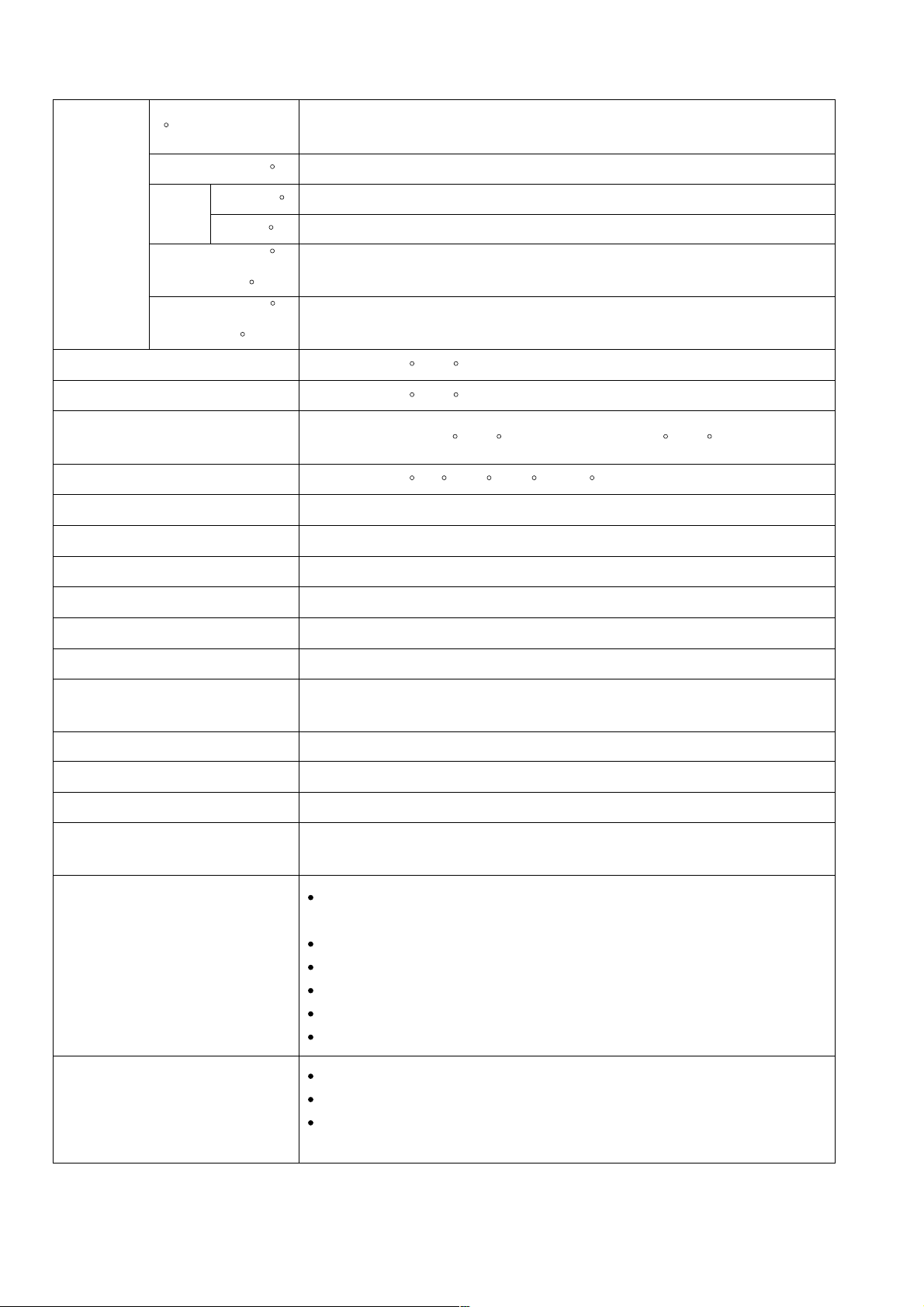

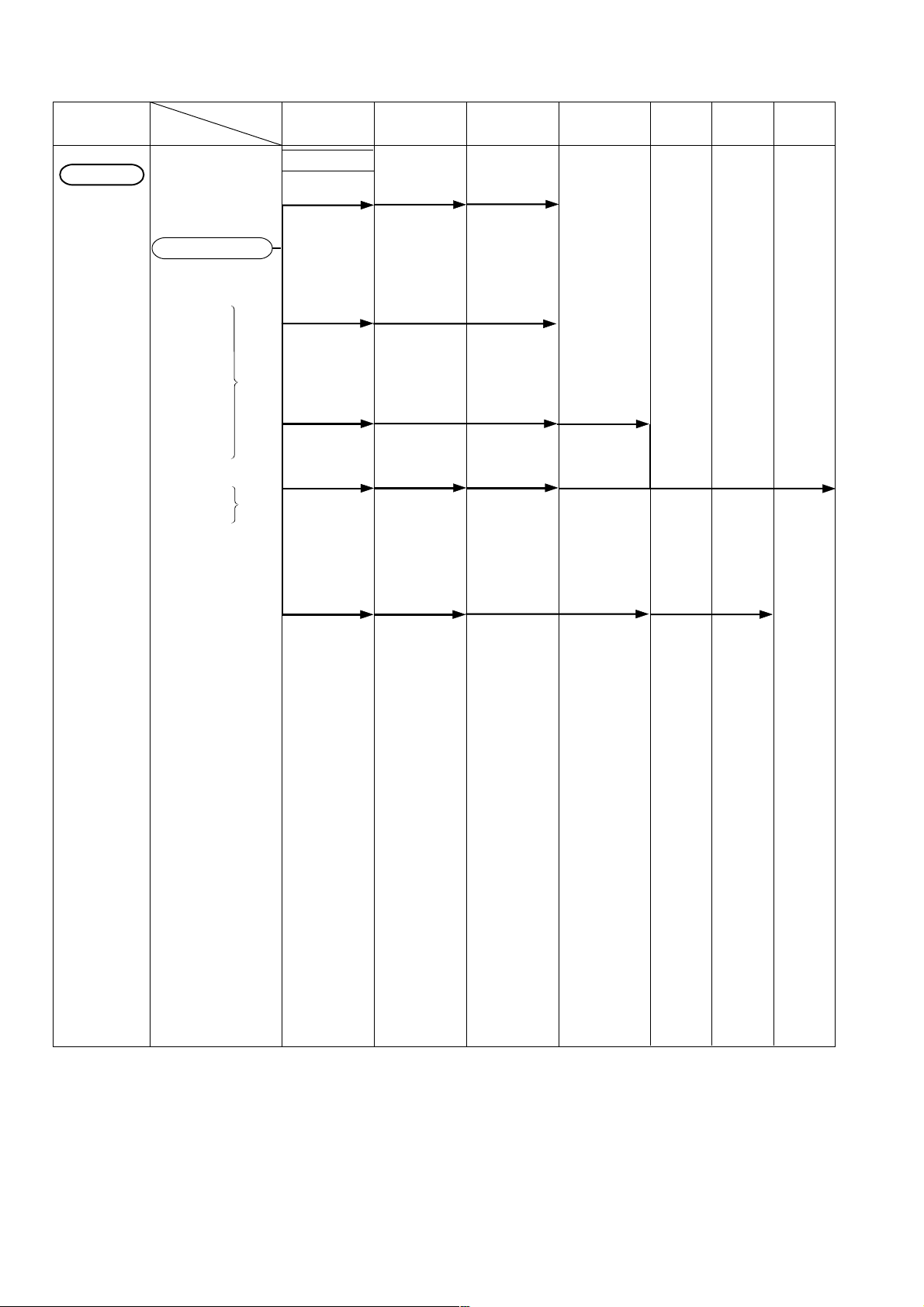

13. STANDARD REPAIR TIME (UNIT) SCHEDULES

MODEL 10 20 30 40 60 70 min.

Fixed

Variable

50

Work Flow

C 10FCD

General Assembly

Fixed Cost

Rear Cover

Handle Cover

Lever

PC-Guard

Handle

Chip Deflector

Connector Box

Cover

Connector Box

Switch

Power Cable

Other 20min.

0 min.

10 min.

