Hitachi BRD-EZ2-110K, BRD-EZ2-55K, BRD-E2-55K, BRD-E2-30K, BRD-EZ2-30K OPERATION MANUAL

HITACHI DYNAMIC BRAKING UNIT (BRD SERIES)

NB4882CX

NOTE: BRD-EZ2-110K is replaced by BRD-EZ3-110K

200V Class (BRD-E2-30K/55K)

400V Class (BRD-EZ2-30K/55K/110K)

OPERATION MANUAL

CONTENTS

1. UNPACKING INSPECTION..................................................................... 1

2. IMPORTANT NOTICES........................................................................... 1

3. INSTALLATION....................................................................................... 2

4. WIRING AND FUNCTION SETTING...................................................... 3

4.1 Wiring Notices ......................................................................................................... 3

4.2 Functional Setting.................................................................................................... 5

4.3 Example of External Connection .............................................................................. 6

4.4 Example of External Connection

(Parallel Connection Operation)............................................................................... 7

5. TROUBLESHOOTING............................................................................. 9

5.1 Alarm contact is activated and the inverter stops ...................................................... 9

5.2 When the inverter trips the 0V during inverter deceleration ...................................... 10

6. PRE-START CHECKS.............................................................................. 11

7. SPECIFICATIONS.................................................................................... 12

7.1 Standard Specifications............................................................................................ 12

8. INTERNAL CIRCUITS............................................................................. 16

9. SELECTION OF DYNAMIC BRAKING UNITS AND

DISCHARGING RESISTORS................................................................... 20

9.1 Braking Energy without a Dynamic Braking Unit ..................................................... 21

9.2 Using the Dynamic Braking Unit.............................................................................. 21

9.3 General Formulas Use for Estimation....................................................................... 23

10.MAINTENANCE AND CHECKS............................................................. 24

10.1 Notices on Maintenance and Checks......................................................................... 24

10.2 Check Items ............................................................................................................. 24

11.PARTS ORDERING AND INQUIRY ....................................................... 26

APPENDIX .................................................................................................... 27

Read and Save this Instruction Manual.

IMPORTANT NOTICES

Keep this manual handy for quick reference.

Read this manual carefully before installing, operating or maintaining the dynamic braking unit.

Familiarize yourself with the device specifications, safety precautions, and handling and operating

procedures and use this device correctly.

For maximum efficiency and safety, use this device at the specified operating rates for which it is

designed. Inspect and maintain this device at specified regular intervals to insure safe and

maximum performance and to prevent malfunction.

LIMITED WARRANTY

Your product is warranted against defective material or workmanship for a period of one year

from the date of installation. Hitachi will repair or replace this device free of charge if any

defective parts or workmanship covered within the limitations of this warranty are found.

The following are not covered by this warranty and will be charged accordingly:

(1) Abnormal handling or use of this device

(2) Failure caused by reasons unrelated to this device

(3) Improper servicing, alteration or modification by any unauthorized personnel

(4) Malfunction and failure caused by natural disasters such as fire and earthquakes

The obligation of the warrantor is solely to repair or replace the device. The warrantor is not

liable for any incidental or consequential damages caused by any defects of this device.

(This warranty is valid only in Japan.)

REPAIR COST

Repairs for normal wear, accidental damage or inspection of this device outside the warranty

period (one-year) will be at the owners' expense. Repairs not described in the above warranty are

possible. For more information on repair cost and inspections, call your local Hitachi distributor

or service center.

ORDERING REPLACEMENT PARTS AND INQUIRY

In the case of device failure, please report the following to your local Hitachi distributor or service

center:

(1) Model number

(2) Date of purchase

(3) Manufacturing number (MFG. No.)

(4) Details of the malfunction

It is recommended you install a back-up device so that your work is not disrupted.

MISCELLANEOUS

• This manual is subject to change without prior notice.

• This manual is included with the device. There is no other manual. Keep this manual handy.

• Reproduction or use of any portion of this manual, without express written permission from

Hitachi is prohibited.

