Page 1

R

M 800 PC Cement Repair Mortar 7.2.4

C

onstruction Chemicals

Construction Chemicals

RM 800 PC Cement Repair Mortar 7.2.4

Listings, Approvals

& Testing Standards

ASTM C 928

7.2.4.2 Material

Specifications

Working Time

5 mins at 75°F (24°C)

1

et Time (ASTM C 266)

S

Initial (Hrs:Min): 0:20

Final (Hrs:Min): 0:30

Flexural Strength

(ASTM C 580) 28 Days

800 psi

Compressive Strength

(ASTM C 109)

3 hrs . . . . . . . . . . . .3000 psi

1 day . . . . . . . . . . . .6000 psi

28 days . . . . . . . . . .7000 psi

Percentage Length Change

(ASTM C 157)

Air-cured . . . . . . .–0.06 max

Moist-cured . . . . .+0.06 max

Resistance to deicing salts

(ASTM C 672)

(10% Calcium Chloride Solution) 25

cycles - 2 Rating

Water Absorption (ASTM C 642)

9.8%

Freeze-Thaw Resistance, 3000 cycles

(ASTM C 666, Procedure A)

88% Dynamic modulus

Flow, 5 min (ASTM C 109)

135%

Color

Concrete gray

7.2.4.1 Product Description

RM 800 PC is a fast setting concrete

patching material which exhibits high

early strength. RM 800 PC is a

self-bonding patching compound

blended with special cements and

additives. No bonding agents are

required. RM 800 PC can accept

ehicular traffic in three hours and its

v

performance exceeds the requirements

of ASTM C 928 for very rapid hardening

material for concrete repair.

Product Features

• DOT approved (Tennesse &

Mississippi)

• Self-bonding, requires no bonding

agents or primers

• Minimizes downtime

• Pre-blended; just add water

• Suitable for vehicular traffic

in 3 hours at 70°F (21°C)

• Initial set time 20 minutes,

final set time 30 minutes

7.2.4.3 Installation Data

Basic Use

RM 800 PC is suitable for repair of

damaged concrete on parking

structures, airport runways, warehouse

floors and loading docks. It can also be

used for setting posts, railing and

parking meters.

Coverage

One 50 lb (22.7 kg) bucket yields 0.42 ft

(0.011 m3) and covers approximately 10

2

ft

when applied 1/2" (13 mm) thick.

Limitations

RM 800 PC is designed for use on

horizontal surfaces in thicknesses from

1/2" to 8".

3

Hilti, Inc. (US) 1-800-879-8000 | www

.us.hilti.com

7.2.4.4 Installation Instructions

Surface Preparation

The damaged area should be prepared

by back-cutting, or sawing of a vertical

edge. This preparation should be

performed in a manner which pr

damage to the surr

ounding concrete.

Loose scale or dust must be r

events

emoved

using compressed air or water blasting,

leaving only clean, sound concr

ete. The

area to be repaired should be saturated

with water, but there should be no

puddles pr

I en español 1-800-879-5000 I Hilti (Canada) Corp. 1-800-363-4458 I www

esent.

Mixing

RM 800 PC may be mixed in a mortar

mixer

mixing paddle. Measure 3 quarts of

potable water and add to the mixer or

bucket, then add RM 800 PC and

a medium speed for 3

time is approximately 10 minutes at

F (24

°

75

the temperature increases. Do Not mix

more product than you can place in 10

minutes. Clean mixer or mixing paddle

with water between mixes and after last

mix, to avoid build-up of product.

