Hilti D-LP 15, DS-TS 22 Operating Instructions Manual

Operating instructions en

D-LP 15/

DS-TS 22

Printed: 13.01.2016 | Doc-Nr: PUB / 5139176 / 000 / 02

2

D-LP15 / DS-TS22

D-LP15 hydraulic unit

D-RC22 remote control unit

DS-RF rail support

D-R200 L rail (length 200 cm)

DS-ES-L end stop

DS-TS22 saw head

DS-B saw blade

DS-BG blade guard

D-PH58-10 5/8ʺ hydraulic hoses

D-FH4/14-10 1/4ʺ hydraulic control hoses

Water supply hose

Printed: 13.01.2016 | Doc-Nr: PUB / 5139176 / 000 / 02

3

Contents

1. General information 4

2. Safety precautions 5

3. The D-LP15 / DS-TS22 modular hydraulic saw system 11

4. General description and technical data D-LP15 / DS-TS22 12

5. Spindle speeds, gear selection, rules of thumb, sawing procedure, saw blades 13

6. Preparing the workplace and saw system 14

7. Setting up the saw system for various applications 15

8. D-LP15 hydraulic unit – setting up, operation, care and maintenance 22

9. Setting up, checking and operating the hydraulic saw system 23

10. Disassembly and fault finding 25

11. Care and maintenance 27

12. Manufacturer's warranty – tools 28

13. EU declaration of conformity (original) 29

Printed: 13.01.2016 | Doc-Nr: PUB / 5139176 / 000 / 02

4

1. General information

The operating instructions must be read carefully

before the equipment is put into operation.

Always keep these operating instructions with the

equipment.

The wire saw system should be handed over to

other persons only complete with the operating

instructions.