• Every effort has been made to supply complete and accurate information. However, errors and

inaccurate information may exist. Please inform us of these errors. Your comments are always

welcome.

• Hitachi assumes no responsibility for any results caused by the use of this manual

History revisions

No. Description Date of revision Manual No.

1 Two manuals have been combined and the contents reviewed. '98-4-25 NB4882C

Misspellings, missing characters, ambiguous descriptions, and similar errors are corrected without

notice.

SAFETY PRECAUTIONS

Title: (Danger.eps)

Creator: Adobe Illustrator(TM) 7.0

:

Title: (Triangle.eps)

Creator: Adobe Illustrator(TM) 5.5

:

This safety reminder indicates potential danger to body and property.

Title: (Triangle.eps)

Creator: Adobe Illustrator(TM) 5.5

Carefully read this manual and other precautionary documents that came with the dynamic

braking unit before installing, operating or maintaining this unit. Familiarize yourself with the

device specifications, safety precautions, and handling and operating procedures and use this

device correctly.

This manual uses two symbols, the first informs of malfunctions and the second indicates danger

of personal injury or property damage.

This safety reminder indicates potentially life-threatening situations.

DANGER

If these instructions are not followed serious injury and in extreme

cases, death could occur.

CAUTION

If these instructions are not followed minor or serious injury and/or

property damage could occur.

Be sure to follow these instructions carefully when you see these symbols.

Also read and follow the instructions for all "Notes" and "Remarks."

1. Installation

CAUTION

l Mount the dynamic braking unit on a fireproof wall (e.g. metallic wall) or a fire may

occur.

(See page 2.)

l Keep the dynamic braking unit away from combustible or flammable materials or a fire

may occur.

(See page 2.)

l Never hold the dynamic braking unit by the front cover when carrying it. It could fall

and an injury could occur.

(See page 2.)

l Never allow any wires, dust, welding spatters, iron filings, or other materials to get into

the unit or a fire may occur.

(See page 2.)

l The dynamic braking unit is very heavy. Install the unit on a solid rigid wall strong

enough to support it. Otherwise, it could fall and an injury may occur.

(See page 2.)

l Do not use any inverter that is partially damaged or incomplete or an injury may occur.

(See page 2.)

l Avoid any dangerous environment

Do not place the dynamic braking unit in hot, damp, or wet locations. Don't use the

dynamic braking unit in the presence of dust, corrosive gases, explosive gases,

flammable gases, oil mist, or salt. Keep the dynamic braking unit out of direct

sunlight.

(See page 2.)

i

2. Wiring

Title: (Danger.eps)

Creator: Adobe Illustrator(TM) 7.0

Title: (Triangle.eps)

Creator: Adobe Illustrator(TM) 5.5

DANGER

l Always connect the grounding wire to the dynamic braking unit to prevent electric

shock or fire.

(See page 3.)

l All wiring should be done by a qualified electrician or electric shock or fire may occur.

(See page 3.)

l Before wiring, make sure the supply power is off (or the P-N voltage is 45 V or less) to

prevent electric shock or fire.

(See page 3.)

l Always install the dynamic braking unit on the wall before wiring to prevent electric

shock and personal injury.

(See page 3.)

l Be sure to provide a thermal relay and a circuit, which shuts off primary power to the

inverter. This is to prevent burning-out the external resistor due to overheating if the

dynamic braking unit malfunctions.

(See page 3.)

For actual connections, see 4.3 and 4.4.

(See page 3.)

CAUTION

l Make sure the voltage rating of the dynamic braking unit is equal to that of the inverter

to prevent fire and personal injury.

(See page 3.)

l Do not connect resistors directly to the D.C. terminals (P and N) or fire may occur.

(See page 3.)

l Tighten screws at their correct specified torque (see table on right). Make sure every

screw is firmly tightened or fire may occur.

(See page 3.)

l The power cables should be MLFC flame-retardant poly-flex wire, allowing a voltage

of 600 V and capable of the specified amperage or fire may occur.

