Page 1

Drill

Taladro

手提電鑽

BU-PN3

Handling instructions

Instrucciones de manejo

使用說明書

Read through carefully and understand these instructions before use.

Leer cuidadosamente y comprender estas instrucciones antes del uso.

使用前務請詳加閱讀

Page 2

1

2

1

Wear limit

2

No. of carbon brush

3

Brush cap

1

43

6 mm

17 mm

English Español 中國語

2

Límite de uso

No. de carbón de contacto

Cápsula de carbón

3

磨損極限

碳刷號

碳刷蓋

1

Page 3

English

GENERAL SAFETY RULES

WARNING!

Read all instructions

Failure to follow all instructions listed below may result in

electric shock, fire and/or serious injury.

The term “power tool” in all of the warnings listed below

refers to your mains operated (corded) power tool or battery

operated (cordless) power tool.

SAVE THESE INSTRUCTIONS

1) Work area

a) Keep work area clean and well lit.

Cluttered and dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust.

Power tools create sparks which may ignite the

dust of fumes.

c) Keep children and bystanders away while operating

a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way.

Do not use any adapter plugs with earthed (grounded)

power tools.

Unmodified plugs and matching outlets will reduce

risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators.

There is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions.

Water entering a power tool will increase the risk

of electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk of

electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication.

A moment of inattention while operating power

tools may result in serious personal injury.

b) Use safety equipment. Always wear eye protection.

Safety equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personal

injuries.

c) Avoid accidental starting. Ensure the switch is in

the off position before plugging in.

Carrying power tools with your finger on the

switch or plugging in power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on.

A wrench or a key left attached to a rotating part

of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance

at all times.

This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts.

Loose clothes, jewellery or long hair can be caught

in moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used.

Use of these devices can reduce dust related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application.

The correct power tool will do the job better and

safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not

turn it on and off.

Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source before

making any adjustments, changing accessories, or

storing power tools.

Such preventive safety measures reduce the risk

of starting the power tool accidentally.

d) Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tools operation.

If damaged, have the power tool repaired before

use.

Many accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories and tool bits etc.,

in accordance with these instructions and in the

manner intended for the particular type of power

tool, taking into account the working conditions and

the work to be performed.

Use of the power tool for operations different from

intended could result in a hazardous situation.

5) Service

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the power tool

is maintained.

PRECAUTION

Keep children and infirm persons away.

When not in use, tools should be stored out of reach of

children and infirm persons.

2

Page 4

English

PRECAUTIONS ON USING DRILL

1. Do not make this drill work beyond the ability.

2. Operate the Electric Drill safely for correct use.

3. Hold the drill firmly and use it.

4. Do not wear the gloves while operating.

5. Never let the drill alone in the rotating conditions.

6. Avoid letting the revolution down largely by means

of pressing it by force.

7. Take care of downward direction in the high position.

8. Before drilling into a wall, floor or ceiling, thoroughly

confirm that no items such as electric cables or

conduits are buried inside.

SPECIFICATIONS

Voltage (by areas)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Power Input 620 W*

No load speed 750/min

Capacity Steel: 13 mm, Wood: 30 mm

Weight (without cord) 4.4 kg

*Be sure to check the nameplate on product as it is subject to change by areas.

STANDARD ACCESSORIES

(1) Chuck wrench ............................................................1

Standard accessories are subject to change without notice.

APPLICATIONS

䡬 Drilling holes on various metal, lumber and plastics.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

2. Grounding

This tool should be grounded while in use to protect

the operator from electric shock. The tool is equipped

with a three conductor cord and grounding type

plug to fit the proper grounding type receptacle. The

green (or green and yellow) conductor in the cord

is the grounding wire. Never connect the green (or

green and yellow) wire to a live terminal.

3. Power switch

Ensure that the power switch is in the OFF position.

If the plug is connected to a receptacle while the

power switch is in the ON position, the power tool

will start operating immediately, inviting serious

accident.

4. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

CAUTION

Damaged cord must be replaced or repaired.

5. Confirming condition of the environment

Confirm that the work site is placed under

appropriate conditions conforming to prescribed

precautions.

6. How to select drill bits

(1) When drilling holes in metals or plastics

Use ordinary metalworking drill bits,

applicable drill sizes range from min. 1.2 mm

to max. 13 mm.

3

(2) When drilling holes in lumber

Use woodworking drill bits of 30 mm diam.

or below. For small holes of 6.5 mm diam.

or below, use metalworking drill bits.

7. Mounting drill bits

Tighten drill bits with the chuck wrench. There are

three holes in which the chuck wrench should be

inserted. Tighten them equally in turn at three holes,

without tightening them only at one holes.