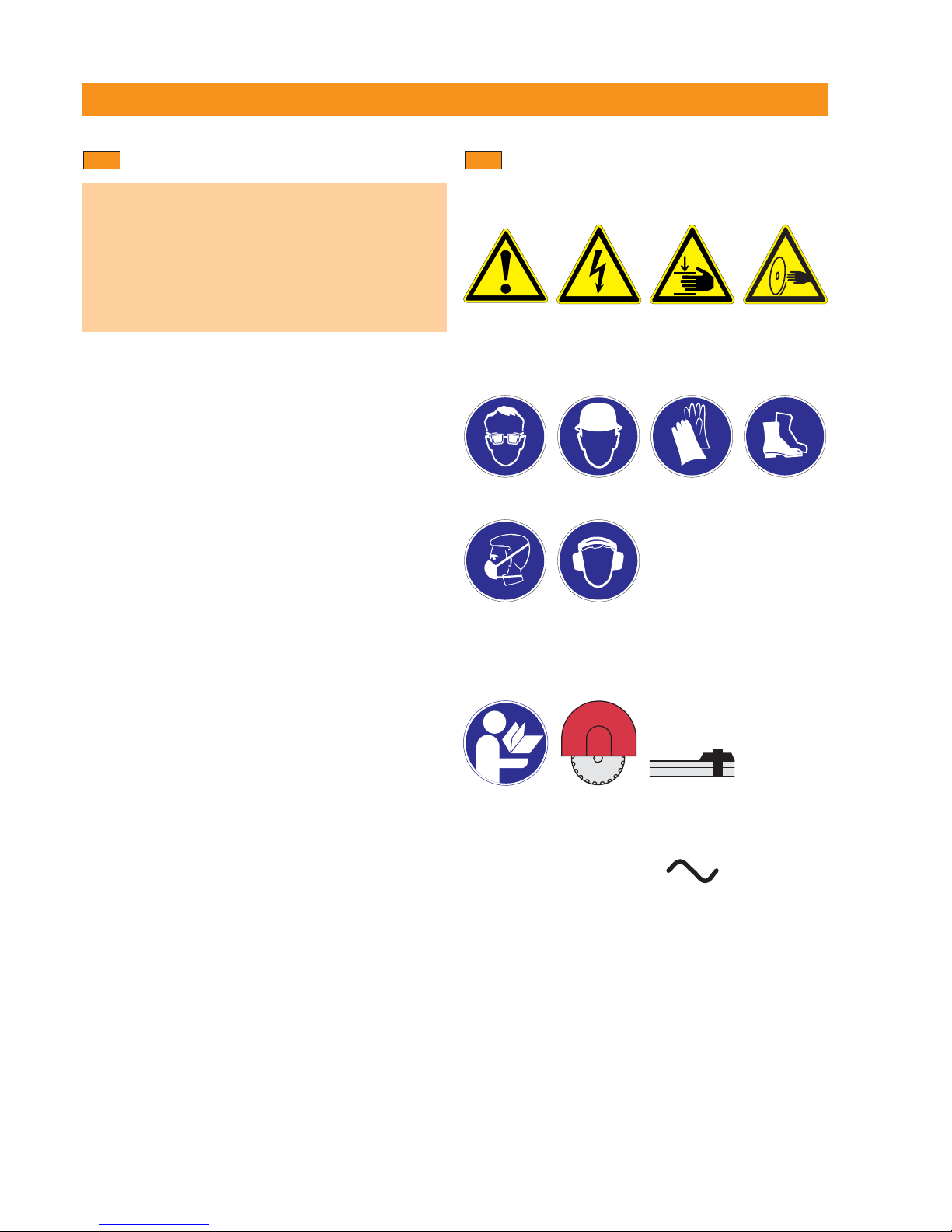

Safety notices and their meaning

1.1

Explanation of the pictograms and other

information

1.2

DANGER

Draws attention to imminent danger that will lead to

serious bodily injury or fatality.

WARNING

Draws attention to a potentially dangerous situation

that could lead to serious personal injury or fatality.

CAUTION

Draws attention to a potentially dangerous situation

that could lead to slight personal injury or damage to

the equipment or other property.

NOTE

Draws attention to an instruction or other useful information.

General warning Warning:

electricity

Warning:

avoid hand injuries

Wear protective

gloves.

Wear safety

footwear.

Wear respiratory

protection.

Wear ear

protection.

Wear eye

protection.

Wear a hard hat.

Warning signs

Obligation signs

Warning:

Risk of cutting

injury

Read the operating

instructions before

use.

Symbols

A

Amps

V

Volts Alternating current

∅

Diameter

Hz

Hertz

n

o

Nominal speed

under no load

mm

Millimeters

/min

Revolutions

per minute

rpm

Revolutions

per minute

Always fit the blade

guard

Always fit the rail

end stops

Printed: 13.01.2016 | Doc-Nr: PUB / 5139176 / 000 / 02

5

2. Safety precautions

Safety precautions 2.1 General safety information 6

2.2 Use of the equipment as directed 7

2.3 Electrical safety precautions 7

2.4 Safety precautions during transport 7

2.5 Safety measures at the working area 8

2.6 Preparations 8

2.7 Safety precautions to be observed when assembling,

securing and operating the wall saw 9

2.8 Securing the objects being cut and disposal of sawing slurry 10

Printed: 13.01.2016 | Doc-Nr: PUB / 5139176 / 000 / 02

6

2. Safety precautions

General safety information

■ Sawing work influences the statics of the structure.

Approval must be obtained from the site engineer or

architect prior to carrying out drilling and sawing

work.

■ You must be fully aware that working with the

D-LP15/DS-TS 22 hydraulic saw system always

involves a certain element of risk due to wear or damage to parts. Check the condition of the entire system,

including accessories, each time before use to ensure

it functions correctly.

Wearing parts such as the blade guard holder rubber,

end stop, blade mounting screw, flush-cutting blade

mounting screws, etc., should be inspected particularly carefully. Check that all parts have been assembled

correctly and consider all other factors that could influence operation of the equipment.

Contact your Hilti representative or Hilti service centre

if faults or deficiencies are found.

■ Use the hydraulic saw system only when you have

read the operating instructions, when you are familiar

with the information contained therein and when you

have been trained to use the equipment safely by a Hilti

specialist. All warnings and safety information must be

observed.