(See page 3.)

ii

3. Control and operation

Title: (Danger.eps)

Creator: Adobe Illustrator(TM) 7.0

Title: (Triangle.eps)

Creator: Adobe Illustrator(TM) 5.5

Title: (Danger.eps)

Creator: Adobe Illustrator(TM) 7.0

DANGER

l Be sure the front cover on the dynamic braking unit is attached before turning on the

power. Never remove the cover of the dynamic braking unit or you may receive an

electric shock

(See page 11.)

l Do not operate with wet hands or you may receive an electric shock.

(See page 3.)

l Never touch any terminal of the dynamic braking unit while the unit power is on (even

when the unit has stopped) or you may receive an electric shock.

(See page 3.)

l Never touch any part or put anything in the dynamic braking unit while the unit's power

is on or you may receive an electric shock or cause a fire.

(See page 3.)

CAUTION

l The heat radiating fins and the discharging resistors during use are hot and can cause

burns. Do not touch.

4. Maintenance, inspection and part replacement

DANGER

l Be sure to turn off the supply power. (Make sure that the DC voltage between

terminals P and N is 45 volts or less.) Otherwise, you may receive a serious electric

shock.

(See page 24.)

l Only an authorized electrician is allowed to check, maintain, and replace parts of the

dynamic braking unit.

(Take off all metallic accessories such as watches and jewelry before operating.)

(Use the insulated tools.)

Otherwise, you may receive a serious electric shock or personal injury.

(See page 24.)

(See page 3.)

iii

5. Appendix

Title: (Danger.eps)

Creator: Adobe Illustrator(TM) 7.0

DANGER

l Never alter or modify the dynamic braking unit.

Improper servicing may cause serious electric shock and/or personal injury.

(See page 1.)

GENERAL NOTICES

For simplicity, some figures and illustrations in this manual are shown without the cover

or peripheral parts of the device. Be sure to remount the cover and other safety features

before running the dynamic braking unit.

iv

1. UNPACKING INSPECTION

Handle the product with care when unpacking. Do not use any excessive force (impacts,

vibration, etc.) on the package. Check the following:

(1) Package damage occurring during delivery

(2) Model name, voltage, etc. (order confirmation)

(3) List of accessories (including operation manual)

2. IMPORTANT NOTICES

Note the following to improve and perform safe operation of the dynamic braking unit:

DANGER

l Never alter or modify the dynamic braking unit.

Improper servicing may cause serious electric shock and/or personal injury.

Note: Do not use the BRD-E2/E2Z braking unit in combination with earlier versions, (e.g.

BRD-VZ or BRD-C1). The operating voltages and terminal configurations are

different and may cause the dynamic braking units to malfunction.

Note: Set the DIP switches and connect the wires correctly when setting or changing the

operating voltage or when running devices in a parallel connection. Be sure to turn

off power to the dynamic braking unit before setting the DIP switches and the

connecting wires. (For more information, see "4. Wiring and Function Setting.")

Note: Check wirings and connections carefully. If they are correct you can turn on the

power to the inverter.

- 1 -

3. INSTALLATION

Title: (Triangle.eps)

Creator: Adobe Illustrator(TM) 5.5

5 cm or more

5 cm or more

5 cm or more

5 cm or more

CAUTION

l Mount the dynamic braking unit on a fireproof wall (e.g. metallic wall) or a fire may

occur.

l Keep the dynamic braking unit away from combustible or flammable materials or a fire

may occur.

l Never hold the dynamic braking unit by the front cover when carrying it. It could fall

and an injury could occur.

l Never allow any wires, dust, welding spatters, iron filings, or other materials to get into

the unit or a fire may occur.

l The dynamic braking unit is very heavy. Install the unit on a solid rigid wall strong

enough to support it. Otherwise, it could fall and an injury may occur.

l Do not use any inverter that is partially damaged or incomplete or an injury may occur.

l Avoid any dangerous environment

Do not place the dynamic braking unit in hot, damp, or wet locations. Don't use the

braking unit in the presence of dust, corrosive gases, explosive gases, flammable gases,

oil mist, or salt. Keep the braking unit out of direct sunlight.