Rear Cover

V-Belt

Connector Box

Cover

Pulley (B)

Handle Cover

Switch

Switch Lock

Spring

Carbon Brush

Lever

PC-Guard

Connector Box

Controller (R)

Power Cable

Spring

Bracket Stop

Bracket Stop

Compression

Spring

Gear Box

Gear Shaft

Ball Bearing

607

Ball Bearing

6001

Handle

Pulley (A)

Armature Ass'y

Cutter Shaft

Ball Bearing

6003

Helix Gear

Ball Bearing

608

Stator

Housing Ass'y

Arm

Fence

Clamp Lever

Locating Bar

Chip Deflector

Spring Plate

Center Shaft

Pivot Shaft

Torsion Spring

Base

Table

Angle

Regulator

--- 32 ---

Assembly Diagram for C 10FCD

--- 33 ---

MOTOR ASS'Y

C 10FCD

HOLDER ASS'Y

--- 34 ---

VISE ASS'Y

C 10FCD

--- 35 ---

PARTS

ITEM

1

CODE NO. DESCRIPTION

No.

1 311-096 CORD GUARD 1

2 317-546 POWER CABLE 1

3 317-547 HANDLE COVER 1

4 311-070 CORD CLAMP 1

5 317-548 TAPPING SCREW D4X12 2

6 949-780 HEX. SOCKET HD. BOLT M8X35 (10 PCS.) 3

7 317-549 HANDLE 1

8 317-550 LOCKING CABLE TIE 2

9 317-551 TAPPING SCREW D4X25 3

10 311-106 SPRING 1

11 317-552 SWITCH LOCK 1

12 311-103 TRUSS HD. TAPPING SCREW D4X12 1

13 317-553 SWITCH 1

14 949-271 MACHINE SCREW M8X20 (10 PCS.) 1

15 949-556 NUT M6 (10 PCS.) 1

16 950-094 HEX. SOCKET SET SCREW M6X20 1

17 968-247 HEX. SOCKET SET SCREW M6X10 2

18 317-554 INTERNAL WIRE 1

19 317-555 FLAT WASHER M13 1

20 317-556 MAGNET 1

21 317-557 PULLEY (A) 1

22 317-558 FLAT WASHER 1/4"X3/4" 1

23 949-613 BOLT M6X16 (10 PCS.) 1

24 317-559 V-BELT 1

25 317-560 WIRE PROTECTOR 1

26 317-561 CONNECTOR BOX 1

27 317-562 PICK UP 1

28 317-563 CONNECTOR BOX COVER 1

29 995-062 TAPPING SCREW (W/WASHER) D4X16 3

30 317-564 REAR COVER 1

31 949-239 MACHINE SCREW M5X16 (10 PCS.) 3

32 317-565 CONTROLLER (R) 1

33 317-566 TAPPING SCREW D4X16 3

34 317-567 ROUND WASHER HD. SCREW M5X8 2

35 607-ZZM BALL BEARING 607ZZMC2PS2S 1

36 317-569 GEAR SHAFT 1

37 317-570 PARALLEL KEY 4X4X20 1

38 600-1VV BALL BEARING 6001VVCMPS2L 1

39 317-571 PULLEY (B) 1

40 317-572 FLAT WASHER 1

41 314-519 NUT CHUCK M8 1

42 949-239 MACHINE SCREW M5X16 (10 PCS.) 3

43 317-573 GEAR BOX 1

44 317-574 PARALLEL KEY 4X4X8 1

45 317-575 BALL BEARING 6003LLU 1

46 317-576 CUTTER SHAFT 1

47 317-577 HELIX GEAR 1

48 317-578 C-RING 1

49 608-VVM BALL BEARING 608VVMC2EPS2L 1

50 314-980 TRUSS HD. STEP SCREW M6X12 1

51 317-579 TRUSS HD. ROUND NECK SCREW M6X10 1

----

99

: ALTERNATIVE PARTS

*

--- 36 ---

NO.

USED

C 10FCD

REMARKS

PARTS

ITEM

* 65 317-590 MOTOR ASS'Y 115V (UL) 1 INCLUD.142-158

* 65 317-591 MOTOR ASS'Y 115V (CSA) 1 INCLUD.142-158

CODE NO. DESCRIPTION

No.