, or in a bucket with a drill and a

mix at

minutes. Working

C), and becomes shorter as

°

.ca.hilti.com

I Pr

echnical Guide 2006 333

oduct T

Page 2

7

.2.5 CG 200 PC Cementitious Grout

C

onstruction Chemicals

Construction Chemicals

7.2.4 RM 800 PC Cement Repair Mortar

• Do Not add excessive amounts of

water

• Do Not mix more than can be used

in 10 minutes

Up to 1 lb of cement colorant may

•

be added to color patch

Application

ir, mix and substrate temperatures

A

should be between 40°F (4°C) and 90°F

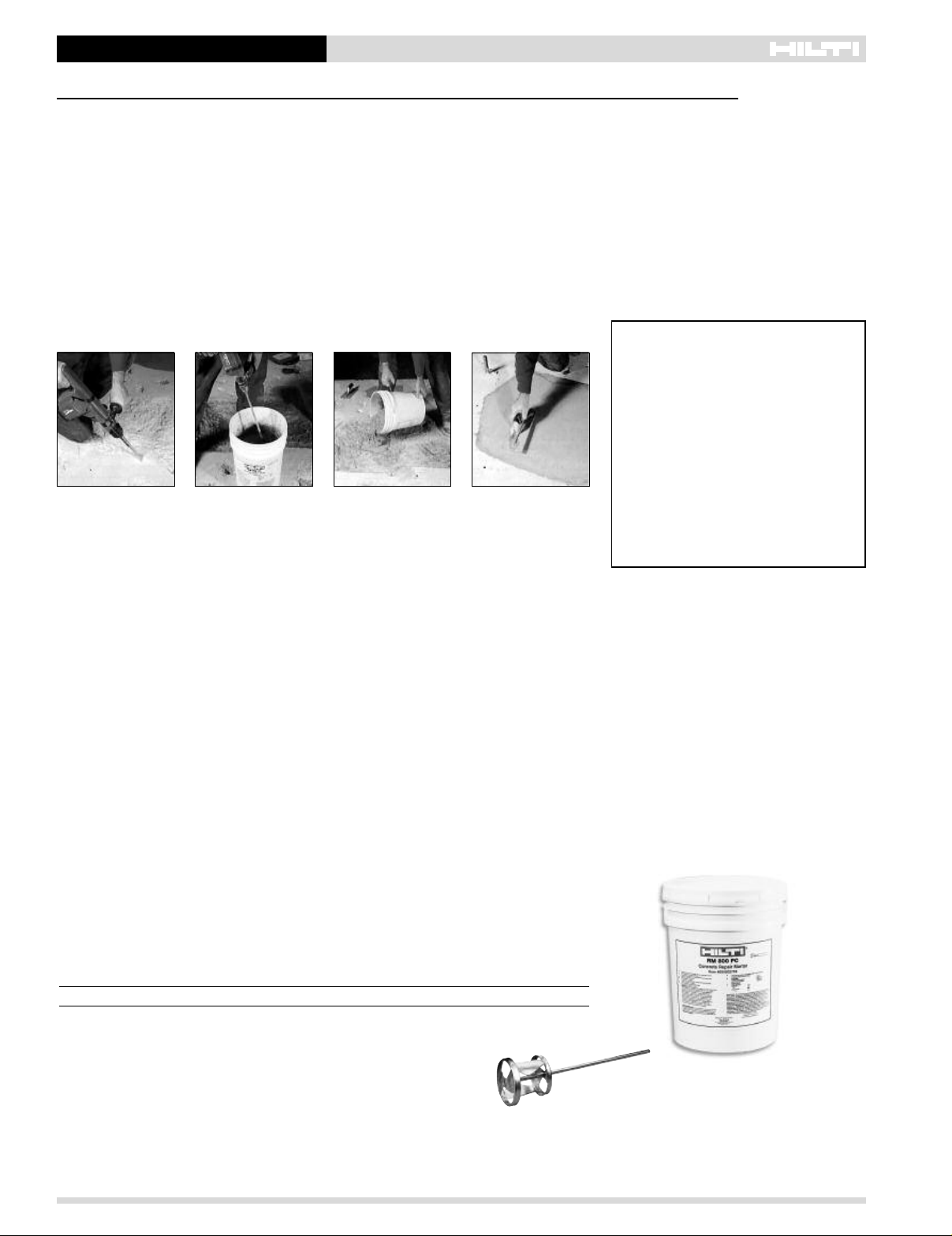

Installation Instructions

1.Score concrete

around damaged area at a

slight backward

angle to a minimum depth of

1/2" using Hilti

Dry Diamond

Blade.

2.Expose fresh

concrete surface and chip

out edges to a

depth of 1/2"

using a Hilti

Combihammer

(Hilti TE 56 suggested) and

chisel or bushing head.

Remove dust

and debris with

vacuum or

compressed air.

3 Saturate pre-

pared area with

water. Add 2

quarts of

potable water

to an empty 5

gallon pail.

Slowly add

powdered RM

800PC and mix

using a drill (or

equivalent) and

a mixing paddle

(sold below)

until free of

lumps. Add an

additional quart

of water, alternating with

remaining powder, until entire

contents have

been

thoroughly

blended.

(32°C) during repair and for 24 hours

fterward. Place RM 800 PC in the area

a

to be repaired, filling flush

with surrounding concrete, and

consolidate during placement by

rodding. Surface is ready for brooming

or texturing in 20 to 30 minutes.

Do Not use in vertical or

•

overhead surfaces

4. After removing

excess water

from prepared

area, Using a

trowel, place

5.Finish patch

with trowel.

Protect patch

from traffic until

cured.

mortar and

push into all

corners and

edges.

Storage Life

One year from date of manufacture, in

riginal, unopened container.

o

Maintenance

RM 800 PC may be cleaned with most

floor cleaning detergents. Aggressive

solvents should be avoided.

CAUTION: Contains Silicon

Dioxide, Portland Cement and

Calcium Hydroxide.

Your skin may be sensitive

to cement. Wearing rubber gloves

is recommended. Avoid contact

with eyes or prolonged contact

with skin. In case of contact, flush

thoroughly with water.

For eyes, flush with clean water

for at least 15 minutes and get

prompt medical attention.

Keep out of reach

of children.

Estimating Formula*

Number of Units Required =

(L * W * (D

ave

/ 12)) / Y

od

pr

L = length of void in feet

W = width of void in feet

D

= ave. depth of void in inches

ave

Y

= Yield for product

prod

Estimated Yield for Repair Mortars

& Grout (Yprod) in ft

3

Product Yprod

RM 800 PC

0.420

* Numbers are approximate and

assume no waste.

7.2.4.5 Ordering Information

RM 800 PC is packaged in convenient, reclosable plastic pails, containing 50 lb

(22.7 kg) of product.

Item No. Description Size

00020270 RM 800 PC 50 lb pail

00024155

334 Hilti, Inc. (US) 1-800-879-8000 | www

Stainless Steel Paddle Mixer smooth shank

Specially designed for repair mortar. Use with Jacobs style chuck.

.us.hilti.com

I en español 1-800-879-5000 I Hilti (Canada) Corp. 1-800-363-4458 I www

.ca.hilti.com

I Pr

echnical Guide 2006

oduct T

Loading...

Loading...