To insure ventilation, mount the dynamic braking unit on the wall with at least 10 cm clearance

above and below the unit and at least 5 cm clearance on the left and right sides of the unit as

shown in Figure 3.1, Figure 3.2 (a), and Figure 3.2 (b).

Do not place the dynamic braking unit with its ventilation openings facing left and right

(horizontally).

Required clearance surrounding the dynamic braking unit

10 cm or more

10 cm or more

10 cm or more

10 cm or more

(a) Horizontal installation (b) Vertical installation(Never place the dynamic braking

unit with its ventilation openings

facing left and right.)

10 cm or more

10 cm or more

Figure 3.1 Clearance around

dynamic braking units

E2-30K/55K and

EZ2-55K/110K

Figure 3.2 Clearance around dynamic braking units EZ2-30K

- 2 -

4. WIRING AND FUNCTION SETTING

Title: (Danger.eps)

Creator: Adobe Illustrator(TM) 7.0

Title: (Triangle.eps)

Creator: Adobe Illustrator(TM) 5.5

4.1 Wiring Notices

DANGER

l Always connect the grounding wire to the dynamic braking unit to prevent electric

shock or fire.

l All wiring should be done by a qualified electrician or electric shock or fire may occur.

l Before wiring, make sure the supply power is off (or the P-N voltage is 45 V or less) to

prevent electric shock or fire.

l Always install the dynamic braking unit on the wall before wiring to prevent electric

shock and personal injury.

l Be sure to provide a thermal relay and a circuit, which shuts off primary power to the

inverter. This is to prevent burning-out the external single resistor due to overheating

if the dynamic braking unit malfunctions.

For actual connections, see 4.3 and 4.4.

CAUTION

l Make sure the voltage rating of the dynamic braking unit is equal to that of the inverter

to prevent fire and personal injury.

l Do not connect resistors directly to the D.C. terminals

(P and N) or fire may occur.