52 317-580 LEVER 1

53 317-505 FLAT WASHER M6 1

54 317-582 COUNTER HD. SCREW M6X16 1

55 317-583 COLLAR 1

56 317-584 PC-GUARD 1

57 314-987 SPRING GUARD 1

58 311-036 RIVET 3/16"X17/32" 1

59 317-585 BUMPER 1

60 317-586 COUNTER HD. SCREW M5X12 1

61 317-587 CUTTER SHAFT GUARD 1

62 314-522 SPECIAL NUT CHUCK M6 1

63 317-588 SHAFT SLEEVE

64 317-589 TORSION SPRING 1

66 317-600 SPRING 1

67 317-601 BRACKET STOP 1

68 317-602 E-RING 1

69 311-016 CAP RUBBER 1

70 317-362 SCREW 1

71 317-363 COMPRESSION SPRING 1

72 317-364 CLAMP LEVER 1

73 317-365 HANDLE COLLAR 1

74 317-603 WASHER 1

75 317-604 NUT CHUCK M10 1

76 317-603 WASHER 1

77 317-606 PIVOT SHAFT 1

78 317-607 LOCATING BAR 1

79 317-608 ANGLE REGULATOR 1

80 317-609 SET BOLT 1

81 317-610 BRACKET STOP 1

82 317-611 COMPRESSION SPRING 1

83 317-612 PLUNGER HANDLE 1

84 949-236 MACHINE SCREW M5X10 (10 PCS.) 2

85 317-613 NEEDLE POINTER (L-SIDE) 1

86 949-822 HEX. SOCKET HD. BOLT M5X35 (10 PCS.) 1

87 317-614 NEEDLE POINTER (R-SIDE) 1

88 949-454 SPRING WASHER M5 (10 PCS.) 1

89 317-615 NUT CHUCK M5 1

90 311-042 DRIVE SCREW D2.3X5 2

91 317-616 TILTING SCALE 1

92 317-617 PLATE COVER 1

93 317-618 BOLT (LEFT HAND) M8X25 1

94 317-619 BLADE WASHER M30 1

95 317-428 ARBOR COLLAR 2

96 317-620 COLLAR D25.4 1

97 949-239 MACHINE SCREW M5X16 (10 PCS.) 2

98 317-621 CHIP DEFLECTOR 1

99 317-622 PIVOT SHAFT 1

100 949-676 BOLT M6X20 (10 PCS.) 2

101 949-556 NUT M6 (10 PCS.) 2

: ALTERNATIVE PARTS

*

--- 37 ---

NO.

USED

REMARKS

C 10FCD

----

1

99

PARTS

ITEM

1

CODE NO. DESCRIPTION

No.