8. Confirm the power receptacle

If the power receptacle only loosely accepts the

plug, the receptacle must be repaired. Contact the

nearest electric store for repair service. If such a

faulty receptacle is used, it may cause overheating,

resulting in a serious hazard.

HOW TO USE THE DRILL

1. Pressing force of drill

You cannot get holes quickly even if pressing it by

strong force more than necessary.

It not only damages the tip of drill bits and decreases

the efficiency of operation, but also shortens the

life of the drill.

2. In case of penetrating holes

It is subject to break the drill bits when penetrating.

It is important to decrease pressing force when

penetrating.

3. Switch operation

Pulling the trigger and pushing the stopper, it keeps

the switched-on condition which is convenient for

continuous running. When switching off, the stopper

can be disconnected by pulling the trigger again.

4. Regarding the drill chuck

The drill chuck is secured to the spindle with a

taper. Should the drill chuck be accidentally detached

from the spindle, deposited on the chuck taper

section and the spindle chuck mount, tap the side

plane of the chuck after retracting its three claws,

and reattach it to the spindle. Carefully handle the

taper section so that its surface does not become

scarred.

Page 5

MAINTENANCE AND INSPECTION

CAUTION

Be sure to switch power OFF and disconnect the

plug during maintenance and inspection.

1. Inspecting the drill bits

Since use of an abraded drill bits will cause motor

malfunctioning and degraded efficiency, replace the

drill bits with a new one or resharpening without

delay when abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool. Exercise due care to ensure the winding

does not become damaged and/or wet with oil or

water.

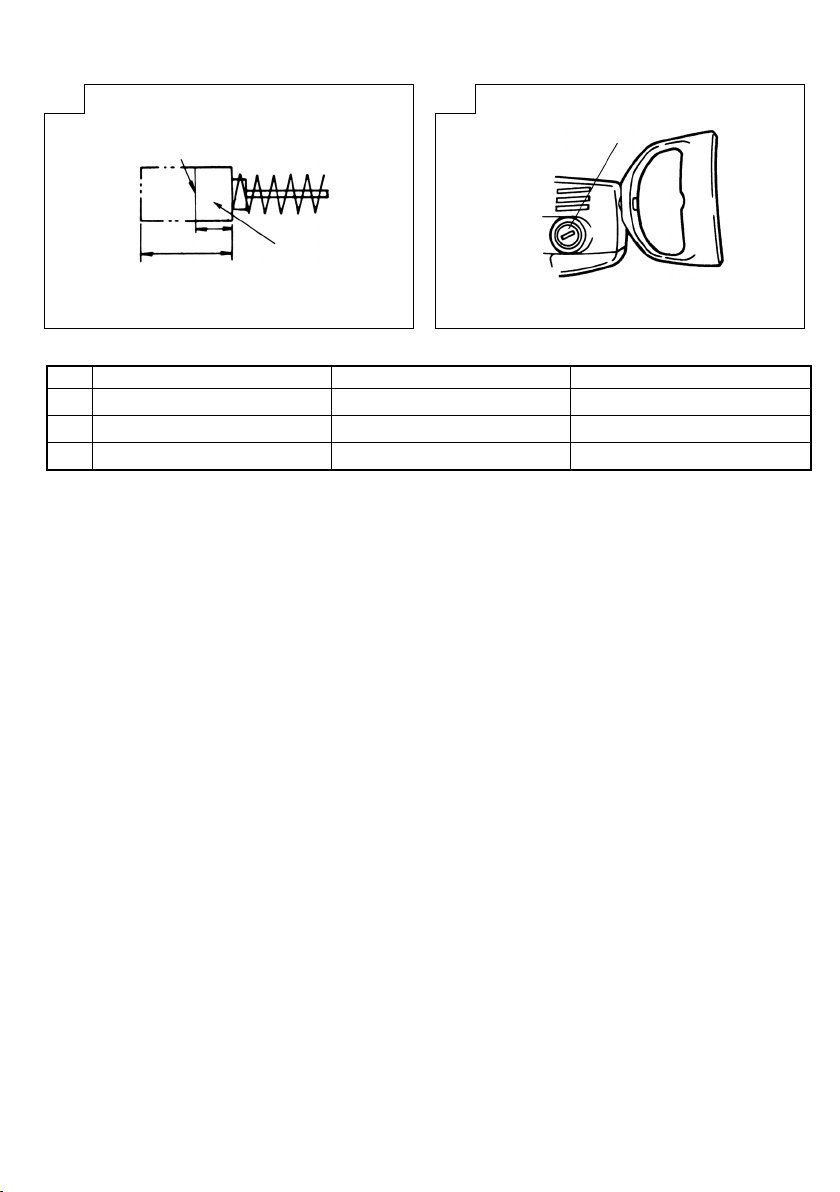

4. Inspecting the carbon brushes (Fig. 1)

The motor employs carbon brushes which are

consumable parts. Since an excessively worn carbon

brush can result in motor trouble, replace the carbon

brushes with new ones having the same carbon

brush No. shown in the figure when it becomes

worn to or near the “wear limit”. In addition, always

keep carbon brushes clean and ensue that they

slide freely within the brush holders.