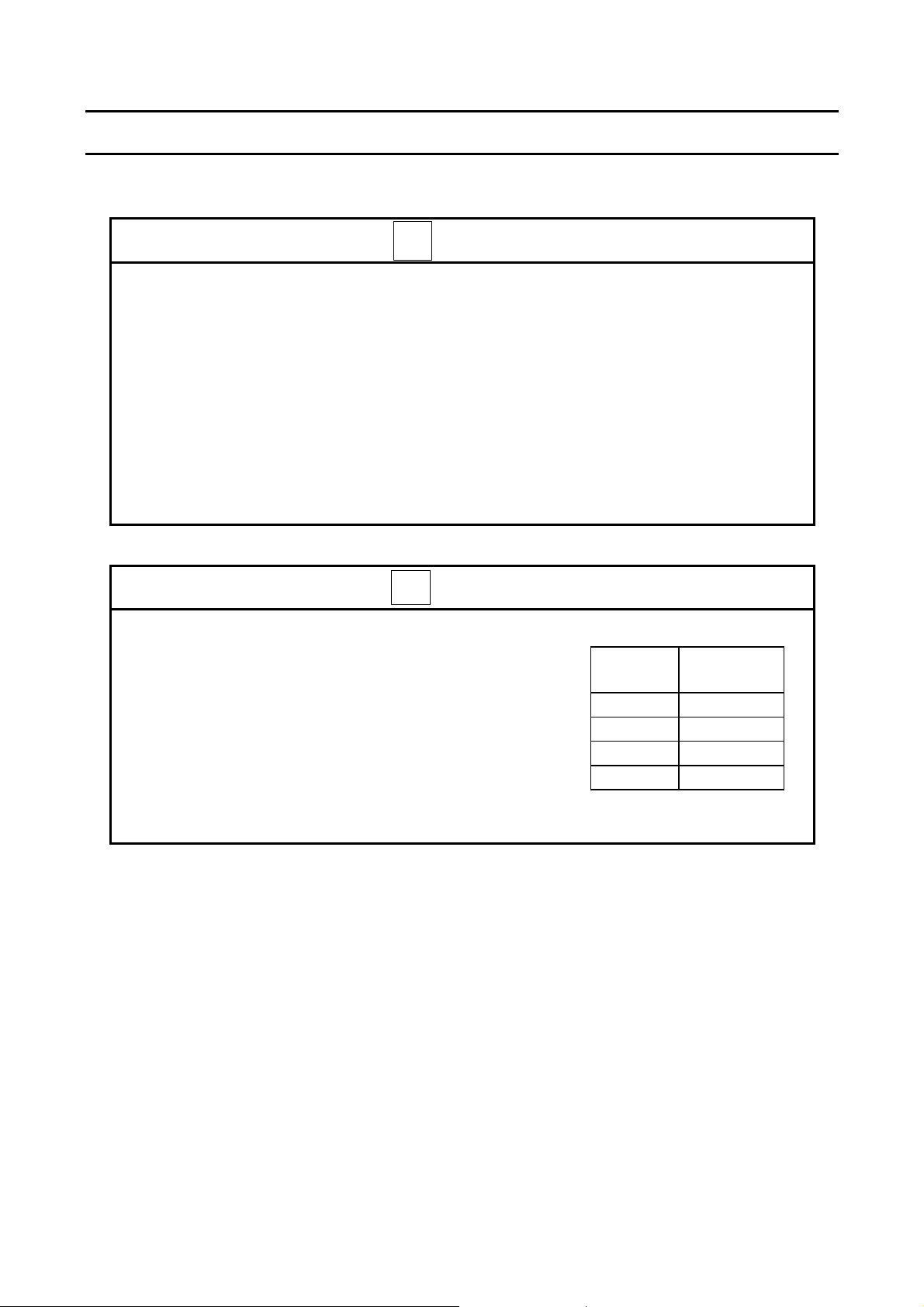

l Tighten screws at their correct specified torque (see

table on right). Make sure every screw is firmly

tightened or fire may occur.

l The power cables should be MLFC flame-retardant

poly-flex wire, allowing a voltage of 600 V and capable

of the specified amperage or fire may occur.

Notes:

1. Be sure to provide alarm contacts (AL1 and AL2) and a circuit, which shuts off

primary power to the inverter to prevent overheating and burning if the dynamic

braking unit malfunctions.

Screw size

M3 0.6 to 0.9

M5 2.8 to 3.9

M8 10 to 13.5

M10 21 to 28

Tightening

torque (N.m)

- 3 -

2. Use cables at their specified ratings as short as possible: up to 5 meters between the

Inverter

dynamic braking unit and the inverter (P, N) and up to 50 meters between the dynamic

braking unit and the discharging resistor (P, RB) (or up to 5 meters for the EZ2-30K).

Also make the wire connections as short as possible. Do not loop extra cable.

Up to

50 meters

(up to 5

meters)*

Discharging

resistor

Example of correct wiring

Up to

5 meters

Dynamic

braking unit

* In the EZ2-30K system, the cable between the dynamic braking unit and the

discharging resistor must be 5 meters or shorter.

Example of incorrect wiring

Inverter

Dynamic

braking unit

Discharging

resistor

The cables must be tied together and supported firmly so there is no excessive load on

the dynamic braking unit.

3. When the parallel connection interlocking function is used, signal cables (MA1, MA2,

SL1, and SL2) between the dynamic braking units must be no more than five meters in

length and no more than 0.75 mm2 in width in its section area. The signal cable must

be fully separated from the main circuit cable.

Signal cableMain circuit cable

10 cm or more

4. When a combination of various resistors are used, the inductance in the resistors may

raise the surge voltage during the switching operation. To prevent this, use larger

cables or twist them.

Always use up to six non-induction resistors as external resistors.

5. Use insulated crimping terminals to connect the cables to the terminal board TM1 (or

TM2 of the EZ2).

6. Use closed-loop terminals with insulated caps to connect cables to the terminal board

TM2 (or TM3 of the EZ2).

- 4 -

Loading...

Loading...