102 314-519 NUT CHUCK M8 1

103 311-047 FLAT WASHER M8 1

104 949-556 NUT M6 (10 PCS.) 1

105 317-623 HEX. SOCKET SET SCREW M6X25 1

106 968-247 HEX. SOCKET SET SCREW M6X10 1

107 311-108 HEX. BOLT M10X65 1

108 317-624 TABLE 1

109 949-216 MACHINE SCREW M4X10 (10 PCS.) 4

110 317-625 TABLE INSERT 1

111 317-626 WASHER

112 317-627 FLAT WASHER 1/4"X5/8" 1

113 317-628 HEX. BOLT (W/WASHER) M6X20 1

114 317-628 HEX. BOLT (W/WASHER) M6X20 2

115 317-630 SPRING PLATE 1

116 317-631 MITER HANDLE 1

117 317-632 HEX. SOCKET HD. BOLT M8X45 3

118 317-633 FENCE 1

119 317-634 EXTENSION STAY 1

120 317-635 BASE 1

121 317-636 TAPPING SCREW D5X10 1

122 317-353 FOLLOWER PLATE 1

123 949-236 MACHINE SCREW M5X10 (10 PCS.) 2

124 317-637 CLAMP BOLT M5X15 1

125 949-555 NUT M5 (10 PCS.) 4

126 949-236 MACHINE SCREW M5X10 (10 PCS.) 1

127 317-638 ANGLE POINTER 1

128 317-639 SLIDE PLATE 3

129 317-640 CENTER SHAFT 1

130 NAME PLATE 1

131 HITACHI LABEL 1

132 310-871 CAUTION LABEL (E) 1

133 310-870 WARNING LABEL (A) 1

134 317-642 VISE ASS'Y (FOR VERTICAL) 1 INCLUD.135-140

135 968-247 HEX. SOCKET SET SCREW M6X10 1

136 317-643 SUPPORT 1

137 317-644 SCREW BAR 1

138 317-645 VISE BEARING 1

139 317-646 FLANGE 1

140 317-647 BUSHING 1

141 317-641 INSULATING SLEEVE 2

142 967-377 HEX. SOCKET SET SCREW M5X8 2

143 880-734

144 317-592 HOUSING ASS'Y 1 INCLUD.145

145 314-577 BEARING BUSHING 1

146 997-841

147 314-586 BRUSH HOLDER 2

148 311-089 CARBON BRUSH 2

149 314-583 BRUSH CAP 2

150 317-593 INTERNAL WIRE 1

151 317-594 STATOR 115V 1

152 317-595 MACHINE SCREW M5X60 2

----

99

MACHINE SCREW (W/WASHERS) M5X25 (BLACK)

MACHINE SCREW (W/WASHERS) M5X50 (BLACK)

: ALTERNATIVE PARTS

*

NO.

USED

2

2

--- 38 ---

C 10FCD

REMARKS

PARTS

ITEM

CODE NO. DESCRIPTION

NO.

153 317-596 FLOW GUIDE 1

154 317-597 ARMATURE ASS'Y 115V 1 INCLUD.155-157

155 317-598 PLAIN WASHER 1

156 620-0VV BALL BEARING 6200VVCMPS2S 1

157 620-2VV BALL BEARING 6202VVCMPS2S 1

158 317-599 ARM 1

159 317-824 COVER PLATE 1

160 317-825 RIVET D3.2X8.1 2

NO.

USED

C 10FCD

REMARKS

: ALTERNATIVE PARTS

*

--- 39 ---

----

1

99

STANDARD ACCESSORIES

ITEM

CODE NO. DESCRIPTION

NO.

701 311-128 TCT SAW BLADE 255MM-D15.88 HOLE-NT24 1

702 311-013 WRENCH 1

703 311-034 DUST BAG 1

USED

NO.

C 10FCD

REMARKS

OPTIONAL ACCESSORIES

ITEM

901 976-472

902 977-671

903 976-473 TCT SAW BLADE 255MM-D15.9 HOLE 1

904 977-673

905 317-542 HOLDER ASS'Y 1 INCLUD.906-910

906 317-654 STOCK STOP 1

907 317-375 WING BOLT 1/4"X3/4" 1

908 317-655 LOCK SUPPORT ROD 2

909 317-656 EXTENSION WING 2

910 949-271 MACHINE SCREW M8X20 (10 PCS.) 2

911 317-541 VISE ASS'Y (FOR LATERAL) 1 INCLUD.912-921

912 317-648 SCREW BAR 1

913 317-649 VISE BEARING 1

914 949-515 ROLL PIN D6X30 (10 PCS.) 1

915 317-650 CLUTCH 1

916 317-629 SET PLATE 1

917 311-126 WASHER 3/16"X1/2" 1

918 317-503 MACHINE SCREW (W/WASHER) M5X10 1

919 317-652 SUPPORT 1

920 949-518 ROLL PIN D3X18 (10 PCS.) 1

921 317-653 KNOB 1

CODE NO. DESCRIPTION

NO.

TCT SAW BLADE CROSS-CUT 255MM-D15.9 HOLE

TCT SAW BLADE (A) 255MM-D15.88 HOLE-NT24

TCT SAW BLADE (B) 255MM-D15.88 HOLE-NT60

NO.

USED

1

1

1

REMARKS

Printed in Japan

(99120 N)

----

1

99

: ALTERNATIVE PARTS

*

--- 40 ---

Loading...

Loading...