5. Replacing carbon brushes

Disassemble the brush caps (Fig. 2) with a slottedhead screwdriver. The carbon brushes can then be

easily removed.

6. Keeping after use

When not in use, the Electric Power Tool should

be kept in a dry place out of the reach of children.

7. Service parts list

A: Item No.

B: Code No.

C: No. Used

D: Remarks

CAUTION

Repair, modification and inspection of Hitachi Power

Tools must be carried out by a Hitachi Authorized

Service Center.

This Parts List will be helpful if presented with the

tool to the Hitachi Authorized Service Center when

requesting repair or other maintenance.

In the operation and maintenance of power tools,

the safety regulations and standards prescribed in

each country must be observed.

MODIFICATION

Hitachi Power Tools are constantly being improved

and modified to incorporate the latest technological

advancements.

Accordingly, some parts (i.e. code numbers and/or

design) may be changed without prior notice.

English

NOTE

Due to HITACHI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

4

Page 6

Español

NORMAS GENERALES DE SEGURIDAD

¡ADVERTENCIA!

Lea todas las instrucciones

Si no se siguen las instrucciones de abajo podría producirse

una descarga eléctrica, un incendio y/o daños graves.

El término “herramienta eléctrica” en todas las

advertencias indicadas a continuación hace referencia a

la herramienta eléctrica que funciona con la red de

suministro (con cable) o a la herramienta eléctrica que

funciona con pilas (sin cable).

CONSERVE ESTAS INSTRUCCIONES

1) Área de trabajo

a) Mantenga la zona de trabajo limpia y bien

iluminada.

Las zonas desordenadas y oscuras pueden

provocar accidentes.

b) No utilice las herramientas eléctricas en entornos

explosivos como, por ejemplo, en presencia de

líquidos inflamables, gases o polvo.

Las herramientas eléctricas crean chispas que

pueden hacer que el polvo desprenda humo.

c) Mantenga a los niños y transeúntes alejados

cuando utilice una herramienta eléctrica.

Las distracciones pueden hacer que pierda el

control.

2) Seguridad eléctrica

a) Los enchufes de las herramientas eléctricas

tienen que ser adecuados a la toma de corriente.

No modifique el enchufe.

No utilice enchufes adaptadores con

herramientas eléctricas conectadas a tierra.

Si no se modifican los enchufes y se utilizan

tomas de corriente adecuadas se reducirá el

riesgo de descarga eléctrica.

b) Evite el contacto corporal con superficies

conectadas a tierra como tuberías, radiadores

y frigoríficos.

Hay mayor riesgo de descarga eléctrica si su

cuerpo está en contacto con el suelo.

c) No exponga las herramientas eléctricas a la

lluvia o a la humedad.

La entrada de agua en una herramienta eléctrica

aumentará el riesgo de descarga eléctrica.

d) No utilice el cable incorrectamente. No utilice

el cable para transportar, tirar de la herramienta

eléctrica o desenchufarla.

Mantenga el cable alejado del calor, del aceite,

de bordes afilados o piezas móviles.

Los cables dañados o enredados aumentan el

riesgo de descarga eléctrica.

e) Cuando utilice una herramienta eléctrica al aire

libre, utilice un cable prolongador adecuado para

utilizarse al aire libre.

La utilización de un cable adecuado para usarse

al aire libre reduce el riesgo de descarga eléctrica.

3) Seguridad personal

a) Esté atento, preste atención a lo que hace y

utilice el sentido común cuando utilice una

herramienta eléctrica.

No utilice una herramienta eléctrica cuando esté

cansado o esté bajo la influencia de drogas,

alcohol o medicación.

5

La distracción momentánea cuando utiliza

herramientas eléctricas puede dar lugar a

importantes daños personales.

b) Utilice equipo de seguridad. Utilice siempre una

protección ocular.

El equipo de seguridad como máscara para el

polvo, zapatos de seguridad antideslizantes, casco

o protección para oídos utilizado para condiciones

adecuadas reducirá los daños personales.

c) Evite un inicio accidental. Asegúrese de que el

interruptor está en “off” antes de enchufarlo.