■ The area in front of, behind or below the surface

where sawing work or drilling work is to be carried out

must be secured in such a way that persons or equipment cannot be injured or damaged by falling objects.

If necessary, concrete cores or blocks of concrete that

have been cut free should be secured to prevent them

falling.

■ The operator in charge must be aware of the possible dangers and of his responsibility for safety, both

with regard to himself and to others.

■ Read the operating instructions carefully before

operating the equipment for the first time and observe

all precautions and instructions contained therein.

■ The influences of the environment in which you

are working must be taken into account. Do not position the equipment where the hydraulic unit is liable

2.1

to become very wet. The hydraulic unit must be kept

level during operation, i.e. on a horizontal surface.

Secure the hydraulic unit at locations where there

may be a risk of it falling (e.g. on scaffolding). The

electric extension cable and its plugs and sockets

must not be allowed to lie in water. Do not use the

equipment in the vicinity of inflammable liquids or

gases. Make provision for water removal and disposal.

■ Always keep the operating instructions with the

equipment and pass them on to any subsequent user

who has been trained in its use.

■ When not in use, store the hydraulic saw system in

a locked, dry place out of reach of children.

■ Use the hydraulic saw system only for the applications for which it has been designed.

■ In addition to carrying out the specified care and

maintenance, careful cleaning is also a prerequisite for

safe, trouble-free operation of the equipment.

■ Always stay alert and carefully observe the

progress of your work. Proceed logically and do not

use the equipment when you are unable to concentrate

on your work.

■ Do not leave tools (e.g. open-end wrenches) in

place on the equipment. Check the drive unit to ensure

that all tools have been removed before switching on.

■ Keep the working area tidy and well lit. An untidy

workplace and inadequate lighting increases the risk

of accident.

■ Wear suitable, close-fitting work clothes including

a hard hat, protective goggles, protective gloves, safety footwear, ear protectors and a hair net, if you have

long hair.

■ Respiratory protection should be worn when working in enclosed or poorly ventilated areas and when

dry cutting is being carried out.

■ Keep children and other persons well away from

the workplace and allow no-one to touch the wall saw

or power cable.

■ Failure to comply with the warnings and safety

information may lead to severe or possibly fatal

injury as well as serious damage to the equipment

and other property.

Printed: 13.01.2016 | Doc-Nr: PUB / 5139176 / 000 / 02

7

2. Safety precautions

■ Before beginning work, check the working area

(e.g. using a metal detector) to ensure that no concealed electric cables or gas and water pipes are

present. External metal parts of the machine may

become live, for example, when an electric cable is

damaged accidentally. This presents a serious risk of

electric shock.

■ The machine is not intended for use by children,

by debilitated persons or those who have received

no instruction or training.

■ Children must be instructed not to play with the

machine.

■ Dust from material such as paint containing lead,

some wood species, minerals and metal may be harmful. Contact with or inhalation of the dust may cause

allergic reactions and/or respiratory diseases to the

operator or bystanders.

Certain kinds of dust are classified as carcinogenic

such as oak and beech dust especially in conjunction

with additives for wood conditioning (chromate, wood

preservative). Material containing asbestos must only

be treated by specialists.

Where the use of a dust extraction device is possible

it shall be used. To achieve a high level of dust

collection, use a suitable vacuum cleaner of the type

recommended by Hilti for wood dust and/or mineral

dust together with this tool. Ensure that the workplace is well ventilated. The use of a dust mask of filter

class P2 is recommended. Follow national requirements for the materials you want to work with.

Use of the equipment as directed

■ The D-LP15/DS-TS 22 hydraulic saw system has

been developed for the technical demolition of steel,

concrete, stone or brickwork structures in construction and civil engineering applications. It can be used

for wet or dry sawing (the wet sawing technique is

normally used). Use extending beyond this is considered to be not as directed and requires to be clarified

in advance with the manufacturer.

■ The hydraulic saw system may be operated only

by specialists trained in concrete cutting techniques,

referred to in the following as “operators”. These persons must be familiar with the content of these operating instructions and must have been trained in their

safe application by a Hilti specialist.