El transporte de herramientas eléctricas con el

dedo en el interruptor o el enchufe de

herramientas eléctricas con el interruptor

encendido puede provocar accidentes.

d) Retire las llaves de ajuste antes de encender la

herramienta eléctrica.

Si se deja una llave en una pieza giratoria de

la herramienta eléctrica podrían producirse daños

personales.

e) No se extralimite. Mantenga un equilibrio

adecuado en todo momento.

Esto permite un mayor control de la herramienta

eléctrica en situaciones inesperadas.

f) Vístase adecuadamente. No lleve prendas sueltas

o joyas. Mantenga el pelo, la ropa y los guantes

alejados de las piezas móviles.

La ropa suelta, las joyas y el pelo largo pueden

pillarse en las piezas móviles.

g) Si se proporcionan dispositivos para la conexión

de extracción de polvo e instalaciones de

recogida, asegúrese de que están conectados y

se utilizan adecuadamente.

La utilización de estos dispositivos puede reducir

los riesgos relacionados con el polvo.

4) Utilización y mantenimiento de las herramientas

eléctricas

a) No fuerce la herramienta eléctrica. Utilice la

herramienta eléctrica correcta para su aplicación.

La herramienta eléctrica correcta trabajará mejor

y de forma más segura si se utiliza a la velocidad

para la que fue diseñada.

b) No utilice la herramienta eléctrica si el interruptor

no la enciende y apaga.

Las herramientas eléctricas que no pueden

controlarse con el interruptor son peligrosas y

deben repararse.

c) Desconecte el enchufe de la fuente eléctrica

antes de hacer ajustes, cambiar accesorios o

almacenar herramientas eléctricas.

Estas medidas de seguridad preventivas reducen

el riesgo de que la herramienta eléctrica se

ponga en marcha accidentalmente.

d) Guarde las herramientas eléctricas que no se

utilicen para que no las cojan los niños y no

permita que utilicen las herramientas eléctricas

personas no familiarizadas con las mismas o

con estas instrucciones.

Las herramientas eléctricas son peligrosas si

son utilizadas por usuarios sin formación.

e) Mantenimiento de las herramientas eléctricas.

Compruebe si las piezas móviles están mal

alineadas o unidas, si hay alguna pieza rota u

otra condición que pudiera afectar al

funcionamiento de las herramientas eléctricas.

Si la herramienta eléctrica está dañada, llévela

a reparar antes de utilizarla.

Page 7

Español

Se producen muchos accidentes por no realizar

un mantenimiento correcto de las herramientas

eléctricas.

f) Mantenga las herramientas de corte afiladas y

limpias.

Las herramientas de corte correctamente

mantenidas con los bordes de corte afilados son

más fáciles de controlar.

g) Utilice la herramienta eléctrica, los accesorios y

las brocas de la herramienta, etc., de acuerdo con

estas instrucciones y de la manera adecuada para

el tipo de herramienta eléctrica, teniendo en cuenta

las condiciones laborales y el trabajo que se va

a realizar.

La utilización de la herramienta eléctrica para

operaciones diferentes a pretendidas podría dar

lugar a una situación peligrosa.

5) Revisión

a) Lleve su herramienta a que la revise un experto

cualificado que utilice sólo piezas de repuesto

idénticas.

Esto garantizará el mantenimiento de la

seguridad de la herramienta eléctrica.

PRECAUCIÓN

Mantenga a los niños y a las personas enfermas alejadas.

Cuando no se utilicen, las herramientas deben almacenarse

fuera del alcance de los niños y de las personas enfermas.

PRECAUCIONES AL UTILIZAR EL TALADRO

1. No haga que este taladro trabaje más de sus

posibilidades.

2. Utilice el taladro eléctrico de forma segura para un

uso correcto.

3. Sujete el taladro con firmeza y utilícelo.

4. No use guantes cuando lo utilice.

5. No deje el taladro sólo y girando.

6. Evite que bajen las revoluciones presionándolo con

fuerza.

7. Tenga cuidado de la dirección hacia abajo en

posición alta.

8. Antes de perforar en una pared, un suelo o el techo,

confirme que no hay dentro ningún elemento como

cables eléctricos o conductos.

ESPECIFICACIONES

Voltaje (por áreas)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Acometida 620 W*

Velocidad de marcha en vacío 750/min

Capacidad Acero: 13 mm, Madera: 30 mm

Peso (sin cable) 4,4 kg

*Verificar indefectiblemente los datos de la placa de características de la máquina, pues varían de acuerdo al país de

destino.

ACCESORIOS ESTANDAR

(1) Velvedor de mandril ................................................ 1

Accesorios estándar están sujetos a cambio sin previo

aviso.

APLICACIONES

䡬 Perforar orificios en diferente metal, madera y

plástico.

ANTES DE LA PUESTA EN MARCHA

1. Alimentación

Asegurarse de que la acometida de red que ha de

ser utilizada es conforme a las exigencias de

corriente espacificadas en la placa de características

del producto.

2. Puesta a tierra

Esta herramienta debe conectarse a tierra cuando

se utilice para proteger al operario de las descargas

eléctricas. La herramienta está equipada con un

cable de tres conductores y un enchufe de puesta

a tierra para encajar en el receptáculo adecuado

tipo puesta a tierra. El conductor verde (o verde

y amarillo) del cable es el cable a tierra. No conecte

el cable verde (o verde y amarillo) a un terminal

con corriente.

3. Conmutador de alimentación

Asegurarse de que el conmutador de acometida

está en posición OFF (desconectado). Si el enchufe

está conectado a la caja del enchufe mientras el

conmutador de acometida está en posición ON

(conectado) la herramienta eléctrica empezará a

trabajar inmediatamente, provocando un serio

accidente.

4. Cable de prolongación

Cuando está alejada el área de trabajo de la red

de acometida, usar un cable de prolongación de un

grosor suficiente y potencia nominal. El cable de

prolongación debe ser mantenido o más corto

posible.

PRECAUCIÓN

El cable dañado debe sustituirse o repararse.

5. Confirmar el estado del medio ambiente

Confirme que el lugar de trabajo está en condiciones

adecuadas de acuerdo con las precauciones

prescritas.

6

Page 8

Español

6. Cómo seleccionar las brocas

(1) Al perforar agujeros en metales o plásticos

Utilice brocas ordinarias para metal; los tamaños

de broca aplicables varían de 1,2 mm como

mínimo a 13 mm como máximo.

(2) Al perforar orificios en madera

Utilice una broca para madera de 30 mm de

diám. o inferior. Para los orificios pequeños de

6,5 mm o inferior utilice brocas de taladro de

metal.

7. Instalación de brocas de taladro

Apriete las brocas de taladro con el portabrocas.

Hay tres orificios en los que el portabrocas debería

insertarse. Apriéte los tres orificios por igual, sin

apretar sólo un orificio.

8. Confirmar el receptáculo eléctrico

Si el enchufe se introduce en el receptáculo

flojamente, deberá ser reparado. Póngase en

contacto con el establecimiento electric más cercano

para su reparación. Si se utiliza el receptáculo

defectuoso, podría causar un recalentamiento,

produciendo una situación de peligro.

COMO SE USA EL TALADRO

1. Fuerza de presión del taladro

No puede obtener orificios rápidamente si los

presiona con más fuerza de lo necesario.

De lo contrario no sólo se dañará la punta de las

brocas del taladro y disminuirá la eficacia de

operación, sino también se acortará la vida de del

taladro.

2. En caso de penetrar en los orificios

Al penetrar, las brocas podrían romperse. Es

importante disminuir la fuerza de presión al penetrar.

3. Operación del interruptor

Tire del gatillo y empuje el tope para mantener

activada la alimentación, lo cual es conveniente

para un funcionamiento continuo. Cuando se lo

desconecta, el tope puede quitarse tirando del gatillo

otra vez.

4. Acerca del portabrocas

El portabrocas está fijado al eje con una cuña. Si

el portabrocas se desprendiera accidentalmente del

eje, se depositara en la sección de la cuña y el

soporte del eje, golpee el plano lateral del

portabrocas tras retraer sus tres pinzas, y vuélvalo

a colocar en el eje. Con cuidado manipule la sección

de la cuña de forma que su superficie no se dañe.

MANTENIMIENTO E INSPECCION

PRECAUCIÓN

Asegúrese de apagar la alimentación y desconectar

el enchufe durante el mantenimiento y la inspección.

1. Inspección de las brocas de barrena

Debido a que el uso de brocas de barrena

desgastadas producen fallos de funcionamiento del

motor y una disminución de la eficiencia, cámbielas

inmediatamente por otras nuevas o reafílelas cuando

note abrasión en las mismas.

2. Inspeccionar la broca de taladro y el macho de

roscar

Como el uso continuado de una broca o macho de

roscar desgastados disminuye la eficiencia operativa

y causa un posible recalentamiento del motor,

reemplazar o afilar la broca o el macho sin demora

si se nota un excesivo desgaste.