■ National regulations and laws, as well as the oper-

2.2

ating instructions and the safety information applicable to the accessories employed (saw blade, fastening accessories etc.) must be observed.

■ Use only the accessories recommended in these

operating instructions. The use of other accessories

may result in damage or injury. Use only original Hilti

spare parts.

■ Use only saw blades approved for a cutting speed

of 63 m/sec.

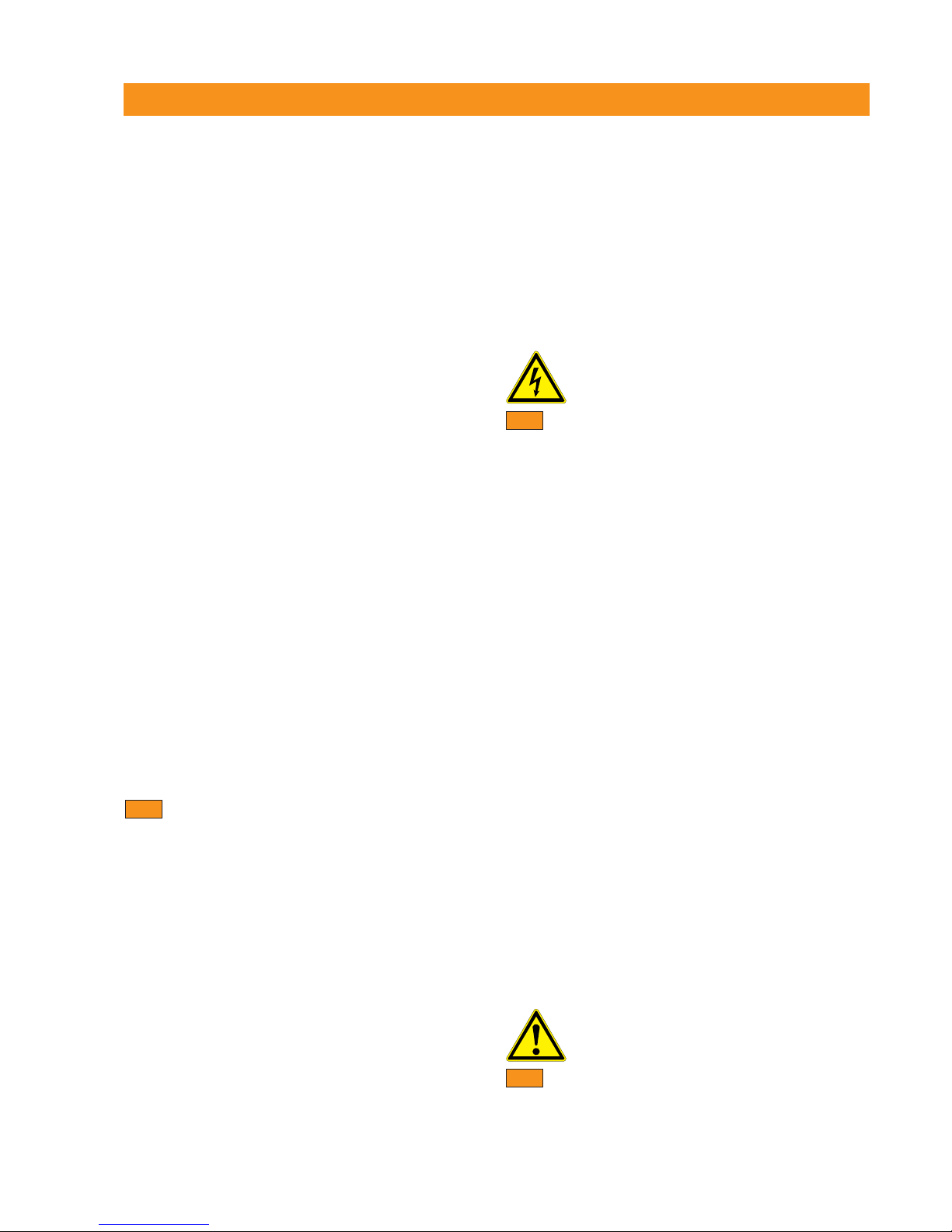

Electrical safety precautions

■ Connect the unit only to a power source equipped

with an earth conductor and ground fault circuit

breaker (PRCD). Check that these items are in perfect

working order before operating the equipment.