3. Mantenimiento del motor

La unidad de devanado del motor es el verdadero

“corazón” del herramientas eléctricas. Prestar el

mayor cuidado a asegurarse de que el devando no

se dañe y/o se humedezca con aceite o agua.

4. Inspección de escobillas de carbón: (Fig. 1)

El motor emplea carbones de contacto que son

partes consumibles. Como un carbón de contacto

excesivamente desgastado podría dar problemas al

motor, reemplazar el carbón de contacto por uno

nuevo, que tenga el mismo número mostrado en

la figura, cuando se haya desgastado o esté cerca

del límite de uso. Adicionalmente, mantener siempre

los carbones de contacto limpios y asegurarse de

que corran libremente dentro de los sujetadores de

carbón.

5. Reemplazar el carbón de contacto:

Quitar la cápsula de carbón (Fig. 2) con un

destornillador con cabeza pequeña. El carbón de

contacto se deja luego quitar facilmente.

6. Almacenamiento después de su uso

Cuando no utilice la herramienta eléctrica, guárdela

en un lugar seco fuera del alcance de los niños.

7. Lista de repuestos

A: N°. ítem

B: N°. código

C: N°. usado

D: Observaciones

PRECAUCIÓN

La reparación, modificación e inspección de las

herramientas eléctricas Hitachi deben ser realizadas

por un Centro de Servicio Autorizado de Hitachi.

Esta lista de repuestos será de utilidad si es

presentada junto con la herramienta al Centro de

Servicio Autorizado de Hitachi, para solicitar la

reparación o cualquier otro tipo de mantenimiento.

En el manejo y el mantenimiento de las herramientas

eléctricas, se deberán observar las normas y

reglamentos vigentes en cada país.

MODIFICACIONES

Hitachi Power Tools introduce constantemente

mejoras y modificaciones para incorporar los últimos

avances tecnológicos.

Por consiguiente, algunas partes (por ejemplo,

números de códigos y/o diseño) pueden ser

modificadas sin previo aviso.

OBSERVACION

Debido al programa continuo de investigación y desarollo

de HITACHI estas especificaciones están sujetas a cambio

sin preaviso.

7

Page 9

一般安全規則

警告!

閱讀所有說明,未遵守下列之說明可能導致電擊、火

災及/或嚴重傷害。

「電動工具」一詞在下列警告中,關係到電源操作

(有線)之電動工具或電池操作(無線)之電動工

具。

記住這些說明

1) 工作場所

a) 保持工作場所清潔及明亮。

雜亂及昏暗區域易發生意外。

b) 勿在易產生爆炸之環境中操作,譬如有易燃液

體、瓦斯或粉塵存在之處。

電動工具產生火花會引燃粉塵或煙氣。

c) 當操作電動工具時,保持兒童及過往人員遠

離。

分神會讓你失去控制。

2) 電氣安全

a) 電動工具插頭必須與插座配合,絕不可以任何

方法修改插頭,且不得使用任何轉接插頭於有

接地之電動工具。

不修改插頭及所結合之插座可減少電擊。

b) 避免身體接觸到接地面諸如管子、散熱器、爐

灶及冰箱。

如果你的身體接地或搭地,會增加電擊的危

險。

c) 勿讓電動工具淋雨或曝露在潮濕的環境下。

電動工具進水會增加電繫的危險。

d) 勿濫用電源線。絕勿使用電源線去纏繞、拖拉

電動工具或拔插頭,保持電源線遠離熱氣、油

氣、尖角或可動零件。

損壞或纏繞的電源線會增加電繫之危險。

e) 電動工具在室外操作時要使用一適合室外用的

延長線。

使用合適之室外用延長線會減少電擊的危險。

3) 人員安全

a) 保持機警,注意你正在做什麼,並運用普通常

識操作電動工具。

當你感到疲勞或受藥品、酒精或醫療影響時,

勿操作電動工具。

操作中瞬間的不注意可能造成人員嚴重的傷

害。

中國語

b) 使用安全裝備,常時佩戴安全眼鏡。

安全裝備有防塵口罩、防滑安全鞋、硬帽,或

在適當情況下使用聽覺防護,可減少人員傷

害。

c) 避免意外地啟動。在插電前確認開關是在

“off”的位置。

以手指放在開關握持電動工具,或在電動工具

的開關於“on”的狀況下插上插頭,都會導致

意外發生。

d) 在將電動工具啟動前,先卸下任何調整用鑰匙

或扳手。

扳手或鑰匙遺留在電動工具的轉動部位時,可

能導致人員傷害。

e) 身體勿過度伸張,任何時間要保持站穩及平

衡。

以便在不預期的狀態下,能對電動工具有較好

的控制。

f) 衣著要合宜,別穿太鬆的衣服或戴首飾。

保持你的頭髮、衣服及手套遠離轉動部位。

寬鬆的衣服、手飾及長髮會被捲入轉動部位。

g) 如果裝置要用於粉塵抽取及集塵設施,要確保

其連接及正當使用。

使用此類裝置能減少與粉塵有關之危害。

4) 電動工具之使用及注意事項

a) 勿強力使用電動工具,使用正確之電動工具為

你所需。

正確使用電動工具會依其設計條件使工作做得

更好更安全。

b) 如果開關不能轉至開及關的位置,勿使用電動

工具。

任何電動工具不能被開關所控制是危險的,必

須要修理。

c) 在做任何調整、更換配件或收存電動工具時,

要將插頭與電源分開,且/或將電池從電動工具

中取出。

此種預防安全措施可減少意外開啟電動機之危

險。

d) 收存停用之電動工具,遠離兒童,且不容許不

熟悉電動工具或未瞭解操作電動工具說明書的

人操作電動工具。

在未受過訓練的人手裡,電動工具極為危險。

e) 保養電動工具,檢核是否有可動零件錯誤的結

合或卡住、零件破裂及可能影響電動工具操作

的任何其他情形。

電動工具如果損壞,在使用前要修好。許多意

外皆肇因於不良的保養。

8

Page 10

中國語

f) 保持切割工具銳利清潔。

適當的保養切割工具,保持銳利之切削鋒口,

可減少卡住並容易控制。

g) 按照說明書使用電動工具、配件及刀具等,使

用特殊型式之電動工具時要考量工作條件及所

執行之工作。

使用電動工具未如預期用途之操作時,會導致

危害。

5) 維修

a) 讓你的電動工具由合格修理人員僅使用相同的

維修零件更換。

如此可確保電動工具的安全得以維持。

注意事項:

不可讓孩童和體弱人士靠近工作場所。

應將不使用的工具存放在孩童和體弱人士伸手不及的

地方。

使用手提電鑽時應注意事項

1. 不要讓手提電鑽做超過性能指定範圍以外的工

作。

2. 正確使用手提電鑽,確保操作安全。

3. 使用時握牢手提電鑽。

4. 操作時不要戴手套。

5. 不使用手提電鑽時絕不可任其處於運轉狀態。

6. 避兔用力壓手提電鑽使轉速顯著下降。

7. 在高處操作時注意下方。

8. 在往牆上,地板或天在板內鑽孔峙,要事先充分了

解其中是杏埋有電纜或其他管道。

規格

電壓(按地區)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

輸入功率 620 W*

額定輸出功率 350 W

無負荷速度 750轉/分

能力 金屬:13 mm,木材: 30 mm

重量(不含線纜) 4.4 kg

*當須改變地區時應檢查產品上的銘牌。

標 準 附 件

(1) 夾盤扳手 ............................... 1

標準附件可能不預先通告而更改。

用途

䡬 在各種金屬,木材和塑料上鑽孔。

作業之前

1. 電源

確認所使用的電源與工具銘牌上標示的規格是否相符

2. 接地

這個工具在使用時一定要接地以防操作者受到電

擊。工其是配備有三導線和接式插銷以適應正常

接地插座。在電纜中的綠色(或綠和黃)導線是

接地線。千萬不要把綠地(綠和黃)線接到火線

上。

9

3. 電源開關

確認電源開關是否切斷。若電源開關接通,則插

頭插入電源插座時電動工具將出其不意地立刻轉

動,從而招致嚴重事故。

4. 延伸線纜

若作業場所移到離開電源的地點,應使用容量足

夠、鎧裝合適的延伸線纜,並且要盡可能地短些。

注意:損壞的導線一定要更換或修理。

5. 確認工作環境

確認工作場地切實符合使用注意事項的條件。

6. 怎樣選擇鑽頭

(1) 在金屬或塑料上鑽孔時

。

用普通金屬加工鑽頭,可用的鑽頭大小:

從最小1.2 mm 到最大13 mm。

(2) 在木材上鑽孔時

用30 mm或尺寸比其小的木工鑽頭。鑽等於或小於

6.5 mm的小孔徑時用金屬加工鑽頭。

Page 11

中國語

7. 安裝鑽頭

用夾頭扳手擰緊鑽頭。在夾頭上有三個夾頭扳手

可以插入的孔,平均用力擰三個孔固定鑽頭,不

要只擰一個孔固定鑽頭。用上述的相反動作即可

拆下鑽頭。

8. 檢查電源插座

如果電源插座上的插頭過鬆,一定要修理。修理

時可與附近的電氣店聯系。

如果用了這種接觸不良的插座,可能過熱引起各

種事故。

手提電鑽的使用方法

1. 手提電鑽的壓力

不可用超過正常的壓力來加快鑽孔速度。這樣不僅

會損壞鑽頭尖,降低工作效率,而且會縮短手提電

鑽壽命。

2. 穿孔時

穿孔時鑽頭容易折斷破損,所以穿孔時一定要減小

壓力。

3. 開關操作

拉起動器並推制動器,保持開關合上狀態,便於連

續運轉。當開關斷開時,再次拉起動器便可釋放制

動器。

4. 關於鑽頭夾頭

鑽頭夾頭是固定在帶圓錐形的主軸上的。如果偶然

將鑽頭夾頭從安放夾頭錐形部分及主軸夾頭座上卸

下,在使夾頭的三個卡爪縮進後堵住夾頭側面,使

夾頭重附在主軸上。小心地裝卸錐形部分,使其表

面不出傷痕。

維護和檢查

注意:

在維修檢查時,應關掉電源開關。並將電源插

頭拔下。

1. 檢查鑽頭

繼續使用已磨損或損傷的鑽頭,不僅使工作效率

大為降低,同時又會導致電動機過載。因此,鑽

頭必須時常檢查,並根據情況需要更換新件。

2. 檢查安裝螺釘

要經常檢查安裝螺釘是否緊固妥善。若發現螺釘

鬆了,應立即重新扭緊,否則會導致嚴重的事

故。

3. 電動機的維護

電動機繞線是電動工具的心臟部。應仔細檢查有

無損傷,是否被油液或水沾濕。

4. 檢查碳刷(圖 1)

電動機上的碳刷是一種消耗品,其磨耗程度一旦

超出了“磨耗極限”,電動機將發生障礙。因

此,磨耗了的碳刷應即更換新件。此外,碳刷必

需常保乾淨狀態,這樣才能在刷握裡自由滑動。

5. 碳刷的更換

用一字形頭螺絲刀拆卸刷蓋(圖 2),碳刷就可簡

單地取下。

6. 使用後的保管

當不使用時,電動工具應保管在乾燥而孩子們又

夠不著的地方。

7. 維修部件目錄

A: 項目號碼

B: 代碼號碼

C: 所使用號碼

D: 備註

注意:

日立電動工具的修理、維護和檢查必須由日立所認

可的維修中心進行。

當尋求修理或其他維護時,將本部件目錄與工具一

起提交給日立所認可的維修中心會對您有所幫助。

在操作和維護電動工具中,必須遵守各國的安全規

則和標准規定。

改進

日立電動工具隨時都在進行改進以適應最新的技術

進步。

因此,有些部件(如,代碼號碼和或設計)可能

未預先通知而進行改進。

註:

為求改進,本手冊所載規格可能不預先通告而徑予

更改。

10

Page 12

ABC D

31 949216 2 M4×10

32 930804 2 M4.0

6203VVCMPS2L

36 ———— 1

39 949241 5 M5×20

40 949292 1 M4×6

41 930778 1

42 930792 1 "71-73"

48 930901 1

50 930791 1

55 949248 2 M5×40

56 949245 2 M5×30

58 930784 1

61 930729 1 "62"

62 930730 1

63 930939 1

64 930732 1 M9×37

68 321810 1 13EL "69"

69 930515 1 10G

70 959144 2

71 930890 1

72 967261 1

33A 931067 1

38-1 958049 1 D8.2

38-2 940778 1 D10.7

65A 1

73 6203VV 1

6200VVCMPS2L

ABC D

1A 930790 1 "8B, 10A"

2 931701 2

3-1 930772C 1 110V-115V "5"

3-2 930772E 1 220V-230V "5"

3-3 930772F 1 240V "5"

5 930703 2

6 949250 2 M5×50

7 949454 11 M5

8B 957051 2

9 930706 2

10A 985114 2 M4×6

11-1 930774C 1 110V-115V

14 6200VV 1

11-2 930774E 1 220V-230V

15 608VVM 4 608VVC2PS2L

11-3 930774F 1 240V

16 930776 1

17 930777 1

19 999043 2

20 935829 2

21 931066 1

23 930153 1

24 930787G 1

28 949217 1 M4×12

29 949453 3 M4

22A 994273 1

30 949554 1 M4

11

Page 13

121314

Page 14

Page 15

Page 16

Hitachi Koki Co., Ltd.

902

Code No. 99236033 N

Printed in Japan

Loading...

Loading...