■ Make sure that the mains voltage corresponds to

the specification given on the rating plate.

■ Protect yourself against electric shock, i.e. avoid

contact with earthed components such as pipes,

radiators and the like.

■ Check the condition of all cables and plugs each

time before use.

■ Keep all electric cables, especially their plug connections, in a dry condition. Close the electric sockets by means of the covers supplied when not in use.

■ Use of extension cables: Use only extension

cables with adequate conductor cross-section which

are approved for the intended field of use. Do not

work with extension cables when they are rolled up.

This can result in a drop in output at the equipment

and may cause the cable to overheat. Replace damaged extension cables.

■ Disconnect the power cable before beginning

cleaning and maintenance work or in the event of a

lengthy interruption between periods of operation.

■ Any generator used must be earthed when in

operation.

Safety precautions during transport

■ Make sure that the hydraulic saw system cannot

move about during transportation.

2.4

2.3

Printed: 13.01.2016 | Doc-Nr: PUB / 5139176 / 000 / 02

8

2. Safety precautions

■ Always avoid adopting a bent-over body position

when carrying heavy items, i.e. keep your back

straight when lifting and carrying. Maintain a secure

stance, especially when using ladders or when working from scaffolding.

■ Use the handles provided for transportation of the

drive unit and control unit. Ensure that the handles

are always kept clean and free of grease.

■ If the drive unit and control unit are to be transported by means of a crane, the lifting points provided must be used.

■ Only suitable, conventional site cranes or mobile

cranes may be used for lifting.

Safety measures at the danger areas

■ Safety measures must be implemented in the area

where sawing is taking place to ensure that operators

and bystanders cannot be injured or property damaged by debris that may fly off or fall down (brokenoff diamond segments, small stones, sawing slurry,

etc.) while sawing is in progress. Safety measures

must also be implemented in the area not directly

visible to the operator, i.e. behind where sawing is

taking place.

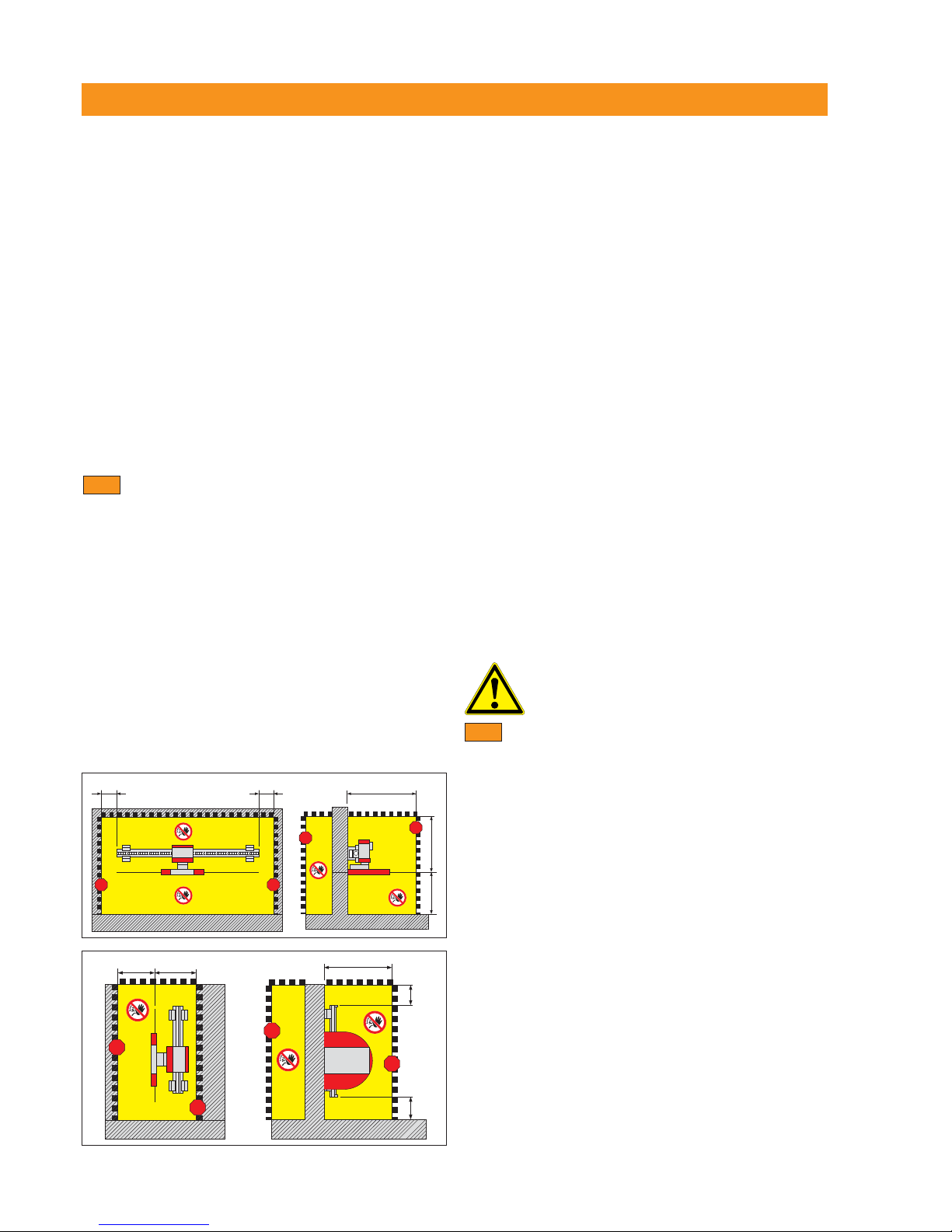

■ Persons must NEVER enter the danger area (3

meters in all directions from the line of the cut to be

made) while the blade drive is switched on.

3m

3m ∞m

3m3m

STOP

STOP

STOP

STOP

2.5

3m 3m

3m

1m ∞m

STOP

STOP

STOPSTOP

CAUTION

Secure the working area. Ensure that no persons can

be injured or property / equipment damaged by falling

objects or debris that may fly off during the sawing

operation.

1. Approval must be obtained from the site engineer or

site management before beginning the sawing

work.

2. Find out whether overcutting at corners is permitted. If not, the corresponding corner holes must be

planned and drilled first.

3. Check that the area is cordoned off, that supports

are in place and warnings to third parties are displayed.

When setting up and operating the saw system and

when removing parts that have been cut away,

always ensure that no persons are below the area in

which you are working. Falling objects could cause

serious injury.

The danger area may be entered only when the machine is switched off at the main switch (emergency-off

button pressed).

Preparations

■ Keep the working area tidy and always unroll the

full length of hoses and cables. Untidiness and bad

organisation of the working area can lead to accidents.

■ Make sure that no gas, water, electricity or other

supply lines are located in the cutting area. Supply

lines located close to the cutting area which could be

damaged by falling parts, for instance, must be specially protected and, if necessary, temporarily switched

off etc.

■ Ensure that the cooling water used is drained or

extracted in a suitably controlled manner. Water that is

allowed to drain away or spray around in an uncontrolled manner can lead to damage or accidents. The

fact that water could drain away into internal, hidden

cavities, e.g. in brickwork or masonry, must also be

taken into account.

■ Make a careful note of any influence the immediate

surroundings may have on operations. Do not use the

hydraulic saw system in areas where there is a risk of

2.6

Printed: 13.01.2016 | Doc-Nr: PUB / 5139176 / 000 / 02

9

2. Safety precautions

explosion or in close proximity to combustible materials, fluids or gases. Flying sparks or electrostatic discharge can lead to fires or explosions.

■ Do not cut materials which may produce toxic or

explosive dust or vapours when cut.

■ Do not cut easily combustible aluminium or magnesium alloys.

Safety precautions to be observed when

assembling, securing and operating the wall

saw

WARNING

Use an anchor suitable for the material on which you

are working and observe the anchor manufacturer’s

instructions.

NOTE

Hilti M12 metal expansion anchors are usually suitable for fastening diamond core drilling equipment to

uncracked concrete. Under certain conditions it may

be necessary to use an alternative fastening method.

Please contact Hilti Technical Service if you have any

questions about secure fastening.

■ Use metal anchors (size M12) for fastening DS-RF

rail supports and DS-RFP angular cutting plates.

Secure fastenings of a type suitable for the material

being cut must be installed, e.g. Hilti HKD-D, HSA-A,

Hilti HIT, HEA / HAS anchors.

■ Use only ISO 8.8 grade fastening screws for the rail

supports.

■ An end stop must always be fitted at the end of the

rail to prevent unintentional advance beyond this point

(prevents saw coming off the end of the rail).

■ The blade guard must always be in place when the

saw is in use. NEVER stand in the direction of radial

flight of a running saw blade. Special precautions must

be taken to secure the danger area when special cutting applications are in progress.

■ Always operate the machine from the closed side

of the blade guard when corner cuts are made with the

2.7

blade guard in the partly open position. The operator

must take additional precautions (fit a cover, plank of

wood, boards etc.) where necessary.

■ Never attempt to connect or disconnect hydraulic

hoses while the hydraulic unit is running and while the

hoses are under pressure.

■ Handle the DS-RFP angular cutting plate carefully.

There is a risk of pinching your fingers.

■ It is essential that the prescribed checks are carried

out before beginning sawing (see section 9.1)

■ Unless special safety precautions are taken, the

D-LP 15/DS-TS 22 must NOT be operated in environments where there is a risk of explosion.

■ The hydraulic unit and the operator with the remote

control unit should be positioned as far as possible

outside the danger zone. The operator with the remote

control unit should remain at a safe location while the

saw is in operation.

■ Use only adequately dimensioned fastening materials to secure the saw (anchors, screws, etc.). Recommendations can be found in our catalogues and brochures.

■ Operate the saw only when the blade guard and

rail-end stops have been fitted and secured.

■ Observe the recommended cutting speeds and

advance pressures while sawing.

■ Protective gloves should be worn as the oil and

parts of the equipment can become very hot.

■ Wear the protective clothing and other items of

protective equipment listed in section 2.1.

■ Before each cut, check that there is no play

between the saw head and the rail and that the eccentric rollers are engaged.

■ When additional safety precautions are taken, overhead sawing is also possible. In this case, the blade

guard must be equipped with a means of water

drainage. Do not stand beneath the saw.

Printed: 13.01.2016 | Doc-Nr: PUB / 5139176 / 000 / 02

10

2. Safety precautions

Securing the objects being cut and disposal

of sawing slurry

■ Steel wedges and/or supports must be used to prevent uncontrolled movement of parts being cut free in

order to avoid injuries and to prevent the saw blade

becoming trapped or jammed.

■ Use only approved and appropriately dimensioned

means of securing and lifting for the removal and

transportation of parts that have been cut free. Such

parts may have a weight of many tons.

■ Never loiter in the vicinity of loads suspended by

cranes.

■ The point at which the cut is made and any resulting opening must be safely and visibly cordoned off to

prevent persons falling and to exclude the risk of damage or injury.

■ Introducing sawing slurry into the drains or sewage

system without suitable pre-treatment is problematic

from an environmental point of view. Ask the local

authority responsible about existing regulations. We

recommend the following pre-treatment:

– Collect the sawing slurry (e.g. using an industrial

vacuum cleaner)

– Allow the slurry to settle and dispose of the solid

portion of the waste at a building waste disposal

location (the separation process can be accelerated

by adding a flocculent).

– Neutralise the residual water by adding a neutralis-

ing agent or dilute it by adding a large quantity of

water before allowing it to enter the drainage system.

■ Always switch off the hydraulic power unit before

setting up or dismantling the saw or before carrying

out any other manipulation of the saw head or blade,

etc.

2.8

Printed: 13.01.2016 | Doc-Nr: PUB / 5139176 / 000 / 02

Loading...

Loading...